Research Advancements in the Mechanical Performance and Functional Properties of Nanocomposites Reinforced with Surface-Modified Carbon Nanotubes: A Review

Abstract

1. Introduction

2. Production of CNTs

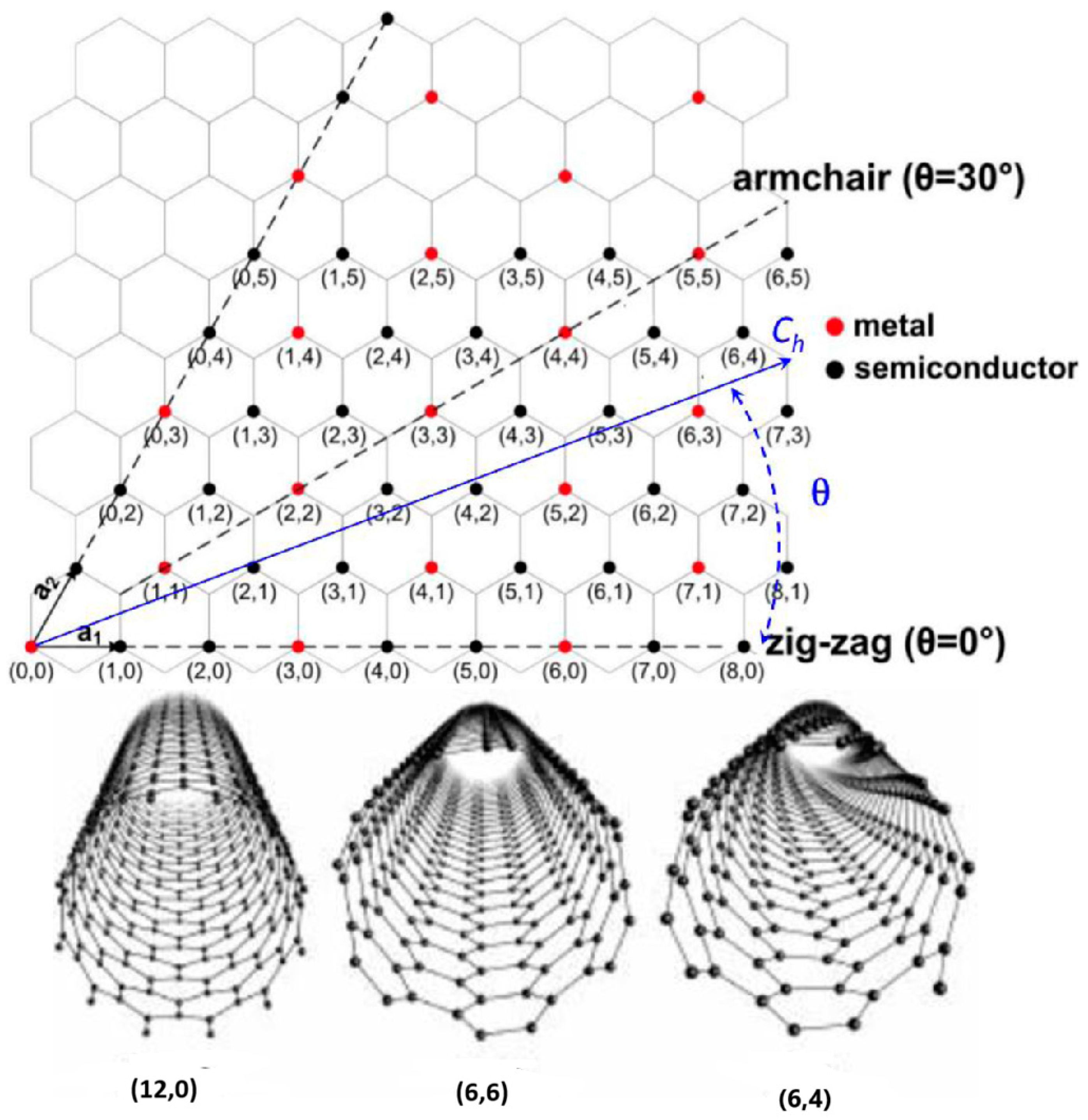

2.1. Single-Walled CNTs (SWCNTs)

2.2. Multi-Walled CNTs (MWCNTs)

3. Composite Matrices and Applications

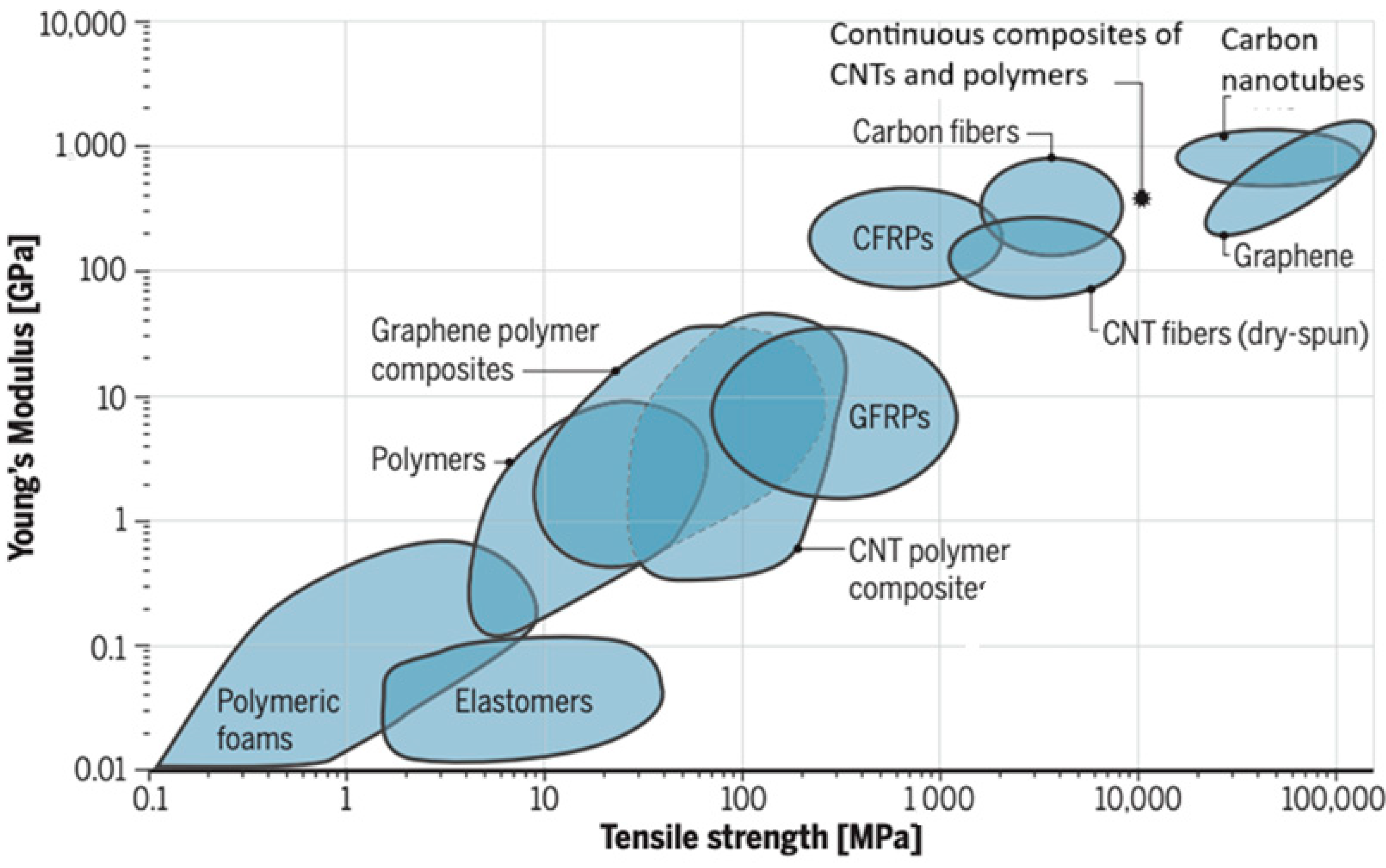

3.1. Polymers

3.2. Metals

3.3. Cement

4. Future Research

5. Conclusions

Funding

Conflicts of Interest

References

- Inagaki, M. Carbon Materials Science and Engineering: From Fundamentals to Applications; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Yasuda, E.; Inagaki, M.; Kaneko, K.; Endo, M.; Oya, A.; Tanabe, Y. Carbon Alloys: Novel Concepts to Develop Carbon Science and Technology; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Zhang, J.; Terrones, M.; Park, C.R.; Mukherjee, R.; Monthioux, M.; Koratkar, N.; Kim, Y.S.; Hurt, R.; Frackowiak, E.; Enoki, T.; et al. Carbon science in 2016: Status, challenges and perspectives. Carbon 2016, 98, 708–732. [Google Scholar] [CrossRef]

- Jagadeesan, A.; Krithiga, T.; Venkatesan, D. Carbon Nanotubes: Synthesis, Properties and Applications; IntechOpen: London, UK, 2020. [Google Scholar]

- Ebbesen, T.W. Carbon nanotubes. Annu. Rev. Mater. Sci. 1994, 24, 235–264. [Google Scholar] [CrossRef]

- Dresselhaus, M.; Dresselhaus, G.; Avouris, P. (Eds.) Carbon Nanotubes; Springer Netherlands: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Ajayan, P.; Otto, Z. Carbon nanotubes: Synthesis, structure, properties, and applications. In Applications of Carbon Nanotubes; Malvern Panalytical: Chennai, India, 2001; pp. 391–425. [Google Scholar]

- De Volder, M.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef]

- Silvestro, L.; Gleize, P.J.P. Effect of carbon nanotubes on compressive, flexural and tensile strengths of Portland cement-based materials: A systematic literature review. Constr. Build. Mater. 2020, 264, 120237. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Danoglidis, P.A.; Falara, M.A.; Nitodas, S.F. Fresh and mechanical properties and multi-functionality of CNT nanomodified ordinary Portland cement mortars. Cem. Concr. Compos. 2017, 82, 137. [Google Scholar] [CrossRef]

- Shoukat, R.; Muhammad, I. Carbon nanotubes: A review on properties, synthesis methods and applications in micro and nanotechnology. Microsyst. Technol. 2021, 27, 4183–4192. [Google Scholar] [CrossRef]

- Ghasempour, R.; Hamid, N. CNT basics and characteristics. In Carbon Nanotube-Reinforced Polymers; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–24. [Google Scholar]

- Nasiri, A.; Shariaty-Niasar, M.; Rashidi, A.; Khodafarin, R. Effect of CNT structures on thermal conductivity and stability of nanofluid. Int. J. Heat Mass Transf. 2012, 55, 1529–1535. [Google Scholar] [CrossRef]

- Lee, J. Carbon Nanotube-Based Membranes for Water Purification. Nanoscale Materials in Water Purification; Elsevier: Amsterdam, The Netherlands, 2019; pp. 309–331. [Google Scholar]

- Wu, Z.; Zhao, Y.; Yang, K.; Guan, J.; Wang, S.; Gu, Y.; Li, M.; Feng, Y.; Feng, W.; Ritchie, R.O. Enhancing the Mechanical Performance of Fiber-Reinforced Polymer Composites Using Carbon Nanotubes as an Effective Nano-Phase Reinforcemen. Adv. Mater. Interfaces 2023, 10, 2201935. [Google Scholar] [CrossRef]

- Wang, G.; Liu, L.; Zhang, Z. Interface mechanics in carbon nanomaterials-based nanocomposites. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106212. [Google Scholar] [CrossRef]

- Mukunda, S.G.; Boppana, S.B.; Palani, I.A.; Dayanand, S.; Aravinda, T. Characterization of AZ31 metal matrix composites reinforced with carbon nanotubes. Sci. Rep. 2023, 13, 17786. [Google Scholar] [CrossRef] [PubMed]

- Esawi; Amal, M.K.; Mahmoud, M. Carbon nanotube reinforced composites: Potential and current challenges. Mater. Des. 2007, 28, 2394–2401. [Google Scholar] [CrossRef]

- Mittal, V. Carbon nanotubes surface modifications: An overview. In Surface Modification of Nanotube Fillers; Wiley: Hoboken, NJ, USA, 2011; pp. 1–23. [Google Scholar]

- Kim, S.; Kim, T.; Kim, Y.S.; Choi, H.S.; Lim, H.J.; Yang, S.J.; Park, C.R. Surface modifications for the effective dispersion of carbon nanotubes in solvents and polymers. Carbon 2012, 50, 3–33. [Google Scholar] [CrossRef]

- Atif, M.; Afzaal, I.; Naseer, H.; Abrar, M.; Bongiovanni, R.M. Surface modification of carbon nanotubes: A tool to control electrochemical performance. ECS J. Solid State Sci. Technol. 2020, 9, 041009. [Google Scholar] [CrossRef]

- Wang, N.; Pandit, S.; Ye, L.; Edwards, M.; Mokkapati, V.; Murugesan, M.; Kuzmenko, V.; Zhao, C.; Westerlund, F.; Mijakovic, I.; et al. Efficient surface modification of carbon nanotubes for fabricating high performance CNT based hybrid nanostructures. Carbon 2017, 111, 402–410. [Google Scholar] [CrossRef]

- Mora, A.; Verma, P.; Kumar, S. Electrical conductivity of CNT/polymer composites: 3D printing, measurements and modeling. Compos. Part B Eng. 2020, 183, 107600. [Google Scholar] [CrossRef]

- Podsiadły, B.; Matuszewski, P.; Skalski, A.; Słoma, M. Carbon nanotube-based composite filaments for 3d printing of structural and conductive elements. Appl. Sci. 2021, 11, 1272. [Google Scholar] [CrossRef]

- Peng, M.; Shi, D.; Sun, Y.; Cheng, J.; Zhao, B.; Xie, Y.; Zhang, J.; Guo, W.; Jia, Z.; Liang, Z.; et al. 3D printed mechanically robust graphene/CNT electrodes for highly efficient overall water splitting. Adv. Mater. 2020, 32, 1908201. [Google Scholar] [CrossRef] [PubMed]

- Xavier, J. A study on the improvement of dielectric, anticorrosive and mechanical properties of newly synthesized epoxy coatings containing silanized CNTs-TiS2 nanocomposites for aerospace and automotive applications. Silicon 2023, 15, 5065–5088. [Google Scholar] [CrossRef]

- Sivalingam, V.; Kumar, P.G.; Prabakaran, R.; Sun, J.; Velraj, R.; Kim, S.C. An automotive radiator with multi-walled carbon-based nanofluids: A study on heat transfer optimization using MCDM techniques. Case Stud. Therm. Eng. 2022, 29, 101724. [Google Scholar] [CrossRef]

- Upadhyay, G.; Saxena, K.K.; Sehgal, S.; Mohammed, K.A.; Prakash, C.; Dixit, S.; Buddhi, D. Development of carbon nanotube (CNT)-reinforced Mg alloys: Fabrication routes and mechanical properties. Metals 2022, 12, 1392. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, X.; Shi, J.; Shen, B.; Huang, J.; Hu, J.; Chen, Z.; Lai, Y. A superhydrophobic TPU/CNTs@ SiO2 coating with excellent mechanical durability and chemical stability for sustainable anti-fouling and anti-corrosion. Chem. Eng. J. 2022, 434, 134605. [Google Scholar] [CrossRef]

- Cai, G.; Xiao, S.; Deng, C.; Jiang, D.; Zhang, X.; Dong, Z. CeO2 grafted carbon nanotube via polydopamine wrapping to enhance corrosion barrier of polyurethane coating. Corros. Sci. 2021, 178, 109014. [Google Scholar] [CrossRef]

- Zhang, F.; Xu, D.; Zhang, D.; Ma, L.; Wang, J.; Huang, Y.; Chen, M.; Qian, H.; Li, X. A durable and photothermal superhydrophobic coating with entwinned CNTs-SiO2 hybrids for anti-icing applications. Chem. Eng. J. 2021, 423, 130238. [Google Scholar] [CrossRef]

- Liu, F.; Mao, Y.; Sun, Z.; Cao, J.; Chen, H. Effect of TiC nanoparticles on microstructure and corrosion resistance of laser cladding Al-CNTs composite coatings on AZ31 alloy. Int. J. Cast Met. Res. 2024, 37, 136–147. [Google Scholar] [CrossRef]

- Penumadu, D.; Dutta, A.; Pharr, G.M.; Files, B. Mechanical properties of blended single-wall carbon nanotube composites. J. Mater. Res. 2003, 18, 1849–1853. [Google Scholar] [CrossRef]

- Zhou, W.; Bai, X.; Wang, E.; Xie, S. Synthesis, structure, and properties of single-walled carbon nanotubes. Adv. Mater. 2009, 21, 4565–4583. [Google Scholar] [CrossRef]

- Iijima, S.; Toshinari, I. Single-shell carbon nanotubes of 1-nm diameter. Nature 1993, 363, 603–605. [Google Scholar] [CrossRef]

- Yao, Z.; Charles, L.; Cees, D. High-field electrical transport in single-wall carbon nanotubes. Phys. Rev. Lett. 2000, 84, 2941. [Google Scholar] [CrossRef]

- Feng, Y.; Sato, Y.; Inoue, T.; Liu, M.; Chiashi, S.; Xiang, R.; Suenaga, K.; Maruyama, S. Drastically reduced thermal conductivity of self-bundled single-walled carbon nanotube. Carbon 2023, 201, 433–438. [Google Scholar] [CrossRef]

- Predtechenskiy, M.; Khasin, A.; Bezrodny, A.; Bobrenok, O.; Dubov, D.; Muradyan, V.; Saik, V.; Smirnov, S. New perspectives in SWCNT applications: Tuball SWCNTs. Part 1. Tuball by itself—All you need to know about it. Carbon Trends 2022, 8, 100175. [Google Scholar] [CrossRef]

- Kuchi, R.; Nguyen, H.M.; Dongquoc, V.; Van, P.C.; Surabhi, S.; Yoon, S.-G.; Kim, D.; Jeong, J.-R. In-Situ Co-Arc Discharge Synthesis of Fe3O4/SWCNT Composites for Highly Effective Microwave Absorption. Phys. Status Solidi 2018, 20, 1700989. [Google Scholar] [CrossRef]

- Kuchi, R.; Nguyen, H.; Dongquoc, V.; Cao Van, P.; Ahn, H.; Viet, D.; Kim, D.; Kim, D.; Jeong, J. Optimization of FeNi/SWCNT composites by a simple co-arc discharge process to improve microwave absorption performance. J. Alloys Compd. 2021, 852, 156712. [Google Scholar] [CrossRef]

- Ismail, R.; Mohsin, M.H.; Ali, A.K.; Hassoon, K.I.; Erten-Ela, S. Preparation and characterization of carbon nanotubes by pulsed laser ablation in water for optoelectronic application. Phys. E Low-Dimens. Syst. Nanostruct. 2020, 119, 113997. [Google Scholar] [CrossRef]

- Spellauge, M.; Loghin, F.-C.; Sotrop, J.; Domke, M.; Bobinger, M.; Abdellah, A.; Becherer, M.; Lugli, P.; Huber, H.P. Ultra-short-pulse laser ablation and modification of fully sprayed single walled carbon nanotube networks. Carbon 2018, 138, 234–242. [Google Scholar] [CrossRef]

- Maruyama, T. Current status of single-walled carbon nanotube synthesis from metal catalysts by chemical vapor deposition. Mater. Express 2018, 8, 1–20. [Google Scholar] [CrossRef]

- Pant, M.; Singh, R.; Negi, P.; Tiwari, K.; Singh, Y. A comprehensive review on carbon nano-tube synthesis using chemical vapor deposition. Mater. Today Proc. 2021, 46, 11250–11253. [Google Scholar] [CrossRef]

- Manawi, Y.; Ihsanullah; Samara, A.; Al-Ansari, T.; Atieh, M.A. A review of carbon nanomaterials’ synthesis via the chemical vapor deposition (CVD) method. Materials 2018, 11, 822. [Google Scholar] [CrossRef]

- Sivamaran, V.; Balasubramanian, V.; Gopalakrishnan, M.; Viswabaskaran, V.; Rao, A.G.; Selvamani, S.T. Carbon nanotubes, nanorings, and nanospheres: Synthesis and fabrication via chemical vapor deposition—A review. Nanomater. Nanotechnol. 2022, 12, 18479804221079495. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Kukovecz, Á.; Kozma, G.; Kónya, Z. Multi-walled carbon nanotubes. In Springer Handbook of Nanomaterials; Springer Nature: Berlin/Heidelberg, Germany, 2013; pp. 147–188. [Google Scholar]

- Arunkumar, T.; Karthikeyan, R.; Subramani, R.R.; Viswanathan, K.; Anish, M. Synthesis and characterisation of multi-walled carbon nanotubes (MWCNTs). Int. J. Ambient. Energy 2020, 41, 452–456. [Google Scholar] [CrossRef]

- Manzetti, S.; Otto, A. Toxicological aspects of nanomaterials used in energy harvesting consumer electronics. Renew. Sustain. Energy Rev. 2012, 16, 2102–2110. [Google Scholar] [CrossRef]

- O’Rear, E.; Suthisa, O.; Thirawudh, P. Mechanical Strength and Conductivity of Cementitious Composites with Multiwalled Carbon Nanotubes: To Functionalize or Not? Nanomaterials 2023, 14, 80. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Han, B.; Zheng, Q.; Yu, X.; Dong, S.; Zhang, L.; Ou, J. Mechanical properties and reinforcing mechanisms of cementitious composites with different types of multiwalled carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2017, 103, 131–147. [Google Scholar] [CrossRef]

- Abdulhameed, A.; Wahab, N.Z.A.; Mohtar, M.N.; Hamidon, M.N. Methods and applications of electrical conductivity enhancement of materials using carbon nanotubes. J. Electron. Mater. 2021, 50, 3207–3221. [Google Scholar] [CrossRef]

- Namazi, H. Polymers in our daily life. BioImpacts BI 2017, 7, 73. [Google Scholar] [CrossRef]

- Le, T.H.; Kim, Y.; Yoon, H. Electrical and electrochemical properties of conducting polymers. Polymers 2017, 9, 150. [Google Scholar] [CrossRef] [PubMed]

- Mohd Nurazzi, N.; Asyraf, M.M.; Khalina, A.; Abdullah, N.; Sabaruddin, F.; Kamarudin, S.; Ahmad, S.; Mahat, A.; Lee, C.; Aisyah, H.; et al. Fabrication, functionalization, and application of carbon nanotube-reinforced polymer composite: An overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef] [PubMed]

- Abubakre, O.K.; Medupin, R.O.; Akintunde, I.B.; Jimoh, O.T.; Abdulkareem, A.S.; Muriana, R.A.; James, J.A.; Ukoba, K.O.; Jen, T.C.; Yoro, K.O. Carbon nanotube-reinforced polymer nanocomposites for sustainable biomedical applications: A review. J. Sci. Adv. Mater. Devices 2023, 8, 100557. [Google Scholar] [CrossRef]

- Rajak, D.; Pratiksha, H.; Emanoil, L. Manufacturing technologies of carbon/glass fiber-reinforced polymer composites and their properties: A review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef] [PubMed]

- Aveen, K.P.; Bhajantri, V.; D’souza, R.; Londe, N.V.; Jambagi, S. Experimental analysis on the effect of various fillers on mechanical properties of glass fiber reinforced polymer composites. AIP Conf. Proc. 2019, 2057, 020044. [Google Scholar]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Kwon, Y.; Park, J.-B.; Jeon, Y.-P.; Hong, J.-Y.; Park, H.-S.; Lee, J.-U. A review of polymer composites based on carbon fillers for thermal management applications: Design, preparation, and properties. Polymers 2021, 13, 1312. [Google Scholar] [CrossRef]

- Ke, K.; Yue, L.; Shao, H.; Yang, M.-B.; Yang, W.; Manas-Zloczower, I. Boosting electrical and piezoresistive properties of polymer nanocomposites via hybrid carbon fillers: A review. Carbon 2021, 173, 1020–1040. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, J.; Hou, G.; Ma, J.; Wang, W.; Wei, F.; Zhang, L. From nano to giant? Designing carbon nanotubes for rubber reinforcement and their applications for high performance tires. Compos. Sci. Technol. 2016, 137, 94–101. [Google Scholar] [CrossRef]

- Roy, A.; Sreejith, C.; Abhishek, S.; Ragul, G.; Ghosh, I. Effect of Multi-Walled Carbon Nanotubes on Automotive and Aerospace Applications—Case Study. Int. J. Emerg. Trends Sci. Technol. 2017, 5, 5102–5113. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical performance and applications of CNTs reinforced polymer composites—A review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef]

- Shekofteh, M.; Gundoshmian, T.M.; Jahanbakhshi, A.; Heidari-Maleni, A. Performance and emission characteristics of a diesel engine fueled with functionalized multi-wall carbon nanotubes (MWCNTs-OH) and diesel–biodiesel–bioethanol blends. Energy Rep. 2020, 6, 1438–1447. [Google Scholar] [CrossRef]

- Kinloch, I.; Suhr, J.; Lou, J.; Young, R.J.; Ajayan, P.M. Composites with carbon nanotubes and graphene: An outlook. Science 2018, 362, 547–553. [Google Scholar] [CrossRef] [PubMed]

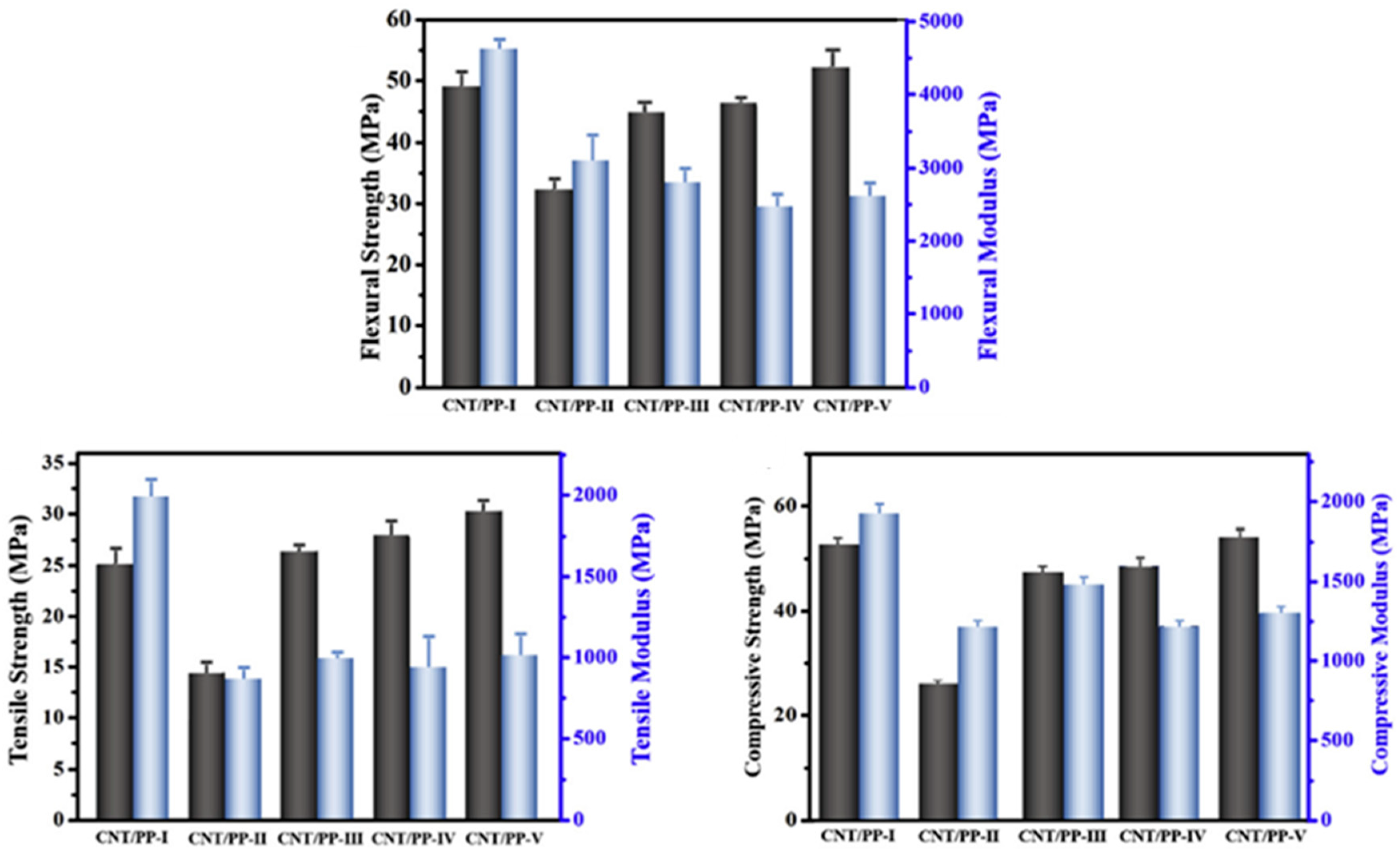

- Wu, H.; Jia, L.-C.; Yan, D.-X.; Gao, J.-F.; Zhang, X.-P.; Ren, P.-G.; Li, Z.-M. Simultaneously improved electromagnetic interference shielding and mechanical performance of segregated carbon nanotube/polypropylene composite via solid phase molding. Compos. Sci. Technol. 2018, 156, 87–94. [Google Scholar] [CrossRef]

- Sastri, V. Regulations for medical devices and application to plastics suppliers: History and overview. In Handbook of Polymer Applications in Medicine and Medical Devices; William Andrew Publishing: Norwich, NY, USA, 2010; pp. 337–346. [Google Scholar]

- Mohammadpourfazeli, S.; Arash, S.; Ansari, A.; Yang, S.; Mallick, K.; Bagherzadeh, R. Future prospects and recent developments of polyvinylidene fluoride (PVDF) piezoelectric polymer; fabrication methods, structure, and electro-mechanical properties. RSC Adv. 2023, 13, 370–387. [Google Scholar] [CrossRef]

- Kundu, M.; Costa, C.M.; Dias, J.; Maceiras, A.; Vilas, J.L.; Lanceros-Méndez, S. On the relevance of the polar β-phase of poly (vinylidene fluoride) for high performance lithium-ion battery separators. J. Phys. Chem. C 2017, 121, 26216–26225. [Google Scholar] [CrossRef]

- Saxena, P.; Prashant, S. A comprehensive review on fundamental properties and applications of poly (vinylidene fluoride)(PVDF). Adv. Compos. Hybrid Mater. 2021, 4, 8–26. [Google Scholar] [CrossRef]

- Holmes-Siedle, A.G.; Wilson, P.D.; Verrall, A.P. PVdF: An electronically-active polymer for industry. Mater. Des. 1983, 4, 910–918. [Google Scholar] [CrossRef]

- Ram, R.; Vandna, S.; Dipak, K. Electrical and thermal conductivity of polyvinylidene fluoride (PVDF)–Conducting Carbon Black (CCB) composites: Validation of various theoretical models. Compos. Part B Eng. 2020, 185, 107748. [Google Scholar] [CrossRef]

- Clausi, M.; Grasselli, S.; Malchiodi, A.; Bayer, I.S. Thermally conductive PVDF-graphene nanoplatelet (GnP) coatings. Appl. Surf. Sci. 2020, 529, 147070. [Google Scholar] [CrossRef]

- Huang, L.; Qu, Y.; Huang, Z.-X.; Qu, J.-P. Enhancing thermal conductivity of segregated structural PE/PVDF/BN composites: Role of viscosities. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106893. [Google Scholar] [CrossRef]

- Guo, H.; Li, X.; Wang, Z.; Li, B.; Wang, J.; Wang, S. Thermal conductivity of PVDF/PANI-nanofiber composite membrane aligned in an electric field. Chin. J. Chem. Eng. 2018, 26, 1213–1218. [Google Scholar] [CrossRef]

- Guo, H.; Li, X.; Li, B.; Wang, J.; Wang, S. Thermal conductivity of graphene/poly(vinylidene fluoride) nanocomposite membrane. Mater. Des. 2017, 114, 355–363. [Google Scholar] [CrossRef]

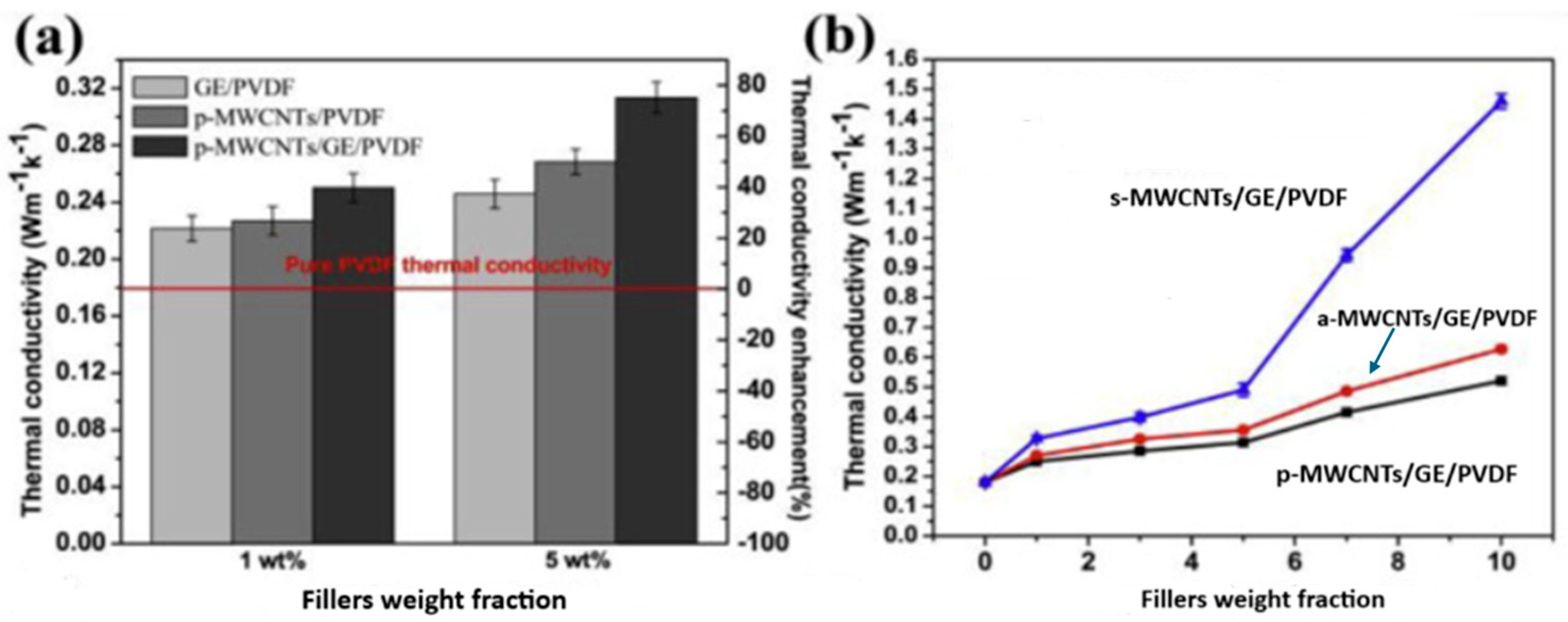

- Guo, H.; Liu, J.; Wang, Q.; Liu, M.; Du, C.; Li, B.; Feng, L. High thermal conductive poly (vinylidene fluoride)-based composites with well-dispersed carbon nanotubes/graphene three-dimensional network structure via reduced interfacial thermal resistance. Compos. Sci. Technol. 2019, 181, 107713. [Google Scholar] [CrossRef]

- Cacciotti, I.; Valentini, M.; Raio, M.; Nanni, F. Design and development of advanced BaTiO3/MWCNTs/PVDF multi-layered systems for microwave applications. Compos. Struct. 2019, 224, 111075. [Google Scholar] [CrossRef]

- Rosemary, M.J. Manufacturing techniques for carbon nanotube-polymer composites. In Handbook of Carbon Nanotubes; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–24. [Google Scholar]

- Wang, R.; Zhu, Z.; Qiu, X.; Bai, L.; Guo, W.; Zuo, L.; Zhao, T.; Shan, G. Determination of epoxide impurity in sarpogrelate hydrochloride intermediate by UHPLC and column-switching liquid chromatography. J. Pharm. Biomed. Anal. 2019, 174, 57–62. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Su, K.; Fan, T.; Cao, L. Mussel-inspired modification of PPS membrane to separate and remove the dyes from the wastewater. Chem. Eng. J. 2018, 341, 371–382. [Google Scholar] [CrossRef]

- Quan, D.; Bologna, F.; Scarselli, G.; Ivankovic, A.; Murphy, N. Interlaminar fracture toughness of aerospace-grade carbon fibre reinforced plastics interleaved with thermoplastic veils. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105642. [Google Scholar] [CrossRef]

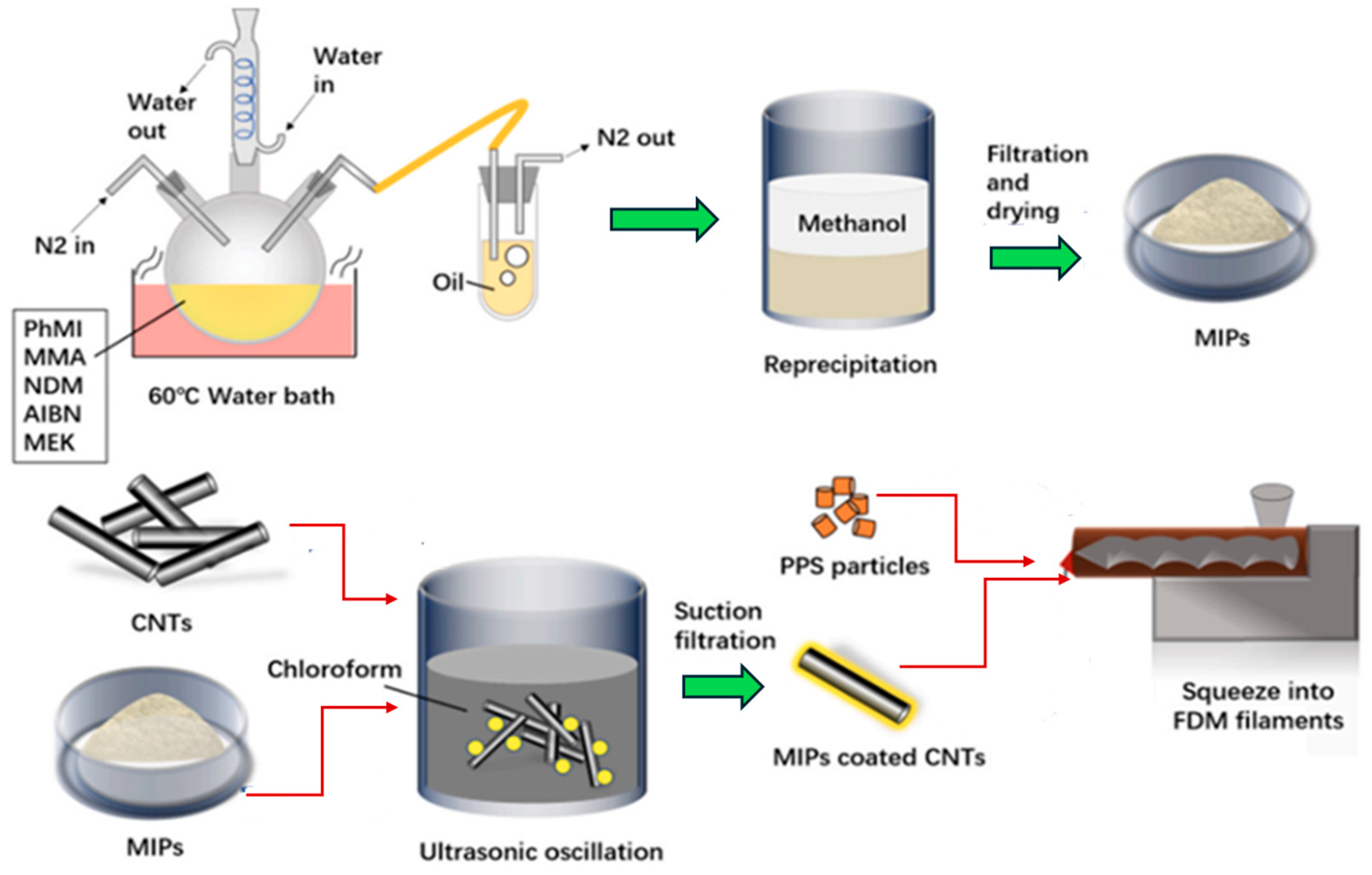

- Pan, S.; Shen, H.; Zhang, L. Effect of carbon nanotube on thermal, tribological and mechanical properties of 3D printing polyphenylene sulfide. Addit. Manuf. 2021, 47, 102247. [Google Scholar] [CrossRef]

- Wu, H.; Fahy, W.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J. Recent developments in polymers/polymer nanocomposites for additive manufacturing. Prog. Mater. Sci. 2020, 111, 100638. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of polymers: Fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef] [PubMed]

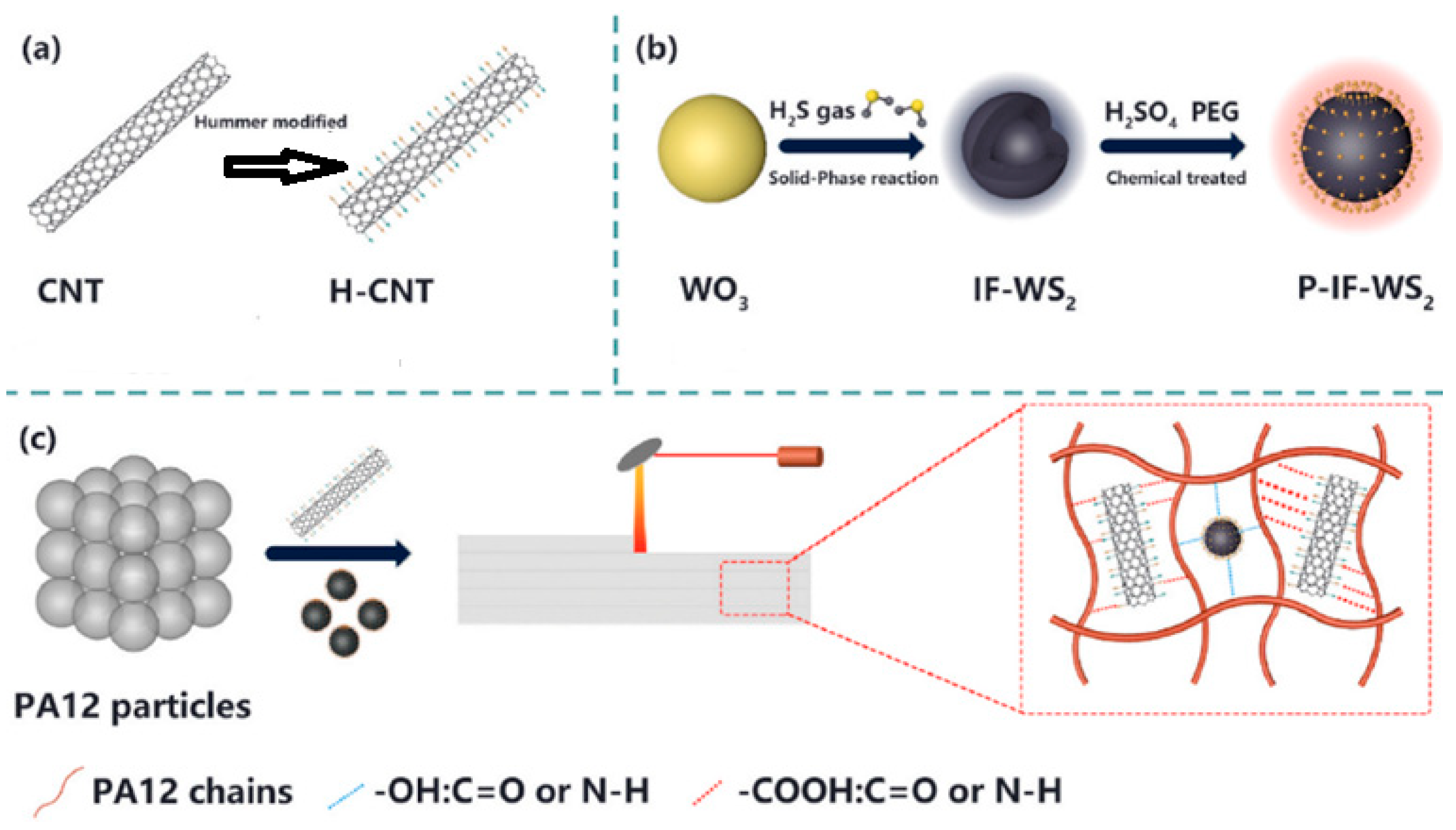

- Chen, D.; Qin, X.; Cao, X.; Wei, F.; Thummavichai, K.; Ola, O.; Wang, N.; Jiang, M.; Zhu, Y. Selective laser sintering of functionalized carbon nanotubes and inorganic fullerene-like tungsten disulfide reinforced polyamide 12 nanocomposites with excellent fire safety and mechanical properties. J. Clean. Prod. 2023, 401, 136630. [Google Scholar] [CrossRef]

- Hashimoto, K. What we have learned from studies on chemical properties of amorphous alloys? Appl. Surf. Sci. 2011, 257, 8141–8150. [Google Scholar] [CrossRef]

- Hanawa, T. Overview of metals and applications. In Metals for Biomedical Devices; Woodhead Publishing: Sawston, UK, 2019; pp. 3–29. [Google Scholar]

- Singh, L.; Bharat, S.; Saxena, K. Manufacturing techniques for metal matrix composites (MMC): An overview. Adv. Mater. Process. Technol. 2020, 6, 441–457. [Google Scholar] [CrossRef]

- Hooker, J.A.; Doorbar, P.J. Metal matrix composites for aeroengines. Mater. Sci. Technol. 2000, 16, 725–731. [Google Scholar] [CrossRef]

- Everett, R.K.; Arsenault, R.J. Metal Matrix Composites: Mechanisms and Properties; Academic Press: London. UK, 1991. [Google Scholar]

- Singh, P.; Gupta, V.; Mishra, R.K.; Singh, B. Effect of micro filler reinforcement on mechanical and wear characteristics of metal matrix composites: A review. AIP Conf. Proc. 2019, 2148, 030011. [Google Scholar]

- Mahato, A.; Subrata, M. Fabrication and microstructure of micro and nano silicon carbide reinforced copper metal matrix composites/nanocomposites. Silicon 2021, 13, 1097–1105. [Google Scholar] [CrossRef]

- Suresh, S.; Gowd, G.; Deva Kumar, M.L.S. Mechanical properties of AA 7075/Al2O3/SiC nano-metal matrix composites by stir-casting method. J. Inst. Eng. Ser. D 2019, 100, 43–53. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites-a review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Singh, K.; Khanna, V.; Sonu; Singh, S.; Bansal, S.A.; Chaudhary, V.; Khosla, A. Paradigm of state-of-the-art CNT reinforced copper metal matrix composites: Processing, characterizations, and applications. J. Mater. Res. Technol. 2023, 24, 8572–8605. [Google Scholar] [CrossRef]

- Chae, S.H.; Lee, Y.H. Carbon nanotubes and graphene towards soft electronics. Nano Converg. 2014, 1, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Chen, R.; Zhou, J.; Liang, J. Recent progress and challenges regarding carbon nanotube on-chip interconnects. Micromachines 2022, 13, 1148. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Fan, G.; Cao, L.; Zhang, D. The use of flake powder metallurgy to produce carbon nanotube (CNT)/aluminum composites with a homogenous CNT distribution. Carbon 2012, 50, 1993–1998. [Google Scholar] [CrossRef]

- Liao, J.; Tan, M. Mixing of carbon nanotubes (CNTs) and aluminum powder for powder metallurgy use. Powder Technol. 2011, 208, 42–48. [Google Scholar] [CrossRef]

- Irhayyim, S.S.; Ahmed, S.R.; Annaz, A.A. Mechanical performance of micro-Cu and nano-Ag reinforced Al-CNT composite prepared by powder metallurgy technique. Mater. Res. Express 2019, 6, 105071. [Google Scholar] [CrossRef]

- Tanaka, H.; Goto, T.; Hamada, K.; Ohashi, K.; Osawa, T.; Sugime, H.; Noda, S. Safe and damage-less dry-purification of carbon nanotubes using FeCl3 vapor. Carbon 2023, 212, 118171. [Google Scholar] [CrossRef]

- He, J.; Chen, J.; Shi, L.; Li, Q.; Lu, W.; Qu, S.; Qiu, W.; Zhou, G. Fabrication of thermally robust carbon nanotube (CNT)/SiO2 composite films and their high-temperature mechanical properties. Carbon 2019, 147, 236–241. [Google Scholar] [CrossRef]

- Daneshvar, F.; Chen, H.; Noh, K.; Sue, H.J. Critical challenges and advances in the carbon nanotube–metal interface for next-generation electronics. Nanoscale Adv. 2021, 3, 942–962. [Google Scholar] [CrossRef]

- Starke Jr, E.A.; Staley, J.T. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Stojanovic, B.; Bukvic, M.; Epler, I. Application of aluminum and aluminum alloys in engineering. Appl. Eng. Lett. J. Eng. Appl. Sci. 2018, 3, 52–62. [Google Scholar] [CrossRef]

- Li, S.; Yue, X.; Li, Q.; Peng, H.; Dong, B.; Liu, T.; Yang, H.; Fan, J.; Shu, S.; Qiu, F.; et al. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Morsi, K.; Esawi, A. Effect of mechanical alloying time and carbon nanotube (CNT) content on the evolution of aluminum (Al)–CNT composite powders. J. Mater. Sci. 2007, 42, 4954–4959. [Google Scholar] [CrossRef]

- Kim, H.; Babu, J.; Kang, C. Fabrication of A356 aluminum alloy matrix composite with CNTs/Al2O3 hybrid reinforcements. Mater. Sci. Eng. A 2013, 573, 92–99. [Google Scholar] [CrossRef]

- Pérez-Bustamante, R.; Pérez-Bustamante, F.; Estrada-Guel, I.; Licea-Jiménez, L.; Miki-Yoshida, M.; Martínez-Sánchez, R. Effect of milling time and CNT concentration on hardness of CNT/Al2024 composites produced by mechanical alloying. Mater. Charact. 2013, 75, 13–19. [Google Scholar] [CrossRef]

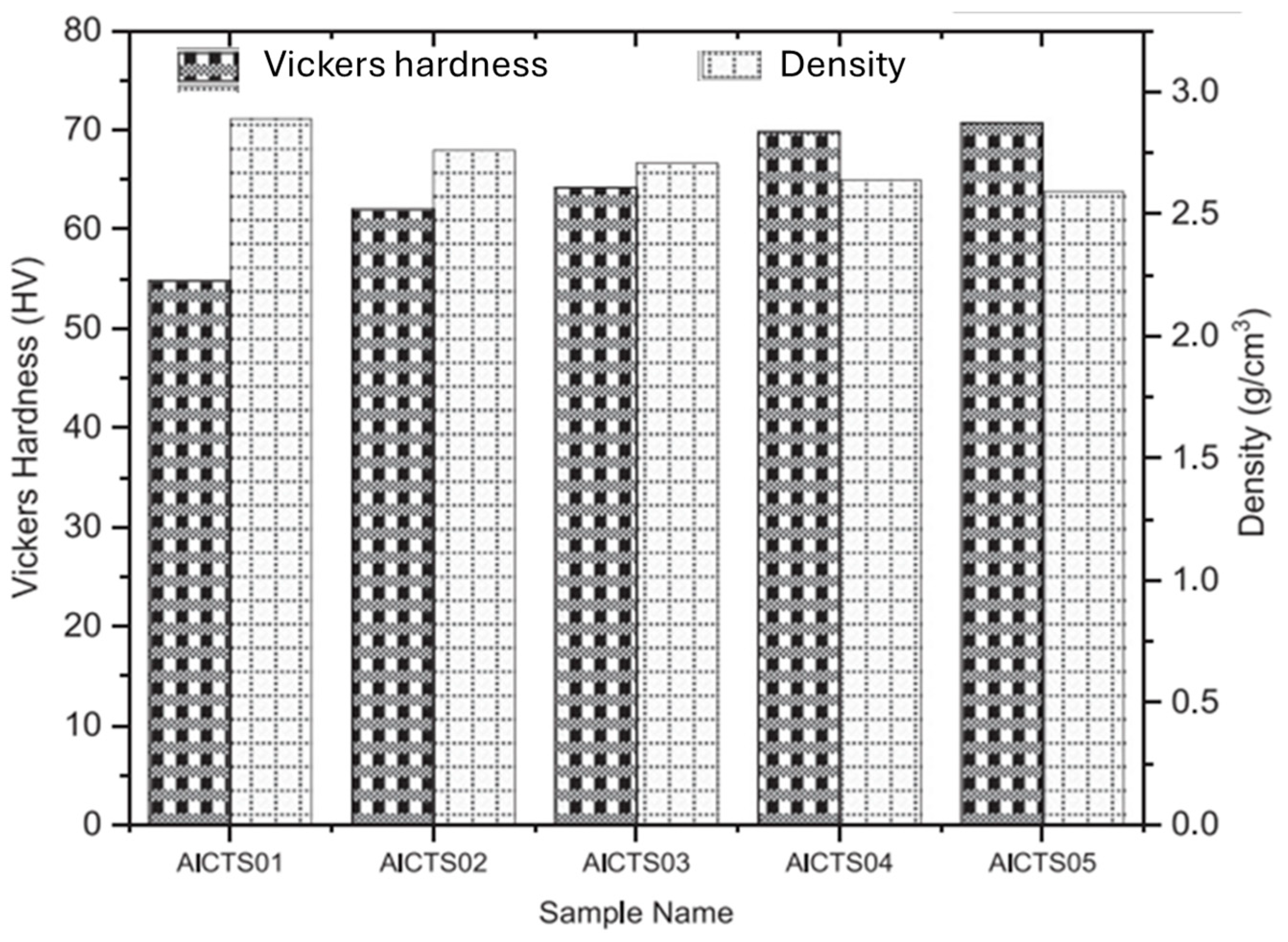

- Nayim, S.T.; Hasan, M.Z.; Seth, P.P.; Gupta, P.; Thakur, S.; Kumar, D.; Jamwal, A. Effect of CNT and TiC hybrid reinforcement on the micro-mechano-tribo behaviour of aluminium matrix composites. Mater. Today Proc. 2020, 21, 1421–1424. [Google Scholar] [CrossRef]

- Say, Y.; Guler, O.; Dikici, B. Carbon nanotube (CNT) reinforced magnesium matrix composites: The effect of CNT ratio on their mechanical properties and corrosion resistance. Mater. Sci. Eng. A 2020, 798, 139636. [Google Scholar] [CrossRef]

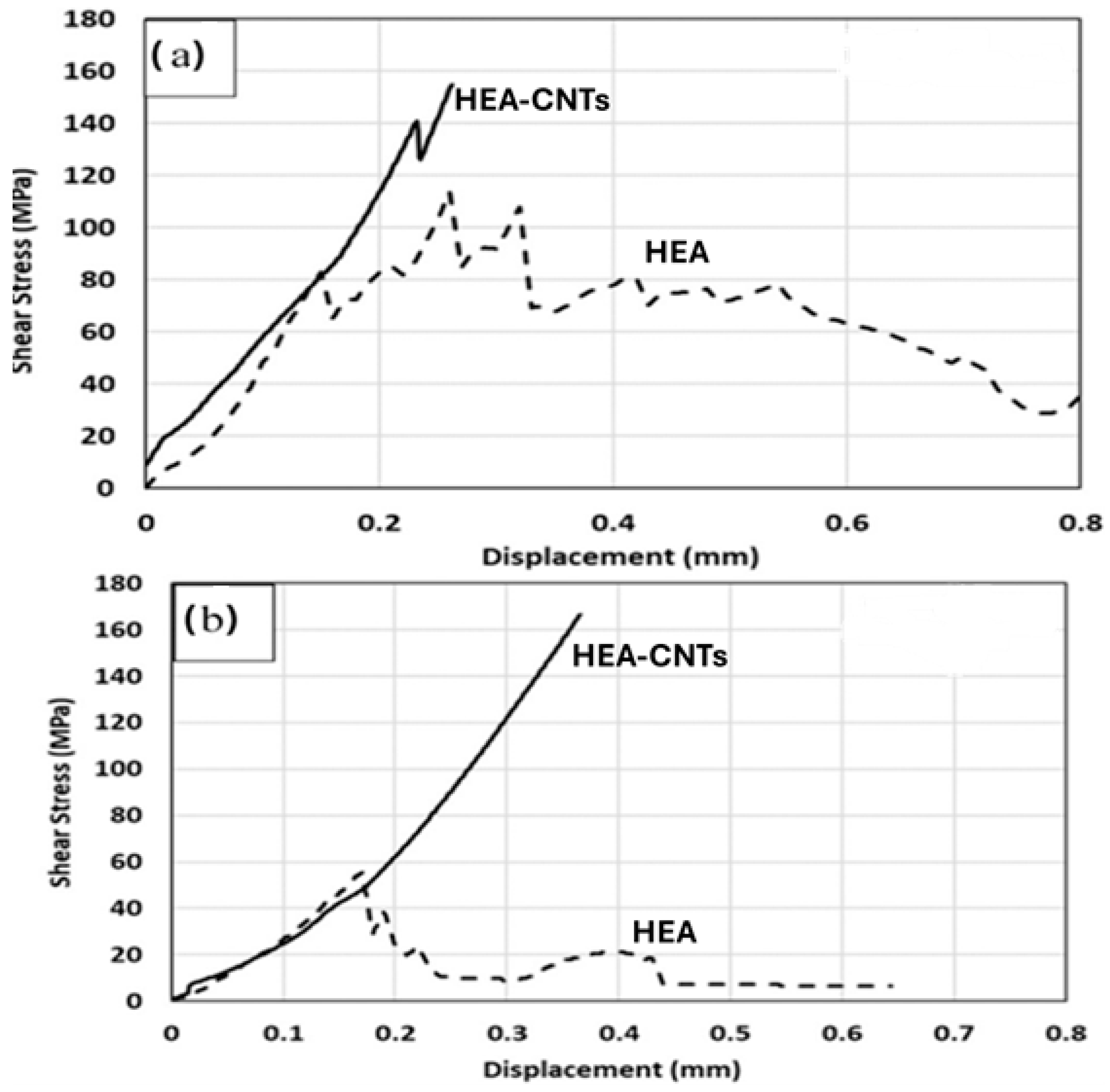

- Bahrami, A.; Mohammadnejad, A.; Sajadi, M. Microstructure and mechanical properties of spark plasma sintered AlCoFeMnNi high entropy alloy (HEA)-carbon nanotube (CNT) nanocomposite. J. Alloys Compd. 2021, 862, 158577. [Google Scholar] [CrossRef]

- Bye, G.C. Portland Cement: Composition, Production and Properties; Thomas Telford: Cambridge, UK, 1999. [Google Scholar]

- Uwasu, M.; Hara, K.; Yabar, H. World cement production and environmental implications. Environ. Dev. 2014, 10, 36–47. [Google Scholar] [CrossRef]

- Ryan, J. The story of Portland cement. J. Chem. Educ. 1929, 6, 1854. [Google Scholar] [CrossRef]

- Papageorgiou, A.; Tzouvalas, G.; Tsimas, S. Use of inorganic setting retarders in cement industry. Cem. Concr. Compos. 2005, 27, 183–189. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.; Ge, C.; Li, Q.; Guo, L.; Shu, X.; Liu, J. Investigation of the effectiveness of PC@ GO on the reinforcement for cement composites. Constr. Build. Mater. 2016, 113, 470–478. [Google Scholar] [CrossRef]

- Naaman, A. Engineered steel fibers with optimal properties for reinforcement of cement composites. J. Adv. Concr. Technol. 2003, 1, 241–252. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K.; Sain, M. Properties of nanofibre reinforced cement composites. Constr. Build. Mater. 2014, 63, 119–124. [Google Scholar] [CrossRef]

- Liew, K.M.; Kai, M.F.; Zhang, L.W. Carbon nanotube reinforced cementitious composites: An overview. Compos. Part A Appl. Sci. Manuf. 2016, 91, 301–323. [Google Scholar] [CrossRef]

- Wang, B.; Pang, B. Properties improvement of multiwall carbon nanotubes-reinforced cement-based composites. J. Compos. Mater. 2020, 54, 2379–2387. [Google Scholar] [CrossRef]

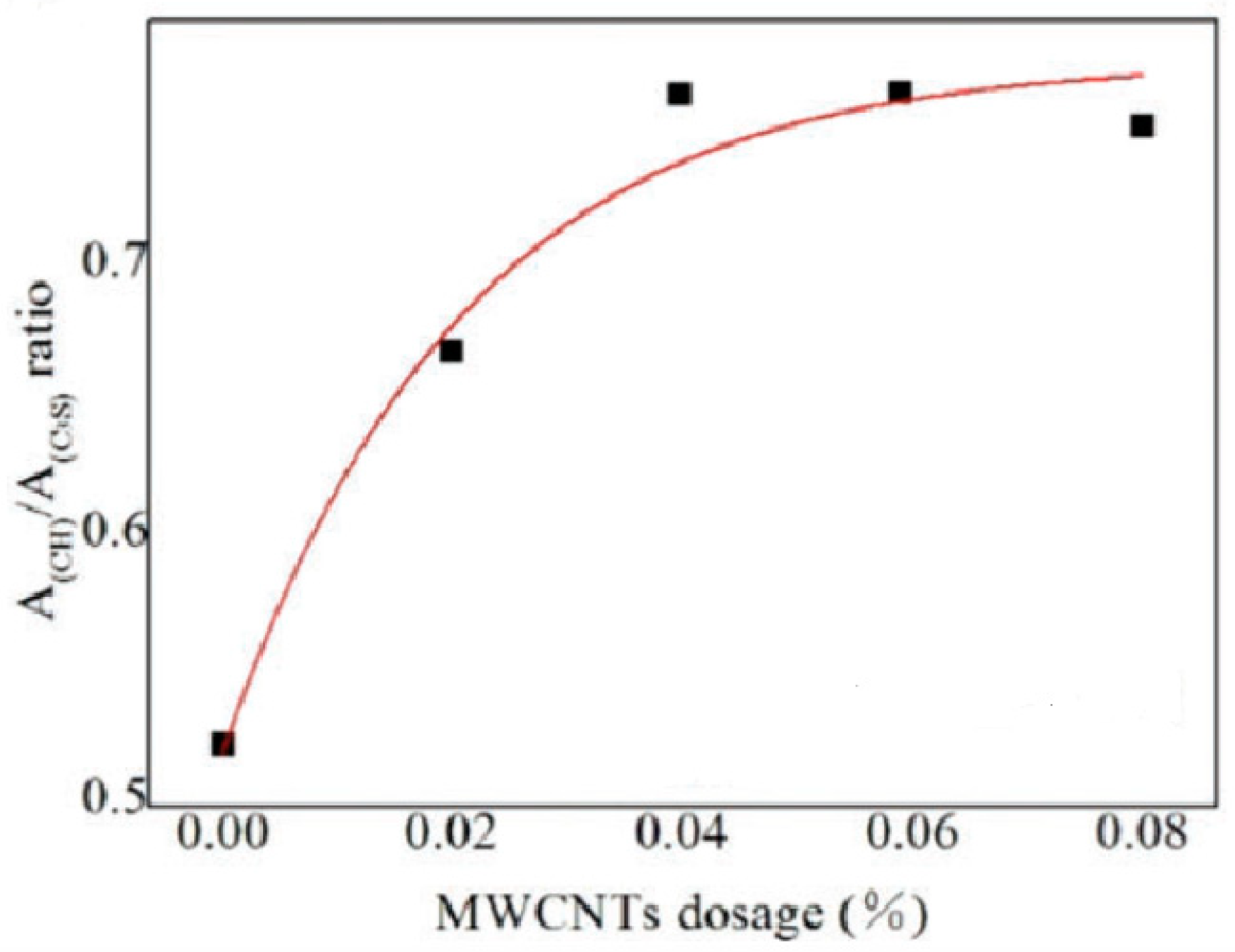

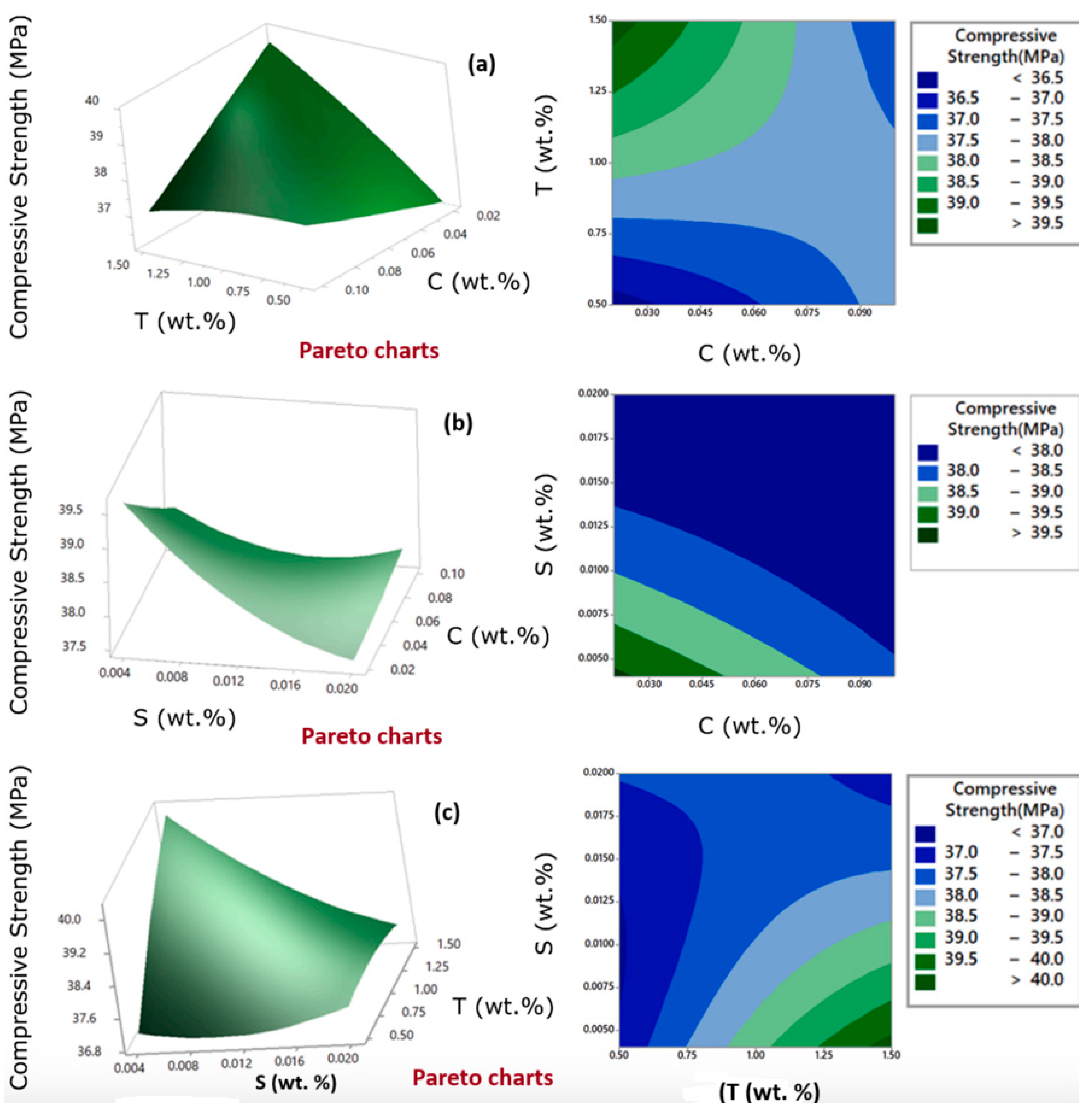

- Mousavi, M.; Sadeghi-Nik, A.; Bahari, A.; Jin, C.; Ahmed, R.; Ozbakkaloglu, T.; de Brito, J. Strength optimization of cementitious composites reinforced by carbon nanotubes and Titania nanoparticles. Constr. Build. Mater. 2021, 303, 124510. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Cheng, C.; Wei, H.; Du, S.; Yan, J. Surface-treated carbon nanotubes in cement composites: Dispersion, mechanical properties and microstructure. Constr. Build. Mater. 2021, 310, 125262. [Google Scholar] [CrossRef]

- Li, Y.; Ji, J.; Wang, Y.; Li, R.; Zhong, W.-H. Soy protein-treated nanofillers creating adaptive interfaces in nanocomposites with effectively improved conductivity. J. Mater. Sci. 2018, 53, 8653–8665. [Google Scholar] [CrossRef]

- Ji, J.Y.; Lively, B.; Zhong, W.H. Soy protein-assisted dispersion of carbon nanotubes in a polymer matrix. Mater. Express 2012, 2, 76–82. [Google Scholar] [CrossRef]

- Sadare, O.O.; Daramola, M.O.; Afolabi, A.S. Synthesis and performance evaluation of nanocomposite soy protein isolate/carbon nanotube (SPI/CNTs) adhesive for wood applications. Int. J. Adhes. Adhes. 2020, 100, 102605. [Google Scholar] [CrossRef]

- Huang, X.; Li, R.; Zeng, L.; Li, X.; Xi, Z.; Wang, K.; Li, Y. A multifunctional carbon nanotube reinforced nanocomposite modified via soy protein isolate: A study on dispersion, electrical and mechanical properties. Carbon 2020, 161, 350–358. [Google Scholar] [CrossRef]

- Xu, N.; Li, Y.; Zheng, T.; Xiao, L.; Liu, Y.; Chen, S.; Zhang, D. A mussel-inspired strategy for CNT/carbon fiber reinforced epoxy composite by hierarchical surface modification. Colloids Surf. A Physicochem. Eng. Asp. 2022, 635, 128085. [Google Scholar] [CrossRef]

- Sadiq, H.; Hu, H.; Huang, S.; Rizwan, M.; Muhammad, A.; Nawaz, M.A.; Zeeshan, M. An Efficient Pressure Sensor Based on Environmental-Friendly Cnts-Graphene-Pdms Film. Phys. Scr. 2024, 99, 0859a9. [Google Scholar] [CrossRef]

| Composites | Formulation | Output |

|---|---|---|

| CNT/PP-I | Solid-phase molding with CNT-coated PP granules | Highest electrical conductivity (70 S/m at 2 wt% CNT) |

| CNT/PP-II | Regular solid-phase molding | High electrical conductivity but lower than CNT/PP-I |

| CNT/PP-III | Regular molding | Lower conductivity than CNT/PP-I and CNT/PP-II |

| CNT/PP-IV | Solution mixing | Conductivity is lower by seven orders of magnitude than CNT/PP-I |

| CNT/PP-V | Melt mixing | Conductivity is significantly lower than CNT/PP-I and CNT/PP-II |

| Composites | Formulation | Output |

|---|---|---|

| PVDF composite | PVDF without fillers | Minimal thermal conductivity |

| p-MWCNTs/GE/PVDF | Pristine MWCNTs and graphene | Moderate thermal conductivity Improvement |

| a-MWCNTs/GE/PVDF | Acidified MWCNTs and graphene | Better dispersion and enhanced thermal conductivity |

| s-MWCNTs/GE/PVDF | Silanized MWCNTs and graphene | Highest thermal conductivity improvement (711.1%) |

| Composites | Formulation | Output |

|---|---|---|

| CNT-MIPs | CNTs mixed with polymer components for MIPs | Increased crystallinity and improved shape accuracy |

| CNT-MIPs/PPS | CNT-MIPs added to PPS filaments | Enhanced tensile strength and flexural modulus |

| CNT-MIPs/PPS (0.9 wt% CNTs) | Higher CNT content | Improved friction coefficient and wear resistance |

| Composites | Formulation | Output |

|---|---|---|

| PA12 | Pure polymer, no fillers | Moderate tensile strength and low flame resistance |

| PA12/3C | PA12 with 3% CNTs | 9.5% increase in tensile strength and slight flame resistance improvement |

| PA12/3C/1W | PA12 with 3% CNTs and 1% WS2 | 19.4% improvement in tensile strength and enhanced flame resistance |

| Matrix | CNT Ratio (wt%) | Corrosion Rate (mm/yr) |

|---|---|---|

| AZ61 | Unreinforced | 0.0336 |

| AZ61 | 0.1 | 0.0388 |

| AZ61 | 0.2 | 0.0324 |

| AZ61 | 0.5 | 0.0678 |

| AZ91 | Unreinforced | 0.0396 |

| AZ91 | 0.1 | 0.0267 |

| AZ91 | 0.2 | 0.0178 |

| AZ91 | 0.5 | 0.0718 |

| Composites | Formulation | Output |

|---|---|---|

| AlCTS01 | 100% Al (aluminum) | Baseline mechanical properties, wear rate ~0.038 mm3/km at 40N load |

| AlCTS02 | 99 wt% Al + 0.5 wt% CNT + 0.5 wt% TiC | Few CNT/TiC particles, minor improvement in tensile strength |

| AlCTS03 | 98.5 wt% Al + 0.5 wt% CNT + 1 wt% TiC | Moderate improvement in wear resistance |

| AlCTS04 | 98 wt% Al + 0.5 wt% CNT + 1.5 wt% TiC | Significant wear resistance improvement |

| AlCTS05 | 97.5 wt% Al + 0.5 wt% CNT + 2 wt% TiC | Maximum wear resistance, wear rate ~0.006 mm3/km (84.21% reduction) |

| Composites | Formulation | Output |

|---|---|---|

| AZ61 Unreinforced | AZ61 alloy (6.5 wt% Al, 1 wt% Zn, and 0.1 wt% Mn) | Baseline corrosion rate: 0.0336 mm/yr |

| AZ61-CNT 0.1 | AZ61 alloy + 0.1 wt% CNT | Decreased compression strength, corrosion rate: 0.0388 mm/yr |

| AZ61-CNT 0.2 | AZ61 alloy + 0.2 wt% CNT | Best corrosion resistance, corrosion rate: 0.0324 mm/yr |

| AZ61-CNT 0.5 | AZ61 alloy + 0.5 wt% CNT | Increased porosity, lower ductility, corrosion rate: 0.0678 mm/yr |

| AZ91 Unreinforced | AZ91 alloy (8.5 wt% Al, 0.8 wt% Zn, and 0.25 wt% Mn) | Baseline corrosion rate: 0.0396 mm/yr |

| AZ91-CNT 0.1 | AZ91 alloy + 0.1 wt% CNT | Improved corrosion resistance, corrosion rate: 0.0267 mm/yr |

| AZ91-CNT 0.2 | AZ91 alloy + 0.2 wt% CNT | Optimal balance, corrosion rate: 0.0178 mm/yr |

| AZ91-CNT 0.5 | AZ91 alloy + 0.5 wt% CNT | Reduced ductility, corrosion rate: 0.0718 mm/yr |

| Composites | Formulation | Output |

|---|---|---|

| HEA (AlCoFeMnNi) | Spark plasma sintering (SPS) at 850 °C | Baseline hardness ~500 VHN, crystallite size ~40 nm |

| HEA-CNT 1% | Mechanical alloying + SPS at 850 °C | Hardness improved to ~650 VHN, crystallite size reduced to ~10 nm |

| HEA-CNT 1% Higher Temperature | Mechanical alloying + SPS at 950 °C | Further hardness increase to ~670 VHN, reduced porosity |

| Composites | Formulation | Output |

|---|---|---|

| MWCNTs + Cement (with DMF) | MWCNTs dispersed with DMF, mixed with cement using ultrasonication | Increased compressive strength (77.2 MPa) and flexural strength (11.2 MPa); DMF dispersion improved mechanical properties |

| MWCNTs + Cement (without DMF) | MWCNTs mixed with cement without DMF | Lower mechanical strength than with DMF; MWCNTs contributed to improved fracture resistance |

| Composites | Formulation | Output |

|---|---|---|

| Cement + p-CNTs | Pristine MWCNTs dispersed with superplasticizer | Improved strength over reference sample, but p-CNTs showed agglomeration, affecting properties negatively |

| Cement + c-CNTs | Carboxyl-functionalized MWCNTs dispersed with superplasticizer | Improved flexural (15.7%) and compressive strength (16.9%) through crack-bridging mechanism |

| Cement + m-CNTs | Plasma-modified MWCNTs dispersed with superplasticizer | Highest flexural strength (37.1% increase) and compressive strength (24.3% increase) due to enhanced dispersion and bridging |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nitodas, S.; Shah, R.; Das, M. Research Advancements in the Mechanical Performance and Functional Properties of Nanocomposites Reinforced with Surface-Modified Carbon Nanotubes: A Review. Appl. Sci. 2025, 15, 374. https://doi.org/10.3390/app15010374

Nitodas S, Shah R, Das M. Research Advancements in the Mechanical Performance and Functional Properties of Nanocomposites Reinforced with Surface-Modified Carbon Nanotubes: A Review. Applied Sciences. 2025; 15(1):374. https://doi.org/10.3390/app15010374

Chicago/Turabian StyleNitodas, Stefanos (Steve), Raj Shah, and Mrinaleni Das. 2025. "Research Advancements in the Mechanical Performance and Functional Properties of Nanocomposites Reinforced with Surface-Modified Carbon Nanotubes: A Review" Applied Sciences 15, no. 1: 374. https://doi.org/10.3390/app15010374

APA StyleNitodas, S., Shah, R., & Das, M. (2025). Research Advancements in the Mechanical Performance and Functional Properties of Nanocomposites Reinforced with Surface-Modified Carbon Nanotubes: A Review. Applied Sciences, 15(1), 374. https://doi.org/10.3390/app15010374