Parameter Correction on Waste Heat Recovery System of a Gas Turbine Using Supercritical CO2 Based on Data Reconciliation

Abstract

1. Introduction

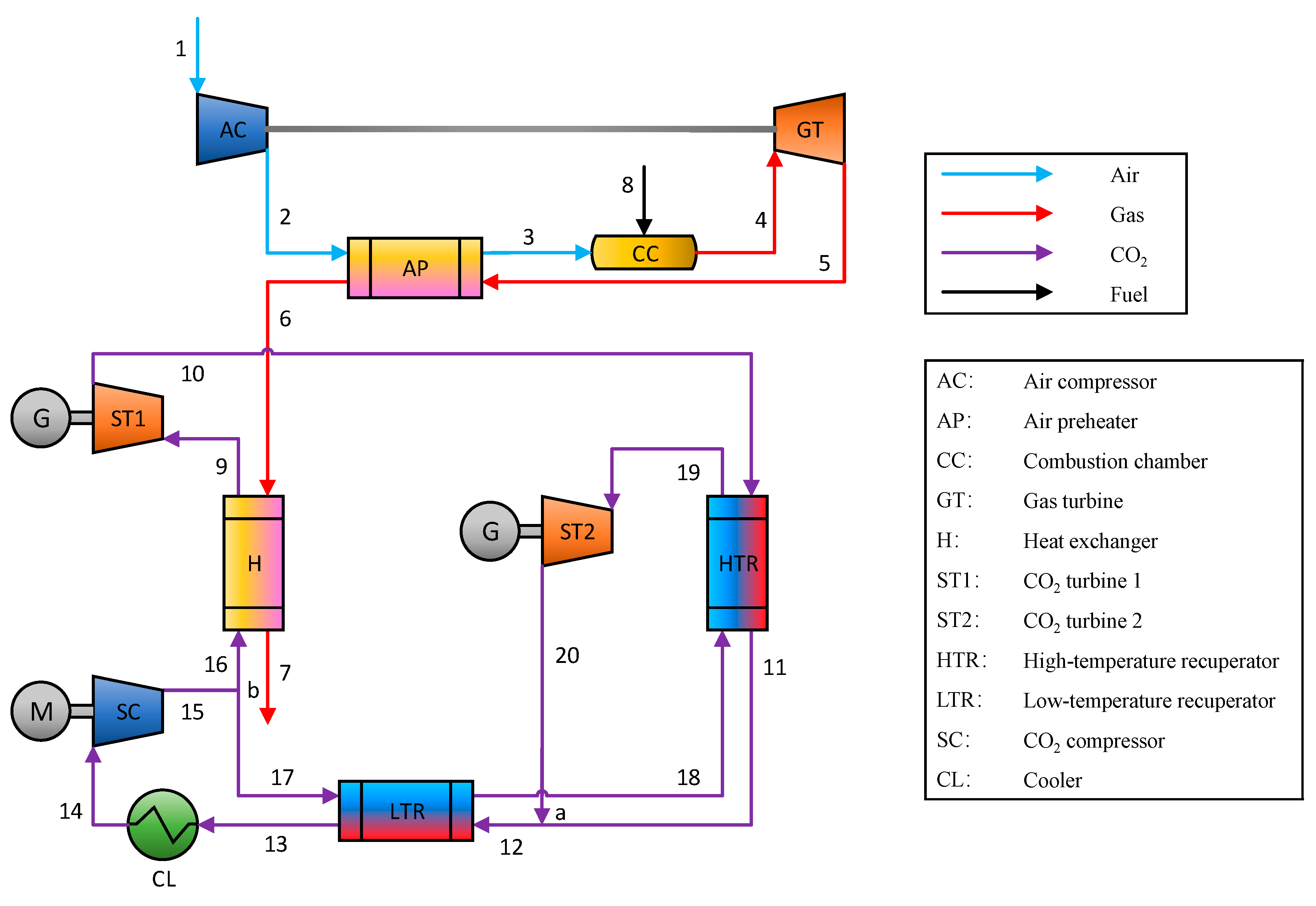

2. System Configuration

- The waste heat recovery system is in a stable state, and the CO2 is always in a supercritical state;

- The external environment and the cooling water used by the cooler are both at 25 °C, 101 kPa;

- The pressure loss and heat loss of circulating equipment and pipelines can be ignored;

- The isentropic efficiencies of the air compressor and the S-CO2 compressor are constants, which are 80% and 85%, respectively;

- The isentropic efficiency of the gas turbine and the two S-CO2 turbines are also constants, which are all 90%.

3. Research Method

3.1. Heat Balance Model

3.2. Data Reconciliation Principle

3.3. Gross Error Identification

3.4. Sensor Arrangement

3.5. Unknown Variables and Redundant Equations

4. Model Verification

5. Results and Discussion

5.1. General Computing Overview

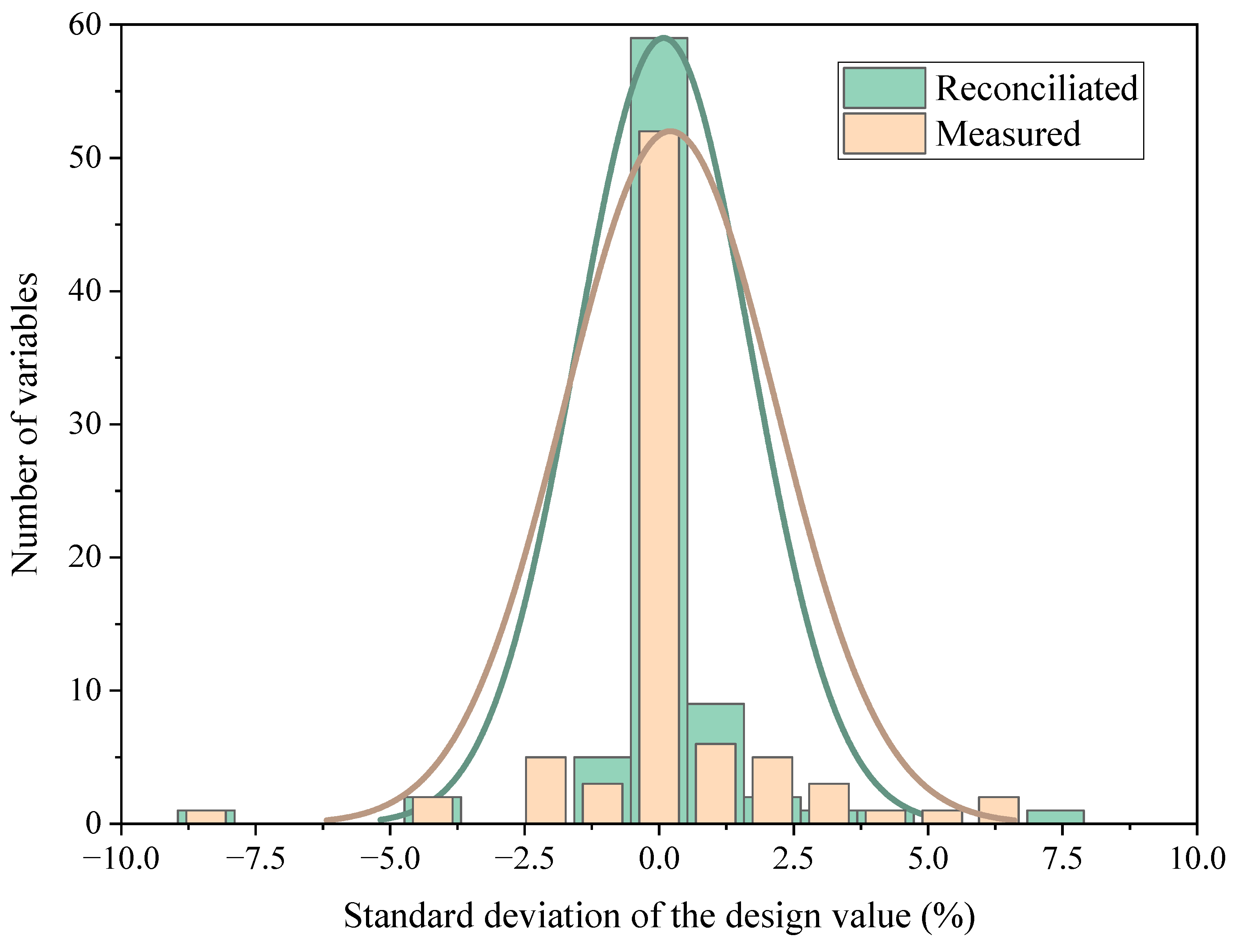

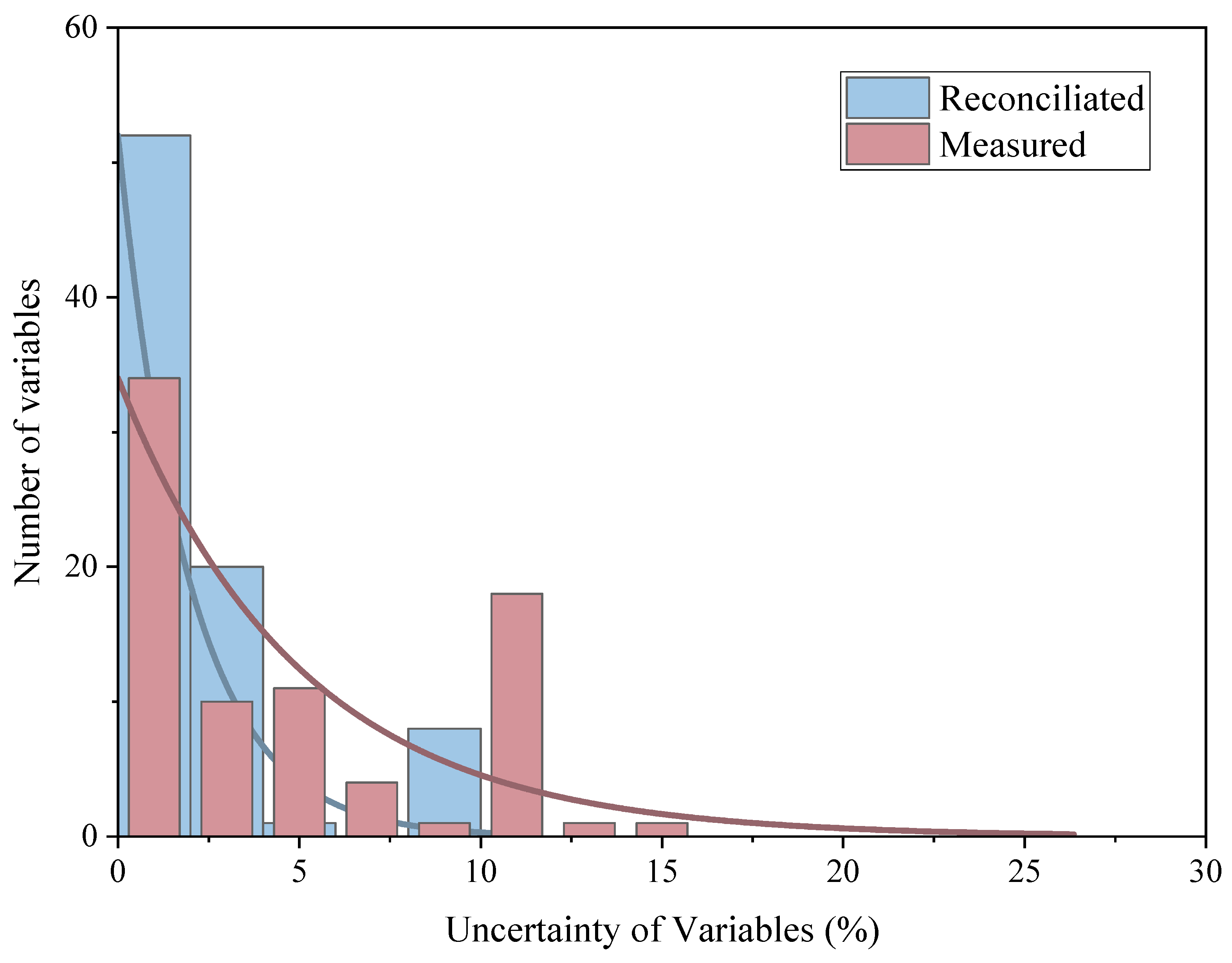

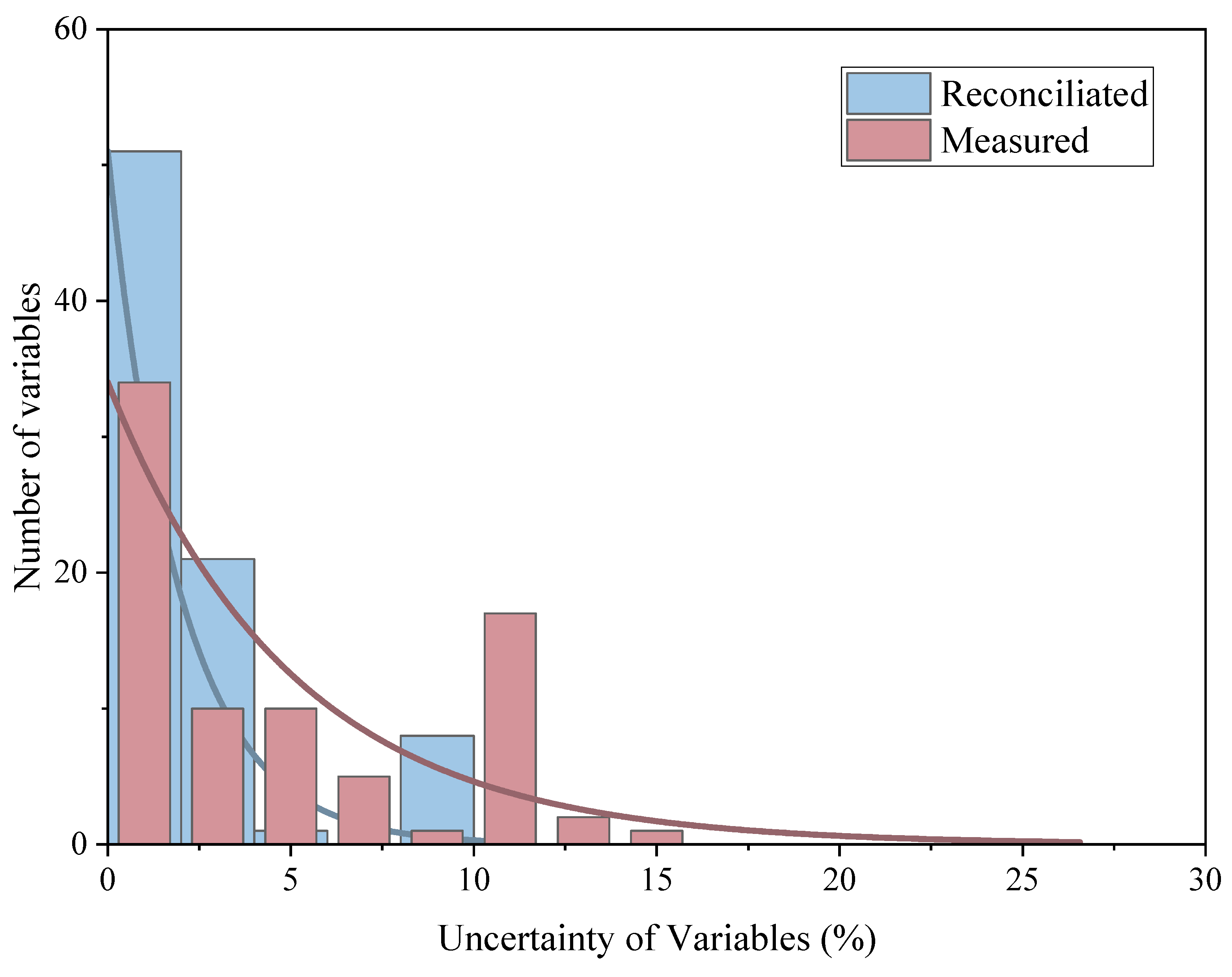

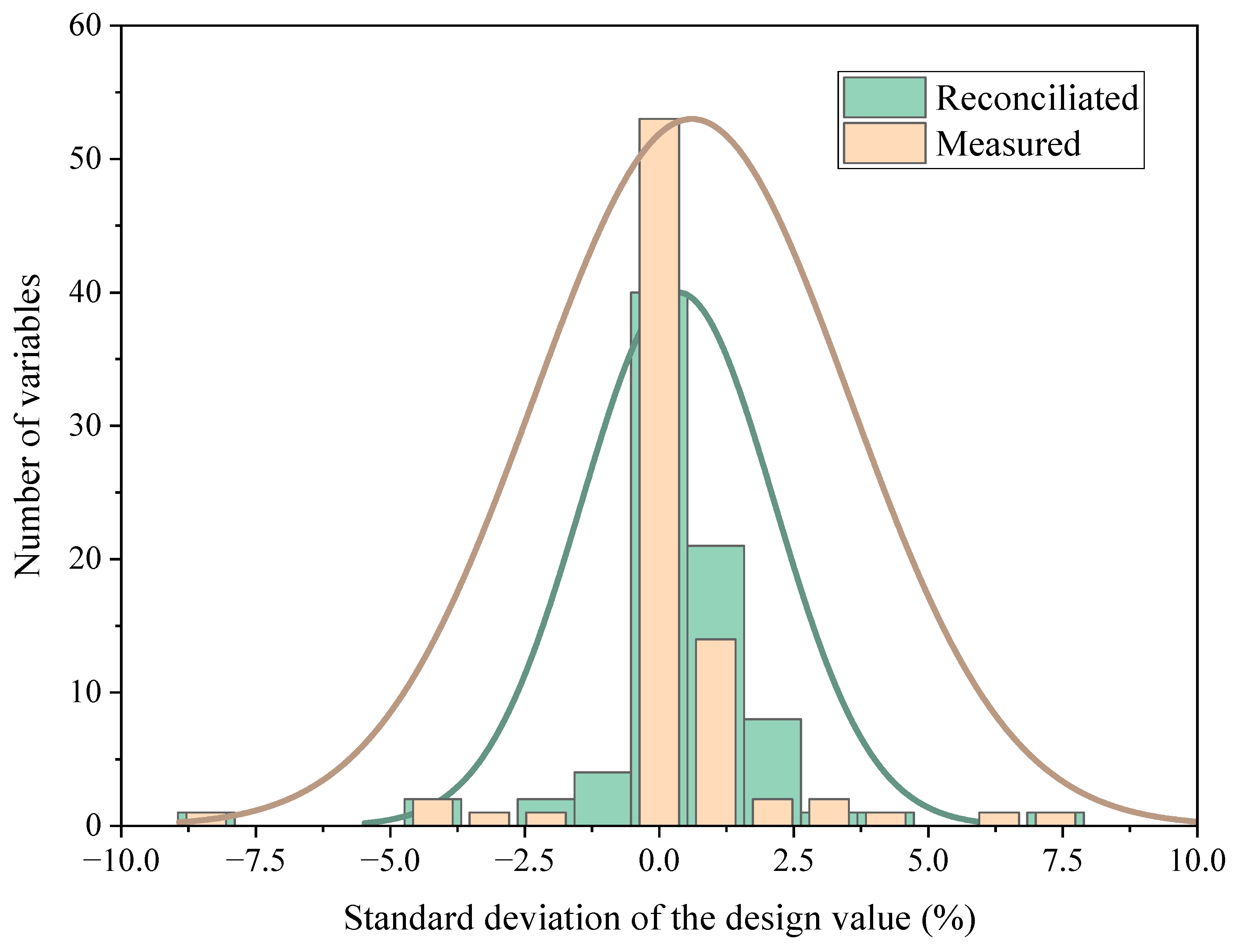

5.2. Data Reconciliation Without Gross Errors

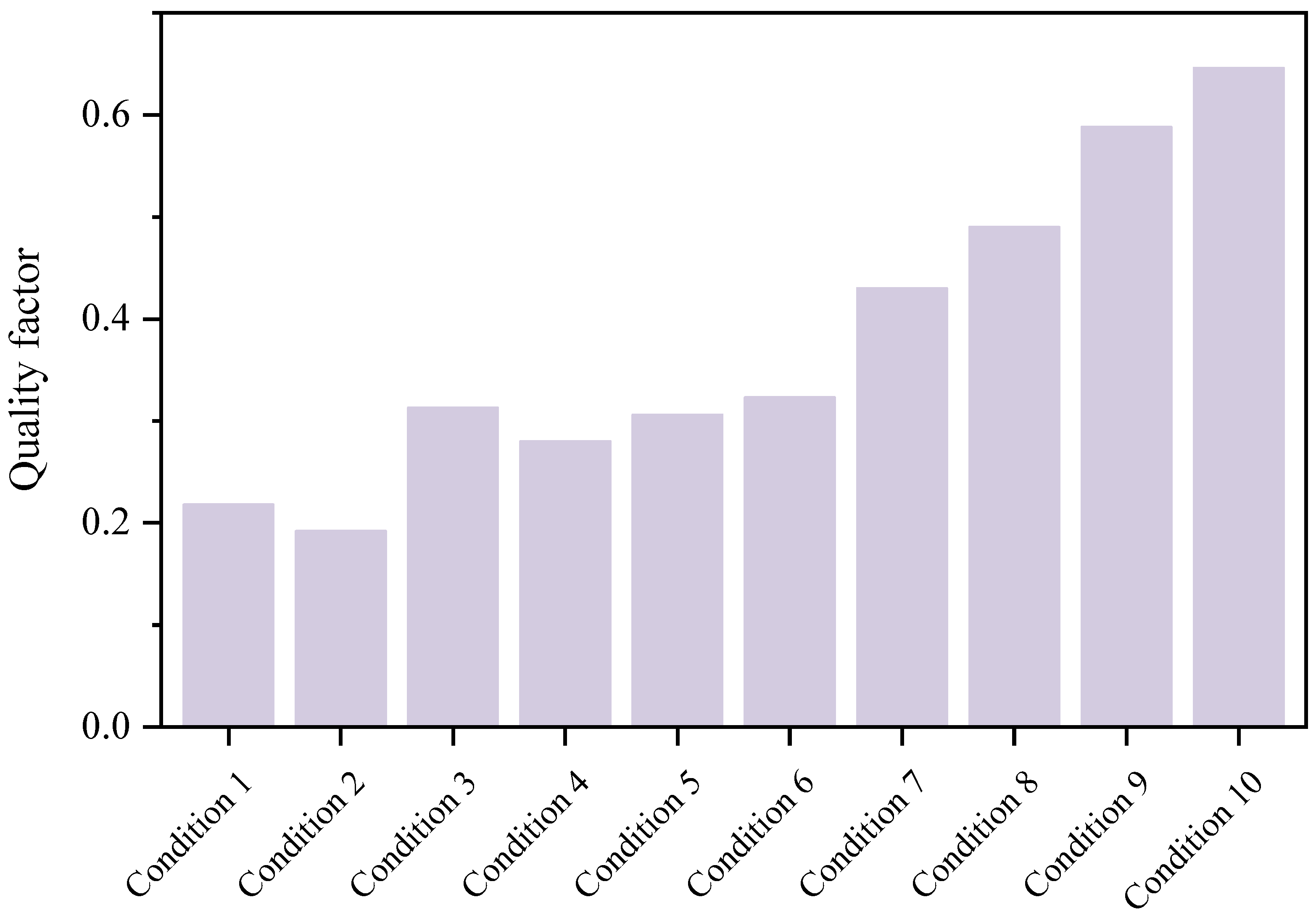

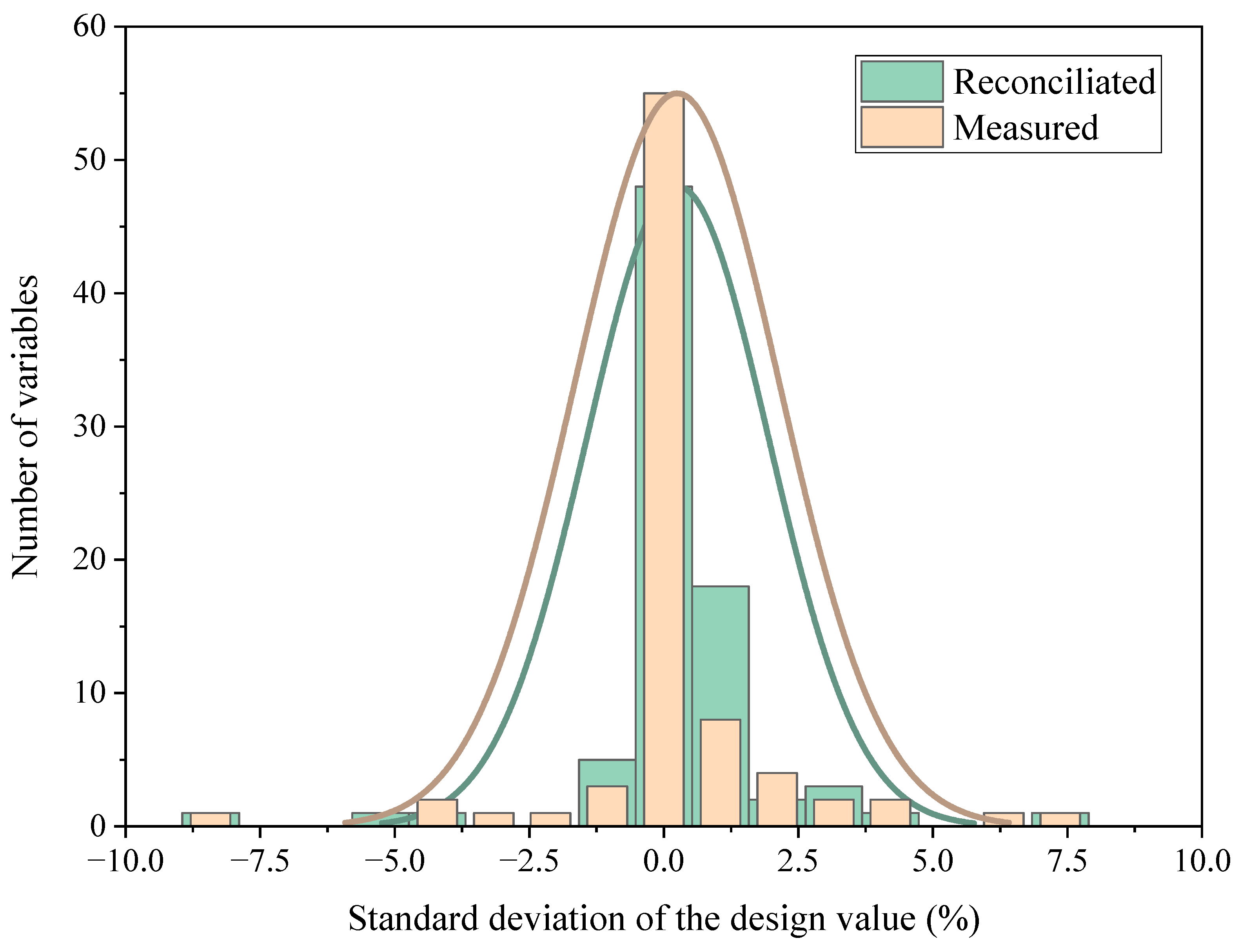

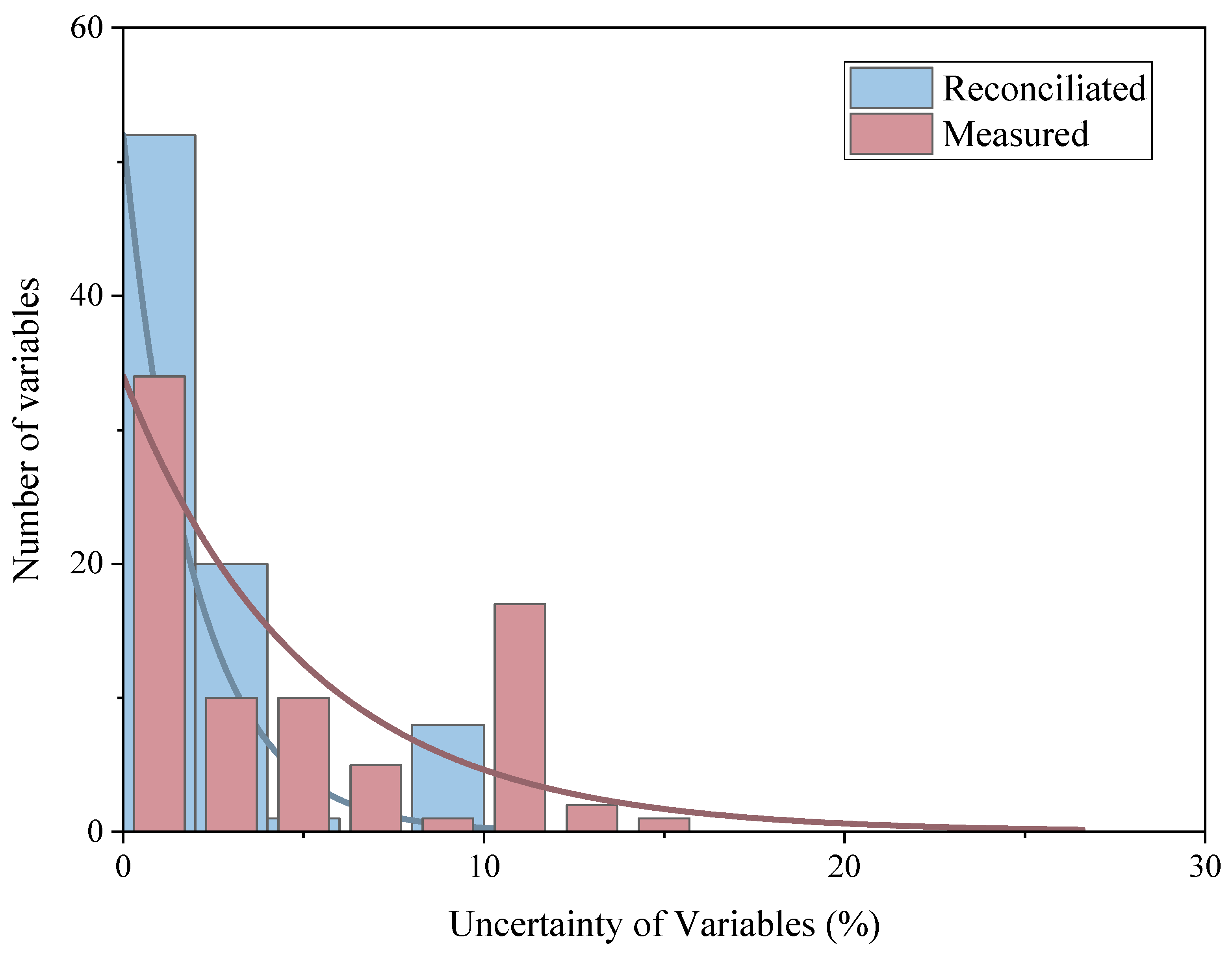

5.3. Data Reconciliation with Gross Errors

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Meaning |

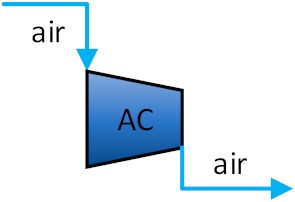

| AC | Air compressor |

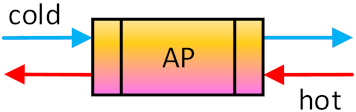

| AP | Air preheater |

| CC | Combustion chamber |

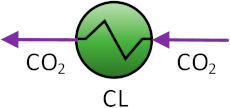

| CL | Cooler |

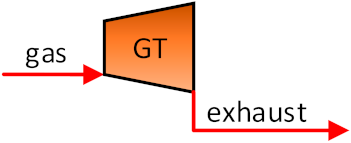

| GT | Gas turbine |

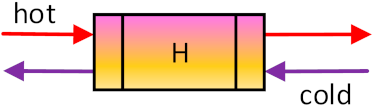

| H | Heat exchanger |

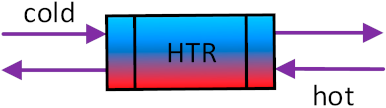

| HTR | High-temperature recuperator |

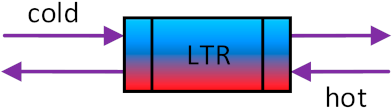

| LTR | Low-temperature recuperator |

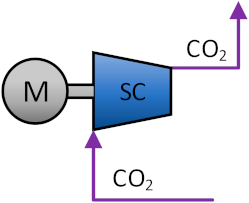

| SC | S-CO2 compressor |

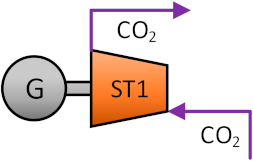

| ST1 | S-CO2 turbine 1 |

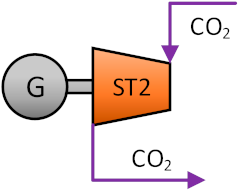

| ST2 | S-CO2 turbine 2 |

| Enthalpy | |

| Mass flow | |

| Heat exchange amount | |

| Power | |

| Efficiency | |

| The equation vector representing a set of algebraic equations | |

| The initial residual vector of the equation vector | |

| The initial residual vector after iterations | |

| The Jacobian matrix of equation vector versus | |

| The test statistics of variable based on the correction vector | |

| The covariance matrix of the equation vector | |

| The covariance matrix of the known variable vector | |

| The vector of the unknown variable. | |

| The component of | |

| The reconciliated value of the known variable | |

| The vector composed of all known variables | |

| The reconciliated value vector of the known variable | |

| The true value vector of the known variable | |

| The lower fraction of the normal distribution | |

| The random error vector | |

| The convergence limit | |

| The correction vector of the initial value vector | |

| The correction value | |

| The correction vector of the initial value vector after iterations | |

| The maximum allowable error | |

| The mean square deviation (standard deviation) | |

| The coefficient of random errors |

References

- Tian, H.; Ding, H.; Bin, W. A Summary of wearable textiles power generation. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 772, p. 012037. [Google Scholar]

- EI Statistical Review of World Energy 2024; Energy Institute: London, UK, 2024.

- Heppenstall, T. Advanced gas turbine cycles for power generation: A critical review. Appl. Therm. Eng. 1998, 18, 837–846. [Google Scholar] [CrossRef]

- Can Gülen, S. Étude on gas turbine combined cycle power plant—Next 20 years. J. Eng. Gas Turbines Power 2016, 138, 051701. [Google Scholar] [CrossRef]

- Zhang, C.; Shu, G.; Tian, H.; Wei, H.; Liang, X. Comparative study of alternative ORC-based combined power systems to exploit high temperature waste heat. Energy Convers. Manag. 2015, 89, 541–554. [Google Scholar] [CrossRef]

- Rajinesh, S.; Miller, S.A.; Rowlands, A.S.; Jacobs, P.A. Dynamic characteristics of a direct-heated supercritical carbon-dioxide Brayton cycle in a solar thermal power plant. Energy 2013, 50, 194–204. [Google Scholar]

- Ruby Meena, A.; Senthil Kumar, S. Genetically tuned fuzzy PID controller in two area reheat thermal power system. Russ. Electr. Eng. 2016, 87, 579–587. [Google Scholar] [CrossRef]

- Chowdhury, J.I.; Thornhill, D.; Soulatiantork, P.; Hu, Y.; Balta-Ozkan, N.; Varga, L.; Nguyen, B.K. Control of supercritical organic Rankine cycle based waste heat recovery system using conventional and fuzzy self-tuned PID controllers. Int. J. Control Autom. Syst. 2019, 17, 2969–2981. [Google Scholar] [CrossRef]

- Christoph, S.; Dimache, L.; Lohan, J. Operational Optimisation of a Heat Pump System with Sensible Thermal Energy Storage using Genetic Algorithm: A Case Study. Therm. Sci. 2018, 22, 2189–2202. [Google Scholar]

- Qian, Y.; Du, W.-J.; Cheng, L. Optimization design of heat recovery systems on rotary kilns using genetic algorithms. Appl. Energy 2017, 202, 153–168. [Google Scholar]

- Reza, B.; Eiamsa-ard, S. Genetic algorithm multiobjective optimization of a thermal system with three heat transfer enhancement characteristics. J. Enhanc. Heat Transf. 2020, 27, 123–141. [Google Scholar]

- Lin, Y.; Wang, H.; Hu, P.; Yang, W.; Hu, Q.; Zhu, N.; Lei, F. A study on the optimal air, load and source side temperature combination for a variable air and water volume ground source heat pump system. Appl. Therm. Eng. 2020, 178, 115595. [Google Scholar] [CrossRef]

- Shankar, N.; Jordache, C. Data Reconciliation and Gross Error Detection: An Intelligent Use of Process Data; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Romagnoli, J.A.; Sánchez, M.C. Data Processing and Reconciliation for Chemical Process Operations; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Kretsovalis, A.; Mah, R.S.H. Observability and redundancy classification in multicomponent process networks. AIChE J. 1987, 33, 70–82. [Google Scholar] [CrossRef]

- Crowe, C.M.; Campos, Y.G.; Hrymak, A. Reconciliation of process flow rates by matrix projection. Part I: Linear case. AIChE J. 1983, 29, 881–888. [Google Scholar] [CrossRef]

- Crowe, C.M. Reconciliation of process flow rates by matrix projection. Part II: The nonlinear case. AIChE J. 1986, 32, 616–623. [Google Scholar] [CrossRef]

- Swartz, C.L.E. Data reconciliation for generalized flowsheet applications. In Proceedings of the ACS National Meeting, Dallas, TX, USA, 9–14 April 1989. [Google Scholar]

- Reilly, P.M.; Carpani, R.E. Application of statistical theory of adjustment to material balances. In Proceedings of the 13th Canadian Chemical Engineering Congress, Montreal, QC, Canada, 23 October 1963. [Google Scholar]

- Mah, R.S.H.; Tamhane, A.C. Detection of gross errors in process data. AIChE J. 1982, 28, 828–830. [Google Scholar] [CrossRef]

- Narasimhan, S.; Mah, R.S. Generalized likelihood ratio method for gross error identification. AIChE J. 1987, 33, 1514–1521. [Google Scholar] [CrossRef]

- Narasimhan, S.; Mah, R.S. Generalized likelihood ratios for gross error identification in dynamic processes. AIChE J. 1988, 34, 1321–1331. [Google Scholar] [CrossRef]

- Holly, W.; Cook, R.; Crowe, C.M. Reconciliation of mass flow rate measurements in a chemical extraction plant. Can. J. Chem. Eng. 1989, 67, 595–601. [Google Scholar] [CrossRef]

- Sriniketh, S.; Billeter, J.; Narasimhan, S.; Bonvin, D. Data reconciliation for chemical reaction systems using vessel extents and shape constraints. Comput. Chem. Eng. 2017, 101, 44–58. [Google Scholar]

- Humaad, I.; Ati, U.M.K.; Mahalec, V. Heat exchanger network simulation, data reconciliation & optimization. Appl. Therm. Eng. 2013, 52, 328–335. [Google Scholar]

- Martínez-Maradiaga, D.; Bruno, J.C.; Coronas, A. Steady-state data reconciliation for absorption refrigeration systems. Appl. Therm. Eng. 2013, 51, 1170–1180. [Google Scholar] [CrossRef]

- Magnus, L.; Jansky, J. Process data reconciliation in nuclear power plants. In Proceedings of the EPRI Nuclear Power Performance Improvement Seminar, Saratoga Springs, NY, USA, 15–16 July 2002. [Google Scholar]

- Magnus, L. Power recapture and power uprate in NPPS with process data reconciliation in accordance with VDI 2048. Int. Conf. Nucl. Eng. 2006, 42428, 7–14. [Google Scholar]

- Svein, S.; Berg, Ö. Data reconciliation and fault detection by means of plant-wide mass and energy balances. Prog. Nucl. Energy 2003, 43, 97–104. [Google Scholar]

- Damianik, V.E.; Schirru, R. Simultaneous model selection, robust data reconciliation and outlier detection with swarm intelligence in a thermal reactor power calculation. Ann. Nucl. Energy 2011, 38, 1820–1832. [Google Scholar]

- Hartner, P.; Petek, J.; Pechtl, P.; Hamilton, P. Model-based data reconciliation to improve accuracy and reliability of performance evaluation of thermal power plants. Turbo Expo Power Land Sea Air 2005, 47276, 195–200. [Google Scholar]

- Jiang, X.; Liu, P.; Li, Z. Data reconciliation and gross error detection for operational data in power plants. Energy 2014, 75, 14–23. [Google Scholar] [CrossRef]

- Chen, P.-C.; Andersen, H. The implementation of the data validation process in a gas turbine performance monitoring system. Turbo Expo Power Land Sea Air 2005, 46997, 609–616. [Google Scholar]

- Can, G.S.; Smith, R.W. A simple mathematical approach to data reconciliation in a single-shaft combined cycle system. J. Eng. Gas Turbines Power. Mar 2009, 131, 021601. [Google Scholar]

- Sun, L.; Wang, D.; Xie, Y. Energy, exergy and exergoeconomic analysis of two supercritical CO2 cycles for waste heat recovery of gas turbine. Appl. Therm. Eng. 2021, 196, 117337. [Google Scholar] [CrossRef]

- VDI-2048: Control and Quality Improvement of Process Data and Their Uncertainties by Means of Correction Calculation for Operation and Acceptance Tests; Association of German Engineers; VDI Verein Deutscher Ingenieure: Düsseldorf, Germany, 2017.

- You, J.; Wu, J.; Xu, L.; Xie, Y.; Qiu, J.; Wan, L.; Qin, Q. Exploration on the comprehensive data reconciliation framework for unknown parameter inference in the nuclear power plant system. Appl. Therm. Eng. 2024, 247, 123138. [Google Scholar] [CrossRef]

- Langenstein, M.; Jansky, J.; Laipple, B.; Eitschberger, H.; Grauf, E.; Schalk, H. Finding megawatts in nuclear power plants with process data reconciliation. Int. Conf. Nucl. Eng. 2004, 46881, 43–52. [Google Scholar]

| Component | Parameter | Value | Unit |

|---|---|---|---|

| Air compressor | Pressure ratio | 15.0 | -- |

| Inlet pressure | 101.0 | kPa | |

| Inlet temperature | 25.0 | °C | |

| Mass flow of air | 91.22 | kg/s | |

| Air preheater | Outlet exhaust pressure | 109.6 | kPa |

| Outlet exhaust temperature | 527.6 | °C | |

| Heat exchanger | Terminal temperature difference | 10 | °C |

| High-temperature recuperator | Terminal temperature difference | 10 | °C |

| Low-temperature recuperator | Terminal temperature difference | 10 | °C |

| S-CO2 compressor | Inlet pressure | 8000 | kPa |

| Outlet pressure | 20,000 | kPa |

| Component | Heat Balance Equation | Description | |

|---|---|---|---|

| AC |  | Load equation of air compressor | |

| Efficiency equation of air compressor | |||

| AP |  | Heat load equation of air preheater | |

| CC |  | Conservation equation of combustion chamber | |

| GT |  | Power equation of gas turbine | |

| Efficiency equation of gas turbine | |||

| H |  | Heat load equation of heat exchanger | |

| ST1 |  | Power equation of S-CO2 turbine 1 | |

| Efficiency equation of S-CO2 turbine 1 | |||

| ST2 |  | Power equation of S-CO2 turbine 2 | |

| Efficiency equation of S-CO2 turbine 2 | |||

| HTR |  | Heat load equation of high-temperature recuperator | |

| LTR |  | Heat load equation of low-temperature recuperator | |

| SC |  | Load equation of S-CO2 compressor | |

| Efficiency equation of S-CO2 compressor | |||

| CL |  | Heat load equation of cooler | |

| Stream Number | Pressure Number | Temperature Number | Mass Flow Number |

|---|---|---|---|

| Stream 1 | TS01 | ||

| Stream 2 | TS02 | MFS01 | |

| Stream 3 | PS01 | TS03 | |

| Stream 4 | PS02 | TS04 | |

| Stream 5 | PS03 | TS05 | MFS02 |

| Stream 6 | TS06 | ||

| Stream 7 | TS07 | ||

| Stream 9 | TS08 TS09 TS10 | ||

| Stream 10 | MFS03 | ||

| Stream 11 | TS11 | ||

| Stream 13 | TS12 | MFS04 | |

| Stream 14 | PS04 | TS13 TS14 TS15 | |

| Stream 15 | PS05 | ||

| Stream 19 | TS16 TS17 TS18 | ||

| Stream 20 | MFS05 |

| Parameter | Reference Model | Present Model | Deviation | |

|---|---|---|---|---|

| Input value | AC pressure ratio | 15.0 | 15.0 | -- |

| AC inlet pressure (kPa) | 101.0 | 101.0 | -- | |

| AC inlet temperature (°C) | 25.0 | 25.0 | -- | |

| AC mass flow of air (kg/s) | 91.22 | 91.22 | -- | |

| AP outlet exhaust pressure (kPa) | 109.6 | 109.6 | -- | |

| AP outlet exhaust temperature (°C) | 527.6 | 527.6 | -- | |

| SC inlet pressure (kPa) | 8000 | 8000 | -- | |

| SC outlet pressure (kPa) | 20,000 | 20,000 | -- | |

| Output Value | SC mass flow of CO2 (kg/s) | 132.53 | 133.420 | 0.67% |

| AC consumption power (kW) | 40,014 | 39,817 | 0.49% | |

| GT output power (kW) | 70,997 | 71,129 | 0.19% | |

| ST1 output power (kW) | 9490 | 9553 | 0.66% | |

| ST2 output power (kW) | 6733 | 6777 | 0.65% | |

| SC consumption power (kW) | 3457 | 3480 | 0.67% | |

| Stream Number | Parameter | Design Value | Reconciliated Value | Deviation |

|---|---|---|---|---|

| Stream 9 | H cold side output temperature (°C) | 517.600 | 517.600 | 0 |

| Stream 10 | ST1 output temperature (°C) | 390.330 | 389.086 | 0.31% |

| Stream 12 | LTR hot side inlet mass flow (kg/s) | 132.530 | 133.419 | 0.67% |

| Stream 15 | SC output temperature (°C) | 62.690 | 62.690 | 0 |

| Stream 16 | H cold side inlet mass flow (kg/s) | 69.890 | 70.357 | 0.67% |

| Stream 17 | LTR cold side inlet mass flow (kg/s) | 62.640 | 63.062 | 0.67% |

| Stream 18 | HTR cold side inlet temperature (°C) | 255.470 | 255.470 | 0 |

| Stream 19 | HTR cold side output temperature (°C) | 380.330 | 380.325 | 0 |

| Working Condition | Sensors | Design Value | Measured Value | Unit |

|---|---|---|---|---|

| Condition 1 | -- | |||

| Condition 2 | -- | |||

| Condition 3 (1 gross error) | TS17 | 380.330 | 383.021 | °C |

| Condition 4 (1 gross error) | PS05 | 24.000 | 23.282 | MPa |

| Condition 5 (1 gross error) | MFS05 | 62.640 | 73.651 | kg/s |

| Condition 6 (1 gross error) | MFS04 | 132.530 | 149.173 | kg/s |

| Condition 7 (2 gross errors) | TS17 | 380.330 | 382.612 | °C |

| PS05 | 24.000 | 23.195 | MPa | |

| Condition 8 (2 gross errors) | MFS05 | 62.640 | 73.067 | kg/s |

| MFS04 | 132.530 | 149.819 | kg/s | |

| Condition 9 (3 gross errors) | TS17 | 380.330 | 383.332 | °C |

| PS05 | 24.000 | 23.208 | MPa | |

| MFS05 | 62.640 | 72.613 | kg/s | |

| Condition 10 (4 gross errors) | TS17 | 380.330 | 382.842 | °C |

| PS05 | 24.000 | 23.211 | MPa | |

| MFS05 | 62.640 | 72.865 | kg/s | |

| MFS04 | 132.530 | 150.383 | kg/s |

| Parameter | Design Val. | Measured | Reconciliated | Unit | ||||

|---|---|---|---|---|---|---|---|---|

| Val. | De. | Un. | Val. | De. | Un. | |||

| Mass flow of gas | 92.900 | 91.140 | 1.89% | 5.00% | 92.476 | 0.46% | 2.54% | kg/s |

| H hot side output temperature | 72.690 | 72.459 | 0.32% | 0.58% | 72.689 | 0.001% | 0.45% | °C |

| H cold side output temperature | 517.600 | 516.618 | 0.19% | 0.25% | 517.585 | 0.003% | 0.12% | °C |

| Mass flow of CO2 in ST1 | 69.890 | 71.942 | 2.94% | 10.00% | 70.085 | 0.28% | 2.55% | kg/s |

| SC inlet pressure | 8.000 | 7.928 | 0.90% | 2.00% | 7.971 | 0.36% | 1.37% | MPa |

| SC output pressure | 24.000 | 23.981 | 0.08% | 2.00% | 23.976 | 0.10% | 1.39% | MPa |

| SC inlet temperature | 32.000 | 31.288 | 2.22% | 0.66% | 31.955 | 0.14% | 0.20% | °C |

| HTR cold side output temperature | 380.330 | 379.476 | 0.22% | 0.31% | 380.278 | 0.01% | 0.13% | °C |

| Mass flow of CO2 | 132.530 | 132.529 | 0.001% | 10.00% | 132.950 | 0.32% | 2.58% | kg/s |

| Mass flow of CO2 in ST2 | 62.640 | 65.759 | 4.98% | 10.00% | 62.865 | 0.36% | 2.74% | kg/s |

| AC power | 40,014 | 39,817 | 0.49% | 12.38% | 39,868 | 0.36% | 2.86% | kW |

| GT power | 70,997 | 70,949 | 0.07% | 11.21% | 71,332 | 0.47% | 2.64% | kW |

| ST1 power | 9490 | 9480 | 0.10% | 11.73% | 9511 | 0.23% | 2.88% | kW |

| ST2 power | 6733 | 6713 | 0.29% | 15.92% | 6752 | 0.29% | 2.85% | kW |

| SC power | 3457 | 3433 | 0.69% | 11.93% | 3456 | 0.01% | 9.37% | kW |

| Parameter | Design Val. | Measured | Reconciliated | Unit | ||||

|---|---|---|---|---|---|---|---|---|

| Val. | De. | Un. | Val. | De. | Un. | |||

| Mass flow of gas | 92.900 | 94.240 | 1.44% | 5.00% | 92.910 | 0.01% | 2.54% | kg/s |

| H hot side output temperature | 72.690 | 73.379 | 0.95% | 0.58% | 72.821 | 0.18% | 0.46% | °C |

| H cold side output temperature | 517.600 | 516.579 | −0.20% | 0.25% | 517.768 | 0.03% | 0.12% | °C |

| Mass flow of CO2 in ST1 | 69.890 | 67.033 | −4.09% | 10.00% | 70.358 | 0.67% | 2.56% | kg/s |

| SC inlet pressure | 8.000 | 8.041 | 0.51% | 2.00% | 8.009 | 0.12% | 1.36% | MPa |

| SC output pressure | 24.000 | 24.154 | 0.64% | 2.00% | 24.081 | 0.34% | 1.39% | MPa |

| SC inlet temperature | 32.000 | 31.799 | −0.63% | 0.66% | 31.973 | −0.08% | 0.19% | °C |

| HTR cold side output temperature | 380.330 | 380.323 | −0.002% | 0.31% | 379.920 | −0.11% | 0.13% | °C |

| Mass flow of CO2 | 132.530 | 136.822 | 3.24% | 10.00% | 133.456 | 0.70% | 2.60% | kg/s |

| Mass flow of CO2 in ST2 | 62.640 | 63.773 | 1.81% | 10.00% | 63.098 | 0.73% | 2.75% | kg/s |

| AC power | 40,014 | 39,817 | −0.49% | 12.38% | 39,692 | −0.80% | 2.87% | kW |

| GT power | 70,997 | 71,330 | 0.47% | 11.21% | 71,707 | 1.00% | 2.64% | kW |

| ST1 power | 9490 | 9516 | 0.28% | 11.80% | 9594 | 1.10% | 2.87% | kW |

| ST2 power | 6733 | 6804 | 1.07% | 15.80% | 6802 | 1.03% | 2.83% | kW |

| SC power | 3457 | 3448 | −0.26% | 12.09% | 3512 | 1.60% | 9.54% | kW |

| Working Condition | Gross Error Detection | Criterion Value of | Design Value | Measured Value | Reconciliated Value |

|---|---|---|---|---|---|

| Condition 3 | TS17 (Temperature, °C) | 2.559 | 380.330 | 383.021 | 380.658 |

| Condition 4 | PS05 (Pressure, MPa) | 2.198 | 24.000 | 23.282 | 23.653 |

| Condition 5 | MFS05 (Mass flow, kg/s) | 2.713 | 62.640 | 73.651 | 63.759 |

| Condition 6 | MFS04 (Mass flow, kg/s) | 2.345 | 132.530 | 149.173 | 131.808 |

| Condition 7 | TS17 (Temperature, °C) | 2.376 | 380.330 | 382.612 | 380.418 |

| PS05 (Pressure, MPa) | 2.097 | 24.000 | 23.195 | 23.651 | |

| Condition 8 | MFS05 (Mass flow, kg/s) | 2.688 | 62.640 | 73.067 | 63.347 |

| MFS04 (Mass flow, kg/s) | 2.147 | 132.530 | 149.819 | 133.867 | |

| Condition 9 | MFS05 (Mass flow, kg/s) | 2.599 | 62.640 | 72.613 | 63.273 |

| TS17 (Temperature, °C) | 2.586 | 380.330 | 383.332 | 380.946 | |

| PS05 (Pressure, MPa) | 2.042 | 24.000 | 23.208 | 23.653 | |

| Condition 10 | MFS05 (Mass flow, kg/s) | 2.512 | 62.640 | 72.865 | 63.803 |

| TS17 (Temperature, °C) | 2.206 | 380.330 | 382.842 | 380.806 | |

| MFS04 (Mass flow, kg/s) | 2.094 | 132.530 | 150.383 | 134.755 | |

| PS05 (Pressure, MPa) | 2.004 | 24.000 | 23.211 | 23.651 |

| Parameter | Design Val. | Measured | Reconciliated | Unit | ||||

|---|---|---|---|---|---|---|---|---|

| Val. | De. | Un. | Val. | De. | Un. | |||

| Mass flow of gas | 92.900 | 92.650 | −0.27% | 5.00% | 93.495 | 0.64% | 2.54% | kg/s |

| H hot side output temperature | 72.690 | 73.416 | 0.10% | 0.58% | 73.512 | 1.13% | 0.46% | °C |

| H cold side output temperature | 517.600 | 518.318 | 0.14% | 0.25% | 517.932 | 0.06% | 0.12% | °C |

| Mass flow of CO2 in ST1 | 69.890 | 70.056 | 0.24% | 10.00% | 70.952 | 1.52% | 2.56% | kg/s |

| SC inlet pressure | 8.000 | 8.033 | 0.42% | 2.00% | 8.013 | 0.17% | 1.36% | MPa |

| SC inlet temperature | 32.000 | 32.086 | 0.27% | 0.66% | 32.396 | 1.24% | 0.18% | °C |

| AC power | 40,014 | 39,817 | −0.49% | 12.38% | 39,908 | −0.26% | 2.85% | kW |

| GT power | 70,997 | 71,131 | 0.19% | 11.21% | 72,305 | 1.84% | 2.64% | kW |

| ST1 power | 9490 | 9549 | 0.63% | 11.86% | 9648 | 1.67% | 2.86% | kW |

| ST2 power | 6733 | 6789 | 0.84% | 15.91% | 6873 | 2.09% | 2.87% | kW |

| SC power | 3457 | 3502 | 1.30% | 12.23% | 3479 | 0.64% | 9.47% | kW |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; You, J.; Wu, J.; Liu, Y.; Zhang, D. Parameter Correction on Waste Heat Recovery System of a Gas Turbine Using Supercritical CO2 Based on Data Reconciliation. Appl. Sci. 2025, 15, 248. https://doi.org/10.3390/app15010248

Xu L, You J, Wu J, Liu Y, Zhang D. Parameter Correction on Waste Heat Recovery System of a Gas Turbine Using Supercritical CO2 Based on Data Reconciliation. Applied Sciences. 2025; 15(1):248. https://doi.org/10.3390/app15010248

Chicago/Turabian StyleXu, Liang, Jiarui You, Jiahua Wu, Yikang Liu, and Di Zhang. 2025. "Parameter Correction on Waste Heat Recovery System of a Gas Turbine Using Supercritical CO2 Based on Data Reconciliation" Applied Sciences 15, no. 1: 248. https://doi.org/10.3390/app15010248

APA StyleXu, L., You, J., Wu, J., Liu, Y., & Zhang, D. (2025). Parameter Correction on Waste Heat Recovery System of a Gas Turbine Using Supercritical CO2 Based on Data Reconciliation. Applied Sciences, 15(1), 248. https://doi.org/10.3390/app15010248