Development and Optimization of Self-Healing Cement for CO2 Injection and Storage Wells: Enhancing Long-Term Wellbore Integrity in Extreme Subsurface Conditions

Abstract

1. Introduction

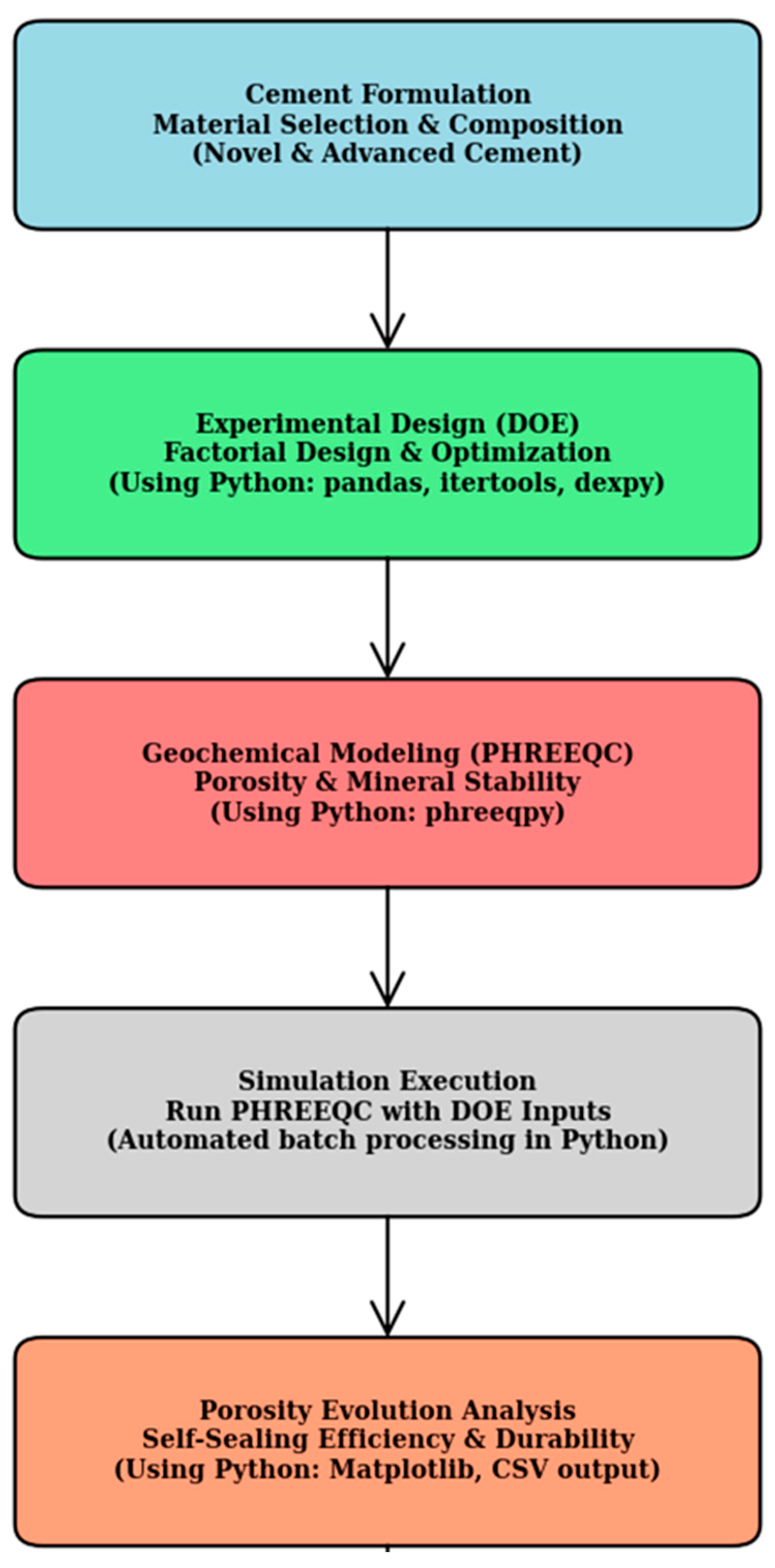

- Design a cement system incorporating Barite, Pozzolan, and Chalcedony/Zeolite that enhances long-term chemical and mechanical stability under CO2-rich and high-temperature conditions.

- Employ a Design of Experiment (DOE) framework to systematically determine the most effective compositions for minimizing porosity and enhancing self-sealing performance.

- Use PHREEQC 3-based geochemical simulations, integrated with Python 3.12 scripting, to evaluate porosity evolution, mineral transformation, and phase volume changes over time.

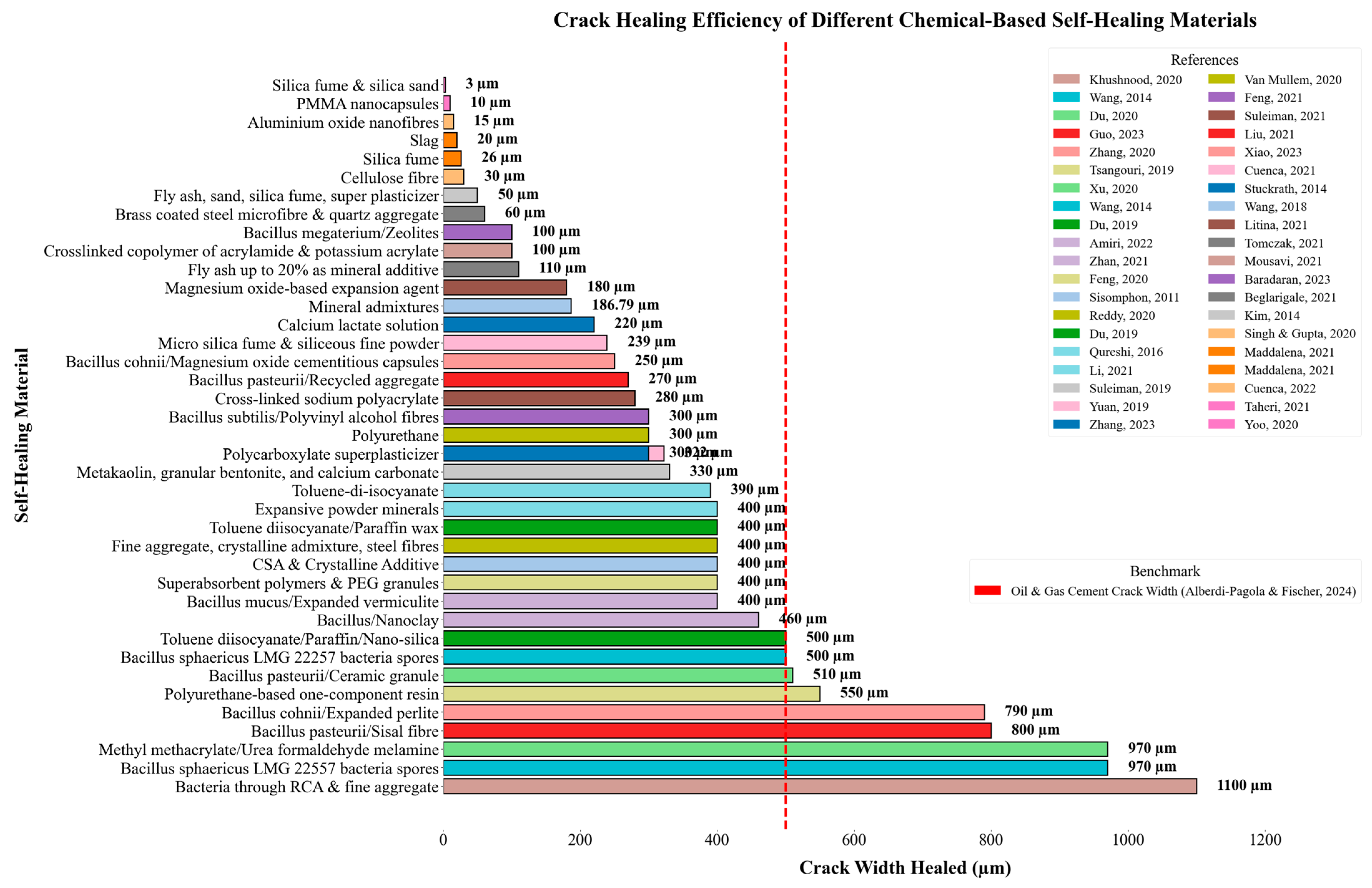

- Benchmark the performance of the proposed self-healing formulations against conventional cement to demonstrate improvements in durability and crack resistance.

2. Well Integrity Considerations in High-Temperature and Harsh Environments

3. Self-Healing Cement

4. Challenges in Self-Healing Cement Technologies

5. Materials and Methods

6. Results and Discussion

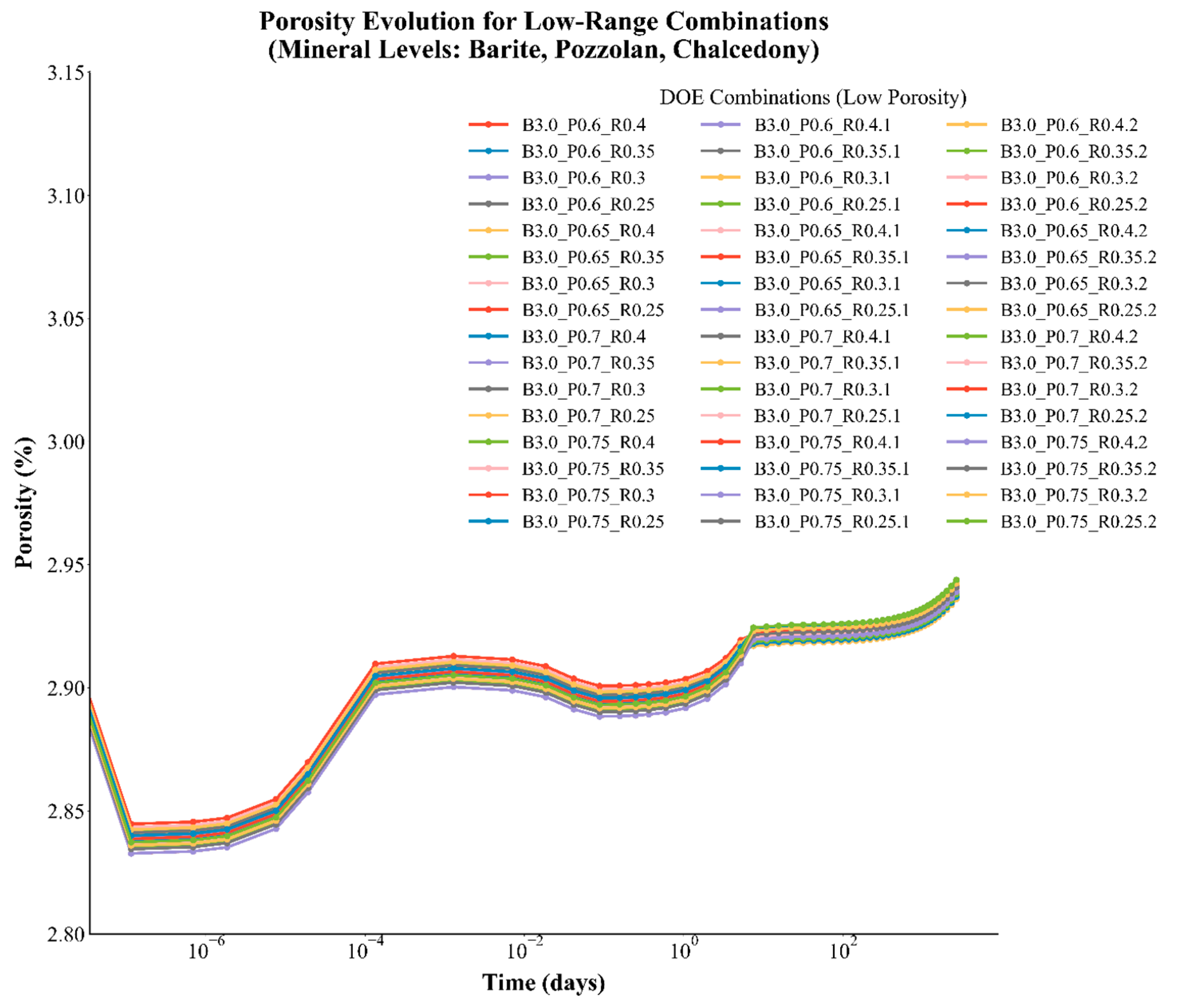

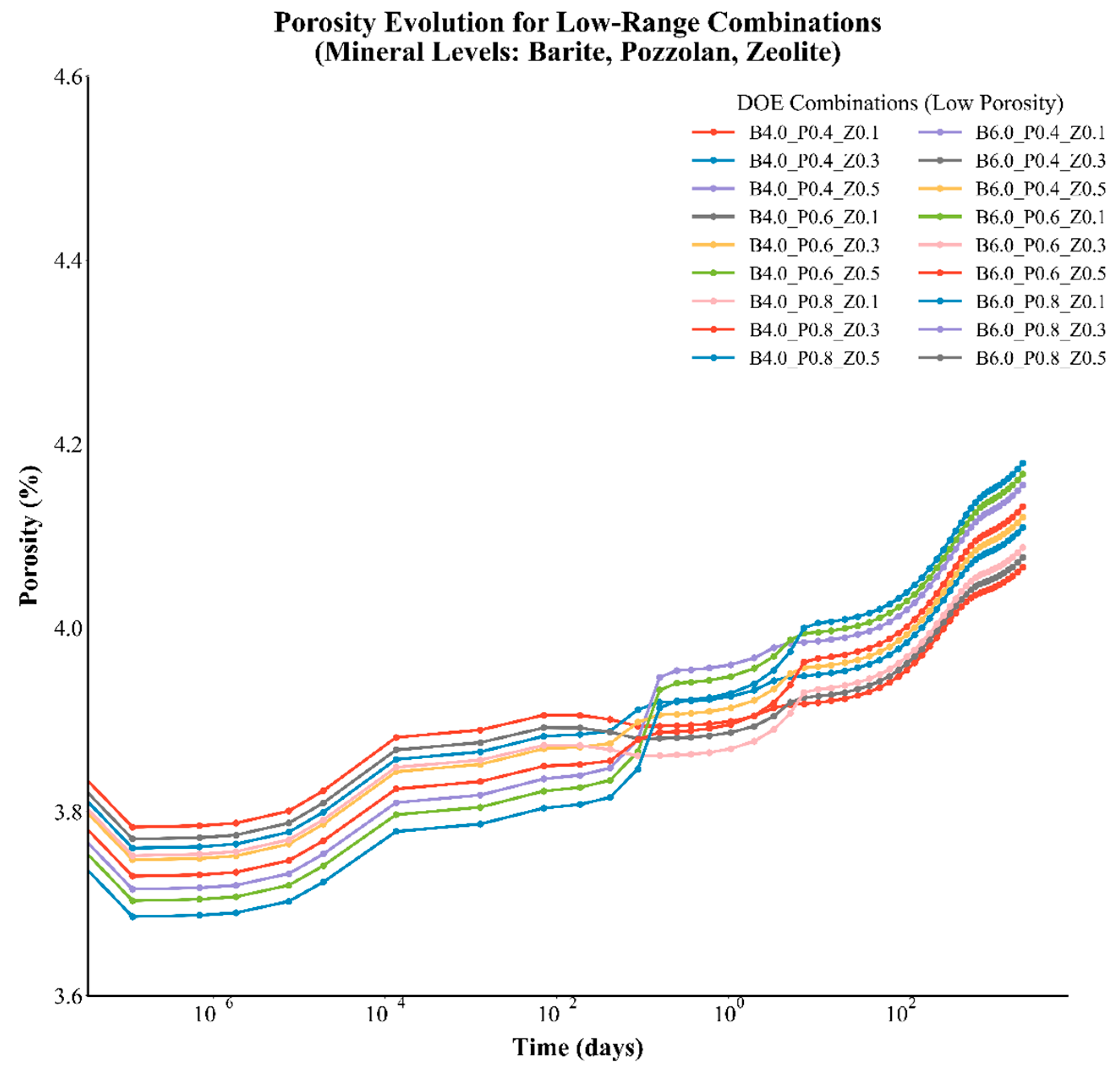

6.1. Porosity Evolution and Self-Healing Efficiency

6.2. Saturation Index (SI) Evolution of Key Minerals

- Calcite, Aragonite, and Vaterite exhibit near-equilibrium SI values, indicating a continuous dissolution–precipitation cycle that contributes to crack healing and permeability reduction.

- Quartz, Chalcedony, and Pozzolan are initially undersaturated, suggesting early-stage silica dissolution, which later stabilizes as these phases reprecipitate into cementitious silicates, reinforcing the matrix.

- Montmorillonite and Barite remain undersaturated, reflecting limited reactivity under the simulated conditions; however, their presence contributes to cement density stability and resistance against chemical degradation.

- Portlandite and ECSH2 display a sustained presence, confirming their role in long-term structural reinforcement and enhancing cement integrity.

- Pyrite and Vivianite remain significantly undersaturated, indicating minimal precipitation in the absence of reducing conditions, which is expected under standard wellbore environments.

6.3. Phase Volume Changes and Mineral Transformations

- ECSH2 (a highly reactive C-S-H phase) exhibits consistent volume stability, reaffirming its role in continuous cement reinforcement and crack-sealing functionality.

- Pozzolan and Chalcedony dissolution contribute to secondary silicate formation, validating their self-healing role through silica gel formation and subsequent precipitation.

- Calcite and Aragonite display controlled precipitation behavior, suggesting a balance between dissolution and secondary reprecipitation, which is critical for maintaining cement integrity in CO2-rich environments.

- Minimal volume loss in key binding phases such as C2S and C3S confirms the structural durability of the cement, as these phases provide essential strength and long-term sealing capabilities in wellbore applications.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Barite wt. (%) | Pozzolan wt. (%) | Chalcedony wt. (%) | Cement Mass (g) | Water Mass (g) | Total Volume (cm3) | Water/Cement Ratio | Slurry Density (g/cm3) |

|---|---|---|---|---|---|---|---|

| 3.00 (20.9%) | 0.60 (43.1%) | 0.40 (35.9%) | 33.098 | 11.82 | 23.64 | 0.357 | 1.88 |

| 3.00 (21.9%) | 0.60 (45.2%) | 0.35 (32.9%) | 30.472 | 11.043 | 21.85 | 0.362 | 1.88 |

| 3.00 (23.0%) | 0.60 (47.4%) | 0.30 (29.6%) | 27.846 | 10.265 | 20.06 | 0.369 | 1.88 |

| 3.00 (24.2%) | 0.60 (49.8%) | 0.25 (26.0%) | 25.22 | 9.488 | 18.27 | 0.376 | 1.88 |

| 3.00 (20.2%) | 0.65 (45.1%) | 0.40 (34.7%) | 33.736 | 12.05 | 24.1 | 0.357 | 1.88 |

| 3.00 (21.1%) | 0.65 (47.1%) | 0.35 (31.7%) | 31.11 | 11.272 | 22.31 | 0.362 | 1.88 |

| 3.00 (22.1%) | 0.65 (49.4%) | 0.30 (28.5%) | 28.483 | 10.495 | 20.51 | 0.368 | 1.88 |

| 3.00 (23.2%) | 0.65 (51.8%) | 0.25 (24.9%) | 25.857 | 9.718 | 18.72 | 0.376 | 1.88 |

| 3.00 (19.5%) | 0.70 (46.9%) | 0.40 (33.5%) | 34.373 | 12.279 | 24.55 | 0.357 | 1.88 |

| 3.00 (20.4%) | 0.70 (49.0%) | 0.35 (30.6%) | 31.747 | 11.502 | 22.76 | 0.362 | 1.88 |

| 3.00 (21.3%) | 0.70 (51.2%) | 0.30 (27.4%) | 29.121 | 10.724 | 20.97 | 0.368 | 1.88 |

| 3.00 (22.3%) | 0.70 (53.7%) | 0.25 (24.0%) | 26.495 | 9.947 | 19.18 | 0.375 | 1.88 |

| 3.00 (18.9%) | 0.75 (48.7%) | 0.40 (32.4%) | 35.011 | 12.509 | 25.01 | 0.357 | 1.88 |

| 3.00 (19.7%) | 0.75 (50.7%) | 0.35 (29.6%) | 32.385 | 11.731 | 23.22 | 0.362 | 1.88 |

| 3.00 (20.6%) | 0.75 (53.0%) | 0.30 (26.5%) | 29.759 | 10.954 | 21.43 | 0.368 | 1.88 |

| 3.00 (21.5%) | 0.75 (55.4%) | 0.25 (23.1%) | 27.133 | 10.177 | 19.64 | 0.375 | 1.88 |

| 3.00 (19.5%) | 0.70 (46.9%) | 0.40 (33.5%) | 34.373 | 12.279 | 24.55 | 0.357 | 1.89 |

| 3.00 (20.4%) | 0.70 (49.0%) | 0.35 (30.6%) | 31.747 | 11.502 | 22.76 | 0.362 | 1.89 |

| 3.00 (21.3%) | 0.70 (51.2%) | 0.30 (27.4%) | 29.121 | 10.724 | 20.97 | 0.368 | 1.89 |

| 3.00 (22.3%) | 0.70 (53.7%) | 0.25 (24.0%) | 26.495 | 9.947 | 19.18 | 0.375 | 1.89 |

| 3.00 (18.9%) | 0.75 (48.7%) | 0.40 (32.4%) | 35.011 | 12.509 | 25.01 | 0.357 | 1.89 |

| 3.00 (19.7%) | 0.75 (50.7%) | 0.35 (29.6%) | 32.385 | 11.731 | 23.22 | 0.362 | 1.89 |

| 3.00 (20.6%) | 0.75 (53.0%) | 0.30 (26.5%) | 29.759 | 10.954 | 21.43 | 0.368 | 1.89 |

| 3.00 (21.5%) | 0.75 (55.4%) | 0.25 (23.1%) | 27.133 | 10.177 | 19.64 | 0.375 | 1.89 |

| 3.00 (20.9%) | 0.60 (43.1%) | 0.40 (35.9%) | 33.098 | 11.82 | 23.64 | 0.357 | 1.89 |

| 3.00 (21.9%) | 0.60 (45.2%) | 0.35 (32.9%) | 30.472 | 11.043 | 21.85 | 0.362 | 1.89 |

| 3.00 (23.0%) | 0.60 (47.4%) | 0.30 (29.6%) | 27.846 | 10.265 | 20.06 | 0.369 | 1.89 |

| 3.00 (24.2%) | 0.60 (49.8%) | 0.25 (26.0%) | 25.22 | 9.488 | 18.27 | 0.376 | 1.89 |

| 3.00 (20.2%) | 0.65 (45.1%) | 0.40 (34.7%) | 33.736 | 12.05 | 24.1 | 0.357 | 1.89 |

| 3.00 (21.1%) | 0.65 (47.1%) | 0.35 (31.7%) | 31.11 | 11.272 | 22.31 | 0.362 | 1.89 |

| 3.00 (22.1%) | 0.65 (49.4%) | 0.30 (28.5%) | 28.483 | 10.495 | 20.51 | 0.368 | 1.89 |

| 3.00 (23.2%) | 0.65 (51.8%) | 0.25 (24.9%) | 25.857 | 9.718 | 18.72 | 0.376 | 1.89 |

| 3.00 (19.5%) | 0.70 (46.9%) | 0.40 (33.5%) | 34.373 | 12.279 | 24.55 | 0.357 | 1.9 |

| 3.00 (20.4%) | 0.70 (49.0%) | 0.35 (30.6%) | 31.747 | 11.502 | 22.76 | 0.362 | 1.9 |

| 3.00 (21.3%) | 0.70 (51.2%) | 0.30 (27.4%) | 29.121 | 10.724 | 20.97 | 0.368 | 1.9 |

| 3.00 (22.3%) | 0.70 (53.7%) | 0.25 (24.0%) | 26.495 | 9.947 | 19.18 | 0.375 | 1.9 |

| 3.00 (18.9%) | 0.75 (48.7%) | 0.40 (32.4%) | 35.011 | 12.509 | 25.01 | 0.357 | 1.9 |

| 3.00 (19.7%) | 0.75 (50.7%) | 0.35 (29.6%) | 32.385 | 11.731 | 23.22 | 0.362 | 1.9 |

| 3.00 (20.6%) | 0.75 (53.0%) | 0.30 (26.5%) | 29.759 | 10.954 | 21.43 | 0.368 | 1.9 |

| 3.00 (21.5%) | 0.75 (55.4%) | 0.25 (23.1%) | 27.133 | 10.177 | 19.64 | 0.375 | 1.9 |

| 3.00 (20.9%) | 0.60 (43.1%) | 0.40 (35.9%) | 33.098 | 11.82 | 23.64 | 0.357 | 1.9 |

| 3.00 (21.9%) | 0.60 (45.2%) | 0.35 (32.9%) | 30.472 | 11.043 | 21.85 | 0.362 | 1.9 |

| 3.00 (23.0%) | 0.60 (47.4%) | 0.30 (29.6%) | 27.846 | 10.265 | 20.06 | 0.369 | 1.9 |

| 3.00 (24.2%) | 0.60 (49.8%) | 0.25 (26.0%) | 25.22 | 9.488 | 18.27 | 0.376 | 1.9 |

| 3.00 (20.2%) | 0.65 (45.1%) | 0.40 (34.7%) | 33.736 | 12.05 | 24.1 | 0.357 | 1.9 |

| 3.00 (21.1%) | 0.65 (47.1%) | 0.35 (31.7%) | 31.11 | 11.272 | 22.31 | 0.362 | 1.9 |

| 3.00 (22.1%) | 0.65 (49.4%) | 0.30 (28.5%) | 28.483 | 10.495 | 20.51 | 0.368 | 1.9 |

| 3.00 (23.2%) | 0.65 (51.8%) | 0.25 (24.9%) | 25.857 | 9.718 | 18.72 | 0.376 | 1.9 |

| 3.00 (19.5%) | 0.70 (46.9%) | 0.40 (33.5%) | 34.373 | 12.279 | 24.55 | 0.357 | 1.91 |

| 3.00 (20.4%) | 0.70 (49.0%) | 0.35 (30.6%) | 31.747 | 11.502 | 22.76 | 0.362 | 1.91 |

| 3.00 (21.3%) | 0.70 (51.2%) | 0.30 (27.4%) | 29.121 | 10.724 | 20.97 | 0.368 | 1.91 |

| 3.00 (22.3%) | 0.70 (53.7%) | 0.25 (24.0%) | 26.495 | 9.947 | 19.18 | 0.375 | 1.91 |

| 3.00 (18.9%) | 0.75 (48.7%) | 0.40 (32.4%) | 35.011 | 12.509 | 25.01 | 0.357 | 1.91 |

| 3.00 (19.7%) | 0.75 (50.7%) | 0.35 (29.6%) | 32.385 | 11.731 | 23.22 | 0.362 | 1.91 |

| 3.00 (20.6%) | 0.75 (53.0%) | 0.30 (26.5%) | 29.759 | 10.954 | 21.43 | 0.368 | 1.91 |

| 3.00 (21.5%) | 0.75 (55.4%) | 0.25 (23.1%) | 27.133 | 10.177 | 19.64 | 0.375 | 1.91 |

| 3.00 (20.9%) | 0.60 (43.1%) | 0.40 (35.9%) | 33.098 | 11.82 | 23.64 | 0.357 | 1.91 |

| 3.00 (21.9%) | 0.60 (45.2%) | 0.35 (32.9%) | 30.472 | 11.043 | 21.85 | 0.362 | 1.91 |

| 3.00 (23.0%) | 0.60 (47.4%) | 0.30 (29.6%) | 27.846 | 10.265 | 20.06 | 0.369 | 1.91 |

| 3.00 (24.2%) | 0.60 (49.8%) | 0.25 (26.0%) | 25.22 | 9.488 | 18.27 | 0.376 | 1.91 |

| 3.00 (20.2%) | 0.65 (45.1%) | 0.40 (34.7%) | 33.736 | 12.05 | 24.1 | 0.357 | 1.91 |

| 3.00 (21.1%) | 0.65 (47.1%) | 0.35 (31.7%) | 31.11 | 11.272 | 22.31 | 0.362 | 1.91 |

| 3.00 (22.1%) | 0.65 (49.4%) | 0.30 (28.5%) | 28.483 | 10.495 | 20.51 | 0.368 | 1.91 |

| 3.00 (23.2%) | 0.65 (51.8%) | 0.25 (24.9%) | 25.857 | 9.718 | 18.72 | 0.376 | 1.91 |

| 3.00 (19.5%) | 0.70 (46.9%) | 0.40 (33.5%) | 34.373 | 12.279 | 24.55 | 0.357 | 1.92 |

| 3.00 (20.4%) | 0.70 (49.0%) | 0.35 (30.6%) | 31.747 | 11.502 | 22.76 | 0.362 | 1.92 |

| 3.00 (21.3%) | 0.70 (51.2%) | 0.30 (27.4%) | 29.121 | 10.724 | 20.97 | 0.368 | 1.92 |

| 3.00 (22.3%) | 0.70 (53.7%) | 0.25 (24.0%) | 26.495 | 9.947 | 19.18 | 0.375 | 1.92 |

| 3.00 (18.9%) | 0.75 (48.7%) | 0.40 (32.4%) | 35.011 | 12.509 | 25.01 | 0.357 | 1.92 |

| 3.00 (19.7%) | 0.75 (50.7%) | 0.35 (29.6%) | 32.385 | 11.731 | 23.22 | 0.362 | 1.92 |

| 3.00 (20.6%) | 0.75 (53.0%) | 0.30 (26.5%) | 29.759 | 10.954 | 21.43 | 0.368 | 1.92 |

| 3.00 (21.5%) | 0.75 (55.4%) | 0.25 (23.1%) | 27.133 | 10.177 | 19.64 | 0.375 | 1.92 |

| 3.00 (20.9%) | 0.60 (43.1%) | 0.40 (35.9%) | 33.098 | 11.82 | 23.64 | 0.357 | 1.92 |

| 3.00 (21.9%) | 0.60 (45.2%) | 0.35 (32.9%) | 30.472 | 11.043 | 21.85 | 0.362 | 1.92 |

| 3.00 (23.0%) | 0.60 (47.4%) | 0.30 (29.6%) | 27.846 | 10.265 | 20.06 | 0.369 | 1.92 |

| 3.00 (24.2%) | 0.60 (49.8%) | 0.25 (26.0%) | 25.22 | 9.488 | 18.27 | 0.376 | 1.92 |

| 3.00 (20.2%) | 0.65 (45.1%) | 0.40 (34.7%) | 33.736 | 12.05 | 24.1 | 0.357 | 1.92 |

| 3.00 (21.1%) | 0.65 (47.1%) | 0.35 (31.7%) | 31.11 | 11.272 | 22.31 | 0.362 | 1.92 |

| 3.00 (22.1%) | 0.65 (49.4%) | 0.30 (28.5%) | 28.483 | 10.495 | 20.51 | 0.368 | 1.92 |

| 3.00 (23.2%) | 0.65 (51.8%) | 0.25 (24.9%) | 25.857 | 9.718 | 18.72 | 0.376 |

| Parameter | Value | Unit | Description |

|---|---|---|---|

| Temperature | 110 | °C | Reservoir temperature |

| pH | 7 | — | Initial fluid pH |

| Pe | 4 | — | Redox potential (log scale) |

| Alkalinity | 500 | ppm | As HCO3− |

| B | 25 | ppm | Boron |

| Ba | 2 | ppm | Barium |

| Br | 70 | ppm | Bromide |

| Ca | 50 | ppm | Calcium |

| Cl | 20,000 | ppm | Chloride |

| I | 4 | ppm | Iodide |

| K | 140 | ppm | Potassium |

| Mg | 20 | ppm | Magnesium |

| Na | 15,000 | ppm | Sodium |

| P | 1.5 | ppm | Phosphorus |

| S (as SO42−) | 300 | ppm | Sulfate sulfur (S(VI)) |

| Si | 15 | ppm | Dissolved silicon |

| Sr | 3 | ppm | Strontium |

| Water mass | 100 | kg | Total water used in simulation |

| CO2(g) partial pressure | 280 | bar | Imposed CO2 pressure in gas phase |

| Mineral Phase | Initial Amount (mol) | Molar Volume (cm3/mol) | log K (25 °C) | Rate Constant (Neutral, a2) | Activation Energy (E2, J/mol) |

|---|---|---|---|---|---|

| C2S | 0.08 | 51.79 | 38.57 | 1.98 × 10−2 | 25,000 |

| C3S | 0.12 | 73.18 | 73.41 | 1.98 × 10−2 | 35,000 |

| ECSH1-TobCa | 0.08 | 68 | 11.02 | 1.71 × 10−14 | 23,000 |

| Calcite | 0.05 | 36.89 | −8.48 | 6.59 × 10−4 | 66,000 |

| Quartz | 0.1 | 22.69 | −3.98 | 1.98 × 10−14 | 77,000 |

| Montmorillonite | 0.05 | 100 | −34.62 | 1.0 × 10−13 | 40,000 |

| Pozzolan | 0.60–0.75 | 22.7 | −2.7 | 0.1 × 10−13 | 50,000 |

| Chalcedony | 0.25–0.40 | 22.7 | −3.55 | 13.99 × 10−10 | 87,600 |

| Barite | 3 | 50.65 | −9.97 | 1.0 × 10−12 | 75,000 |

| Vivianite | 0.25 | 110 | −36 | 1.0 × 10−12 | 45,000 |

| Portlandite | 1.2 | 33 | 22.8 | 1.0 × 10−8 | 25,000 |

| Aragonite | 0 | 34.15 | −8.34 | 1.0 × 10−9 | 66,000 |

| Vaterite | 0 | 37.63 | −7.91 | 1.0 × 10−9 | 66,000 |

References

- Wood, D.A. Well integrity for underground gas storage relating to natural gas, carbon dioxide, and hydrogen. In Sustainable Natural Gas Drilling: Technologies and Case Studies for the Energy Transition; Elsevier: Amsterdam, The Netherlands, 2024; pp. 551–576. [Google Scholar] [CrossRef]

- Su, X.; Liu, S.; Zhang, L.; Liu, G.; Wang, Y.; Gan, M.; Li, X. Wellbore leakage risk management in CO2 geological utilization and storage: A review. Energy Rev. 2023, 2, 100049. [Google Scholar] [CrossRef]

- Alsubaih, A.; Sepehrnoori, K.; Delshad, M. Environmental Impacts of Orphaned and Abandoned Wells: Methane Emissions, and Implications for Carbon Storage. Appl. Sci. 2024, 14, 11518. [Google Scholar] [CrossRef]

- Ma, C.; Deng, J.; Wu, R.; Yu, B.; Zhou, Y.; Lin, S. A novel self-healing spacer fluid for sustained casing pressure mitigation. J. Pet. Sci. Eng. 2018, 163, 722–730. [Google Scholar] [CrossRef]

- De Souza, D.J.; Sanchez, L.F.M. Understanding the efficiency of autogenous and autonomous self-healing of conventional concrete mixtures through mechanical and microscopical analysis. Cem. Concr. Res. 2023, 172, 107219. [Google Scholar] [CrossRef]

- De Andrade, J.; Sangesland, S. Cement Sheath Failure Mechanisms: Numerical Estimates to Design for Long-Term Well Integrity. J. Pet. Sci. Eng. 2016, 147, 682–698. [Google Scholar] [CrossRef]

- Kiran, R.; Teodoriu, C.; Dadmohammadi, Y.; Nygaard, R.; Wood, D.; Mokhtari, M.; Salehi, S. Identification and evaluation of well integrity and causes of failure of well integrity barriers (A review). J. Nat. Gas Sci. Eng. 2017, 45, 511–526. [Google Scholar] [CrossRef]

- Yousuf, N.; Olayiwola, O.; Guo, B.; Liu, N. A comprehensive review on the loss of wellbore integrity due to cement failure and available remedial methods. J. Pet. Sci. Eng. 2021, 207, 109123. [Google Scholar] [CrossRef]

- Barlet-Gouédard, V.; Rimmelé, G.; Goffé, B.; Porcherie, O. Well Technologies for CO2 Geological Storage:CO2-Resistant Cement. Oil Gas Sci. Technol.-Revue d’IFPEN 2007, 62, 325–334. [Google Scholar] [CrossRef]

- Al-Yami, A.S.; Alqam, M.H.; Riefky, A.; Shafqat, A.U. Self Healing Durable Cement; Development, Lab Testing, and Field Execution. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirates, 29–31 January 2018. [Google Scholar] [CrossRef]

- Segre, N.; Galves, A.D.; Rodrigues, J.A.; Joekes, I. Tire rubber-cement composites: Effect of slag on properties. Cerâmica 2006, 52, 283–292. [Google Scholar] [CrossRef]

- Wray, B.; Bedford, D.; Leotaud, L.; Hunter, B. The Application of High-Density Elastic Cements to Solve HPHT Challenges in South Texas: The Success Story. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009; Volume 1, pp. 135–151. [Google Scholar] [CrossRef]

- Taoutaou, S.; Bermea, J.A.V.; Bonomi, P.; Elatrache, B.; Pasturel, C.; Brangetto, M. Avoiding Sustained Casing Pressure in Gas wells using Self Healing Cement. In Proceedings of the Society of Petroleum Engineers-International Petroleum Technology Conference 2012, IPTC 2012, Bangkok, Thailand, 7–9 February 2012; Volume 1, pp. 365–373. [Google Scholar] [CrossRef]

- Reddy, B.R.; Liang, F.; Fitzgerald, R. Self-Healing Cements that Heal without Dependence on Fluid Contact. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 20–22 April 2009; Volume 1, pp. 430–436. [Google Scholar] [CrossRef]

- Johnson, C.; Gai, A.; Ioan, T.; Landa, J.; Gervasi, G.; Bourgeois, B.; Bouteldja, M. Self-Healing Cement for Long-Term Safe Exploitation of Gas Wells: A New Technology Case Study. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019. [Google Scholar] [CrossRef]

- Mahmood, A.A.; Jan, U.A.; Khan, A.Y.; Rasheed, H.; Salazar, J.; Shah, K.A.; Khan, S. Step-Change in Cement Design Assures Well Integrity Under Dynamic Stress. In Proceedings of the Society of Petroleum Engineers-SPE 2023 Symposium Compilation, SYM 2023, Richardson, TX, USA, 19 December 2023. [Google Scholar] [CrossRef]

- Langley, M.; Cleveland, M.; Eulberg, J.; Hudson, M. Flexible, Self-Healing Cement Eliminates Sustained Casing Pressure in Denver-Julesburg Basin Unconventional Wells. In Proceedings of the Society of Petroleum Engineers-IADC/SPE Drilling Conference and Exhibition, DC 2018, Fort Worth, TX, USA, 6–8 March 2018. [Google Scholar] [CrossRef]

- Knowles, J.S.; Johnson, C.R.; Liapunova, N.; Syslak, H. Specialized Carbon Dioxide Self-Healing Cement System Engineered for Carbon Capture and Storage Well in Norwegian Continental Shelf. In Proceedings of the Offshore Technology Conference Asia, OTCA 2024, Kuala Lumpur, Malaysia, 27 February–1 March 2024. [Google Scholar] [CrossRef]

- Pyatina, T.; Sugama, T. Aluminum-Rich Cements for High Temperature Geothermal Wells. In Proceedings of the 49th Workshop Geothermal Reservoir Engineering, Stanford, CA, USA, 12-14 February 2024. [Google Scholar]

- Wu, Y.; Patel, H.; Salehi, S. Thermal Considerations of Cement Integrity in Geothermal Wells. In Proceedings of the 45th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 10–12 February 2020. [Google Scholar]

- Torres, A. Challenges of Casing Design in Geothermal Wells. In Proceedings of the Society of Petroleum Engineers-IADC/SPE Asia Pacific Drilling Technology Conference 2014: Driving Sustainable Growth Through Technology and Innovation, Bangkok, Thailand, 25–27 August 2014; pp. 210–221. [Google Scholar] [CrossRef]

- Lambrescu, I.; Abid, K.; Teodoriu, C. Cement-Formation Debonding Due to Temperature Variation in Geothermal Wells: An Intensive Numerical Simulation Assessment. Energies 2024, 17, 4953. [Google Scholar] [CrossRef]

- Southon, J.A. Geothermal Well Design, Construction and Failures. In Proceedings of the World Geothermal Congress, Antalya, Turkey, 24–29 April 2005. [Google Scholar]

- Treseder, R.S.; Wieland, R. Down-Hole Corrosion in a Salton Sea Geothermal Well. In SPE International Conference on Oilfield Chemistry? Society of Petroleum Engineers: Richardson, TX, USA, 1977; pp. 241–248. [Google Scholar] [CrossRef]

- Allahvirdizadeh, P. A review on geothermal wells: Well integrity issues. J. Clean. Prod. 2020, 275, 124009. [Google Scholar] [CrossRef]

- Pyatina, T.; Sugama, T. Cements with supplementary cementitious materials for high-temperature geothermal wells. Geothermics 2020, 86, 101840. [Google Scholar] [CrossRef]

- Sugama, T. Advanced Cements for Geothermal Wells; Brookhaven National Laboratory: Upton, NY, USA, 2007. Available online: https://www.osti.gov/biblio/909955 (accessed on 1 April 2025).

- Olivine-Portland Cement as a Solution to Wellbore Integrity Issues in CO2-Rich Geothermal Reservoirs | GRC 2020 Annual Meeting. Available online: https://grc2020.mygeoenergynow.org/olivine-portland-cement-solution-wellbore-integrity-issues-co2-rich-geothermal-reservoirs (accessed on 30 January 2025).

- Suleiman, A.R.; Nelson, A.J.; Nehdi, M.L. Visualization and quantification of crack self-healing in cement-based materials incorporating different minerals. Cem. Concr. Compos. 2019, 103, 49–58. [Google Scholar] [CrossRef]

- Arce, G.A.; Hassan, M.M.; Mohammad, L.N.; Rupnow, T. Characterization of Self-Healing Processes Induced by Calcium Nitrate Microcapsules in Cement Mortar. J. Mater. Civ. Eng. 2016, 29, 04016189. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Pang, S.D. Healing cement mortar by immobilization of bacteria in biochar: An integrated approach of self-healing and carbon sequestration. Cem. Concr. Compos. 2018, 86, 238–254. [Google Scholar] [CrossRef]

- Wang, X.F.; Zhang, J.H.; Zhao, W.; Han, R.; Han, N.X.; Xing, F. Permeability and pore structure of microcapsule-based self-healing cementitious composite. Constr. Build. Mater. 2018, 165, 149–162. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Q.; Ashour, A.; Han, B. Self-healing cement concrete composites for resilient infrastructures: A review. Compos B Eng. 2020, 189, 107892. [Google Scholar] [CrossRef]

- Azenha, M.; Faria, R.; Ferreira, D. Identification of early-age concrete temperatures and strains: Monitoring and numerical simulation. Cem. Concr. Compos. 2009, 31, 369–378. [Google Scholar] [CrossRef]

- Ruan, S.; Qiu, J.; Weng, Y.; Yang, Y.; Yang, E.H.; Chu, J.; Unluer, C. The use of microbial induced carbonate precipitation in healing cracks within reactive magnesia cement-based blends. Cem. Concr. Res. 2019, 115, 176–188. [Google Scholar] [CrossRef]

- Bhaskar, S.; Hossain, K.M.A.; Lachemi, M.; Wolfaardt, G.; Kroukamp, M.O. Effect of self-healing on strength and durability of zeolite-immobilized bacterial cementitious mortar composites. Cem. Concr. Compos. 2017, 82, 23–33. [Google Scholar] [CrossRef]

- Ghosh, S.K. Self-Healing Materials: Fundamentals, Design Strategies, and Applications; Wiley-VCH: Weinheim, Germany, 2009; pp. 1–28. [Google Scholar] [CrossRef]

- Youngblood, J.P.; Sottos, N.R. Bioinspired materials for self-cleaning and self-healing. MRS Bull. 2008, 33, 732–738. [Google Scholar] [CrossRef]

- Liu, H.; Chen, W.L.; Pan, R.K.; Shan, Z.T.; Qiao, A.; Drewitt, J.W.E.; Hennet, L.; Jahn, S.; Langstaff, D.P.; Chass, G.A.; et al. From molten calcium aluminates through phase transitions to cement phases. Adv. Sci. 2020, 7, 1902209. [Google Scholar] [CrossRef] [PubMed]

- Kutchko, B.G.; Strazisar, B.R.; Huerta, N.; Lowry, G.V.; Dzombak, D.A.; Thaulow, N. CO2 reaction with hydrated class H well cement under geologic sequestration conditions: Effects of flyash admixtures. Environ. Sci. Technol. 2009, 43, 3947–3952. [Google Scholar] [CrossRef] [PubMed]

- Strazisar, B.; Kutchko, B.; Huerta, N. Chemical Reactions of Wellbore Cement Under CO2 Storage Conditions: Effects of Cement Additives. Energy Procedia 2009, 1, 3603–3607. [Google Scholar] [CrossRef]

- Carey, J.W. Geochemistry of Wellbore Integrity in CO2 Sequestration: Portland Cement-Steel-Brine-CO2 Interactions. Rev. Miner. Geochem. 2013, 77, 505–539. [Google Scholar] [CrossRef]

- Rod, K.A.; Fernandez, C.A.; Nguyen, M.T.; Gardiner, J.B.; Huerta, N.J.; Glezakou, V.A.; Varga, T.; Rousseau, R.; Koech, P.K. Polymer-cement composites with adhesion and re-adhesion (healing) to casing capability for geothermal wellbore applications. Cem. Concr. Compos. 2020, 107, 103490. [Google Scholar] [CrossRef]

- Childers, M.I.; Nguyen, M.T.; Rod, K.A.; Koech, P.K.; Um, W.; Chun, J.; Glezakou, V.A.; Linn, D.; Roosendaal, T.J.; Wietsma, T.W.; et al. Polymer-Cement Composites with Self-Healing Ability for Geothermal and Fossil Energy Applications. Chem. Mater. 2017, 29, 4708–4718. [Google Scholar] [CrossRef]

- Muhammad, A.; Taoutaou, S.; Shafqat, A.U.; Noor, S.M.; Salehpour, A. The Use of Self-Healing Cement to Ensure Long-Term Zonal Isolation for HPHT Wells Subject to Hydraulic Fracturing Operations in Pakistan. In Proceedings of the International Petroleum Technology Conference (IPTC), Doha, Qatar, 7–9 December 2009; International Petroleum Technology Conference: Richardson, TX, USA, 2009. [Google Scholar] [CrossRef]

- Xin, H.; Yang, K.; Zhang, M.; Deng, Q.; Zeng, J.; Zou, J.; Sun, F. Exploratory Research on Water-Channeling Self-Healing Agent for Cementing. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Shanghai, China, 11–16 October 2020. [Google Scholar]

- Peng, Z.G.; Yu, C.Y.; Feng, Q.; Zheng, Y.; Huo, J.H.; Wu, J.R. Synthesis, characterisation and application of self-healing material in oil well cement for healing microcracks. Adv. Cem. Res. 2019, 32, 519–526. [Google Scholar] [CrossRef]

- Noshi, C.I.; Schubert, J.J. A Novel Microbially Induced Self-Healing Cement/Concrete for Underwater Concrete Offshore Structures. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Hague, The Netherlands, 5–7 March 2019. [Google Scholar] [CrossRef]

- Baltaeva, M.; Stamer, K.; Orlov, M. Complex Micro-Containers (CMC) Transporting Compartmentalized Reaction Mixture for Self-Healing Cement. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 19–21 February 2023. [Google Scholar] [CrossRef]

- Ravi, K.; Bosma, M.; Hunter, L. Optimizing the Cement Sheath Design in HPHT Shearwater Field. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, 19–21 February 2003. [Google Scholar] [CrossRef]

- Noshi, C.I.; Schubert, J.J. Self-Healing Biocement and Its Potential Applications in Cementing and Sand-Consolidation Jobs: A Review Targeted at the Oil and Gas Industry. In Proceedings of the Society of Petroleum Engineers-SPE Liquids-Rich Basins Conference-North America 2018, LRBC 2018, Midland, TX, USA, 5–6 September 2018. [Google Scholar] [CrossRef]

- Alberdi-Pagola, P.; Fischer, G. Quantification of Casing Expansion-Induced Cracking in Oilwell Cement Sheaths. SPE J. 2024, 29, 714–724. [Google Scholar] [CrossRef]

- Wang, J.Y.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Cem. Concr. Res. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Stuckrath, C.; Serpell, R.; Valenzuela, L.M.; Lopez, M. Quantification of chemical and biological calcium carbonate precipitation: Performance of self-healing in reinforced mortar containing chemical admixtures. Cem. Concr. Compos. 2014, 50, 10–15. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, B.; Shi, L.; Yang, K.; Li, P.; Sun, F.; Zeng, J.; Hou, W.; Yang, L. Research and Application of Ultra-High Density Natural Gas Self-Healing Slurry System. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Ottawa, ON, Canada, 18–23 June 2023. [Google Scholar]

- Maddalena, R.; Taha, H.; Gardner, D. Self-healing potential of supplementary cementitious materials in cement mortars: Sorptivity and pore structure. Dev. Built Environ. 2021, 6, 100044. [Google Scholar] [CrossRef]

- Cuenca, E.; Criado, M.; Giménez, M.; Alonso, M.C.; Ferrara, L. Effects of Alumina Nanofibers and Cellulose Nanocrystals on Durability and Self-Healing Capacity of Ultrahigh-Performance Fiber-Reinforced Concretes. J. Mater. Civ. Eng. 2022, 34, 04022154. [Google Scholar] [CrossRef]

- Du, W.; Yu, J.; Gu, Y.; Li, Y.; Han, X.; Liu, Q. Preparation and application of microcapsules containing toluene-di-isocyanate for self-healing of concrete. Constr. Build. Mater. 2019, 202, 762–769. [Google Scholar] [CrossRef]

- Xu, J.; Tang, Y.; Wang, X.; Wang, Z.; Yao, W. Application of ureolysis-based microbial CaCO3 precipitation in self-healing of concrete and inhibition of reinforcement corrosion. Constr. Build. Mater. 2020, 265, 120364. [Google Scholar] [CrossRef]

- Liu, C.; Xing, L.; Liu, H.; Huang, W.; Nong, X.; Xu, X. Experimental on repair performance and complete stress-strain curve of self-healing recycled concrete under uniaxial loading. Constr. Build. Mater. 2021, 285, 122900. [Google Scholar] [CrossRef]

- Guo, Y.; Xiang, K.; Wang, H.; Liu, X.; Ye, Q.; Wang, X. Experimental study on self-healing and mechanical properties of sisal fiber-loaded microbial concrete. Mater. Res. Express 2023, 10, 045701. [Google Scholar] [CrossRef]

- Feng, J.; Chen, B.; Sun, W.; Wang, Y. Microbial induced calcium carbonate precipitation study using Bacillus subtilis with application to self-healing concrete preparation and characterization. Constr. Build. Mater. 2021, 280, 122460. [Google Scholar] [CrossRef]

- Baradaran, M.; Sadeghpour, M. Effect of bacteria on the self-healing ability of concrete containing zeolite. Innov. Infrastruct. Solut. 2023, 8, 256. [Google Scholar] [CrossRef]

- Amiri, Y.; Hassaninasab, S.; Chehri, K.; Zahedi, M. Investigating the effect of adding bacillus bacteria and nano-clay on cement mortar properties. Case Stud. Constr. Mater. 2022, 17, e01167. [Google Scholar] [CrossRef]

- Zhan, Q.; Zhou, J.; Wang, S.; Su, Y.; Liu, B.; Yu, X.; Pan, Z.; Qian, C. Crack self-healing of cement-based materials by microorganisms immobilized in expanded vermiculite. Constr. Build. Mater. 2021, 272, 121610. [Google Scholar] [CrossRef]

- Litina, C.; Bumanis, G.; Anglani, G.; Dudek, M.; Maddalena, R.; Amenta, M.; Papaioannou, S.; Pérez, G.; García Calvo, J.L.; Asensio, E.; et al. Evaluation of Methodologies for Assessing Self-Healing Performance of Concrete with Mineral Expansive Agents: An Interlaboratory Study. Materials 2021, 14, 2024. [Google Scholar] [CrossRef] [PubMed]

- Khushnood, R.A.; Qureshi, Z.A.; Shaheen, N.; Ali, S. Bio-mineralized self-healing recycled aggregate concrete for sustainable infrastructure. Sci. Total Environ. 2020, 703, 135007. [Google Scholar] [CrossRef] [PubMed]

- Taheri, S.; Clark, S.M. Preparation of Self-healing Additives for Concrete via Miniemulsion Polymerization: Formulation and Production Challenges. Int. J. Concr. Struct. Mater. 2021, 15, 8. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Shin, W.; Chun, B.; Banthia, N. Assessment of steel fiber corrosion in self-healed ultra-high-performance fiber-reinforced concrete and its effect on tensile performance. Cem. Concr. Res. 2020, 133, 106091. [Google Scholar] [CrossRef]

- Cuenca, E.; Serna, P. Autogenous Self-Healing Capacity of Early-Age Ultra-High-Performance Fiber-Reinforced Concrete. Sustainability 2021, 13, 3061. [Google Scholar] [CrossRef]

- Yuan, L.; Chen, S.; Wang, S.; Huang, Y.; Yang, Q.; Liu, S.; Wang, J.; Du, P.; Cheng, X.; Zhou, Z. Research on the Improvement of Concrete Autogenous Self-healing Based on the Regulation of Cement Particle Size Distribution (PSD). Materials 2019, 12, 2818. [Google Scholar] [CrossRef]

- Beglarigale, A.; Eyice, D.; Tutkun, B.; Yazıcı, H. Evaluation of enhanced autogenous self-healing ability of UHPC mixtures. Constr. Build. Mater. 2021, 280, 122524. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J.; Kotwica, Ł. Enhanced autogenous self-healing of cement-based composites with mechanically activated fluidized-bed combustion fly ash. Constr. Build. Mater. 2021, 300, 124028. [Google Scholar] [CrossRef]

- Kim, D.J.; Kang, S.H.; Ahn, T.H. Mechanical Characterization of High-Performance Steel-Fiber Reinforced Cement Composites with Self-Healing Effect. Materials 2014, 7, 508–526. [Google Scholar] [CrossRef]

- Reddy, T.C.S.; Ravitheja, A.; Sashidhar, C. Micromechanical Properties of Self-Healing Concrete with Crystalline Admixture and Silica Fume. ACI Mater. J. 2020, 117, 63–74. [Google Scholar] [CrossRef]

- Suleiman, A.R.; Nehdi, M.L. Effect of autogenous crack self-healing on mechanical strength recovery of cement mortar under various environmental exposure. Sci. Rep. 2021, 11, 7245. [Google Scholar] [CrossRef] [PubMed]

- Van Mullem, T.; Anglani, G.; Dudek, M.; Vanoutrive, H.; Bumanis, G.; Litina, C.; Kwiecień, A.; Al-Tabbaa, A.; Bajare, D.; Stryszewska, T.; et al. Addressing the need for standardization of test methods for self-healing concrete: An interlaboratory study on concrete with macrocapsules. Sci. Technol. Adv. Mater. 2020, 21, 661–682. [Google Scholar] [CrossRef]

- Tsangouri, E.; Lelon, J.; Minnebo, P.; Asaue, H.; Shiotani, T.; Van Tittelboom, K.; De Belie, N.; Aggelis, D.G.; Van Hemelrijck, D. Feasibility study on real-scale, self-healing concrete slab by developing a smart capsules network and assessed by a plethora of advanced monitoring techniques. Constr. Build. Mater. 2019, 228, 116780. [Google Scholar] [CrossRef]

- Feng, J.; Dong, H.; Wang, R.; Su, Y. A novel capsule by poly (ethylene glycol) granulation for self-healing concrete. Cem. Concr. Res. 2020, 133, 106053. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Kanellopoulos, A.; Al-Tabbaa, A. Encapsulation of expansive powder minerals within a concentric glass capsule system for self-healing concrete. Constr. Build. Mater. 2016, 121, 629–643. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J.; Cao, Z.; He, P.; Liu, Q.; Han, X.; Wan, Y. Preparation and application of novel microcapsules ruptured by microwave for self-healing concrete. Constr. Build. Mater. 2021, 304, 124616. [Google Scholar] [CrossRef]

- Wang, J.; Dewanckele, J.; Cnudde, V.; Van Vlierberghe, S.; Verstraete, W.; De Belie, N. X-ray computed tomography proof of bacterial-based self-healing in concrete. Cem. Concr. Compos. 2014, 53, 289–304. [Google Scholar] [CrossRef]

- Singh, H.; Gupta, R. Cellulose fiber as bacteria-carrier in mortar: Self-healing quantification using UPV. J. Build. Eng. 2020, 28, 101090. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Guizani, L.; Bhojaraju, C.; Ouellet-Plamondon, C. The effect of air-entraining admixture and superabsorbent polymer on bond behaviour of steel rebar in pre-cracked and self-healed concrete. Constr. Build. Mater. 2021, 281, 122568. [Google Scholar] [CrossRef]

- Xiao, X.; Ho, D.S.W.; Yang, E.H. The use of low alkalinity MgO-SiO2 formulation to encapsulate bacteria for self-healing concrete. Constr. Build. Mater. 2023, 401, 132908. [Google Scholar] [CrossRef]

- Du, W.; Yu, J.; Gu, S.; Wang, R.; Li, J.; Han, X.; Liu, Q. Effect of temperatures on self-healing capabilities of concrete with different shell composition microcapsules containing toluene-di-isocyanate. Constr. Build. Mater. 2020, 247, 118575. [Google Scholar] [CrossRef]

- Sisomphon, K.; Çopuroğlu, O.; Fraaij, A. Application of Encapsulated Lightweight Aggregate Impregnated with Sodium Monofluorophosphate as a Self-Healing Agent in Blast Furnace slag Mortar). 2011. Available online: https://repository.tudelft.nl/record/uuid:989836d6-dd5c-4bb0-8d9f-925390dddbae (accessed on 5 May 2025).

- MacLaren, D.C.; White, M.A. Cement: Its Chemistry and Properties. J. Chem. Educ. 2003, 80, 623–635. [Google Scholar] [CrossRef]

- Kutchko, B.G.; Strazisar, B.R.; Dzombak, D.A.; Lowry, G.V.; Thauiow, N. Degradation of well cement by CO2 under geologic sequestration conditions. Environ. Sci. Technol. 2007, 41, 4787–4792. [Google Scholar] [CrossRef]

- Nygaard, R. Well Design and Well Integrity: Wabamun Area CO2 Sequestration Project; University of Calgary: Calgary, AB, Canada, 2010; Available online: https://www.ucalgary.ca/wasp/Well%20Integrity%20Analysis.pdf (accessed on 5 March 2025).

- Abid, K.; Gholami, R.; Choate, P.; Nagaratnam, B.H. A review on cement degradation under CO2-rich environment of sequestration projects. J. Nat. Gas Sci. Eng. 2015, 27, 1149–1157. [Google Scholar] [CrossRef]

- Ahmed, A.; Mahmoud, A.A.; Elkatatny, S.; Chen, W. The Effect of Weighting Materials on Oil-Well Cement Properties While Drilling Deep Wells. Sustainability 2019, 11, 6776. [Google Scholar] [CrossRef]

- Wang, L.; He, Z.; Cai, X. Characterization of pozzolanic reaction and its effect on the C-S-H gel in fly ash-cement paste. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 319–324. [Google Scholar] [CrossRef]

- Duguid, A.; Radonjic, M.; Bruant, R.; Mandecki, T.; Scherer, G.; Celia, M. The effect of CO2 sequestration on oll well cements. In Greenhouse Gas Control Technologies 7; Elsevier: Oxford, UK, 2005; pp. 1997–2001. [Google Scholar] [CrossRef]

- Geological. In PHREEQC Version 3|U.S. Geological Survey. Available online: https://www.usgs.gov/software/phreeqc-version-3 (accessed on 11 April 2025).

- Geloni, C.; Giorgis, T.; Battistelli, A. Modeling of Rocks and Cement Alteration due to CO2 Injection in an Exploited Gas Reservoir. Transp. Porous Media 2011, 90, 183–200. [Google Scholar] [CrossRef]

- Szabó-Krausz, Z.; Gál, N.E.; Gável, V.; Falus, G. Wellbore cement alteration during decades of abandonment and following CO2 attack—A geochemical modelling study in the area of potential CO2 reservoirs in the Pannonian Basin. Appl. Geochem. 2020, 113, 104516. [Google Scholar] [CrossRef]

- Wasch, L.J.; Koenen, M.; Wollenweber, J.; Tambach, T.J. Sensitivity of chemical cement alteration—Modeling the effect of parameter uncertainty and varying subsurface conditions. Greenh. Gases Sci. Technol. 2015, 5, 323–338. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsubaih, A.; Sepehrnoori, K.; Delshad, M. Development and Optimization of Self-Healing Cement for CO2 Injection and Storage Wells: Enhancing Long-Term Wellbore Integrity in Extreme Subsurface Conditions. Appl. Sci. 2025, 15, 5428. https://doi.org/10.3390/app15105428

Alsubaih A, Sepehrnoori K, Delshad M. Development and Optimization of Self-Healing Cement for CO2 Injection and Storage Wells: Enhancing Long-Term Wellbore Integrity in Extreme Subsurface Conditions. Applied Sciences. 2025; 15(10):5428. https://doi.org/10.3390/app15105428

Chicago/Turabian StyleAlsubaih, Ahmed, Kamy Sepehrnoori, and Mojdeh Delshad. 2025. "Development and Optimization of Self-Healing Cement for CO2 Injection and Storage Wells: Enhancing Long-Term Wellbore Integrity in Extreme Subsurface Conditions" Applied Sciences 15, no. 10: 5428. https://doi.org/10.3390/app15105428

APA StyleAlsubaih, A., Sepehrnoori, K., & Delshad, M. (2025). Development and Optimization of Self-Healing Cement for CO2 Injection and Storage Wells: Enhancing Long-Term Wellbore Integrity in Extreme Subsurface Conditions. Applied Sciences, 15(10), 5428. https://doi.org/10.3390/app15105428