Mechanical Properties of Aramid Fiber Fabrics and Composites Enhanced by Phthalic Anhydride Catalyzed with Anhydrous Aluminum Chloride

Abstract

1. Introduction

2. Experimental Study

2.1. Materials and Reagents

2.2. Experimental Method

2.2.1. PPTA Pretreatment

2.2.2. Surface Modification of PPTA by Phthalic Anhydride

2.2.3. Catalytic Modification of PPTA with Phthalic Anhydride by Anhydrous AlCl3

2.2.4. Preparation of PPTA-Reinforced Composite

2.3. Test Characterization Method

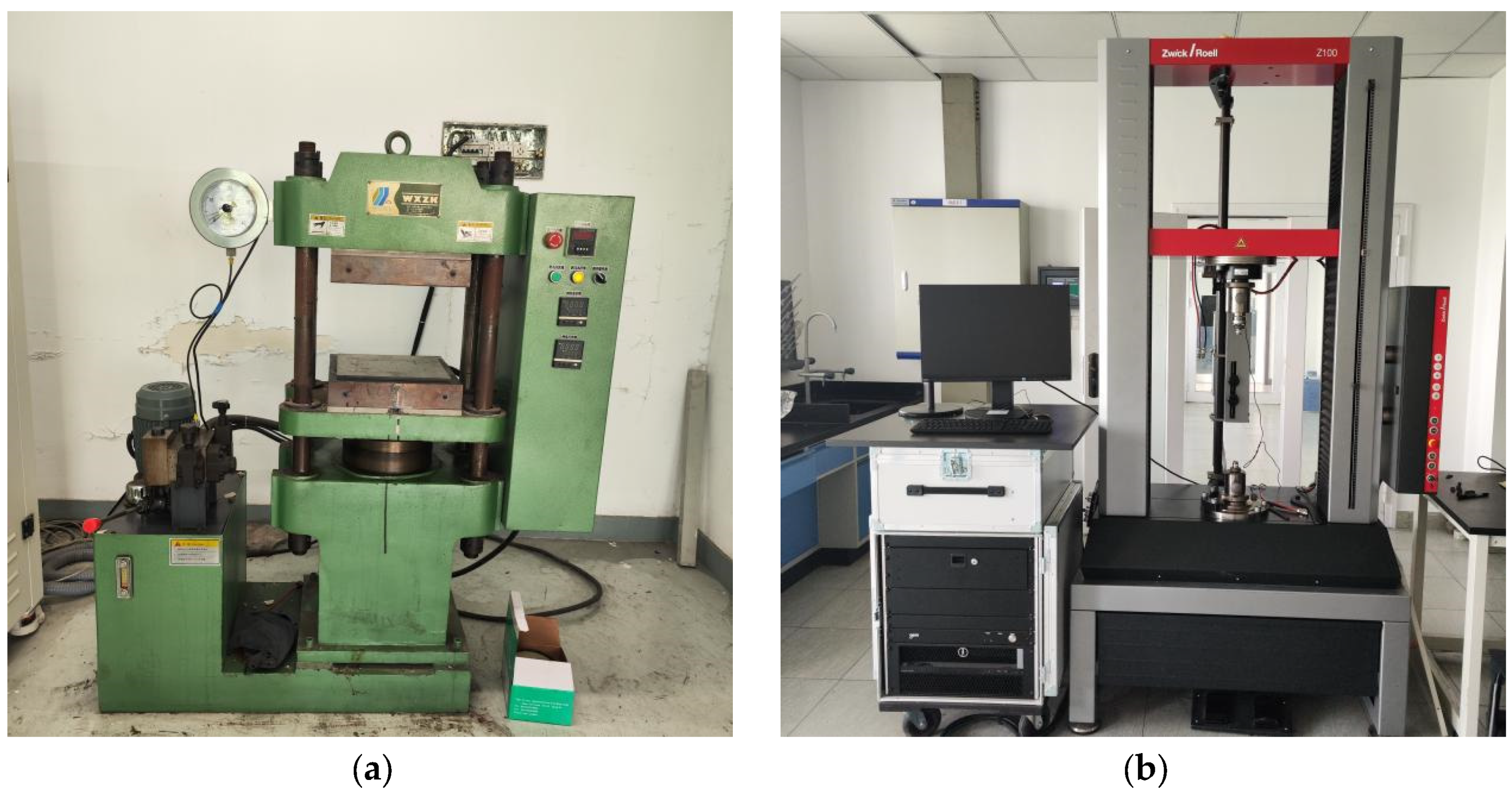

2.3.1. Test Equipment

2.3.2. Characterization of Fiber Microstructure

2.3.3. Mechanical Properties Tests of Composite Materials

2.3.4. Interface Performance Tests of Composite Materials

3. Results and Discussion

3.1. Influence of Phthalic Anhydride Solution Concentration on the Surface Properties of PPTA Fiber

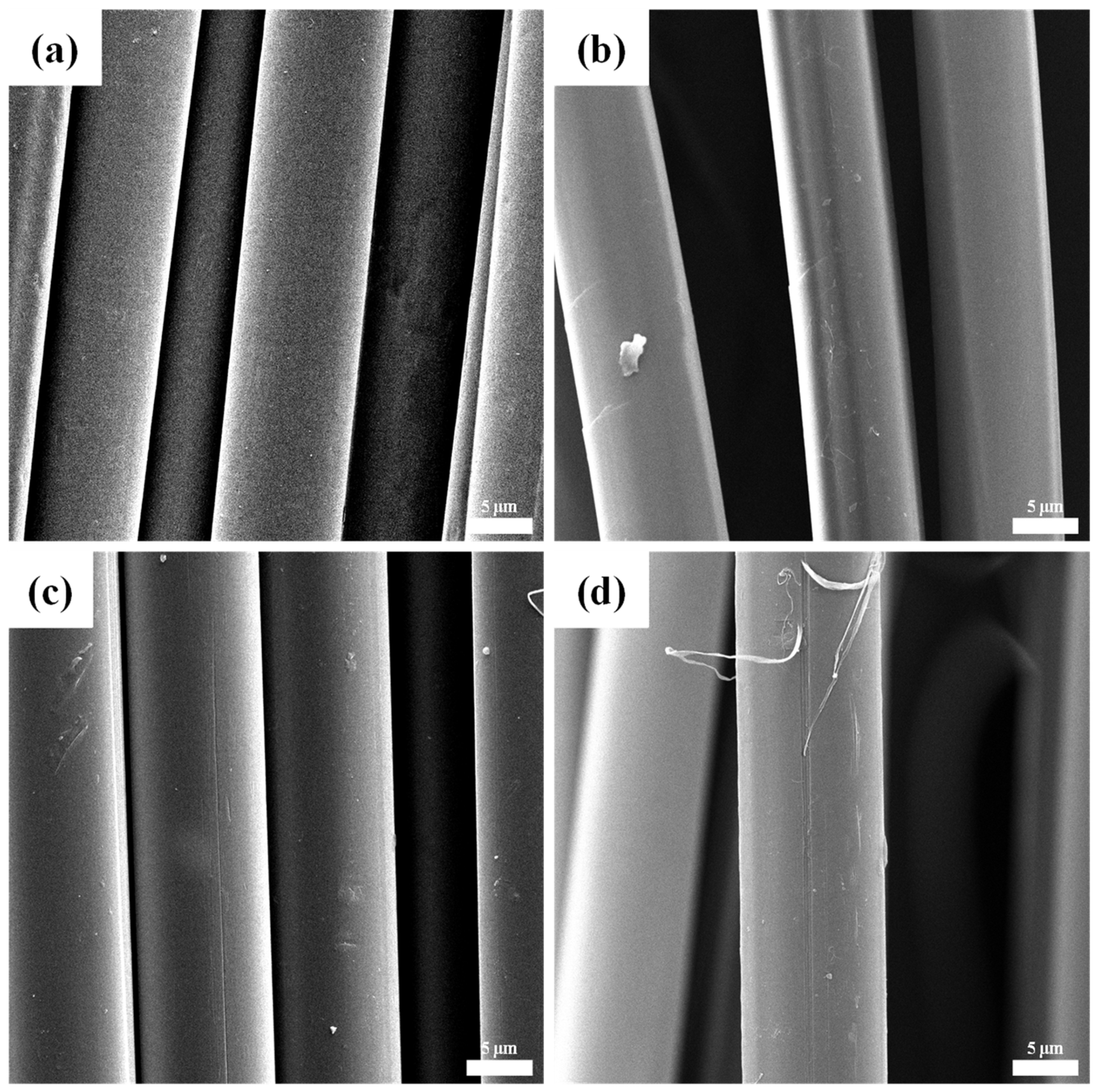

3.1.1. Study on Microstructures of PPTA Fiber Surface before and after Modification

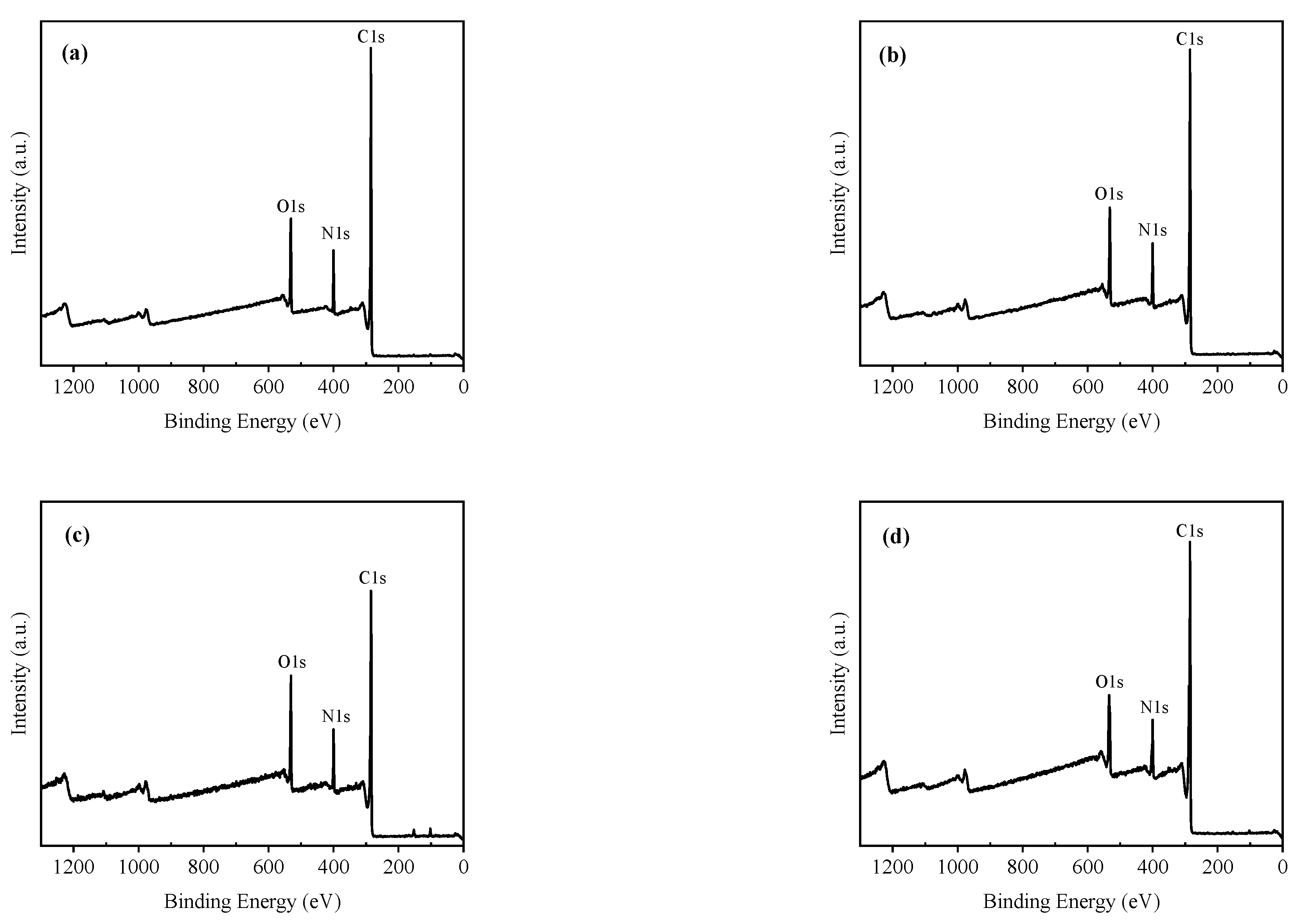

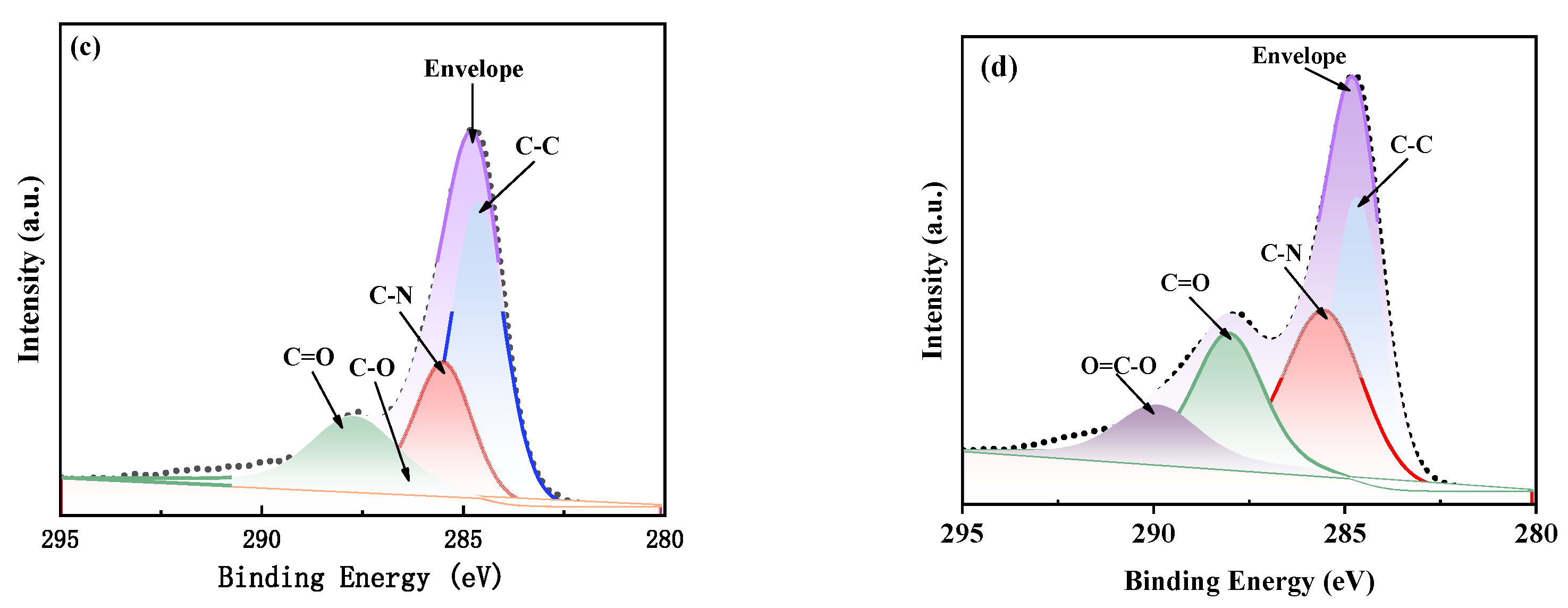

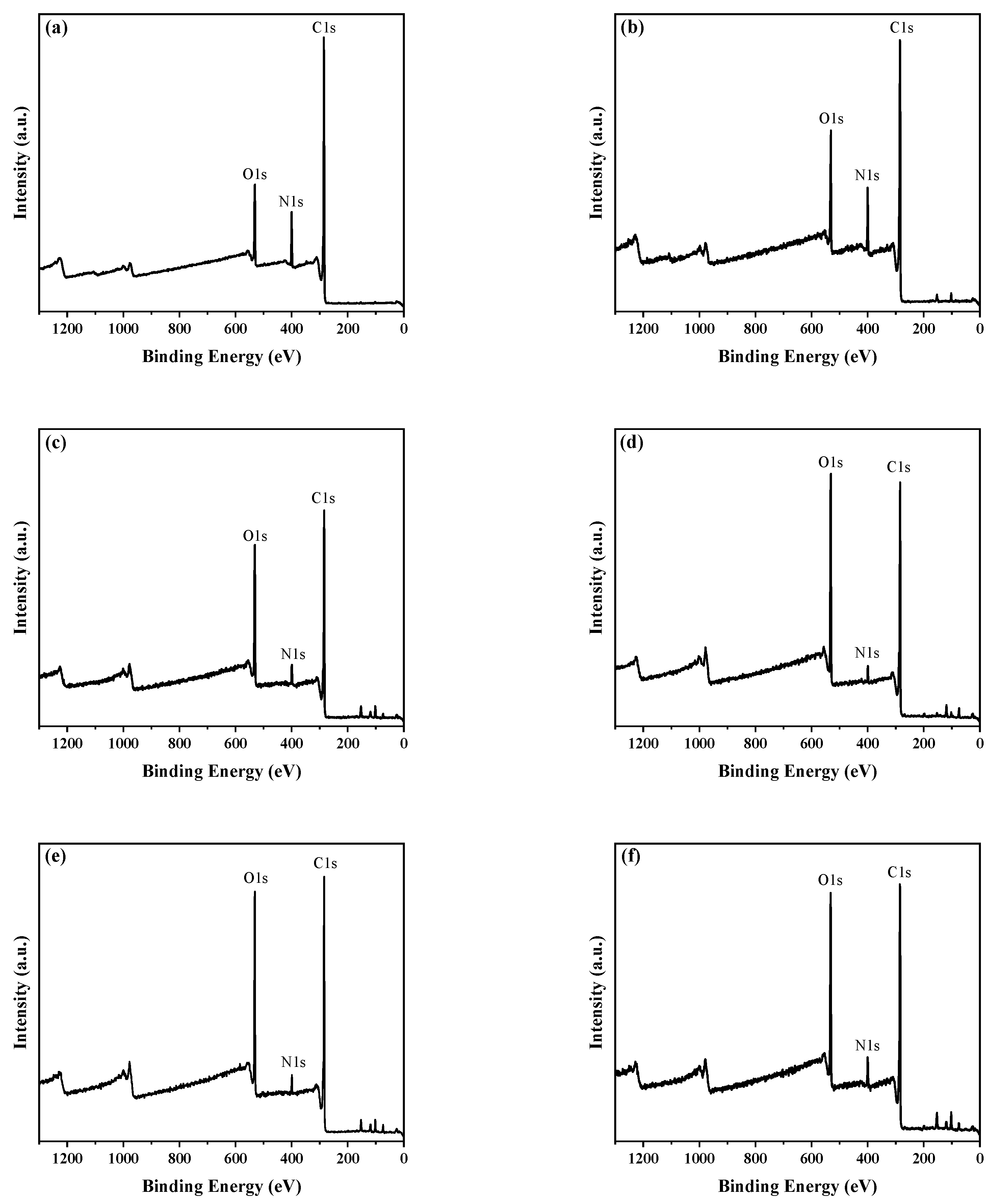

3.1.2. Study on Surface Element Compositions of Aramid Fiber before and after Modification

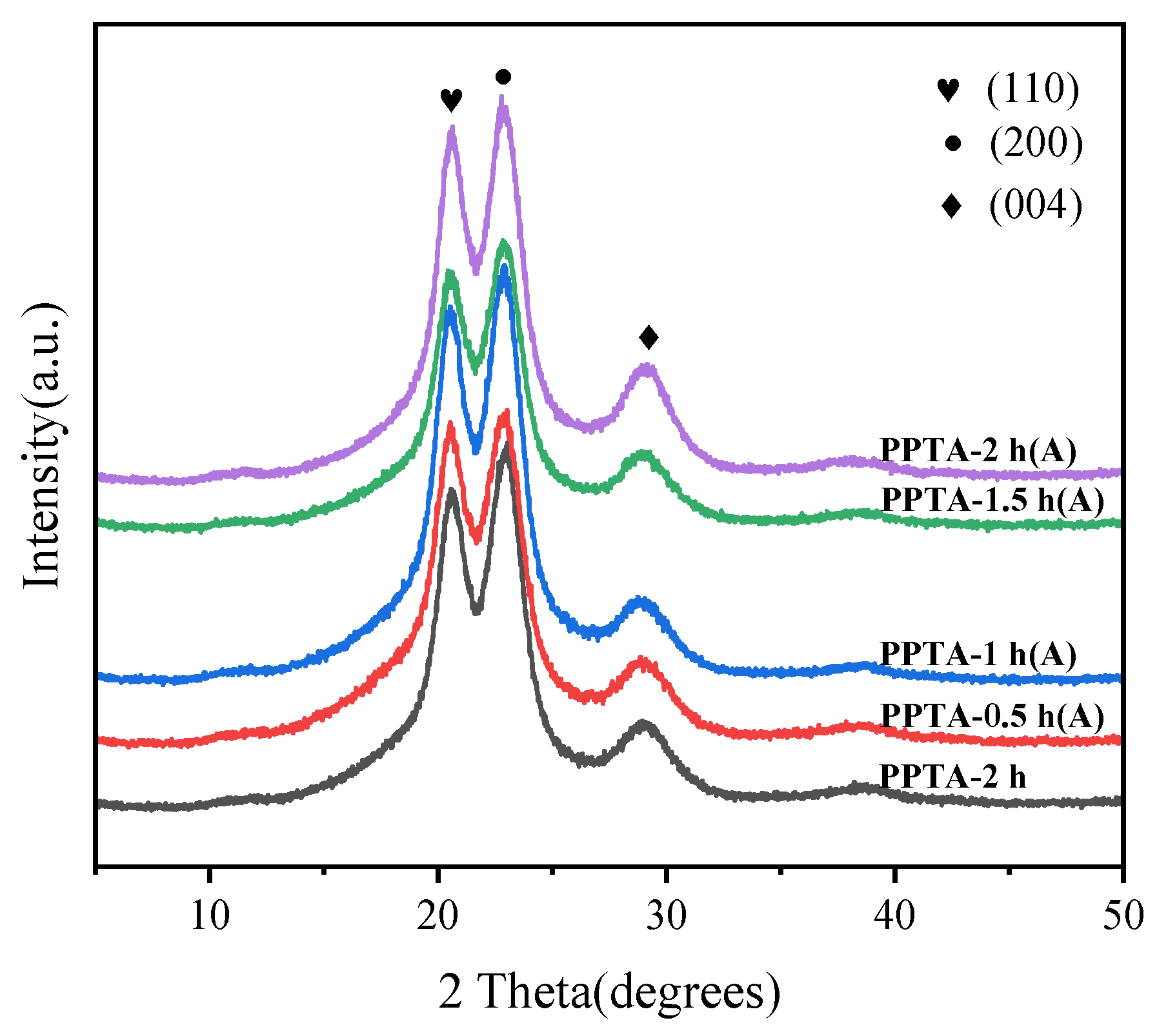

3.1.3. Study on Crystalline Structures of Aramid Fibers before and after Modification

3.2. Influence of Anhydrous AlCl3 Catalysis Modification Time on Surface Properties of PPTA Fiber

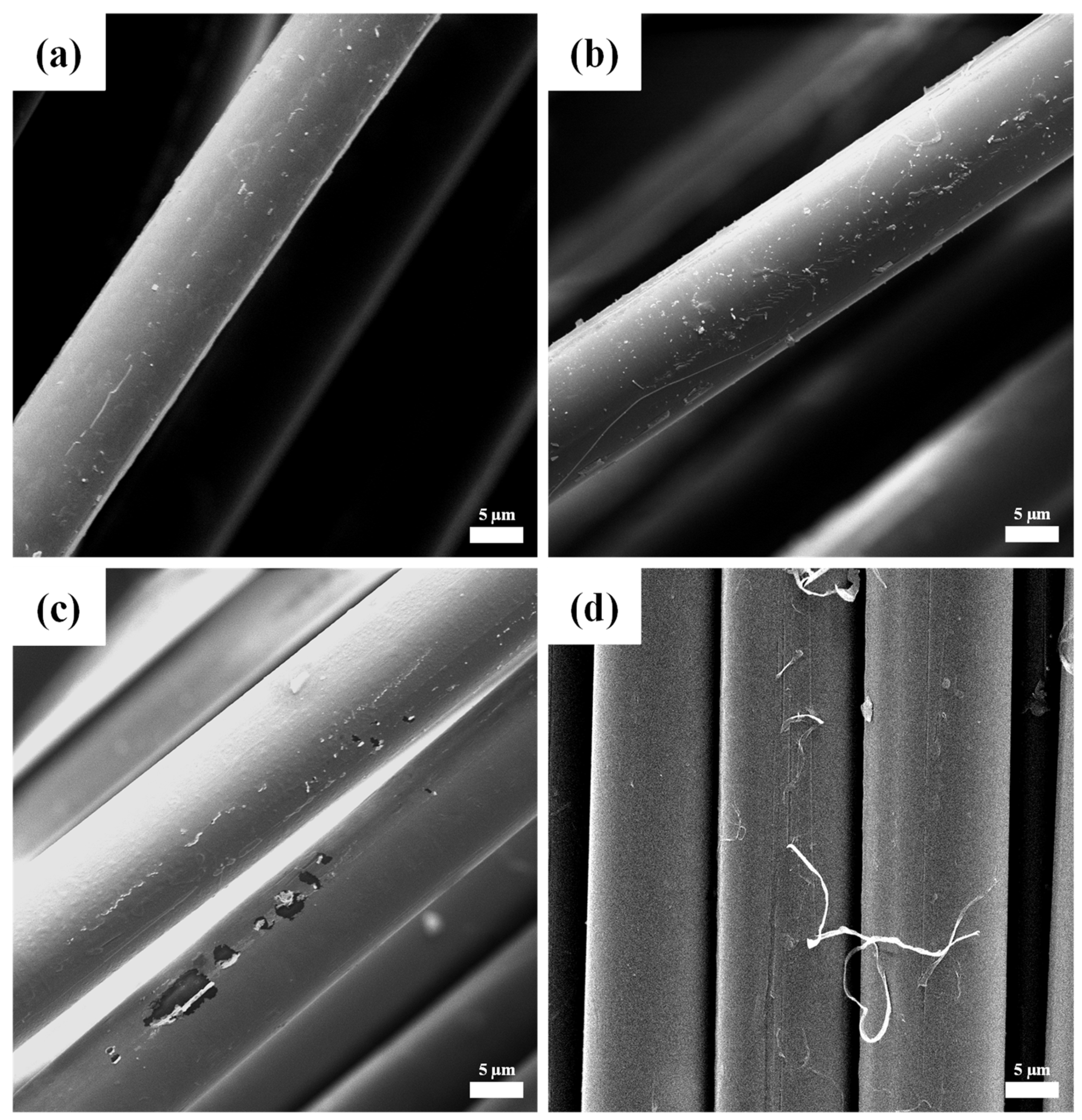

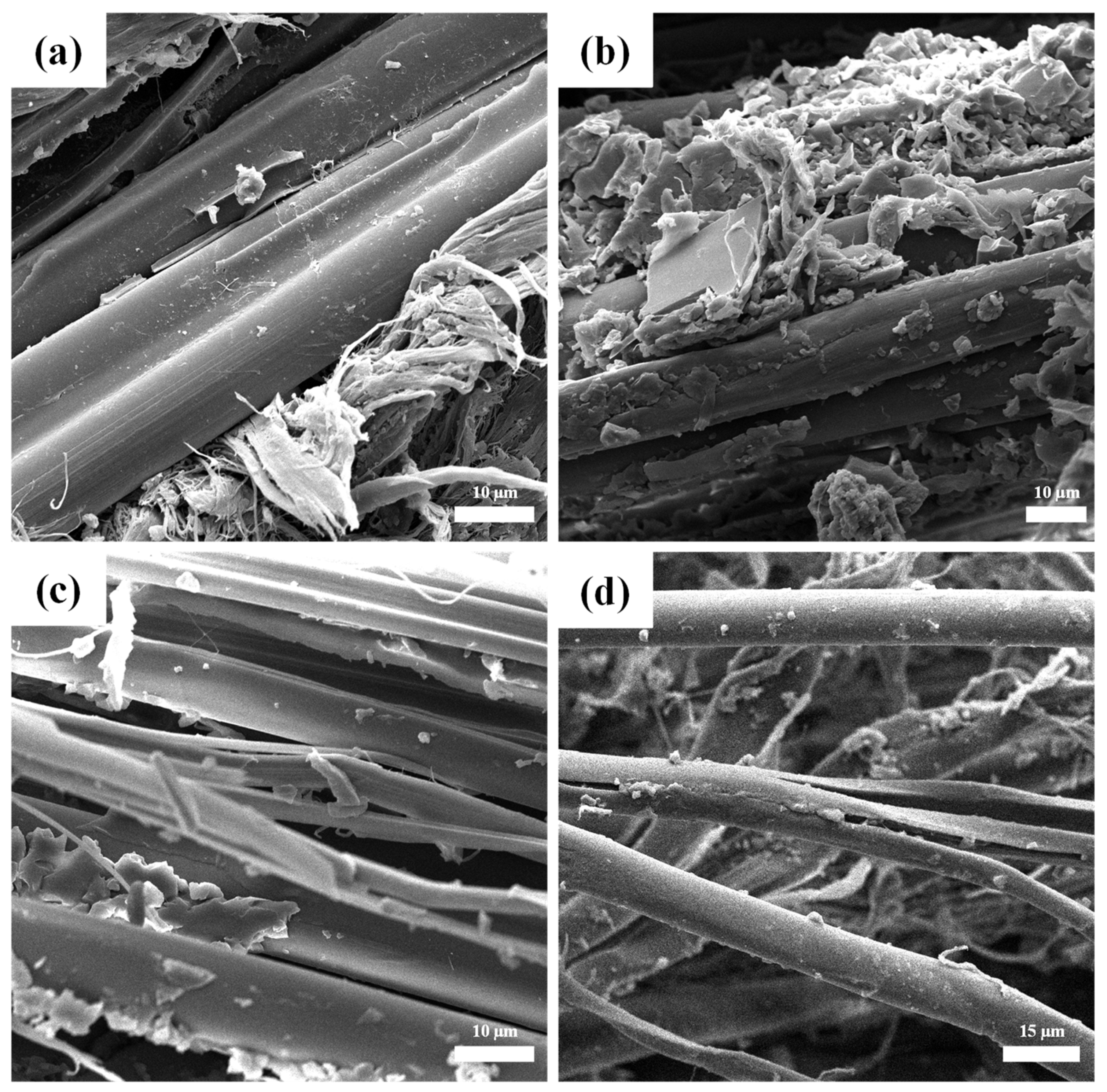

3.2.1. SEM Analysis of Fiber Surface Morphology before and after Modification

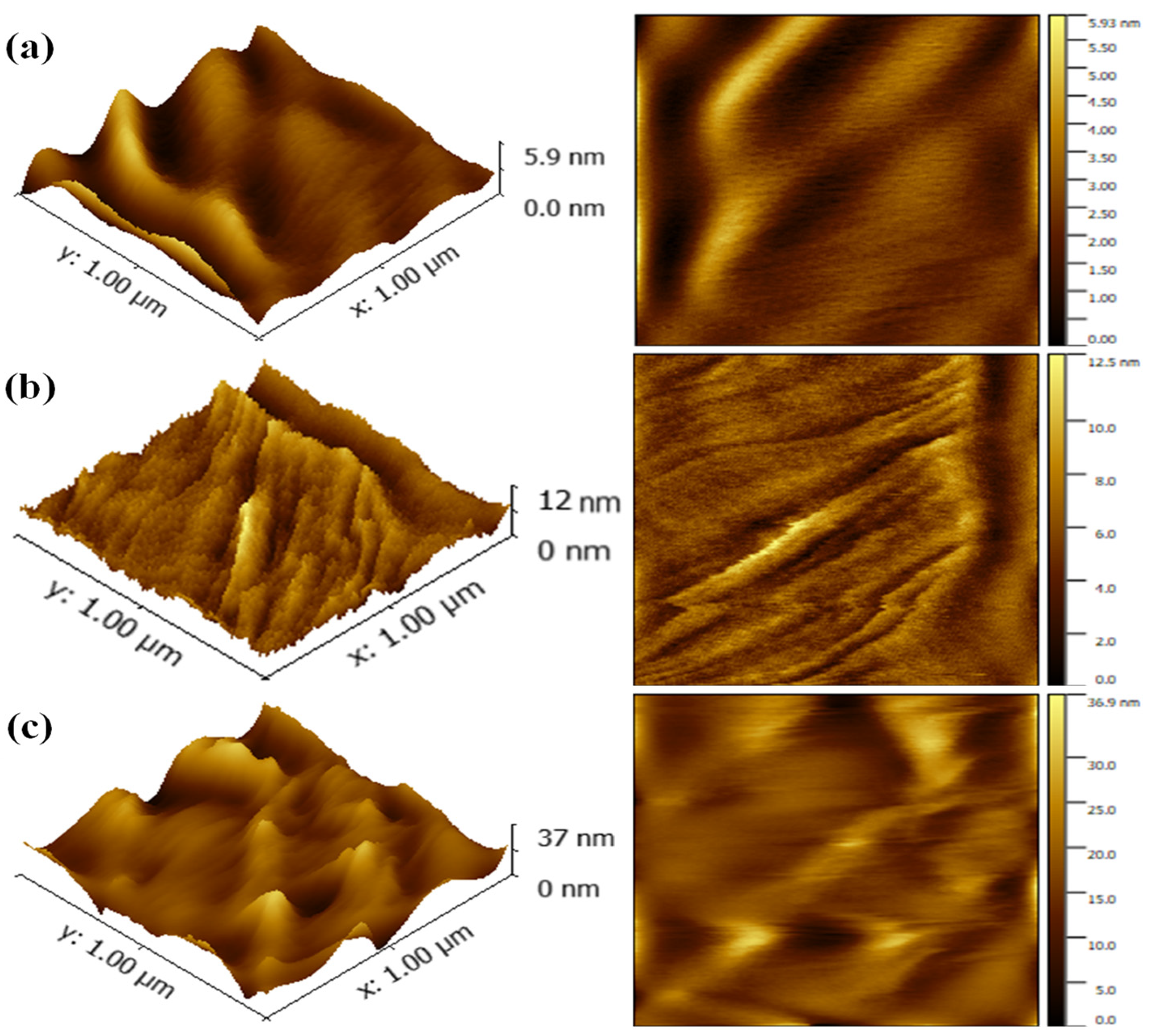

3.2.2. Analysis of AFM on Surface Morphology of Fibers before and after Modification

3.2.3. Study of Surface Elemental Composition before and after Catalytic Modification of Fiber

3.2.4. Fiber Crystal Structures before and after Catalytic Modification

3.3. Influence of Modification Treatment on Properties of PPTA/DGEBA Composite Materials

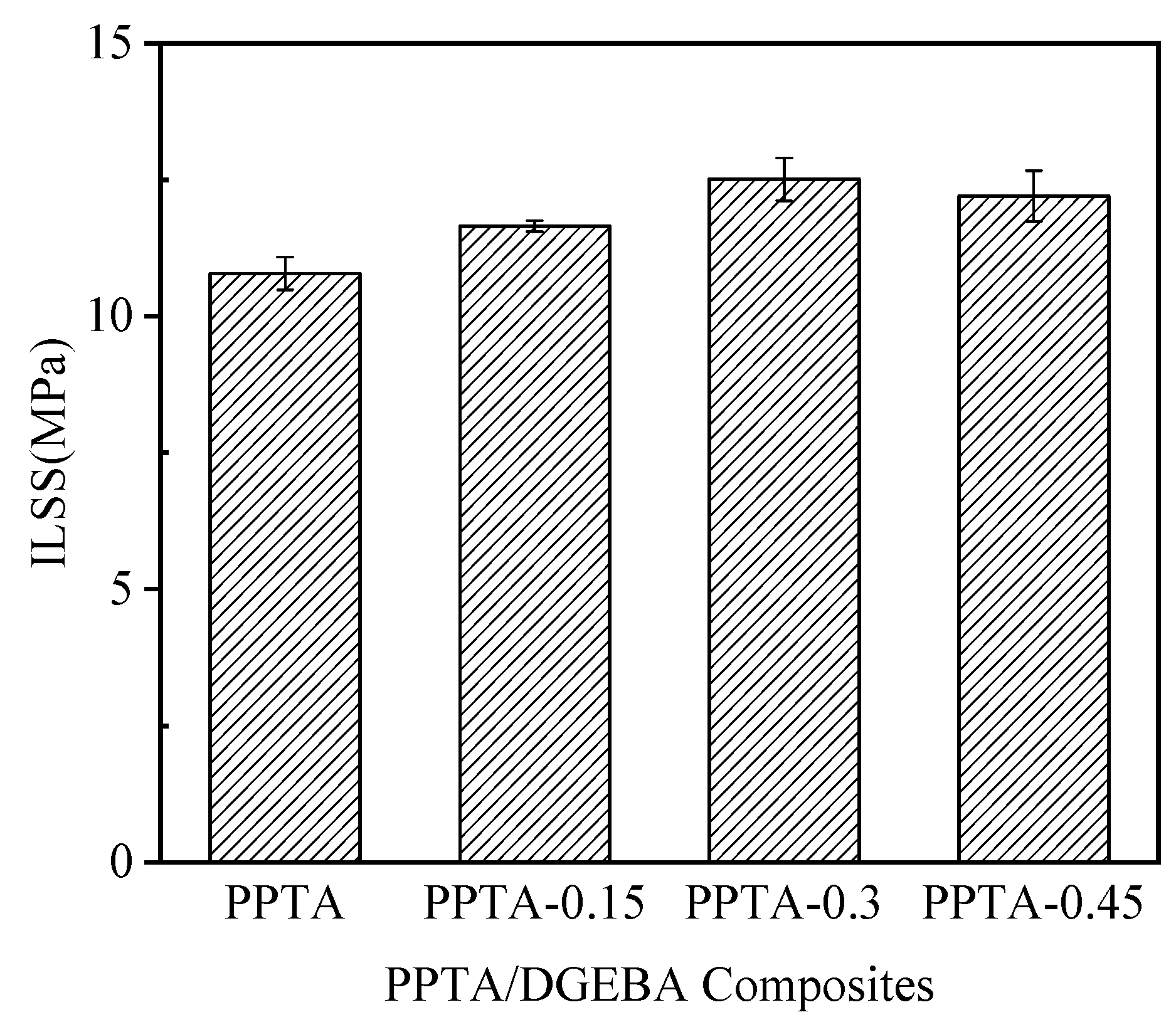

3.3.1. Interfacial Properties of PPTA/DGEBA Composites before and after Anhydride Modification

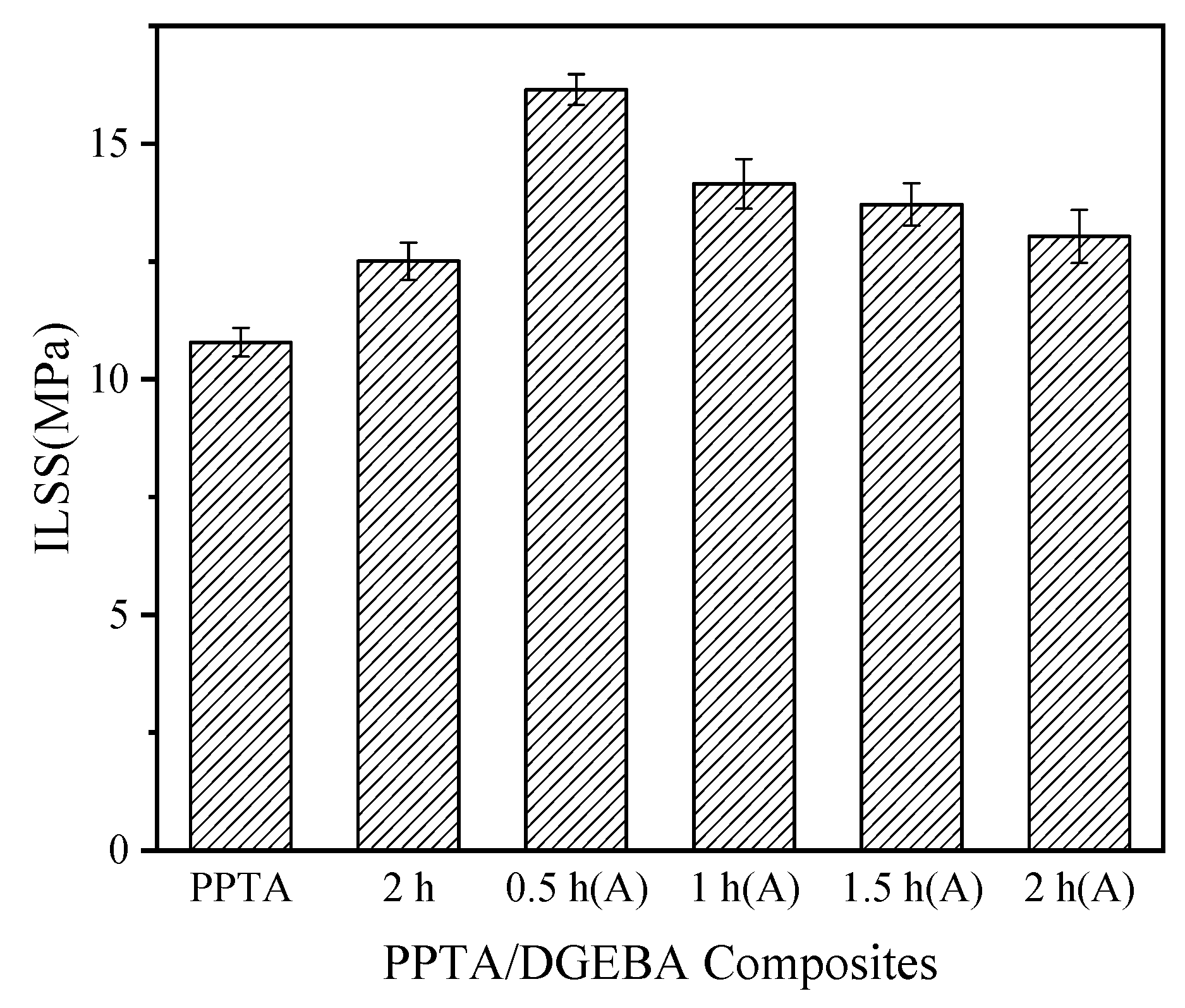

3.3.2. Interfacial Properties of PPTA/DGEBA Composite Materials before and after Catalytic Modification

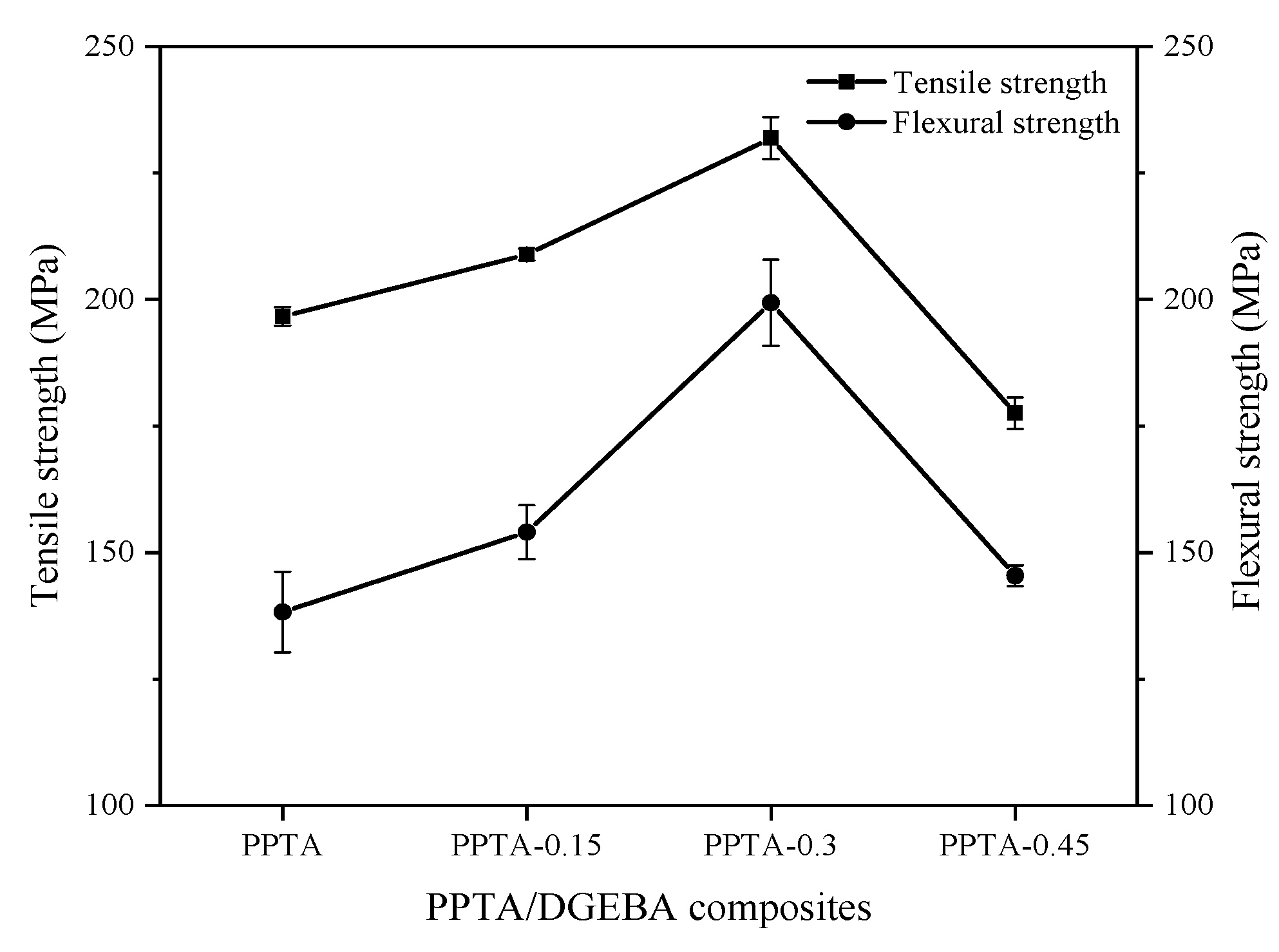

3.3.3. Mechanical Properties of PPTA/DGEBA Composite Materials before and after Maleic Anhydride Modification

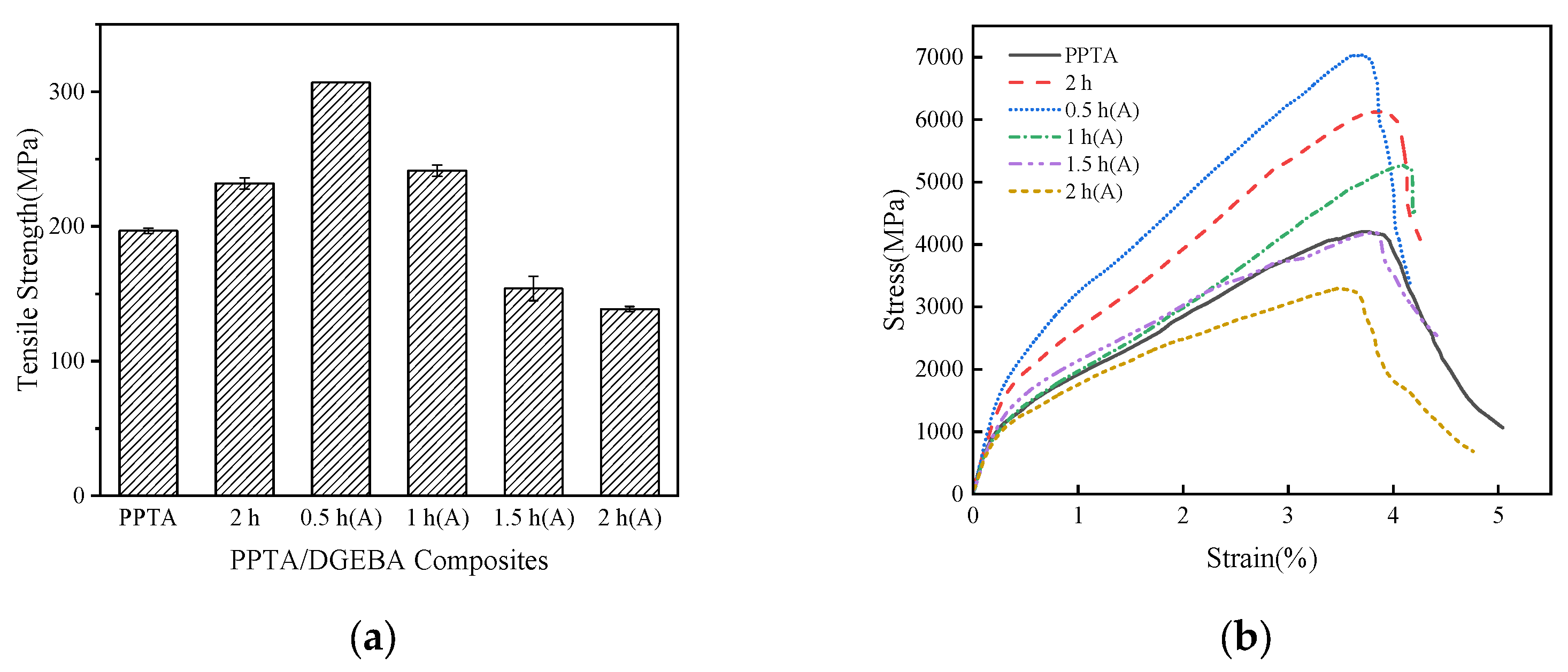

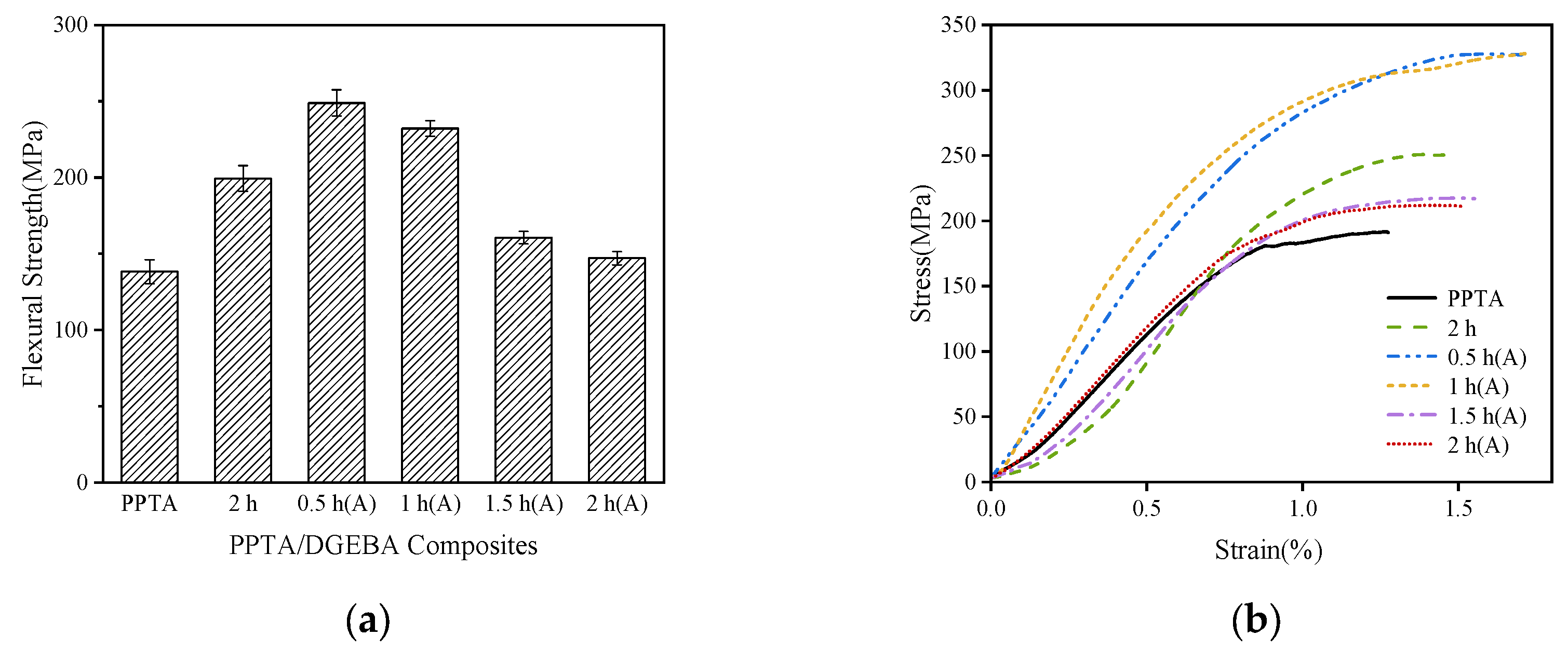

3.3.4. Mechanical Properties of PPTA/DGEBA Composite Materials before and after Catalytic Modification

4. Conclusions

- Phthalic anhydride can undergo an acylation reaction with PPTA fiber, introducing -OH active functional groups onto the phenyl rings of the fibers. Some of the amide bonds on the fibers undergo hydrolysis to form -COOH, increasing the O/C elemental ratio on the fiber surface. With increase in the concentration of phthalic anhydride, the O/C ratio initially increases and then decreases. When the concentration of pyromellitic anhydride is 0.3 mol/L, the O/C ratio reaches its maximum value of 0.176, representing an 18.12% increase compared to unmodified PPTA fiber.

- After modification with 0.3 mol/L phthalic anhydride, the tensile strength, flexural strength, and interlaminar shear strength of the PPTA/DGEBA composite materials all increased to their maximum values, showing improvements of 17.94%, 44.18%, and 15.94%, respectively, compared to unmodified specimens.

- Anhydrous AlCl3 can serve as a catalyst for the acylation reaction between phthalic anhydride and PPTA fiber, reducing the modification time and increasing the introduction rate of oxygen-containing functional groups on the fiber surface, resulting in an increase in the O/C elemental ratio on the fiber surface. After catalytic modification for 0.5 h, 1 h, 1.5 h, and 2 h, the O/C elemental ratio on the fiber surface shows an increasing trend. Compared to PPTA fiber modified without the addition of catalyst, the O/C elemental ratio increased by 74.43%, 121.02%, 101.70%, and 80.68%, respectively.

- After catalytic modification for 0.5 h, the tensile strength, flexural strength, and interlaminar shear strength of the PPTA/DGEBA composite materials all increased to their maximum values. Compared to non-catalyzed modified samples, there were improvements of 32.28%, 24.91%, and 29.10%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lertwassana, W.; Parnklang, T.; Mora, P.; Jubsilp, C.; Rimdusit, S. High Performance Aramid Pulp/carbon Fiber-reinforced Polybenzoxazine Composites as Friction Materials. Compos. Part B Eng. 2019, 177, 107280. [Google Scholar] [CrossRef]

- Keita, S.; Osamu, T.; Mikiya, T.; Junji, O.; Jun, M.; Toshihiko, N. Research on Prevention of Collapse of Existing Dangerous Masonry Walls by Reinforcement Using Polyurea Resin and Aramid Fiber Tape. In EASEC16: Proceedings of the 16th East Asian-Pacific Conference on Structural Engineering and Construction, Brisbane, Australia, 23 December 2020; Springer: Singapore, 2020; Volume 101, pp. 515–528. [Google Scholar] [CrossRef]

- Karthik, K.; Rajamani, D.; Raja, T.; Subramani, K. Experimental Investigation on the Mechanical Properties of Carbon/Kevlar Fibre Reinforced Epoxy LY556 Composites. Mater. Today Proc. 2021, 52, 668–674. [Google Scholar] [CrossRef]

- He, A.; Xing, T.; Liang, Z.; Luo, Y.; Zhang, Y.; Wang, M.; Huang, Z.; Bai, J.; Wu, L.; Shi, Z.; et al. Advanced Aramid Fibrous Materials: Fundamentals, Advances, and Beyond. Adv. Fiber. Mater. 2024, 6, 3–35. [Google Scholar] [CrossRef]

- Callomamani, L.A.P.; Bala, N.; Hashemian, L. Comparative Analysis of the Impact of Synthetic Fibers on Cracking Resistance of Asphalt Mixes. Int. J. Pavement Res. Technol. 2023, 16, 992–1008. [Google Scholar] [CrossRef]

- Hong, C.; Li, H.; Yang, D.; Li, H.; Zhang, H.; Lorenzo, R. Compressive Performance of AFRP Reinforced Laminated Bamboo Stub Columns. Archiv. Civ. Mech. Eng. 2022, 22, 31. [Google Scholar] [CrossRef]

- Rolland, A.; Chataigner, S.; Benzarti, K.; Quiertant, M.; Argoul, P.; Paul, J.M. Experimental Investigation and Modeling of the Bond between Aramid Fiber-reinforced Polymer Bars and Concrete. Adv. Civ. Eng. Mater. 2016, 5, 115–128. [Google Scholar] [CrossRef]

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine Application of Fiber Reinforced Composites: A Review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Qiang, X.; Chen, L.; Jiang, X. Experimental and Theoretical Study on Flexural Behavior of Steel-concrete Composite Beams Strengthened by CFRP Plates with Unbonded Retrofit Systems. Compos. Struct. 2023, 309, 116763. [Google Scholar] [CrossRef]

- Qiang, X.; Shu, Y.; Jiang, X.; Xiao, Y.; Jin, P. Mechanical Behavior of Carbon Fiber-reinforced Polymer/steel Bonded Joints after Large-space Fires and Thermal Conductivity of Non-intumescent Coatings. J. Build. Eng. 2024, 86, 108803. [Google Scholar] [CrossRef]

- Chen, L.; Qiang, X.; Sun, P.; Zhang, S.; Jiang, X. Experimental and Theoretical Study on Flexural Behavior of Prestressed Concrete Beams Strengthened by CFRP Tendons with External Unbonded Retrofit System. J. Build. Eng. 2024, 89, 109301. [Google Scholar] [CrossRef]

- Honickman, H.; Fam, A. Investigating a Structural form System for Concrete Girders Using Commercially Available GFRP Sheet-pile Sections. J. Compos. Constr. 2009, 13, 455–465. [Google Scholar] [CrossRef]

- Mathieson, H.; Fam, A. High Cycle Fatigue under Reversed Bending of Sandwich Panels with GFRP Skins and Polyurethane Foam Core. Compos. Struct. 2014, 113, 31–39. [Google Scholar] [CrossRef]

- Sanya, O.T.; Shi, J. Ultra-high-performance Fiber Reinforced Concrete Review: Constituents, Properties, and Applications. Innov. Infrastruct. Solut. 2023, 8, 188. [Google Scholar] [CrossRef]

- Palola, S.; Vuorinen, J.; Noordermeer, J.W.M.; Sarlin, E. Development in Additive Methods in Aramid Fiber Surface Modification to Increase Fiber-Matrix Adhesion: A Review. Coatings 2020, 10, 556. [Google Scholar] [CrossRef]

- Kumar, S.; Malek, A.; Babu, R.; Mathur, S. Ballistic Efficiency of Multilayered Armor System Reinforced with Jute-Kevlar Epoxy Composite against High-Energy Steel Core Projectile. J. Mater. Eng. Perform. 2021, 30, 8447–8464. [Google Scholar] [CrossRef]

- Zhang, B.; Jia, L.; Tian, M.; Ning, N.; Zhang, L.; Wang, W. Surface and Interface Modification of Aramid Fiber and Its Reinforcement for Polymer Composites: A Review. Eur. Polym. J. 2021, 147, 110352. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, Z.; Yuan, J.; Wu, L.; Li, P.; Zhao, X.; Men, X. Enhanced Mechanical and Tribological Properties of Kevlar/PTFE-phenolic Composites by Improving Interfacial Properties by Aramid Nanofibers. Polym. Compos. 2020, 41, 4192–4201. [Google Scholar] [CrossRef]

- Zhang, S.; Shi, Z.; Cui, P.; Duan, N.; Li, X. Surface Modification of Aramid Fibers with CaCl2 Treatment and Secondary Functionalization of Silane Coupling Agents. J. Appl. Polym. Sci. 2020, 137, 49159. [Google Scholar] [CrossRef]

- Kandekar, S.B.; Talikoti, R.S. Torsional Behaviour of Reinforced Concrete Beams Retrofitted with Aramid Fiber. Adv. Concr. Constr. 2020, 9, 1–7. [Google Scholar] [CrossRef]

- Li, Y.-F.; Wang, H.-F.; Syu, J.-Y.; Ramanathan, G.K.; Tsai, Y.-K.; Lok, M.H. Mechanical Properties of Aramid Fiber-reinforced Composites and Performance on Repairing Concrete Beams Damaged by Corrosion. Songklanakarin J. Sci. Technol. 2020, 42, 637–644. [Google Scholar]

- Wiśniewski, D.; Słowik, M.; Kempa, J.; Lewandowska, A.; Malinowska, J. Assessment of Impact of Aramid Fibre Addition on the Mechanical Properties of Selected Asphalt Mixtures. Materials 2020, 13, 3302. [Google Scholar] [CrossRef]

- Bohara, R.P.; Tanapornraweekit, G.; Tangtermsirikul, S. An Experimental Study on Mechanical Properties and Cracking Behaviors of AFRC Used as Functional Material in Hybrid Beams. Int. J. Civ. Eng. 2019, 17, 1433–1444. [Google Scholar] [CrossRef]

- Zakaib, S.; Fam, A. Flexural Performance and Moment Connection of Concrete-filled GFRP Tube–encased Steel I-sections. J. Compos. Constr. 2012, 16, 604–613. [Google Scholar] [CrossRef]

- Betts, D.; Sadeghian, P.; Fam, A. Experimental Behavior and Design-oriented Analysis of Sandwich Beams with Bio-based Composite Facings and Foam Cores. J. Compos. Constr. 2018, 22, 04018020. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, L.; Zhou, K. Improvement in the Mechanical Performance of Multi Jet Fusion–printed Aramid fiber/Polyamide 12 Composites by Fiber Surface Modification. Addit. Manuf. 2022, 51, 102576. [Google Scholar] [CrossRef]

- Lin, G.; Wang, H.; Yu, B.; Qu, G.; Chen, S.; Kuang, T.; Yu, K.; Liang, Z. Combined Treatments of Fiber Surface Etching/silane Coupling for Enhanced Mechanical Strength of Aramid Fiber-reinforced Rubber Blends. Mater. Chem. Phys. 2020, 255, 123486. [Google Scholar] [CrossRef]

- Li, Y.; Xie, G.; Li, R.; Wu, Y.; Chen, C.; Luo, Z. Supercritical carbon dioxide assisted impregnation and graft of polyamide acid into aramid fiber for formation of polar interface. J. Mater. Res. Technol. 2022, 21, 1–11. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, B.; Li, X.; Wang, W.; Tian, M.; Fan, Z.; Zhang, L. Enhanced Adhesion Property of Aramid Fibers by Polyphenol-metal Iron Complexation and Ailane Grafting. J. Adhes. 2021, 97, 346–360. [Google Scholar] [CrossRef]

- Zuo, L.S.; Li, K.; Ren, D.X.; Xu, M.Z.; Tong, L.F.; Liu, X.B. Surface Modification of Aramid Fiber by Crystalline Polyarylene Ether Nitrile Sizing for Improving Interfacial Adhesion with Polyarylene Ether Nitrile. Compos. Part B 2021, 217, 107608. [Google Scholar] [CrossRef]

- Han, Y.T.; Tada, K.; Osawa, K.; Uchida, H.; Tamura, K. Surface Modification of Aramid Fiber with Acrylic Acid Assisted by Supercritical Carbon Dioxide. J. Supercrit. Fluids. 2023, 192, 105787. [Google Scholar] [CrossRef]

- Miao, L.; Wang, X.; Li, S.; Tu, Y.Y.; Hu, J.W.; Huang, Z.Z.; Lin, S.D.; Gui, X.F. An Ultra-Stretchable Polyvinyl Alcohol Hydrogel Based on Tannic Acid Modified Aramid Nanofibers for Use as a Strain Sensor. Polymers 2022, 14, 3532. [Google Scholar] [CrossRef] [PubMed]

- Zahra, M.; Zulfiqar, S.; Skene, W.G.; Sarwar, M.I. Crosslinking of Polyamides Using Dianhydrides, Diacid Chloride and Dialdehyde: A Promising Approach for Water Treatment. Polym. Int. 2020, 69, 50–60. [Google Scholar] [CrossRef]

- Xu, T.; Qi, Z.H.; Yin, Q.; Jiao, Y.M.; An, L.Z.; Tan, Y.F. Effects of Air Plasma Modification on Aramid Fiber Surface and Its Composite Interface and Mechanical Properties. Polymers 2022, 14, 4892. [Google Scholar] [CrossRef] [PubMed]

- Sohbatzadeh, F.; Shakerinasab, E.; Mirzanejhad, S. Surface Modification of Aramid Yarn by Atmospheric Pressure Plasma: Reinforcement and Floating Properties. Polym. Test. 2023, 117, 107836. [Google Scholar] [CrossRef]

- Chen, W.T.; Qi, W.; Du, J.F.; Zhao, L. Radiation Effects on Kevlar Fibers through High Energy Electron beam. Polym. Eng. Sci. 2023, 63, 3083–3090. [Google Scholar] [CrossRef]

- Jia, C.; Zhang, R.; Yuan, C.; Ma, Z.; Du, Y.; Liu, L.; Huang, Y. Surface Modification of Aramid Fibers by Amino Functionalized Silane Grafting to Improve Interfacial Property of Aramid Fibers Reinforced Composite. Polym. Compos. 2020, 41, 2046–2053. [Google Scholar] [CrossRef]

- Safamanesh, A.; Mousavi, S.M.; Khosravi, H.; Tohidlou, E. On the low-velocity and high, velocity impact behaviors of aramid fiber/epoxy composites containing modified-graphene oxide. Polym. Compos. 2020, 42, 608–617. [Google Scholar] [CrossRef]

- Dharmavarapu, P.; Sreekara Reddy, M.B.S. Mechanical, Low Velocity Impact, Fatigue and Tribology Behaviour of Silane Grafted Aramid Fibre and Nano-silica Toughened Epoxy Composite. Silicon 2020, 13, 1741–1750. [Google Scholar] [CrossRef]

- Chen, Z.; Luo, J.; Huang, Z.; Cai, C.; Tusiime, R.; Li, Z.; Wang, H.; Cheng, C.; Liu, Y.; Sun, Z.; et al. Synergistic Toughen Epoxy Resin by Incorporation of Polyetherimide and Amino Groups Grafted MWCNTs. Compos. Commun. 2020, 21, 100377. [Google Scholar] [CrossRef]

- Esmaeili, A.; Ma, D.; Manes, A.; Oggioni, T.; Jiménez-Suárez, A.; Ureña, A.; Hamouda, A.; Sbarufatti, C. An Experimental and Numerical Investigation of Highly Strong and Tough Epoxy Based Nanocomposite by Addition of MWCNTs: Tensile and Mode I Fracture Tests. Compos. Struct. 2020, 252, 112692. [Google Scholar] [CrossRef]

- Sun, H.; Kong, H.; Ding, H.; Xu, Q.; Zeng, J.; Jiang, F.; Yu, M.; Zhang, Y. Improving UV Resistance of Aramid Fibers by Simultaneously Synthesizing TiO2 on Their Surfaces and in the Interfaces Between Fibrils/Microfibrils Using Supercritical Carbon Dioxide. Polymers 2020, 12, 147. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.H.; Liu, L.; Wang, Z.Z. Mesoporous Silica via Self-assembly of Nano Zinc Amino-tris-(methylenephosphonate) Exhibiting Reduced Fire Hazards and Improved Impact Toughness in Epoxy Resin. J. Hazard. Mater. 2020, 392, 122343. [Google Scholar] [CrossRef] [PubMed]

- Rohit, L.V. A review of ionic liquids: Applications Towards Catalytic Organic Transformations. J. Mol. Liq. 2017, 227, 44. [Google Scholar] [CrossRef]

- Morales-Rivera, C.A.; Cormack, G.; Burrington, J.; Proust, N.; Mpourmpakis, G. Understanding and Optimizing the Behavior of Al-and Ru-Based Catalysts for the Synthesis of Polyisobutenyl Succinic Anhydrides. Ind. Eng. Chem. Res. 2022, 61, 14462–14471. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Yan, Y.; Zhao, X.; Wang, Y. Acylation Reaction of Benzene with Phthalic Anhydride Catalyzed by Amide-AlCl3 Ionic Liquid Analogs. Acta Pet. Sin. (Pet. Process. Sect.) 2022, 38, 292. [Google Scholar] [CrossRef]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of Interfacial Properties between Fibre and Polymer Matrix in Composite Materials–A Critical Review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Koyanagi, J.; Ogihara, S.; Nakatani, H.; Okabe, T.; Yoneyama, S. Mechanical Properties of Fiber/Matrix Interface in Polymer Matrix Composites. Adv. Compos. Mater. 2014, 23, 551–570. [Google Scholar] [CrossRef]

| Performance | Warp Direction | Latitudinal Direction |

|---|---|---|

| Single layer thickness (mm) | 0.5 | 0.5 |

| Mass per unit area (g/m2) | 340 | 340 |

| Density (Yarns/10 cm) | 150 | 148 |

| Rupture strength (N/50 mm) | 13,215 | 14,370 |

| Elongation at break (%) | 8.42 | 5.59 |

| Coefficient of variation of fracture strength (%) | 2.92 | 1.79 |

| Number of Fiber Layers | Molding Temperature (T0) °C | Molding Pressure (P0) MPa | Molding Time (t) h |

|---|---|---|---|

| 7 | 60 | 5 | 2 |

| Fiber Name | Fiber Modification Conditions |

|---|---|

| unmodified PPTA | unmodified |

| PPTA-0.15 | 0.15 mol/L phthalic anhydride + 80 °C +2 h |

| PPTA-0.30 | 0.30 mol/L phthalic anhydride + 80 °C + 2 h |

| PPTA-0.15 | 0.45 mol/L phthalic anhydride + 80 °C + 2 h |

| Fiber Name | Surface Element Content | Element Ratio O/C | ||

|---|---|---|---|---|

| C | N | O | ||

| unmodified PPTA | 79.02 | 9.21 | 11.77 | 0.149 |

| PPTA-0.15 | 78.32 | 9.45 | 12.23 | 0.156 |

| PPTA-0.30 | 76.58 | 9.93 | 13.49 | 0.176 |

| PPTA-0.15 | 78.58 | 9.78 | 11.64 | 0.148 |

| Fiber Name | Fiber Modification Conditions |

|---|---|

| unmodified PPTA | unmodified |

| PPTA-2 h | 0.30 mol/L phthalic anhydride + 80 °C + 2 h |

| PPTA-0.5 h (A) | 0.3 mol/L phthalic anhydride + anhydrous AlCl3 + 80 °C + 0.5 h |

| PPTA-1 h (A) | 0.3 mol/L phthalic anhydride + anhydrous AlCl3 + 80 °C + 1 h |

| PPTA-1.5 h (A) | 0.3 mol/L phthalic anhydride + anhydrous AlCl3 + 80 °C + 1.5 h |

| PPTA-2 h (A) | 0.3 mol/L phthalic anhydride + anhydrous AlCl3 + 80 °C + 2 h |

| Fiber | Unmodified PPTA | PPTA-2 h | PPTA-0.5 h (A) |

|---|---|---|---|

| Ra (nm) | 0.10 | 0.59 | 1.31 |

| Fiber Name | Surface Element Content | Element Ratio O/C | ||

|---|---|---|---|---|

| C | N | O | ||

| unmodified PPTA | 79.02 | 9.21 | 11.77 | 0.149 |

| PPTA-2 h | 76.58 | 9.93 | 13.49 | 0.176 |

| PPTA-0.5 h (A) | 73.01 | 4.61 | 22.38 | 0.307 |

| PPTA-1 h (A) | 70.01 | 2.75 | 27.24 | 0.389 |

| PPTA-1.5 h (A) | 70.83 | 4.05 | 25.12 | 0.355 |

| PPTA-2 h (A) | 70.53 | 7.02 | 22.45 | 0.318 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; E, Y.; Gao, H.; Li, H.; Xu, G.; Qiang, X. Mechanical Properties of Aramid Fiber Fabrics and Composites Enhanced by Phthalic Anhydride Catalyzed with Anhydrous Aluminum Chloride. Appl. Sci. 2024, 14, 3800. https://doi.org/10.3390/app14093800

Xiao Y, E Y, Gao H, Li H, Xu G, Qiang X. Mechanical Properties of Aramid Fiber Fabrics and Composites Enhanced by Phthalic Anhydride Catalyzed with Anhydrous Aluminum Chloride. Applied Sciences. 2024; 14(9):3800. https://doi.org/10.3390/app14093800

Chicago/Turabian StyleXiao, Yi, Yibo E, Hanmei Gao, Honggang Li, Guowen Xu, and Xuhong Qiang. 2024. "Mechanical Properties of Aramid Fiber Fabrics and Composites Enhanced by Phthalic Anhydride Catalyzed with Anhydrous Aluminum Chloride" Applied Sciences 14, no. 9: 3800. https://doi.org/10.3390/app14093800

APA StyleXiao, Y., E, Y., Gao, H., Li, H., Xu, G., & Qiang, X. (2024). Mechanical Properties of Aramid Fiber Fabrics and Composites Enhanced by Phthalic Anhydride Catalyzed with Anhydrous Aluminum Chloride. Applied Sciences, 14(9), 3800. https://doi.org/10.3390/app14093800