Abstract

In order to solve the problems of stress concentration in the roadway peripheral rock and poor support effect in a wide range of high-stress areas under the high-stress environment of MaKeng Iron Mine, this study is based on the theory of loose circle support, combined with the calculation of the anchor suspension theory to determine the reasonable length of pipe slit anchors and other key parameters. Through the two methods of punching and bonding, we examined the destructive effect to determine the thickness of the spray concrete and, finally, put forward the pipe slit anchor mesh spraying support technology program. The numerical model was constructed by using three-dimensional numerical simulation software (FLAC3D 5.0), and the support effect analysis of the support scheme was carried out systematically. The research results show the following: under the high-stress environment dominated by external horizontal tectonic stress, the use of pipe slit anchor net spray support technology can significantly improve the distribution characteristics of the plastic zone, stress field and displacement around the roadway; after the support, the deformation and displacement of the surrounding rock around the empty zone are significantly reduced, effectively preventing the destruction of the surrounding rock under the high-stress environment. The program not only unifies the mine support form and support parameters but also specifies the support construction method and construction quality inspection standard, which provides a scientific technical guarantee for mine shaft support and has an important reference value for the support design and construction of a mine roadway under a similar high-stress environment.

1. Introduction

In the process of deep mining development, the deformation control of the roadway surrounding rock is a major technical difficulty. Particularly with the increase in mining depth, various obvious large deformation phenomena occur in the roadway peripheral rock under high levels of stress, and the roadway produces serious bottom plate bulging under high levels of stress, which affects the normal use of the roadway. Under high overburden and tectonic stresses, the roadway may collapse or undergo excessive deformation, which not only endangers mining personnel but also reduces the function of the roadway and stops production. Therefore, ensuring the stability of the roadway perimeter rock and the safety and reliability of the support structure during deep excavation is extremely important for the safe and efficient mining of underground resources [1,2,3,4,5,6,7,8].

Deep mining is in a high-stress state, so the surrounding rock is more likely to reach the limit state, which leads to deformation and damage. In terms of surrounding rock control, scholars have proposed various theories and techniques, ranging from the new Austrian tunneling method [9] to the collapse arch [10,11]. Scholars have proposed the idea of surrounding rock management from the perspective of improving the bearing capacity of surrounding rock and combining it with support. With the development of energy theory [12], the interaction between surrounding rock and support was studied from the perspective of energy regulation. Aydan, Ö et al. [13,14] proposed the joint support theory according to the engineering practice. Kang et al. [15] proposed a resin full-length prestressed anchorage joint support technology. Jia et al. [16] considered that high geostress is an important factor leading to the deformation of deep surrounding rock, analyzed the damage mechanism of soft rock, and proposed a support method applicable to soft rock.

However, most of the existing studies on perimeter rock support are aimed at shallow roads. Influenced by traditional concepts, deep roadway support always adopts the engineering analogy method and empirical method, which leads to the uncertainty of rationality and excessive or insufficient support intensity of the surrounding rock control methods and technical parameters. The disadvantage of the former is that it wastes the support material and increases the support cost, while the latter brings great hidden danger to safety production.

Based on the above, in view of the mining characteristics of the middle zone of Makeng Iron Ore Mine, the distribution law of geostress, the deformation and damage characteristics of the deep roadway, and the peripheral rock support characteristics of the roadway, this study determines the reasonable support process and support design parameters through on-site measurements, theoretical analyses, numerical simulations, and on-site industrial tests and develops the support effect checking inspection standards to meet the specification requirements, so as to form a set of mine-based actual support control methods of the crushed rock body. This study is a reference for the support technology of this kind of broken rock body.

2. Project Overview

Makeng Iron Ore Mine, located 15 km south of Longyan City, Fujian Province, employs a large-diameter deep-hole staged stoping with backfill method. A longitudinal fault runs through the center of the mine, and under the influence of geostress and groundwater, fissures in the surrounding rock transition from a closed to an open state, compromising roadway stability and posing risks to key infrastructure.

The mining of Makeng Iron Mine is carried out by the method of open stope and subsequent filling. The mining activity of the ore body induces the mechanical response mechanism of disturbance and failure in the surrounding rock. With the development of mining, the surrounding rock of the roadway is dynamically driven by the mining stress field (including the initial stress release and secondary stress concentration effect) and presents significant asymmetric deformation characteristics: progressive settlement occurs in the roof, and continuous uplift occurs on the floor. The historical monitoring results show that the deformation of the roof and floor increases nonlinearly with the increase in mining disturbance, and the deformation region shows the expansion behavior of spatio-temporal correlation. The cumulative damage effect of surrounding rock leads to the gradual expansion of the plastic zone, which ultimately poses a direct threat to the stability of the roadway structure and the safety of underground production.

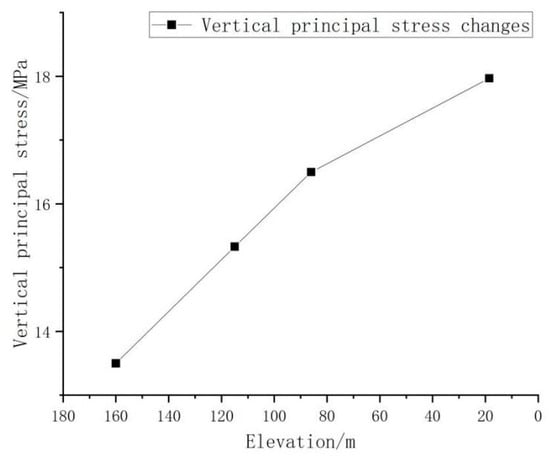

Based on the results of the current stress tests at each section, the component values in the north–south, east–west, vertical and other directions were calculated. The test results of each measuring point are shown in Table 1 and Table 2. According to the test results at this time, the maximum principal stress in the mining production area below 90 m and at a level of 18 m reached above 30 MPa, and the horizontal component stress also showed relatively high stress. This indicates that the stress value of the deep part of the ground stress was relatively high. With the expansion of mining, there is a possibility of stress concentration and the emergence of large-scale high-stress areas, which require special attention and high-level concern. The maximum principal stress at the 18 m section measuring point reached 31.33 MPa, with a direction of 224.9° and an inclination angle of 7.0°, which was nearly horizontal. A phenomenon of increased lateral pressure due to the influence of horizontal stress was clearly observed. With the increase in depth, the increase in horizontal stress became more obvious, which is in line with the characteristics of ground stress in a mountainous terrain environment. Figure 1 indicates that as the mining progresses, the stress concentration and the high-stress zones keep expanding. Therefore, active ground pressure management, timely void zone treatment and reinforcement measures need to be adopted to prevent rock failure and ensure the safety of operations. Existing support systems mainly rely on ϕ43 mm hollow grouted rock bolts, supplemented with 100 mm sprayed concrete in weak sections. However, the absence of standardized support selection and evaluation methods results in inconsistent designs and suboptimal performance. Without clear construction quality standards, timely acceptance and assessment of support measures remain challenging, affecting overall site stability.

Table 1.

Raw rock stress test results.

Table 2.

Calculation results of stress components.

Figure 1.

Vertical stress variation from 160 m to −18 m.

To improve safety and efficiency, the mine urgently needs systematic optimization of support technologies, including standardized selection criteria, process controls, and evaluation methods. Establishing a scientific approach to support design based on rock mass conditions will be key to enhancing shaft stability and long-term mining sustainability.

3. Loose Ring Measurement

3.1. Loose Ring Field Test

- Drilling measurement hole: Drilling with φ90 or higher drilling rig. Each measuring point is drilled according to the designed drilling position, the drilling azimuth is 5–10° down the tying angle, the drilling depth is at least 5 m, and the hole depth is measured with a ruler.

- Hole cleaning and water filling: Clean the drilling slag in the drilling hole, send the test probe into the bottom of the hole through the extendable tube of the self-made probe, and then send the water filling pipe into the drilling hole to fill the water.

- Test process: Measure the distance between receivers, input data such as project number, hole depth and distance between receivers into the test equipment. After the hole is filled with water, keep the hole full of water, and then slowly and evenly pull the test line to pull out the probe. As the probe is pulled out, readings are taken every 20 cm until the transducer is completely detached from the borehole, as shown in the top view. With the different position of the drill, that is, the different depth from the two sides of the roadway, the reading on the tester changes due to the different degrees of fragmentation of the rock mass. After the measurement, the computer data analysis system is used to take the best and representative readings as the final analysis data of the measurement results.

The testing process is shown in Figure 2.

Figure 2.

Field work drawing. (a) Measure the distance between receiving points, (b) pull out 20 cm each time during measurement, (c) acquisition head wave, (d) data reading and storage.

3.2. Sonic Method for Testing Loose Rings

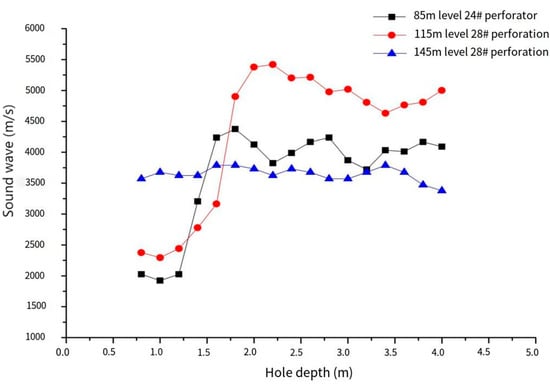

Due to rock fragmentation within the loosening ring, ultrasound propagates through the fractured rock at a lower velocity compared to intact rock. The extent of the loosening circle can be determined by identifying the inflection point on the velocity curve, where a sudden change in sound speed occurs. By screening, analyzing, and processing the data collected from the measurement points at the Makeng Iron Mine, a depth–sound velocity variation curve for the lithology at each measurement point was obtained, as shown in Table 3 and Figure 3.

Table 3.

Locations of test holes and measured sound velocities for each ore body at Makeng Iron Ore Mine.

Figure 3.

Curve of hole depth versus sound velocity in the ore body.

In the 85 m, 115 m, and 145 m subsections, the relationship between ore body hole depth and acoustic wave velocity was analyzed. As shown in Figure 3, the measurement section at the 85 m level ranges from 0.8 m to 4.0 m. Within the 1.5 m to 4.0 m range, the rock wave velocity remains relatively stable between 3800 m/s and 4300 m/s, indicating that this section of the ore body is relatively intact. It has not been significantly affected by the stress changes induced by roadway excavation.

However, between 1.2 m and 1.8 m, the wave velocity shows a noticeable decline. Specifically, within the 0.8 m to 1.4 m range, the average wave velocity is approximately 2112 m/s, which is significantly lower than the intact rock. This suggests that the rock mass in this section contains more fissures and is more fragmented due to the influence of roadway excavation. Based on this analysis, the loosening circle radius for the 85 m section is determined to be 1.2 m.

Similarly, in the 115 m subsection, as shown in Figure 3, the acoustic wave test data exhibit the same trend as the 85 m section. Based on these results, the loosening circle radius for the 115 m level is determined to be 1.4 m.

For the 145 m level, the measured wave velocity remains relatively stable within the 0.8 m to 4.0 m range. However, an overall decreasing trend in wave velocity suggests that, while the rock mass in this section remains largely intact, it is still influenced by excavation activities near the roadway. Consequently, the loosening circle radius in this section is relatively small.

The sonic test results across different roadway sections within the ore body rock layers exhibit a consistent distribution pattern, with multiple factors influencing the extent of the rock loosening circle. Based on sonic testing and data analysis, it is concluded that the loosening circle size in the 85 m section is approximately 1.2 m, while in the 115 m section, it is around 1.4 m. In the 145 m section, the ore body exhibits better integrity, with only a small loosening circle present. These findings provide valuable insights into roadway stability and serve as a basis for optimizing support measures.

4. Determination of Parameters for Slit Pipe Anchor Net Spray Support

In the combined support system of anchor, mesh, and sprayed concrete, the addition of a metal mesh enhances the crack resistance of the sprayed concrete layer while improving its overall flexural, tensile, and shear strength. This reinforcement helps to effectively seal the surrounding rock, preventing weathering and protecting anchor rods from water erosion. Additionally, it optimizes the joint support function of the anchor rods and metal mesh, ensuring a more stable roadway structure. The sprayed concrete also acts as an isolating layer, further safeguarding the anchor rods and metal mesh from environmental factors. For economic efficiency, a metal mesh size of 2000 mm × 1000 mm with a 100 mm × 100 mm mesh hole is selected.

The drill bit specification used for excavation in the Makeng Iron Mine is φ38 mm, with the actual construction hole diameter ranging between 38 mm and 40 mm. For analysis, the 115 m level, section 28# through the vein, is chosen as the application site. Based on the loosening circle calculation, the loosening circle radius at the 115 m level for section 28# is 1.4 m. The roadway specifications are 3.9 m in width and 3.6 m in height.

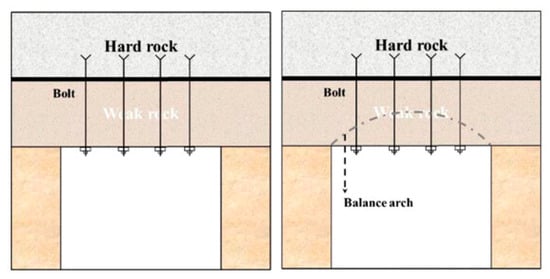

According to the suspension theory, after the excavation of the roadway, the original in situ stress in the surrounding rock redistributes, changing from the original three-dimensional stress to two-dimensional corresponding stress and creating a stress concentration area. In this area, the original joints, fissures, bedding, faults, and other discontinuities in the rock mass may further develop. Affected by this development, some rock loosening, sliding and fracture phenomena will occur. Further, new discontinuities may be generated, and caving may occur under the action of self-weight. The suspension function of the anchor bolt is to give sufficient restraint to the subregion at this time and anchor these loose and broken rocks in the hard and stable rock stratum inside the surrounding rock (Figure 4).

Figure 4.

Schematic diagram of suspension theory.

Using the anchor suspension theory and inputting these parameters into the calculation formula (Equation (1)), it is determined that the distance should not be less than 1.02 m. Based on the mesh specifications, the distance between anchor rods is set to 1 m × 1 m.

where: a—anchor bar spacing, row spacing, m;

G is the anchor design anchoring force, taken as 70 KN/root;

k is the safety factor, take 2;

Lb is the thickness of the unstable rock layer to be suspended, determined by the radius of the circle of loose surrounding rock, here taken as 1.4 m;

γ is the bulk weight of the rock, determined by the nature of the surrounding rock, here take 24 KN/.

The total length L of the anchor consists of three parts: the anchoring length La of the anchor deeper into the more stable rock layer, the thickness Lb of the unstable rock layer to be suspended and the thickness Lc of the upper pallet and anchorage, where the thickness Lc of the upper pallet and anchorage is taken as 0.15 m.

L = La + Lb + Lc

The anchorage length La for deeper penetration into the more stable rock layer is determined by Equation (3). The anchorage length is calculated to be 0.45 m, so the total length of the anchor L is 2 m.

where: K is a safety factor, generally taken as 2;

d is the diameter of the anchor, 0.02 m;

fs is the tensile strength of the anchor, taken as 315 MPa;

fc is the bonding strength of anchor and cement paste, taken as 7 MPa.

Spray layer damage is mainly dominated by cut layer damage and bonding damage. According to the previous report, the weight of the dangerous stone is 12,096 kg, and the length of the dangerous stone periphery is 3519 cm; therefore, substituting the relevant parameters into Equation (4), the thickness of the spray layer under the cut layer damage is not less than 14.32 mm.

where: Hc—thickness of spray layer, cm;

G—weight of dangerous stones, G = 12,096 kg;

S—dangerous rock perimeter long, S = 3519 cm;

δ—concrete shear strength, generally taken as δ = 6 kg/cm2;

—safety factor, k = 2.5.

Equation (5) shows that the thickness of the spray layer under the bonding damage should not be less than 34.37 mm.

where:

δN—bond strength of shotcrete, 3 kg/cm2;

K—rock elasticity tensile coefficient, 1 × 104 kg/cm2;

E—modulus of elasticity of rocks, E = 415,100 kg/cm2

—safety factor, k = 3.

The results demonstrate that, based on calculations considering both the punching and cutting destructive effects and the bonding effects, the minimum thickness of the sprayed concrete layer should not be less than 34.37 mm. Furthermore, a protective concrete layer with a thickness of at least 20 mm is required to ensure the integrity of the metal mesh and to provide a smoother roadway surface, thereby promoting a more uniform distribution of stress. To achieve consistency in the design of support parameters, a 100 mm thick concrete layer is adopted. This thickness aligns with the specifications used for plain sprayed concrete support in roadways characterized by more developed joints and fissures, as well as lower stability conditions. This approach ensures both structural reliability and compatibility with existing support practices.

5. Simulation Analysis of Support Effectiveness

5.1. Modelling

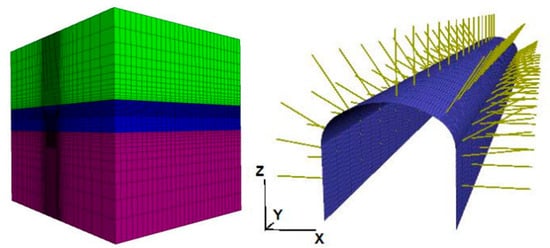

To assess the damage status of the roadway and determine an appropriate support scheme for the Makeng Iron Ore Mine, an engineering geological model was developed. This model considers key factors, such as roadway location, surrounding rock lithology, and fault distribution. The model dimensions are 36 m × 30 m × 34 m, comprising 144,600 units and 153,078 nodes. The relevant parameters required for numerical simulation are shown in Table 4 and Table 5.

Table 4.

Rock mechanical parameter.

Table 5.

Supporting mechanical parameters.

Boundary conditions are defined as follows: the bottom boundary is subject to vertical constraints, the four side boundaries are constrained horizontally, and the upper boundary is a free surface. Stress boundary conditions are applied based on measured in situ stress data. The Mohr–Coulomb model is adopted as the yield criterion. The numerical simulation model is illustrated in Figure 5.

Figure 5.

Numerical simulation model.

To ensure that the numerical calculations accurately reflect the actual engineering geological conditions of the Makeng Iron Ore Mine, the following assumptions are made in the modeling process:

- The ore-bearing rock mass is considered an ideal elastic–plastic material. After reaching the yield point, neither the material strength nor volume changes with plastic flow, and strain hardening or softening effects are not taken into account.

- Both the ore body and surrounding rock are assumed to be locally homogeneous and isotropic. The plastic flow does not alter the isotropic nature of the materials.

- All physical parameters involved in the analysis are considered time-independent, reflecting the brittle nature of the rock.

- Given the limitations of finite difference calculations, tectonic activity is disregarded. The in situ stress field is assumed to be geostatic, rock layers are in full contact with each other, and the interior of each rock layer is treated as a continuous medium. Groundwater effects are also excluded from the model.

- The calculation considers only the effects of geostress, neglecting the impact of seismic waves, explosive shock waves, and groundwater on the stability of the rock mass.

5.2. Stress Analysis of the Roadway Perimeter Rock

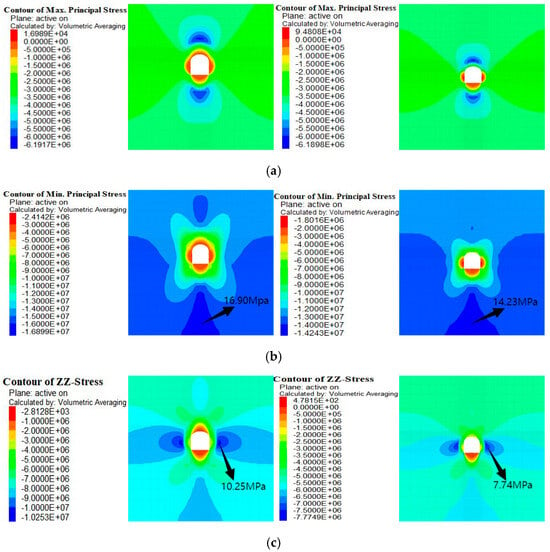

Figure 6 illustrates the distribution characteristics of the maximum principal stress, minimum principal stress, and vertical stress (z-direction) in the surrounding rock under two working conditions: without support and with anchor net shotcrete support.

Figure 6.

Diagram of stress distribution before and after support. (a) Decreasing trend of maximum principal stress before and after support, (b) decreasing trend of minimum principal stress before and after support, (c) decreasing trend of vertical stress before and after support.

Under unsupported conditions, stress concentration is primarily observed in the shoulder area of the roadway and at the base of the sidewalls. The maximum principal stress reaches 16.90 MPa, concentrated at the roadway shoulders, indicating that this zone experiences high compressive stress due to excavation-induced disturbance and is, thus, prone to compressive shear failure. The minimum principal stress is concentrated near the floor, exhibiting tensile characteristics, which may lead to tensile failure of the rock mass. The maximum vertical stress is 10.25 MPa, and although its distribution is relatively uniform, localized concentration is still present at the junction between the roof and floor, potentially causing structural stress imbalance.

With the application of the anchor net shotcrete support, the stress distribution within the surrounding rock improves significantly. The maximum principal stress is reduced to 14.23 MPa, reflecting a 15.8% decrease, and the extent of the stress concentration zone is markedly reduced. This indicates that the support system effectively redistributes and alleviates the high compressive stress at the roadway shoulders, thus mitigating the risk of localized failure. Additionally, the range of tensile stress is significantly reduced, with the minimum principal stress increasing, suggesting that the support system suppresses tensile stress development, particularly at the wall bases. The maximum vertical stress decreases to 7.74 MPa, a reduction of approximately 24.5%, and its distribution becomes more uniform, which facilitates the maintenance of overall stress equilibrium in the surrounding rock mass.

From a mechanical perspective, the anchor rods link the shallow fractured rock with the deeper stable strata, thereby enhancing the structural integrity and overall load-bearing capacity of the surrounding rock. Meanwhile, the shotcrete layer and steel mesh rapidly seal surface cracks, restrict deformation and crack propagation, and inhibit the formation of new stress concentration zones. As a result, the stress within the surrounding rock is redistributed more uniformly, and localized high-stress regions are effectively weakened, significantly improving the stability and safety of the roadway.

In summary, the anchor net shotcrete support exhibits a notable capacity to relieve local stress concentrations and optimize the stress distribution in the surrounding rock, providing a critical safeguard for the long-term stable performance of the roadway structure.

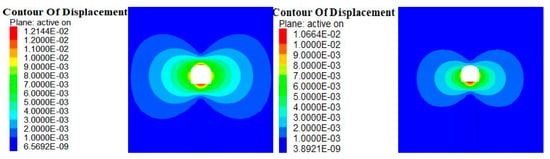

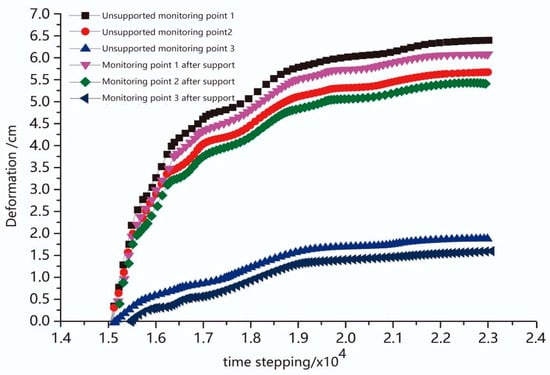

5.3. Analysis of the Deformation of the Roadway Perimeter Rock

The deformation characteristics of surrounding rock are an important index for evaluating the support effect, which directly reflects the stability of the roadway in the excavation and support process. In this study, three monitoring points were selected at the top plate and gang part of the roadway for displacement analysis; the distances of the monitoring points from the top plate were 0.2 m, 0.6 m and 1.0 m, respectively, and the results are shown in Figure 7 and Figure 8. The position diagram of the measuring point is shown in Figure 9.

Figure 7.

Comparison of deformation of surrounding rock in unsupported condition and spray anchor net support condition.

Figure 8.

Distribution of monitoring points for tunneling and support of the perimeter rock roadway.

Figure 9.

Schematic diagram of measuring point location.

Under the unsupported condition, the deformation of the tunnel perimeter rock is more significant. The maximum displacement of the roof plate reaches 7.0 cm, which is mainly concentrated in the middle part of the roof plate, indicating that the peripheral rock in this area has insufficient bearing capacity and there is a greater risk of deformation. The maximum displacement of the gang section was 6.2 cm, which was mainly distributed in the middle and upper part of the gang section, indicating that the peripheral rock of the gang section also deformed significantly under the unsupported condition. In addition, the displacement of the top plate at 0.6 m was 6.5 cm, and the displacement of the top plate at 1.0 m was 5.9 cm, which further indicated that the deformation of the top plate gradually decreased from the surface to the depth of the roadway, but the overall deformation was still large.

After adopting anchor net spray support, the deformation of surrounding rock was effectively controlled. The top slab displacement was reduced to 5.8 cm, which was about 17.1% less, indicating that the support system played a significant role in restraining the deformation of the top plate and surrounding rock. Gang displacement decreased to 5.1 cm, a reduction of about 17.7%, indicating that the support measures also have a good effect on the deformation of the surrounding rocks at the gang section. In addition, the displacement at 0.6 m of the roof slab decreased from 6.5 cm to 5.4 cm, a decrease of about 16.9%, and the displacement at 1.0 m of the roof slab decreased from 5.9 cm to 4.9 cm, a decrease of about 16.9%. These data show that the support system can not only effectively control the deformation on the surface of the roadway but also inhibit the displacement of the deep surrounding rock, thus improving the overall stability of the roadway.

By comparing the deformation characteristics under the two conditions, it can be found that the anchor net spraying support significantly reduces the deformation of the surrounding rock and improves the deformation distribution law of the roadway, which provides an important guarantee for the safe use of the roadway.

5.4. Analysis of the Damage to the Roadway Perimeter Rock

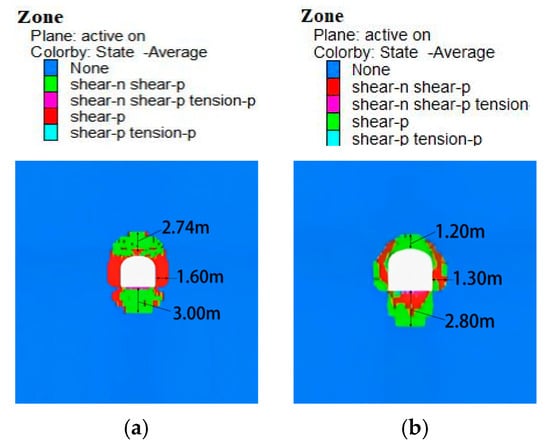

The distribution range of the plastic zone directly reflects the damage degree of surrounding rock, which is an important index for evaluating the stability of the roadway. Figure 10 shows the distribution of the plastic zone of the surrounding rock under different support conditions.

Figure 10.

Comparison of the plastic zone in the unsupported condition and the spray anchor network supported condition of the enclosing rock. (a) Unsupported state of the surrounding rock, (b) supporting state of surrounding rock.

In the unsupported condition, the plastic zone of the surrounding rock of the roadway has a large range. The maximum depth of the plastic zone in the top slab is 2.74 m, which is mainly concentrated in the middle of the top slab, indicating that the surrounding rock in this area has undergone significant plastic deformation and there is a high risk of damage. The maximum depth of the plastic zone in the bottom plate is 3.0 m, which is slightly larger than that of the top plate, indicating that the surrounding rock of the bottom plate has undergone a wide range of plastic damage under the condition of no support. The maximum depth of the plastic zone in the gang section is 1.6 m, which is mainly concentrated in the middle and upper part of the gang section, indicating that the surrounding rock in this area has insufficient bearing capacity and is prone to plastic deformation. These data show that the plastic zone of the tunnel peripheral rock in the unsupported condition is large, and there is a high risk of instability.

After adopting the anchor net spraying support, the range of the plastic zone of the roadway surrounding rock was significantly reduced. The depth of the plastic zone of the top slab was reduced from 2.74 m to 1.20 m, which was reduced by about 56.0%, indicating that the support system had significantly suppressed the plastic deformation of the surrounding rock of the top slab. The depth of the plastic zone in the base plate is reduced from 3.00 m to 2.80 m, with a reduction of about 6.7%, indicating that the supporting measures also have a certain effect on the plastic deformation of the base plate surrounding rock. The depth of the plastic zone in the gang section is reduced from 1.60 m to 1.30 m, which is about 19.0%, indicating that the support system can effectively enhance the bearing capacity of the surrounding rock in the gang section and reduce the range of plastic damage.

By comparing the distribution characteristics of the plastic zone under the two conditions, it can be found that the anchor mesh spraying support significantly reduces the range of the plastic zone of the tunnel surrounding rock, especially the plastic zone of the roof plate, which has the largest reduction, indicating that the support measures can effectively enhance the bearing capacity of the surrounding rock and reduce the risk of plastic damage, so as to improve the long-term stability of the tunnel.

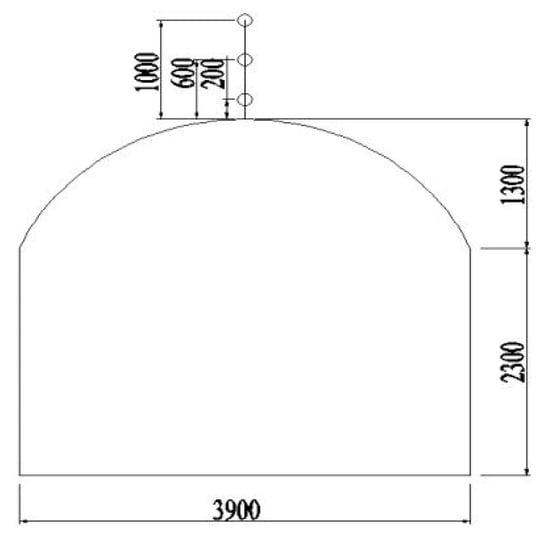

6. Engineering Applications

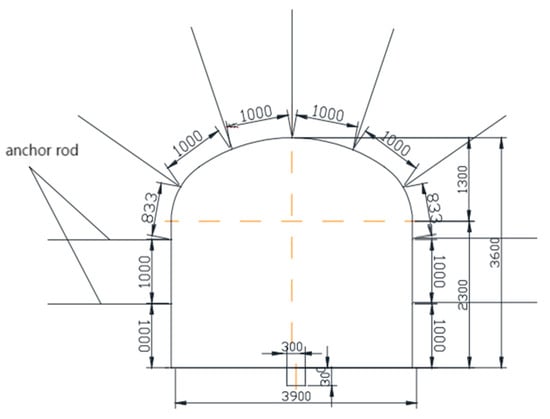

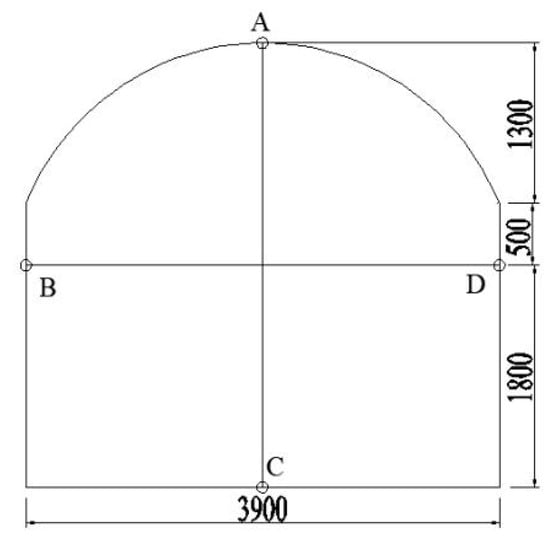

6.1. Rock Support

Based on the above calculations and the geological conditions of the site, the anchor-mesh spray support system is adopted. The pipe slit anchors have a length of 2.0 m and are arranged in a 1.0 × 1.0 m grid pattern. The anchors are spaced 1000 mm apart in each row, with nine anchors per row, and the distance between the anchor and the base plate is 100 mm. Steel mesh is added, with each mesh panel measuring 2000 × 1000 mm, a diameter of 6 mm, and a grid size of 100 × 100 mm. The sprayed concrete has a thickness of 100 mm and a strength rating of C20. This support system enhances roadway stability by effectively controlling deformation and minimizing plastic zone expansion. Figure 11 shows a schematic diagram of the design.

Figure 11.

Support program diagram.

6.2. Monitoring Method of Tunnel Convergence Deformation and Setting of Measuring Point

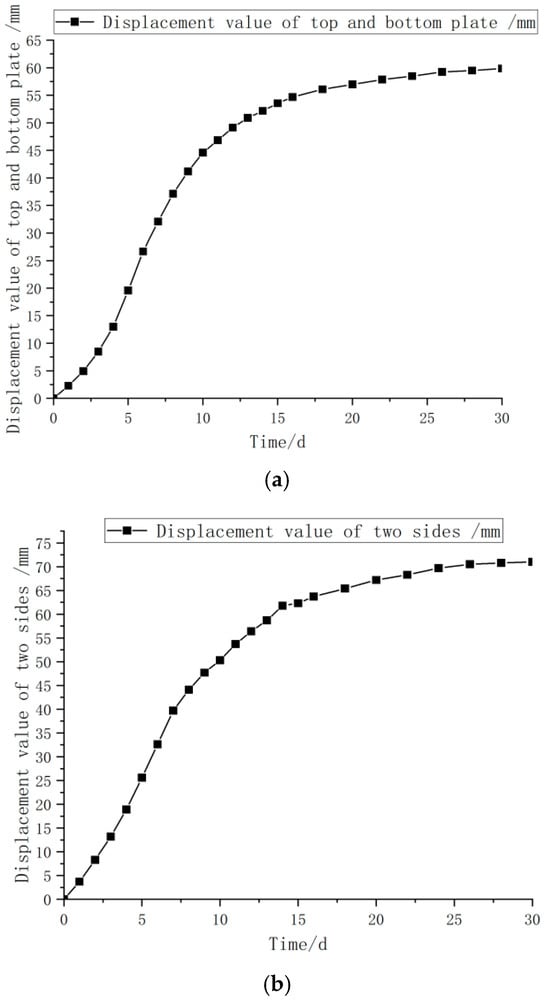

Roadway surface displacement is the most direct basis for the evaluation of the roadway supporting effect and surrounding rock stability, and its monitoring content includes the displacement of two sides and the displacement of the top and bottom. According to the monitoring results, the improved support effect and deformation rule of surrounding rock can be judged, and the feasibility of support can be verified. The convergence deformation of surrounding rock on the roadway surface was monitored using the cross-distribution method, as shown in Figure 12.

Figure 12.

Distribution diagram of key points in roadway section.

Figure 13 shows that in the initial stage of measuring point arrangement, the coupling between the supporting system and surrounding rock is weak, supporting bodies such as the anchor net have not fully played their roles, and the deformation rate of the roadway is fast. With the increase in roadway deformation, the coupling between roadway surrounding rock and the supporting system was greatly enhanced on the 10th to 15th days, and the roadway deformation rate slowed down significantly. After the 15th day, the roadway deformation rate tended to be stable.

Figure 13.

Tunnel convergence deformation monitoring. (a) Roof-to-floor convergence, (b) two sides move closer.

Through field monitoring, the displacement value of the surrounding rock of the roadway measuring station can be obtained, and then the stability of the roadway can be evaluated using the convergence rate, as shown in Table 6. Based on the empirical value summarized from long-term engineering practice, when the relative convergence rate of the largest two sides and roof and floor of the roadway does not exceed 2%, the roadway is judged to be in a stable state, indicating that the roadway supporting parameters are feasible.

Table 6.

Stability evaluation of mining roadway.

As can be seen from Table 6, the relative convergence rates of the top and bottom plates and the two sides of the measuring points are 1.66% and 1.82%, respectively, both of which are less than 2% and within the allowable convergence rate range. Therefore, the roadway is judged to be in a stable state. It shows that the roadway supporting parameters are feasible and can provide reference for similar roadway supporting.

After determining the parameters of anchor net spraying support and implementing the engineering application in Makeng Iron Mine, under the influence of the vibration of deep hole blasting in the quarry, the sprayed concrete layer close to the blasting point will be cracked, but no spalling phenomenon will occur. Due to the blasting disturbance, the service life of the roadway near the blasting point supported by sewing pipe-type anchor net spraying is relatively short. In order to improve this situation, the mine adopts the method of filling after the stage mining room and follows the principle of “quick mining, quick exit, quick filling” for the management of the quarry. By filling the hollow area in time, it effectively reduces the deformation and displacement of surrounding rocks around the hollow area, inhibits the further expansion of cracks in the shotcrete layer, and, thus, avoids the occurrence of concrete layer spalling. After the filling is completed, only the local cracked area needs to be shotcrete repaired to restore its integrity and ensure the long-term stability of the supporting structure. Practice shows that this method can significantly improve the stability of the roadway surrounding rock, providing a strong guarantee for the safe production of the mine.

6.3. Field Analysis and Follow-Up Measures

After determining the parameters of anchor net spraying support and implementing the engineering application in MaKeng Iron Mine, under the influence of vibration of deep hole blasting in the quarry, the sprayed concrete layer close to the blasting point will be cracked, but no spalling phenomenon occurs. Due to the blasting disturbance, the service life of the roadway near the blasting point supported by sewing pipe type anchor net spraying is relatively short. In order to improve this situation, the mine adopts the method of filling after the stage mining room, and follows the principle of “quick mining, quick exit, quick filling” for the management of the quarry. By filling the hollow area in time, it effectively reduces the deformation and displacement of surrounding rocks around the hollow area, inhibits the further expansion of cracks in the shotcrete layer, and thus avoids the occurrence of concrete layer spalling. After the filling is completed, only the local cracked area needs to be shotcrete repaired to restore its integrity and ensure the long-term stability of the supporting structure. Practice shows that this method can significantly improve the stability of the roadway surrounding rock, providing a strong guarantee for the safe production of the mine.

7. Conclusions

- Based on the loosening zone theory, the quantitative analysis of the support requirements of the surrounding rock of the roadway was conducted, and an optimized scheme of combined support with grouting, anchor rods and mesh was proposed. Through theoretical calculations, key parameters such as the length of anchor rods (2.5–3.0 m), spacing (0.8 × 0.8 m) and thickness of the sprayed layer (120–150 mm) were determined. A quantitative design system for supporting parameters of high-stress roadways was established.

- The support system reduces the maximum principal stress to 14.23 MPa, a decrease of 15.8%, and the vertical stress to 7.74 MPa, a decrease of 24.5%, while weakening the stress concentration and promoting uniform distribution. The increase in minimum principal stress and reduction in the tensile zone indicate the effective suppression of tensile stress, particularly at wall bases.

- After applying the anchor net shotcrete support, roof and gang displacements are reduced by 17.1% and 17.7%, respectively, with consistent 16.9% reductions at 0.6 m and 1.0 m depths. The support system effectively controls both surface and deep deformation, enhancing the overall stability and safety of the roadway.

- After applying anchor net shotcrete support, the plastic zone was significantly reduced: the roof decreased from 2.74 m to 1.20 m, a reduction of 56%; the base plate from 3.00 m to 2.80 m, a reduction of 6.7%; and the gang section from 1.60 m to 1.30 m, a reduction of 19%. These results indicate that the support system effectively enhances the bearing capacity and suppresses plastic deformation, particularly in the roof, thereby improving the tunnel’s long-term stability.

- Displacement monitoring shows that support–rock coupling improves significantly after 10–15 days, leading to stabilized deformation. The relative convergence rates of roof–floor and sidewalls are 1.66% and 1.82%, confirming the support effectiveness and roadway stability. In Makeng Mine, local cracking near blasting points was controlled through timely backfilling, which reduced deformation and prevented spalling. This strategy enhances long-term structural stability and ensures safe mining operations.

- After applying anchor net shotcrete support in Makeng Iron Mine, blasting-induced vibrations caused local cracking of the concrete layer near the blasting point, but no spalling occurred. To address this, the mine adopted a “rapid mining, rapid exit, rapid filling” approach, backfilling hollow areas to reduce surrounding rock deformation, prevent crack propagation, and avoid spalling. Localized shotcrete repairs were applied after filling, restoring structural integrity and ensuring long-term stability. This method significantly improves roadway stability and ensures safe mining operations.

Author Contributions

Validation, L.Z. and G.L.; Formal analysis, Z.D.; Writing—original draft, Z.D.; Visualization, Z.D.; Funding acquisition, G.L. All authors have read and agreed to the published version of the manuscript.

Funding

National Natural Science Foundation of China: 52174077.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hao, Y.; Liu, C.; Wu, Y.; Pu, H.; Chen, Y.; Shen, L.; Li, G. Numerical Modeling on Strain Energy Evolution in Rock System Interaction with Energy-Absorbing Prop and Rock Bolt. Int. J. Min. Sci. Technol. 2023, 33, 1273–1288. [Google Scholar] [CrossRef]

- Jiang, B.; Xin, Z.; Zhang, X.; Deng, Y.; Wang, M.; Li, S.; Ren, W. Mechanical Properties and Influence Mechanism of Confined Concrete Arches in High-Stress Tunnels. Int. J. Min. Sci. Technol. 2023, 33, 829–841. [Google Scholar] [CrossRef]

- Kang, Y.; Geng, Z.; Liu, B.; Chen, J. Study on Gas Extraction Efficiency Using In-Seam Borehole Method Considering Influence of Plastic Zone Induced by Borehole Drilling. Geomech. Energy Environ. 2023, 33, 100426. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Lou, J.; Crompton, B. Dynamic Performance of Energy-Absorbing Rockbolts Based on Laboratory Test Results. Part I: Evolution, Deformation Mechanisms, Dynamic Performance and Classification. Tunn. Undergr. Space Technol. 2020, 105, 103510. [Google Scholar] [CrossRef]

- Zhang, Z.; Deng, M.; Bai, J.; Yan, S.; Yu, X. Stability Control of Gob-Side Entry Retained under the Gob with Close Distance Coal Seams. Int. J. Min. Sci. Technol. 2021, 31, 321–332. [Google Scholar] [CrossRef]

- Zuo, J.; Wen, J.; Liu, D.; Wu, L.; Sun, Y. Control Theory of Uniform Strength Support in Deep Roadway. J. Min. Sci. Technol. 2021, 6, 148–159. [Google Scholar] [CrossRef]

- Shen, B. Coal mine roadway stability in soft rock: A case study. Rock Mech. Rock Eng. 2014, 47, 2225–2238. [Google Scholar] [CrossRef]

- Li, H.; Lin, B.; Hong, Y.; Gao, Y.; Yang, W.; Liu, T.; Huang, Z. Effects of in-situ stress on the stability of a roadway excavated through a coal seam. Int. J. Min. Sci. Technol. 2017, 27, 917–927. [Google Scholar] [CrossRef]

- Farmer, I.W. Stress Distribution along a Resin Grouted Rock Anchor. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1975, 12, 347–351. [Google Scholar] [CrossRef]

- Cai, M.; He, M.; Liu, D. Rock Mechanics and Engineering; Science and Technology Press: Beijing, China, 2002. [Google Scholar]

- Hoek, E.; Carranza-Torres, C.; Corkum, B. Hoek-Brown Failure Criterion-2002 Edition. Proc. NARMS-Tac 2002, 1, 267–273. [Google Scholar]

- Gao, M.-s.; Zhang, N.; Dou, L.-m.; Wang, K.; Kan, J.-g. Study of Roadway Support Parameters Subjected to Rock Burst Based on Energy Balance Theory. Zhongguo Kuangye Daxue Xuebao 2007, 36, 426–430. [Google Scholar]

- Aydan, Ö. Rock Mechanics and Rock Engineering: Volume 2: Applications of Rock Mechanics-Rock Engineering; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Hashemi, M.; Moghaddas, S.; Ajalloeian, R. Application of Rock Mass Characterization for Determining the Mechanical Properties of Rock Mass: A Comparative Study. Rock Mech. Rock Eng. 2010, 43, 305–320. [Google Scholar] [CrossRef]

- Kang, H.; Wang, J.; Lin, J. Case Studies of Rock Bolting in Coal Mine Roadways. Yanshilixue Yu Gongcheng Xuebao 2010, 29, 649–664. [Google Scholar]

- Jia, H.; Wang, H. Principle and Application of the Double Cacheable and Gradually Deformable Supporting Shells for Soft Rock Tunneling. Rock Soil Mech. 2015, 36, 1119–1126. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).