Enhancing Food Integrity through Artificial Intelligence and Machine Learning: A Comprehensive Review

Abstract

1. Introduction

2. Methodology

2.1. Data Sources

2.2. Study Inclusion and Exclusion Criteria

3. Artificial Intelligence (AI) and Machine Learning (ML)

3.1. Artificial Intelligence (AI)

3.2. Machine Learning (ML)

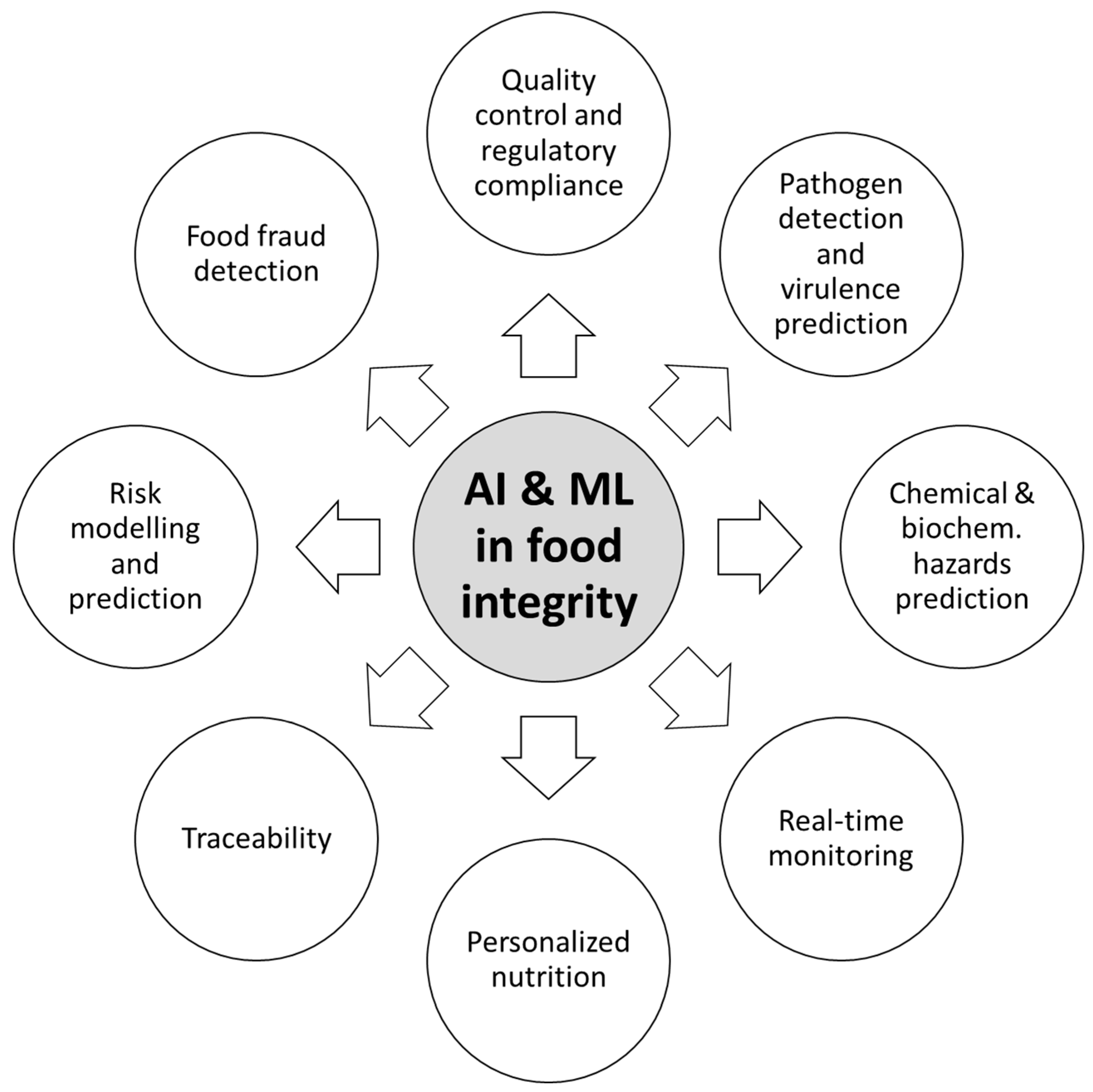

4. Application of AI in Food Integrity

4.1. AI and ML in Food Quality Control and Regulatory Compliance

4.2. AI and ML in Food Supply Chain Traceability

4.3. AI and ML in Predictive Analytics for Risk Assessment

4.4. AI and ML in Real-Time Monitoring of Food in the Supply Chain

4.5. AI and ML in Food Pathogen Detection, Classification, and Virulence/Resistance Prediction

4.6. AI and ML for Chemical and Biochemical Food Hazard Prediction and Analysis

4.7. AI and ML in the Formulation of New Recipe and Personalized Nutrition for Improved Quality and Safety

4.8. AI and ML in the Detection of Food Fraud

5. Study Limitations

6. Future Prospects and Directions

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, Z.; Yemets, M.; Muneem, S.; Shannon, K.; Gowher, F.; Malloy, J.; Kafka, E.; Mitchell, C.; King, J.; Urban, S. Food Fraud: Insights from Investigating a near-Fatal Poisoning with Global Implications. medRxiv 2023, 2023–2029. [Google Scholar] [CrossRef]

- Kemsawasd, V.; Jayasena, V.; Karnpanit, W. Incidents and Potential Adverse Health Effects of Serious Food Fraud Cases Originated in Asia. Foods 2023, 12, 3522. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, M.; Sun, N.; Chen, H.; Zhang, C.; Wang, Q.; Zhang, W. Analysis of the Economically Motivated Food Adulteration in China Based on 6477 Events from 2000 to 2020. Qual. Assur. Saf. Crops Foods 2023, 15, 222–231. [Google Scholar] [CrossRef]

- Lawrence, S.; Elliott, C.; Huisman, W.; Dean, M.; van Ruth, S. The 11 Sins of Seafood: Assessing a Decade of Food Fraud Reports in the Global Supply Chain. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3746–3769. [Google Scholar] [CrossRef]

- Gwenzi, W.; Makuvara, Z.; Marumure, J.; Simbanegavi, T.T.; Mukonza, S.S.; Chaukura, N. Chicanery in the Food Supply Chain! Food Fraud, Mitigation, and Research Needs in Low-Income Countries. Trends Food Sci. Technol. 2023, 136, 194–223. [Google Scholar] [CrossRef]

- WHO. Estimating the Burden of Foodborne Diseases. Available online: https://www.who.int/activities/estimating-the-burden-of-foodborne-diseases#:~:text=Eachyearworldwide%2Cunsafefood,numberislikelyanunderestimation (accessed on 21 October 2022).

- Lee, H.; Yoon, Y. Etiological Agents Implicated in Foodborne Illness World Wide. Food Sci. Anim. Resour. 2021, 41, 1. [Google Scholar] [CrossRef]

- WHO. WHO Estimates of the Global Burden of Foodborne Diseases; World Health Organization: Geneva, Switzerland, 2015. [Google Scholar]

- WHO. The Burden of Foodborne Diseases in the WHO European Region; World Health Organization: Geneva, Switzerland, 2017. [Google Scholar]

- European Commission. Commission Regulation (EU) 2022/1370 of 5 August 2022 Amending Regulation (EC) No 1881/2006 as Regards Maximum Levels of Ochratoxin A in Certain Foodstuffs. Off. J. Eur. Union 2022, L 206, 11–14. [Google Scholar]

- Phytocontrol New Limits for Ochratoxin A. Available online: https://www.phytocontrol.com/en/regulatory-watch/new-limits-for-ochratoxin-a/ (accessed on 12 February 2024).

- SGS EU Updates Maximum Levels for Ochratoxin A in Certain Foodstuffs. Available online: https://www.digicomply.com/blog/eu-updates-maximum-levels-for-ochratoxin-a-in-certain-foodstuffs (accessed on 12 February 2024).

- Sharpless, N.E. Statement from Acting FDA Commissioner Ned Sharpless, MD, and Deputy Commissioner Frank Yiannas on Steps to Usher the US into a New Era of Smarter Food Safety; US Food and Drug Administration (FDA): Silver Spring, MD, USA, 2019.

- Deng, X.; Cao, S.; Horn, A.L. Emerging Applications of Machine Learning in Food Safety. Annu. Rev. Food Sci. Technol. 2021, 12, 513–538. [Google Scholar] [CrossRef]

- Gbashi, S.; Adebo, O.A.; Doorsamy, W.; Njobeh, P.B. Systematic Delineation of Media Polarity on COVID-19 Vaccines in Africa: Computational Linguistic Modeling Study. JMIR Med. Inf. 2021, 9, e22916. [Google Scholar] [CrossRef]

- Vinci, G.; Ruggieri, R.; Ruggeri, M.; Prencipe, S.A. Rice Production Chain: Environmental and Social Impact Assessment—A Review. Agriculture 2023, 13, 340. [Google Scholar] [CrossRef]

- Ehret, D.L.; Hill, B.D.; Helmer, T.; Edwards, D.R. Neural Network Modeling of Greenhouse Tomato Yield, Growth and Water Use from Automated Crop Monitoring Data. Comput. Electron. Agric. 2011, 79, 82–89. [Google Scholar] [CrossRef]

- Resnick, S. Artificial Intelligence in Eye Care? Naturally! Clin. Refract. Optom. J. 2023, 79, 82–89. [Google Scholar] [CrossRef]

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; De Felice, F. Artificial Intelligence and Machine Learning Applications in Smart Production: Progress, Trends, and Directions. Sustainability 2020, 12, 492. [Google Scholar] [CrossRef]

- Burati, M.; Tagliabue, F.; Lomonaco, A.; Chiarelli, M.; Zago, M.; Cioffi, G.; Cioffi, U. Artificial Intelligence as a Future in Cancer Surgery. Artif. Intell. Cancer 2022, 3, 11–16. [Google Scholar] [CrossRef]

- Cannataro, M.; Guzzi, P.H.; Agapito, G.; Zucco, C.; Milano, M. Chapter 3—Artificial Intelligence. In Artificial Intelligence in Bioinformatics; Cannataro, M., Guzzi, P.H., Agapito, G., Zucco, C., Milano, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 29–33. ISBN 978-0-12-822952-1. [Google Scholar]

- Helm, J.M.; Swiergosz, A.M.; Haeberle, H.S.; Karnuta, J.M.; Schaffer, J.L.; Krebs, V.E.; Spitzer, A.I.; Ramkumar, P.N. Machine Learning and Artificial Intelligence: Definitions, Applications, and Future Directions. Curr. Rev. Musculoskelet. Med. 2020, 13, 69–76. [Google Scholar] [CrossRef]

- Galanos, V. Expectations and Expertise in Artificial Intelligence: Specialist Views and Historical Perspectives on Conceptualisation, Promise, and Funding. Ph.D. Thesis, University of Edinburgh, Edinburgh, UK, 2023. [Google Scholar]

- Le, Q.V. Building High-Level Features Using Large Scale Unsupervised Learning. In Proceedings of the 2013 IEEE International Conference on Acoustics, Speech and Signal Processing, Vancouver, BC, Canada, 26–31 May 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 8595–8598. [Google Scholar]

- Delipetrev, B.; Tsinaraki, C.; Kostic, U. Historical Evolution of Artificial Intelligence. JRC Publications Repository. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC120469 (accessed on 6 January 2024).

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, Ł.; Polosukhin, I. Attention Is All You Need. In Proceedings of the 31st Conference on Neural Information Processing Systems (NIPS 2017), Long Beach, CA, USA, 4–9 December 2017. [Google Scholar]

- Flowers, J.C. Strong and Weak AI: Deweyan Considerations. In Proceedings of the AAAI Spring Symposium: Towards Conscious AI Systems, Palo Alto, CA, USA, 25–27 March 2019; Volume 2287. [Google Scholar]

- Fjelland, R. Why General Artificial Intelligence Will Not Be Realized. Humanit. Soc. Sci. Commun. 2020, 7, 1–9. [Google Scholar] [CrossRef]

- Asay, C.D. Artificial Stupidity. Wm. Mary L. Rev. 2019, 61, 1187. [Google Scholar]

- Kuusi, O.; Heinonen, S. Scenarios from Artificial Narrow Intelligence to Artificial General Intelligence—Reviewing the Results of the International Work/Technology 2050 Study. World Futures Rev. 2022, 14, 65–79. [Google Scholar] [CrossRef]

- Varshney, H.; Khan, R.A.; Khan, U.; Verma, R. Approaches of Artificial Intelligence and Machine Learning in Smart Cities: Critical Review. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1022, p. 012019. [Google Scholar]

- Ullah, Z.; Al-Turjman, F.; Mostarda, L.; Gagliardi, R. Applications of Artificial Intelligence and Machine Learning in Smart Cities. Comput. Commun. 2020, 154, 313–323. [Google Scholar] [CrossRef]

- Saravanan, R.; Sujatha, P. A State of Art Techniques on Machine Learning Algorithms: A Perspective of Supervised Learning Approaches in Data Classification. In Proceedings of the 2018 Second International Conference on Intelligent Computing and Control Systems (ICICCS), Madurai, India, 14–15 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 945–949. [Google Scholar]

- Dridi, S. Supervised Learning-a Systematic Literature Review. PERINTIS eJournal 2020, 10, 1–24. [Google Scholar]

- Muhammad, I.; Yan, Z. Supervised machine learning approaches: A survey. ICTACT J. Soft Comput. 2015, 5, 946–952. [Google Scholar] [CrossRef]

- Shetty, S.H.; Shetty, S.; Singh, C.; Rao, A. Supervised Machine Learning: Algorithms and Applications. In Fundamentals and Methods of Machine and Deep Learning: Algorithms, Tools and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022; pp. 1–16. [Google Scholar]

- Verma, R.; Nagar, V.; Mahapatra, S. Introduction to Supervised Learning. In Data Analytics in Bioinformatics; Wiley: Hoboken, NJ, USA, 2021; pp. 1–34. [Google Scholar]

- Sindhu Meena, K.; Suriya, S. A Survey on Supervised and Unsupervised Learning Techniques. In Proceedings of the International Conference on Artificial Intelligence, Smart Grid and Smart City Applications: AISGSC, Coimbatore, India, 3–5 January 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 627–644. [Google Scholar]

- Usama, M.; Qadir, J.; Raza, A.; Arif, H.; Yau, K.-L.A.; Elkhatib, Y.; Hussain, A.; Al-Fuqaha, A. Unsupervised Machine Learning for Networking: Techniques, Applications and Research Challenges. IEEE Access 2019, 7, 65579–65615. [Google Scholar] [CrossRef]

- Rajoub, B. Supervised and Unsupervised Learning. In Biomedical Signal Processing and Artificial Intelligence in Healthcare; Elsevier: Amsterdam, The Netherlands, 2020; pp. 51–89. [Google Scholar]

- Chauhan, T.; Rawat, S.; Malik, S.; Singh, P. Supervised and Unsupervised Machine Learning Based Review on Diabetes Care. In Proceedings of the 2021 7th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 19–20 March 2021; IEEE: Piscataway, NJ, USA, 2021; Volume 1, pp. 581–585. [Google Scholar]

- Balamurali, M. T-Distributed Stochastic Neighbor Embedding. In Encyclopedia of Mathematical Geosciences; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–9. [Google Scholar]

- Naeem, S.; Ali, A.; Anam, S.; Ahmed, M.M. An Unsupervised Machine Learning Algorithms: Comprehensive Review. Int. J. Comput. Digit. Syst. 2023, 13, 911–921. [Google Scholar] [CrossRef]

- Dong, H.; Dong, H.; Ding, Z.; Zhang, S. Chang Deep Reinforcement Learning; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 9811540942. [Google Scholar]

- Wiering, M.A.; Van Otterlo, M. Reinforcement Learning. Adapt. Learn. Optim. 2012, 12, 729. [Google Scholar]

- Martín-Guerrero, J.D.; Lamata, L. Reinforcement Learning and Physics. Appl. Sci. 2021, 11, 8589. [Google Scholar] [CrossRef]

- Zihan, D.; Huang, Y.; Yuan, H.; Dong, H. Introduction to Reinforcement Learning. In Deep Reinforcement Learning: Fundamentals, Research and Applications; Dong, H., Ding, Z., Zhang, S., Eds.; Springer Nature Singapore Pte Ltd.: Gateway East, Singapore, 2020; pp. 47–123. [Google Scholar]

- Coronato, A.; Naeem, M.; De Pietro, G.; Paragliola, G. Reinforcement Learning for Intelligent Healthcare Applications: A Survey. Artif. Intell. Med. 2020, 109, 101964. [Google Scholar] [CrossRef]

- AgShift Hydra—Power the Transformation of Food through AI. Available online: https://www.agshift.com/ (accessed on 21 December 2023).

- Zaynub. How Can AI Technology Be Used in Food Safety Implementation? Available online: https://medium.com/@jenny_sBlogs/how-can-ai-technology-be-used-in-food-safety-implementation-efec411e29f0 (accessed on 29 November 2023).

- Chen, S.; Xiong, J.; Guo, W.; Bu, R.; Zheng, Z.; Chen, Y.; Yang, Z.; Lin, R. Colored Rice Quality Inspection System Using Machine Vision. J. Cereal Sci. 2019, 88, 87–95. [Google Scholar] [CrossRef]

- Alavi, N. Date Grading Using Rule-Based Fuzzy Inference System. J. Agric. Technol. 2012, 8, 1243–1254. [Google Scholar]

- Ireri, D.; Belal, E.; Okinda, C.; Makange, N.; Ji, C. A Computer Vision System for Defect Discrimination and Grading in Tomatoes Using Machine Learning and Image Processing. Artif. Intell. Agric. 2019, 2, 28–37. [Google Scholar] [CrossRef]

- Huang, H.; Liu, L.; Ngadi, M.O. Recent Developments in Hyperspectral Imaging for Assessment of Food Quality and Safety. Sensors 2014, 14, 7248–7276. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; ElMasry, G.; Sun, D.-W.; Allen, P. Non-Destructive Prediction and Visualization of Chemical Composition in Lamb Meat Using NIR Hyperspectral Imaging and Multivariate Regression. Innov. Food Sci. Emerg. Technol. 2012, 16, 218–226. [Google Scholar] [CrossRef]

- Rivera, N.V.; Gómez-Sanchis, J.; Chanona-Pérez, J.; Carrasco, J.J.; Millán-Giraldo, M.; Lorente, D.; Cubero, S.; Blasco, J. Early Detection of Mechanical Damage in Mango Using NIR Hyperspectral Images and Machine Learning. Biosyst. Eng. 2014, 122, 91–98. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Y.-R.; Kim, M.S.; Chan, D.E.; Lefcourt, A.M. Development of Simple Algorithms for the Detection of Fecal Contaminants on Apples from Visible/near Infrared Hyperspectral Reflectance Imaging. J. Food Eng. 2007, 81, 412–418. [Google Scholar] [CrossRef]

- Gómez-Sanchís, J.; Gómez-Chova, L.; Aleixos, N.; Camps-Valls, G.; Montesinos-Herrero, C.; Moltó, E.; Blasco, J. Hyperspectral System for Early Detection of Rottenness Caused by Penicillium Digitatum in Mandarins. J. Food Eng. 2008, 89, 80–86. [Google Scholar] [CrossRef]

- Lee, J.; Nazki, H.; Baek, J.; Hong, Y.; Lee, M. Artificial Intelligence Approach for Tomato Detection and Mass Estimation in Precision Agriculture. Sustainability 2020, 12, 9138. [Google Scholar] [CrossRef]

- FDA. Tracking and Tracing of Food. Available online: https://www.fda.gov/food/new-era-smarter-food-safety/tracking-and-tracing-food (accessed on 21 December 2023).

- Hassoun, A.; Alhaj Abdullah, N.; Aït-Kaddour, A.; Ghellam, M.; Beşir, A.; Zannou, O.; Önal, B.; Aadil, R.M.; Lorenzo, J.M.; Mousavi Khaneghah, A. Food Traceability 4.0 as Part of the Fourth Industrial Revolution: Key Enabling Technologies. Crit. Rev. Food Sci. Nutr. 2022, 64, 873–889. [Google Scholar] [CrossRef]

- Ling, C.; Zeng, T.; Su, Y. Research on Intelligent Supervision and Application System of Food Traceability Based on Blockchain and Artificial Intelligence. In Proceedings of the 2021 IEEE 2nd International Conference on Information Technology, Big Data and Artificial Intelligence (ICIBA), Chongqing, China, 17–19 December 2021; IEEE: Piscataway, NJ, USA, 2021; Volume 2, pp. 370–375. [Google Scholar]

- Archana Sristy Blockchain in the Food Supply Chain—What Does the Future Look Like? Available online: https://tech.walmart.com/content/walmart-global-tech/en_us/news/articles/blockchain-in-the-food-supply-chain.html (accessed on 10 December 2023).

- Roger Aitken IBM & Walmart Launching Blockchain Food Safety Alliance in China with Fortune 500’s JD.Com. Available online: https://www.forbes.com/sites/rogeraitken/2017/12/14/ibm-walmart-launching-blockchain-food-safety-alliance-in-china-with-fortune-500s-jd-com/?sh=22a372277d9c (accessed on 10 December 2023).

- Shahbazi, Z.; Byun, Y.-C. A Procedure for Tracing Supply Chains for Perishable Food Based on Blockchain, Machine Learning and Fuzzy Logic. Electronics 2020, 10, 41. [Google Scholar] [CrossRef]

- Li, S.; Yu, X.; Zhen, Z.; Huang, M.; Lu, J.; Pang, Y.; Wang, X.; Gao, Y. Geographical Origin Traceability and Identification of Refined Sugar Using UPLC-QTof-MS Analysis. Food Chem. 2021, 348, 128701. [Google Scholar] [CrossRef] [PubMed]

- Shang, J.; Liu, N.; Cheng, J.; Gao, W.; Sun, X.; Guo, M. Analysis and Comparison of Lipids in Saanen Goat Milk from Different Geographic Regions in China Based on UHPLC-QTOF-MS Lipidomics. Food Res. Int. 2022, 157, 111441. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, M.; Wang, X.; Li, C.; Liu, Z.; Shen, X.; Zhou, D. Investigation of Oyster Crassostrea Gigas Lipid Profile from Three Sea Areas of China Based on Non-Targeted Lipidomics for Their Geographic Region Traceability. Food Chem. 2022, 386, 132748. [Google Scholar] [CrossRef]

- Balamurugan, S.; Ayyasamy, A.; Joseph, K. An Efficient Bayes Classifiers Algorithm for Traceability of Food Supply Chain Management Using Internet of Things. Int. J. Eng. Adv. Technol. 2019, 9, 2995–3005. [Google Scholar] [CrossRef]

- Wang, J.; Yue, H.; Zhou, Z. An Improved Traceability System for Food Quality Assurance and Evaluation Based on Fuzzy Classification and Neural Network. Food Control 2017, 79, 363–370. [Google Scholar] [CrossRef]

- Violino, S.; Ortenzi, L.; Antonucci, F.; Pallottino, F.; Benincasa, C.; Figorilli, S.; Costa, C. An Artificial Intelligence Approach for Italian EVOO Origin Traceability through an Open Source IoT Spectrometer. Foods 2020, 9, 834. [Google Scholar] [CrossRef] [PubMed]

- Frąckiewicz, M. The Role of Predictive Analytics in Food Safety Risk Assessment. Available online: https://ts2.space/en/the-role-of-predictive-analytics-in-food-safety-risk-assessment/#gsc.tab=0 (accessed on 29 November 2023).

- Wu, L.-Y.; Weng, S.-S. Ensemble Learning Models for Food Safety Risk Prediction. Sustainability 2021, 13, 12291. [Google Scholar] [CrossRef]

- Zhang, Y. Food Safety Risk Intelligence Early Warning Based on Support Vector Machine. J. Intell. Fuzzy Syst. 2020, 38, 6957–6969. [Google Scholar] [CrossRef]

- Liu, N.; Bouzembrak, Y.; Van den Bulk, L.M.; Gavai, A.; van den Heuvel, L.J.; Marvin, H.J.P. Automated Food Safety Early Warning System in the Dairy Supply Chain Using Machine Learning. Food Control 2022, 136, 108872. [Google Scholar] [CrossRef]

- Rortais, A.; Barrucci, F.; Ercolano, V.; Linge, J.; Christodoulidou, A.; Cravedi, J.-P.; Garcia-Matas, R.; Saegerman, C.; Svečnjak, L. A Topic Model Approach to Identify and Track Emerging Risks from Beeswax Adulteration in the Media. Food Control 2021, 119, 107435. [Google Scholar] [CrossRef]

- Marvin, H.J.P.; Bouzembrak, Y.; Janssen, E.M.; van der Fels-Klerx, H.J.; van Asselt, E.D.; Kleter, G.A. A Holistic Approach to Food Safety Risks: Food Fraud as an Example. Food Res. Int. 2016, 89, 463–470. [Google Scholar] [CrossRef] [PubMed]

- Bouzembrak, Y.; Camenzuli, L.; Janssen, E.; Van der Fels-Klerx, H.J. Application of Bayesian Networks in the Development of Herbs and Spices Sampling Monitoring System. Food Control 2018, 83, 38–44. [Google Scholar] [CrossRef]

- Zhang, R.; Zhou, L.; Zuo, M.; Zhang, Q.; Bi, M.; Jin, Q.; Xu, Z. Prediction of Dairy Product Quality Risk Based on Extreme Learning Machine. In Proceedings of the 2018 2nd International Conference on Data Science and Business Analytics (ICDSBA), Changsha, China, 21–28 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 448–456. [Google Scholar]

- Nogales, A.; Díaz-Morón, R.; García-Tejedor, Á.J. A Comparison of Neural and Non-Neural Machine Learning Models for Food Safety Risk Prediction with European Union RASFF Data. Food Control 2022, 134, 108697. [Google Scholar] [CrossRef]

- Alfian, G.; Syafrudin, M.; Farooq, U.; Ma’arif, M.R.; Syaekhoni, M.A.; Fitriyani, N.L.; Lee, J.; Rhee, J. Improving Efficiency of RFID-Based Traceability System for Perishable Food by Utilizing IoT Sensors and Machine Learning Model. Food Control 2020, 110, 107016. [Google Scholar] [CrossRef]

- Liu, Y.; Han, W.; Zhang, Y.; Li, L.; Wang, J.; Zheng, L. An Internet-of-Things Solution for Food Safety and Quality Control: A Pilot Project in China. J. Ind. Inf. Integr. 2016, 3, 1–7. [Google Scholar] [CrossRef]

- Khan, P.W.; Byun, Y.-C.; Park, N. IoT-Blockchain Enabled Optimized Provenance System for Food Industry 4.0 Using Advanced Deep Learning. Sensors 2020, 20, 2990. [Google Scholar] [CrossRef] [PubMed]

- Geng, Z.; Zhao, S.; Tao, G.; Han, Y. Early Warning Modeling and Analysis Based on Analytic Hierarchy Process Integrated Extreme Learning Machine (AHP-ELM): Application to Food Safety. Food Control 2017, 78, 33–42. [Google Scholar] [CrossRef]

- Tian, F. A Supply Chain Traceability System for Food Safety Based on HACCP, Blockchain & Internet of Things. In Proceedings of the 2017 International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–6. [Google Scholar]

- Sadilek, A.; Caty, S.; DiPrete, L.; Mansour, R.; Schenk Jr, T.; Bergtholdt, M.; Jha, A.; Ramaswami, P.; Gabrilovich, E. Machine-Learned Epidemiology: Real-Time Detection of Foodborne Illness at Scale. NPJ Digit. Med. 2018, 1, 36. [Google Scholar] [CrossRef] [PubMed]

- Tutul, M.J.I.; Alam, M.; Wadud, M.A.H. Smart Food Monitoring System Based on Iot and Machine Learning. In Proceedings of the 2023 International Conference on Next-Generation Computing, IoT and Machine Learning (NCIM), Gazipur, Bangladesh, 16–17 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Wang, H.; Cui, W.; Guo, Y.; Du, Y.; Zhou, Y. Machine Learning Prediction of Foodborne Disease Pathogens: Algorithm Development and Validation Study. JMIR Med. Inf. 2021, 9, e24924. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Wang, S.; Qiu, J.; Li, M.; Li, D.; Xu, D.; Li, D.; Liu, Q. Raman Spectroscopy Combined with Machine Learning for Rapid Detection of Food-Borne Pathogens at the Single-Cell Level. Talanta 2021, 226, 122195. [Google Scholar] [CrossRef] [PubMed]

- Pesesky, M.W.; Hussain, T.; Wallace, M.; Patel, S.; Andleeb, S.; Burnham, C.-A.D.; Dantas, G. Evaluation of Machine Learning and Rules-Based Approaches for Predicting Antimicrobial Resistance Profiles in Gram-Negative Bacilli from Whole Genome Sequence Data. Front. Microbiol. 2016, 7, 1887. [Google Scholar] [CrossRef]

- Teyhouee, A.; McPhee-Knowles, S.; Waldner, C.; Osgood, N. Prospective Detection of Foodborne Illness Outbreaks Using Machine Learning Approaches. In Proceedings of the Social, Cultural, and Behavioral Modeling: 10th International Conference, SBP-BRiMS 2017, Washington, DC, USA, 5–8 July 2017; Proceedings 10. Springer: Berlin/Heidelberg, Germany, 2017; pp. 302–308. [Google Scholar]

- Vangay, P.; Steingrimsson, J.; Wiedmann, M.; Stasiewicz, M.J. Classification of Listeria Monocytogenes Persistence in Retail Delicatessen Environments Using Expert Elicitation and Machine Learning. Risk Anal. 2014, 34, 1830–1845. [Google Scholar] [CrossRef]

- Wheeler, N.E.; Gardner, P.P.; Barquist, L. Machine Learning Identifies Signatures of Host Adaptation in the Bacterial Pathogen Salmonella Enterica. PLoS Genet. 2018, 14, e1007333. [Google Scholar] [CrossRef]

- Yi, J.; Wisuthiphaet, N.; Raja, P.; Nitin, N.; Earles, J.M. AI-Enabled Biosensing for Rapid Pathogen Detection: From Liquid Food to Agricultural Water. Water Res. 2023, 242, 120258. [Google Scholar] [CrossRef]

- Her, H.-L.; Wu, Y.-W. A Pan-Genome-Based Machine Learning Approach for Predicting Antimicrobial Resistance Activities of the Escherichia Coli Strains. Bioinformatics 2018, 34, i89–i95. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, S.K.; Mahanti, N.K.; Mansuri, S.M.; Tripathi, M.K.; Kotwaliwale, N.; Jayas, D.S. Non-Destructive Classification and Prediction of Aflatoxin-B1 Concentration in Maize Kernels Using Vis–NIR (400–1000 Nm) Hyperspectral Imaging. J. Food Sci. Technol. 2021, 58, 437–450. [Google Scholar] [CrossRef] [PubMed]

- Ye, W.; Yan, T.; Zhang, C.; Duan, L.; Chen, W.; Song, H.; Zhang, Y.; Xu, W.; Gao, P. Detection of Pesticide Residue Level in Grape Using Hyperspectral Imaging with Machine Learning. Foods 2022, 11, 1609. [Google Scholar] [CrossRef] [PubMed]

- Baghel, A.S.; Bhardwaj, A.; Ibrahim, W. Optimization of Pesticides Spray on Crops in Agriculture Using Machine Learning. Comput. Intell. Neurosci. 2022, 2022, 9408535. [Google Scholar]

- Shen, Y.; Zhao, E.; Zhang, W.; Baccarelli, A.A.; Gao, F. Predicting Pesticide Dissipation Half-Life Intervals in Plants with Machine Learning Models. J. Hazard. Mater. 2022, 436, 129177. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, S.; Albarrak, A.S. A Blockchain-Driven Food Supply Chain Management Using QR Code and XAI-Faster RCNN Architecture. Sustainability 2023, 15, 2579. [Google Scholar] [CrossRef]

- Petrea, Ș.-M.; Costache, M.; Cristea, D.; Strungaru, Ș.-A.; Simionov, I.-A.; Mogodan, A.; Oprica, L.; Cristea, V. A Machine Learning Approach in Analyzing Bioaccumulation of Heavy Metals in Turbot Tissues. Molecules 2020, 25, 4696. [Google Scholar] [CrossRef]

- Yu, Q.; Li, J.; Yao, L.; Li, C.; Cao, J.; Qiao, J.; Wu, Q. Estimation of Heavy-Metal Concentrations in Winter Wheat Leaves from Typical Sewage Irrigation Area Based on Canopy Reflectance Spectra. J. Appl. Remote Sens. 2018, 12, 36019. [Google Scholar] [CrossRef]

- Park, D.; Kim, K.; Kim, S.; Spranger, M.; Kang, J. FlavorGraph: A Large-Scale Food-Chemical Graph for Generating Food Representations and Recommending Food Pairings. Sci. Rep. 2021, 11, 931. [Google Scholar] [CrossRef]

- Iwendi, C.; Khan, S.; Anajemba, J.H.; Bashir, A.K.; Noor, F. Realizing an Efficient IoMT-Assisted Patient Diet Recommendation System through Machine Learning Model. IEEE Access 2020, 8, 28462–28474. [Google Scholar] [CrossRef]

- Vairale, V.S.; Shukla, S. Recommendation of Diet Using Hybrid Collaborative Filtering Learning Methods. In Advances in Computational Intelligence and Informatics, Proceedings of ICACII 2019, Hyderabad, India, 20–21 December 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 309–318. [Google Scholar]

- Sowah, R.A.; Bampoe-Addo, A.A.; Armoo, S.K.; Saalia, F.K.; Gatsi, F.; Sarkodie-Mensah, B. Design and Development of Diabetes Management System Using Machine Learning. Int. J. Telemed. Appl. 2020, 2020, 8870141. [Google Scholar] [CrossRef] [PubMed]

- Naik, P.A. Intelligent Food Recommendation System Using Machine Learning. Nutrition 2020, 5, 616–619. [Google Scholar]

- Buyuktepe, O.; Catal, C.; Kar, G.; Bouzembrak, Y.; Marvin, H.; Gavai, A. Food Fraud Detection Using Explainable Artificial Intelligence. Expert. Syst. 2023, e13387. [Google Scholar] [CrossRef]

- Bouzembrak, Y.; Marvin, H.J.P. Prediction of Food Fraud Type Using Data from Rapid Alert System for Food and Feed (RASFF) and Bayesian Network Modelling. Food Control 2016, 61, 180–187. [Google Scholar] [CrossRef]

- Mithun, B.S.; Shinde, S.; Bhavsar, K.; Chowdhury, A.; Mukhopadhyay, S.; Gupta, K.; Bhowmick, B.; Kimbahune, S. Non-Destructive Method to Detect Artificially Ripened Banana Using Hyperspectral Sensing and RGB Imaging. In Proceedings of the Sensing for Agriculture and Food Quality and Safety X, Orlando, FL, USA, 17–18 April 2018; Volume 10665, pp. 122–130. [Google Scholar]

- Pulluri, K.K.; Kumar, V.N. Qualitative and Quantitative Detection of Food Adulteration Using a Smart E-Nose. Sensors 2022, 22, 7789. [Google Scholar] [CrossRef] [PubMed]

- de Santana, F.B.; Neto, W.B.; Poppi, R.J. Random Forest as One-Class Classifier and Infrared Spectroscopy for Food Adulteration Detection. Food Chem. 2019, 293, 323–332. [Google Scholar] [CrossRef] [PubMed]

- Lim, K.; Pan, K.; Yu, Z.; Xiao, R.H. Pattern Recognition Based on Machine Learning Identifies Oil Adulteration and Edible Oil Mixtures. Nat. Commun. 2020, 11, 5353. [Google Scholar] [CrossRef] [PubMed]

- Mu, T.; Chen, S.; Zhang, Y.; Chen, H.; Guo, P.; Meng, F.D. Portable Detection and Quantification of Olive Oil Adulteration by 473-Nm Laser-Induced Fluorescence. Food Anal. Methods 2016, 9, 275–279. [Google Scholar] [CrossRef]

- Laga, S.A.; Sarno, R. Temperature Effect of Electronic Nose Sampling for Classifying Mixture of Beef and Pork. Indones. J. Electr. Eng. Comput. Sci. 2020, 19, 1626–1634. [Google Scholar] [CrossRef]

- Wang, X.; Bouzembrak, Y.; Lansink, A.O.; van der Fels-Klerx, H.J. Application of Machine Learning to the Monitoring and Prediction of Food Safety: A Review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 416–434. [Google Scholar] [CrossRef]

| Aspect | AI | ML |

|---|---|---|

| Description | AI is the emulation of human intelligence processes by machines, particularly computer systems. It entails creating systems or algorithms capable of carrying out activities that usually demand human intelligence, like comprehending natural language, identifying patterns, acquiring knowledge from experience, and making judgements | ML is a branch of AI that concentrates on creating algorithms and statistical models to empower computers to carry out tasks without absolute instructions. |

| Goal/objective | To create systems with the ability to carry out activities that usually demand human intelligence | To allow machines to enhance their performance on a particular activity by learning from data without the need for explicit programming |

| Focus/scope | Has a broader scope, encompassing a wide range of approaches, including ML | More focused on extracting patterns and insights from data to enhance the performance of a certain activity or application. |

| Techniques and methodologies | Incorporates a variety of methods and techniques, including computer vision, natural language processing, expert systems, etc. | Primarily focuses on mathematical and statistical techniques algorithms for analyzing data and forecasting outcomes |

| Data dependency | May or may not depend strongly on acquired data | Strongly data-dependent for model training and predictions |

| Human intervention | Capable of functioning autonomously or with human involvement | Dependent on human involvement for training, validation, and adjusting parameters |

| Decision making | Can make decisions based on predetermined rules or acquired patterns | Utilizes data-driven patterns to make decisions. |

| Adaptability | Capable of adjusting to novel circumstances by following predetermined guidelines or assimilating information from fresh data | Enhances and refines its performance through increased data and iterations |

| Examples | Chatbots, expert systems, virtual assistants, autonomous cars, robotics, natural language processing, computer vision, game-playing AI, etc. | Regression, classification, clustering algorithms, neural networks, decision trees, SVM, and reinforcement learning algorithms are examples of ML techniques |

| S/No. | Intelligent Approach | Model(s) | Application | Objective | Food Commodity | Reference |

|---|---|---|---|---|---|---|

| 1. | AI | Food quality control and regulatory compliance | Food inspection system | Raspberries, almonds, strawberries, cashew, carrots, and blueberries | [49] | |

| 2. | ML | SVM | Food quality control and regulatory compliance | Discriminate defective grains | Rice | [51] |

| 3. | ML | Fuzzy system | Food quality control and regulatory compliance | Categorizing and grading | Mozafati dates | [52] |

| 4. | ML | Radial basis function (RBF) kernel-SVM classifier | Food quality control and regulatory compliance | Identify and grade food products | Tomatoes | [53] |

| 5. | ML | Partial least squares (PLS) regression | Food quality control and regulatory compliance | Predict nutritional/chemical composition | Mutton | [55] |

| 6. | ML | KNN | Food quality control and regulatory compliance | Detection and classification of mechanically- damaged fruits | ‘Manila’ mangos | [56] |

| 7. | ML | PCA | Food quality control and regulatory compliance | Detection of fecal contamination | Apple skins | [57] |

| 8. | AI | Mask-RCNN | Food quality control and regulatory compliance | Fruit detection, identification, and dimensions estimation | Tomatoes | [59] |

| 9. | ML | classification and regression trees (CART) and LDA | Food quality control and regulatory compliance | Early detection of rottenness caused by Penicillium digitatum | Mandarins | [58] |

| 10 | AI and ML | Food supply chain traceability | Swift source tracking of agricultural commodities | Various food products | [63] | |

| 11. | ML | Bayesian regression and random forest | Food supply chain traceability | Food supply chain tracing | Perishable foods | [65] |

| 12. | ML | SVM | Food supply chain traceability | Trace geographical origin of food | Refined sugar | [66] |

| 13. | ML | OPLS-DA | Food supply chain traceability | Trace geographical origin of food | Saanen goat milk | [67] |

| 14. | ML | PCA and PLS-DA | Food supply chain traceability | Trace geographical origin of food | Crassostrea gigas oyster species | [68] |

| 15. | ML | Bayes classifier algorithm | Food supply chain traceability | Detect anomalies such as contaminated food items along the supply chain that may need to be recalled | Various food commodities | [69] |

| 16. | AI and ML | Fuzzy classification and ANN models | Food supply chain traceability | Both forward tracking and varied tracing along the supply chain with real-time evaluations of food quality along the entire supply chain | Various food commodities. Case study conducted on a pork producer | [70] |

| 17. | AI | ANN | Food supply chain traceability | Trace geographical origin of food | Italian Extra Virgin Olive Oil (EVOO) | [71] |

| 18. | ML | Numerous ensemble learning models including Bagging-Logistic, Bagging-CART, Bagging-C5.0, Bagging-NB (Bayesian classification), and Bagging-RF. | Predictive analytics for risk assessment | Forecast food safety hazards, with a specific emphasis on enhancing border inspection techniques for imported food | Various food commodities | [73] |

| 19. | ML | SVM | Predictive analytics for risk assessment | Food safety risk intelligent early warning system | Various food commodities | [74] |

| 20. | ML | Bayesian network | Predictive analytics for risk assessment | Food safety early warning system with the goal of detecting indicators that precede the emergence of food safety hazards from adjacent domains of the food supply chain | Dairy supply chain | [75] |

| 21. | ML | Latent Dirichlet Allocation topic model | Predictive analytics for risk assessment | Promptly identify instances of food fraud reported in the media | Beeswax | [76] |

| 22. | ML | Bayesian network | Predictive analytics for risk assessment | Estimate the likelihood of food fraud events | Various food commodities including fish and seafood”, meat, and fruits and vegetables | [77] |

| 23. | ML | Bayesian network | Predictive analytics for risk assessment | Forecast significant food safety risks and their corresponding food products | Herbs and spices | [78] |

| 24. | ML | Kernel-based extreme learning machine (K-ELM) | Predictive analytics for risk assessment | Predict food safety risks | Dairy products | [79] |

| 25. | AI and ML | Logistic regression, decision trees, random forest, boosted tree, SVM, Support Vector Regression (SVR), and multilayer perceptron (MLP) | Predictive analytics for risk assessment | Predict food safety risks | Various food commodities | [80] |

| 26. | ML | XGBoost | Real-time monitoring of food in the supply chain | Monitor the temperature and humidity of perishable foods. Also establish the direction of movement of the products along the supply chain | Perishable foods | [81] |

| 27. | ML | Real-time monitoring of food in the supply chain | Real-time monitoring and tracing the food supply chain, specifically targeting food safety issues | Various food commodities | [82] | |

| 28. | AI and ML | A combination of advanced deep learning (ADL) and IoT-blockchain technologies | Real-time monitoring of food in the supply chain | Optimize provenance of the food supply chain | Various food commodities | [83] |

| 29. | AI | Analytic hierarchy process integrated extreme learning machine (AHP-ELM) | Real-time monitoring of food in the supply chain | Real-time food monitoring and early warning | Various food commodities | [84] |

| 30. | Blockchain and IoT | Real-time monitoring of food in the supply chain | Real-time food safety supply chain traceability | Various food commodities | [85] | |

| 31. | ML | Real-time monitoring of food in the supply chain | Real-time detection of foodborne illness | Various food commodities | [86] | |

| 32. | ML | PCA and t-distributed Stochastic Neighbor Embedding (t-SNE) | Real-time monitoring of food in the supply chain | Continuous monitoring of food products in real-time | Various food commodities | [87] |

| 33. | ML | Decision tree, random forest, gradient boost decision tree (GBDT), and adaptive boosting models | Food pathogen detection, classification, and virulence/resistance prediction | Prediction of microorganisms that cause foodborne illnesses | [88] | |

| 34. | ML | PCA, Kernel principal component analysis (KPCA), decision tree (DT), CART, and PCA-SVM classifier | Food pathogen detection, classification, and virulence/resistance prediction | Rapidly identify food-borne pathogens at the single-cell level | [89] | |

| 35. | ML | Rules-based (RB) algorithm and logistic regression algorithm | Food pathogen detection, classification, and virulence/resistance prediction | Prediction of antimicrobial resistance profiles | [90] | |

| 36. | ML | Hidden Markov Models (HMMs) and SVM | Food pathogen detection, classification, and virulence/resistance prediction | Syndromic surveillance monitoring and disease outbreak detection | Various food commodities | [91] |

| 37. | ML | Variations of random forest, SVM, logistic regression, and linear regression | Food pathogen detection, classification, and virulence/resistance prediction | Classification and estimation of pathogenic bacterial persistence | Various food commodities | [92] |

| 38. | ML | Random forest | Food pathogen detection, classification, and virulence/resistance prediction | Distinguish between invasive and long-established gastrointestinal Salmonella serovars | [93] | |

| 39. | AI | R-CNN deep learning model | Food pathogen detection, classification, and virulence/resistance prediction | Rapid pathogen detection | From liquid food to agricultural water | [94] |

| 40. | ML | SVM, Naïve Bayes, Adaboost, and random forest | Food pathogen detection, classification, and virulence/resistance prediction | Forecast antimicrobial resistance behaviors of E. coli strains | [95] | |

| 41. | ML | Different ML models including PCA, PLS-DA, and KNN | Chemical and biochemical food hazards prediction and analysis | Classification and prediction of aflatoxin B1 (AFB1) levels | Maize kernels | [96] |

| 42. | AI and ML | Logistic regression, SVM, random forest, convolutional neural network (CNN), and residual neural network (ResNet) | Chemical and biochemical food hazards prediction and analysis | Detection of pesticide levels | Grapes | [97] |

| 43. | ML | Logistic regression classification, polynomial regression, and KNN | Chemical and biochemical food hazards prediction and analysis | Optimization of pesticides spray on crops | Various crops | [98] |

| 44. | ML | Gradient boosting regression tree (GBRT), random forest, support vector classifier (SVC), and logistic regression | Chemical and biochemical food hazards prediction and analysis | Prediction of pesticide dissipation half-life intervals in plants | [99] | |

| 45. | AI | Deep reinforcement learning-based supply chain management (DR-SCM) and explainable artificial intelligence-based faster regions with convolutional neural networks (XAI-based Faster RCNN) | Chemical and biochemical food hazards prediction and analysis | Identification of hazardous chemical components in foods | Various food commodities | [100] |

| 46. | ML | Stepwise multiple linear regression and random forest | Chemical and biochemical food hazards prediction and analysis | Estimation of the concentrations of heavy metals food commodities | Turbot muscle and liver tissues | [101] |

| 47. | AI and ML | Back-propagation neural network (BPNN), PLS, and stepwise multiple linear regression | Chemical and biochemical food hazards prediction and analysis | Estimation of the concentrations of heavy metals food commodities | Wheat leaves | [102] |

| 48. | AI and ML | Logistic regression, naive Bayes, recurrent neural network (RNN), MLP, gated recurrent units (GRU), and long short-term memory (LSTM) | Formulation of new recipe and personalized nutrition | Diet recommendation. Automatically determine the appropriate food and make recommendations for patients based on their specific diseases and other features such as age, gender, weight, calories, protein, fat, sodium, fiber, and cholesterol | Different food recipes | [104] |

| 49. | ML | KNN with alternating least squares (KNN-ALS) and KNN with stochastic gradient decent (KNN-SGD) | Formulation of new recipe and personalized nutrition | Diet and exercise recommendation system for a balanced diet for thyroid patients | Various diets | [105] |

| 50. | ML | KNN | Formulation of new recipe and personalized nutrition | Meal recommendation system for diabetic patients | Various diets | [106] |

| 51. | AI | Word Embedding and deep learning | Formulation of new recipe and personalized nutrition | Intelligent food recommendation | Various diets | [107] |

| 52. | AI | DNN and explainable artificial intelligence (XAI) techniques such as Local Interpretable Model-Agnostic Explanations (LIME), Shapley Additive exPlanations (SHAP), and What-If Tool (WIT) | Detection of food fraud | Predict food fraud categories and interpret the predictions of the AI model | Various food commodities | [108] |

| 53. | ML | BN | Detection of food fraud | Prediction of several types of food fraud | Various food commodities | [109] |

| 54. | ML | BN | Detection of food fraud | Prediction of food fraud categories | Various food commodities | [77] |

| 55. | AI and ML | Deep learning, random forest, and MLP | Detection of food fraud | Discrimination between bananas that ripened naturally and those that were artificially ripened | Bananas | [110] |

| 56. | AI and ML | SVM and MLP | Detection of food fraud | Detection of meat adulteration | Beef and pork | [111] |

| 57. | ML | Random forest, PLS-DA, and SIMCA | Detection of food fraud | Detection of food adulteration | Evening primrose oils and ground nutmeg | [112] |

| 58. | AI and ML | t-stochastic neighborhood embedding, PCA, PLS2, Gaussian mixture model | Detection of food fraud | Discrimination of different types of plant oils | Vegetable oils including groundnut oil, high-erucic acid rapeseed oil, high-oleic acid sunflower oil, low-erucic acid rapeseed oil, linseed oil, low-oleic acid sunflower oil, maize oil, rice bran oil, soybean oil, and sesame oil | [113] |

| 59. | AI and ML | PLS, ANN, and SVM | Detection of food fraud | Prediction of oil adulteration | Olive oil, rapeseed oil, peanut oil, and blend oils | [114] |

| 60. | ML | KNN, SVM, Naïve Bayes, and random forest | Detection of food fraud | Distinction between pure beef and mixed beef | Beef | [115] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gbashi, S.; Njobeh, P.B. Enhancing Food Integrity through Artificial Intelligence and Machine Learning: A Comprehensive Review. Appl. Sci. 2024, 14, 3421. https://doi.org/10.3390/app14083421

Gbashi S, Njobeh PB. Enhancing Food Integrity through Artificial Intelligence and Machine Learning: A Comprehensive Review. Applied Sciences. 2024; 14(8):3421. https://doi.org/10.3390/app14083421

Chicago/Turabian StyleGbashi, Sefater, and Patrick Berka Njobeh. 2024. "Enhancing Food Integrity through Artificial Intelligence and Machine Learning: A Comprehensive Review" Applied Sciences 14, no. 8: 3421. https://doi.org/10.3390/app14083421

APA StyleGbashi, S., & Njobeh, P. B. (2024). Enhancing Food Integrity through Artificial Intelligence and Machine Learning: A Comprehensive Review. Applied Sciences, 14(8), 3421. https://doi.org/10.3390/app14083421