Research on Key Parameters and Engineering Experiments of Coal Gangue Slurry Filling Technology

Abstract

1. Introduction

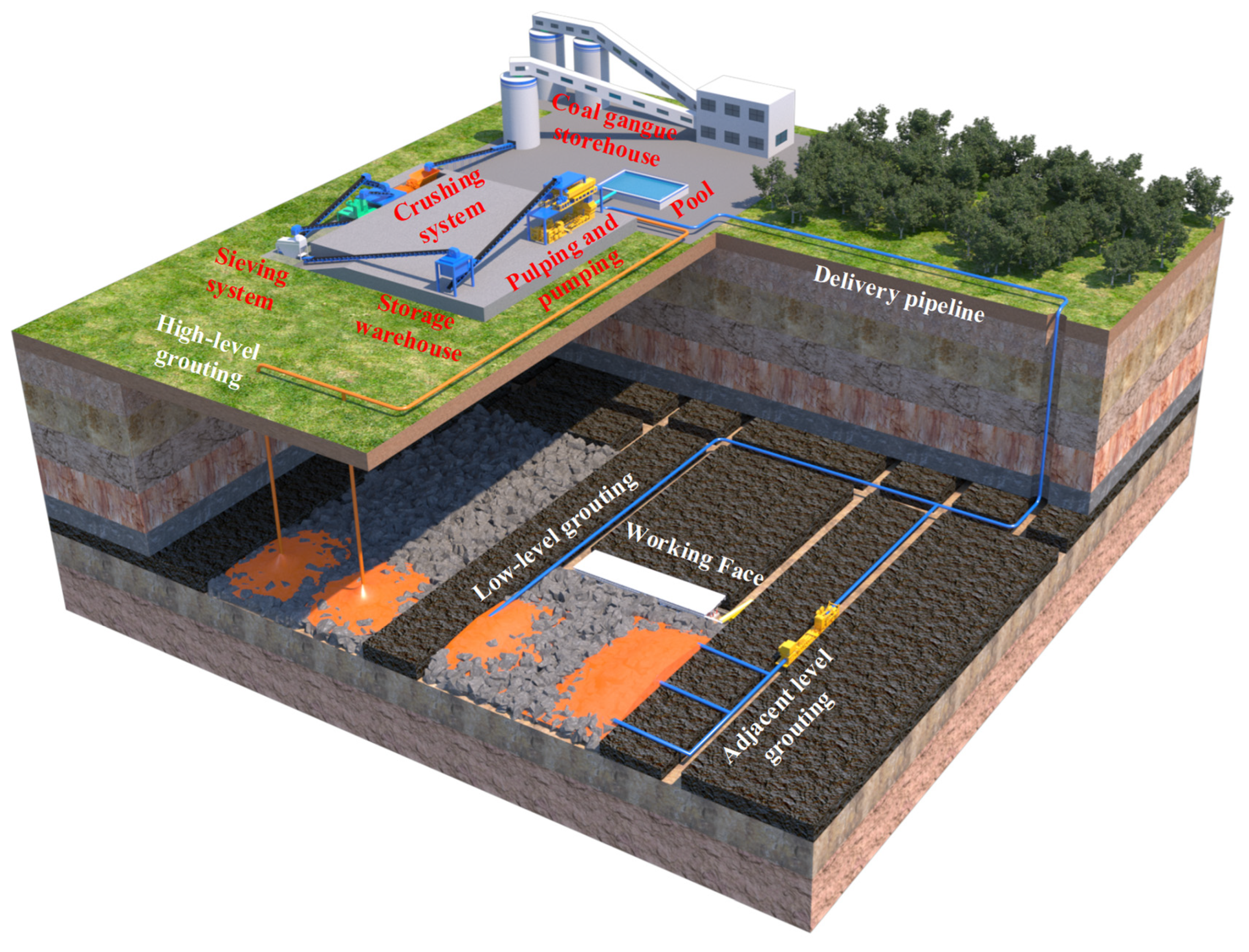

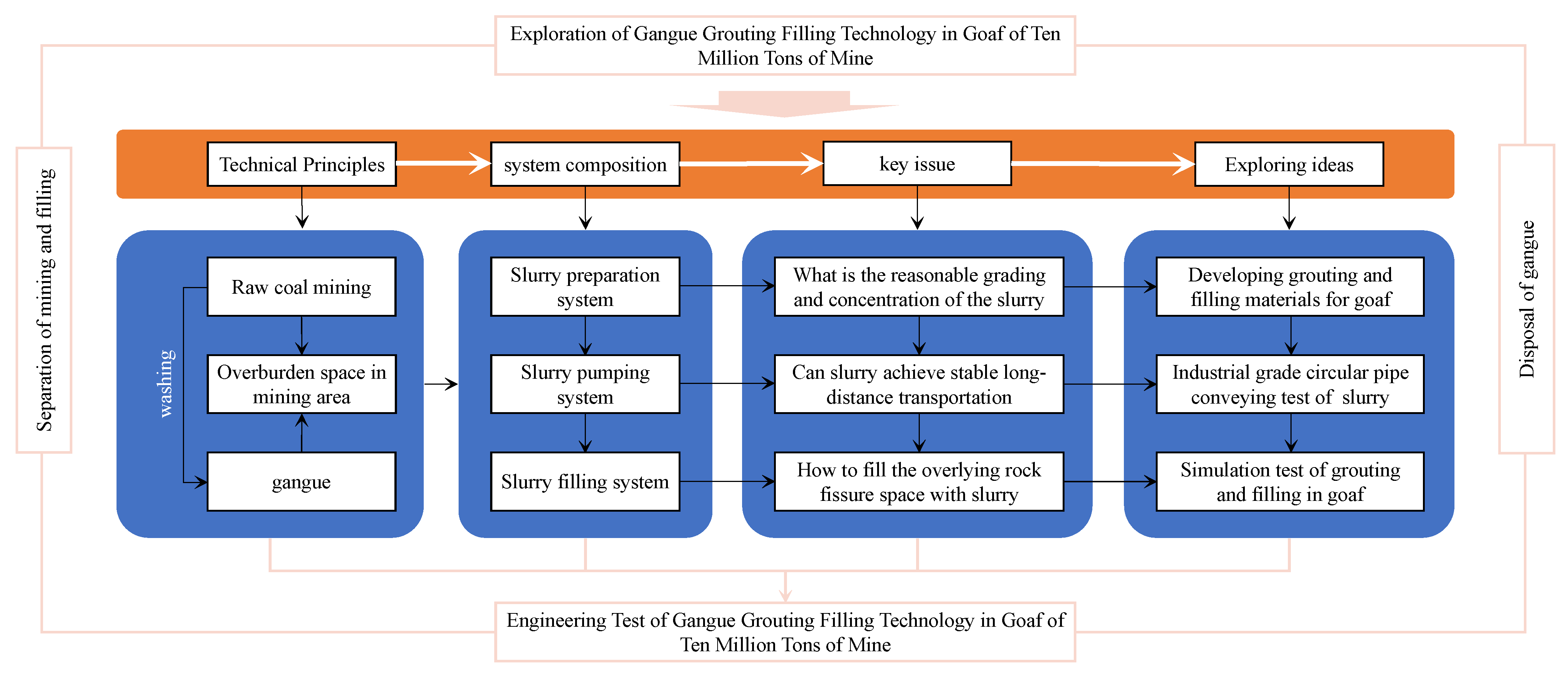

2. Gangue Grouting Filling Technology in Goafs

2.1. Principle and System Composition of Gangue Grouting Filling Technology in Goafs

2.2. Technical Difficulties and Solutions of Gangue Grouting Filling in Goafs

3. Research and Development of Millimeter-Grade Gangue Grouting Filling Material

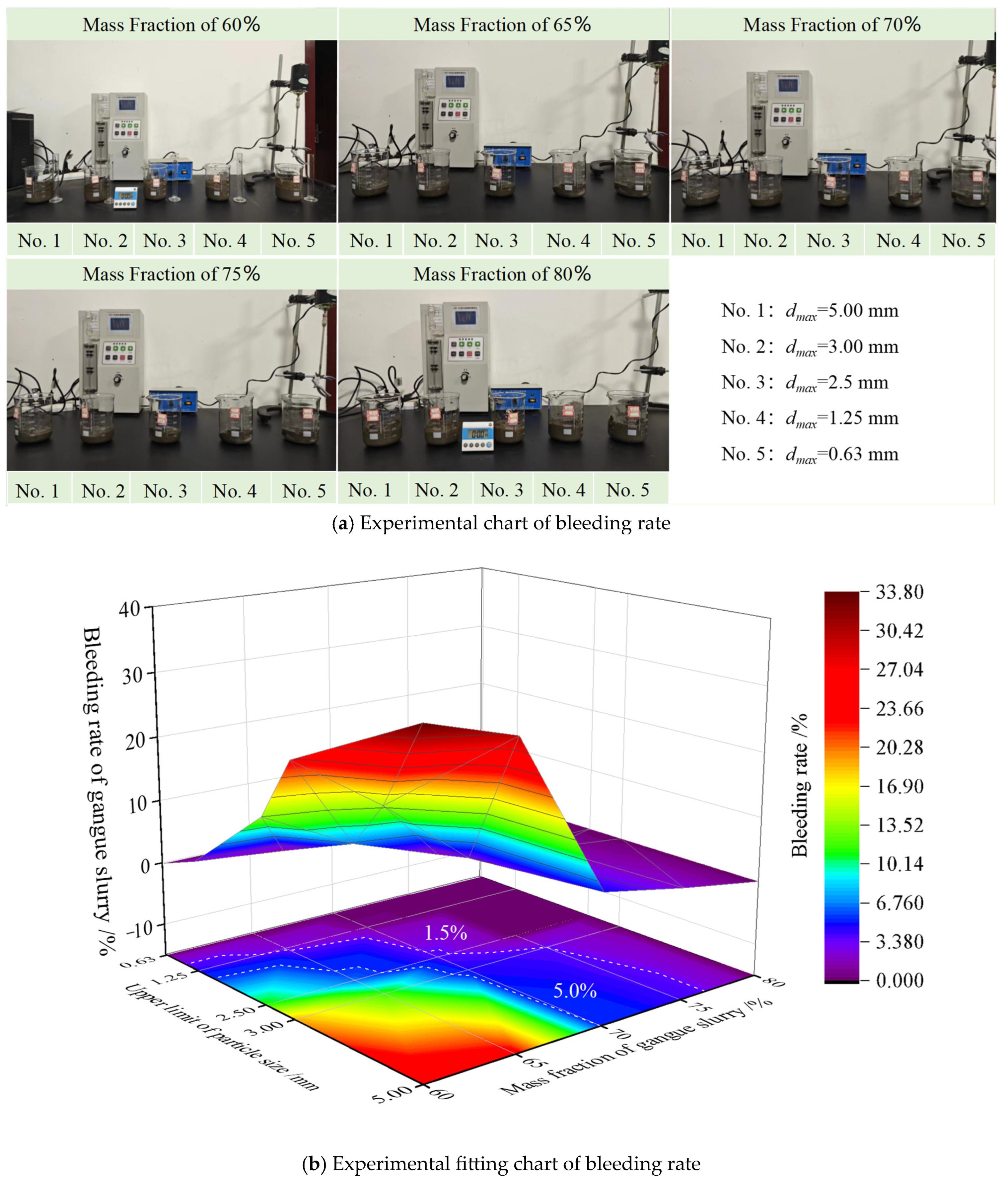

3.1. The Bleeding Performance of Different Gangue Grades and Slurry Concentrations

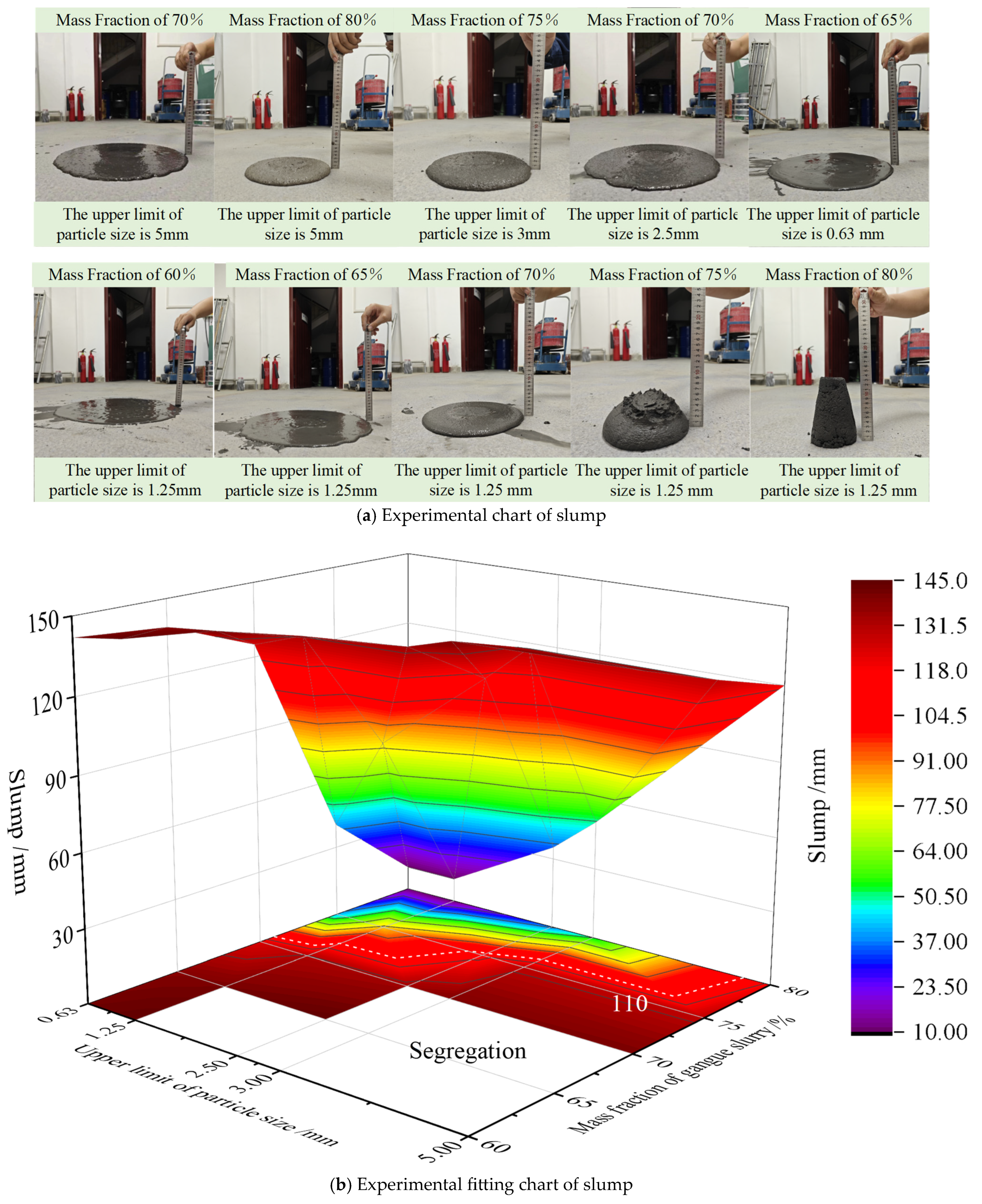

3.2. Collapse Performance of Different Gangue Grades and Slurry Concentrations

3.3. Preliminary Parameters of Millimeter-Grade Gangue Slurry

4. Industrial-Grade Circular Pipe Conveying Test of Gangue Slurry

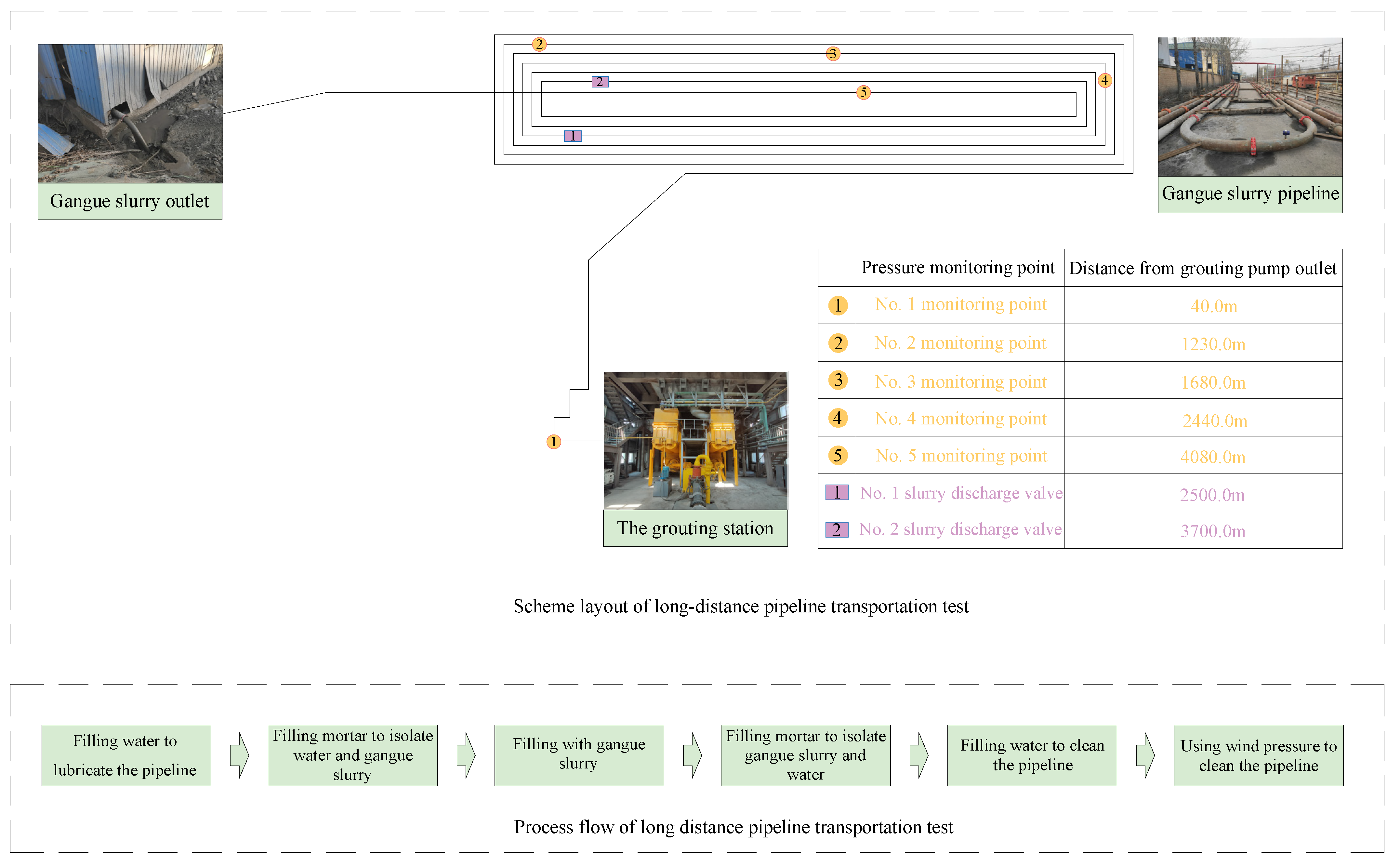

4.1. Scheme for Long-Distance Pipeline Transportation Test

4.2. Design of Long-Distance Pipeline Transportation Test

4.2.1. Test Parameters of Long-Distance Pipeline Transportation

4.2.2. Process of Long-Distance Pipeline Transportation Test

4.2.3. Monitoring System for Long-Distance Pipeline Transportation Test

4.3. Experimental Analysis of Long-Distance Pipeline Transportation

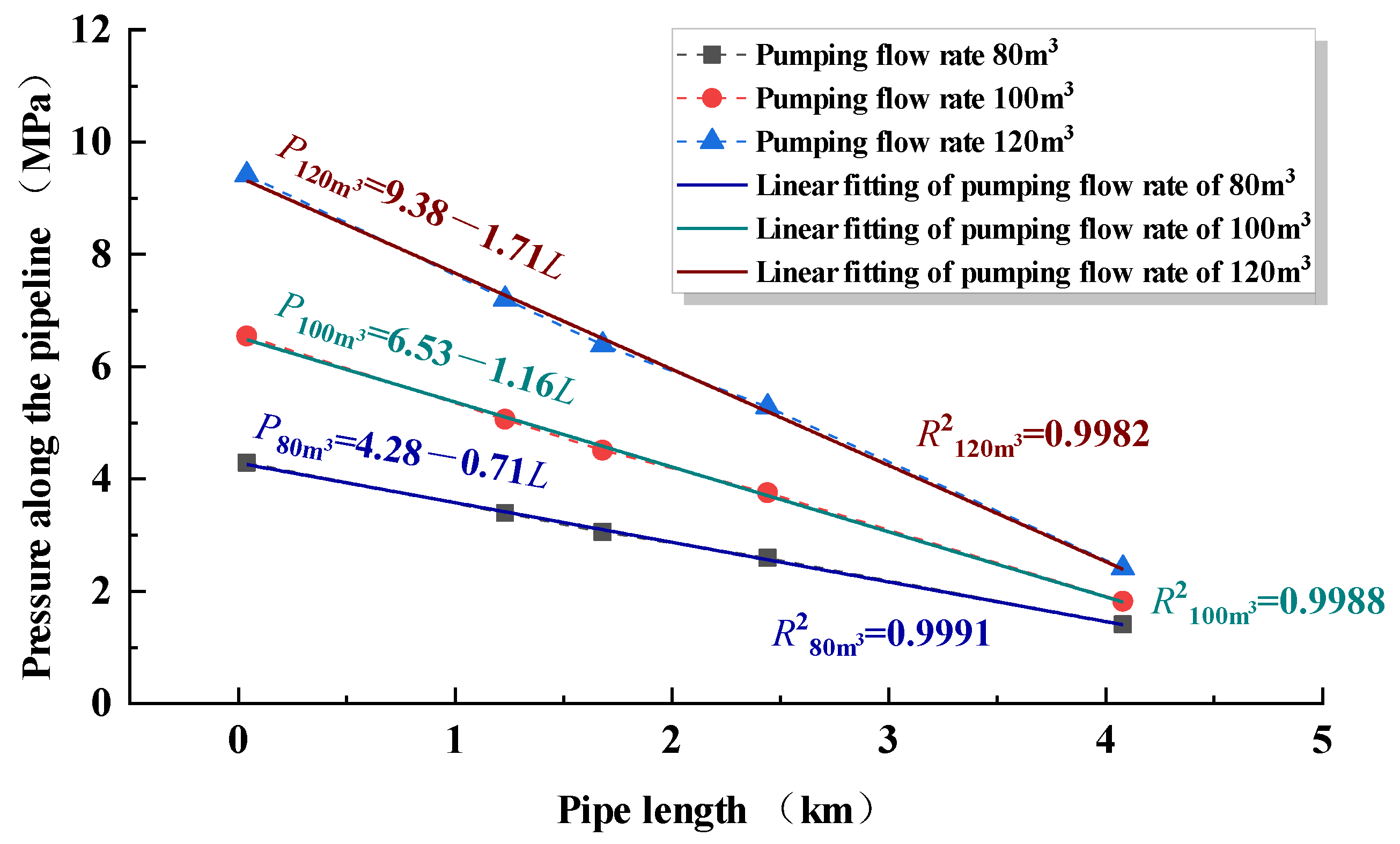

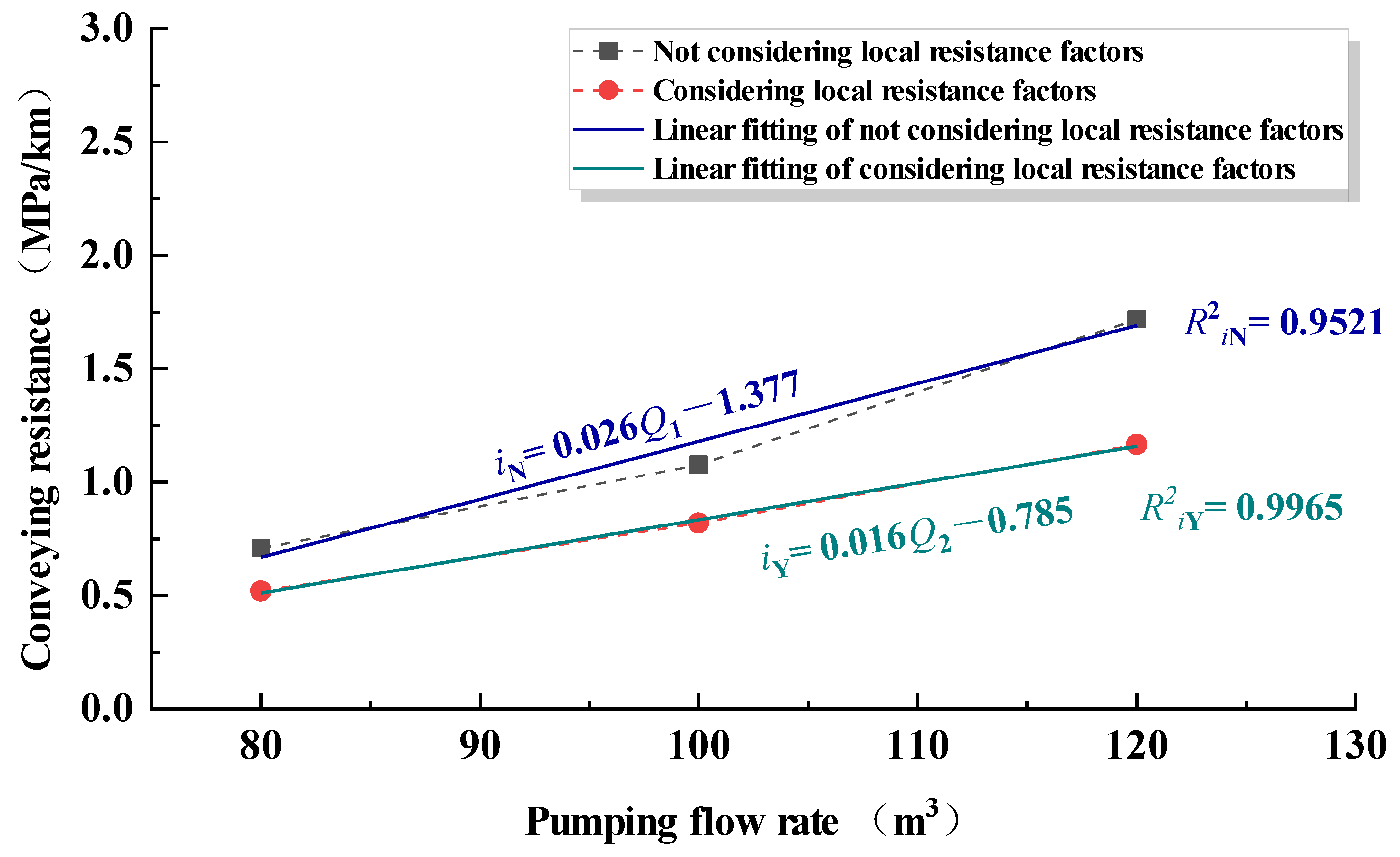

4.3.1. The Relationship Between the Pumping Flow Rate and Conveying Resistance

4.3.2. Evaluation of the Effect of Long-Distance Pipeline Transportation

5. Simulation Test of Grouting and Filling in Goafs

5.1. Gangue Accumulation Model and Test Process in Goafs

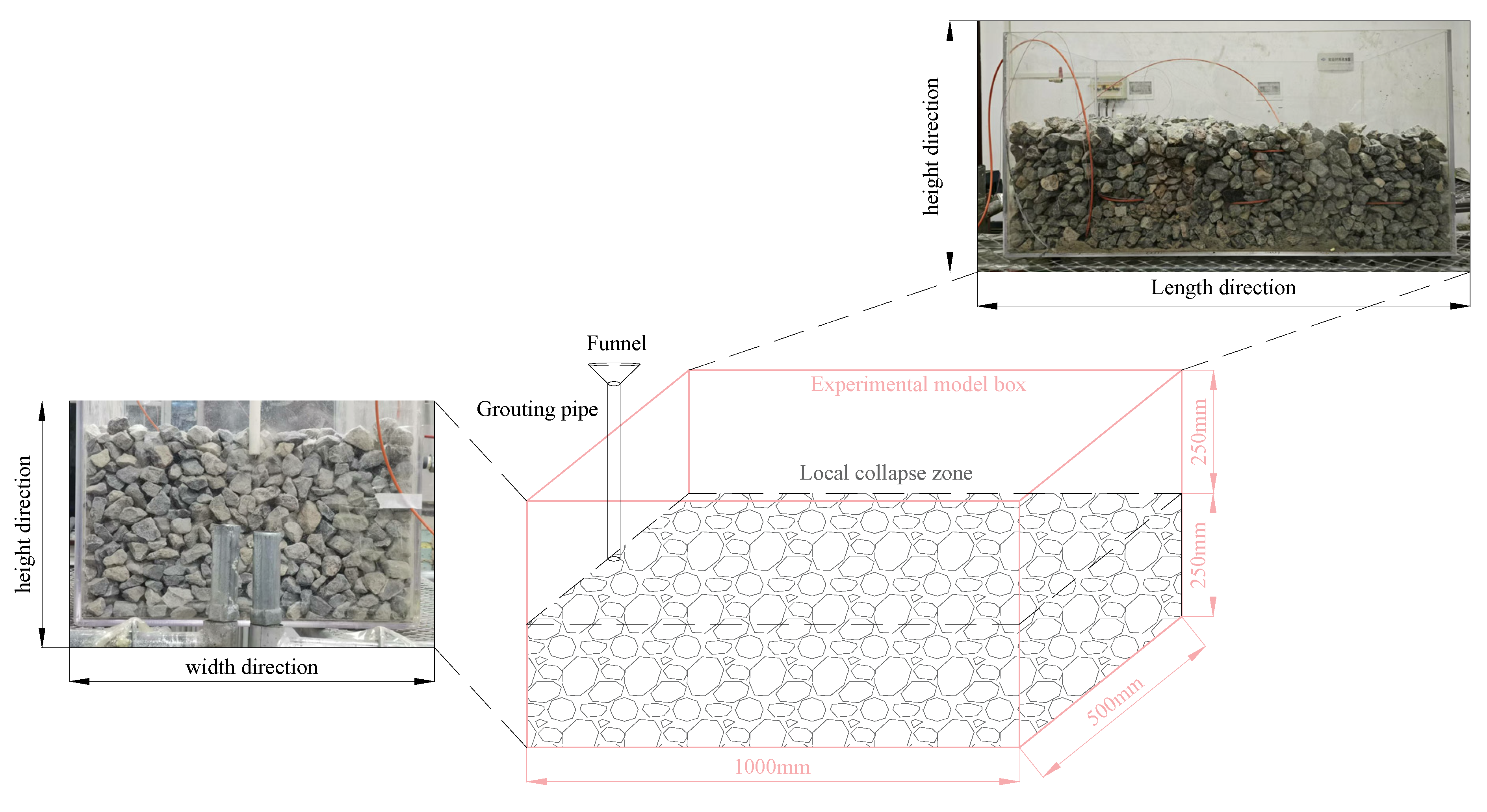

5.1.1. A Model of Gangue Accumulation in Local Collapse Zone

5.1.2. Process of Grouting Filling Simulation Test

5.2. Analysis of Gangue Grouting Filling Test in Goafs

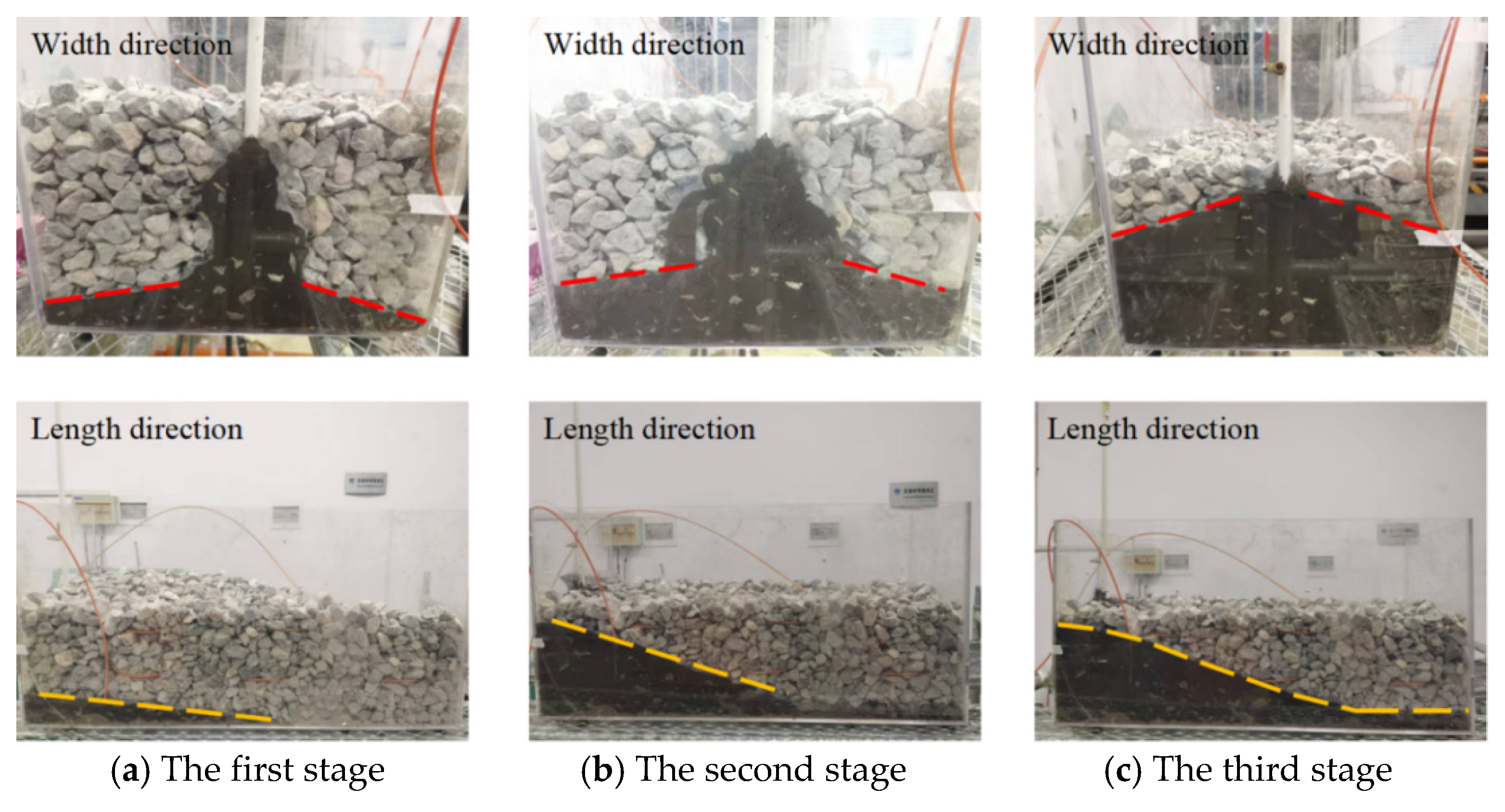

5.2.1. Flow Law of Gangue Slurry

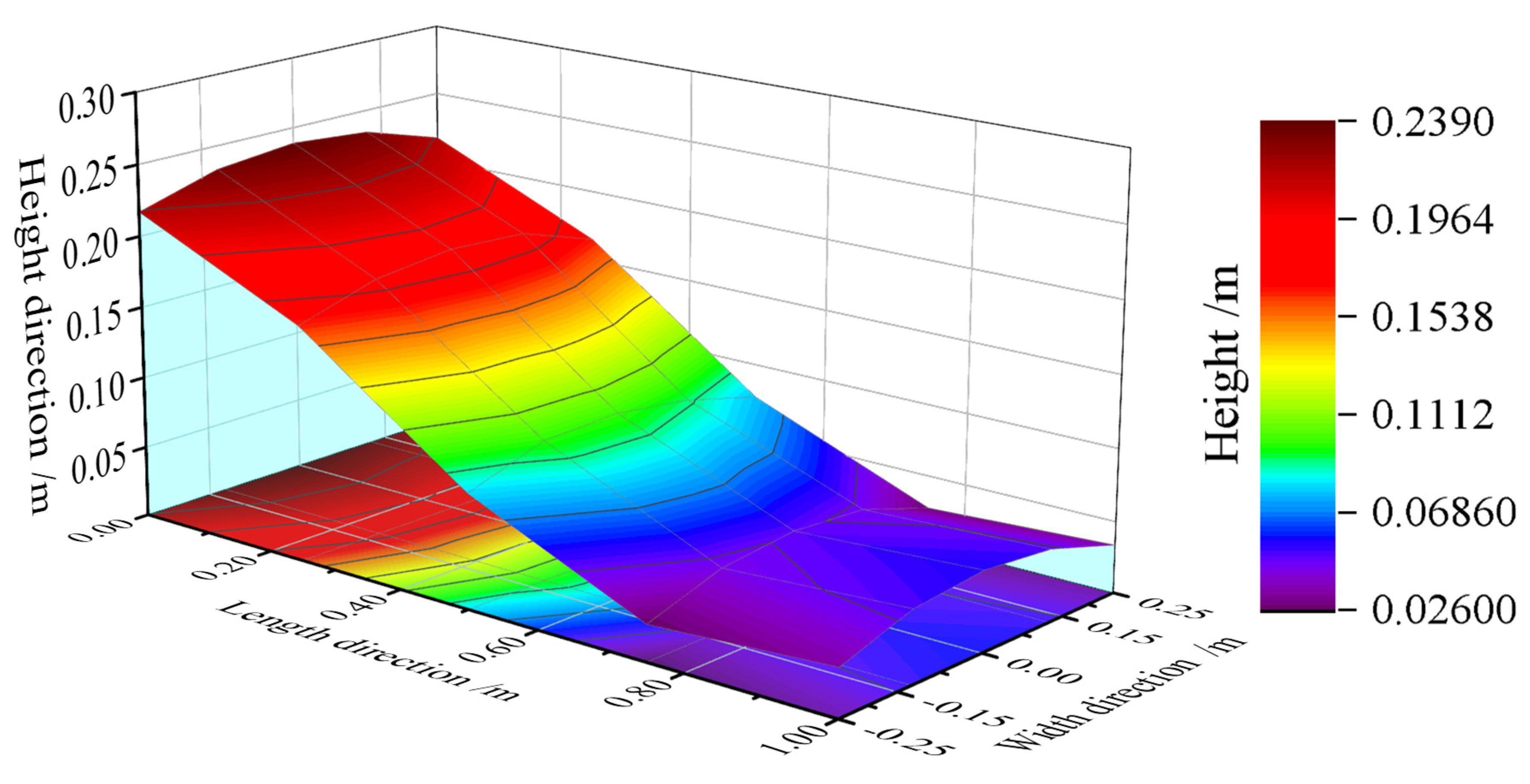

5.2.2. Distribution Pattern of Gangue Slurry

- (1)

- The accumulation height of the gangue slurry was highest at the slurry outlet, and its height was 0.24 m. The minimum accumulation height of the gangue slurry was 0.026 m, which was located at 0.7 m in the length direction and ±0.25 m in the width direction, not at the boundary of the length direction of the test model box (1.0 m).

- (2)

- In the process of exposing the rock fragments, the gangue slurry did not fully fill the gaps between the rock fragments, and there was no gangue slurry between the local rock fragments, that is, the gangue slurry could not pass through the gaps between all the rock fragments.

6. Industrial Test of Gangue Grouting Filling Technology in Goafs

6.1. Background of Grouting Filling Test

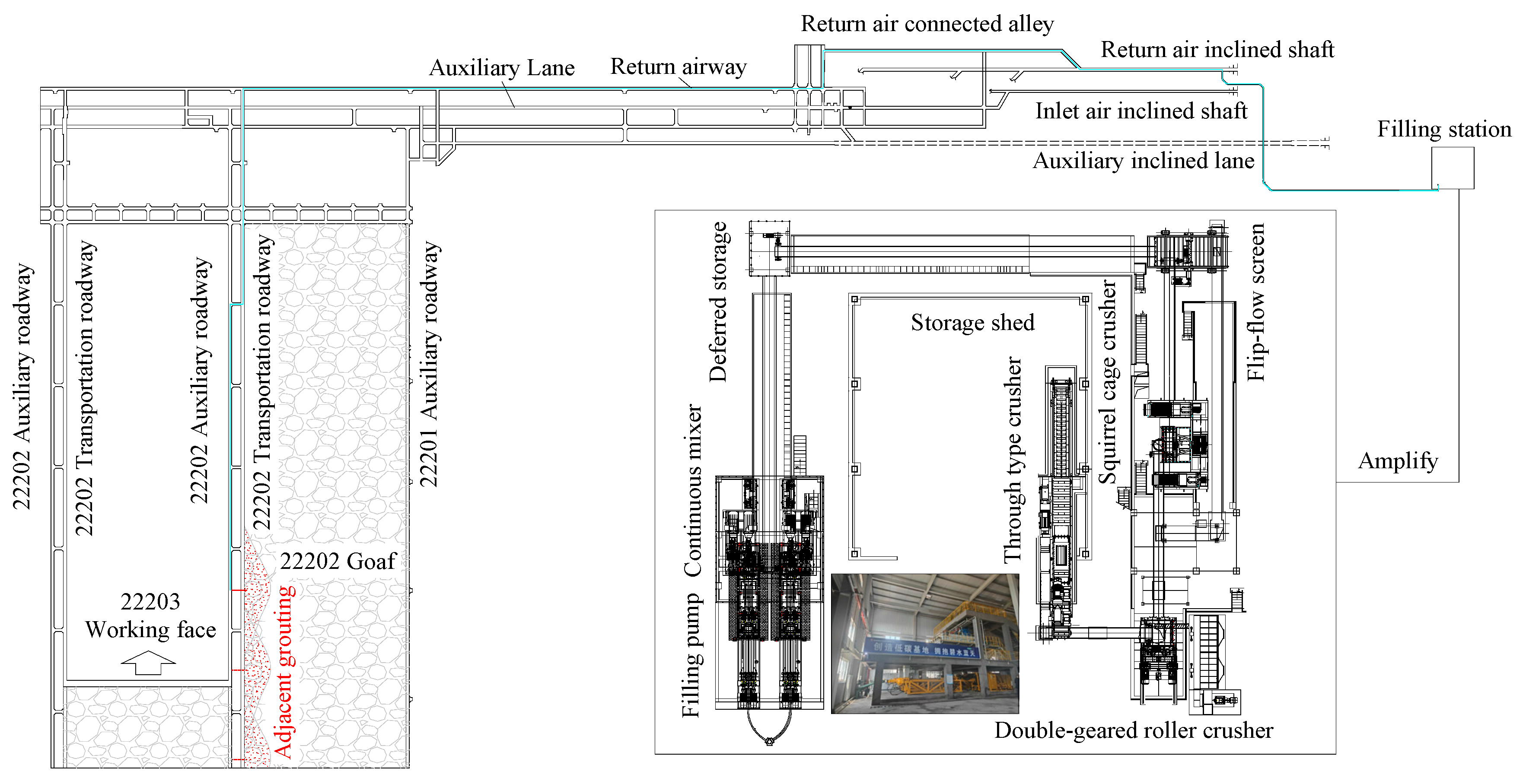

6.2. The Process and Layout of Grouting Filling

6.2.1. The Process of the Grouting Filling Test

- (1)

- The gangue in the gangue bin of the coal washing plant was transported by automobile to the storage shed.

- (2)

- The scraper was used to load the gangue to the first-stage crusher. The crushed gangue entered the second-stage crusher and then was transferred to the third-stage crusher through the belt, and it then entered the screening machine for screening. The finished gangue powder under the screen was transferred to the deferred storage through the well belt, and the unqualified gangue on the screen entered the third-stage crusher through the return belt to continue crushing.

- (3)

- The quantitative feeder under the deferred storage and water supply system transported the gangue powder and water to the first-stage mixer quantitatively according to a ratio of 7:3, and it then made the gangue slurry with a 70% concentration.

- (4)

- The gangue powder and water were stirred in the first-stage mixer, and the initially qualified gangue slurry overflowed to the second-stage mixer to continue stirring. Finally, the qualified gangue overflowed from the second-stage mixer to the hopper of the filling pump.

- (5)

- The filling pump transported the gangue slurry in the slurry hopper to the number 22202 goaf through the adjacent grouting borehole through the pipeline.

6.2.2. Grouting Filling Equipment and Parameters

6.3. Process and Effect of Grouting Filling Test

7. Conclusions

- (1)

- The concept of “fluidized filling” is proposed in this paper, and the principle, system composition, technical difficulties, and solutions of gangue grouting filling technology in goafs in a mine producing ten million tons of coal are provided.

- (2)

- A millimeter-grade gangue grouting material was developed, providing a gangue slurry concentration of 70.0~76.7%, corresponding to an upper limit of a 5 mm gangue particle size, 70~74.9%, corresponding to an upper limit of a 3 mm gangue particle size, 66.5~70.8%, corresponding to an upper limit of a 2.5 mm gangue particle size, and 60.0~63.5%, corresponding to an upper limit of a 1.25 mm gangue particle size.

- (3)

- The calculation method of frictional losses along the pipeline and local frictional losses are given. When the pumping flow was80~120 m3, the equivalent pipe length corresponding to a 90-degree elbow was 48.01~62.15 m, and the equal pipe length corresponding to a 135-degree elbow was 29.76~38.11 m, which verifies the feasibility of long-distance pipeline transportation of “gangue + water” two-phase flow.

- (4)

- Laboratory and field industrial grouting filling tests were carried out. Field experiments have shown that the gangue grouting filling technology in goafs can achieve the underground filling of ten million tons of coal gangue in a mine without affecting the average production of the mine.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.P.; Ren, S.H.; Xie, Y.C.; Jiao, X.M. Development opportunities of the industry towards the goal of carbon neutrality. J. China Coal Soc. 2021, 46, 2197–2211. [Google Scholar]

- Xie, H.P.; Wang, J.H.; Wang, G.F.; Ren, H.Y.; Liu, J.Z.; Ge, S.R.; Zhou, H.W.; Wu, G.; Ren, S.H. New ideas of coal revolution and layout of coal science and technology development. J. China Coal Soc. 2018, 43, 1187–1197. [Google Scholar]

- Zhang, J.X.; Ju, Y.; Zhang, Q.; Ju, F.; Xiao, X.; Zhang, W.Q.; Zhou, N.; Li, M. Low ecological environment damage technology and method in coal mines. J. Minging Strat. Control Eng. 2019, 1, 56–68. [Google Scholar]

- Zhang, J.X.; Ju, Y.; Li, M.; Zhou, N.; Zhang, Q. Method of coal gangue separation and coordinated in-situ backfill mining. J. China Coal Soc. 2020, 45, 131–140. [Google Scholar]

- Wu, Q.; Liu, H.L.; Chen, Q.; Sun, W.J.; Chen, Y. Theoretical study of mine geo-environmental restoration model and its application. J. China Coal Soc. 2017, 42, 1085–1092. [Google Scholar]

- Wang, X.H.; Liu, F.; Ni, M.; Liu, Z.X. Research and application of spontaneous combustion control and ecological restoration of waste dump. Coal Sci. Technol. 2020, 48 (Suppl. S2), 128–131. [Google Scholar]

- Wu, Q.; Liu, H.L.; Zhao, H.Q.; Zhang, M.; Liu, S.Q.; Zeng, Y.F. Discussion on the nine aspects of addressing environmental problems of mining. J. China Coal Soc. 2019, 44, 10–22. [Google Scholar]

- Hu, B.N. Backfill mining technology and development tendency in China coal mine. Coal Sci. Technol. 2012, 40, 1–5. [Google Scholar]

- Yan, S.H.; Zhang, H.X. Status of filling mining technology in coal mines of China. Coal Min. Technol. 2008, 13, 1–3+10. [Google Scholar]

- Liu, J.G.; Li, X.W.; He, T. Application status and prospect of backfill mining in Chinese coal mines. J. China Coal Soc. 2020, 45, 141–150. [Google Scholar]

- Xu, J.L. Research and progress of coal mine green mining in 20 years. Coal Sci. Technol. 2020, 48, 1–15. [Google Scholar]

- Yang, S.L.; Bai, Y.G.; Li, J. Comprehensive analysis on present status of mine backfill mining and prospects. Coal Eng. 2013, 45, 4–6, 10. [Google Scholar]

- Zhou, N.; Zhang, J.X.; Ouyang, S.Y.; Deng, X.J.; Dong, C.W.; Du, E.B. Feasibility study and performance optimization of sand-based cemented paste backfill materials. J. Clean. Prod. 2020, 259, 120798. [Google Scholar] [CrossRef]

- Xu, J.L.; Xuan, D.Y.; Zhu, W.B.; Wang, X.Z.; Wang, X.L.; Teng, H. Study and application of coal mining with partial backfilling. J. China Coal Soc. 2015, 40, 1303–1312. [Google Scholar]

- Zou, H.Q.; Hou, C.J.; Sun, X.K.; Zhai, Q.D.; Chen, D.J. Solid waste paste filling for non-village-relocation coal mining. J. China Univ. Min. Technol. 2004, 33, 154–158. [Google Scholar]

- Miao, X.X.; Zhang, J.X.; Guo, G.L. Study on waste-filling method and technology in fully-mechanized coal mining. J. China Coal Soc. 2010, 35, 1–6. [Google Scholar]

- Xuan, D.Y.; Xu, J.L.; Zhu, W.B. Backfill mining practice in China coal mines. J. Mines Met. Fuels 2013, 61, 225–234. [Google Scholar]

- Zhu, W.B.; Xu, J.L.; Lai, W.Q.; Wang, Z.G. Research of isolated section-grouting technology for overburden bed separation space to reduce subsidence. J. China Coal Soc. 2007, 32, 458–462. [Google Scholar]

- Xu, J.L.; Ni, J.M.; Xuan, D.Y.; Wang, X.Z. Coal mining technology without village relocation by isolated grout injection into overburden. Coal Sci. Technol. 2015, 43, 8–11. [Google Scholar]

- Sun, J. Mechanics criterion and factors affecting overburden stability in solid dense filling mining. Int. J. Min. Sci. Technol. 2017, 27, 407–413. [Google Scholar] [CrossRef]

- Zhang, J.X.; Tu, S.H.; Cao, Y.J.; Tan, Y.L.; Xin, H.Q.; Pang, J.L. Research progress of technologies for intelligent separation and in-situ backfill in deep coal mines in China. J. Min. Saf. Eng. 2020, 37, 1–10. [Google Scholar]

- Huang, P.; Zhang, J.X.; Yan, X.J.; Anthony John Spencer Spearing; Li, M.; Liu, S.W. Deformation response of roof in solid backfilling coal mining based on viscoelastic properties of waste gangue. Int. J. Min. Sci. Technol. 2021, 31, 279–289. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, S.G.; Zhang, N.; Chang, Z. The application of short-wall block backfill mining to preserve surface water resources in northwest China. J. Clean. Prod. 2020, 261, 121232. [Google Scholar] [CrossRef]

- Xie, S.R.; Gao, M.M.; Chen, D.D.; Yue, S.S.; Pan, H.; Zeng, J.C.; Suo, H.X. Study on the distribution and evolution characteristics of spherical stress shell in backfilling mining stope. J. Min. Saf. Eng. 2019, 36, 16–23. [Google Scholar]

- Xu, P.; Zhou, Y.J.; Zhang, M.X.; Li, J.W.; Cao, Z.Z. Fracture development of overlying strata by backfill mining under thick alluvium and thin bedrock. J. Min. Saf. Eng. 2015, 32, 617–622. [Google Scholar]

- Liu, W.T.; Wu, H.F.; Shen, J.J. Based on Box-Behnken method superfine cement grouting material ratioandperformance optimization model. Coal Sci. Technol. 2024, 52, 146–158. [Google Scholar]

- Ruan, Z.N.; Wu, A.X.; Wang, Y.M.; Wang, S.Y.; Wang, J.D. Multiple response optimization of key performance indicators of cemented pastebackfill of total solid waste. Chin. J. Eng. 2020, 44, 496–503. [Google Scholar]

- Zhou, Z.B.; Liu, J.H.; Wu, R.D.; Wu, A.X.; Wang, H.J.; Wang, S.Y. Analysisof bleeding of low concentration full tailings filling materialand its regulate-control. Chin. J. Mater. Res. 2020, 34, 481–488. [Google Scholar]

- Wang, X.F.; Gao, M.Z.; Li, L.Q. Spatiotemporal coupling law of mining pressure strata movement and fracture field distribution in deep stope. J. Min. Saf. Eng. 2016, 33, 604–610. [Google Scholar]

- Yang, C.; Guo, L.J.; Zhang, L.; Hu, L.M.; Xu, W.Y. Study of the rheological characteristics of copper tailings and calculation of resistance in pipeline transportation. Chin. J. Eng. 2021, 39, 663–668. [Google Scholar]

- Hou, Y.Q.; Yin, S.H.; Dai, C.Q.; Cao, Y. Rheological properties and pipeline resistance calculation model in tailings paste. Chin. J. Nonferrous Met. 2021, 31, 510–519. [Google Scholar]

- Wang, H.J.; Wang, Y.; Wu, A.X.; Zhai, Y.G.; Jiao, H.Z. Research of paste new definition from the view point of saturation ratio and bleeding rate. J. Wuhan Univ. Technol. 2011, 33, 85–89. [Google Scholar]

- Wu, A.X.; Wang, H.J. Theory and Technology of Metal Ore Paste Filling; Science Press: Beijing, China, 2015. [Google Scholar]

- Yang, X.B.; Yan, Z.P.; Yin, S.H.; Yang, H. Transportation Pressure Model and Optimization of Coarse Aggregate Paste Backfill Based on Pipe Loop Test. J. Hunan Univ. (Nat. Sci.) 2022, 49, 181–191. [Google Scholar]

- Liu, H.L.; Hou, C.; Li, L.; Du, J.F.; Yan, B.X. Experimental investigation on flow properties of cemented paste backfill through L-pipe and loop-pipe tests. J. Cent. S. Univ. 2021, 28, 2830–2842. [Google Scholar] [CrossRef]

- Zheng, B.K.; Yao, W.; Huang, T.L.; Zhang, L.Y.; Yin, X.Y. Transportable performance of modified unclassed tailingsfilling slurry based on loop test. Chin. J. Nonferrous Met. 2021, 31, 520–529. [Google Scholar]

- Zhe, L.; Pan, H.; Gu, W.Z.; Zhao, M.Y.; Zhang, X.F.; Xu, K. Experimental study on flow and diffusion law of gangue filling slurry in caving zone. J. China Coal Soc. 2021, 46 (Suppl. S2), 629–638. [Google Scholar]

- Zhe, L.; Song, T.Q.; Gu, W.Z.; Xu, K.; Liu, Z.C.; Qiu, F.Q.; Yuan, C.F. Experimental research on transport-resistance characteristics of gangue slurry andits flow trend in goaf. J. China Coal Soc. 2022, 47 (Suppl. S1), 39–48. [Google Scholar]

| Particle Size | Proportion |

|---|---|

| >5.0 mm | 5.25% |

| 3.0–5.0 mm | 10.03% |

| 2.5–3.0 mm | 8.95% |

| 1.25–2.5 mm | 13.35% |

| 630 μm–1.25 mm | 12.95% |

| 315–630 μm | 10.70% |

| <315 μm | 38.77% |

| Upper Limit of Particle Size Mass Fraction | 60% | 65% | 70% | 75% | 80% |

|---|---|---|---|---|---|

| 5.00 mm | 33.76% | 29.71% | 4.93% | 2.25% | 0% |

| 3.00 mm | 23.26% | 13.93% | 2.92% | 1.50% | 0% |

| 2.50 mm | 13.50% | 6.50% | 1.75% | 0% | 0% |

| 1.25 mm | 2.50% | 1.10% | 0.20% | 0% | 0% |

| 0.63 mm | 0% | 0% | 0% | 0% | 0% |

| Upper Limit of Particle Size Mass Fraction | 60% | 65% | 70% | 75% | 80% |

|---|---|---|---|---|---|

| 5.00 mm | / | / | 141 mm | 130 mm | 120 mm |

| 3.00 mm | / | / | 140 mm | 130 mm | 50 mm |

| 2.50 mm | / | 145 mm | 135 mm | 115 mm | 35 mm |

| 1.25 mm | 145 mm | 141 mm | 132 mm | 80 mm | 10 mm |

| 0.63 mm | 142 mm | 139 mm | 125 mm | 40 mm | 10 mm |

| Spacing/km | Number of 90-Degree Angles Included | Number of 135-Degree Angles Included | Pressure Difference at a Flow Rate of 80 m3/MPa | Pressure Difference at a Flow Rate of 100 m3/MPa | Pressure Difference at a Flow Rate of 120 m3/MPa |

|---|---|---|---|---|---|

| 1.19 | 10 | 2 | 0.90 | 1.48 | 2.21 |

| 0.45 | 4 | 0 | 0.33 | 0.55 | 0.82 |

| 0.76 | 3 | 0 | 0.47 | 0.75 | 1.10 |

| 1.64 | 13 | 0 | 1.18 | 1.94 | 2.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, H.; Xie, S.; Gu, W.; Song, T.; Qiu, F.; Chen, D. Research on Key Parameters and Engineering Experiments of Coal Gangue Slurry Filling Technology. Appl. Sci. 2025, 15, 5475. https://doi.org/10.3390/app15105475

Pan H, Xie S, Gu W, Song T, Qiu F, Chen D. Research on Key Parameters and Engineering Experiments of Coal Gangue Slurry Filling Technology. Applied Sciences. 2025; 15(10):5475. https://doi.org/10.3390/app15105475

Chicago/Turabian StylePan, Hao, Shengrong Xie, Wenzhe Gu, Tianqi Song, Fengqi Qiu, and Dongdong Chen. 2025. "Research on Key Parameters and Engineering Experiments of Coal Gangue Slurry Filling Technology" Applied Sciences 15, no. 10: 5475. https://doi.org/10.3390/app15105475

APA StylePan, H., Xie, S., Gu, W., Song, T., Qiu, F., & Chen, D. (2025). Research on Key Parameters and Engineering Experiments of Coal Gangue Slurry Filling Technology. Applied Sciences, 15(10), 5475. https://doi.org/10.3390/app15105475