Abstract

Aircraft mechanical maintenance involves high loads, repetitive movements, and awkward postures, significantly increasing the risk of work-related musculoskeletal disorders (WMSDs). Traditional static evaluation methods based on posture analysis fail to capture the complexity and dynamic nature of these tasks, limiting their applicability in maintenance settings. To address this limitation, this study introduces a novel quantitative WMSD risk assessment model that leverages 3D motion data collected through an optical motion capture system. The model evaluates dynamic human postures and employs an inverse trigonometric function algorithm to quantify the loading effects on working joints. Experimental validation was conducted through quasi-real-life scenarios to ensure the model’s reliability and applicability. The findings demonstrate that the proposed methodology provides both innovative and practical advantages, overcoming the constraints of conventional assessment techniques. Specifically, it enables precise quantification of physical task loads and enhances occupational injury risk assessments. The model is particularly valuable in physically demanding industries, such as aircraft maintenance, where accurate workload and fatigue monitoring are essential. By facilitating real-time ergonomic analysis, this approach allows managers to monitor worker health, optimize task schedules, and mitigate excessive fatigue and injury risks, ultimately improving both efficiency and workplace safety.

1. Introduction

Air transportation has emerged as a crucial and efficient means of transporting people, cargo, and mail via airplanes and other aircraft, positioning itself as a foundation of modern transportation. Ensuring the safe operation of air transportation heavily relies on the motor behaviors of aircraft maintenance personnel, which are influenced by numerous factors. A recent study highlighted that the demanding nature of aircraft maintenance, characterized by high physical loads, extended work durations, and challenging environmental conditions, significantly increases the risk of work-related musculoskeletal disorders (WMSDs), leading to a notable decline in motor performance [1]. WMSDs are attributed to the overuse of the human musculoskeletal system [2]. Due to the often subtle onset of WMSD symptoms among maintenance personnel, timely detection and control remain particularly challenging [3]. Consequently, biomechanical risk assessment during aircraft maintenance is essential for reducing the prevalence of occupational illnesses and enhancing work efficiency [4].

With the rapid growth of the air transportation industry over the past half-century, research in this domain has gained prominence as a critical area within ergonomics studies globally. At the close of the 20th century, ergonomic audit software systems were introduced to enhance the performance of aircraft inspectors [5]. In the 21st century, greater attention has been given to the workloads experienced by aircraft maintenance personnel. Mohammed H. Alhaag et al. (2022) highlighted that these workers are often subjected to physically and psychologically demanding environments [6]. The complexity of maintenance tasks can lead to varying degrees of muscle fatigue, thereby affecting overall work effectiveness. Nongtian Chen et al. (2013) examined the physical fatigue experienced during aviation maintenance by analyzing human error data, developing a human error impact and prevention model, and exploring the causes of errors within the human-machine environment [7]. Zhou et al. (2022) refined accessibility evaluations by integrating comfort as a factor in virtual maintenance models, thus improving the precision and accuracy of maintenance fatigue assessments [8]. These factors significantly influence the quality of aviation maintenance, necessitating research to enhance safety and efficiency within maintenance environments [9]. However, the collective and dynamic nature of motor behavior poses challenges in quantifying the risk factors impacting work effectiveness [10]. This highlights the urgent need for new methodologies to address these challenges and close existing gaps in risk quantification. The present study aims to address this need by developing a novel biomechanical framework to quantify dynamic risks in motor behaviors during aircraft maintenance.

Survey-based ergonomic assessment tools have long been a cornerstone of workplace risk evaluation, providing practical and accessible means of identifying ergonomic hazards caused by three dominant influencing factors—loading duration, human posture, and force/loading intensity [11]. Among these, two of the most widely utilized methods are the Rapid Upper Limb Assessment (RULA) [12] and the Rapid Entire Body Assessment (REBA) [13]. While RULA is designed to evaluate the upper extremities during work tasks, REBA extends its scope to encompass full-body postures. Both methods assess key biomechanical factors, including body posture, movement type and repetition, joint and/or segmental range of motion, and coupling, making them particularly well-suited for analyzing the risk working postures prevalent in service industries. Building on these foundational models, specialized survey-based assessment tools have been developed to address the unique risks encountered in aircraft maintenance. For instance, the effects of task duration on aircraft maintenance personnel are predominantly evaluated through questionnaire surveys [14]. This pilot study, conducted in 2021, employed survey-based data collection to investigate occupational health and safety concerns among aircraft maintenance machinists. Similarly, an expert-driven questionnaire was designed to assess critical human risk factors for aircraft maintenance technicians, enabling the categorization of risk factors based on survey results [15]. However, while extensive questionnaire-based data collection provides valuable insights into workload-related risks, it remains inherently vulnerable to observer subjectivity and individual variability [16]. Moreover, the potential for errors arising from subjective judgment cannot be entirely eliminated [17].

To achieve precise quantification of musculoskeletal overuse, quantitative methods such as 3D motion capture [18,19] and biomechanical modeling [20,21] based on anthropometric parameters [22,23] have been introduced. Despite their high level of accuracy [24,25], these techniques are often impractical for routine risk assessment due to their high cost [26,27]. Additionally, 3D motion analysis technology is primarily designed for motor skill quantification [28] rather than for simultaneously analyzing the three dominant influencing factors—loading duration, human posture, and force/loading intensity [11].

To bridge the gap between subjective judgment and technological constraints, survey-based tracking instruments have been developed to minimize human assessment errors while overcoming technological limitations [29]. These advanced approaches refine REBA/RULA assessments, enhancing workplace safety by providing more precise ergonomic evaluations. For example, a semi-automatic RULA evaluation tool utilizing the Microsoft Kinect v2 depth camera was designed for real-time and offline detection of awkward postures with greater accuracy [30,31]. Additionally, other tracking technologies, such as inertial motion capture systems, have been integrated with conventional ergonomic assessment methods to provide more granular insights into the biomechanical risks associated with aircraft maintenance tasks [32]. The integration of motion-tracking technology into postural risk assessments has facilitated more intuitive monitoring of hazardous postures in working durations [33] and enabled real-time ergonomic analyses. However, the survey-based tracking instruments introduced so far cannot be universally applied, as they address only partial aspects of WMSDs during aircraft maintenance, typically covering one or two of the three dominant influencing factors.

Finally, when assessing the impact of physical loading intensity, model simulations are a widely utilized approach. Golabchi et al. (2015) introduced a motion data-driven framework that integrates ergonomic analysis with 3D virtual visualization of the workplace, enabling a comprehensive risk assessment of musculoskeletal strain [34]. This approach first evaluates worker motions for potential ergonomic risks and then employs biomechanical simulations to estimate internal joint loads, refining both movement patterns and workplace design to enhance safety. However, this approach also addresses only a limited subset of WMSD-related factors.

In summary, the advancement of ergonomic assessment methods has increasingly shifted toward quantitative approaches, yet existing techniques still exhibit notable limitations. Current methods often rely on one or two isolated indicators to evaluate workload-related risks, failing to capture the inherently dynamic and continuous nature of work. For a comprehensive workload assessment, it is essential to simultaneously consider three dominant influencing factors—loading duration, human posture, and force/loading intensity—ensuring a more holistic and accurate evaluation of occupational risks [11].

Reliability Engineering is a structured engineering discipline grounded in mathematical principles, particularly probability theory and statistics, aimed at the systematic and rigorous analysis of functional issues in components and systems to achieve a reliable design [35]. System reliability, which evaluates problems from a holistic system perspective, was introduced into ergonomic assessments in 1988 when Heiner Bubb proposed the concept of system ergonomics [36]. This approach views the human as an integral component of the human–machine–environment system, analyzing individual human behavioral perceptions to enhance overall system reliability.

Anchored in system reliability principles and the Postural Ergonomic Risk Assessment (PEBA) methodology, this study introduces a novel biomechanical framework that quantifies dynamic workload risks through the integration of 3D motion data of human joints. Unlike traditional approaches, which often consider posture, duration, or loading intensity in isolation, the proposed model simultaneously incorporates all three dominant risk factors, providing a comprehensive and dynamic evaluation of WMSD risks in aircraft maintenance tasks. This integrative approach represents a significant advancement in ergonomic assessment by capturing the real-time variability and complexity of human movement under operational conditions. By integrating human factors and ergonomics into task evaluations [37], the model ensures both theoretical robustness and practical applicability. It was validated using optical motion tracking data collected during quasi-realistic maintenance scenarios, guaranteeing methodological rigor and contextual relevance. In essence, this study delivers two core innovations: (1) the development of a unified methodological framework capable of dynamically identifying and mitigating occupational injury risks among maintenance personnel, and (2) the enhancement of workforce efficiency and safety through the implementation of real-time ergonomic risk monitoring and task refinement strategies.

2. Materials and Methods

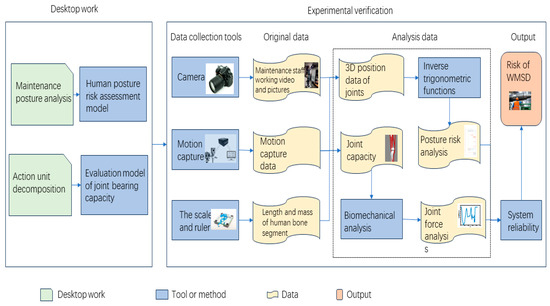

2.1. Technological Roadmap for Workload Evaluation in Aircraft Maintenance Personnel

Aircraft maintenance plays a pivotal role in ensuring the safety and efficiency of the aviation industry. However, the dynamic and unpredictable nature of maintenance tasks introduces significant variability in workload assessment. A comprehensive evaluation of aircraft maintenance personnel’s workload necessitates a thorough understanding of the job characteristics, task complexities, and key risk factors contributing to occupational injuries. This study systematically deconstructs and reorganizes the components of aircraft maintenance tasks to develop a structured, rational, and practical assessment framework (Figure 1). By integrating these elements, a holistic workload evaluation system is established to enhance the accuracy and applicability of ergonomic risk assessments [38].

Figure 1.

Technology.

2.2. Decomposition of Maintenance Tasks Using Hierarchical Task Analysis (HTA)

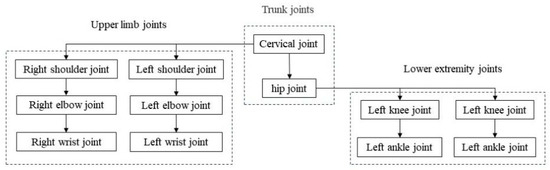

Hierarchical Task Analysis (HTA) is a structured methodology that decomposes complex tasks into hierarchical sub-components, effectively representing the system’s sub-objectives to facilitate systematic analysis and problem-solving [39]. To systematically evaluate the workload of aircraft maintenance personnel, maintenance tasks can be classified into five primary categories based on task processes and modes: human movement, mobility, human posture, object manipulation, and maintenance units [40]. By applying HTA principles, maintenance tasks are further categorized into two fundamental components—human posture and action units—enabling the decomposition and reorganization of any given maintenance task into a structured and analyzable framework.

2.2.1. Analysis of Human Posture

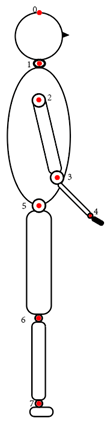

The human body functions as a multi-jointed, chain-like structure with multiple degrees of freedom, which can be modeled as a system of rigid bodies interconnected by joints with varying degrees of mobility. Motion capture technology deconstructs this complex structure by representing the human skeleton as a series of rigid segments, each possessing mass and connected by joints modeled as hinge structures with specific degrees of freedom. The NOKOV motion capture system employs this approach by defining the human body as a chain-like rigid structure composed of 15 actuated joints, facilitating precise kinematic analysis (Figure 2).

Figure 2.

Human joint cascade diagram.

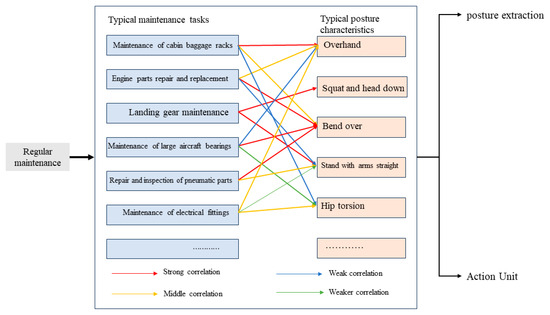

Tasks associated with potential risk factors for work-related musculoskeletal disorders (WMSDs) in aircraft maintenance include the manual handling of heavy aircraft components [3] and maintenance activities that require limb postures deviating significantly from the body’s natural alignment. Given the physically demanding nature of aircraft maintenance, workers frequently perform tasks under high loads and in awkward postures. Among the various methodologies used to assess WMSD risk exposure, posture-based ergonomic assessment remains one of the most widely applied approaches [41]. Consequently, decomposing and categorizing maintenance postures provides a structured framework for systematically conducting ergonomic risk evaluations (Figure 3).

Figure 3.

Breakdown and categorization of maintenance work postures.

2.2.2. Breakdown and Generalization of Movement Units

Aircraft maintenance is officially defined as “any one or a combination of overhaul, repair, inspection, replacement, modification, or correction of defects on an aircraft or its components, with the exception of pre-flight inspection” [42]. To systematically analyze and categorize maintenance tasks, individual maintenance units are refined into discrete work units, forming a structured maintenance work library (Table 1). This framework enables the decomposition of any maintenance task into standardized action units within the maintenance action library. The action units can be systematically categorized and recombined to represent various maintenance activities. This classification approach enhances the organization of maintenance work and facilitates more precise workload analysis.

Table 1.

Summary of maintenance action units.

2.3. Development of a Human Body Load Evaluation Model

Physical load refers to the biomechanical stresses exerted on the body, which are influenced by factors such as working posture, external forces (e.g., hand loads and ground reaction forces), as well as the frequency and duration of these forces or postures [43]. In mechanical maintenance tasks, imposed loads and work postures are the primary determinants of physical strain, with excessive workloads recognized as a fundamental cause of occupational injuries [44]. By systematically assessing the degree of physical load, this evaluation model provides a more accurate representation of the risk state of maintenance personnel, thereby contributing to occupational health and safety improvements.

In this evaluation model, the neck, shoulder, hip, and knee joints are selected as key assessment points based on the biomechanical demands and load intensity experienced by maintenance personnel during mechanical maintenance tasks [10]. The risk of joint injury is evaluated in a systematic and objective manner by incorporating critical factors such as joint angles, joint tolerance moments, and exposure duration, ensuring a comprehensive assessment of musculoskeletal strain.

2.3.1. Human Posture Risk Classification on Inverse Trigonometric Function

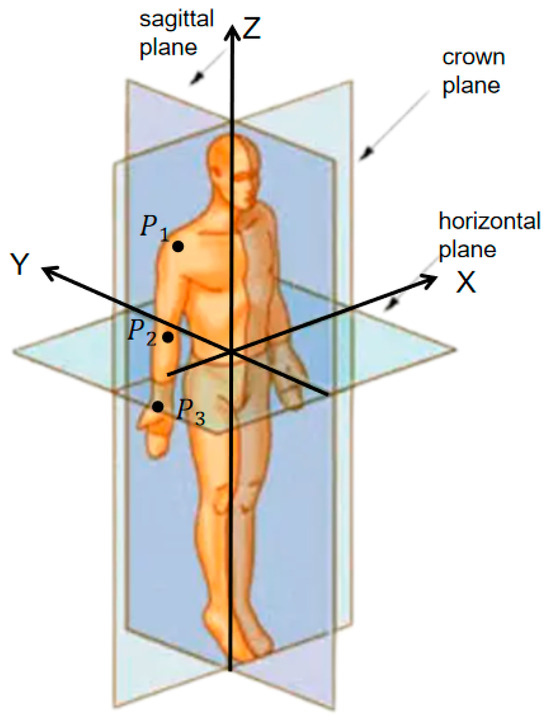

The reference planes of the human body are defined as the sagittal, coronal and horizontal planes as shown in Figure 4, the normal direction of the sagittal, coronal and horizontal planes of the human body are defined as the X-axis, Y-axis and Z-axis of the human body coordinate system, and the projection angles of the human body limbs in the horizontal, coronal and sagittal planes are defined as torsion angles θ, deflection angles φ and bending angles ψ.

Figure 4.

Schematic diagram of the human spatial coordinate system.

Biomechanics analysis evaluates physical workloads in terms of joint force or torque. The force between adjacent bone segments is determined by the angle of the adjacent bone segments and the applied load, therefore, the angle between the adjacent bone segments needs to be calculated first. The three joint points controlling two adjacent limbs are defined as ,,. The relative angle, the relative torsion angle, the relative deflection angle, and the relative bending angle of two adjacent limbs are calculated from inverse trigonometric functions with the equations shown below:

Advances in aircraft maintenance technology and equipment have allowed maintenance personnel to often work straight during the process of the maintenance work, with each joint working within a defined range, greatly reducing the risk of WMSD associated with abnormal body postures. For example, the likelihood of the upper limb during maintenance is almost non-existent, so this situation should be ignored. The risk level coding table (Table 2) is established based on the RULA and REBA theories for assessing the risk level of limb joint angles based on real repair situations.

Table 2.

Joint injury risk scale.

The evaluation of human posture risk level is affected by temporal overlap in dynamic job analysis. The posture risk level score should be determined by the sum of the individual joint scores under the time series.

1 represents the mean value of the posture risk level assessment rating when the joint risk level is not 1 in a single maintenance task; represents the human posture joint angle risk level score when all joints are at the highest risk level rating.

2.3.2. Risk Classification of Joint Force Moments

There are individual differences in joint strength. The same external loads and task demands are reflected differently in different people; therefore, population-based data are used to determine the risk of skeletal injury from internal load [45]. Joint forces are calculated from biomechanical analysis of known maintenance personnel postures and external loads [43]. Maximal isometric strength (MVIC) is a metric widely used to assess the biomechanical capabilities of the human body. Based on the results of more than 500 experiments, the National Isometric Muscle Strength Database Consortium (NIMSDC 1996) developed a regression equation using gender, age, height, and weight as influencing factors to predict maximal isometric strength (MVIC) [46]. This model constructs a standardized theoretical threshold to compare with the torque borne by the joints in the actual working state, avoiding the interference of the differences in strength among individuals on the robustness, and thus quantifying the joint fatigue risk. By focusing on the physiological limits of the human body, the model can eliminate the complex variables brought about by the differences in job types, which is modeled as the following:

where represents the maximum torque applied to the joint; represents the length of the force arm for measuring external loads; male = 1, female = 0; a, b, c, and d are the coefficients, whose value is given in Table 3. The units of age, weight, and height are year, kg, and m, respectively.

Table 3.

Joint capability regression coefficients.

Since the neck joints are not actually subjected to applied loads, only three joints other than the neck joints are evaluated when assessing joint force moment loads.

The criteria for classifying the risk level of the human body τ to withstand moments are based on the actual withstanding of the joint force moments F and the maximum load capacity of the individual . The judgement formula is:

In accordance with the national standard ‘Chinese adult human body size’ [47] and ‘adult human body inertia parameters’ [48], it can be known that the central position of gravity relative to each segment and the percentage of each bone segment relative to the body weight are shown in Table 4.

Table 4.

The centralized location of gravity relative to individual segments and the percentage of each bone segment relative to body weight.

Where the center position of gravity is the ratio of the distance from the center of gravity of the segment to the parent, to the length of the segment.

Joint force moments are present during handling or lifting in aircraft maintenance. The joints are subjected to negligible loads, and only muscle use is considered in other upper limb work. Advances in maintenance technology have minimized muscle use in practical maintenance. Therefore, the human model is simplified when considering joint loads and only focuses on the case of applied loads that exist vertically downward in the sagittal plane.

The degree of joint loading is calculated by the following formula:

represents the mean value of the joint loads in typical postures extracted from the time series.

2.3.3. WMSD Risk Assessment Model

The physiological situation of the human body in aircraft maintenance is affected by three factors: posture, force and duration. Based on The Cube Method and the PEBA method [49], the relationship that exists between the three factors is:

According to ergonomics theory, the probability of a maintenance worker suffering WMSD is determined by the ratio of the actual workload to the maximum value of the prescribed load:

as well

in which

represents the length of time that the risk level assessment of the joint posture at the time of the actual repair is greater than 1 (If the risk level assessment of the joint point is less than or equal to 1, maintenance personnel in a state of natural relaxation of the body without discomfort); Max{timeT} represents the actual repair time in hours for joint i in the whole repair task.

Based on the system reliability theory, the probability R that the personnel will keep working in a normal state during the actual working time t is:

Then the probability of their risk of WMSD is:

This paper constructs a risk rating scale divided according to linear intervals, as shown in Table 5, dividing the WMSD risk probability into five levels at equal intervals or in equal proportions. By converting continuous data into discrete categories, it is convenient to intuitively assess the degree of risk. The following table shows the WMSD rating scale for machine maintenance personnel constructed on the basis of linear regression rates:

Table 5.

Maintenance staff WMSD rating evaluation form.

2.4. Validation of the Proposed Model

The applicability of the proposed method was evaluated using typical maintenance postures observed in maintenance tasks.

2.4.1. Subject

In order to strictly control the experimental variables, reduce the interference of individual differences, and focus on the logical closed loop of the method itself, this paper selects a single subject. A male participant (age: 25 years, height: 1.76 m, weight: 65 kg) was recruited for the study. The participant received a comprehensive briefing on the experimental procedures and was provided with an informed consent form. The study protocol and consent procedure were reviewed and approved by the human-subject committee of the host university, ensuring compliance with ethical guidelines for research involving human participants. Before the commencement of the study, the participant formally signed the consent form, indicating his voluntary agreement to partake in the research.

2.4.2. Validation Protocol and Process

The proposed methodology was validated using the NOKOV Optical 3D Motion Capture System (NOKOV Science & Technology Co., Ltd., Beijing) in conjunction with the JACK9.0 software virtual simulation platform (Siemens Industry Software). The selected maintenance movements were captured using the NOKOV 3D motion capture system and subsequently processed into a human skeletal model using XINGYING software, provided by NOKOV. To facilitate data interoperability and application, the processed motion data from XINGYING software were integrated into JACK software, a widely recognized tool for human-machine ergonomics evaluation. The resulting analyses were generated by the processing platform.

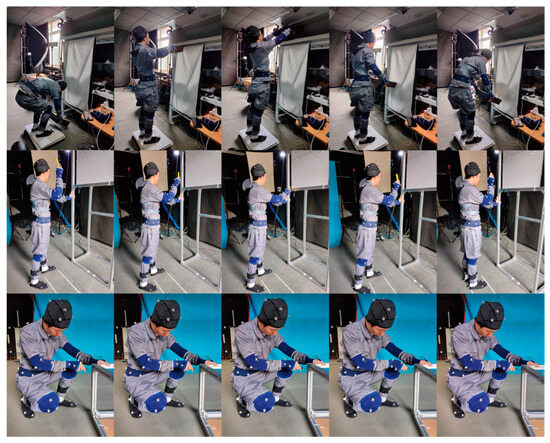

For validation, three typical aircraft maintenance scenarios were selected: (1) replacement of the aircraft cabin roof baggage hatch hold-up (Figure 5, top), (2) disassembly and installation of landing gear linkage components (Figure 5, middle), and (3) engine nut removal and installation in conjunction with landing gear linkage component knockdown installation (Figure 5, bottom). Motion data were collected using an eight-camera NOKOV system, adhering to the manufacturer’s specified calibration procedures and marker placement guidelines. Calibration precision yielded an accuracy of within 0.3 mm. Data acquisition was performed at a sampling rate of 60 frames per second, ensuring a detailed examination of the selected maintenance movements. Additionally, in order to avoid the loss of detailed information caused by averaging the data from multiple experiments, this paper adopts the data from a single experiment. The experimental process was recorded using a high-definition smartphone camera to provide visual references for subsequent analysis.

Figure 5.

The 3 selected typical aircraft maintenance scenarios.

3. Results

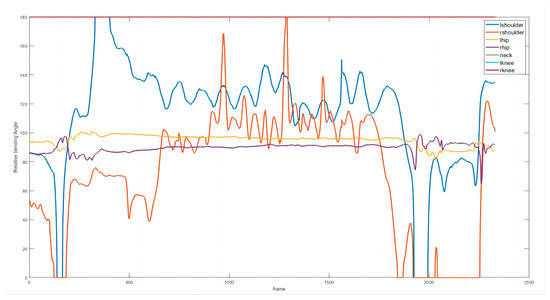

3.1. Risk Level Analysis of Joint Angles

The risk levels of joints during work were determined using the inverse trigonometric function algorithm outlined in the Method, with variations over time depicted in Figure 6. The experimental findings demonstrate that the relative flexion angles of joints do not follow a consistent pattern during human movement but instead fluctuate in response to joint positions as posture changes. Therefore, a static evaluation of human posture is insufficient for a comprehensive risk assessment. Instead, a more accurate and holistic evaluation should incorporate the dynamic variations in human posture throughout the duration of work tasks.

Figure 6.

Results of relative flexion angles of joints in action postures.

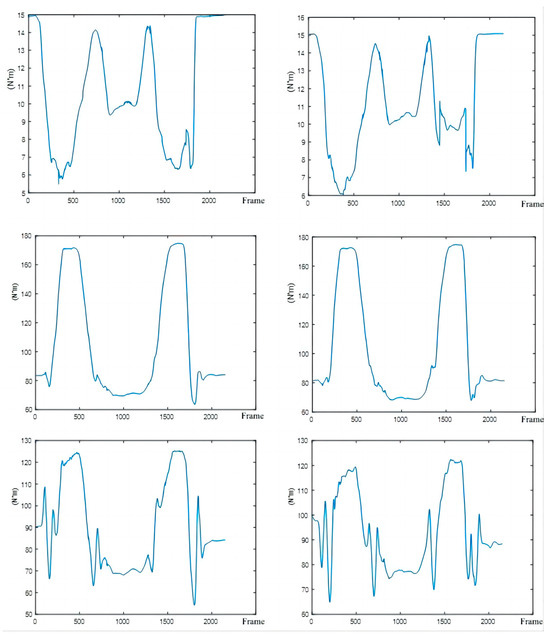

3.2. Risk Level Analysis of Joint Force Moments

Moment is a physical quantity that represents the rotational effect of a force acting on an object. Joint moment refers to the effect of applied loads and the mass of the body’s bone segments on each corresponding joint point, which is affected by the joint spatial position, the mass of the relevant bone segments, the position of the center of mass, and the combined effect of applied loads. In the aircraft maintenance scenario, the movement speeds of most operations are relatively slow. The inertial force caused by acceleration is much smaller than the gravitational force and the active force exerted by human muscles. Its contribution to the joint torque can be approximately ignored. Therefore, when analyzing the degree of joint torque, this paper adopts the quasi-static assumption to simplify the dynamic equations, focusing on the core interaction between gravity and human mechanics to ensure the interpretability and computational efficiency of the model. In order to analyze the joint load under the time cumulative effect, this paper constructs a joint load model using the principle of inverse kinematics. The joint bearing capacity during the dynamic process is treated and analyzed as a static situation. It calculates the influence of the applied load and the weight of the limbs on the corresponding joints under the action of gravity in each frame, and analyzes the degree of joint load under the time cumulative effect.

According to the principle of leverage, the joints are subjected to moments calculated by the formula:

where represents the mass of the applied load, represents the length of the force arm from the center of gravity of the applied load to the joint; represents the mass of the body bone segment, represents the length of the force arm from the center of gravity of the body bone segment to the joint.

Based on the inverse trigonometric function and the moment calculation method, we can obtain the change in the moment borne by the joints under the time series of the set task (Figure 7).

Figure 7.

Changes in joint force moment (From left to right, top to bottom: left shoulder joint, right shoulder joint, left hip joint, right hip joint, left knee joint, right knee joint).

The degree of joint loading in typical postures under the time series during the task is extracted, and the degree of joint loading is constructed based on the joint torque and the joint capability data, as shown in Table 6.

Table 6.

The joint capability data and the joint torque.

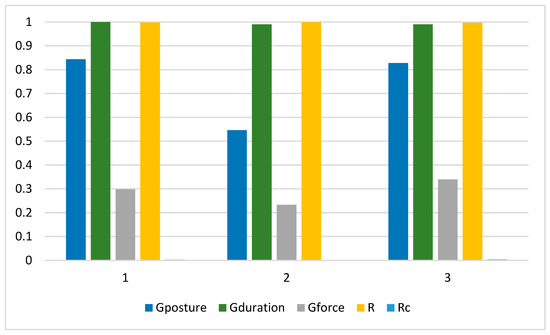

3.3. Risk Level Analysis of WMSD

In order to enhance the reliability and accuracy of the assessment results, this paper adopts a comprehensive analysis approach. Unlike the analysis of a single risk factor, multiple dimensions of risk factors are fully considered, and the safety of the operation is assessed in an all-round way through a comprehensive multi-indicator assessment model. Based on the experimental data, the results of the risk scores of each index and the risk probability of maintaining the normal operation state without operational fatigue of the subjects under different tasks is outputted separately as shown in Figure 8:

Figure 8.

Experimental data results.

Energy metabolism refers to the metabolism of substances in the organism produced by human movement, accompanied by the phenomena of energy release, transfer, and utilization. Aircraft maintenance work requires a lot of physical effort, which inevitably generates relative energy consumption [50]. In order to assess the accuracy of the data, the experimental task is broken into separate action units based on the Metabolic Energy Expenditure (MEE) of JACK. The type of action, its duration, and frequency are specified in the experimental task. The risk levels are calculated by comparing the energy consumption rate of the analyzed output with the recommended energy consumption rate of the National Institute for Occupational Safety and Health (NIOSH) energy consumption standard using the following formula.

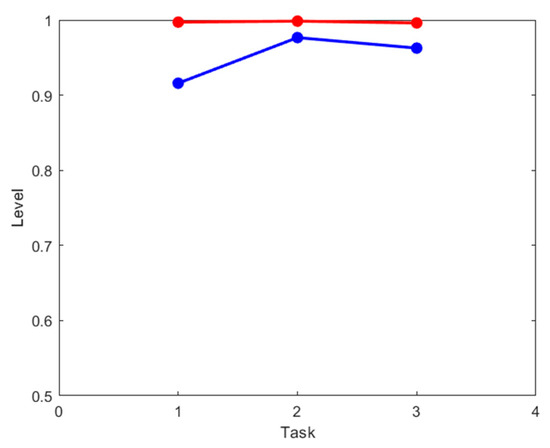

The output of the assessment model is compared with the results of the JACK energy metabolism simulation based on a one-way ANOVA. The results (Figure 9) indicated that the root mean square error (RMSE) between the two was RMSE = 0.0523, indicating that the model can be used to assess the probability of risk of occupational musculoskeletal injuries at work by disaggregating work postures and applied loads.

Figure 9.

Comparison of model results with simulation results (The red line represents the normal operating probability result from the Jack software, while the green line represents the normal operating probability result from the model in this paper).

4. Discussion

This study introduces a novel quantitative approach for Work-Related Musculoskeletal Disorder (WMSD) risk assessment, integrating the three primary influencing factors—loading duration, human posture, and force/loading intensity [11]—to provide a more comprehensive and precise evaluation of occupational risks among aircraft maintenance personnel. The findings demonstrate that the proposed model effectively estimates actual human workloads and accurately predicts WMSD risks through 3D motion tracking, offering a reliable framework for ergonomic risk assessment in maintenance tasks.

Compared to traditional methods such as questionnaires and physiological measurements [51,52,53], optical motion capture systems offer significant advantages in fatigue risk assessment due to their high precision and real-time capabilities. Questionnaire-based approaches, although widely applied, rely heavily on participants’ subjective self-perception and recall, which can introduce bias and limit the accuracy of risk assessments [51,52]. Moreover, previous studies have reported that physiological measurement techniques, while more objective, often exhibit relatively low reliability when compared to questionnaire-based approaches, especially in dynamic work settings [53]. In contrast, optical motion capture systems employ high-precision cameras to objectively and accurately track real-time changes in posture and joint movement throughout task execution. This enables a more comprehensive and reliable evaluation of physical workloads related to work-related WRMDs. By acknowledging and building upon these traditional methodologies, the novelty and contribution of our approach, grounded in dynamic motion analysis, are further emphasized.

This technology facilitates continuous monitoring of an individual’s physical movements, collecting detailed data on gait, posture, movement speed, and angle variations. Unlike traditional methods, it eliminates subjective bias, providing a more objective and reliable assessment. Furthermore, optical motion capture systems can use 3D coordinate data to analyze the forces exerted on joints during the work process in depth. This allows for precise modeling of joint angles and forces, enabling the quantification and evaluation of how different postures impact joint load and muscle fatigue, leading to a more detailed health risk assessment. The 3D data analysis reveals potential sources of fatigue and identifies hazardous movements and improper postures that could lead to musculoskeletal problems. In highly collaborative tasks such as aircraft maintenance, it is difficult to accurately measure individual contributions, especially in terms of fatigue. While traditional subjective questionnaires may provide preliminary information on common injury sites within a group, they are limited in quantifying individual risks in complex work environments.

This paper proposes an innovative comprehensive fatigue assessment model for aircraft maintenance work, aiming to address these limitations. Using motion capture technology, a rigid body chain structure of the human body is created to record joint movements and accurately capture 3D motion data of each joint. These data allow for precise calculation of joint trajectories and load levels, which can be aggregated over time to assess posture changes, joint loads, and potential risks at different time intervals. This approach provides a more objective and quantitative assessment of fatigue risk in physically demanding tasks, offering a stronger foundation for assessing work-related health risks. At the same time, the work of this paper still belongs to basic methodology research. The proposed model has the potential for cross-domain applications, and the application requirements vary significantly among different scenarios. Therefore, this study chooses to prioritize strengthening the underlying architecture of the model, laying a foundation for subsequent diversified applications.

In summary, the fatigue assessment method based on optical motion capture technology has significant innovation and practical value. This model overcomes the limitations of traditional methods, particularly in accurately quantifying physical task loads and assessing occupational injury risks. It is especially useful in environments where precise measurement of workload and fatigue accumulation is crucial, such as in physically intensive industries and aircraft maintenance. The model supports real-time, dynamic fatigue monitoring, enabling managers to monitor workers’ health, adjust work schedules as needed, and prevent excessive fatigue and potential injuries.

5. Conclusions

A quantitative workload evaluation model is proposed by combining motion capture technology and biomechanics analysis methods, which can assess and predict the risk probability of WMSD for maintenance workers. The method accurately records the motion data and posture of workers in a given job through motion capture technology, with an experimental error of 3 cm per joint for non-invasive human motion data collection. The evaluation model is shown to be able to successfully estimate actual human workloads and predict the risk of WMSD based on 3D motion data and biomechanics analyses. The model helps to collect data on the behavior of aircraft maintenance workers and assess their physiological load quantitatively. Moreover, the decomposition method proposed in this paper is more suitable for analyzing complex aircraft maintenance work.

Author Contributions

Conceptualization, M.Y. and D.Z.; methodology, M.Y. and D.Z.; software, D.Z.; validation, M.Y., D.Z. and J.C.; formal analysis, D.Z.; investigation, Y.Z. and Y.C.; resources, M.Y.; data curation, D.Z.; writing—original draft preparation, D.Z., M.Y. and G.S.; writing—review and editing, M.Y. and G.S.; visualization, Y.Z.; supervision, M.Y. and J.Y.; project administration, M.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was carried out in accordance with the policy of the Ethical Committee of Northwestern Polytechnical University (protocol number: 202502043).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request and after appropriate IRB approvals.

Acknowledgments

We would like to thank all the subjects of the study who donated their time.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jaiswal, K.; Dalkilic, S.; Papageorgiou, E.; Singh, B. Aviation MRO: Impact of Physical Environment Factors on Job Performance in Aircraft Maintenance Organization. Adv. Sci. Technol. Eng. Syst. J. 2020, 5, 148–154. [Google Scholar] [CrossRef]

- Turner, C.; Visentin, P.; Shan, G. Wrist internal loading and tempo-dependent, effort-reducing motor behaviour strategies for two elite pianists. Med. Probl. Perform. Artist. 2021, 36, 141–149. [Google Scholar] [CrossRef] [PubMed]

- Yusof, N.N.M.; Nur, N.M.; Roslin, E.N. The Prevalence of Work-Related Musculoskeletal Disorders and Work Productivity of Aviation Maintenance Personnel. In Industrial Revolution in Knowledge Management and Technology; Springer Nature: Cham, Switzerland, 2023; pp. 41–50. [Google Scholar]

- Ge, W.; Peng, L. Ergonomic Analysis and Risk Assessment Model Construction of Civil Aviation Aircraft Maintenance Based on Deep Learning. In Proceedings of the Third International Conference on Electronics, Electrical and Information Engineering (ICEEIE 2023), Xiamen, China, 11–13 August 2023. [Google Scholar]

- Meghashyam, G. Electronic Ergonomic Audit System for Maintenance and Inspection. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting; SAGE Publications: Los Angeles, CA, USA, 1995; Volume 39, pp. 75–78. [Google Scholar]

- Alhaag, M.H.; Ramadan, M.Z.; Al-Harkan, I.M.; Alessa, F.M.; Alkhalefah, H.; Abidi, M.H.; Sayed, A.E. Determining the Fatigue Associated with Different Task Complexity during Maintenance Operations in Males Using Electromyography Features. Int. J. Ind. Ergon. 2022, 88. [Google Scholar] [CrossRef]

- Chen, N.; Li, R. Ergonomics Model of Aviation Maintenance Human Error Analysis and Control. In Proceedings of the ICTIS 2013: Improving Multimodal Transportation Systems-Information, Safety, and Integration, Wuhan, China, 29 June–2 July 2013. [Google Scholar]

- Zhou, D.; Wu, H.; Guo, Z.; Zhou, Q.; Liang, Y. Maintenance Accessibility Evaluation Method Based on D-H Model and Comfort in a Virtual Maintenance Environment. Int. J. Adv. Manuf. Technol. 2022, 121, 1429–1442. [Google Scholar] [CrossRef]

- Soares, M.M.; Jacobs, K.; Nogueira, H.C.; Diniz, A.C.; Barbieri, D.F.; Padula, R.S.; Carregaro, R.L.; de Oliveira, A.B. Musculoskeletal disorders and psychosocial risk factors among workers of the aircraft maintenance industry. Work 2012, 41 (Suppl. S1), 4801–4807. [Google Scholar]

- Asadi, H.; Yu, D.; Mott, J.H. Risk Factors for Musculoskeletal Injuries in Airline Maintenance, Repair & Overhaul. Int. J. Ind. Ergon. 2019, 70, 107–115. [Google Scholar] [CrossRef]

- Lowe, B.D.; Dempsey, P.G.; Jones, E.M. Ergonomics assessment methods used by ergonomics professionals. Appl. Ergon. 2019, 81, 102882. [Google Scholar] [CrossRef]

- McAtamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Hignett, S.; McAtamney, L. Rapid Entire Body Assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef]

- Gharib, S.; Martin, B.; Neitzel, R.L. Pilot Assessment of Occupational Safety and Health of Workers in An Aircraft Maintenance Facility. Saf. Sci. 2021, 141. [Google Scholar] [CrossRef]

- Chang, Y.-H.; Wang, Y.-C. Significant Human Risk Factors in Aircraft Maintenance Technicians. Saf. Sci. 2020, 48, 54–62. [Google Scholar] [CrossRef]

- Su, J.-M.; Chang, J.-H.; Indrayani, N.L.D.; Wang, C.-J. Machine Learning Approach to Determine the Decision Rules in Ergonomic Assessment of Working Posture in Sewing Machine Operators. J. Saf. Res. 2023, 87, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Golabchi, A.; Han, S.; Fayek, A.R. A fuzzy logic approach to posture-based ergonomic analysis for field observation and assessment of construction manual operations. Can. J. Civ. Eng. 2016, 43, 294–303. [Google Scholar] [CrossRef]

- Shan, G.; Visentin, P. A quantitative three-dimensional analysis of arm kinematics in violin performance. Med. Probl. Perform. Artist. 2003, 18, 3–10. [Google Scholar] [CrossRef]

- Chiou, S.S.; Pan, C.S.; Bhattacharya, A. Kinematics and kinetics of gait on stilts: Identification of risk factors associated with construction stilt use. Ergonomics 2008, 51, 1814–1829. [Google Scholar] [CrossRef]

- Visentin, P.; Shan, G. The kinetic characteristics of the bow arm during violin performance: An examination of internal loads as a function of tempo. Med. Probl. Perform. Artist. 2003, 18, 91–97. [Google Scholar] [CrossRef]

- Shan, G.; Visentin, P.; Schultz, A. Multidimensional signal analysis as a means of better understanding factors associated with repetitive use in violin performance. Med. Probl. Perform. Artist. 2004, 19, 129–139. [Google Scholar] [CrossRef]

- Winter, D.A. Chapter 9: Kinesiological Electromyography. In Biomechanics and Motor Control of Human Movement, 3rd ed.; Winter, D.A., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Shan, G.; Bohn, C. Anthropometrical data and coefficients of regression related to gender and race. Appl. Ergon. 2003, 34, 327–337. [Google Scholar] [CrossRef]

- Shan, G.; Westerhoff, P. Soccer: Full-body kinematic characteristics of the maximal instep soccer kick by male soccer players and parameters related to kick quality. Sports Biomech. 2005, 4, 59–72. [Google Scholar] [CrossRef]

- Wan, B.; Shan, G. Biomechanical modeling as a practical tool for predicting injury risk related to repetitive muscle lengthening during learning and training of human complex motor skills. SpringerPlus 2016, 5, 1–13. [Google Scholar] [CrossRef]

- Han, S.; Achar, M.; Lee, S.; Peña-Mora, F. Empirical assessment of a RGB-D sensor on motion capture and action recognition for construction worker monitoring. Vis. Eng. 2013, 1, 1–13. [Google Scholar] [CrossRef]

- Yu, Y.; Umer, W.; Yang, X.; Antwi-Afari, M.F. Posture-related data collection methods for construction workers: A review. Autom. Constr. 2021, 124. [Google Scholar] [CrossRef]

- Shan, G.; Visentin, P.; Zhang, X.; Hao, W.; Yu, D. Bicycle kick in soccer: Is the virtuosity systematically entrainable? Sci. Bull. 2015, 60, 819–821. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Khan, A.M.; Ayub, S.; Jousseaume, N. A survey-based approach of framework development for improving the application of internet of things in the construction industry of Malaysia. Results Eng. 2024, 21. [Google Scholar] [CrossRef]

- Manghisi, V.M.; Uva, A.E.; Fiorentino, M.; Bevilacqua, V.; Trotta, G.F.; Monno, G. Real Time RULA Assessment Using Kinect V2 Sensor. Appl. Ergon. 2017, 65, 481–491. [Google Scholar] [CrossRef]

- Al Madani, D.; Dababneh, A. Rapid Entire Body Assessment: A Literature Review. Am. J. Eng. Appl. Sci. 2016, 9, 107–118. [Google Scholar] [CrossRef]

- Irwin, E.; Streilein, K. Use of Field-based Motion Capture to Augment Observational Data in Ergonomic Assessment of Aircraft Maintenance. Procedia Manuf. 2015, 3, 4501–4508. [Google Scholar] [CrossRef]

- Puthenveetil, S.C.; Daphalapurkar, C.P.; Zhu, W.; Leu, M.C.; Liu, X.F.; Gilpin-Mcminn, J.K.; Snodgrass, S.D. Computer-automated Ergonomic Analysis Based on Motion Capture and Assembly Simulation. Virtual Real. 2015, 19, 119–128. [Google Scholar] [CrossRef]

- Golabchi, A.; ASCE, S.M.; Han, S.H.; Seo, J.O.; Han, S.U.; ASCE, A.M.; Lee, S.H.; ASCE, A.M.; Al-Hussein, M.; ASCE, M. An Automated Biomechanics Simulation Approach to Ergonomic Job Analysis for Workplace Design. J. Constr. Eng. Manag. 2015, 141, 04015020. [Google Scholar] [CrossRef]

- Coit, D.W.; Zio, E. The Evolution of System Reliability Optimization. Reliab. Eng. Syst. Saf. 2019, 192, 106259. [Google Scholar] [CrossRef]

- Bubb, H. System Ergonomics as an Approach to Improve Human Reliability. Nucl. Eng. Des. 1988, 2, 233–245. [Google Scholar] [CrossRef]

- Bernard, F.; Zare, M.; Sagot, J.-C.; Paquin, R. Integration of Human Factors into the Design Process of Helicopter Maintainability. Hum. Factors Ergon. Manuf. Serv. Ind. 2019, 29, 350–360. [Google Scholar] [CrossRef]

- Qiao, Y.; Chen, D.; Sun, Y.; Wang, H. Dynamics simulation model for risk probability assessment based on cognitive modeling in manned deep dive mission scenario. Ocean. Eng. 2024, 302, 117688. [Google Scholar] [CrossRef]

- Stanton, N.A. Hierarchical task analysis: Developments, Applications, and Extensions. Appl. Ergon. 2006, 37, 55–79. [Google Scholar] [CrossRef]

- Vujosevic, R. Maintainability Analysis in Concurrent Engineering of Mechanical Systems. Concurr. Eng. 1995, 3, 61–73. [Google Scholar] [CrossRef]

- Wang, J.; Chen, D.; Zhu, M.; Sun, Y. Risk assessment for musculoskeletal disorders based on the characteristics of work posture. Autom. Constr. 2021, 131, 103921. [Google Scholar] [CrossRef]

- European Aviation Safety Agency (EASA). Continuing Airworthiness Management: EASA part M. In Official Journal of EASA; Patrick, G., Ed.; European Aviation Safety Agency: Cologne, Germany, 2010; pp. 1–325. [Google Scholar]

- Yu, Y.; Li, H.; Umer, W.; Dong, C.; Yang, X.; Skitmore, M.; Wong, A.Y.L. Automatic Biomechanical Workload Estimation for Construction Workers by Computer Vision and Smart Insoles. J. Comput. Civ. Eng. 2019, 33. [Google Scholar] [CrossRef]

- Hugo, A.; Fajardo, R.; Viviana, A.; Ortiz, M. Characterization of Low Back Pain in Pilots and Maintenance Tech-nicians on a Commercial Airline. Aerosp. Med. Hum. Perform. 2016, 87, 795–799. [Google Scholar] [CrossRef]

- Seo, J.O.; Starbuck, R.; Han, S.U.; Lee, S.H.; Armstrong, T.J. Motion Data-Driver Biomechanics Analysis during Construction Tasks on Sites. J. Comput. Civ. Eng. 2015, 29, B4014005. [Google Scholar] [CrossRef]

- Finision, L.J.; Brooks, B.R.; Ringel, S.P.; Munsat, T.L.; Neville, H.E.; Murphy, J.R.; England, J.D.; Lee, J.Y.; Brinkmann, J.R.; Ziter, F.; et al. Muscular Weakness Assessment: Use of Normal Isometric Strength Data. Arch. Phys. Med. Rehabil. 1996, 77, 1251–1255. [Google Scholar]

- GB/T10000-2023; State Bureau of Technical Supervision. Chinese Adult Human Body Size. China Standards Press: Beijing, China, 2023.

- GB/T17245-2004; Standardization Administration of the People’s Republic of China. Adult Human BodyInertia Parameters. China Standards Press: Beijing, China, 2004.

- Chander, D.S.; Cavatorta, M.P. An Observational Method for Postural Ergonomic Risk Assessment (PE-RA). Int. J. Ind. Ergon. 2017, 57, 32–41. [Google Scholar] [CrossRef]

- Pilati, F.; Tronconi, R. Multi-objective Optimisation for Sustainable Few-to-many Pickup and Delivery Vehicle Routing Problem. Int. J. Prod. Res. 2024, 62, 3146–3175. [Google Scholar] [CrossRef]

- Punnett, L.; Wegman, D.H. Work-related musculoskeletal disorders: The epidemiologic evidence and the debate. J. Electromyogr. Kinesiol. 2004, 14, 13–23. [Google Scholar] [CrossRef] [PubMed]

- David, G.C. Ergonomic methods for assessing exposure to risk factors for work-related musculoskeletal disorders. Occup. Med. 2005, 55, 190–199. [Google Scholar] [CrossRef]

- Wang, D.; Dai, F.; Ning, X. Risk assessment of work-related musculoskeletal disorders in construction: State-of-the-art review. J. Constr. Eng. Manag. 2015, 141. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).