Strength, Deformation and Fracture Properties of Hard Rocks Embedded with Tunnel-Shaped Openings Suffering from Dynamic Loads

Abstract

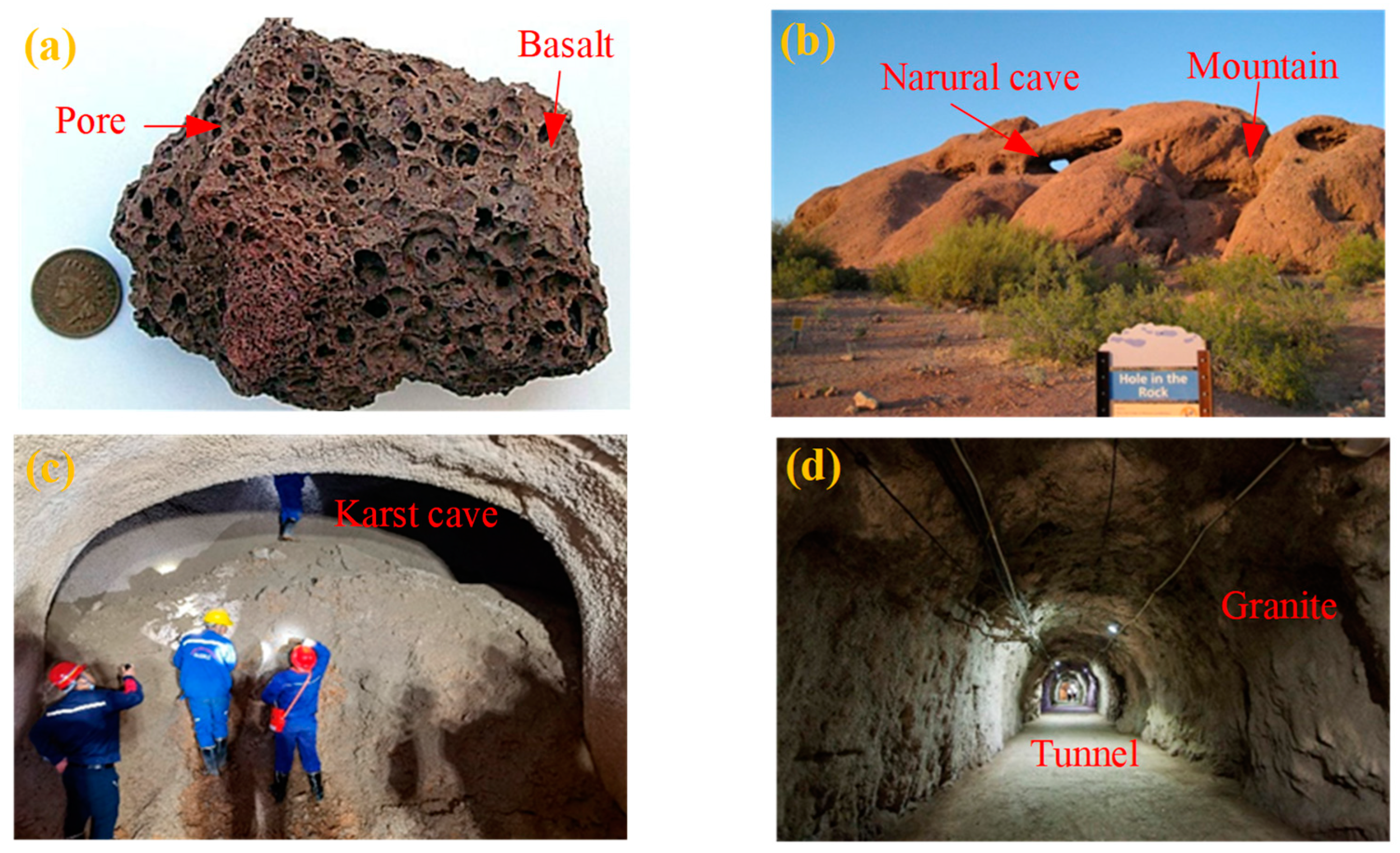

1. Introduction

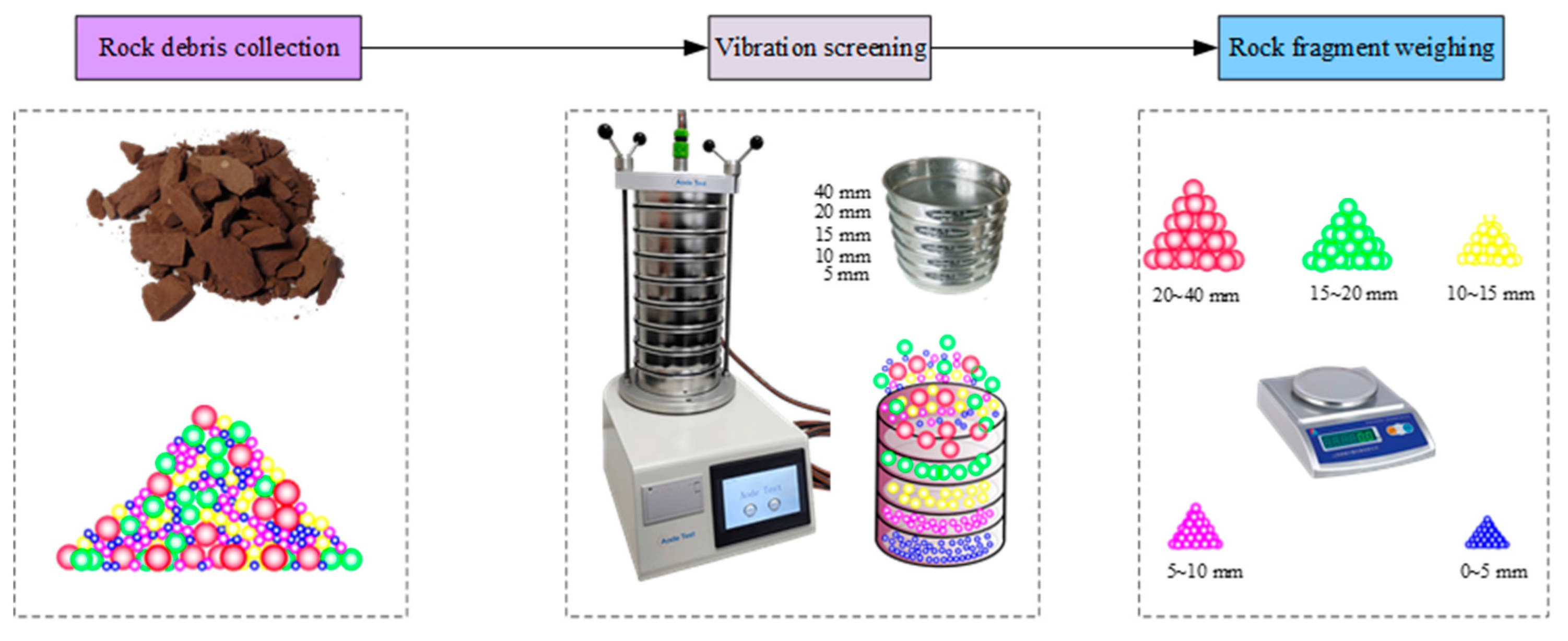

2. Experimental Material and Method

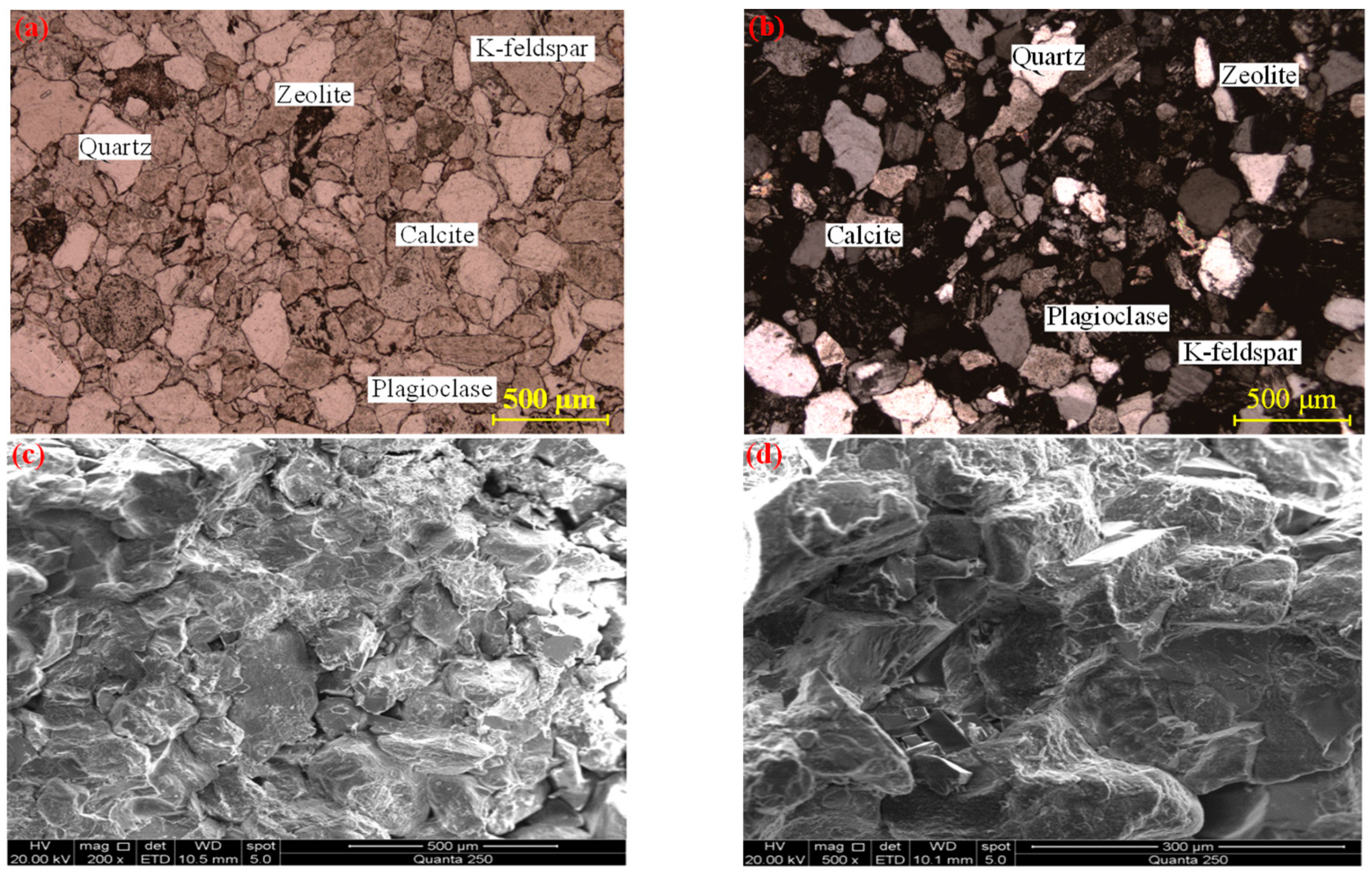

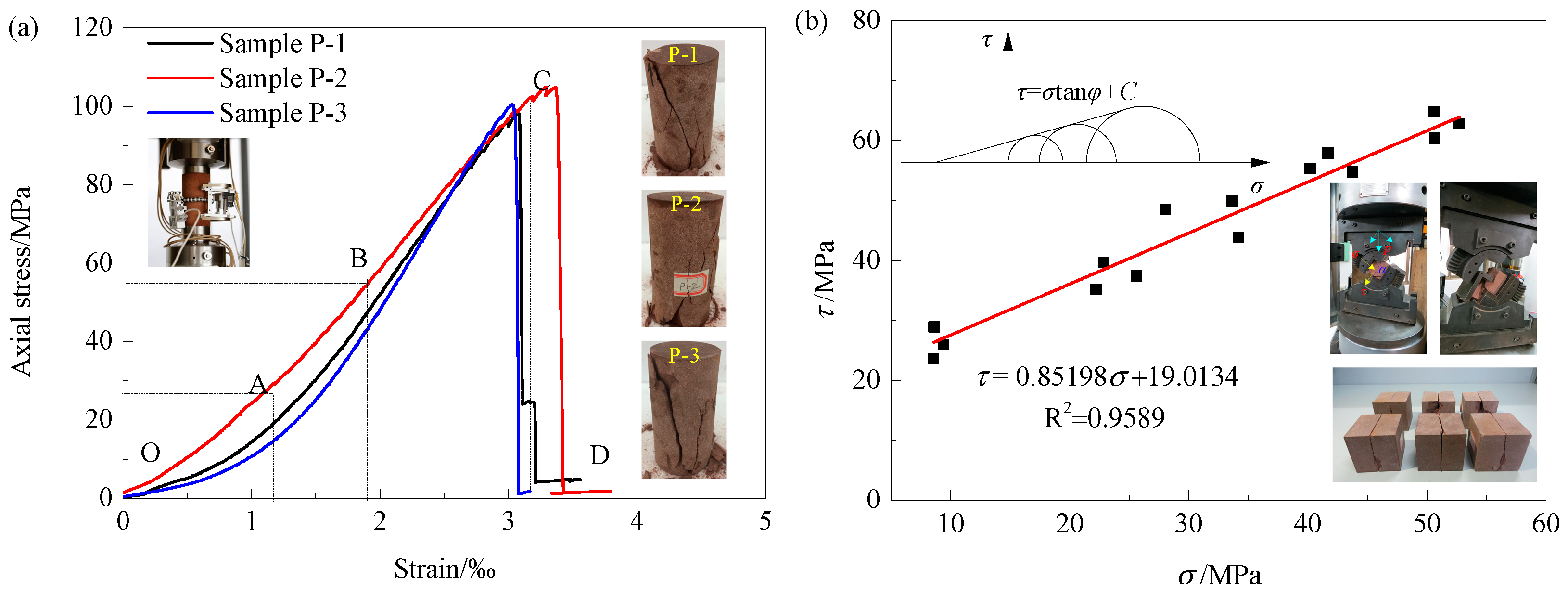

2.1. Rock Material and Physical-Mechanical Properties

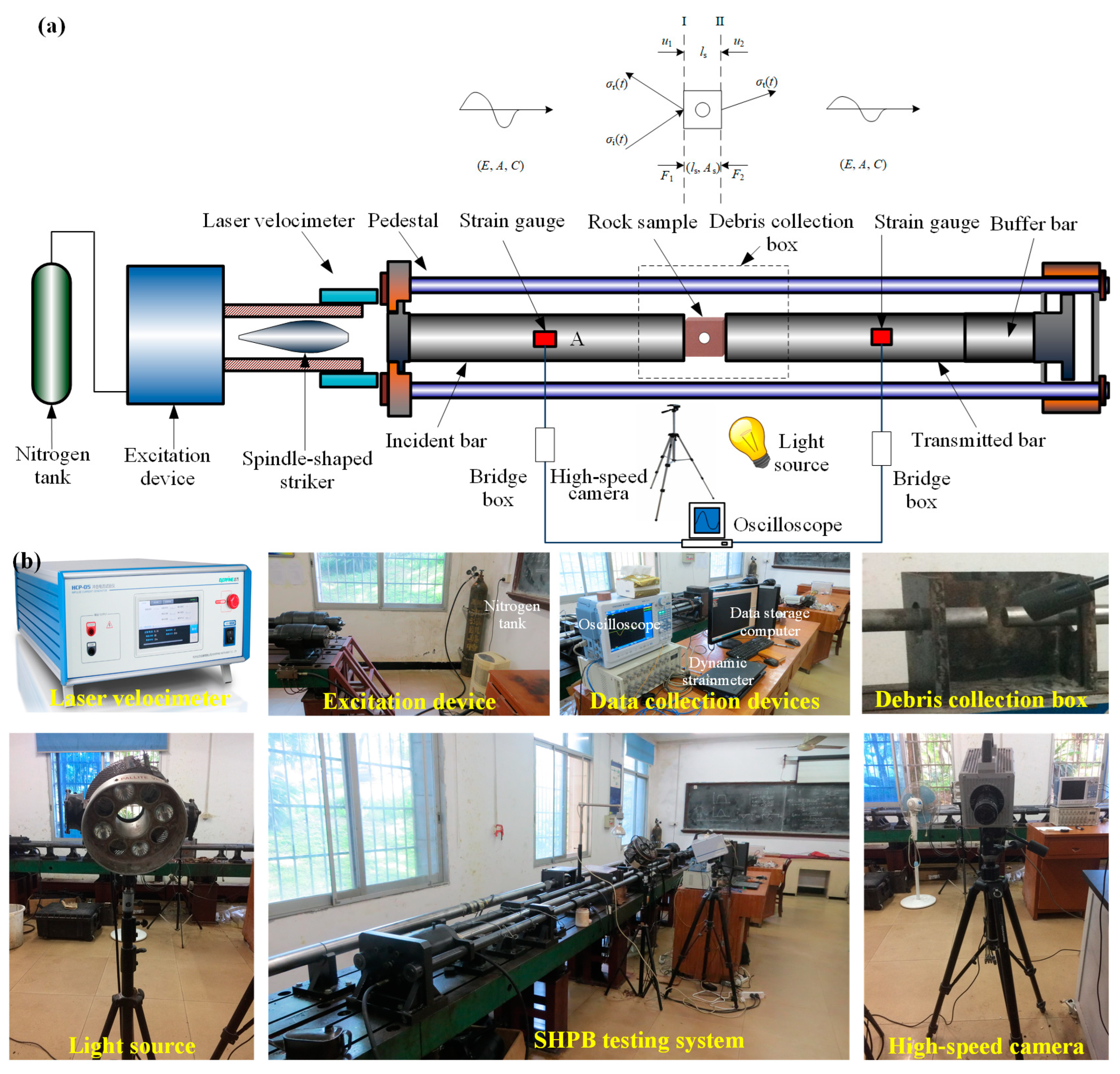

2.2. Experimental Apparatus and Principle

3. Experimental Program

4. Results and Analysis of Impact Tests

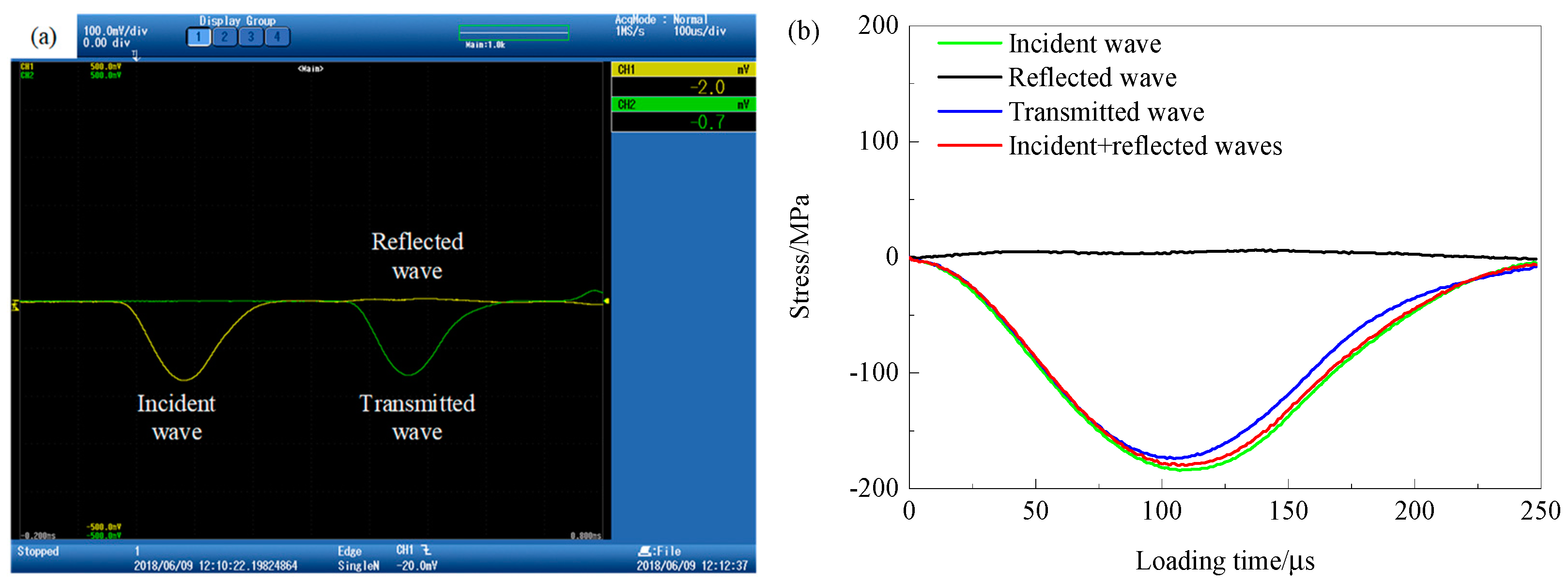

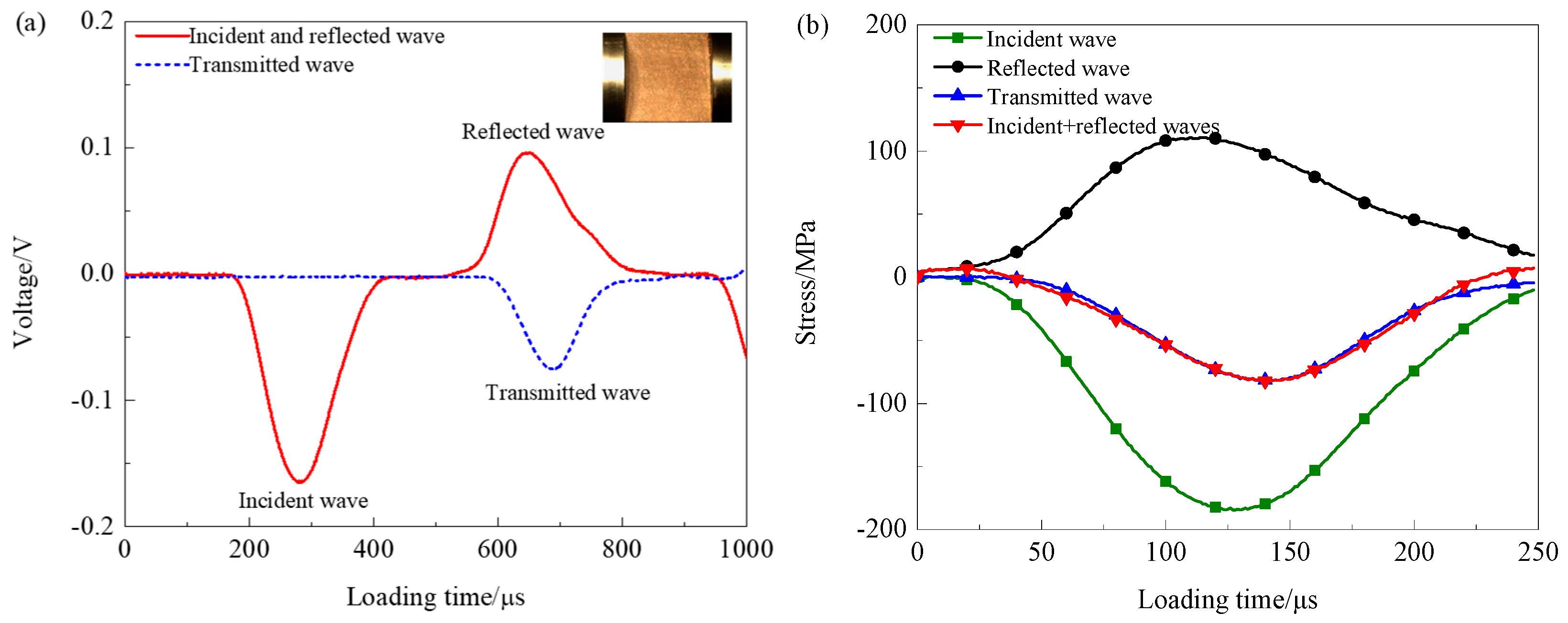

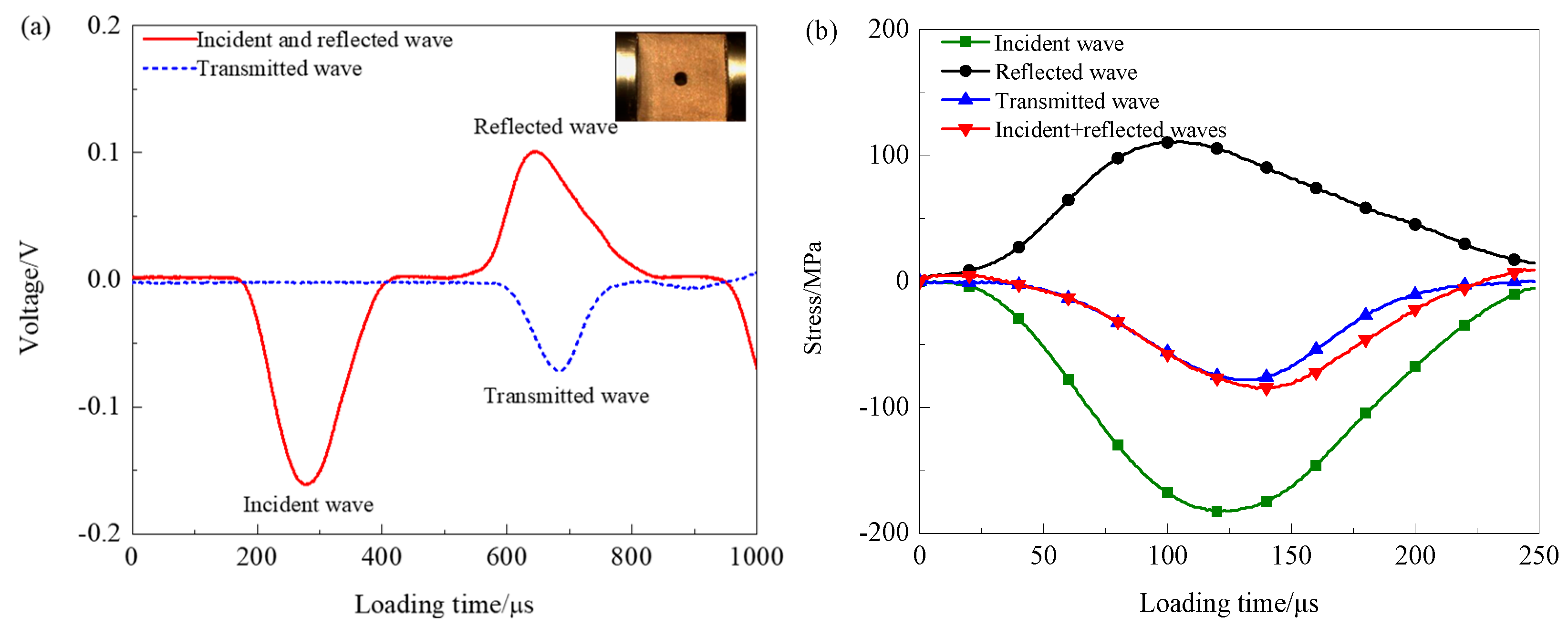

4.1. Stress Uniformity Verification of Prismatic Sample

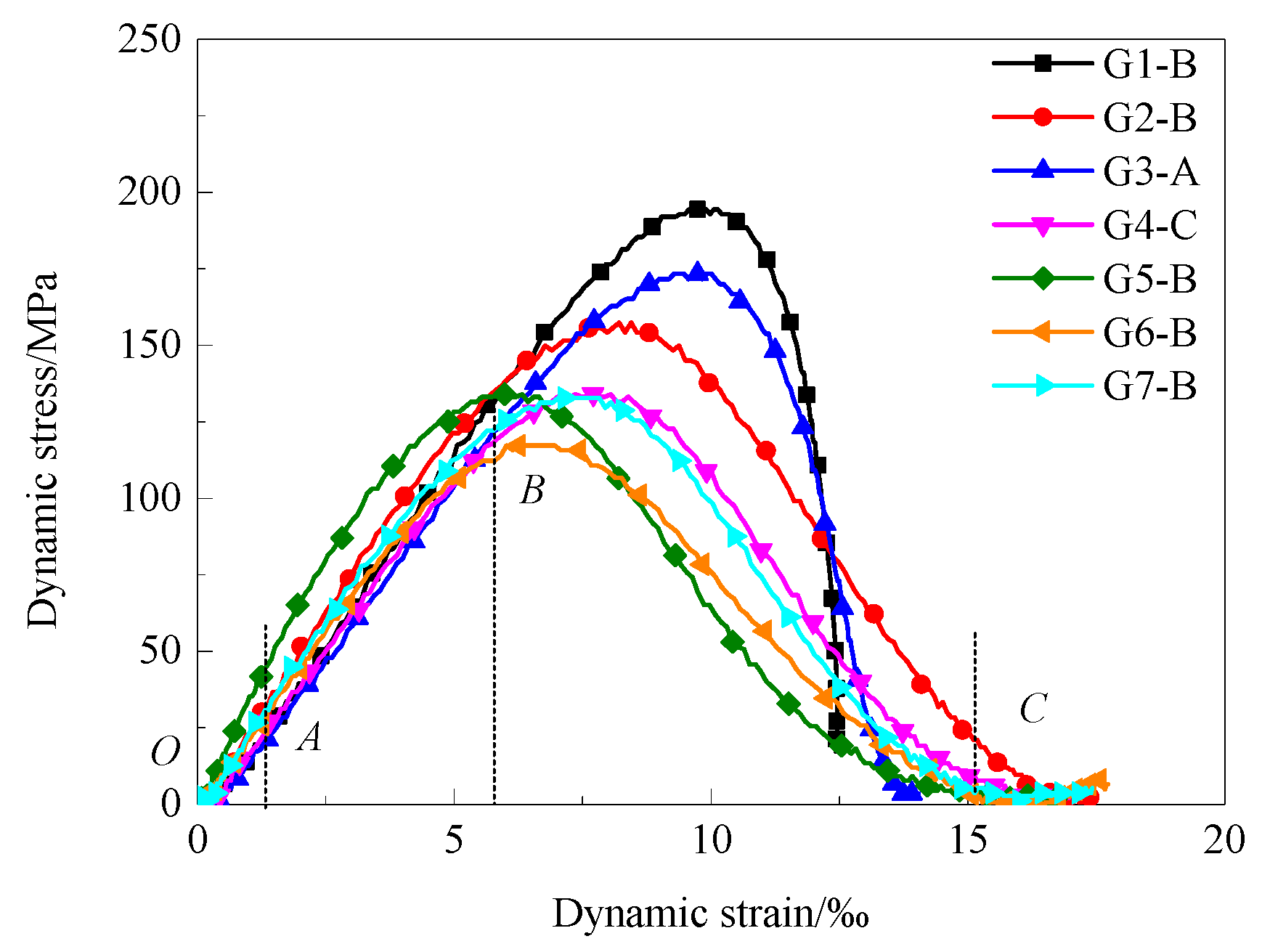

4.2. Mechanical Performance of Samples under Dynamic Loading

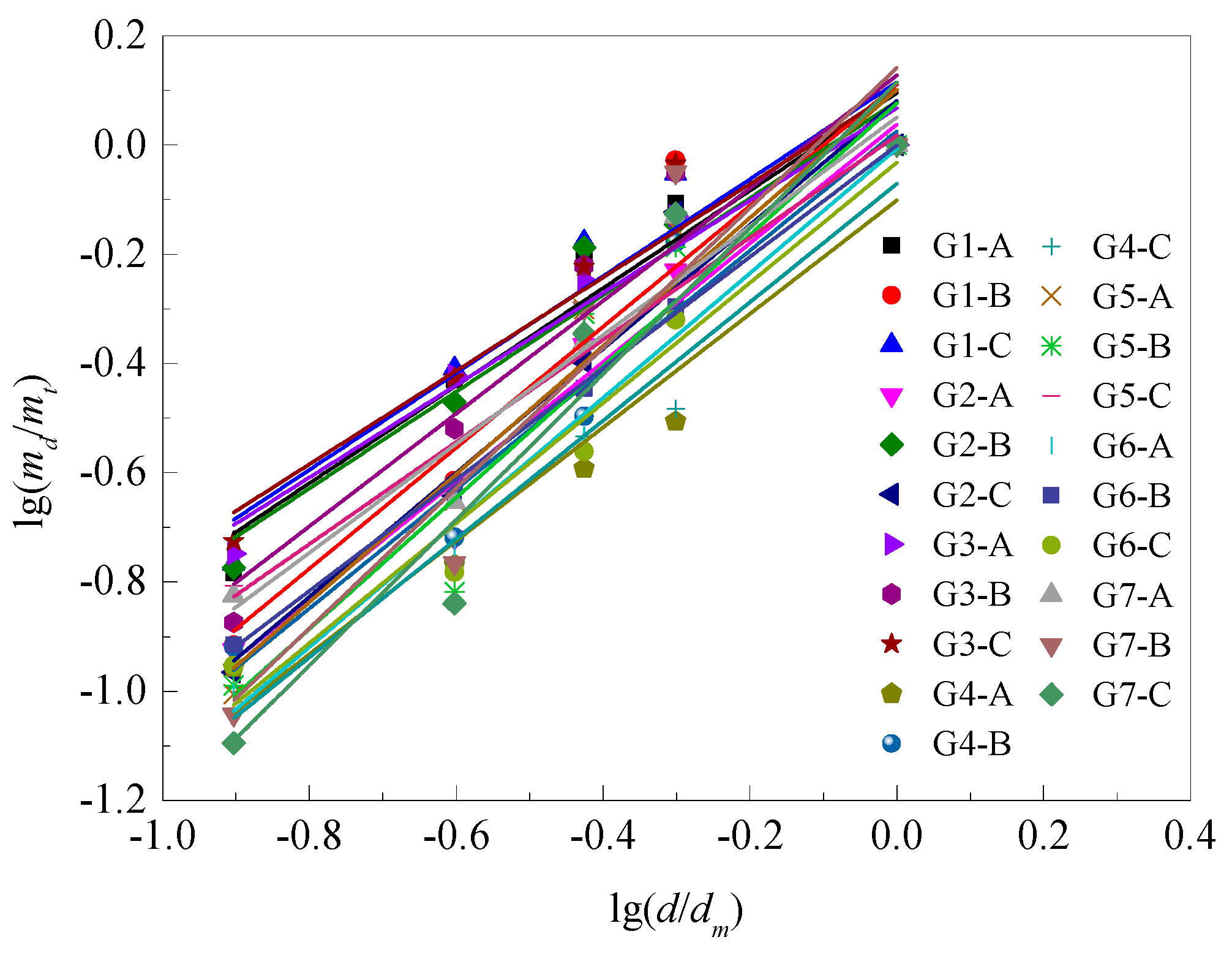

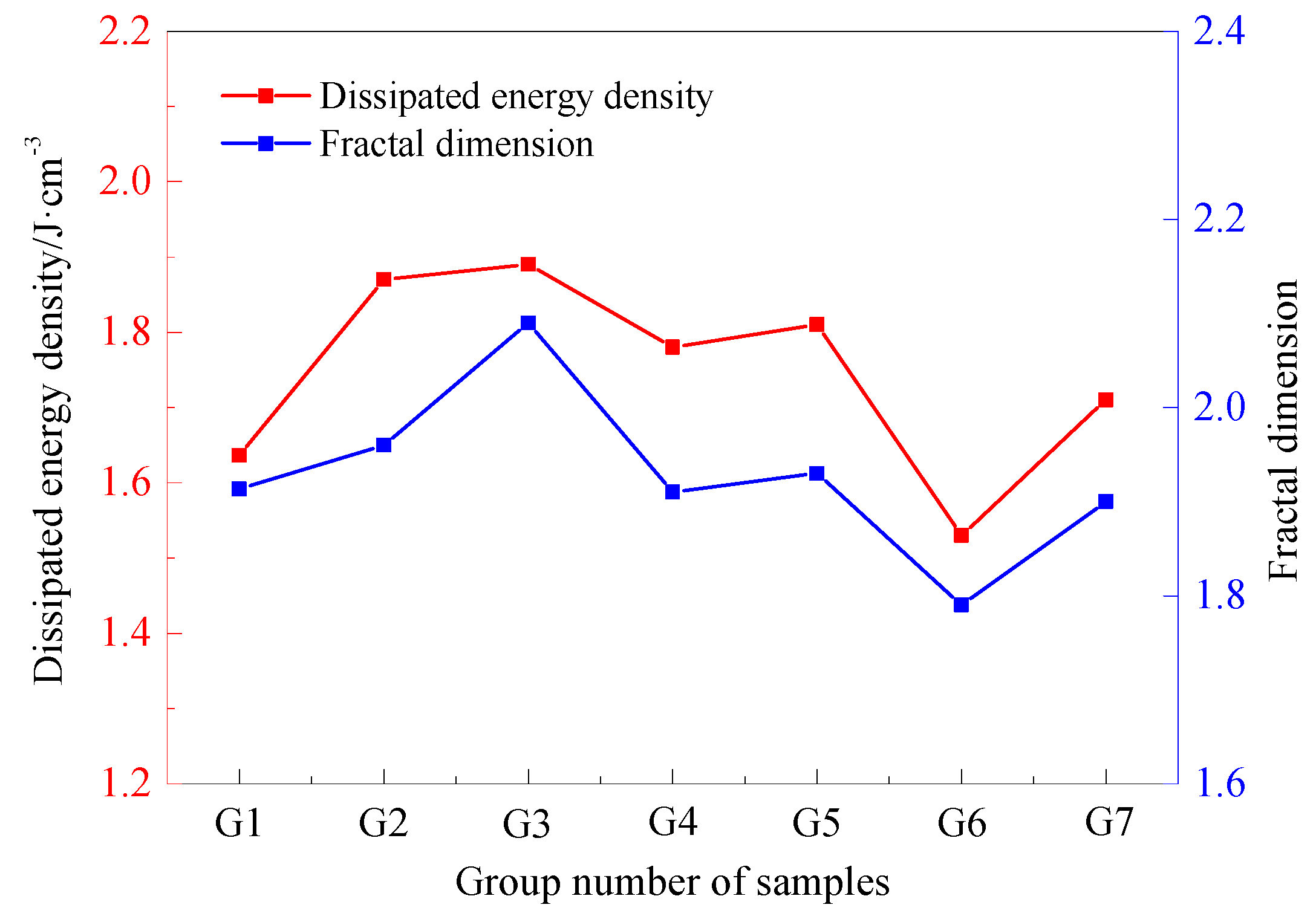

4.3. Energy Dissipation Characteristics of Specimens

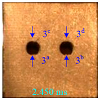

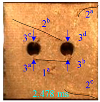

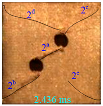

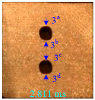

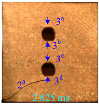

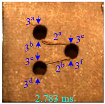

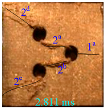

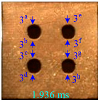

4.4. Failure Features of Samples under Impact Loading

5. Conclusions

- (1)

- A series of tests on rock chemical composition, microstructure and basic physical-mechanical parameters indicate that this kind of rock can be graded as tuffaceous–feldspar–quartz sandstone which has a fine–medium sand texture and a blocky structure, and belongs to medium-strength brittle rock.

- (2)

- The prismatic specimens applied for dynamic experiments using SHPB device meet the stress uniformity assumption, and the stress waves attenuate when encountering holes. The dynamic compressive strength of the specimens is significantly deteriorated by the opening number and layout. The dynamic deformation process of the samples containing holes under impact loads could be parted into three phases: the elastic deformation phase, plastic deformation phase and the post peak phase. However, no regularity was found in the dynamic elastic modulus and peak strain of the pre-holed samples.

- (3)

- The dissipated energy densities and the dynamic compressive strength of several groups of samples showed the same change rule. The size order of the sample fragmentation can be listed as G3 < G2 < G5 < G4 < G7 < G6, which is consistent with the result derived from employing fractal dimensions to describe the rock fragmentation. In addition, the dynamic fracturing process of the sample with openings could be clearly captured with a high-speed camera, and it was found that there are three sorts of cracks, namely spalling cracks, shear cracks and tensile cracks, which formed around the holes during the tests. The samples of groups G2 and G4 suffered from shear-dominated failure, while the samples of groups G3, G5, G6 and G7 presented tensile-shear failure, suggesting that the fracturing behaviors are highly related to the opening configuration.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, M.; Rao, K.S.; Ramamurthy, T. Strength and deformational behaviour of a jointed rock mass. Rock Mech. Rock Eng. 2002, 35, 45–64. [Google Scholar] [CrossRef]

- Jade, S.; Sitharam, T.G. Characterization of strength and deformation of jointed rock mass based on statistical analysis. Int. J. Geomech. 2003, 3, 43–54. [Google Scholar] [CrossRef]

- Cao, R.H.; Cao, P.; Lin, H.; Fan, X.; Zhang, C.Y.; Liu, T.Y. Crack initiation, propagation, and failure characteristics of jointed rock or rock-like specimens: A review. Adv. Civ. Eng. 2019, 2019, 6975751. [Google Scholar] [CrossRef]

- Wu, H.; Kulatilake, P.; Zhao, G.Y.; Liang, W.Z. Stress distribution and fracture evolution around a trapezoidal cavity in sandstone loaded in compression. Theor. Appl. Fract. Mech. 2019, 104, 102348. [Google Scholar] [CrossRef]

- Wu, H.; Dai, B.; Cheng, L.; Lu, R.; Zhao, G.Y.; Liang, W.Z. Experimental study of dynamic mechanical response and energy dissipation of rock having a circular opening under impact loading. Min. Metall. Explor. 2021, 38, 1111–1124. [Google Scholar] [CrossRef]

- Hoek, E. Rock Fracture under Static Stress Conditions. Ph.D. Dissertation, The Faculty of Engineering, University of Cape Town, Cape Town, South Africa, 1965. [Google Scholar]

- Kobayashi, A.S.; Johnson, B.; Wade, B.G. Crack approaching a hole. Fract. Anal. 1974, 560, 53–68. [Google Scholar]

- Gay, N.C. Fracture growth around openings in large blocks of rock subjected to uniaxial and biaxial compression. Int. J. Rock Mech. Min. Sci. 1976, 13, 231–243. [Google Scholar] [CrossRef]

- Lajtai, E.Z.; Carter, B.J.; Duncan, E.J.S. Mapping the state of fracture around cavities. Eng. Geol. 1991, 31, 277–289. [Google Scholar] [CrossRef]

- Wong, R.H.C.; Lin, P.; Tang, C.A. Experimental and numerical study on splitting failure of brittle solids containing single pore under uniaxial compression. Mech. Mater. 2006, 38, 142–159. [Google Scholar] [CrossRef]

- Sammis, C.G.; Ashby, M.F. The failure of brittle porous solids under compressive stress states. Acta Metall. 1986, 34, 511–526. [Google Scholar] [CrossRef]

- Li, D.Y.; Zhu, Q.Q.; Zhou, Z.L.; Li, X.B.; Ranjith, P.J. Fracture analysis of marble specimens with a hole under uniaxial compression by digital image correlation. Eng. Fract. Mech. 2017, 183, 109–124. [Google Scholar] [CrossRef]

- Zhu, W.C.; Liu, J.S.; Tang, C.A.; Zhao, X.D.; Brady, B.H. Simulation of progressive fracturing processes around underground excavations under biaxial compression. Tunn. Undergr. Space Technol. 2005, 20, 231–247. [Google Scholar] [CrossRef]

- Zeng, W.; Yang, S.Q.; Tian, W.L. Experimental and numerical investigation of brittle sandstone specimens containing different shapes of holes under uniaxial compression. Eng. Fract. Mech. 2018, 200, 430–450. [Google Scholar] [CrossRef]

- Wu, H.; Fan, A.Q.; Ma, D.; Spearing, A.J.S.; Zheng, Z. Fracturing process and initiation mechanism of hard rock tunnels with different shapes: Particle flow modeling and analytical study. Comput. Part. Mech. 2023, 10, 1859–1875. [Google Scholar] [CrossRef]

- Aker, E.; Kühn, D.; Vavryčuk, V.; Soldal, M.; Oye, V. Experimental investigation of acoustic emissions and their moment tensors in rock during failure. Int. J. Rock Mech. Min. Sci. 2014, 70, 286–295. [Google Scholar] [CrossRef]

- Zhang, S.R.; Sun, B.; Wang, C.; Yan, L. Influence of intermediate principal stress on failure mechanism of hard rock with a pre-existing circular opening. J. Cent. South Univ. 2014, 21, 1571–1582. [Google Scholar] [CrossRef]

- Van De Steen, B.; Vervoort, A.; Napier, J.A.L. Observed and simulated fracture pattern in diametrically loaded discs of rock material. Int. J. Fract. 2005, 131, 35–52. [Google Scholar] [CrossRef]

- Tao, M.; Zhao, R.; Du, K.; Cao, W.Z.; Li, Z.W. Dynamic stress concentration and failure characteristics around elliptical cavity subjected to impact loading. Int. J. Solids Struct. 2020, 191–192, 401–417. [Google Scholar] [CrossRef]

- Li, Y.H.; Peng, J.Y.; Zhang, F.P.; Qiu, Z.G. Cracking behavior and mechanism of sandstone containing a pre-cut hole under combined static and dynamic loading. Eng. Geol. 2016, 213, 64–73. [Google Scholar] [CrossRef]

- Tao, M.; Ma, A.; Cao, W.Z.; Li, X.B.; Gong, F.Q. Dynamic response of pre-stressed rock with a circular cavity subject to transient loading. Int. J. Rock Mech. Min. Sci. 2017, 99, 1–8. [Google Scholar] [CrossRef]

- Weng, L.; Li, X.B.; Taheri, A.; Wu, Q.H.; Xie, X.F. Fracture evolution around a cavity in brittle rock under uniaxial compression and coupled static–dynamic loads. Rock Mech. Rock Eng. 2018, 51, 531–545. [Google Scholar] [CrossRef]

- Wang, S.Y.; Sun, L.; Yang, C.; Yang, S.Q.; Tang, C.A. Numerical study on static and dynamic fracture evolution around rock cavities. J. Rock Mech. Geotech. Eng. 2013, 5, 262–276. [Google Scholar] [CrossRef]

- Tang, Z.L.; Yao, W.; Zhang, J.C.; Xu, Q.J.; Xia, K.W. Experimental evaluation of PMMA simulated tunnel stability under dynamic disturbance using digital image correlation. Tunn. Undergr. Space Technol. 2019, 92, 101039. [Google Scholar] [CrossRef]

- Long, Y.; Liu, J.P.; Lei, G.; Si, Y.T.; Zhang, C.Y.; Wei, D.C.; Shi, H.X. Progressive fracture processes around tunnel triggered by blast disturbances under biaxial compression with different lateral pressure coefficients. Trans. Nonferrous Met. Soc. China 2020, 30, 2518–2535. [Google Scholar] [CrossRef]

- Qiu, J.D.; Li, X.B.; Li, D.Y.; Zhao, Y.Z.; Hu, C.W.; Liang, L.S. Physical model test on the deformation behavior of an underground tunnel under blasting disturbance. Rock Mech. Rock Eng. 2021, 54, 91–108. [Google Scholar] [CrossRef]

- Li, X.B.; Wu, Q.H.; Tao, M.; Weng, L.; Dong, L.J.; Zou, Y. Dynamic Brazilian splitting test of ring-shaped specimens with different hole diameters. Rock Mech. Rock Eng. 2016, 49, 4143–4151. [Google Scholar] [CrossRef]

- Zhao, Z.L.; Jing, H.W.; Shi, X.S.; Han, G.S. Experimental and numerical study on mechanical and fracture behavior of rock-like specimens containing pre-existing holes flaws. Eur. J. Environ. Civ. Eng. 2022, 26, 299–319. [Google Scholar] [CrossRef]

- Yang, S.Q.; Huang, Y.H.; Tan, W.L.; Zhu, J.B. An experimental investigation on strength, deformation and crack evolution behavior of sandstone containing two oval flaws under uniaxial compression. Eng. Geol. 2017, 217, 35–48. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Tan, L.H.; Cao, W.Z.; Zhou, Z.Y.; Cai, X. Fracture evolution and failure behaviour of marble specimens containing rectangular cavities under uniaxial loading. Eng. Fract. Mech. 2017, 184, 183–201. [Google Scholar] [CrossRef]

- Tang, C.A.; Wong, R.H.C.; Chau, K.T.; Lin, P. Modeling of compression-induced splitting failure in heterogeneous brittle porous solids. Eng. Fract. Mech. 2005, 72, 597–615. [Google Scholar] [CrossRef]

- Lin, P.; Wong, R.H.C.; Tang, C.A. Experimental study of coalescence mechanisms and failure under uniaxial compression of granite containing multiple holes. Int. J. Rock Mech. Min. Sci. 2015, 77, 313–327. [Google Scholar] [CrossRef]

- Wu, H.; Ma, D.; Spearing, A.J.S.; Zhao, G.Y. Fracture response and mechanisms of brittle rock with different numbers of openings under uniaxial loading. Geomech. Eng. 2021, 25, 481–493. [Google Scholar]

- Wu, H.; Zhao, G.Y.; Liang, W.Z. Mechanical response and fracture behavior of brittle rocks containing two inverted U-shaped holes under uniaxial loading. Appl. Sci. 2019, 9, 5327. [Google Scholar] [CrossRef]

- Haeri, H.; Khaloo, A.; Marji, M.F. Fracture analyses of different pre-holed concrete specimens under compression. Acta Mech. Sin. 2015, 31, 855–870. [Google Scholar] [CrossRef]

- Jespersen, C.; Maclaughlin, M.; Hudyma, N. Strength, deformation modulus and failure modes of cubic analog specimens representing macroporous rock. Int. J. Rock Mech. Min. Sci. 2010, 47, 1349–1356. [Google Scholar] [CrossRef]

- Wang, S.H.; Lee, C.I.; Ranjith, P.J.; Tang, C.A. Modeling the Effects of Heterogeneity and Anisotropy on the Excavation Damaged/Disturbed Zone (EDZ). Rock Mech. Rock Eng. 2009, 42, 229–258. [Google Scholar] [CrossRef]

- Yang, S.Q.; Tian, W.L.; Huang, Y.H. Failure mechanical behavior of pre-holed granite specimens after elevated temperature treatment by particle flow code. Geothermics 2018, 72, 124–137. [Google Scholar] [CrossRef]

- Xie, H.P.; Chen, Z.D. Fractal geometry and fracture of rock. Acta Mech. Sin. 1988, 4, 255–264. [Google Scholar]

- Choi, Y.C.; Park, B. Effects of high-temperature exposure on fractal dimension of fly-ash-based geopolymer composites. J. Mater. Res. Technol. 2020, 9, 7655–7668. [Google Scholar] [CrossRef]

| σc/MPa | σt/MPa | Ee/GPa | μ | Fc/MPa | θ /° | Tf/MPa·m½ |

|---|---|---|---|---|---|---|

| 102.61 | 5.28 | 20.78 | 0.258 | 19.01 | 40.43 | 0.59 |

| Specimen Number | Length /mm | Width /mm | Height /mm | Density /g∙cm−3 | Hit Velocity/ m∙s−1 | Dynamic Compressive Strength/MPa | Dynamic Elastic Modulus /GPa | Peak Strain/‰ | Strain Rate/s−1 |

|---|---|---|---|---|---|---|---|---|---|

| G1-A | 45.7 | 19.8 | 45.6 | 2.44 | 10.05 | 180.50 | 22.99 | 9.18 | 64.65 |

| G1-B | 45.0 | 19.9 | 44.9 | 2.45 | 9.76 | 194.46 | 26.03 | 10.09 | 74.78 |

| G1-C | 45.1 | 20.7 | 45.2 | 2.47 | 10.18 | 185.11 | 30.60 | 7.48 | 50.67 |

| G2-A | 45.5 | 19.9 | 45.7 | 2.43 | 9.97 | 169.16 | 26.22 | 8.82 | 68.81 |

| G2-B | 45.1 | 19.8 | 45.1 | 2.43 | 10.27 | 157.36 | 25.44 | 8.21 | 79.52 |

| G2-C | 45.2 | 19.8 | 45.2 | 2.45 | 9.83 | 157.18 | 24.58 | 7.30 | 66.73 |

| G3-A | 45.0 | 20.1 | 45.1 | 2.43 | 9.96 | 173.29 | 22.47 | 9.64 | 75.42 |

| G3-B | 44.7 | 19.9 | 45.7 | 2.40 | 9.97 | 150.00 | 23.79 | 7.72 | 75.18 |

| G3-C | 45.1 | 20.0 | 45.1 | 2.44 | 9.92 | 173.20 | 24.35 | 9.35 | 75.50 |

| G4-A | 45.1 | 19.9 | 45.1 | 2.43 | 9.85 | 134.39 | 23.13 | 8.03 | 79.17 |

| G4-B | 45.0 | 19.7 | 45.0 | 2.42 | 9.89 | 131.61 | 25.50 | 6.87 | 76.29 |

| G4-C | 45.5 | 19.9 | 45.5 | 2.42 | 10.03 | 134.00 | 23.87 | 7.70 | 78.72 |

| G5-A | 45.0 | 19.7 | 45.0 | 2.44 | 9.92 | 139.88 | 27.84 | 7.26 | 75.89 |

| G5-B | 44.7 | 19.9 | 45.5 | 2.41 | 9.99 | 134.01 | 27.53 | 6.10 | 74.91 |

| G5-C | 45.1 | 19.8 | 45.1 | 2.43 | 9.94 | 138.94 | 25.37 | 7.72 | 76.12 |

| G6-A | 45.1 | 20.1 | 45.0 | 2.43 | 9.92 | 117.42 | 22.22 | 6.69 | 80.56 |

| G6-B | 45.1 | 20.1 | 45.1 | 2.43 | 9.86 | 117.22 | 23.14 | 6.49 | 79.53 |

| G6-C | 45.1 | 20.2 | 45.1 | 2.42 | 9.94 | 97.97 | 27.18 | 4.92 | 78.46 |

| D7-A | 45.1 | 19.7 | 45.1 | 2.42 | 9.96 | 127.49 | 26.40 | 6.40 | 75.32 |

| D7-B | 45.0 | 19.8 | 45.0 | 2.42 | 9.97 | 132.84 | 24.81 | 7.43 | 75.14 |

| D7-C | 45.1 | 20.0 | 45.1 | 2.43 | 9.96 | 118.21 | 25.81 | 5.82 | 68.50 |

| Specimen Number | WI/J | WR/J | WT/J | WS/J | ρw/J∙cm−3 |

|---|---|---|---|---|---|

| G1-A | 142.08 | 52.69 | 22.57 | 66.82 | 1.62 |

| G1-B | 136.65 | 44.31 | 28.83 | 63.51 | 1.58 |

| G1-C | 140.35 | 40.89 | 27.32 | 72.14 | 1.71 |

| G2-A | 143.46 | 57.15 | 10.80 | 75.51 | 1.95 |

| G2-B | 144.97 | 62.06 | 9.72 | 73.19 | 1.86 |

| G2-C | 142.35 | 61.41 | 10.45 | 70.50 | 1.80 |

| G3-A | 143.69 | 49.00 | 20.43 | 74.27 | 1.87 |

| G3-B | 144.41 | 55.10 | 13.73 | 75.57 | 1.91 |

| G3-C | 142.85 | 47.65 | 20.52 | 74.67 | 1.89 |

| G4-A | 140.69 | 61.66 | 9.89 | 69.14 | 1.76 |

| G4-B | 141.96 | 62.25 | 9.18 | 70.53 | 1.82 |

| G4-C | 145.51 | 64.89 | 10.08 | 70.55 | 1.76 |

| G5-A | 143.38 | 68.47 | 8.33 | 66.58 | 1.76 |

| G5-B | 145.69 | 65.40 | 9.72 | 70.57 | 1.86 |

| G5-C | 143.47 | 66.20 | 7.74 | 69.53 | 1.81 |

| G6-A | 141.72 | 53.62 | 18.03 | 70.07 | 1.72 |

| G6-B | 150.02 | 69.50 | 14.22 | 66.31 | 1.67 |

| G6-C | 133.16 | 49.25 | 14.76 | 69.14 | 1.73 |

| G7-A | 141.72 | 53.62 | 18.03 | 70.07 | 1.72 |

| G7-B | 150.02 | 69.50 | 14.22 | 66.31 | 1.67 |

| G7-C | 133.16 | 49.25 | 14.76 | 69.14 | 1.73 |

| Sample Number | md < 5 /g | md < 10 /g | md < 15 /g | md < 20 /g | md < 40 /g | mt /g | D | R2 |

|---|---|---|---|---|---|---|---|---|

| G1-A | 12.32 | 27.82 | 47.57 | 58.63 | 74.90 | 74.90 | 2.11 | 0.91 |

| G1-B | 10.13 | 20.30 | 36.39 | 78.30 | 83.57 | 83.57 | 1.89 | 0.88 |

| G1-C | 12.06 | 27.44 | 46.86 | 62.4 | 70.45 | 70.45 | 2.11 | 0.87 |

| G2-A | 9.15 | 14.69 | 33.08 | 45.40 | 76.91 | 76.91 | 1.91 | 0.95 |

| G2-B | 14.25 | 28.69 | 55.03 | 60.72 | 84.80 | 84.80 | 2.11 | 0.92 |

| G2-C | 9.63 | 20.22 | 35.60 | 67.01 | 88.97 | 88.97 | 1.86 | 0.94 |

| G3-A | 15.37 | 32.58 | 48.68 | 63.83 | 86.17 | 86.17 | 2.15 | 0.95 |

| G3-B | 10.93 | 24.71 | 49.23 | 72.72 | 81.83 | 81.83 | 1.97 | 0.88 |

| G3-C | 15.06 | 29.95 | 47.89 | 73.9 | 80.06 | 80.06 | 2.14 | 0.89 |

| G4-A | 8.68 | 15.85 | 25.66 | 43.23 | 87.26 | 87.26 | 1.86 | 0.98 |

| G4-B | 11.52 | 22.54 | 33.96 | 47.88 | 94.71 | 94.71 | 1.98 | 0.99 |

| G4-C | 10.08 | 14.96 | 24.89 | 43.35 | 90.58 | 90.58 | 1.90 | 0.95 |

| G5-A | 9.73 | 15.03 | 22.55 | 27.52 | 88.30 | 88.30 | 1.96 | 0.92 |

| G5-B | 9.55 | 15.15 | 25.27 | 52.6 | 79.27 | 79.27 | 1.91 | 0.93 |

| G5-C | 8.57 | 14.46 | 24.75 | 27.79 | 84.41 | 84.41 | 1.92 | 0.96 |

| G6-A | 12.29 | 18.22 | 35.76 | 60.79 | 82.17 | 82.17 | 2.00 | 0.92 |

| G6-B | 7.56 | 14.31 | 41.99 | 74.36 | 83.45 | 83.45 | 1.72 | 0.86 |

| G6-C | 7.02 | 12.66 | 39.52 | 65.53 | 87.49 | 87.49 | 1.66 | 0.89 |

| G7-A | 8.29 | 18.75 | 42.10 | 58.94 | 84.06 | 84.06 | 1.83 | 0.93 |

| G7-B | 9.59 | 14.25 | 46.00 | 60.97 | 93.75 | 93.75 | 1.80 | 0.89 |

| G7-C | 13.01 | 20.40 | 36.13 | 50.36 | 83.38 | 83.38 | 2.06 | 0.98 |

| Sample No. | Moment 1 | Moment 2 | Moment 3 | Moment 4 | Moment 5 |

|---|---|---|---|---|---|

| G1-B |  |  |  |  |  |

| G2-C |  |  |  |  |  |

| G3-C |  |  |  |  |  |

| G4-C |  |  |  |  |  |

| G5-B |  |  |  |  |  |

| G6-A |  |  |  |  |  |

| G7-A |  |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Jia, Y. Strength, Deformation and Fracture Properties of Hard Rocks Embedded with Tunnel-Shaped Openings Suffering from Dynamic Loads. Appl. Sci. 2024, 14, 3175. https://doi.org/10.3390/app14083175

Wu H, Jia Y. Strength, Deformation and Fracture Properties of Hard Rocks Embedded with Tunnel-Shaped Openings Suffering from Dynamic Loads. Applied Sciences. 2024; 14(8):3175. https://doi.org/10.3390/app14083175

Chicago/Turabian StyleWu, Hao, and Yongsheng Jia. 2024. "Strength, Deformation and Fracture Properties of Hard Rocks Embedded with Tunnel-Shaped Openings Suffering from Dynamic Loads" Applied Sciences 14, no. 8: 3175. https://doi.org/10.3390/app14083175

APA StyleWu, H., & Jia, Y. (2024). Strength, Deformation and Fracture Properties of Hard Rocks Embedded with Tunnel-Shaped Openings Suffering from Dynamic Loads. Applied Sciences, 14(8), 3175. https://doi.org/10.3390/app14083175