1. Introduction

Advancements in Information and Communication Technology (ICT) have significantly contributed to various research fields, thereby enhancing overall quality of life. Engaging in sufficient physical activity—whether through recreational pursuits, amateur involvement, or professional sports—is vital for maintaining health and well-being. A diverse array of devices and systems, varying in complexity, are employed to record and evaluate physical activity by measuring parameters such as daily step counts and analyze movements during athletic activities.

The integration of ICT is particularly impactful in the development of biomechanical feedback systems for sports and rehabilitation, which we address in this paper. These systems aim to acquire, monitor, analyze, assess, and improve human movement patterns in real time. While initially developed for sports performance enhancement, biomechanical feedback has also found applications in physical rehabilitation, helping patients regain mobility and correct movement patterns [

1,

2].

Biomechanical feedback systems are implemented with different types of devices, from professional high-precision motion capture systems to commercial mass products such as wristbands. While the former provide detailed data on the activity or movement of a specific body part, they are also expensive and require trained professionals and an adapted environment for use. The latter, on the other hand, are primarily intended for recreational use and generally only provide simple statistical data on activity. In light of the above, it is clear that we need devices that fill the gap between the two extremes. These are usually devices that are designed for a specific sport, activity, or even just a single movement. Most of these devices are wearable devices that do not interfere with activity and have wireless connectivity. These devices are worn on the body as accessories, attachments, or implants and encompass a broad spectrum—from smart devices like smartphones and smartwatches to small accessories such as smart eyewear, and specialized sensor devices or intelligent sports equipment [

3]. The commercially available devices mentioned are only intended for a set of predefined activities and cannot be adapted to specific requirements, e.g., to measure a specific activity parameter. Furthermore, they usually do not offer the possibility to view the raw data and therefore do not allow in-depth analysis. Researchers in the field of biomechanical feedback systems are therefore developing their own wearable devices that enable the capture and analysis of specific activities and parameters. Our own experience in this research has led us to realize that we can meet a variety of biomechanical feedback system requirements with the same or similar devices, but with different settings and under different conditions. Therefore, there is a need to develop a solution for the acquisition and wireless streaming of sensor data with wearable devices that can cover a variety of applications, which is the main objective of this work.

A crucial aspect of biomechanical feedback systems is the timing of feedback delivery [

1], which determines when corrective information is provided to the user. Feedback can be terminal (delivered after task completion), concurrent (provided in real time during the movement), or cyclic (offered immediately after completing a repeating motion cycle). Wearable devices play a key role in enabling real-time feedback, as they allow unobtrusive monitoring and wireless communication with processing units. Comprehensive overviews of wearable devices and their associated challenges are provided in [

4,

5], while their technical challenges and limitations are explored in [

1,

6,

7].

When evaluating wearable sensor devices for real-time biomechanical feedback (RTBF), our focus was primarily on kinematic sensors, such as inertial measurement units (IMUs) [

8]. They are widely used in wearable technologies for performance enhancement and risk assessment in various fields, including sports, industry [

9], and rehabilitation [

10]. IMUs employ gyroscopes and accelerometers to capture body motion, and are sometimes used to supplement marker-based optical systems for monitoring high-speed motion in sports [

11]. Other types of sensors, such as piezoelectric [

12] or triboelectric [

13], are available for measuring human activities, body processes, and states, but they do not fall into the scope of this work. A promising future development is the integration of kinematic sensors in textiles, which will significantly improve wearability in sports and rehabilitation [

14].

Real-time biomechanical feedback applications for analysing human motion require strict time guarantees, especially when high sampling frequencies are required, often exceeding 100 or 200 Hz [

15]. We have previously conducted a study to determine the most commonly used approaches in RTBF applications [

16] and were surprised to find that none of the articles we reviewed explicitly discussed specific software mechanisms for handling real-time constraints. Even when timing requirements were mentioned, they were often vague or not directly related to software implementation. For instance, in [

17], the authors stated that “the microcontroller continuously calculates the current position,” but did not provide specific details about the timing constraints. In another study, [

18], the authors reported choosing a time window of 12 s and a sampling frequency of 64 Hz for EEG signals, but did not specify any timing requirements for the accelerometer readings, which they described as “instantaneous measurements”. The most stringent timing requirements we found were in [

11], where a capture rate of 1000 Hz was required, but even in this article, no details were provided on how the system ensured precise timing and synchronization.

Wearable sensor devices for RTBF systems must execute multiple processes in parallel, including acquiring sensor data at uniform time intervals, formatting and assembling data packets, and transmitting sensor data wirelessly while maintaining minimal latency. Ensuring precise timing and synchronization across these processes presents a technical challenge, particularly given the limited computational resources of battery-powered microcontrollers. Several Real-Time Operating System (RTOS) solutions are available for real-time embedded applications, including FreeRTOS, ChibiOS, and NuttX. These systems provide features like pre-emptive multitasking, priority-based scheduling, and inter-task communication, making them suitable for general-purpose real-time applications. However, for RTBF applications, these features introduce unnecessary overhead, making them less suitable for resource-constrained wearable devices.

To address these challenges, we developed a lightweight periodic scheduler tailored to the specific needs of real-time biomechanical feedback applications. Unlike full RTOS solutions, which provide complex task management features, our scheduler follows a cooperative round-robin execution model, ensuring minimal overhead and precise timing control. This design allows us to achieve the following:

Minimal overhead—It is lean and efficient, avoiding excessive memory usage or processing time that could interfere with other processes.

Task-specific design—It performs only the essential functions required for our wireless sensor device, without unnecessary complexity.

Configurability—It is adaptable to various application scenarios, such as streaming, logging, or event detection.

Cost-effective and energy-efficient design—Since wireless systems often operate on battery power, energy efficiency is important for prolonged use. However, considering that our device is intended for shorter operational intervals in environments with accessible charging options, cost efficiency also plays a key role. The scheduler should therefore maintain a balance between low power consumption and affordability, ensuring an optimal trade-off between performance, energy usage, and price.

The primary research question addressed in this study is the following: What is the maximum sensor sampling frequency that can be supported by a given wearable device in streaming mode? In answering the question, the following contributions were identified: (a) development and implementation of a lightweight periodic scheduler tailored to the specific needs of real-time biomechanical feedback applications and adaptable for other real-time data acquisition tasks, (b) a wearable RTBF system with flexible sensor sample streaming capabilities covering a range of possible needs in sports and rehabilitation, (c) determination of the upper limit of the sampling frequency for the specific hardware we used with different formats and numbers of samples in a packet, (d) analyzing the correlations between sampling frequency and the duration required to execute all processes involved in sensor data acquisition, packet assembly, and transmission, taking into account the number of samples contained within each packet and the structure of the formatted sensor data values.

2. Materials and Methods

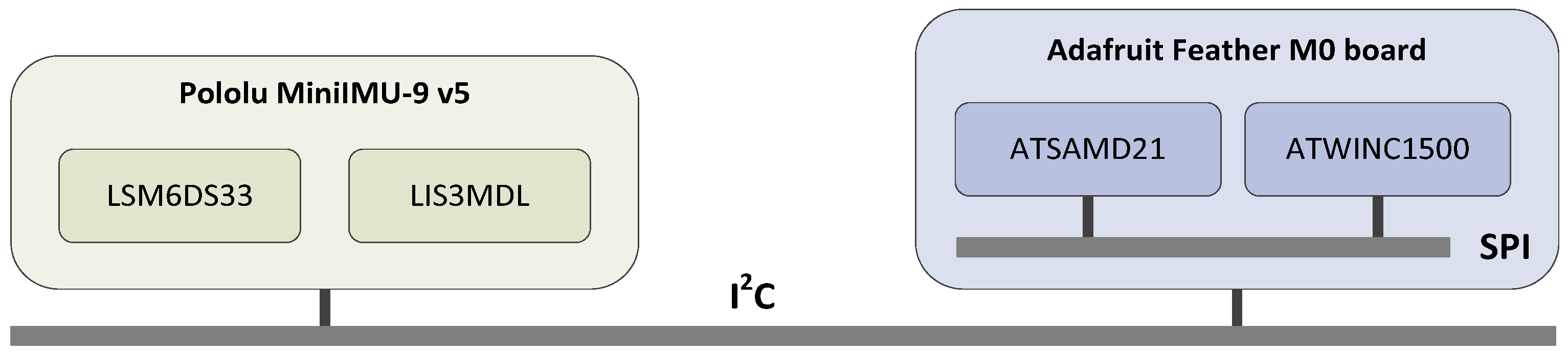

In order to meet the requirements of being lightweight and autonomous, we chose the Adafruit Feather M0 board (Adafruit, New York, NY, USA), which features an ATSAMD21 microcontroller and ATWINC1500 network controller, as a base of our system. The compact size and weight of the board make it unobtrusive to the wearer’s movement, and it can be mounted discreetly.

2.1. System Architecture and Implementation

To acquire comprehensive motion data, we utilized the MinIMU-9 v5 board (Pololu Corporation, Las Vegas, NV, USA) [

8], which integrates two sensor chips manufactured by STMicroelectronics: the LIS3MDL magnetometer [

19] and the LSM6DS33 accelerometer and gyroscope [

20]. Together, these sensors provide measurements along three axes each, totaling nine degrees of freedom essential for detailed analysis of human movement. Sensors with more degrees of freedom can capture more detailed and precise data about movements, ensuring greater accuracy and precision. This can be beneficial for detailed analysis, but may require advanced algorithms and computing power to effectively process and interpret the data. The sensor assembly was connected to the Adafruit Feather M0 microcontroller board via the I

2C communication interface, as shown in

Figure 1. For our initial testing phase, we employed the Arduino IDE 2.0 with the library supplied by Pololu to configure the sensors and retrieve raw data outputs.

We utilized Pololu’s Arduino library to maintain compatibility with the Arduino environment, but for effective debugging, a more advanced Integrated Development Environment (such as a Cmake 4.0.2 project in Visual Studio Code 1.100.2 using the Cortex-Debug extension) is necessary.

In

Figure 2, we present three examples of system implementations that we use in various biofeedback applications developed in our laboratory [

21]. These are prototypes that will later be built into different enclosures and used as 9 DoF wearable devices with wireless communication. These are some of the devices used in the tests and measurements presented in later sections of this article.

2.2. Scheduler Implementation

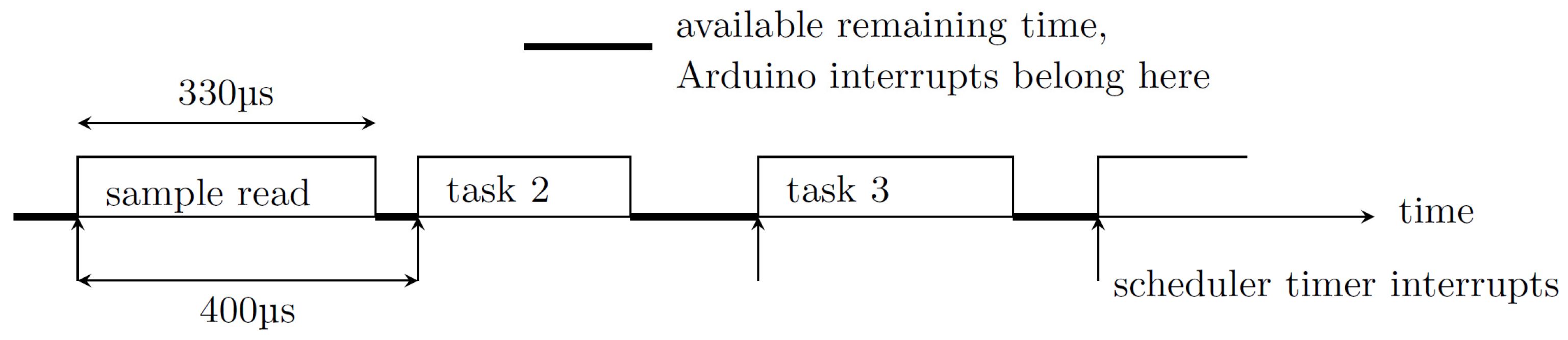

To achieve uniformly spaced sensor readings, we developed a custom cooperative periodic scheduler without task prioritization. This scheduler employs a round-robin execution model capable of handling a variable number of finite tasks, each of which must be completed within a predefined time slice. By utilizing a modular and transparent software architecture, our system prevents race conditions and CPU starvation through cooperative task scheduling without priorities. This implementation leverages a single timer interrupt, as illustrated in

Figure 3. As shown in the figure, the system masks native Arduino interrupts during the execution of the timer interrupt and permits them only between the scheduled tasks.

By imposing stringent constraints on the tasks supported by our system, we were able to simplify it to its bare minimum. As shown in

Figure 3, tasks are executed in a strict round-robin fashion, and it is the user’s responsibility to ensure that each task completes before the next timer interrupt occurs. Upon each interrupt, the scheduler simply retrieves the address of the next task to be executed and runs it. This approach imposes only about 3 μs of overhead, which is significantly lower than the overhead imposed by any of the RTOS solutions mentioned in the Introduction. For comparison, lightweight RTOS solutions such as FreeRTOS typically incur a task switch overhead ranging from 5 to 15 µs on ARM Cortex-M microcontrollers, with much higher delays on less capable platforms.

Due to the deterministic nature of task execution, no conflicts or unexpected task delays were observed under normal operation, as long as each task adhered to its allocated time slice. This approach not only reduces the system complexity but also eliminates the need for additional fault tolerance mechanisms such as watchdog timers, as the risk of unanticipated system hangs or deadlocks is inherently minimized by design. The primary challenge arises in high-load scenarios where a transmitted packet is not successfully received due to network conditions or interference. This, however, is not a limitation of the scheduler itself; rather, it is handled at the communication protocol level, where the system simply requests a packet resend as needed. This ensures that data transmission remains reliable without disrupting the strict timing requirements of the real-time biofeedback process.

As a direct consequence of the aforementioned simplification and overhead reduction, we were able to utilize a less powerful, energy-efficient microcontroller without compromising real-time performance. This design choice inherently contributes to lower power consumption, as the selected processor operates with reduced computational demands. (Although the expected average power draw of the selected ATSAMD21 controller is quite low (approximately 3 mA in active mode), certain other low-power models, such as the STM32L4 series, can achieve even lower active mode currents. However, these models are typically two to three times more expensive.) Additionally, the scheduler itself occupies less than 1 kB of the 256 kB of available flash memory, and its RAM usage is limited to just a few tens of bytes, primarily for maintaining task pointers and context, leaving sufficient capacity for the remaining program code and future extensions. In contrast, systems like FreeRTOS typically require 5 to 10 kB of flash memory and at least hundreds of bytes of RAM for task management and scheduling, even in their most basic configurations. The SRAM utilization in our system is similarly low, as this memory primarily serves as a buffer for sensor readings prior to transmission via the Wi-Fi interface. Since data are transmitted continuously with minimal buffering, the required SRAM remains well below 1 kB.

The selected microcontroller board (Adafruit Feather M0) is available at a unit price of approximately USD 20, while the IMU sensor module (Pololu MinIMU-9 v5) costs around USD 30, based on purchases in small quantities (fewer than 10 units). This brings the total hardware cost of the prototype system to approximately USD 50, excluding housing and power supply. The affordability of these components—even at low-volume pricing—combined with the efficiency of the proposed software architecture, underscores the potential for scalable and cost-effective deployment in industrial or consumer applications.

2.3. Preliminary Tests

Preliminary tests indicate that the minimum feasible time slice is constrained by the duration of a single raw data reading, which is approximately 330 μs for one nine-degrees-of-freedom data sample. Assuming no additional tasks are executed, the maximum achievable sampling rate is 3000 samples per second, given that the scheduler’s overhead is approximately 1% (i.e., 3 μs per cycle). With a time slice of 400 μs, a stable sampling rate of 2500 samples per second can be achieved when no other tasks are running.

To demonstrate proof of concept, we established a continuous data stream via a Universal Asynchronous Receiver-Transmitter (UART) connection through a Universal Serial Bus (USB) to a personal computer. The UART interface was chosen because the terminal software used for testing supports this type of communication. It is important to emphasize that this connection was used solely for testing purposes—to verify that the data were transmitted correctly—and is not part of the final implementation. The conversion from UART to USB was handled by a dedicated interrupt routine within the Arduino software framework. To prevent interference with real-time tasks, we assigned the routine a lower priority than the scheduler’s timer interrupt.

We successfully maintained a continuous data stream at 2500 sample packages per second. Each sample contains an 8-byte synchronization header, a 4-byte timestamp, a 4-byte sample number, and three 3D sensor vectors (magnetometer, accelerometer, and gyroscope). Each vector component is stored as a 16-bit integer, resulting in a gross sample package size of 34 bytes.

2.4. System Operation

The wearable device we designed primarily functions in a streaming mode, continuously capturing sensor data and wirelessly transmitting it to the processing unit of the RTBF system. To ensure smooth and efficient streaming, several tasks must be executed in a specific sequence:

Sensor Data Acquisition—Collect readings from the three sensors integrated on Pololu’s MinIMU-9 v5 board.

Data Formatting—Convert the raw sensor values into a format compatible with the UDP transport protocol.

Packet Assembly—Compile the formatted data into packets containing one or more sensor samples.

Data Transmission—Send the assembled packets to the processing unit via the Wi-Fi controller.

Ensuring that sensor data acquisition occurs at uniform time intervals is critical for accurate data representation. We achieve this by embedding the sampling task within the timer interrupt routine of our periodic scheduler. This routine is triggered at precise times defined by , where is the sample index and is the sampling period. This setup ensures a consistent sampling frequency of .

The Data Formatting step involves converting the sensor readings and timestamps—originally represented as unsigned 16-bit or 32-bit integers—into ASCII-encoded decimal or hexadecimal values. This conversion is required by the UDP protocol used in the microcontroller’s IP stack library. In practice, this step is often integrated with the packet assembly process.

During Packet Assembly, the formatted sensor data are combined with control data and metadata, such as sensor identifiers, timestamps, and sample numbers. Each packet may contain multiple sensor samples collected over consecutive sampling intervals.

The final step, Data Transmission, involves sending the assembled packet to the ATWINC1500 Wi-Fi controller through the SPI interface on the Feather M0 board, as illustrated in

Figure 1. Depending on various parameters such as sampling frequency and I

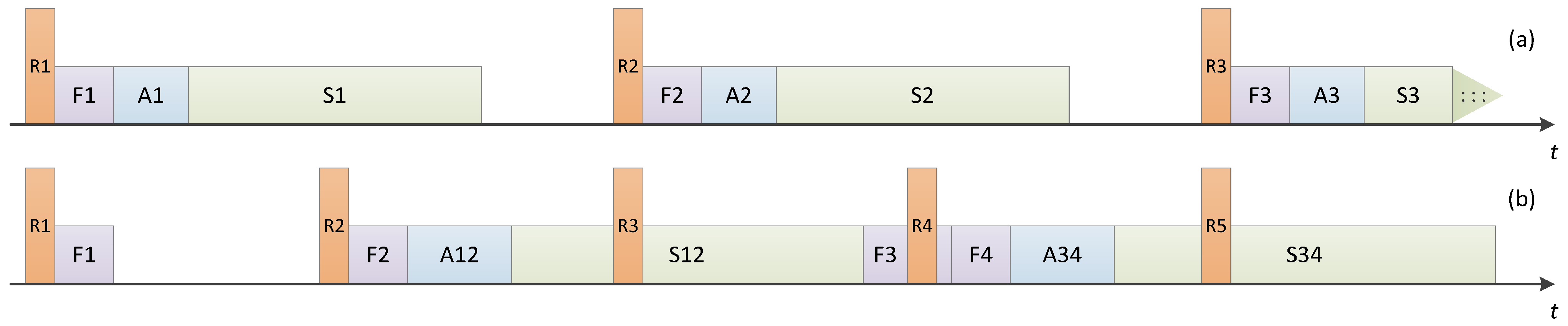

2C bus speed, the system operates in one of two modes: Single-Sample Mode—each streaming packet contains a single sensor sample. All tasks must be executed within the sampling period (

), as shown in

Figure 4a. Multi-Sample Mode—Each streaming packet contains multiple sensor samples, usually spanning several sampling periods (e.g., S12 or F3 in

Figure 4b). It can be observed that the formatting task is executed as soon as possible after each sensor sample is read. The assembly and transmission tasks are executed only after all expected sensor samples have been read and formatted. For example, in

Figure 4b, samples 1 and 2 are assembled and sent together.

2.5. Measurement Methodology

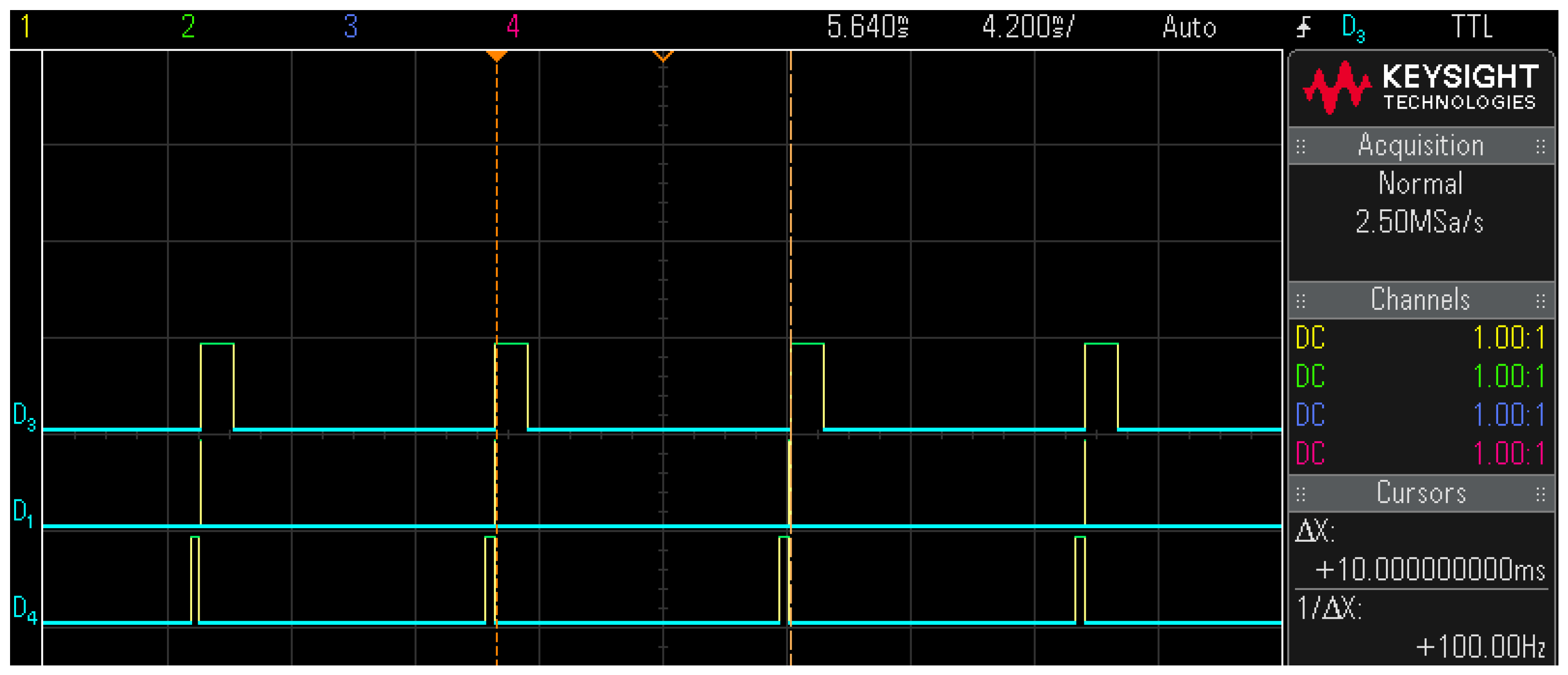

We carried out extensive measurements to record the results. For each measurement, we first checked the correct operation of the scheduler by monitoring the pin states of the microcontroller board with the oscilloscope, as described in

Section 3.1. Once we had established the correct operation of the system, we carried out various measurements of the parameters that are the subject of this article.

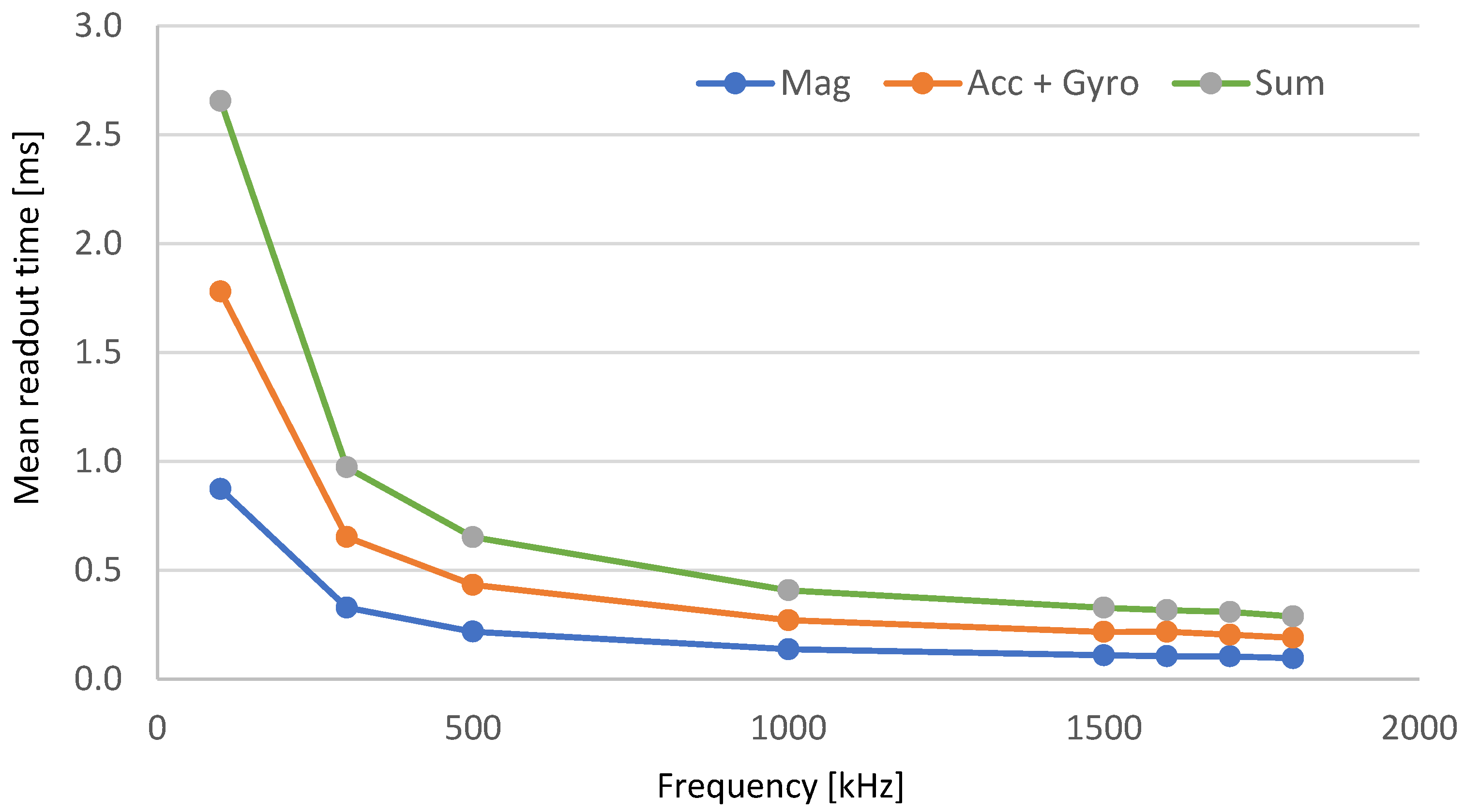

The first measurement phase was dedicated to measuring the sensor readout times at different I

2C bus frequencies. Its main purpose was to determine the stable operating frequency of the I

2C bus based on the results shown later in Table 1. As a result of these measurements, we used the stable I

2C bus frequency of 1500 kHz for all subsequent tests, as described in more detail in

Section 3.2.

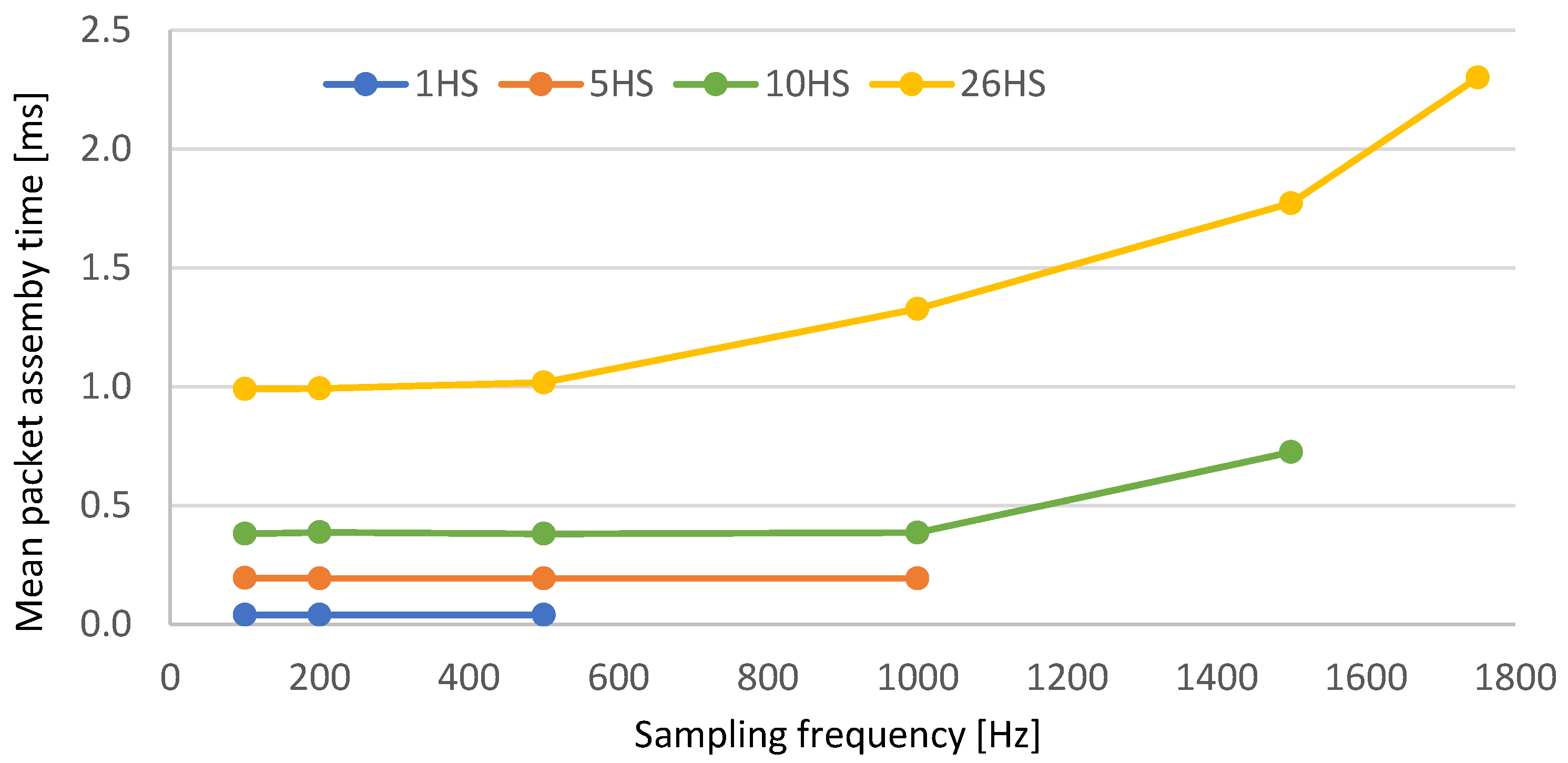

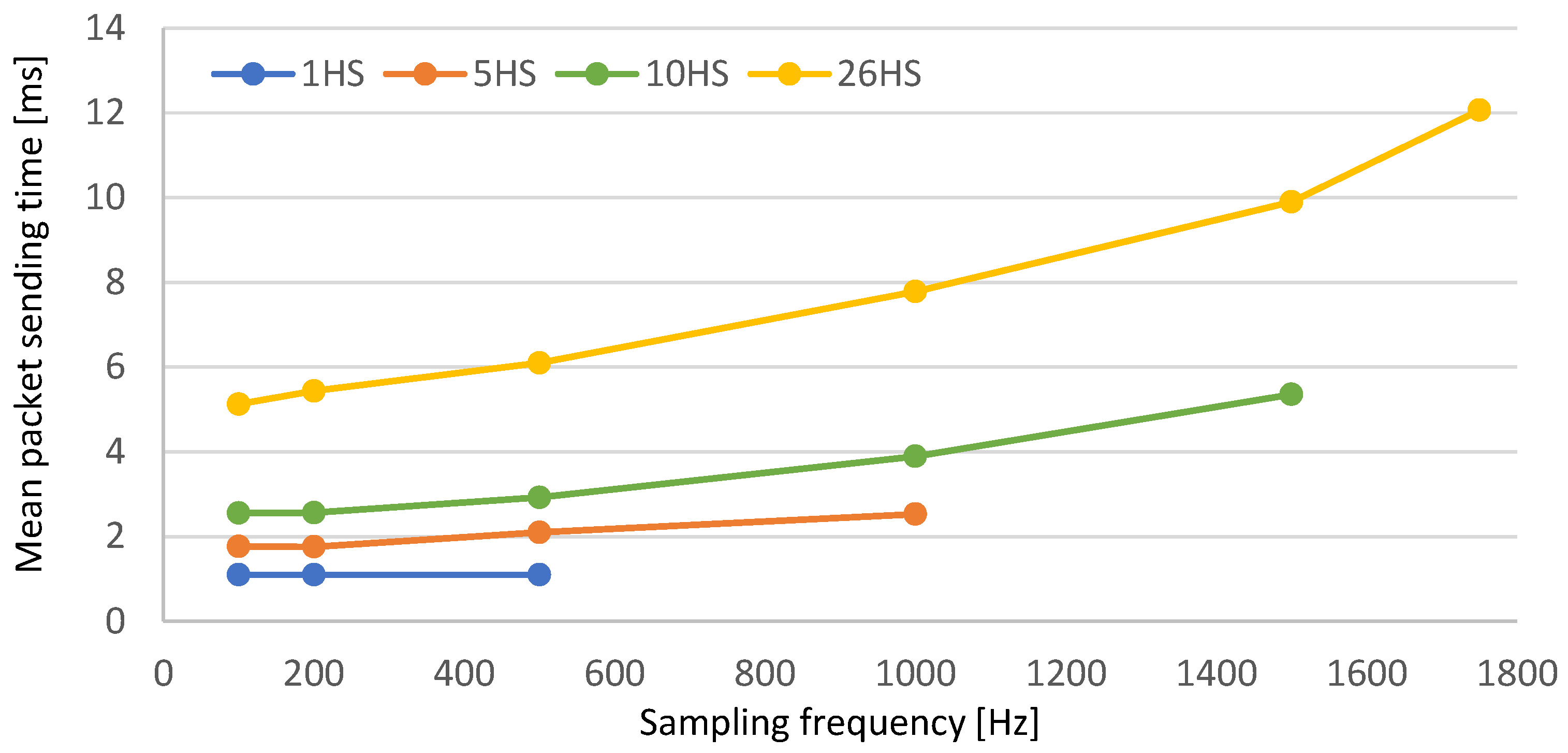

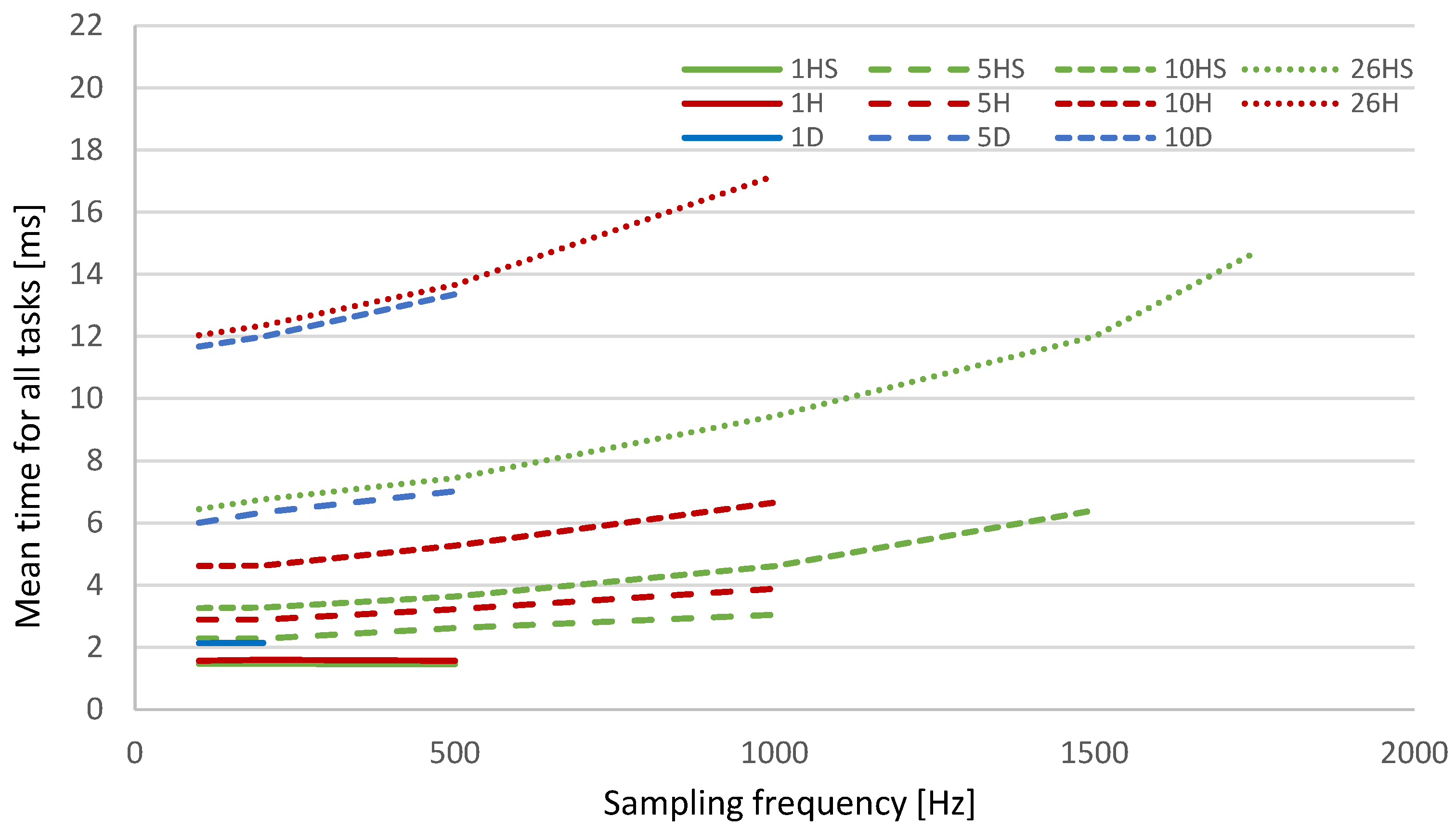

In the second phase, we used the stable I

2C bus frequency of 1500 kHz for all measurements in which we determined the times for assembling and sending packets for a variety of combinations of single/multi-sensor sample streaming modes. It must be noted that we included the time for formatting the sensor samples as part of the packet assembly time (see

Figure 4). We tested scenarios with 1 or more (2, 5, 10, 26) sensor samples in one packet. We also made code optimizations to speed up the execution of the tasks and achieve better results, i.e., we replaced the decimal ASCII representation of 16- or 32-bit integer values for packet assembly with the hexadecimal representation computed by two different functions. The results and comparisons are given in

Section 3.3.

Finally, we measured the packet delay and its variations in the remote processing device (receiver) connected over the WiFi to our wearable device, although this was not our primary objective in this research. This issue needs to be further investigated with measurements in different environments and with a number of different commercial WiFi devices. See

Section 3.4 for the results.

4. Discussion

In this study, we conducted comprehensive tests using wearable devices specifically assembled for research in various biomechanical applications within sports and physical rehabilitation [

22]. These applications span a wide range of actions with differing requirements: some necessitate low sampling frequencies and minimal streaming latency, while others demand high temporal resolution (i.e., high sampling frequencies) and can tolerate greater latency [

16]. This section discusses factors that could enhance the performance and usability of the presented systems.

It should be reiterated that the primary research objective of this study is the maximum sensor sampling frequency that can be supported by a given wearable device in streaming mode [

3]. For this reason, we did not take any measures to mitigate packet loss in the wireless Wi-Fi connection. Some RTBF applications are highly insensitive to packet loss and do not require any measures to mitigate this loss. For applications that require reliable data transmission, additional tasks need to be implemented on the wearable device, lowering the highest achievable sampling frequency determined in our experiments. The reduction depends on the complexity of the data loss mitigation measures and protocols, but the detailed study of these measures is outside the scope of this paper.

In this study, we did not consider the possible differences between the output rates of the sensor data and the sampling frequency of the device. While the former is a property of the sensor [

19,

20] and is controlled by its registers, the latter depends on the settings of the periodic scheduler. For our results, it does not matter if there is a discrepancy between the two, as we only measure the capabilities of the wearable device, which depend on its sampling frequency. For real applications, the output data rate of the sensor and the sampling frequency of the device must be adjusted and set correctly.

Optimizing the representation of sensor sample values in ASCII format for the UDP protocol is also crucial. By reducing the number of characters required for data representation, we increased the number of sensor samples that can be included in a single packet. The Wi-Fi protocol standard imposes a payload limit of approximately 1500 bytes, including IP and UDP headers. Considering these constraints, two options are available: (a) a decimal representation requires 138 bytes per sample and allows a maximum of 10 samples per packet and (b) a hexadecimal representation requires 53 bytes per sensor sample; therefore, a packet can hold up to 26 samples. Decimal representations are suitable for simple applications with low sampling frequencies of up to a few hundred hertz. Hexadecimal representations are required for demanding applications with high sampling frequencies or applications with additional processing load on the microcontroller.

We have used UDP at the transport layer of the communication protocol stack for several reasons: it is lightweight, has low overhead, high throughput, and is very suitable for low-latency data transmission in real-time applications [

23]. However, UDP is also unreliable and suffers from packet loss [

24]. While the advantageous features of UDP match well with the requirements of our RTBF applications, its disadvantages may affect some of the applications. This depends on the functions and requirements of the applications. It should be noted that many RTBF applications allow some degree of packet loss, so the disadvantages do not seriously affect them. However, if the application requires reliable data transmission, mitigation measures must be taken at higher protocol levels or within the application [

23,

25]. Such measures inevitably require additional processing on the microcontroller, which decreases the maximum achievable performance as measured in this paper.

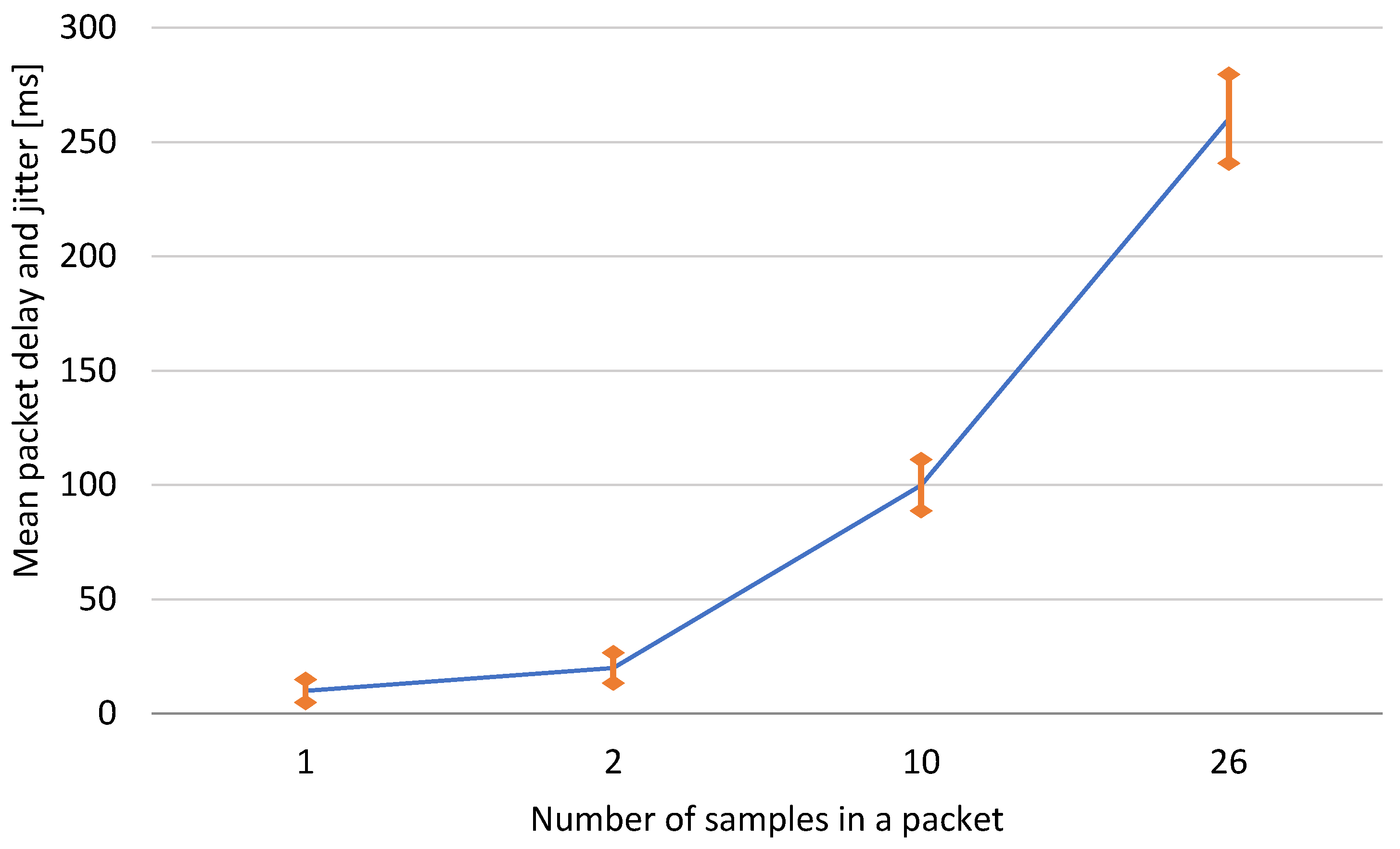

The results demonstrate that our wearable device, coupled with the developed scheduler, offers numerous combinations of sampling frequencies and packet delays, along with flexibility in payload formats. The optimal configuration depends on the specific requirements of the intended application. When assembling packets with multiple sensor samples, the packet delay at the receiver comprises the product of the number of samples and the sampling period, plus the time required to send the packet from the Wi-Fi module to the receiver (measured in milliseconds). The following three examples illustrate this.

Maximizing Sampling Frequency: To achieve the highest possible sampling frequency, the maximum number of sensor samples per packet should be used, effectively utilizing the microcontroller’s processing capacity. However, this approach results in increased packet delay at the receiver. For instance, at a sampling frequency of 1750 Hz with 26 samples per packet, the packet delay exceeds 15 ms.

Minimizing Receiver Delay: If minimizing delay at the receiver is paramount, transmitting one sample per packet is preferable. This configuration is feasible up to 650 Hz using hexadecimal representation and up to 450 Hz using decimal representation, with expected receiver delays of only a few milliseconds.

Intermediate Scenarios: Other configurations fall between these extremes. For example, as shown in

Figure 11, at a sampling frequency of 100 Hz with 10 samples per packet, the receiver delay exceeds 100 ms. This is because the system must collect 10 samples (taking slightly more than 90 ms) before the packet can be transmitted. Developers of RTBF applications [

16] or other systems employing such wearable devices with a scheduler now have multiple options at their disposal. In scenarios requiring maximum sampling frequencies or minimal receiver delays at the highest achievable frequencies, the microcontroller’s computing resources are almost entirely dedicated to data streaming. By avoiding these extreme cases, additional processing power remains available for other tasks unrelated to streaming, which may be necessary for the application’s successful operation [

1,

22].

To relate these figures to the application-specific requirements of RTBF applications, we divide them into three groups: low, medium, and high, depending on the required sampling frequency. The first group with low sampling frequency includes the streaming of motion signals with low dynamics and/or physiological parameters. An example of such an application is [

18], where the sampling frequency was 64 Hz. Other examples from this group are gait and balance analysis, rehabilitation applications [

2,

16], and others. For this group, we can use practically any combination from

Table 2. The group of medium sampling frequencies includes sports and rehabilitation applications with medium to high dynamic movements, with required frequencies from 100 Hz to 500 Hz [

1]. These include various movements of the human body in different sports such as running, swimming, golf, skiing, and others [

16]. For this group of applications, developers need to make a decision on the right combination of sampling frequency and number of samples in a packet, depending on the timing requirements of the application. If low delay is critical, fewer samples per packet are acceptable. For example, if the sampling frequency must be at least 500 Hz and the delay at the receiver must be less than 10 ms, we can only put five or fewer samples in a packet. The high sampling frequency group deals with frequencies above 500 Hz. Applications include human movements, often in combination with sports equipment, with very high dynamics and with impacts. Examples of such movements are skiing, ice skating, rugby, and others [

16]. The aim here is to capture transient phenomena in movements that involve multiple joints or impacts of body parts and/or equipment and where the time spans are very short, sometimes less than 1 ms [

7,

11,

15,

22]. For such cases, sampling frequencies of 1000 Hz and more are required and we have to look for the solution in combinations with hexadecimal representation and multiple samples in one packet. For example, if we use 10 samples per packet and a hexadecimal representation with bit-shift, we can easily achieve a sampling frequency of 1500 Hz. This would give us a delay at the receiver of less than 10 ms.

Note that the described results represent the upper performance limit of the proposed scheduler on the current hardware configuration. Should we employ a faster processor, the scheduler’s overhead remains constant in terms of CPU cycles, meaning that its relative computational load would be lower in percentage terms, thereby increasing processing capacity. In scenarios with additional sensors or computational tasks, the feasibility of maintaining real-time performance depends primarily on the available CPU power and memory capacity. However, since the scheduler itself does not introduce complex task management overhead, it remains a lightweight and scalable solution. When increasing the sampling frequency beyond 1750 Hz, potential bottlenecks arise primarily from sensor communication limits (e.g., I2C bus speed), data formatting overhead, and wireless transmission constraints, rather than from the scheduler. Optimizing hardware components—such as using a higher-clocked processor, faster memory access, or more efficient sensor interfaces—can extend the system’s capabilities beyond the reported performance thresholds. We can assert that our findings apply to all wearable devices with similar architecture, where sensors are connected to a microcontroller and data packets are transmitted over a Wi-Fi interface. The relationships between sampling frequency, data format, and the number of samples per packet would remain consistent, with only the absolute values changing.

While our scheduler was designed specifically for real-time biomechanical feedback applications, its simplicity makes it adaptable for other real-time data collection tasks. However, unlike a full RTOS, it lacks the task management and prioritization features required for complex, multi-threaded applications such as advanced robotics or large-scale industrial automation systems with numerous concurrent processes. For simpler applications, such as continuous sensor monitoring in industrial or environmental settings, the scheduler remains a lightweight and efficient solution.

5. Conclusions

This study presents the design and validation of a lightweight periodic scheduler for microcontroller-based wearable sensor devices, aimed at enabling reliable, low-latency communication for real-time biomechanical feedback (RTBF) applications. The proposed system supports sensor sampling frequencies up to 650 Hz when transmitting one sample per packet and up to 1750 Hz when transmitting 26 samples per packet. These two values represent the extremes of system performance, while the scheduler is capable of accommodating a wide range of real-world application needs by balancing sampling frequency and data packet size.

The main contribution of this work is the demonstration that a simplified, cooperative scheduling approach can achieve real-time performance on resource-constrained devices, offering a practical and low-cost solution for RTBF systems in sports and physical rehabilitation. By minimizing computational overhead and memory usage, our scheduler allows the use of energy-efficient, low-cost hardware—making the design suitable for both prototyping and potential industrial-scale implementation.

We acknowledge that the limited sample size—five measurements on four hand-assembled systems—reduces the statistical power of our results. For instance, a 100% success rate in 20 trials corresponds to a Clopper–Pearson 95% confidence interval lower bound of approximately 0.83, which indicates encouraging, though not statistically conclusive, reliability. Nevertheless, the results offer valuable performance benchmarks and conservative estimates that practitioners can use when developing or evaluating similar systems.

Future work will focus on extending the analysis to include receiver-side performance, such as delay and jitter under varying environmental conditions, including Wi-Fi quality and frequency spectrum occupancy. We also plan to explore adaptive scheduling strategies and further optimize packet transmission protocols, particularly for more demanding multi-sensor or multi-user scenarios.