Featured Application

This study explores the valorization of mango waste in the brewing industry, demonstrating its potential to promote the circular economy and reduce agro-industrial waste. Its practical application includes formulating specialty beers enriched with bioactive and antioxidant compounds derived from these residues. This approach can be adopted by both craft and industrial breweries, contributing to sustainable supply chains, new business models, and increasing competitiveness in the sector.

Abstract

The brewing sector is under increasing pressure to implement sustainable practices, particularly by integrating agro-industrial waste into its value chains. This study explores the potential of mango (Mangifera indica L.) residues as functional and sustainable ingredients within Brazil’s craft beer industry. A qualitative and exploratory methodology was employed, based on a literature review and political, economic, social, and technological (PEST) and strengths, weaknesses, opportunities, and threats (SWOT) analyses, to assess both the external and internal factors influencing the reuse of mango waste. The results highlight the environmental advantages and opportunities for value creation, especially in alignment with circular economy principles. Moreover, growing consumer interest in innovative and sustainable products presents an opportunity for market differentiation. Nonetheless, barriers such as limited infrastructure, cost-related challenges, regulatory constraints, and logistical limitations remain. By bridging sustainability, innovation, and waste minimization, this research offers strategic insights for stakeholders aiming to develop more resilient and responsible production chains. The valorization of mango waste contributes meaningfully to the Sustainable Development Goals—particularly SDGs 8, 9, and 12.

1. Introduction

Strengths, weaknesses, opportunities, and threats (SWOT) analysis is a well-established strategic tool widely employed to assess the strengths, weaknesses, opportunities, and threats associated with a specific practice, sector, or innovation [1]. In the brewing context, it is a valuable framework to explore both the challenges and advantages of adopting alternative raw materials, such as agro-industrial by-products. As sustainability and innovation become increasingly central to global market demands [2], applying this tool becomes essential to support informed, strategic decision-making [3] in an industry undergoing rapid transformation.

Beer ranks among the most consumed beverages worldwide, with profound cultural and economic relevance [4]. Traditionally brewed from four basic ingredients—water, barley malt, hops, and yeast [5,6]—its production has evolved considerably in response to changing consumer preferences, emerging market trends, and the demand for more differentiated and sustainable offerings [7,8]. In Brazil, although the market remains heavily concentrated in the hands of a few large corporations [9], the past decade has seen the rise of a vibrant craft beer segment [10]. This movement has encouraged product diversification, fostered regional experimentation, and created fertile ground for innovations integrating, cultural value, and economic potential [11].

Within this context, unconventional raw materials have gained prominence, particularly the incorporation of fruits and their by-products. These ingredients contribute to flavor complexity and uniqueness and offer functional benefits due to their bioactive and antioxidant properties [12,13]. Although the use of fruits in brewing is not new, it remains an area of growing scientific and commercial interest, especially in pursuing sustainable innovation [14].

Mango (Mangifera indica), a tropical fruit of high commercial relevance, is one of Brazil’s most widely produced and consumed fruits, with the Northeast region alone responsible for nearly 80% of the national output. Known for its distinctive aroma and flavor, as well as its rich nutritional profile and industrial applications—particularly as a starch source [15]—mango also presents critical post-harvest challenges. It is highly perishable, with losses estimated to range between 20% and 40%, mainly due to inadequate handling, storage, and transportation conditions. Furthermore, mango processing generates significant volumes of organic waste—including peels and seeds—which may account for up to 60% of the fruit’s total weight. These inefficiencies reduce profitability and pose environmental challenges, reinforcing the need for valorization strategies aimed at resource optimization and waste reduction [15,16].

Integrating mango waste into beer production presents an opportunity to develop value-added products while simultaneously mitigating environmental and economic losses. This approach aligns with the principles of the circular economy, as it encourages repurposing agro-industrial residues as raw materials for new applications. It supports cost reduction, product diversification, and the exploration of new markets, while addressing pressing sustainability challenges. It also reflects the increasing consumer demand for innovative, eco-conscious products.

Despite the expanding global interest in circular economy practices, few studies have systematically explored, within the Brazilian context, the strategic feasibility of utilizing fruit waste in brewing using a SWOT-based framework. This research aims to bridge that gap by offering an exploratory, qualitative assessment of the opportunities and limitations of such an approach. Additionally, the insights presented in this study are intended to assist craft brewers, policymakers, and sustainability-driven entrepreneurs in identifying viable innovation pathways and promoting business models that align with both environmental and economic objectives.

Accordingly, this study aims to evaluate the potential of mango waste utilization in the production of specialty beers in Brazil by employing a qualitative SWOT analysis to identify the primary strengths, weaknesses, opportunities, and threats associated with this practice. Furthermore, it seeks to demonstrate how the valorization of agro-industrial residues can contribute to the development of a more sustainable and inclusive brewing model—one aligned with the Sustainable Development Goals (SDGs) and reflective of the broader global transformation of the agrifood and beverage industries.

2. Materials and Methods

This research follows a qualitative and exploratory approach [17,18] to evaluate the strategic feasibility of incorporating mango agro-industrial waste into specialty beer production. This approach is suitable for exploring complex issues, such as integrating sustainability practices into the brewing industry, which quantitative methods do not capture easily [19]. Secondary data [17,18] were used to provide insights into the variables involved. This study was conducted in two stages, employing PEST and SWOT analyses. The integration of PEST and SWOT methodologies allowed for a multidimensional diagnosis—PEST capturing macro-environmental dynamics, and SWOT synthesizing strategic implications—thus enhancing the analytical depth of the study.

Data collection involved a structured documentary analysis of secondary sources, including academic databases (ScienceDirect, MDPI, and Google Scholar), Brazilian regulations on beverage production and waste management, and market insights from Mintel reports. Additional sectoral studies from institutions like CervBrasil (Brazilian Association of the Beer Industry) and SINDICERV (National Union of the Beer Industry) were included, alongside interviews with master brewers. Data from government agencies were also incorporated to contextualize macro-environmental trends and regulatory challenges. Documents were selected based on predefined criteria: (i) relevance to the brewing industry or waste valorization, (ii) publication preferably within the last five years, with occasional inclusion of older foundational works when relevant, and (iii) alignment with themes of sustainability, innovation, or mango waste reuse. These materials provided the basis for both the PEST and SWOT analyses.

2.1. PEST Analysis

The first stage of the study involved a PEST analysis to examine the macro-environmental factors that influence the strategic incorporation of mango agro-industrial waste into the brewing sector. This framework assesses four key dimensions: Political–Legal, Economic–Natural, Sociocultural, and Sectoral–Technological [1]. The document selection criteria mentioned earlier were consistently applied in this phase to ensure the analysis’s consistency and reliability.

2.2. SWOT Analysis

In the second stage, a SWOT analysis was applied, identifying strengths, weaknesses, opportunities, and threats [1] by integrating insights from the PEST analysis to articulate strategic scenarios and innovation pathways for mango waste utilization. This strategic tool evaluates the internal and external factors that influence the performance of a technology or business model [20] and is widely used to support planning, risk management, and decision-making [21,22,23]. While the evaluation of strengths and weaknesses focused on internal aspects of the production process, the analysis of opportunities and threats considered external variables that affect the proposal’s implementation, such as market demands, regulations, and sector competitiveness [24].

The SWOT matrix was built based on the key insights identified in the PEST analysis. Internal factors were defined by analyzing of technological feasibility, raw material characteristics, and production constraints. External factors reflected the broader institutional, economic, and market conditions previously mapped, enabling a structured strategic diagnosis.

3. Results

3.1. PEST Analysis

The PEST analysis was conducted to identify and evaluate the external factors influencing the adoption of mango waste in the production of specialty beers. These factors were addressed from four main dimensions: political–legal, economic–natural, sociocultural, and technological–sectoral. Table 1 summarizes of these factors, followed by an in-depth discussion of each.

Table 1.

Summary of the PEST analysis examining the political–legal, economic–natural, sociocultural, and technological–sectoral factors influencing the integration of mango waste into brewing. The table highlights key advantages and disadvantages associated with each dimension.

3.1.1. Political–Legal Aspects

- Norms and Regulations

In Brazil, the Ministry of Agriculture, Livestock, and Food Supply (MAPA) is responsible for the registration, classification, standardization, control, inspection, and regulation of beer [25].

Decree No. 9902 of 8 July 2019, amends Decree No. 6871 of 4 June 2009, which regulates Law No. 8918 of 14 July 1994, concerning the standardization, classification, registration, inspection, production, and regulation of beverages. According to Brazilian legislation, Article 36 of the aforementioned Decree states: “Beer is the beverage resulting from fermentation, using brewing yeast, of wort made from malted barley or malt extract, previously subjected to a boiling process with the addition of hops or hop extract, in which part of the malted barley or malt extract may be partially replaced by brewing adjuncts” [26].

Additionally, beer may include plant-based ingredients, animal-derived ingredients, processing aids, and additives, as regulated by specific legal provisions. Moreover, any brewing adjuncts and other ingredients added to the beer must be listed on the product label, following the specifications established by the Minister of Agriculture, Livestock, and Food Supply [26].

Malted or unmalted grains may be used as brewing adjuncts, provided that they do not exceed 45% of the original extract. Other food ingredients considered adjuncts include honey, plant-based ingredients, starch sources, and sugars suitable for human consumption, which must not exceed 25% by weight relative to the original extract [27,28].

According to legal definitions, completely substituting any of the four main ingredients alters the product’s classification, making it “beer-like” [8].

To market new beers, they must be registered in the Integrated System of Agricultural Products and Establishments (SIPEAGRO) of MAPA. Registration with MAPA for the manufacturing establishment is mandatory to approve new products. If more than one production facility or third parties are involved, they must also be registered with MAPA. The beer formulation must comply with all current regulations. After submitting the registration request in SIPEAGRO, approval is granted automatically. However, if MAPA identifies any irregularities, the registration may be canceled and invalid [27].

In addition to regulatory provisions regarding labeling, classification, and brewing adjuncts, incorporating fruit residues into alcoholic beverages must comply with food safety standards. Fruit-based ingredients—especially those derived from by-products or residues—are subject to strict microbiological and toxicological controls to ensure consumer safety [29].

One of the challenges and areas for future development in the use of upcycled foods is their regulation. Jurisdictions have yet to establish a specific legal framework for these products, and current regulation relies primarily on general food safety and labeling requirements. In Brazil, the standards set by the National Health Surveillance Agency (ANVISA), such as Resolution RDC No. 331/2019, define the microbiological criteria for food products, including fermented beverages [30]. These standards aim to control contaminants such as yeasts, molds, and pathogenic microorganisms, ensuring that products are safe for consumption.

Furthermore, fruit residues’ handling, storage, and traceability must comply with the General Guidelines for Good Manufacturing Practices (GMP), as established by Ordinance SVS/MS No. 326/1997 [31]. These guidelines cover all process stages—from sourcing and processing to storage—ensuring that such residues do not cause contamination or compromise product quality. Adhering to these regulations is essential to guarantee the integrity and safety of waste-derived ingredients. Thus, integrating innovative fermentation inputs must be accompanied by strict hygienic protocols and validated processing techniques [29].

3.1.2. Economic and Natural Aspects

- Specialty Beer Market in Brazil: Overview

Beer is the most widely consumed alcoholic beverage worldwide. Despite regional particularities, global consumption and the number of small breweries continue to rise. The movement toward specialty beer consumption began in Europe, expanded to the United States in the late 1970s, and eventually reached Latin America [32,33].

Global beer consumption reaches 192 million kiloliters annually, with China being the largest consumer, accounting for approximately 22% of this total, followed by the United States and Brazil. In per capita consumption (L/hab), the Czech Republic has held the top position for the 30th consecutive year, while Brazil ranks second among Latin American and Central American countries [34].

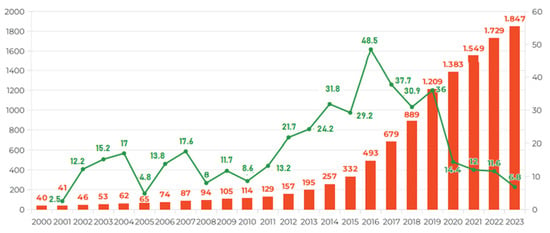

Despite recent challenges, including the impact of COVID-19 on beer consumption, the industry has shown signs of recovery in recent years. In this context, the craft beer segment has emerged as a promising investment opportunity in Brazil. According to the 2024 Beer Yearbook published by MAPA, the country recorded 1847 breweries in 2023, marking a 6.8% growth compared to the previous year, as demonstrated in Figure 1 [10].

Figure 1.

Total registered establishments (orange) and growth percentage (green) over the years. Source: 2024 Beer Yearbook, Ministry of Agriculture, Livestock, and Food Supply (MAPA), Brazil.

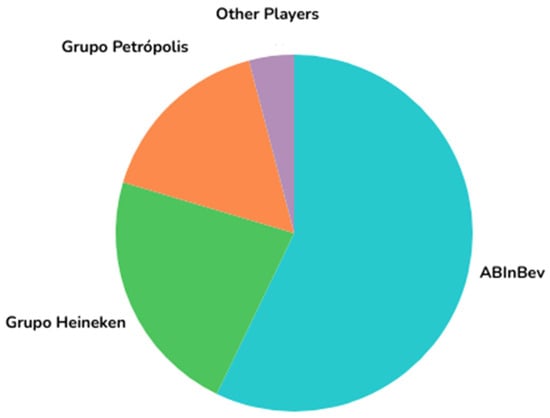

According to the Brazilian Beer Industry Association (CervBrasil), the beer sector represents 2.5% of the national GDP and generated BRL 77 billion in 2021 [9,35]. Of this total, 95% of the market is still dominated by three major players: AB InBev (59.4%), Grupo Heineken (24.4%), and Grupo Petrópolis (11.3%), as illustrated in Figure 2. The Brazilian market appears relatively modest compared to more mature craft beer markets, such as the United States, where small and medium-sized breweries account for nearly 30% of sales. However, the sector continues to grow, highlighting significant potential for expansion [9].

Figure 2.

Market share of the three leading brewing companies operating in Brazil.

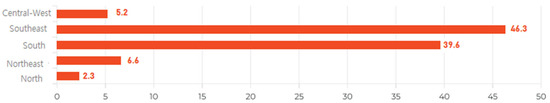

The Southeast region of Brazil concentrates 46.3% of all breweries, with São Paulo standing out as the leading state. This regional predominance is illustrated in Figure 3. In 2023, only two states—Bahia and Alagoas—experienced a decline in breweries, each losing one unit. Additionally, brewery dispersion increased, with at least one registered in 13.8% of Brazilian municipalities [10].

Figure 3.

Percentage of breweries by region in Brazil. Source: 2024 Beer Yearbook, Ministry of Agriculture, Livestock, and Food Supply (MAPA), Brazil.

Once a brewery is registered, it becomes eligible to register its products. In 2023, Brazil recorded 45,648 product registrations, reflecting a 6.6% increase compared to 2022. This trend reflects the continuous expansion of new beer varieties. As with the distribution of breweries, the South and Southeast regions dominate product registrations, accounting for 91.9% of the total. São Paulo has the highest number of registered beers, while Amapá has the fewest [10].

This steady diversification of beer products underscores the dynamism and maturation of the Brazilian brewing sector, offering a strategic context for innovations involving alternative raw materials, such as fruit by-products.

- Challenges and Opportunities in the Mango Production Chain

Mango (Mangifera indica L.), a member of the Anacardiaceae family [36], is one of the most important tropical fruits in terms of both production volume and consumer acceptance [37].

Mango is a drupe composed of three main parts: the peel (epicarp), the pulp (mesocarp), and the seed (endocarp). The fruit varies in shape, ranging from round, oval, and elliptical to heart-shaped, and exhibits a wide range of sizes and weights. Its length varies between 3 and 26 cm, width between 1.5 and 10 cm, and weight between 132 and 702 g, depending on the cultivar and growing conditions [38].

With a balanced profile of sweetness and acidity, mango—often referred to as the “king of fruits” [39]—is widely consumed worldwide at different ripening stages. Beyond fresh consumption, a significant portion of mango production is allocated to manufacturing juices, nectars, purées, pulps, slices, jams, and preserves, among other products [36]. In addition to its commercial value, mango is recognized for its high nutritional value [39], being a rich source of antioxidants such as ascorbic acid, carotenoids, and phenolic compounds [37].

Mango is the second most traded tropical fruit globally and ranks fifth in total fruit production [36]. In 2021, global production of mangoes, mangosteens, and guavas reached 57.01 million metric tons [40]. Brazil stands out as a major mango producer, with a total production of 1.51 million metric tons in 2021, cultivated over 76.06 thousand hectares [41], predominantly in the country’s Northeast and Southeast regions. Within Brazil, the states of Pernambuco (624.6 thousand metric tons), Bahia (470.5 thousand metric tons), and São Paulo (217.2 thousand metric tons) are the three largest producers [42].

In addition to its significant production volume, Brazil, like other South American countries, employs floral induction techniques to enable off-season mango production, thereby increasing the fruit’s availability throughout the year. Similarly to other Latin American nations, Brazil has an extended harvest season, solidifying its position as a leading global producer, consistently supplying both domestic and export markets, which enhances its competitiveness in the sector [43].

With year-round production expansion, Brazil’s mango agribusiness faces considerable challenges related to losses throughout the supply chain. It is estimated that from 30% to 50% of global mango production is wasted [15], primarily due to the fruit’s high perishability and inadequate handling during harvesting, transportation, and storage. In Brazil, fruits that do not meet commercial standards—such as immature or damaged mangoes—are often discarded directly in orchards, generating economic and environmental impacts [42]. Additionally, industrial processing further contributes to losses. During co-processing, from approximately 30% to 50% of the raw mango material is discarded as waste [36], primarily consisting of peels and seeds.

Despite being underutilized, these residues are highly nutritional and rich in fiber, antioxidants, polyphenols, and carotenoids [37,38].

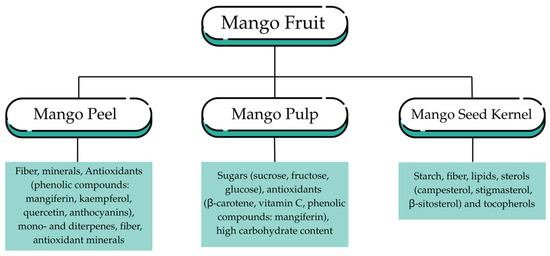

Recent studies have increasingly emphasized mango by-products’ high nutritional and phytochemical richness, including peel, pulp, and seed. These components’ composition and functional properties are influenced by factors such as variety, ripening stage, region, and post-harvest handling [44]. Mango peels, accounting for approximately 7–24% of the fruit’s weight, are particularly rich in bioactive compounds such as polyphenols, carotenoids, dietary fibers, and flavonoids like quercetin and kaempferol, all of which exhibit antioxidant and antimicrobial activities [45]. Some phenolic compounds in the peel, such as ethyl gallate and penta-O-galloyl-glucoside, have been associated with hepatoprotective and cardiovascular-protective effects [45,46]. With a dietary fiber content ranging from 40.6% to 72.5%, mango peel has already been incorporated into food formulations without compromising sensory acceptance [45].

In addition to the peel, both the pulp and the seed kernel offer relevant bioactive and nutritional characteristics. During ripening, the pulp undergoes significant biochemical changes, with a reduction in organic acids and an increase in sweet sugars—primarily sucrose, fructose, and glucose—contributing to its high carbohydrate content (68.5–76.8% of dry weight). It also contains notable antioxidants, including β-carotene, vitamin C, and phenolic compounds such as mangiferin, which present hypoglycemic, anti-inflammatory, and anticancer properties [44]. The mango seed, another significant residue from fruit processing, contains a kernel that representing up to 85% of the seed and about 20% of the whole fruit. Rich in crude fat (7.1–15%), the kernel has attracted interest due to its lipid composition, similar to cocoa butter, composed mainly of stearic and oleic acids. Besides its nutritional profile, the seed kernel exhibits high antioxidant and tyrosinase inhibitory activities, reinforcing its applicability in food, cosmetic, nutraceutical, and pharmaceutical sectors [45]. The nutritional richness of mango by-products is summarized in Figure 4.

Figure 4.

Nutritional and functional compounds in mango by-products. Source: Adapted from Ajila et al. (2015) [46].

However, their lack of commercial value often results in improper disposal, exacerbating environmental pollution and posing logistical challenges due to high transportation costs and limited landfill capacity. Furthermore, the rapid decomposition of these residues can contribute to insect proliferation and an increase in organic load in the environment, elevating Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) levels, which pose additional challenges for safe disposal [47]. The leachates generated from decomposition can also seep into the soil and contaminate water bodies, impacting aquatic ecosystems and biodiversity, with further consequences for agricultural irrigation [48].

In this scenario, recovering mango by-products for use in brewing represents an opportunity to reduce food waste and optimize resource use, in line with circular economy strategies.

- Circular Economy (CE) and Sustainable Development Goals (SDGs)

Most human activities generate waste as an inevitable by-product. Regardless of its origin, waste represents a primary global concern, contributing to climate change, environmental degradation, and public health issues. To mitigate these impacts, effective waste management practices—such as reduction, safe handling, and appropriate treatment—are essential. A promising pathway is the transition to a circular economy, which encourages collaborative policies among governments, industries, and individuals, aiming for sustainable growth and more efficient resource management [49].

Sustainability today goes beyond environmental concerns, encompassing economic and social dimensions, such as poverty alleviation and the empowering vulnerable populations [50]. In this context, the principles of the circular economy—resource efficiency, waste reduction, and sustainable practices—offer a systemic approach that addresses environmental challenges and promotes resilience and social well-being [49]. Its growing relevance is evidenced by increasing research and policy interest in food sector applications, particularly in strategies to reduce food loss and environmental impacts [51].

In response to this global challenge, the United Nations launched the 2030 Agenda, which includes 17 Sustainable Development Goals (SDGs) and 169 specific targets to integrate the three dimensions of sustainable development: economic, social, and environmental. Within the scope of this study, three SDGs are directly addressed:

- (a)

- SDG 12—Responsible Consumption and Production: The reuse of mango residues in beer production contributes directly to the goal of halving global food waste by 2030. By transforming agro-industrial waste into raw material for new products, this practice promotes a more efficient use of natural resources and reduces the environmental impact of the food chain [49,51].

- (b)

- SDG 8—Decent Work and Economic Growth: The creation of new value chains centered on waste valorization opens opportunities for employment and income generation, particularly for small farmers and local producers. This dynamic stimulates regional economies and supports sustainable economic growth through innovation and entrepreneurship [52].

- (c)

- SDG 9—Industry, Innovation, and Infrastructure: The development of new processes and products using mango waste fosters innovation and encourages the modernization of industrial practices. It contributes to more sustainable and inclusive industrialization and promotes investment in resilient infrastructure, especially in regions with agro-industrial potential [52].

Beyond these direct contributions, circular economy (CE) practices have shown strong conceptual relationships with a broader set of SDG targets. Studies indicate that CE initiatives directly contribute to 21 targets and indirectly to another 28, especially within SDGs 6 (Clean Water and Sanitation), 7 (Affordable and Clean Energy), 8, 12, and 15 (Life on Land). Moreover, CE is seen as a strategic framework for promoting synergies among goals such as ending poverty (SDG 1), ensuring food security and sustainable agriculture (SDG 2), and protecting biodiversity both on land and in oceans (SDGs 14 and 15) [53].

Although not all SDG targets are equally impacted by CE strategies—some show little to no connection—the literature consistently highlights a strong conceptual alignment between the circular economy and the SDGs [53]. This relationship has been reported by multiple organizations and research efforts, emphasizing the role of the CE in generating employment, stimulating innovation, creating competitive advantages for companies, and safeguarding the environment [54].

Circular economy strategies, therefore, function not only as tools for improving resource use and reducing environmental impact, but also as structural mechanisms for promoting inclusive economic development and long-term stability, aligned with the broader goals of the 2030 Agenda.

3.1.3. Sociocultural Aspects

- Consumption Trends and Consumer Profile

Consumption patterns and consumer profiles are constantly evolving. According to Mintel data, consumers are reassessing their priorities, influencing their needs and desires and their perception of value. Attributes such as sustainability, convenience, and origin remain important but must be presented through a quality-driven lens to enhance product functionality and the overall experience [55]. For instance, healthy aging is being redefined in the food and beverage sector, eliminating traditional stigmas and emphasizing longevity and vitality as functional lifestyle goals [56].

These trends are also transforming beer consumption. While overall demand remains high, aligning product development with emerging consumer preferences is essential, which increasingly favors innovation, sustainability, and functionality. Consumers seek to reduce their intake of alcohol, gluten, sugar, and carbohydrates without giving up on indulgence and flavor [57], and many now recognize beer as a source of functional compounds such as vitamins and antioxidants. Breweries that communicate a strong commitment to environmental and social sustainability can differentiate their products and attract more conscious consumers [2].

Non-alcoholic options, for example, have gained traction among young Brazilians—primarily women aged from 18 to 24—revealing a growing interest in alternatives that combine sophistication with health-conscious choices [58]. This segment also demonstrates a preference for quality over quantity: 57% of consumers report choosing smaller amounts of premium beers over more significant volumes of cheaper ones, especially among socioeconomic classes A and B. Flavor innovation has become central to this trend, with 42% citing “a new or innovative flavor” as a primary purchase motivator, particularly for fruity or honey-flavored beers [59].

Despite increased interest in novel products, consumers remain cautious with their spending. According to Furtado and Fernandes (2024), optimism is growing, but with an emphasis on cost–benefit. Even middle- and upper-class consumers seek value, preferring products that offer a unique experience without exceeding their financial limits [60]. This highlights an opportunity for breweries to meet demand through differentiated, functional, and accessible offerings.

While beer production once adhered to the Reinheitsgebot, the German purity law which established three basic ingredients—water, barley malt, and hops—without the addition of additives [61], the Belgian approach expanded the horizons by seeking more complex flavors and distinct sensations, such as the incorporation of fruits in recipes [62]. Since 2012, the trend of using fruits as the “fifth ingredient” has gained momentum again in Europe. Since then, brands, including major players, have started incorporating concentrated juice, extracts, and fruit peels into their formulas, reviving the tradition of fruit beers and compensating for declining sales of more classic styles [63].

According to master brewer Alessandro Oliveira from Way Beer, Brazil’s biodiversity and climate are ideal for fruit beer production. He notes that fruits contribute refreshment, acidity, sweetness, color, and a sensory familiarity that enhances the drinking experience. Their versatility makes them ideal for creating innovative recipes that merge tradition with unique ingredients [64].

In this context, craft beers establish themselves as a dominant global trend, offering an ever-expanding range of styles. This diversity reinforces the perception of beer as a sophisticated and artisanal product [65]. Craft beers occupy a special niche due to the belief that they are made with more excellent care and less industrial automation. With so many options available, consumers can select those that best match their taste, occasion, or meal pairing [57]. This growing diversity has also attracted new consumers who previously viewed beer as generic or unappealing [65].

Within this dynamic context, upcycled ingredients represent a promising yet underexplored frontier, particularly in Brazil. While upcycled food and beverages face challenges, studies suggest that younger, environmentally conscious consumers are more open to such innovations, especially when benefits like sustainability, quality, and alignment with Sustainable Development Goals (SDGs) are clearly communicated. Educational efforts and transparency regarding the upcycling process—especially its role in circular economy models—can further strengthen consumer acceptance. However, the stigma surrounding food waste and the lack of specific regulatory frameworks hinder market integration [66,67].

International studies provide encouraging evidence: for example, research in New Zealand shows that even unfamiliarity with the term “upcycling” can be overcome through education, particularly when paired with tastings and environmental messaging. Acceptance rises significantly when consumers are informed about the nutritional and environmental benefits of using food by-products in beer production. Offering price parity and maintaining sensory quality is key to building trust [68].

Nonetheless, further research focused on Brazilian consumers is urgently needed. Local perceptions, cultural nuances, and behavioral intentions must be better understood to tailor effective communication, marketing, and product strategies. Upcycled craft beers—especially those incorporating native fruits like mangoes—hold strong potential as sustainable, innovative, and culturally relevant products in Brazil’s evolving beer market.

3.1.4. Technological and Sectoral Aspects

- Technological Advances for Mango Waste Valorization

Recent technological advances have enabled better utilization of agricultural waste, such as fruit peels and seeds, opening new possibilities for their incorporation into value-added products. Mango residues, including peel and seed, are rich in bioactive compounds such as antioxidants, polyphenols, and dietary fibers, which interest the food, pharmaceutical, cosmetic, and bioenergy industries [47]. Mango peel, for example, has been used to develop functional beverages, enrich bakery products, and for biodegradable packaging. In contrast, mango seed has demonstrated potential in the formulation of nutraceuticals due to its high content of essential fatty acids and compounds with anti-inflammatory and anticancer properties [51,69].

One of the main challenges for the valorization of mango waste lies in efficiently extracting and stabilizing its bioactive components. Conventional methods often result in low yields [70]; therefore, emerging and environmentally friendly technologies such as ultrasound-assisted extraction (UAE), enzyme-assisted extraction (EAE), microwave-assisted extraction (MAE), and pressurized liquid extraction (PLE) are being studied to improve compound recovery and maintain functional integrity during processing. These techniques reduce the need for chemical solvents, align with sustainable production practices, and allow for the development of clean-label ingredients [70,71].

Before being incorporated into fermented beverages or subjected to extraction processes, mango residues must undergo technical treatments such as drying and grinding. Drying methods—including convection drying at around 60 °C or air-drying under controlled light conditions—are essential to reduce moisture content, preserve bioactive compounds, and ensure microbiological safety [72]. Grounding the dried material to a uniform size facilitates its application in brewing or formulation processes [73,74]. Although there is no specific regulation for mango flour in Brazil, RDC no. 263/2005 from Anvisa stipulates a maximum moisture content of 15% for flours, a limit that can be adopted to ensure the quality and stability of mango-based ingredients [15].

The upcycling of food waste is already a reality across various sectors. In Brazil, the company Rubian Extratos, linked to Unicamp, produces anti-aging cosmetics and dietary supplements using residues such as jabuticaba peel and passion fruit pomace from the juice and pulp industry [75,76]. Nestlé launched six upcycled beverage lines in China, incorporating coffee cherry husk (cáscara), coconut water, and oat milk. These clean-label drinks aim to offer fiber-rich, low-sugar, and low-fat alternatives while promoting a circular economy and regenerative food systems [77]. In Brazil, Grão Malte exemplifies innovative upcycling by converting brewery residues into new food products [78].

Scientific studies have explored the use of various fruit residues in fermented beverages, reinforcing the feasibility and potential of these applications [79]. Zhu et al. [80] reported that sequential fermentation of Chinese bayberry pomace enhanced phenolic content and preserved anthocyanins. Hien et al. [81] and Aguilar [82] investigated the fermentation of pineapple peel residues, demonstrating improved stability and performance when pre-treated with ultrasound. Leonarski et al. [83] utilized acerola by-products to produce kombucha-like drinks and bacterial cellulose, while Vieira et al. [84,85] showed that fermented soy beverages enriched with acerola residues promoted beneficial effects on gut microbiota. Additional examples include the use of apple, carrot, and pumpkin by-products in cereal-based fermented drinks [86], black tea residues fermented with Lactobacillus plantarum [38], and spent coffee grounds fermented with non-conventional yeasts to enhance aroma and ethanol yield [87]. Álvarez et al. [88] developed a probiotic drink using prickly pear peels, where ultrasound-assisted extraction improved pectic content and probiotic stability.

Functional fermented beverages are among the fastest-growing segments in the functional food market due to their ease of storage, capacity to incorporate bioactive compounds, and alignment with consumer preferences for convenient, health-oriented products [71]. Mango waste—such as peel and seed—has shown potential as a brewing ingredient, offering nutritional and sensory benefits while reinforcing a sustainable product narrative. This strategy could contribute to cost reduction, product diversification, and strengthening the mango production chain within a circular economy model. While fruits have been increasingly incorporated into beer production, using fruit residues as upcycled ingredients is still underexplored in this sector. In contrast, other beverage industries have made more progress in valorizing fruit by-products. Therefore, further experimental validation is needed to assess technical feasibility, microbiological safety, sensory performance, and consumer acceptance. Continued research on bioprocessing and valorization techniques will be essential to advance the use of mango by-products and promote scalable, sustainable innovation in the food and beverage industry.

4. Discussion

4.1. Sustainable Development Goals (SDGs)

The valorization of mango waste in beer production directly contributes to several key Sustainable Development Goals (SDGs), particularly SDG 12 (“Responsible Consumption and Production”), SDG 9 (“Industry, Innovation, and Infrastructure”), and SDG 8 (“Decent Work and Economic Growth”). This innovative approach offers significant environmental, economic, and social benefits while promoting a circular economy model that integrates waste into production.

- (a)

- SDG 12: Responsible Consumption and Production: Reusing mango waste in beer production supports SDG 12 by promoting more responsible consumption and production patterns. This practice aligns with the principles of a circular economy, where agricultural by-products are transformed into valuable products, reducing waste and minimizing environmental impact. The integration of mango waste directly addresses the issue of food waste, which remains a significant global challenge. By utilizing what would otherwise be discarded, this approach reduces the overall carbon footprint of beer production, optimizes resource use, and helps mitigate the environmental impacts of traditional manufacturing methods, particularly water and energy consumption. Furthermore, it encourages industries to rethink waste as a resource, which is essential for driving the transition toward sustainable production models.

- (b)

- SDG 8: Decent Work and Economic Growth: The valorization of mango waste can create new economic opportunities, contributing to SDG 8 by fostering job creation and economic growth. This practice stimulates the creation of new markets for agricultural by-products, providing farmers with alternative revenue streams and enhancing the overall profitability of agricultural enterprises. Furthermore, it opens up new opportunities within the brewing industry, particularly in areas such as waste management, product innovation, and the marketing of sustainable beverages. By promoting sustainable practices, this initiative not only strengthens the economic viability of small-scale farmers, but also contributes to the creation of decent work opportunities within the local community, particularly in regions traditionally underrepresented in the brewing industry.

- (c)

- SDG 9: Industry, Innovation, and Infrastructure: The incorporation of mango waste into beer production exemplifies industrial innovation, as it challenges conventional brewing processes and encourages the adoption of new technologies and sustainable practices. This innovative approach creates new products and stimulates advancements in biotechnology and waste processing. Moreover, it highlights the need for infrastructure that supports the collection, processing, and transportation of agricultural by-products, an essential component for developing resilient supply chains. By integrating mango waste into brewing, this initiative strengthens local infrastructure, particularly in rural areas, which can have broader economic and social impacts. Such infrastructure development promotes local economies and supports the establishment of circular supply chains that can benefit both the brewing and agricultural sectors.

This initiative exemplifies how integrating agricultural waste into industrial production can contribute to broader sustainability goals. As consumers increasingly demand more sustainable products, this practice offers a unique competitive advantage, differentiating products in a crowded market. However, achieving commercial success will require overcoming consumer skepticism regarding unconventional ingredients. Therefore, it will be essential to implement targeted marketing strategies that communicate the environmental and functional benefits of products made from mango waste, ensuring that consumers understand the value and quality of these ingredients.

In conclusion, the valorization of mango waste in beer production presents a promising pathway for contributing to multiple SDGs, particularly through its environmental, economic, and social benefits. However, for this initiative to achieve widespread adoption, it will be essential to continue fostering innovation, strengthening infrastructure, and educating consumers about the value of sustainable products, ensuring alignment with global sustainability objectives.

4.2. SWOT Analysis

Table 2 presents an assessment of strengths, weaknesses, opportunities, and threats related to the valorization of mango waste in the brewing industry based on the collected data and the analysis of key contextual factors.

Table 2.

SWOT analysis summarizing the strengths, weaknesses, opportunities, and threats of incorporating mango waste into craft beer production. This strategic tool provides insights into the feasibility, potential benefits, and challenges associated with this approach.

- Strengths (S)

Incorporating mango waste into beer production reveals a range of strategic advantages that reinforce the relevance of this valorization pathway. From an environmental standpoint, it reduces food loss across the entire mango production chain, reintegrating residues such as peels, pulp, and seeds into the economy as valuable raw materials. This practice supports circular economy models and strengthens adherence to global sustainability agendas, especially the United Nations Sustainable Development Goals 8 (decent work and economic growth), 9 (industry, innovation, and infrastructure), and 12 (responsible consumption and production), as discussed in the previous section.

From a nutritional and functional perspective, mango by-products are rich in bioactive compounds that enhance the beer’s health profile and appeal to health-conscious consumers. Mango peels are particularly high in polyphenols, carotenoids, and flavonoids like quercetin and kaempferol, known for their antioxidant and antimicrobial properties. The pulp provides a significant source of bioactive compounds such as mangiferin, a flavonoid with hypoglycemic, anti-inflammatory, and anticancer properties. The mango kernel, rich in healthy fats, further contributes by offering antioxidants and promoting heart health. Incorporating these compounds into beer production adds functional benefits and aligns with the rising consumer interest in beverages that deliver both taste and wellness benefits.

In parallel, the constant and geographically diverse availability of mango waste—unaffected by seasonality—ensures stability and predictability in the supply chain, facilitating integration into production routines and reducing dependence on traditional ingredients.

Using these unconventional materials also drives product innovation, enabling the development of exclusive and sensorially distinctive beers that meet consumers’ expectations of novelty and authenticity.

Finally, the valorization of these residues strengthens the broader production chain by promoting local partnerships, stimulating income generation, and contributing to regional development. These combined advantages reinforce the viability of integrating mango waste into brewing processes, offering a strategy that is both environmentally responsible and commercially promising.

- Weaknesses (W)

Despite the promising potential of using mango waste in beer production, several challenges must be addressed. One key weakness is the lack of comprehensive studies exploring the viability and implications of incorporating mango by-products into brewing processes. Limited scientific data can create uncertainties regarding optimal usage, long-term stability, and the overall impact on beer quality. The absence of robust research may deter potential investors or producers from fully embracing this approach.

Additionally, while the raw materials are abundant and easily accessible, integrating mango waste into brewing may involve high production costs. The need for process adjustments, logistics management, and specialized equipment can increase the overall expense. Craft beer production already carries higher costs due to premium ingredients, and incorporating new, unconventional materials may further raise these costs. Consumer acceptance may be limited without clear communication to justify these costs and demonstrate the added value of health, sustainability, and uniqueness. This could result in a niche market appeal, restricting broader consumer adoption and hindering scalability.

- Opportunities (O)

The craft beer market is expanding, and using unique ingredients, such as mango waste, presents an excellent opportunity to capture a growing segment of consumers seeking exclusive and innovative products. Integrating unconventional ingredients can attract consumers willing to try new sensations and flavors, providing a competitive edge in the market.

While “reuse” might initially raise concerns for some consumers, the rising awareness of health and sustainability trends provides a unique opportunity to align the product with these values. The growing consumer interest in functional and eco-friendly products creates a favorable environment for promoting the health benefits and sustainable nature of using mango by-products in beer production.

In addition, the potential for strategic partnerships with mango producers and processing industries offers significant opportunities to strengthen the supply chain. These collaborations can ensure a steady and reliable raw material source, facilitate more sustainable practices, and create mutual value across the production network. By integrating mango waste into the brewing process, these partnerships can enhance the overall efficiency and sustainability of production, benefiting both the beer industry and the broader agricultural sector.

- Threats (T)

The increasing innovation and intense competition in the beverage and craft beer market can significantly threaten the differentiation and prominence of products that use mango waste. With the variety of options available to consumers, it may be challenging to highlight products that use less conventional ingredients, such as mango waste.

Additionally, consumer perception of ingredient quality is central to accepting products made with upcycled materials. Although a growing segment of consumers value sustainability, innovation, and functional attributes in food and beverages, this openness is often associated with specific profiles, such as younger, more educated, and environmentally conscious individuals. However, in Brazil, where the concept of upcycled foods is still relatively new and not widely understood, using by-products in beer production may raise concerns about hygiene, quality, and overall product acceptance.

Given these cultural and perceptual barriers, it is essential to develop targeted communication strategies that go beyond highlighting environmental benefits and reinforce safety, quality, and the technological rigor behind the process. In this context, further research on the Brazilian consumer profile is crucial to better understand expectations, values, and points of resistance. These insights can inform more effective marketing and product positioning strategies, ensuring that innovations based on waste reuse are well received and not misinterpreted locally.

Another significant threat is the regulatory ambiguity surrounding upcycled foods and beverages. While these products adhere to existing food safety and labeling standards, the lack of specific regulations for upcycled ingredients opens the door to potential legal and bureaucratic challenges. Future regulatory changes could necessitate adjustments in product formulations, potentially slowing innovation and market entry. Although safety and quality will always be prioritized, evolving regulations may affect the development and commercialization of products that incorporate by-products or residues.

4.3. Future Perspectives and Research Opportunities

This study aimed to provide a comprehensive overview of the potential for incorporating mango waste into beer production, establishing a foundation for future research and practical applications. By mapping key strengths, weaknesses, opportunities, and threats, the analysis highlights this valorization pathway’s promise and complexity.

As a first step toward broadening this field, future studies should address the lack of scientific evidence on how mango by-products affect the brewing process, sensory quality, and product stability. Controlled experiments and pilot-scale trials are necessary to validate the functional potential of these ingredients and ensure reproducibility and safety.

Building on the opportunities identified, strategic collaborations across the mango and brewing sectors could enhance supply chain efficiency and promote circularity. However, they require further investigation into operational feasibility and economic viability.

The analysis also revealed cultural and perceptual challenges related to consumer acceptance of upcycled ingredients, especially in the Brazilian context. Research into consumer behavior, targeted communication strategies, and market positioning will be essential to overcome skepticism and ensure alignment with consumer expectations.

By advancing in these directions, future work can transform the initial insights presented here into tangible, scalable, and sustainable solutions for the brewing industry.

5. Conclusions

The SWOT analysis reveals key internal and external factors that influence the feasibility and scalability of this approach. Among its strengths are the potential for product differentiation, the valorization of bioactive compounds, and alignment with circular economy principles. These advantages position the brewing industry to innovate and add value to underutilized resources. Additionally, the constant availability of mango waste ensures a stable supply chain, reinforcing its appeal for integration into regular production routines.

However, challenges remain. The weaknesses identified include the lack of comprehensive studies on the application of mango waste in brewing, which limits technical validation and industrial scalability, and the high production costs associated with incorporating new ingredients. These factors can hinder broader adoption, especially in a market that demands cost-efficiency and proven performance.

Despite these challenges, significant opportunities lie ahead. The expanding craft beer market and increasing consumer interest in functional eco-friendly products provide a favorable environment for introducing mango-based beers. Strategic partnerships within the mango and brewing sectors can enhance supply chain efficiency and promote circularity, further contributing to the industry’s sustainability.

In conclusion, the future of beer production is increasingly linked to innovative and sustainable practices that prioritize the valorization of underutilized resources. By overcoming current challenges and leveraging opportunities for innovation and market growth, this approach has the potential to significantly contribute to a circular and responsible economic model aligned with the Sustainable Development Goals (SDGs). This path offers a more promising and sustainable future for the brewing industry, where waste is seen not as a burden, but as a resource to drive both environmental and economic benefits.

Author Contributions

Conceptualization, M.S.R., M.L., S.A.D.d.C. and S.L.; methodology, M.S.R., L.F.d.O., N.Z.M., S.A.D.d.C. and S.A.V.M.; data curation, M.S.R.; writing—original draft preparation, M.S.R., M.L., S.A.D.d.C., S.L. and S.A.V.M.; writing—review and editing, M.S.R., S.A.D.d.C. and M.L.; supervision, S.A.D.d.C. and M.L. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the financial support of the National Council for Scientific and Technological Development (CNPq) (Grant numbers 302848/2021-5, 302611/2021-5). This study was financed in part by PROPG/UNESP through call nº 01/2025.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the findings of this study are derived from previously published sources, which are cited throughout the manuscript. These data are available in the referenced literature and publicly accessible databases. Further details can be obtained from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SDGs | Sustainable Development Goals |

| CE | circular economy |

| MAPA | Ministry of Agriculture, Livestock, and Supply |

| ANVISA | National Health Surveillance Agency |

| GDP | Gross Domestic Product |

| UN | United Nations |

References

- De Oliveira, H.M.; Rossi, R.M. Análise Estratégica. In Administração Estratégica: Da Teoria à Prática no Brasil, 1st ed.; Abdalla, M.M., Conejero, M.A., Oliveira, M.A., Eds.; Editora Atlas: São Paulo, Brazil, 2019; pp. 79–98. [Google Scholar]

- Nieto-Villegas, R.; Bernabéu, R.; Rabadán, A. Effects on beer attribute preferences of consumers’ attitudes towards sustainability: The case of craft beer and beer packaging. J. Agric. Food Res. 2024, 21, 1–7. [Google Scholar] [CrossRef]

- Veiga, R.F. Priorização de diretrizes na gestão estratégica de uma microcervejaria. Bachelor Thesis, Universidade Federal de Santa Maria, Santa Maria, Brazil, 2017. [Google Scholar]

- Baigts-Allende, D.K.; Pérez-Alva, A.; Ramírez-Rodrigues, M.A.; Palacios, A.; Ramírez-Rodrigues, M.M. A comparative study of polyphenolic and amino acid profiles of commercial fruit beers. J. Food Compos. Anal. 2021, 100, 103921. [Google Scholar] [CrossRef]

- Cela, N.; Condelli, N.; Caruso, M.C.; Perretti, G.; Di Cairano, M.; Tolve, R.; Galgano, F. Gluten-free brewing: Issues and perspectives. Fermentation 2020, 6, 53. [Google Scholar] [CrossRef]

- Wannenmacher, J.; Gastl, M.; Becker, T. Phenolic substances in beer: Structural diversity, reactive potential and relevance for brewing process and beer quality. Compr. Rev. Food Sci. Food Saf. 2018, 17, 953–988. [Google Scholar] [CrossRef]

- Zhao, X.; Yin, Y.; Fang, W.; Yang, Z. What happens when fruit married with beer? Int. J. Gastron. Food Sci. 2023, 32, 100716. [Google Scholar] [CrossRef]

- Radu, E.-D.; Mureșan, V.; Coldea, T.E.; Mudura, E. Unconventional raw materials used in beer and beer-like beverages production: Impact on metabolomics and sensory profile. Food Res. Int. 2024, 183, 114203. [Google Scholar] [CrossRef]

- Lupinacci, H. Cervejas Artesanais: Como Navegar Nesse Mercado. Você S/A. 2023. Available online: https://vocesa.abril.com.br/empreendedorismo/cervejas-artesanais-como-navegar-nesse-mercado (accessed on 6 September 2024).

- MAPA. Anuário da Cerveja 2024; Ministério da Agricultura e Pecuária: Brasília, Brazil, 2024; p. 56. [Google Scholar]

- Rebelo, R.H.V. What Does the Brazilian Craft Beer Scene Look Like? BrauBeviale Industry Insights. 5 September 2024. Available online: https://www.braubeviale.com/en-US/industry-insights/what-does-the-brazilian-craft-beer-scene-look-like/ (accessed on 18 April 2025).

- Paiva, R.A.M.; Mutz, Y.S.; Conte-Junior, C.A. A review on the obtaining of functional beers by addition of non-cereal adjuncts rich in antioxidant compounds. Antioxidants 2021, 10, 1332. [Google Scholar] [CrossRef]

- Lemoine, M.L.; Fontana, U.; Hurtado, J.B.; Pintos, F.M.; Arena, M.E.; Vicente, A.R.; Rodoni, L.M. Wild barberry (Berberis microphylla G. Forst.) as a natural ingredient for beer brewing. Chil. J. Agric. Anim. Sci. 2021, 37, 313–324. [Google Scholar] [CrossRef]

- Brito Júnior, M.R.; Ugalde, F.Z.; Gonzaga, L.V.; Schulz, M.; Fett, R.; Costa, A.C.; Tribuzi, G. Physicochemical characteristics and antioxidant potential of a fruit beer produced with Juçara (Euterpe edulis Martius) fruit pulp. Braz. Arch. Biol. Technol. 2023, 66, e220324. [Google Scholar] [CrossRef]

- Lossolli, N.A.B.; Leonel, M.; Leonel, S.; Izidoro, M.; Cândido, H.T.; Assis, J.L.J.; Oliveira, L.A. Exploring differences in the physicochemical and nutritional properties of mango flours and starches. Food Sci. Technol. Int. 2024, 30, 1–15. [Google Scholar] [CrossRef]

- Choudhury, M.M.; Costa, T.S. Perdas na Cadeia de Comercialização da Manga, 1st ed.; Embrapa Semi-Árido: Petrolina, Brazil, 2004. [Google Scholar]

- Mattar, F.N.; Oliveira, B.; Motta, S.L.S. Pesquisa de Marketing: Metodologia, Planejamento, Execução E Análise, 7th ed.; Elsevier: Rio de Janeiro, Brazil, 2014; Chapter 3; pp. 42–59. [Google Scholar]

- Gil, A.C. Como Elaborar Projetos de Pesquisa, 4th ed.; Atlas: São Paulo, Brazil, 2002; Chapter 4; pp. 41–57. [Google Scholar]

- Moser, A.; Korstjens, I. Series: Practical Guidance to Qualitative Research. Part 1: Introduction. Eur. J. Gen. Pract. 2017, 23, 271–273. [Google Scholar] [CrossRef] [PubMed]

- Costa Júnior, J.F.; Bezerra, D.M.C.; Cabral, E.L.S.; Moreno, R.C.P.; Pires, A.K.S. A Matriz SWOT e suas Subdimensões: Uma Proposta de Inovação Conceitual. Res. Soc. Dev. 2021, 10, e25710212580. [Google Scholar] [CrossRef]

- Kurttila, M.; Pesonen, M.; Kangas, J.; Kajanus, M. Utilizing the analytic hierarchy process (AHP) in SWOT analysis—A hybrid method and its application to a forest-certification case. For. Policy Econ. 2000, 1, 41–52. [Google Scholar] [CrossRef]

- Nakagawa, M.; Ferramenta Análise SWOT (clássico). Serviço Brasileiro de Apoio Às Micro E Pequenas Empresas (SEBRAE)-Movimento Empreendedor. 2023. Available online: https://www.sebrae.com.br/Sebrae/Portal%20Sebrae/Anexos/ME_Analise-Swot.PDF (accessed on 15 March 2025).

- Martins, G.O.; de Carvalho, S.A.D.; Fernandes, L.G.L.; Cesarino, I.; de Oliveira, R.C. Market Research and SWOT Analysis for Fibers Composite Materials Usage in the Vehicular Components Supply Chain. J. Nat. Fibers 2024, 21, 16. [Google Scholar] [CrossRef]

- Ghazinoory, S.; Abdi, M.; Azadegan-Mehr, M. SWOT methodology: A state-of-the-art review for the past, a framework for the future. J. Bus. Econ. Manag. 2011, 12, 24–48. [Google Scholar] [CrossRef]

- Venturini Filho, W.G.; Cereda, M.P. Cerveja. In Biotecnologia Industrial, 6th ed.; Aquarone, E., Borzani, W., Schmidell, W., Lima, U.A., Eds.; Bucher: São Paulo, Brazil, 2014; Volume 4, Chapter 4; pp. 91–144. [Google Scholar]

- Brasil. Decreto nº 9.902, de 8 de Julho de 2019. Altera o Anexo ao Decreto nº 6.871, de 4 de Junho de 2009, que Regulamenta a Lei nº 8.918, de 14 de Julho de 1994, Sobre a Padronização, Classificação, Registro, Inspeção, Produção e Fiscalização de Bebidas. Diário Oficial da União, Brasília, DF. 8 July 2019. Available online: https://www.planalto.gov.br/ccivil_03/_Ato2019-2022/2019/Decreto/D9902.htm (accessed on 6 September 2024).

- SINDICERV. Manual for Beer Registration with MAPA Through SIPEAGRO; SINDICERV: São Paulo, Brazil, 2020; p. 61. Available online: https://sindicerv.com.br/2025/wp-content/uploads/2020/11/manual-registro-cerveja-sindicerv.pdf (accessed on 6 September 2024).

- Brasil. Instrução Normativa nº 65, de 10 de Dezembro de 2019. Dispõe Sobre os Ingredientes, Aditivos e Coadjuvantes Autorizados Para a Elaboração de Bebidas. Diário Oficial da União, Brasília, DF. 11 December 2019. Available online: https://www.in.gov.br/en/web/dou/-/instrucao-normativa-n-65-de-10-de-dezembro-de-2019-232655384 (accessed on 6 September 2024).

- Avîrvarei, A.C.; Salantă, L.C.; Pop, C.R.; Mudura, E.; Pasqualone, A.; Anjos, O.; Barboza, N.; Usaga, J.; Dărab, C.P.; Burja-Udrea, C.; et al. Fruit-Based Fermented Beverages: Contamination Sources and Emerging Technologies Applied to Assure Their Safety. Foods 2023, 12, 838. [Google Scholar] [CrossRef]

- BRASIL. Agência Nacional de Vigilância Sanitária (ANVISA). Resolução RDC N° 331, De 23 De Dezembro de 2019 Dispõe Sobre os Requisitos Microbiológicos Para Alimentos E Bebidas. Diário Oficial da União 2019. Brasília, DF. 23 December 2019. Available online: https://bvsms.saude.gov.br/bvs/saudelegis/anvisa/2019/rdc0331_23_12_2019.pdf (accessed on 19 April 2025).

- BRASIL. Ministério da Agricultura, Pecuária E Abastecimento (MAPA). Portaria N° 326, De 30 De Julho De 1997. Aprova O Regulamento Técnico Sobre As Boas Práticas De Fabricação E O Controle De Qualidade Para Indústria De Alimentos. Diário Oficial Da União, Brasília, DF. 30 July 1997. Available online: https://www.gov.br/agricultura/pt-br/assuntos/inspecao/produtos-vegetal/legislacao-de-produtos-origem-vegetal/biblioteca-de-normas-vinhos-e-bebidas/portaria-no-326-de-30-de-julho-de-1997.pdf/view (accessed on 19 April 2025).

- Callejo, M.J.; Tesfaye, W.; González, M.C.; Morata, A. Craft beers: Current situation and future trends. In New Advances on Fermentation Processes; Martínez-Espinosa, R.M., Ed.; IntechOpen: London, UK, 2019; p. 240. [Google Scholar] [CrossRef][Green Version]

- Medina, K.; Boido, E.; Dellacassa, E.; Carrau, F. Commercial craft beers produced in Uruguay: Volatile profile and physicochemical composition. Food Res. Int. 2022, 162, 112349. [Google Scholar] [CrossRef]

- Kirin Beer University Report. Global Beer Production by Country in 2022. Kirin Holdings. 2023. Available online: https://www.kirinholdings.com/en/newsroom/release/2023/1222_04.html (accessed on 6 September 2024).

- CervBrasil. Dados do Setor. CervBrasil. 2024. Available online: https://www.cervbrasil.org.br/novo_site/mercado-cervejeiro/ (accessed on 6 September 2024).

- Mwaurah, P.W.; Kumar, S.; Kumar, N.; Panghal, A.; Attkan, A.K.; Singh, V.K.; Garg, M.K. Physicochemical characteristics, bioactive compounds and industrial applications of mango kernel and its products: A review. Compr. Rev. Food Sci. Food Saf. 2020, 16, 1–26. [Google Scholar] [CrossRef]

- Ribeiro, S.M.R.; Barbosa, L.C.A.; Queiroz, J.H.; Knödler, M.; Schieber, A. Phenolic compounds and antioxidant capacity of Brazilian mango (Mangifera indica L.) varieties. Food Chem. 2008, 110, 620–626. [Google Scholar] [CrossRef]

- Izidoro, M.; Leonel, M.; Leonel, S.; Lossoli, N.A.B.; Cândido, H.T.; Züge, P.G.U.; Assis, J.L.J. Nutritional and technological properties of pulp and peel flours from different mango cultivars. J. Food Sci. Technol. 2023, 43, e107922. [Google Scholar] [CrossRef]

- Lebaka, V.R.; Wee, Y.-J.; Ye, W.; Korivi, M. Nutritional composition and bioactive compounds in three different parts of mango fruit. Int. J. Environ. Res. Public Health 2021, 18, 741. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations (FAO). FAOSTAT: Production-Crops. FAO. 2023. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 6 September 2024).

- Instituto Brasileiro De Geografia E Estatística (IBGE). Produção Agrícola Municipal. IBGE. 2023. Available online: https://www.ibge.gov.br/estatisticas/economicas/agricultura-e-pecuaria/9117-producao-agricola-municipal.html (accessed on 6 September 2024).

- Lossolli, N.A.B.; Leonel, M.; Leonel, S.; Izidoro, M.; de Paula, G.V.; dos Santos, T.P.R.; de Oliveira, L.A. Cultivars and fruit part as differentiating factors of physicochemical characteristics of mango starches. Horticulturae 2023, 9, 69. [Google Scholar] [CrossRef]

- Mitra, S.K. Mango production in the world—present situation and future prospect. Acta Hortic. 2016, 1111, 287–296. [Google Scholar] [CrossRef]

- Sanou, M.; Kanté-Traoré, H.; Haro, K.; Somda, S.; Offei, F.; Zhang, Y.; Parkouda, C.; Dicko, M.H. Biochemical Properties and Biotechnological Potential of Mango Biowastes for Economical Valorization in Burkina Faso. Waste Biomass Valorization 2025, 16, 53–73. [Google Scholar] [CrossRef]

- Jahurul, M.H.A.; Zaidul, I.S.M.; Ghafoor, K.; Al-Juhaimi, F.Y.; Nyam, K.-L.; Norulaini, N.A.N.; Sahena, F.; Mohd Omar, A.K. Mango (Mangifera indica L.) By-Products and Their Valuable Components: A Review. Food Chem. 2015, 183, 173–180. [Google Scholar] [CrossRef]

- Ajila, C.M.; Rao, U.J.S.P. Mango Peel Dietary Fibre: Composition and Associated Bound Phenolics. J. Funct. Foods 2013, 5, 444–450. [Google Scholar] [CrossRef]

- Puligundla, P.; Obulam, V.S.; Sang, E.O.; Mok, C. Biotechnological potentialities and valorization of mango peel waste: A review. Sains Malays. 2014, 43, 1901–1906. [Google Scholar] [CrossRef]

- Cárdenas-Hernández, E.; Torres-León, C.; Chávez-González, M.L.; Matos Ximenes, R.; Gonçalves Da Silva, T.; Ascacio-Valdés, J.A.; Martínez-Hernández, J.L.; Aguilar, C.N. From agroindustrial waste to nutraceuticals: Potential of mango seed for sustainable product development. Trends Food Sci. Technol. 2024, 154, 104754. [Google Scholar] [CrossRef]

- Najar, I.N.; Prayatna, A.; Kumar, S.; Kumar, A.; Kumar, V.; Kumar, A.; Singh, J. From waste management to circular economy: Leveraging thermophiles for sustainable growth and global resource optimization. J. Environ. Manag. 2024, 360, 121136. [Google Scholar] [CrossRef]

- Organização das Nações Unidas (ONU). Objetivos de Desenvolvimento Sustentável; ONU: New York, NY, USA, 2015. [Google Scholar]

- Cela, N.; Pazaitis, D.; Banovic, M.; Aschemann-Witzel, J. Impact of circular economy information on sensory acceptability, purchase intention and perceived value of upcycled foods by young consumers. Food Res. Int. 2024, 175, 113765. [Google Scholar] [CrossRef]

- Ram, M.; Bracci, E. Waste Management, Waste Indicators and the Relationship with Sustainable Development Goals (SDGs): A Systematic Literature Review. Sustainability 2024, 16, 8486. [Google Scholar] [CrossRef]

- Schroeder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2018, 23, 77–95. [Google Scholar] [CrossRef]

- Valverde, J.-M.; Avilés-Palacios, C. Circular Economy as a Catalyst for Progress towards the Sustainable Development Goals: A Positive Relationship between Two Self-Sufficient Variables. Sustainability 2021, 13, 12652. [Google Scholar] [CrossRef]

- Mintel. Tendências Globais de Consumo 2024; Mintel: London, UK, 2024; pp. 1–31. [Google Scholar]

- Mintel. Tendências Globais de Alimentos E Bebidas 2024; Mintel: London, UK, 2024; pp. 1–21. [Google Scholar]

- Habschied, K.; Živković, A.; Krstanović, V.; Mastanjević, K. Functional beer—A review on possibilities. Beverages 2020, 6, 51. [Google Scholar] [CrossRef]

- Zegler, J. Cervejas Mais Saudáveis Têm Espaço Para Crescer No BRASIL. MINTEL. 2020. Available online: https://brasil.mintel.com/blog/cervejas-mais-saudaveis-tem-espaco-para-crescer-no-brasil (accessed on 17 September 2024).

- Mintel. Consumidor Brasileiro de Cerveja Prefere Qualidade À Quantidade. Mintel. 2018. Available online: https://brasil.mintel.com/imprensa/alimentos-e-bebidas/consumidor-brasileiro-de-cerveja-prefere-qualidade-a-quantidade (accessed on 17 September 2024).

- Furtado, B.; Fernandes, P. O Otimismo Do Consumidor Brasileiro Se Recupera Em Linha Com O Crescimento Econômico. Mckinsey & Company. 2024. Available online: https://www.mckinsey.com.br/our-insights/all-insights/o-otimismo-do-consumidor-brasileiro-se-recupera-em-linha-com-o-crescimento-economico (accessed on 6 November 2024).

- Crescenti, M. O Que Determina Uma Boa Cerveja? ‘Lei Da Pureza’ Alemã Completa 500 Anos. BBC Brasil. 2016. Available online: https://www.bbc.com/portuguese/noticias/2016/01/160119_500_anos_lei_cerveja_alemanha_rb (accessed on 18 September 2024).

- Cerveja Da Casa. Série Escolas Cervejeiras: Escola Belga. Cerveja Da Casa. 2024. Available online: https://www.cervejadacasa.com/noticias/serie-escolas-cervejeiras-escola-belga (accessed on 18 September 2024).

- Forsyth, J. Cerveja Frutada. Mintel. 2017. Available online: https://brasil.mintel.com/blog/noticias-mercado-alimentos-bebidas/cerveja-frutada (accessed on 18 September 2024).

- A Gazeta. Cervejas Frutadas São Tendência Para O Verão 2024. A Gazeta. 2023. Available online: https://www.agazeta.com.br/hz/gastronomia/cervejas-frutadas-sao-tendencia-para-o-verao-2024-1223 (accessed on 18 September 2024).

- Forsyth, J. Conheça Dez Cervejas Inovadoras Ao Redor Do Mundo. Mintel. 2018. Available online: https://brasil.mintel.com/blog/noticias-mercado-alimentos-bebidas/conheca-dez-cervejas-inovadoras-ao-redor-do-mundo (accessed on 18 September 2024).

- Lu, P.; Parrella, J.A.; Xu, Z.; Kogut, A. A scoping review of the literature examining consumer acceptance of upcycled foods. Food Qual. Prefer. 2024, 114, 105098. [Google Scholar] [CrossRef]

- Melios, S.; Johnson, H.; Grasso, S. Sensory quality and regulatory aspects of upcycled foods: Challenges and opportunities. Food Res. Int. 2025, 199, 115360. [Google Scholar] [CrossRef]

- Goodman-Smith, F.; Bhatt, S.; Grasso, S.; Deutsch, J.; Mirosa, M. Consumer acceptance of upcycled craft beer: A New Zealand case study. Front. Nutr. 2023, 10, 1235137. [Google Scholar] [CrossRef]

- Lenucci, M.S.; Tornese, R.; Mita, G.; Durante, M. Bioactive compounds and antioxidant activities in different fractions of mango fruits (Mangifera indica L., cultivar Tommy Atkins and Keitt). Antioxidants 2022, 11, 484. [Google Scholar] [CrossRef]

- Bitwell, C.; Indra, S.S.; Luke, C.; Kakoma, M.K. A review of modern and conventional extraction techniques and their applications for extracting phytochemicals from plants. Sci. Afr. 2023, 19, e01585. [Google Scholar] [CrossRef]

- Pérez-Marroquín, X.A.; Estrada-Fernández, A.G.; García-Ceja, A.; Aguirre-Álvarez, G.; León-López, A. Agro-Food Waste as an Ingredient in Functional Beverage Processing: Sources, Functionality, Market and Regulation. Foods 2023, 12, 1583. [Google Scholar] [CrossRef]

- Torres-León, C.; Ramírez-Guzmán, N.; Londoño-Hernández, L.; Martínez-Medina, G.A.; Díaz-Herrera, R.; Navarro-Macías, V.; Alvarez-Pérez, O.B.; Picazo, B.; Villarreal-Vázquez, M.; Ascacio-Valdés, J.A.; et al. Solid-state fermentation with Aspergillus niger to enhance the phenolic contents and antioxidative activity of Mexican mango seed: A promising source of natural antioxidants. Lebensm.-Wiss. Technol. 2019, 112, 108236. [Google Scholar] [CrossRef]

- Kučuk, N.; Primožič, M.; Kotnik, P.; Knez, Ž.; Leitgeb, M. Mango peels as an industrial by-product: A sustainable source of compounds with antioxidant, enzymatic, and antimicrobial activity. Foods 2024, 13, 553. [Google Scholar] [CrossRef] [PubMed]

- Alvarenga, L.M.; Dutra, M.B.L.; Alvarenga, R.M.; Lacerda, I.C.A.; Yoshida, M.I.; Oliveira, E.S. Analysis of Alcoholic Fermentation of Pulp and Residues from Pineapple Processing. CyTA J. Food 2015, 13, 10–16. [Google Scholar] [CrossRef]

- Exame. Upcycling de Alimentos: A Tendência Sustentável. Exame. Available online: https://exame.com/negocios/upcycling-food-e-tendencia-sustentavel/?utm_source=copiaecola&utm_medium=compartilhamento (accessed on 19 April 2025).

- Rubian Extratos. Página Inicial. Rubian. Available online: https://www.rubian.com.br/# (accessed on 19 April 2025).

- Upcycling Solutions. Nestlé Lança Produtos Upcycled. Upcycling Solutions. Available online: https://upcyclingsolutions.com.br/2024/06/08/nestle-lanca-produtos-upcycled/ (accessed on 19 April 2025).

- Exame. Bolinho, Farofa e Snacks de Malte: Como a Cerveja Virou Matéria-Prima Para Uma Foodtech Milionária. Exame. Available online: https://exame.com/negocios/bolinho-farofa-e-snacks-de-malte-como-a-cerveja-virou-materia-prima-para-uma-foodtech-milionaria/ (accessed on 19 April 2025).

- Alexandre, E.M.C.; Aguiar, N.F.B.; Voss, G.B.; Pintado, M.E. Properties of Fermented Beverages from Food Wastes/By-Products. Beverages 2023, 9, 45. [Google Scholar] [CrossRef]

- Zhu, Y.; Lv, J.; Gu, Y.; He, Y.; Chen, J.; Ye, X.; Zhou, Z. Mixed Fermentation of Chinese Bayberry Pomace Using Yeast, Lactic Acid Bacteria and Acetic Acid Bacteria: Effects on Color, Phenolics and Antioxidant Ingredients. Learn. Technol. 2022, 163, 113503. [Google Scholar] [CrossRef]

- Hien, T.T.; Khang, V.C.; Van Muoi, N.; Truc, T.T. Production of a Fermented Beverage from Pineapple (Ananas comosus) Byproduct Crumbs. Mater. Today Proc. 2022, 60, 2034–2042. [Google Scholar] [CrossRef]

- Aguilar, K. Evaluating Ultrasound Pre-Treatment as a Tool for Improving the Process of a Fermented Beverage Made from Pineapple By-Products. Braz. J. Food Sci. Technol. 2022, 25, e2021195. [Google Scholar] [CrossRef]

- Leonarski, E.; Cesca, K.; Zanella, E.; Stambuk, B.U.; de Oliveira, D.; Poletto, P. Production of Kombucha-Like Beverage and Bacterial Cellulose by Acerola Byproduct as Raw Material. Learn. Technol. 2021, 135, 110075. [Google Scholar] [CrossRef]

- Vieira, A.D.S.; Battistini, C.; Bedani, R.; Saad, S.M.I. Acerola By-Product May Improve the In Vitro Gastrointestinal Resistance of Probiotic Strains in a Plant-Based Fermented Beverage. Learn. Technol. 2021, 141, 110858. [Google Scholar] [CrossRef]

- Vieira, A.D.S.; de Souza, C.B.; Padilha, M.; Zoetendal, E.G.; Smidt, H.; Saad, S.M.I.; Venema, K. Impact of a Fermented Soy Beverage Supplemented with Acerola By-Product on the Gut Microbiota from Lean and Obese Subjects Using an In Vitro Model of the Human Colon. Appl. Microb. Biotechnol. 2021, 105, 3771–3785. [Google Scholar] [CrossRef]

- Konrade, D.; Lidums, I.; Klava, D.; Ence, E.; Kirse-Ozolina, A. Investigation of Extruded Cereals Enriched with Plant By-Products and Their Use in Fermented Beverage Production. Agron. Res. 2019, 17, 1346–1355. [Google Scholar]

- Liu, H.; Xu, X.; Cui, H.; Xu, J.; Yuan, Z.; Liu, J.; Li, C.; Li, J.; Zhu, D. Plant-Based Fermented Beverages and Key Emerging Processing Technologies. Food Rev. Int. 2022, 39, 5844–5863. [Google Scholar] [CrossRef]

- Álvarez, S.A.; Rocha-Guzmán, N.E.; Moreno-Jiménez, M.R.; Gallegos-Infante, J.A.; Pérez-Martínez, J.D.; Rosas-Flores, W. Functional Fermented Beverage Made with Apple, Tibicos, and Pectic Polysaccharides from Prickly Pear (Opuntia ficus-indica L. Mill) Peels. J. Food Process. Preserv. 2021, 45, e15745. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).