Abstract

Granite residual soil exhibits a tendency to collapse and disintegrate upon exposure to water, displaying highly unstable mechanical properties. This makes it susceptible to landslides, mudslides, and other geological hazards. In this study, three common biopolymers, i.e., xanthan gum (XG), locust bean gum (LBG), and guar gum (GG), are employed to improve the strength and stability of granite residual soil. A series of experiments were conducted on biopolymer-modified granite residual soil, varying the types of biopolymers, their concentrations, and curing times, to examine their effects on the soil’s strength properties and failure characteristics. The microscopic structure and interaction mechanisms between the soil and biopolymers were analyzed using scanning electron microscopy and X-ray diffraction. The results indicate that guar gum-treated granite residual soil exhibited the highest unconfined compressive strength and shear strength. After adding 2.0% guar gum, the unconfined compressive strength and shear strength of the modified soil are 1.6 times and 1.58 times that of the untreated granite residual soil, respectively. Optimal strength improvements were observed when the biopolymer concentration ranged from 1.5% to 2%, with a curing time of 14 days. After treatment with xanthan gum, locust bean gum, and guar gum, the cohesion of the soil is 1.36 times, 1.34 times, and 1.55 times that of the untreated soil, respectively. The biopolymers enhanced soil bonding through cross-linking, thereby improving the soil’s mechanical properties. The gel-like substances formed by the reaction of biopolymers with water adhered to encapsulated soil particles, significantly altering the soil’s deformation behavior, toughness, and failure modes. Furthermore, interactions between soil minerals and functional groups of the biopolymers contributed to further enhancement of the soil’s mechanical properties. This study demonstrates the feasibility of using biopolymers to improve granite residual soil, offering theoretical insights into the underlying microscopic mechanisms that govern this improvement.

1. Introduction

Granite Residual Soil (GRS) is a product of the long-term weathering of granite, and it is widely distributed in the southern regions of China, particularly along the southeastern coastal areas. GRS is primarily influenced by subtropical and tropical climatic conditions, as well as the properties of the parent rock, resulting in complex pore and fracture structures. During weathering, a variety of oxides, such as iron oxide and aluminum oxide, are generated, with their content varying according to the degree of weathering the soil has undergone [1]. This gives the soil a brown-red, brown-yellow, and off-white surface character. These surface traits provide an intuitive basis for assessing the degree of weathering in GRS. GRS exhibits a loose structure, high permeability, and is easily softened and disintegrated when in contact with water, and it shows remarkable anisotropy [2]. These properties make GRS highly susceptible to external factors, such as rainfall, which can trigger landslides [3]. Therefore, GRS is used in engineering construction, and it needs to be strengthened.

Soil solidification is a technique that enhances the bearing capacity and shear strength of soil by incorporating hardening agents or curing materials. In engineering applications, chemical curing agents such as lime and cement are commonly used to improve the properties of GRS. These agents work by initiating physical and chemical reactions, significantly increasing the soil’s bearing capacity and disintegration resistance [4]. However, disintegration resistance like lime and cement release substantial amounts of greenhouse gases during both production and application, resulting in direct or indirect negative environmental impacts. Microbial-Induced Calcite Precipitation (MICP) technology can also reinforce GRS [5], improving not only the shear strength but also reducing its permeability, making the soil more stable against external loads and water erosion, and improve its anti-disintegration ability [6,7]. However, the microbial reaction process of MICP technology is more sensitive to environmental conditions and the cost is relatively high.

Biopolymers are high-molecular compounds derived from living organisms or their metabolic products. These polymers are typically produced through biosynthesis processes and include proteins, polysaccharides, nucleic acids, and other substances. As a renewable material [8], biopolymers can be recycled through natural biodegradation or artificial treatment, aligning with the concept of sustainable development [9,10]. When mixed with soil, biopolymers form composite materials that show great potential for use in geotechnical and construction engineering, positioning them as a promising and environmentally friendly option for ground improvement [11]. Biopolymers commonly used for soil solidification include xanthan gum (XG), sodium alginate, carrageenan, locust bean gum (LBG), agar, gellan gum [12], thermogels [13], dextran [14], and guar gum (GG) [15]. Among these, XG and GG are particularly notable for their widespread use in soil solidification [16,17]. Research has demonstrated that these biopolymers exhibit excellent soil solidification properties and can be effectively applied to improve and reinforce soils. The inclusion of biopolymers in soil has several advantages: they enhance soil structure, reduce erosion, and increase the soil’s load-bearing capacity [18]. Biopolymers combine with water in soil to form hydrogels, which have good hydrophilicity and degradability [19,20]. The hydrogel film has a good water retention ability [21], thereby increasing the water retention performance of the soil and helping to alleviate the problem of soil drought. Furthermore, biopolymers contribute nutrients to the soil, fostering the growth and activity of soil microorganisms and plants [22], thus improving soil fertility and health. As a result, the appropriate application of biopolymers can positively impact soil texture, moisture content, nutrient levels, and other key properties. To evaluate the overall performance of biopolymer–soil mixtures, a series of tests are typically conducted, including measurements of soil compressive strength [23], shear strength [24,25], and other related parameters. These experiments are crucial for understanding how biopolymers influence the physical and mechanical properties of soil [26], providing a scientific foundation for their practical application. Biopolymers, by binding soil particles, can significantly enhance the mechanical strength of the soil, improving its compressive and shear strengths. The soil modified with biopolymers retains moisture more effectively, reducing soil moisture loss. Biopolymers can effectively increase the soil’s cohesion, reducing erosion caused by water flow. Biopolymers also help restore plant growth [22], providing support for ecosystem restoration. As biodegradable and environmentally friendly materials, biopolymers, when used to modify soil, do not cause long-term environmental pollution. The modification of granite residual soil with biopolymers not only enhances the stability and bearing capacity of the soil in geotechnical engineering [11] but also mitigates soil erosion and contributes to ecological restoration in environmental protection.

The current solidification methods for granite residual soil mainly include chemical stabilizers and MICP technology. Biopolymers, which are natural polymer compounds derived from living organisms, can reduce environmental damage and pollution compared to chemical stabilizers. In comparison to MICP technology, biopolymers offer significant advantages in terms of solidification speed, adaptability, ease of construction, and resistance to harsh environmental conditions. Although existing studies have investigated the use of biopolymers in soil improvement [27,28], research on their effectiveness and the microscopic mechanisms by which biopolymers enhance the strength of GRS remains limited. This study fills this gap in the field by focusing on the curing effects and mechanisms of biopolymers on granite residual soils. Compared to traditional homogeneous soils, granite residual soils have significant heterogeneity and differences in soil properties, making the study of biopolymer stabilization of these soils both theoretically and practically significant. Compared to existing stabilization solutions, the biopolymer stabilization method proposed in this study shows clear advantages in curing heterogeneous soils and provides a more competitive solution in terms of environmental friendliness and cost-effectiveness. Given this context, conducting an in-depth investigation into the application of biopolymers for stabilizing GRS is of considerable practical importance. In this study, three types of biopolymers-XG, LBG, and GG-were selected as soil stabilizers to enhance the strength characteristics of GRS. To evaluate the effectiveness of these biopolymers, unconfined compressive strength tests and direct shear tests were performed. Additionally, scanning electron microscopy (SEM) and X-ray diffraction (XRD) techniques were employed to examine changes in the soil’s microscopic structure and to explore the underlying mechanisms responsible for the observed improvements in strength due to biopolymer treatment. Unconfined compressive strength tests and direct shear tests provide quantitative data on the soil’s mechanical properties, evaluating the effect of biopolymers on soil strength and stability. SEM provides insights into the impact of biopolymers on the soil’s microstructure, helping to understand the interaction between biopolymers and soil particles. XRD reveals the potential impact of biopolymers on the soil’s mineral composition.

2. Materials and Methods

2.1. Materials

2.1.1. Soil

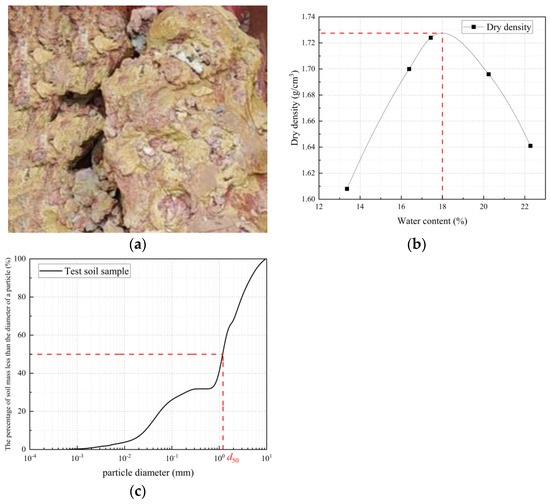

The granite residual soil used in this study was collected from a foundation pit in Guangdong Province, China. The basic physical parameters of the granite residual soil were measured by geotechnical tests, including water content test, particle analysis test, compaction test and limit water content test. Standard vibrating screen and laser particle size analyzer were used for particle analysis. Multi-function electric compacting instrument was used in the compaction test. The limit water content test was carried out with a combined liquid-plastic limit tester. The soil sample was first crushed and then sieved through a 2 mm circular mesh (as shown in Figure 1a). The main purpose of sieving the soil is to remove larger particles, ensuring that the soil used is purer and more uniform so that the remaining soil meets the experimental standards. The results of compaction tests are represented by the compaction curve of GRS in Figure 1b. Additionally, the particle size distribution of the soil sample is depicted in the gradation curve shown in Figure 1c. The d50 in the figure refers to the particle diameter in the soil sample, where 50% of the particles have a diameter smaller than this value, and 50% have a diameter larger than this value. This is also known as the median particle size, which represents the midpoint of the particle size distribution in the soil sample. A smaller d50 indicates a higher proportion of fine particles in the soil, which typically results in lower soil permeability. The basic physical properties of the GRS are summarized in Table 1. The selected granite residual soil originates from a specific geological environment, and its particle composition and mineral content differ from those of other common soils.

Figure 1.

Test soil samples: (a) GRS; (b) compaction curve; (c) gradation curve.

Table 1.

Basic physical parameters of the soil samples.

2.1.2. Biopolymers

This study utilized three biopolymers as binders: xanthan gum (XG), locust bean gum (LBG), and guar gum (GG). The xanthan gum used in this experiment was produced by Erdos Zhongxuan Biochemical Co., Ltd. in Hohhot, Inner Mongolia Autonomous Region, China, the locust bean gum was produced by Wanbang Chemical Technology Co., Ltd. in Shangqiu, Henan Province, China, and the guar gum was produced by Tongsheng Biological Technology Co., Ltd. in Hangzhou, Zhejiang Province, China.

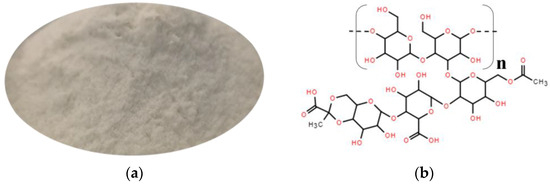

Xanthan gum (XG) is a natural polysaccharide produced by the fermentation of Xanthomonas campestris, a bacterium from wild rapeseed. It is typically produced through a fermentation process that converts corn starch or other starch-containing raw materials into xanthan gum. The XG, shown as a white powder in Figure 2a, readily dissolves in water at room temperature. It is a polysaccharide substance produced by the fermentation of Xanthomonas bacteria and is primarily composed of D-glucose, D-mannose, and D-glucuronic acid in a 2:2:1 ratio, forming a high-molecular-weight polysaccharide compound (see Figure 2b).

Figure 2.

(a) XG powder; (b) structural formula of XG.

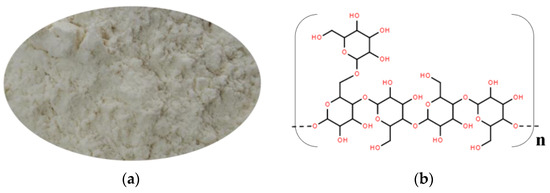

Locust bean gum (LBG), also known as carob gum, is a natural polysaccharide primarily derived from the seeds of the carob tree. The LBG appears as a white powder (see Figure 3a). It partially dissolves in water at room temperature but dissolves completely at 80 °C. LBG consists of mannose and galactose in a 4:1 ratio, forming a galactomannan structure. The mannose units form the main chain, with a galactose molecule attached to every fourth mannose unit (see Figure 3b).

Figure 3.

(a) LBG powder; (b) structural formula of LBG.

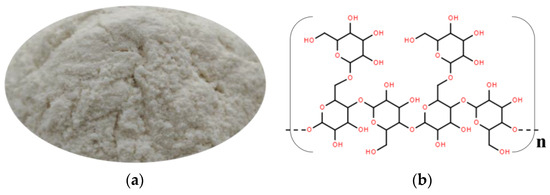

Guar gum (GG) is a natural polysaccharide extracted from guar bean seeds, also appearing as a white powder (see Figure 4a), and it is easily soluble in cold water. It consists of mannose and galactose in a 2:1 ratio, forming a galactomannan structure. Mannose forms the main chain, with a galactose molecule attached to every two mannose units (see Figure 4b). The properties of biopolymers are shown in Table 2.

Figure 4.

(a) GG powder; (b) structural formula of GG.

Table 2.

Properties of biopolymers.

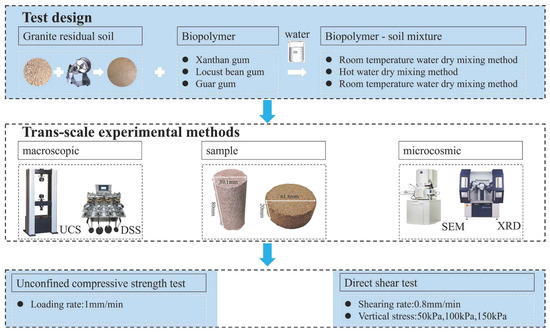

2.2. Testing Program

To evaluate the strength of GRS treated with biopolymers, unconfined compressive strength (UCS) tests and direct shear tests were conducted under varying types and contents of biopolymers, as well as different curing times. The UCS test was conducted using the WDW-10E microcomputer-controlled electronic universal testing machine produced by Jinan Naier Testing Machine Co., Ltd. in Shandong Province, China. The direct shear test was conducted using the ZJ strain-controlled direct shear apparatus produced by Nanjing Soil Instrument Co., Ltd. in Jiangsu Province, China. The experimental setup for the samples in these two mechanical tests is detailed in Table 3.

Table 3.

Biopolymer content and curing time.

The biopolymer contents used were 0%, 0.5%, 1%, 1.5%, and 2% of the dry soil mass. Based on the optimal moisture content of the soil sample, the moisture content was set at 18%. The curing times for the samples were 0, 3, 7, and 14 days. The selection of biopolymer content and curing times was informed by previous research on biopolymer-treated soils [29,30]. Different biopolymers were mixed using various methods. Due to the different solubility of the biopolymer, two mixing methods were used: room-temperature water–dry mixing and hot water–dry mixing. This mixing method refers to previously used research methods [12]. Room-temperature water–dry mixing refers to first thoroughly mixing the soil particles and biopolymer powder and then adding water. Due to the fact that xanthan gum and guar gum easily dissolve in water at room temperature, the room-temperature water–dry mixing method was used to prepare the soil samples. However, locust bean gum requires high temperature to fully dissolve, so the hot water–dry mixing method was used to prepare the soil samples. The sample preparation process was carried out according to the standards of soil testing methods (GB/T 50123-2019) [31]. The specific steps are as follows: The mass of each material was calculated according to the experimental plan. First, different concentrations of biopolymer powder were added to dry soil and manually mixed until uniform. Then, the mixture was combined with a suitable amount of pure water or hot water and stirred manually until evenly mixed. Finally, the prepared soil samples were sealed and stored for 24 h to ensure that the moisture was evenly absorbed by the soil. The mass of the samples was calculated based on the maximum dry density of the soil. The same mass of soil was weighed to prepare the samples. The dimensions of the unconfined compressive strength test samples were 80 mm in height and 39.1 mm in diameter, while the direct shear test samples had dimensions of 20 mm in height and 61.8 mm in diameter. For the unconfined compressive strength samples, the soil was placed in the mold in three layers and compacted layer by layer, then demolded using an electric demolding machine. For the direct shear test samples, the soil was placed in the mold, compacted, and demolded. After demolding, the samples were sealed in plastic wrap and placed in a curing box under conditions of 25 °C temperature and 90% humidity. The curing time was defined as the time for different curing durations.

The UCS and direct shear tests were conducted in accordance with the GB/T 50123-2019 “Geotechnical Test Methods” standard. In the unconfined compressive strength test, the axial loading rate was set to 1 mm/min. After the axial force reached its peak and stabilized, compression continued for 2–3 mm, after which the test was stopped, and the failure mode of the specimen was recorded. In the direct shear test, the shear rate was set to 0.8 mm/min, and the specimen was sheared. The test was stopped when the shear displacement reached 6 mm, as shown in Figure 5.

Figure 5.

Experimental process for preparing biopolymer improved soil.

3. Test Results and Analysis

The effects of biopolymers on the mechanical properties of GRS were investigated through UCS and direct shear tests. In these experiments, the type, content, and curing time of the biopolymers were the primary variables. The influence of these factors on the strength, stiffness, toughness, and failure behavior of GRS was analyzed.

3.1. Effect of Biopolymer on Compressive Strength

The UCS and shear strength obtained from the tests were used to assess the impact of biopolymers on the compressive and shear performance of GRS.

3.1.1. Unconfined Compressive Strength

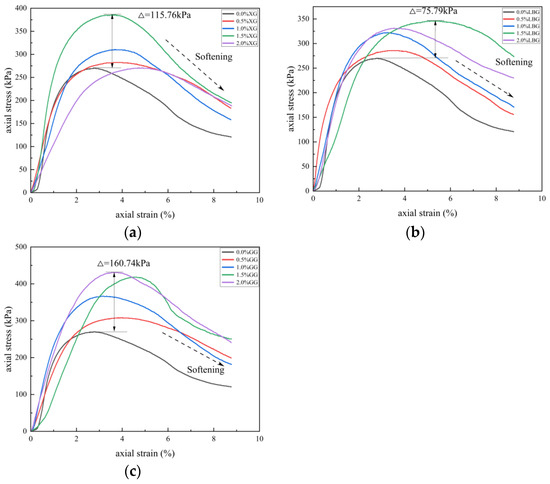

Figure 6 illustrates the effect of biopolymer binders on the UCS of GRS after 14 days of curing, at different contents. Both before and after treatment, the stress–strain curves of GRS exhibited strain-softening behavior, indicating that the addition of biopolymers did not significantly alter the soil’s mechanical behavior. Although the stress–strain curves generally displayed a strain-softening trend, the degree and characteristics of softening varied with different biopolymer contents. At low biopolymer content, the strain-softening phenomenon was more gradual. However, as the biopolymer content increased, the rate of decline after reaching peak stress accelerated. The value of ∆ in the figure indicates the difference in unconfined compressive strength between the soil treated with biopolymers and the untreated soil.

Figure 6.

Stress–strain curves of biopolymer-treated soil: (a) XG; (b) LBG; and (c) GG.

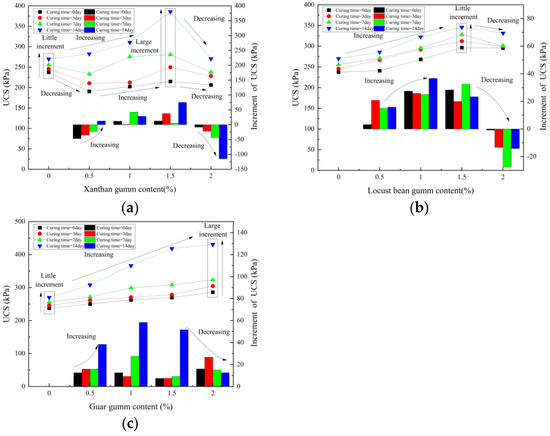

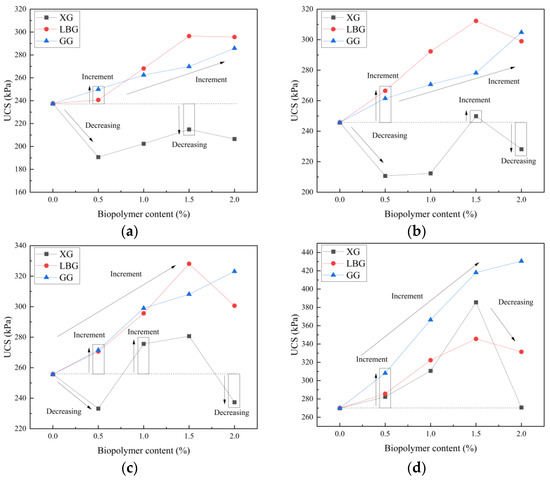

The unconfined compressive strength of soil treated with biopolymer at different contents is shown in the line chart in Figure 7, and the unconfined compressive strength increment between the current and previous content is shown in the bar chart in Figure 7. Under short-term curing, the UCS of GRS treated with XG initially decreased, then increased, and finally decreased again as the XG content increased. After longer curing periods, the UCS followed a trend of first decreasing and then increasing with the increasing XG content. The effect of XG content on the strength of GRS differed from that observed in other types of soil [32], suggesting that the influence of XG varies across different soil types. As LBG content increased, the compressive strength of GRS initially increased and then decreased, peaking at 1.5% LBG content. The addition of LBG enhanced the strength of both GRS and other types of soil, though the growth trends varied [33]. As GG content increased, the compressive strength of GRS generally showed an upward trend for the same curing times. The effect of GG on different soils varied, but it generally improved soil strength [34], which is consistent with the findings of this study. However, for some soils, low levels of GG may reduce strength [15]. The strain value corresponding to peak intensity increased after treatment with XG, and the rate of stress decrease in XG-treated soil was slower than in untreated soil. This study confirms that the reinforcing effect of XG and LBG in GRS has an optimal content, consistent with previous research [35]. This indicates that the reinforcing effect of biopolymers on soil does not necessarily improve with higher addition amounts. The observed trends in GRS are important for practical engineering applications. For instance, in road foundation solidification, the optimal amount of biopolymer can be determined based on the required strength, ensuring project quality while minimizing material waste.

Figure 7.

UCS of biopolymer-treated soil at different contents: (a) XG; (b) LBG; and (c) GG.

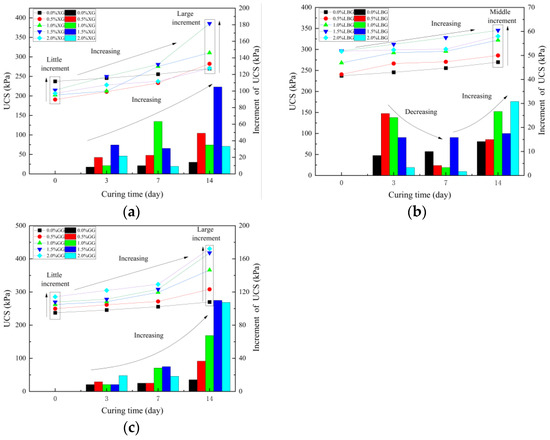

The unconfined compressive strength of soil treated with biopolymer at different curing times is shown in the line chart in Figure 8, and the unconfined compressive strength increment between the current and previous curing times is shown in the bar chart in Figure 8. Regardless of the XG content, the UCS of the soil gradually increases with curing time. In the early stages, the growth in compressive strength is relatively slow. As curing continues, the internal particle structure of the soil gradually stabilizes, resulting in progressive increases in strength. When LBG content is fixed, the UCS of the soil shows an overall upward trend with extended curing time. In the initial curing stage (0–3 days), strength increase is slow due to incomplete reactions between LBG and soil particles. Between 3 and 7 days, the strength growth accelerates, indicating that physical and chemical reactions between LBG and soil particles intensify, thereby stabilizing the soil structure. From 7 to 14 days, strength continues to increase but at a slower rate, suggesting that the reaction between LBG and soil particles has reached equilibrium. As GG content increases, the compressive strength of GRS generally shows an upward trend at the same curing time. On day 0 of curing, variations in GG content have minimal impact on compressive strength. However, as curing time increases, the cementing effect of GG becomes more prominent, leading to progressively greater improvements in compressive strength. This indicates that the reaction between GG and soil particles requires a certain amount of time to fully develop, thus enhancing the overall stability of the soil.

Figure 8.

UCS of biopolymer-treated soil at different curing times: (a) XG; (b) LBG; and (c) GG.

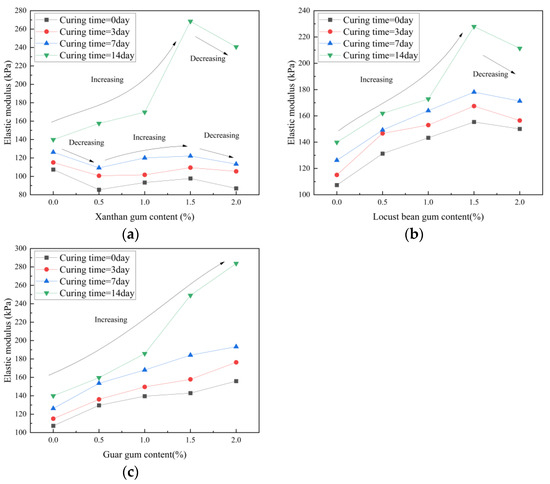

3.1.2. Elastic Modulus

This study evaluates the impact of biopolymers on the stiffness of GRS using the elastic modulus (E-value) [36], the tangent modulus corresponding to half of the peak strength is used, as shown in Figure 9. The trend in the E-value of biopolymer-treated soil follows a pattern similar to that of UCS but with different growth rates. In the short-term curing stage, the E-value of XG-treated soil initially decreases, then increases, and subsequently decreases again, always remaining lower than that of untreated GRS. However, as the curing time increases, the E-value of XG-treated soil first increases and then decreases, always remaining higher than that of untreated soil. This indicates that long-term curing significantly enhances the stiffness of soil treated with XG. Specifically, soil treated with 1.5% XG shows the most significant enhancement in stiffness. The E-value of XG-treated soil clearly demonstrates time dependence on GRS. For LBG and GG treatments, the E-value of the soil is generally higher than that of untreated GRS and gradually increases with curing time. Soil treated with 1.5% LBG exhibits the highest stiffness, while GG at a 2% content shows the most substantial effect. Overall, among the three biopolymers, GG-treated soil demonstrates the highest stiffness.

Figure 9.

Elastic modulus of biopolymer-treated GRS: (a) XG; (b) LBG; and (c) GG.

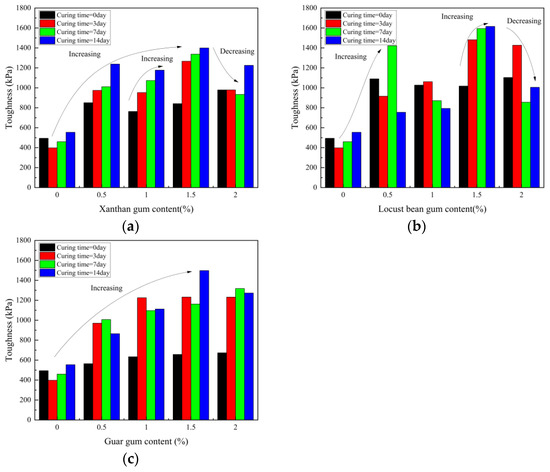

3.1.3. Toughness Index

To better understand and quantify the toughening characteristics in the post peak region, the load axis of the load deformation diagram was normalized with respect to the peak load. To focus only on the post peak behavior, a dimensionless split tensile toughness index value (TI value) is defined as follows:

where dp = deformation at peak load Pmax; d = any deformation that is greater than the dp value; Ap = area under the normalized curve up to the peak; and Ad = area under the normalized curve up to the deformation ratio d/dp. This study investigates the toughening effect of biopolymers on GRS using the TI value, which is calculated based on the equal strain values derived from the stress–strain curve [37], as shown in Figure 10. The results reveal that the addition of biopolymers significantly enhances the toughness of GRS, with the TI value exhibiting relatively stable changes over time as the curing period progresses. Soil treated with XG showed a substantial increase in TI value on day 0, and the value continued to rise as curing time increased. The toughening effect of XG intensified with its increasing content, but when the XG content surpassed 1.5%, the TI value experienced a slight decrease.

Figure 10.

Toughness index of biopolymer-treated GRS: (a) XG; (b) LBG; and (c) GG.

The toughening effect of LBG follows a similar pattern to that of XG, but LBG is less sensitive to variations in curing time. When the content of LBG exceeds 1.5%, the TI value significantly decreases. At 1.0% LBG, the growth rate of the TI value noticeably slows compared to 0.5%, though the index still shows an upward trend. At 1.5%, the TI value reaches a local peak, suggesting that the soil structure is nearing the limit of optimization achievable by LBG. When the LBG content exceeds 1.5%, excessive usage leads to a substantial decline in the TI value. This result indicates that, to optimize the toughening effect of LBG, its content should be carefully controlled, as overuse can have detrimental effects. A content range of 0.5% to 1.5% appears to be the optimal choice for enhancing soil toughness while avoiding the negative effects associated with excessive LBG usage.

For soils treated with GG, no significant difference in the TI value was observed at day 0 compared to the untreated GRS. This suggests that GG did not significantly enhance the soil’s toughness in the initial stage. However, as curing time progressed, the situation changed. After 3 days of curing, the TI value of the GG-treated soil significantly increased, As the GG content increased, the TI value of the soil also steadily improved, with the toughness performance remaining relatively stable and not easily influenced by the curing time. This characteristic makes GG advantageous in applications where curing time is not a major concern.

Overall, GG exhibits a distinct pattern in enhancing the toughness of GRS. At low concentrations, GG has a minimal impact on increasing the TI value. However, once the concentration reaches 1%, the TI value begins to rise significantly. As the curing time extends, the TI value of the GG-treated soil continues to grow steadily, without the slight or pronounced decrease in TI value seen with higher concentrations of XG and LBG.

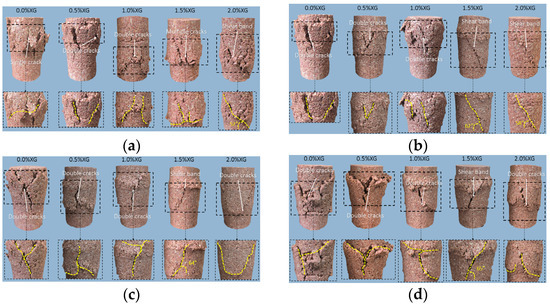

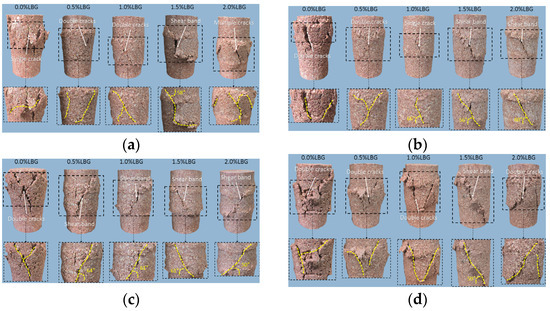

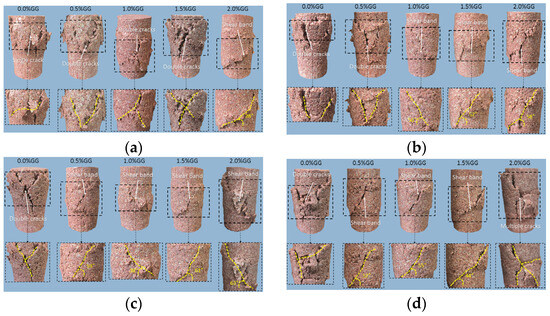

3.1.4. Failure Behavior

The failure modes of GRS treated with different biopolymers in unconfined compressive tests are presented in Figure 11, Figure 12 and Figure 13. From the Figures, it is evident that as the biopolymer content increases, the samples exhibit more cracks. Furthermore, as the content continues to rise, distinct shear bands become visible in the samples. This suggests that biopolymer content plays a significant role in influencing the compressive behavior of GRS. This failure characteristic is closely linked to the action mechanism of biopolymers in GRS. The addition of biopolymers alters the bonding mechanisms and stress distribution between soil particles. At low concentrations, more cracks are observed within the soil, indicating that the structural failure is more dispersed. This may be due to biopolymers acting as binders or fillers, which changes how soil particles are interconnected. As the biopolymer content increases, the bonding strength between soil particles gradually improves. However, this enhanced bonding can also lead to uneven stress distribution within the soil. As the biopolymer content rises further, distinct shear bands form in the sample under higher stress. The appearance of shear bands signifies that internal stress within the soil becomes concentrated, leading to preferential failure along the shear band areas. Under different curing times, the failure modes of the samples show no significant differences. This suggests that curing time has a minimal effect on the failure modes observed in the unconfined compressive tests.

Figure 11.

Failure behavior of XG-treated GRS in UCS test at different curing times: (a) 0; (b) 3; (c) 7; and (d) 14 days.

Figure 12.

Failure behavior of LBG-treated GRS in UCS test at different curing times: (a) 0; (b) 3; (c) 7; and (d) 14 days.

Figure 13.

Failure behavior of GG-treated GRS in UCS test at different curing times: (a) 0; (b) 3; (c) 7; and (d) 14 days.

3.2. Effect of Biopolymer on Shear Strength of Granite Residual Soil

3.2.1. Shear Strength

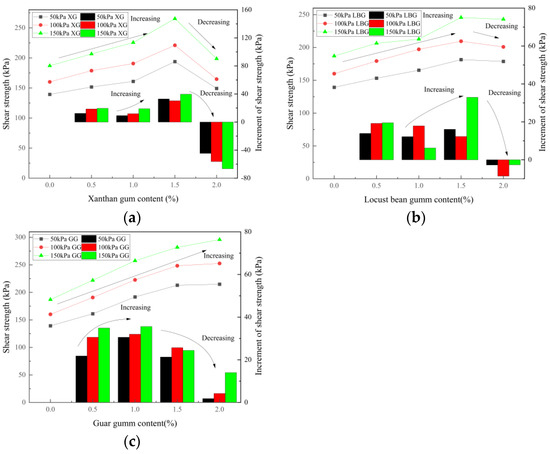

According to the results from the unconfined compressive tests, the sample strength peaked after 14 days of curing. Therefore, all samples were cured for 14 days before conducting the direct shear tests. The peak shear stresses obtained from the direct shear tests are presented in Figure 14. The shear strength of soil treated with biopolymer at different contents is shown in the line chart in Figure 14, and the shear strength increment between the current and previous contents is shown in the bar chart in Figure 14. The variation in soil shear strength follows a trend similar to that of the UCS.

Figure 14.

Shear strength of biopolymer-treated GRS: (a) XG; (b) LBG; and (c) GG.

Within the range of 0.5% to 1.5% XG content, a significant improvement in the shear strength of GRS is observed. Notably, the increase in shear strength is most pronounced at a 1.5% content. Specifically, under vertical stresses of 50 kPa, 100 kPa, and 150 kPa, the shear strength increases. At a vertical stress of 150 kPa, the shear strength reaches 265.3 kPa, marking an increase of 78.31 kPa compared to the untreated soil (186.99 kPa), which represents the highest increment. This indicates that XG has a strong cementing effect and can effectively enhance the soil’s shear strength. As vertical stress increases, the cementing effect of XG becomes more pronounced. Especially at a vertical stress of 150 kPa, the overall structure of the soil stabilizes, allowing it to withstand greater shear forces. However, at a 2.0% content, the shear strength decreases. This decline is especially noticeable under vertical stresses of 100 kPa and 150 kPa. Excessive XG may lead to local aggregation within the soil, disrupting the optimal interaction between particles. This disruption can compromise the stability of the soil structure, resulting in a reduction in shear strength.

In the application of LBG, the shear strength of GRS is significantly enhanced within the 0.5% to 1.5% content range, with the greatest improvement observed at 1.5%. The shear strength shows the most substantial increase under vertical stresses of 50 kPa, 100 kPa, and 150 kPa, particularly under 150 kPa, where it increased by 58.66 kPa, from 186.99 kPa to 245.65 kPa. LBG creates a binding network between soil particles, and as the content increases, this network strengthens, effectively binding the particles together and enhancing shear resistance. At 1.5% content, the LBG network is strong enough to resist shear forces, yielding the best performance. However, at 2.0% content, shear strength slightly decreases. Under vertical stresses of 100 kPa and 150 kPa, the shear strength at 2.0% is 8.59 kPa and 2.65 kPa lower than the shear strength at 1.5%, although still higher than untreated GRS. This suggests that excessive LBG content may negatively impact soil structure and reduce shear strength. Overall, LBG performance remains stable, peaking at 1.5%, with only a minimal decrease at 2.0%, indicating good stability.

GG, in contrast, consistently improved the shear strength of GRS at all concentrations, with the most significant enhancement at 2.0%. As GG content increased, the shear strength of the soil continued to improve, aligning with previous research [38]. Notably, under 150 kPa vertical stress, shear strength at 2.0% GG showed a more significant increase compared to 50 kPa and 100 kPa, indicating that GG is more effective in enhancing shear strength under higher vertical stresses. Across all experimental conditions, 2.0% GG exhibited the best performance.

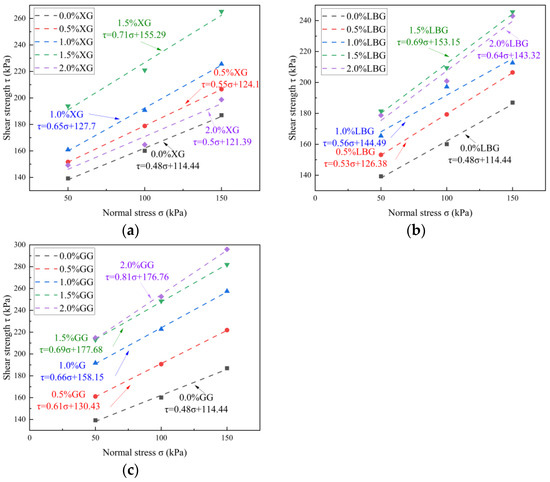

3.2.2. Direct Shear Strength Parameters

The relationship between peak shear stress (τ) and vertical stress (σ) for GRS treated with biopolymers was analyzed and is presented in Figure 15. The results show that biopolymers significantly influence the shear strength of GRS. As vertical stress increases, the shear strength of the soil exhibits a linear increase. Furthermore, the content of biopolymers affects the magnitude of the shear strength improvement, with different concentrations producing varying degrees of enhancement. Additionally, different types of biopolymers demonstrate distinct effects on the strength of GRS.

Figure 15.

Relationship between peak shear stress and vertical stress of biopolymer-treated GRS: (a) XG; (b) LBG; and (c) GG.

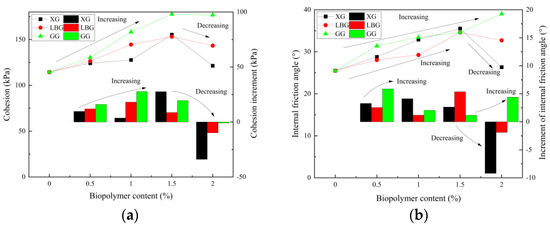

Based on the intercept and slope of the fitted line in Figure 15, the cohesion and internal friction angle of the soil were calculated and are shown in Figure 16. The shear strength index of soil treated with biopolymer at different contents is shown in the line chart in Figure 16, and the shear strength index increment between the current and previous contents is shown in the bar chart in Figure 16. The results indicate that different concentrations of XG (0.5%, 1.0%, 1.5%) progressively increased the soil’s cohesion. At a 1.5% concentration, the cohesion reached 155.29 kPa, significantly higher than the GRS cohesion of 114.44 kPa. However, at 2% XG content, the cohesion decreased to 121.39 kPa, suggesting that beyond a certain threshold, the thickening effect weakens. Excessive XG may affect the bonding force between particles, reducing cohesion. The thickening effect of LBG is also notable. Within the range of 0.5% to 1.5%, cohesion steadily increased, reaching 153.15 kPa at 1.5%, which is comparable to XG. At 2%, however, LBG caused a slight decrease in cohesion, dropping to 143.32 kPa. This reduction is due to excessive LBG, which leads to over-bonding between particles, affecting water absorption and soil stability. GG outperformed both XG and LBG in thickening effect. Cohesion continuously increased within the 0.5% to 1.5% range, reaching 177.68 kPa at 1.5%. At 2%, GG caused only a slight decrease, maintaining a high cohesion of 176.76 kPa, indicating that GG has a strong and stable effect in enhancing cohesion.

Figure 16.

Cohesion and internal friction angle of biopolymer-treated GRS: (a) cohesion; and (b) internal friction angle.

The incorporation of XG significantly increased the soil’s internal friction angle. Within the addition range of 0.5% to 1.5%, the internal friction angle steadily rose from 25.5° to 35.54°, demonstrating XG’s role in enhancing the soil’s shear strength and friction properties. However, when the XG content increased to 2%, the internal friction angle dropped to 26.34°. This decline may be attributed to the high XG content disrupting the soil structure, reducing particle contact, and lowering the friction angle. Similarly, the addition of LBG improved the internal friction angle, reaching 34.61° at 1.5%. Like XG, LBG showed a slight reduction in friction angle at 2%, decreasing to 32.72°. This could be due to excessive cementation, which reduces particle friction and lowers the internal friction angle. The incorporation of GG had the most significant impact on increasing the internal friction angle. At 0.5%, the internal friction angle rose to 31.38°, and at 2%, it further increased to 39.01°. This shows a consistent and stable improvement, indicating that GG is particularly effective in enhancing the soil’s friction properties. In contrast, XG and LBG displayed reduced effects at the 2% concentration.

4. Discussion

4.1. Effects of Biopolymers on Macroscale

After longer curing times, the UCS of the XG-treated soil was generally higher than that of untreated GRS, indicating that extended curing time can effectively enhance the soil’s stiffness. While short-term curing slightly reduced strength, the failure strain of the soil generally increased. The addition of LBG significantly improved compressive strength at different curing times, with an increase in content also leading to a rise in failure strain. This suggests that LBG enhances both the stiffness and toughness of the soil. Notably, in the 1.0% to 2.0% content range, the improvement in UCS was particularly significant, with the most notable effect at 1.5%. Adding LBG (especially at 1.5%) significantly enhanced the soil’s compressive strength. However, when LBG content reached 2.0%, the strength improvement effect began to level off and even slightly decrease. When the content of guar gum is too high, it can make the particle surfaces overly smooth, increasing the relative movement or sliding between particles, which reduces friction. Excessive guar gum may not disperse uniformly, leading to the formation of localized colloid-rich regions. These regions of colloid are prone to deformation under compression, causing discontinuous interfaces within the soil, reducing the overall structural stability and leading to a decrease in compressive strength. As GG content increased, the UCS of the soil initially increased and then stabilized. At lower GG contents, the bonding effect of GG helped form a more stable particle structure, effectively resisting external forces and leading to a gradual increase in UCS. Once GG content reached a certain level, the soil particles became fully coated by GG. At this point, further increases in GG content had little effect on structural stability, and the UCS stabilized.

The effect of XG content and curing time on the soil’s compressive strength is not independent; rather, there is an interaction between these two factors. For instance, when the XG content is low, extending the curing time does not significantly increase the soil’s compressive strength. Conversely, when the XG content is high, insufficient curing time fails to achieve ideal compressive strength. Understanding this interaction is crucial for optimizing the soil’s compressive strength by controlling both XG content and curing time. The variation in LBG content shows a relatively stable trend in the soil’s compressive strength across different curing times. For different LBG contents, as curing time increases, the soil’s compressive strength steadily increases before reaching a point of stabilization. GG content and curing time are also interrelated, impacting the soil’s compressive strength. When GG content is low, extending the curing time does not significantly improve compressive strength. However, when GG content reaches a certain level, insufficient curing time limits the potential improvement in compressive strength. Thus, an in-depth study of the interaction between GG content and curing time is necessary to effectively enhance the soil’s compressive strength.

The UCS of GRS treated with different biopolymers is shown in Figure 17. As the curing time increases, the UCS of both the untreated GRS and the soils modified with XG, LBG, and GG generally exhibit an upward trend. Specifically, the effect of XG on GRS shows some fluctuation. During the early curing period (e.g., 0 and 3 days), the UCS of the XG-treated soil is lower than that of the untreated soil. This could be attributed to the fact that the addition of XG disrupts the hydration process of the soil particles, weakening the bond between them and thus reducing the compressive strength. However, as the curing time progresses, the beneficial effects of XG begin to emerge. Notably, after 3 days of curing, an improvement is observed. After 14 days, the UCS of the soil with 1.5% XG is significantly higher than that of the untreated GRS, indicating that XG at this concentration can substantially enhance the soil’s compressive strength. This improvement is due to the formation of a dense network structure between the XG molecular chains and the soil particles, which effectively increases the soil’s bearing capacity. Additionally, the hydroxyl (–OH) and ether bonds (–O–) in the XG molecules interact with free iron oxide particles in the GRS, strengthening the bonding force between particles and consequently enhancing the compressive strength.

Figure 17.

UCS of biopolymer-treated GRS: (a) 0; (b) 3; (c) 7; and (d) 14 days.

LBG significantly enhances the UCS of GRS. Throughout the curing periods, the UCS of the modified soil increases as the content of LBG rises. Specifically, after 14 days of curing, the compressive strength of the soil modified with 1.5% LBG is substantially higher than that of the untreated soil, demonstrating the positive effect of LBG in improving the compressive strength of GRS. LBG forms a “network” structure with soil particles through physical adsorption, hydrogen bonding, and electrostatic attraction, thereby improving the bond between soil particles and increasing the soil’s compressive strength. The sugar and hydroxyl groups in the LBG molecules interact with the hydroxyl groups on iron oxide particles, further enhancing the bonding between soil particles and improving the moisture retention capacity. The combination of LBG with free iron oxide results in a more compact and stable soil structure, ultimately enhancing its compressive strength.

GG also affects the UCS of GRS to varying degrees depending on the curing time and concentration. As both the curing time and GG concentration increase, the compressive strength of the modified soil improves significantly. After 14 days of curing, the UCS of the soil modified with 2% GG is noticeably higher than that of the untreated soil, indicating the significant role of GG in enhancing the compressive strength of GRS. The molecular structure of GG, rich in hydroxyl and sugar groups, interacts with iron oxide particles similarly to LBG, substantially increasing the soil’s compressive strength.

In conclusion, under appropriate concentrations and curing times, XG, LBG, and GG can all effectively enhance the UCS of GRS. Among these, GG provides the most significant improvement at higher concentrations and longer curing times, while LBG shows a relatively stable enhancement across all curing stages. XG, on the other hand, improves soil compressive strength most effectively with longer curing times and optimal concentrations. Overall, as the curing time increases, the compressive strength of the soil modified with various biopolymers tends to increase. Under the same curing time, soils modified with LBG and GG generally exhibit higher compressive strength, whereas soils modified with XG show lower compressive strength. These differences may be attributed to the unique chemical structures and properties of the biopolymers, which lead to varying interaction mechanisms with GRS and consequently affect the soil’s mechanical properties.

The mechanisms by which these biopolymers affect the soil’s E-value are closely related to their molecular structure and chemical properties. The effect of biopolymers on the E-value of different soils also shows distinct differences [35,39]. The molecules of XG have a unique helical structure, which may require time to adjust during the short-term curing period in order to interact with soil particles, leading to complex changes in the E-value. After long-term curing, XG can effectively fill the voids between soil particles, enhancing the connections between particles and improving the soil’s stiffness. In contrast, the molecular structures of LBG and GG are more favorable for tightly binding with soil particles during the early stages of curing, resulting in a higher E-value at the beginning of the curing process. Over time, the E-value tends to steadily increase.

The most pronounced improvement in the TI value occurred at 0.5% XG content. As the content increased further, the rate of improvement gradually slowed. This behavior is attributed to the molecular structure and action mechanism of XG in soil. XG molecules feature a unique long-chain structure, which, at low concentrations, effectively fills the voids between soil particles, enhancing the bonding force and significantly improving the soil’s toughness. The optimal effect occurs when the content is at 0.5%, where filling and bonding are most effective. However, as the XG content increases beyond 0.5%, the molecules may begin to entangle or locally aggregate, weakening the toughening effect. At concentrations exceeding 1.5%, this entanglement or aggregation becomes more pronounced, leading to a slight decrease in the TI value. The effect of LBG on soil toughness was similar to that of XG. At the age of 0 days, this could be due to GG not fully interacting with the soil particles when first applied, and factors such as the soil’s moisture distribution and interparticle void structure may have temporarily hindered GG’s strengthening effect. At the age of 3 days, GG molecules gradually penetrated the soil particles and interacted with them through hydrogen bonds and other forces, thereby altering the soil’s structural characteristics.

Gum substances such as XG, LBG, and GG improve soil cohesion by strengthening the bonding force between particles. These colloidal substances fill soil voids and adhere to particle surfaces, forming a cemented structure that boosts cohesion. The molecular structure, intermolecular forces, and affinity for soil particles vary among gums, leading to different effects. GG, with its longer molecules, stronger water absorption, and superior adhesive properties, forms more stable cemented structures, resulting in the highest cohesion improvement. At lower dosages, gums effectively fill gaps between soil particles, enhancing bonding and cohesion. However, excessive gum concentrations can cause over-bonding, reducing friction between particles and potentially weakening cohesion. At a 2% concentration, XG and LBG show decreased cohesion, while GG maintains stable performance.

XG, LBG, and GG, as natural polymers, improve cohesion between soil particles and enhance soil stability by forming cementitious structures. However, excessive concentrations of these colloids may reduce friction between particles, which negatively affects the soil’s mechanical properties. GG, with its longer molecular chains and stronger water absorption, maintains superior performance even at higher concentrations, especially in improving both the internal friction angle and cohesion.

Compared with other common stabilizers (such as chemical curing agents, microbial curing, etc.), biopolymers have unique advantages in improving the mechanical properties of granite residual soil, such as excellent environmental protection, sustainability, and high strength enhancement efficiency shown in the soil stabilization process.

4.2. Effects of Biopolymers on Microscale

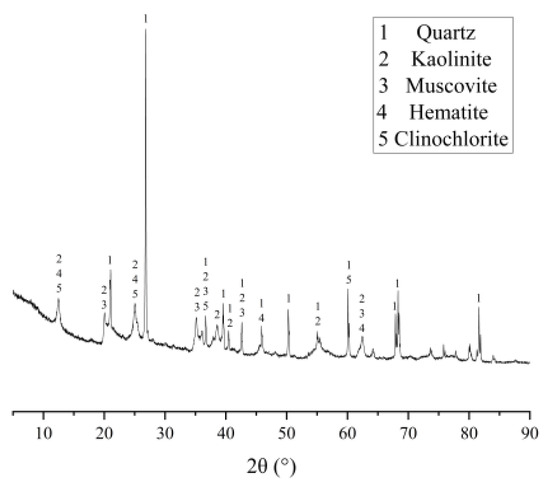

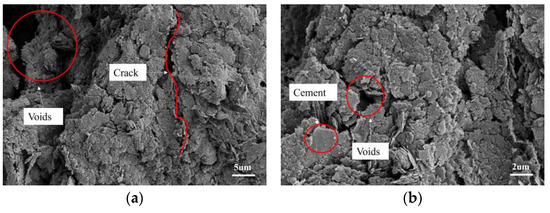

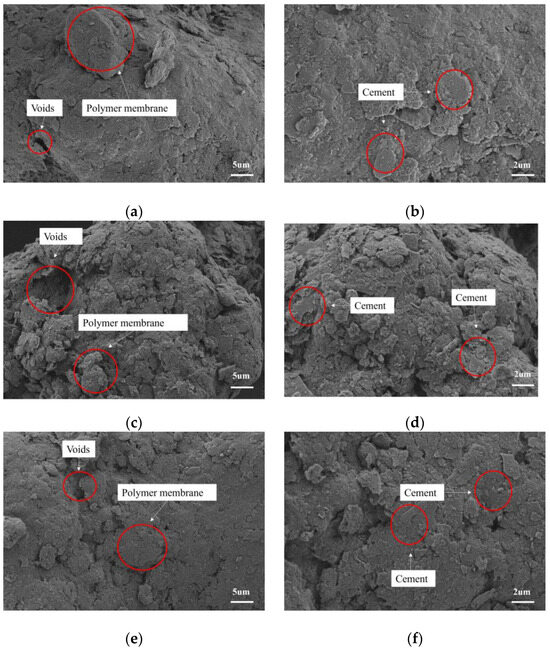

The XRD analysis results of GRS are shown in Figure 18. The scanning range of XRD is from 5° to 90°. Based on the crystalline characteristics of the peaks, the main mineral components of the soil are quartz and kaolinite, along with other minerals such as mica, iron minerals, and chlorite. However, quartz and kaolinite are the predominant components. Since SEM requires the sample to have good conductivity, a thin metallic coating was applied to the soil surface to enhance conductivity. The accelerating voltage was set to 15 kV, and images were generated by detecting secondary electrons emitted from the sample surface. The magnifications were 2000 times and 5000 times respectively. The SEM image of GRS is shown in Figure 19, revealing that most soil particles are irregular and angular, indicating their origin from the rock weathering process. The particle surfaces are covered with cracks and contain large pores. Additionally, a bonding phenomenon between particles is observed, typically composed of iron oxides or clay minerals. The SEM results of GRS treated with biopolymers are shown in Figure 20. After treatment, the soil particles appear irregular and sub-angular, suggesting that the biopolymers have altered the particle morphology to some extent. A coating film has formed on the particle surfaces, making them appear smoother and more continuous. Compared to LBG, XG and GG treatment resulted in even smoother surfaces on the soil particles. The filling effect of the biopolymers also reduced the porosity of the soil particles.

Figure 18.

XRD results of GRS.

Figure 19.

SEM results of GRS: (a) 5 um; (b) 2 um.

Figure 20.

SEM results of biopolymer-treated GRS: (a) XG 5 um; (b) XG 2 um; (c) LBG 5 um; (d) LBG 2 um; (e) GG 5 um; (f) GG 2 um.

4.3. Microscopic Mechanism of Biopolymers

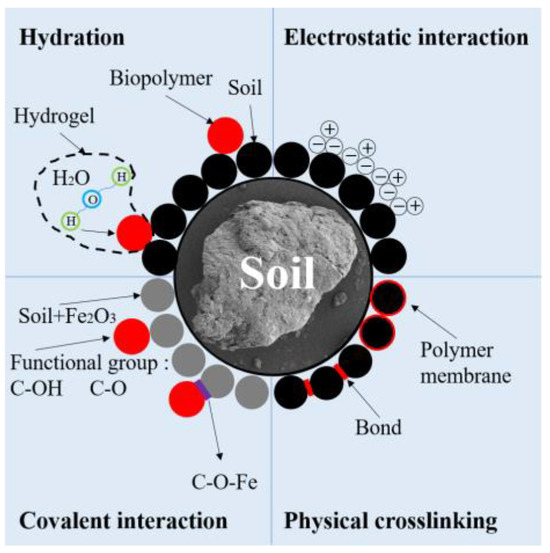

As shown in Figure 21, when biopolymers combine with water, they form a gel-like substance that enhances the bonding between soil particles. This colloidal effect contributes to the formation of a more stable soil structure and improves the soil’s aggregate composition. The biopolymers can form a network structure upon interacting with water, which further enhances the soil’s water retention capacity. XG, LBG, and GG all contain hydrophilic carboxyl or hydroxyl groups, as well as hydrophobic sugar chain components. These structures can undergo physical cross-linking with the surface of soil particles, improving the soil’s water and gas properties. All three biopolymers are rich in hydroxyl (–OH) functional groups, which form hydrogen bonds with water molecules, facilitating interactions with soil moisture. As shown in Figure 2, Figure 3 and Figure 4, GG has the highest hydroxyl content, followed by LBG, with XG having the lowest. The strength of the soil treated with biopolymers correlates with their hydroxyl content. GG-treated soil exhibits the highest strength, followed by LBG, and XG shows the weakest strength. A higher hydroxyl content in a biopolymer leads to greater strength in treating the soil. The hydrophobic portion of the biopolymer interacts with hydrophobic minerals in the soil, enhancing the soil’s hydrophobicity and reducing moisture loss. Moreover, the combination of hydrophilic and hydrophobic sections in the biopolymer forms water–soil–biopolymer complexes in the soil. On the surface of soil particles, the biopolymer adsorbs moisture through its hydrophilic groups, while its hydrophobic segments interact with the soil particles. XG, LBG, and GG all contain functional groups such as C–OH and C–O, which interact with the soil. In GRS containing iron minerals, iron oxide reacts with these functional groups through acid-base interactions, leading to the formation of covalent bonds, such as C–O–Fe bonds [40]. Biopolymers interact with iron oxide particles through both covalent and non-covalent electrostatic interactions, which enhances the macro-stability and coagulation effect of the soil [41]. Additionally, biopolymers typically contain charged groups, which impart a certain charge density in aqueous solutions. These charged groups can attract soil particles via electrostatic forces, adsorbing onto the surface of the particles. This interaction forms charge pairs or complexes, stabilizing the connections between soil particles and improving the overall soil structure. Through physical adsorption, biopolymers bind with soil particles, creating a stable cross-linked structure. This cross-linking effect increases the cohesion between soil particles, leading to a more compact soil structure. The physical cross-linking also helps fill the tiny pores in the soil, further optimizing the soil’s overall structure. Biopolymers interact with the mineral components in granite residual soils at the microscopic scale, forming more stable compounds.

Figure 21.

Interaction between biopolymers and GRS.

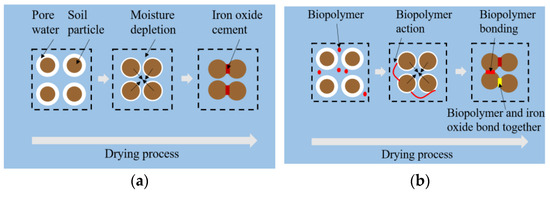

As shown in Figure 22 are the changes in moisture caused by water loss during the curing process are another key factor influencing the effectiveness of biopolymer treatment. In GRS, pore water is evenly distributed in the initial state. As the soil moisture gradually decreases, the adhesive force between soil particles is mainly provided by iron oxide. For soil treated with biopolymers, a thin film of biopolymer initially forms on the surface of the soil particles. As moisture decreases, the biopolymer enhances its bonding effect. The adhesive force between soil particles gradually transitions, with the combination of iron oxide, biopolymer gel, and iron oxide–biopolymer complexes providing the primary bonding force.

Figure 22.

Curing differences between GRS and biopolymer-treated soil: (a) GRS; (b) biopolymer-treated soil.

5. Conclusions

This study investigates the impact of biopolymers (XG, LBG, and GG) on the mechanical properties of GRS. The analysis focuses on variations in UCS and shear strength under different biopolymer concentrations (0%, 0.5%, 1.0%, 1.5%, and 2.0%) and curing times (0, 3, 7, and 14 days). UCS and direct shear tests were conducted on samples with varying biopolymer contents and curing times to evaluate the macro-mechanical properties of the soil. Additionally, SEM and XRD techniques were employed to explore the effects of biopolymers on the microstructure of GRS and the mechanisms involved. The main conclusions are as follows:

- (1)

- Biopolymers significantly improved the strength of GRS, enhancing both its E-value and TI value. The beneficial effect of biopolymers became more pronounced as the curing time increased.

- (2)

- Each biopolymer exhibited an optimal content for improving GRS strength, with variations between biopolymers. The optimal concentrations for XG and LBG were 1.5%, while for GG, it was 2.0%.

- (3)

- Among all the biopolymers, GG had the most significant impact on improving the strength of GRS. With the addition of 2.0% GG, the UCS and shear strength of the treated soil increased by 1.6 and 1.58 times, respectively, compared to untreated GRS.

- (4)

- The content of biopolymers influenced the macroscopic failure behavior of the soil. As biopolymer content increased, the failure shear band in the UCS test became more distinct.

- (5)

- Biopolymers had a more significant effect on improving the cohesion of GRS than the internal friction angle. After treatment with XG, LBG, and GG, the soil cohesion increased by 1.36, 1.34, and 1.55 times, respectively, compared to untreated soil.

However, the maximum curing time in this study was 14 days. Future research could consider extending the curing period to explore the changes in the mechanical properties of granite residual soil over a longer timescale with biopolymers. Additionally, the optimal concentration of guar gum was not determined in this study. The research primarily focused on the effect of a single biopolymer, and only three types of biopolymers were selected. Future work could further explore the synergistic effects of multiple biopolymers and identify the optimal mixing ratio to enhance the mechanical properties of the soil. In practical engineering, granite residual soil may be influenced by a combination of environmental factors, such as temperature, rainfall, and wet–dry cycles. Future experiments could investigate the performance of biopolymer-modified soil under complex environmental conditions and analyze its long-term stability and durability.

Author Contributions

Writing—original draft, L.Y.; writing—review and editing, Y.L.; project administration, J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (52078195, U22A20232).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, X.; Zhang, X.; Kong, L.; Wang, G.; Lu, J. Disintegration of granite residual soils with varying degrees of weathering. Eng. Geol. 2022, 305, 106723. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X.; Kong, L.; Yin, S.; Xu, Y. Shear Strength Anisotropy of Natural Granite Residual Soil. J. Geotech. Geoenviron. Eng. 2022, 148, 04021168. [Google Scholar] [CrossRef]

- Li, C.; Kong, L.; An, R. Evolution of cracks in the shear bands of granite residual soil. J. Rock Mech. Geotech. Eng. 2022, 14, 1956–1966. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Q.; Xu, H.; Wang, Y.; Tang, L. Influences of different modifiers on the disintegration of improved granite residual soil under wet and dry cycles. Int. J. Min. Sci. Technol. 2022, 32, 831–845. [Google Scholar] [CrossRef]

- Feng, D.; Wang, Y.; Chen, D.; Liang, S. Experimental study on the influence mechanism of clay particles on the microbial treatment of granite residual soil. Constr. Build. Mater. 2024, 411, 134659. [Google Scholar] [CrossRef]

- Feng, D.; Yu, Y.; Wang, J.; Fang, C.; Liang, S. Experimental study on shear and disintegration resistance of MICP-treated residual granite soil. Environ. Earth Sci. 2024, 83, 179. [Google Scholar] [CrossRef]

- Liang, S.; Xiao, X.; Fang, C.; Feng, D.; Wang, Y. Experimental Study on the Mechanical Properties and Disintegration Resistance of Microbially Solidified Granite Residual Soil. Crystals 2022, 12, 132. [Google Scholar] [CrossRef]

- Ilman, B.; Balkis, A.P. Review on Biopolymer Binders as Renewable, Sustainable Stabilizers for Soils. Int. J. Geosynth. Ground Eng. 2023, 9, 49. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of Problematic Soils with Biopolymer—An Environmentally Friendly Soil Stabilizer. J. Mater. Civ. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Raj, N.; Selvakumar, S.; Soundara, B.; Kulanthaivel, P. Sustainable utilization of biopolymers as green adhesive in soil improvement: A review. Environ. Sci. Pollut. Res. 2023, 30, 118117–118132. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.-M.; Im, J.; Cho, G.-C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Cheng, Z.; Geng, X. Investigation of unconfined compressive strength for biopolymer treated clay. Constr. Build. Mater. 2023, 385, 131458. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.-C. Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.-C. Strengthening of Korean residual soil with β-1,3/1,6-glucan biopolymer. Constr. Build. Mater. 2012, 30, 30–35. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Saisree, S. Geotechnical behaviour of guar gum-treated soil. Soils Found. 2019, 59, 2155–2166. [Google Scholar] [CrossRef]

- Dehghan, H.; Tabarsa, A.; Latifi, N.; Bagheri, Y. Use of xanthan and guar gums in soil strengthening. Clean Technol. Environ. Policy 2018, 21, 155–165. [Google Scholar] [CrossRef]

- Vydehi, K.V.; Moghal, A.A.B. Effect of Biopolymeric Stabilization on the Strength and Compressibility Characteristics of Cohesive Soil. J. Mater. Civ. Eng. 2022, 34, 04021428. [Google Scholar] [CrossRef]

- Soldo, A.; Miletic, M. Durability against Wetting-Drying Cycles of Sustainable Biopolymer-Treated Soil. Polymers 2022, 14, 4247. [Google Scholar] [CrossRef]

- Asina, N.; Kavaz, D. Preparation and characterization of poly(ethylene glycol) dimethacrylate/methylcellulose hydrogels via photopolymerization for tissue engineering applications. J. Polym. Res. 2024, 31, 236. [Google Scholar] [CrossRef]

- Obaleye, M.; Kavaz, D.; Olaifa, J. Freeze-dried crosslinked anionic hydrogels composed of poly(vinyl pyrrolidone) and poly(vinyl alcohol): Synthesis, characterization and degradability performance. Acta Bioeng. Biomech. 2022, 24, 65–73. [Google Scholar] [CrossRef]

- Omoyeni, T.M.; Kavaz, D. Phytochemical screening of an essential oil-loaded PVA/GA hydrogel membrane for potential wound healing application. Int. J. Biol. Macromol. 2024, 283, 137711. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Zhang, J.; Jiang, T.; Wang, S.; Zhao, J.; Meng, Z. Water retention characteristics and vegetation growth of biopolymer-treated silt soils. Soil Tillage Res. 2023, 225, 105544. [Google Scholar] [CrossRef]

- Ni, J.; Li, S.-S.; Ma, L.; Geng, X.-Y. Performance of soils enhanced with eco-friendly biopolymers in unconfined compression strength tests and fatigue loading tests. Constr. Build. Mater. 2020, 263, 120039. [Google Scholar] [CrossRef]

- Soldo, A.; Miletić, M. Study on Shear Strength of Xanthan Gum-Amended Soil. Sustainability 2019, 11, 6142. [Google Scholar] [CrossRef]

- Lee, M.; Im, J.; Cho, G.C.; Ryu, H.H.; Chang, I. Interfacial Shearing Behavior Along Xanthan Gum Biopolymer-Treated Sand and Solid Interfaces and Its Meaning in Geotechnical Engineering Aspects. Appl. Sci. 2020, 11, 139. [Google Scholar] [CrossRef]

- Ayeldeen, M.K.; Negm, A.M.; El Sawwaf, M.A. Evaluating the physical characteristics of biopolymer/soil mixtures. Arab. J. Geosci. 2016, 9, 371. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.-C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Choi, S.-G.; Chang, I.; Lee, M.; Lee, J.-H.; Han, J.-T.; Kwon, T.-H. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, N.; Akram, O.; Fang, C.; Ghani, M.U.; Ijaz, Z.; Noshin, S.; Madni, M.F. Geotechnical behavior of high-plastic clays treated with biopolymer: Macro–micro-study. Environ. Earth Sci. 2023, 82, 91. [Google Scholar] [CrossRef]

- Lee, S.; Chang, I.; Chung, M.-K.; Kim, Y.; Kee, J. Geotechnical shear behavior of Xanthan Gum biopolymer treated sand from direct shear testing. Geomech. Eng. 2017, 12, 831–847. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019. (In Chinese)

- Sujatha, E.R.; Atchaya, S.; Sivasaran, A.; Keerdthe, R.S. Enhancing the geotechnical properties of soil using xanthan gum—An eco-friendly alternative to traditional stabilizers. Bull. Eng. Geol. Environ. 2020, 80, 1157–1167. [Google Scholar] [CrossRef]

- Shen, X.; Wang, L.; Yang, B.; Han, J.; Zhang, L. Effect of locust bean gum biopolymer on mechanical properties of organic soil. Environ. Earth Sci. 2024, 84, 34. [Google Scholar] [CrossRef]

- Rong, X.; Deng, S.; Liang, B.; Zhuang, J.; Yu, Y.; Wu, Z. Mechanical behavior and strengthening mechanism of loess stabilized with xanthan gum and guar gum biopolymers. Mater. Res. Express 2024, 11, 105305. [Google Scholar] [CrossRef]

- Ni, J.; Hao, G.-L.; Chen, J.-Q.; Ma, L.; Geng, X.-Y. The Optimisation Analysis of Sand-Clay Mixtures Stabilised with Xanthan Gum Biopolymers. Sustainability 2021, 13, 3732. [Google Scholar] [CrossRef]

- Liu, J.; Che, W.; Lan, X.; Hu, M.; Qi, M.; Song, Z.; Sun, M.; Jing, M.; Qian, W.; Qi, C. Performance and mechanism of a novel biopolymer binder for clayey soil stabilization: Mechanical properties and microstructure characteristics. Transp. Geotech. 2023, 42, 101044. [Google Scholar] [CrossRef]

- Sobhand, K.; Mashnad, M. Tensile Strength and Toughness of Soil-Cement-Fly-Ash Composite Reinforced with Recycled High-Density Polyethylene Strips. J. Mater. Civ. Eng. 2002, 14, 177–184. [Google Scholar] [CrossRef]

- Banne, S.P.; Kulkarni, S.; Baldovino, J.A. Effect of Guar Gum Content on the Mechanical Properties of Laterite Soil for Subgrade Soil Application. Polymers 2024, 16, 2202. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, N.; Ameer, M.F.; Ijaz, Z. Geotechnical properties of problematic expansive subgrade stabilized with xanthan gum biopolymer. Road Mater. Pavement Des. 2022, 24, 1869–1883. [Google Scholar] [CrossRef]

- Armistead, S.J.; Rawlings, A.E.; Smith, C.C.; Staniland, S.S. Biopolymer Stabilization/Solidification of Soils: A Rapid, Micro-Macro, Cross-Disciplinary Approach. Environ. Sci. Technol. 2020, 54, 13963–13972. [Google Scholar] [CrossRef]

- Armistead, S.J.; Smith, C.C.; Staniland, S.S. Sustainable biopolymer soil stabilisation: The effect of microscale chemical characteristics on macroscale mechanical properties. Acta Geotech. 2022, 18, 3213–3227. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).