Study on Fatigue Life of PC Composite Box Girder Bridge with Corrugated Steel Webs under the Combined Action of Temperature and Static Wind Loads

Abstract

1. Introduction

2. Collation and Analysis of Measured Data of Temperature and Wind

2.1. Wind Speed Warning and Monitoring System

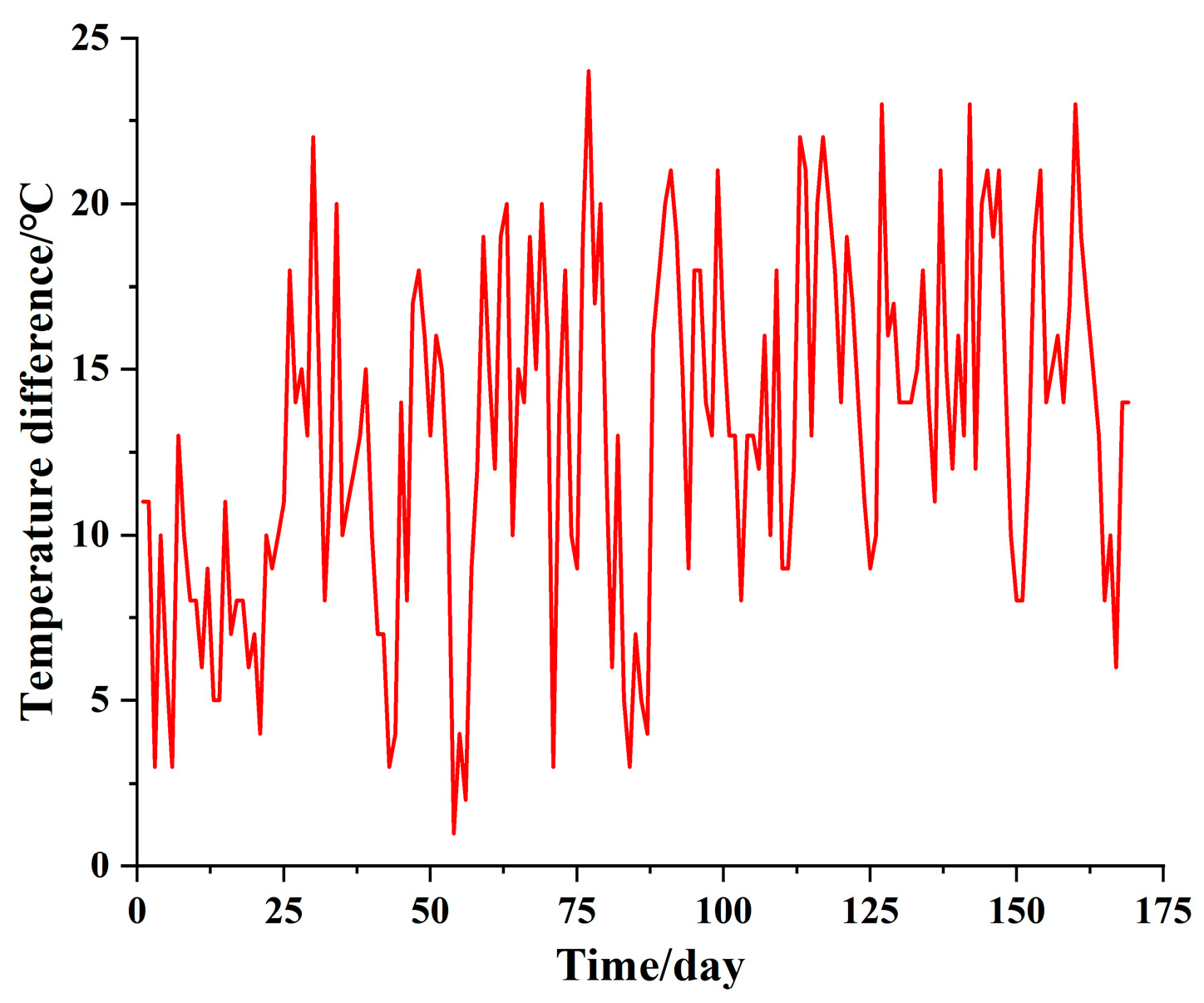

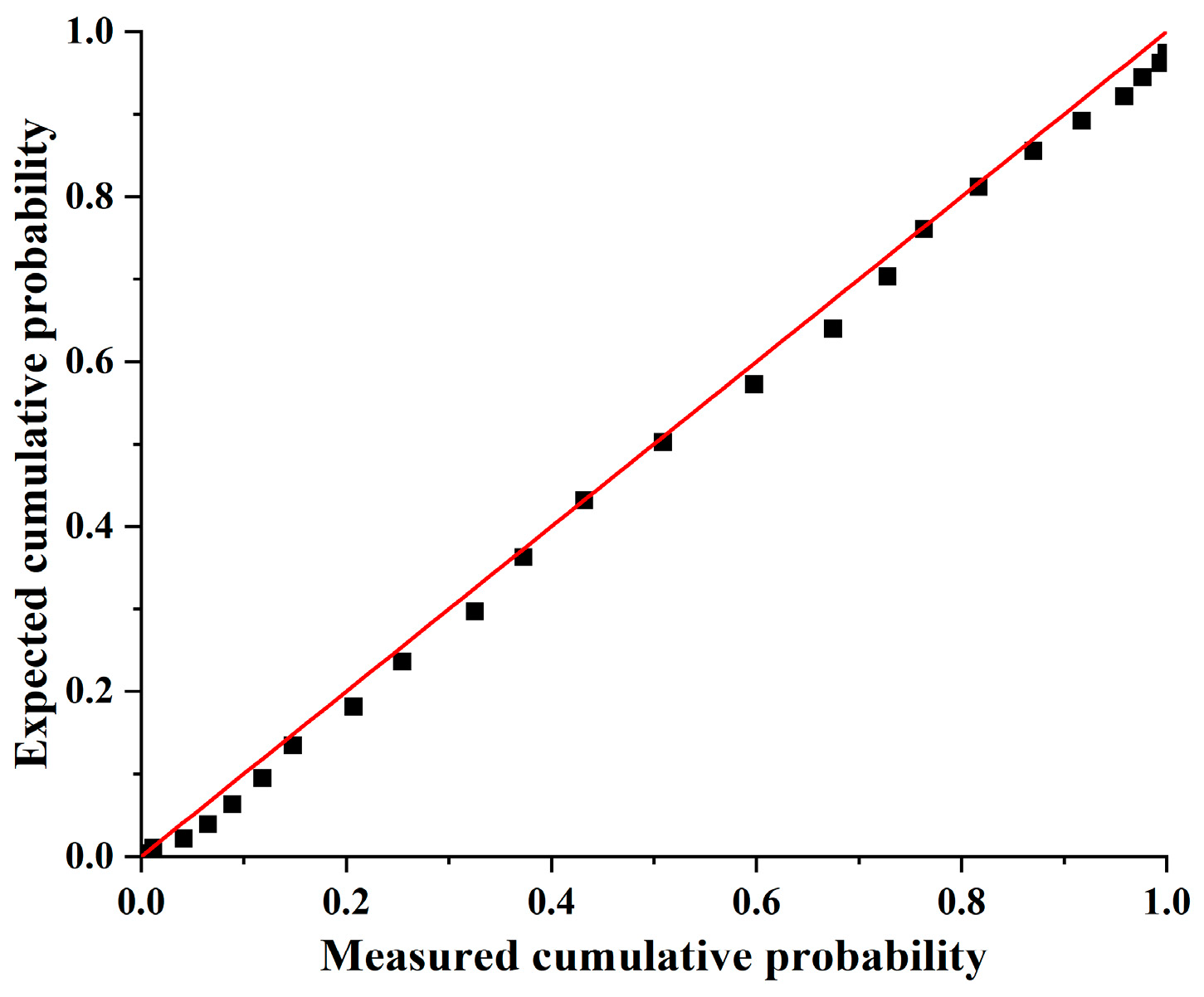

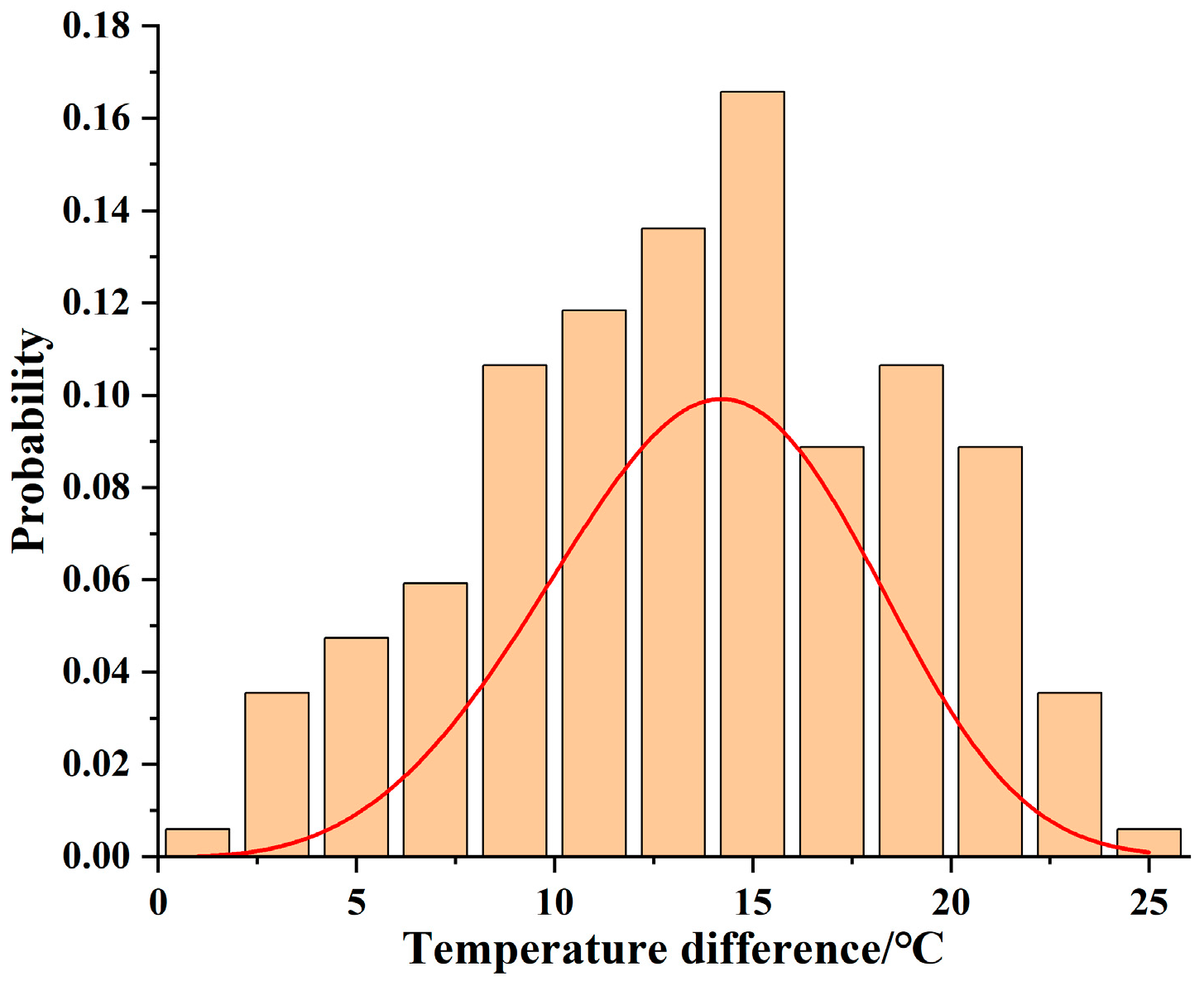

2.2. Representative Value of Atmospheric Temperature Difference between Day and Night Based on Statistical Analysis

2.3. Probability Model Fitting of Wind Speed and Direction

2.3.1. Fitting Method

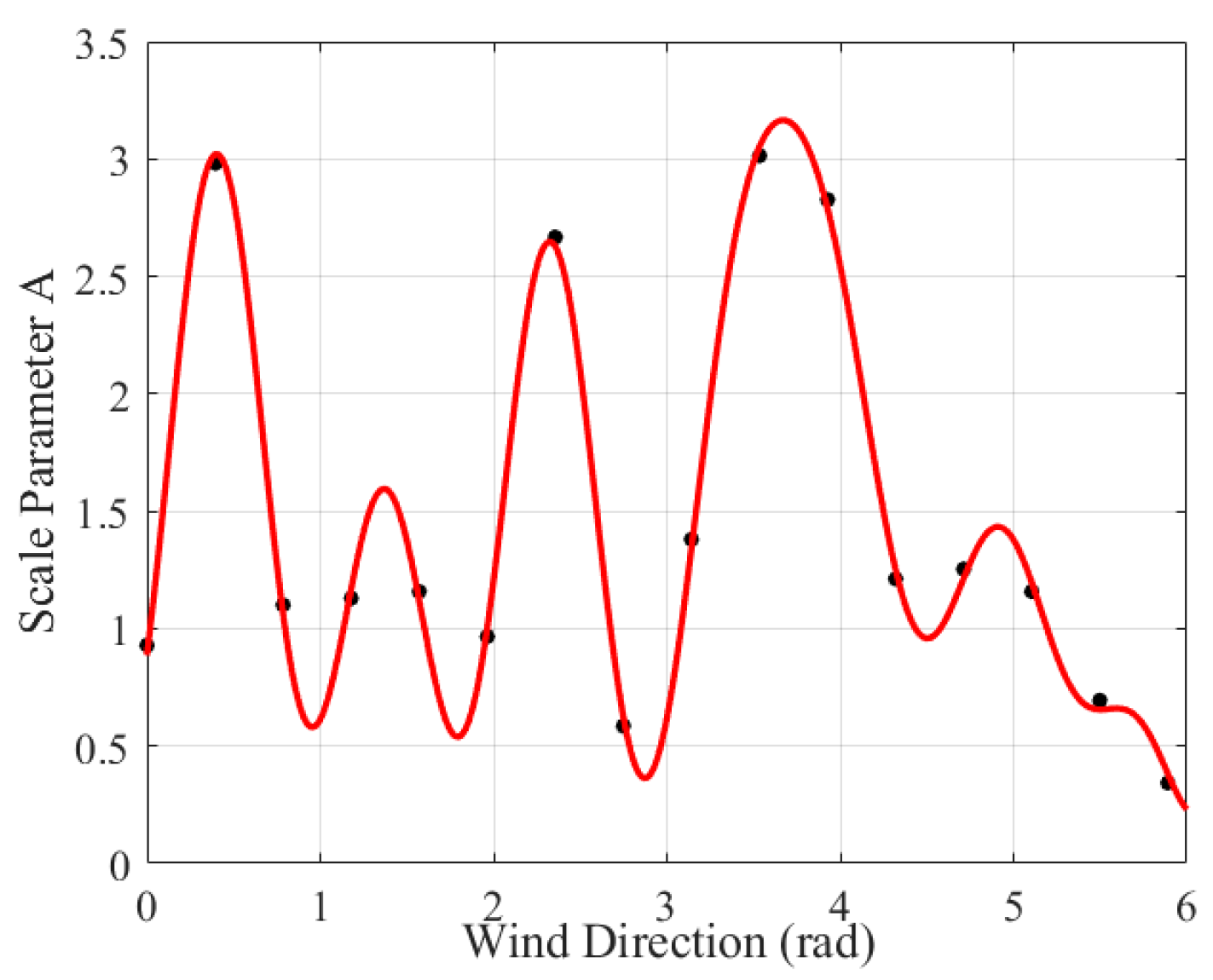

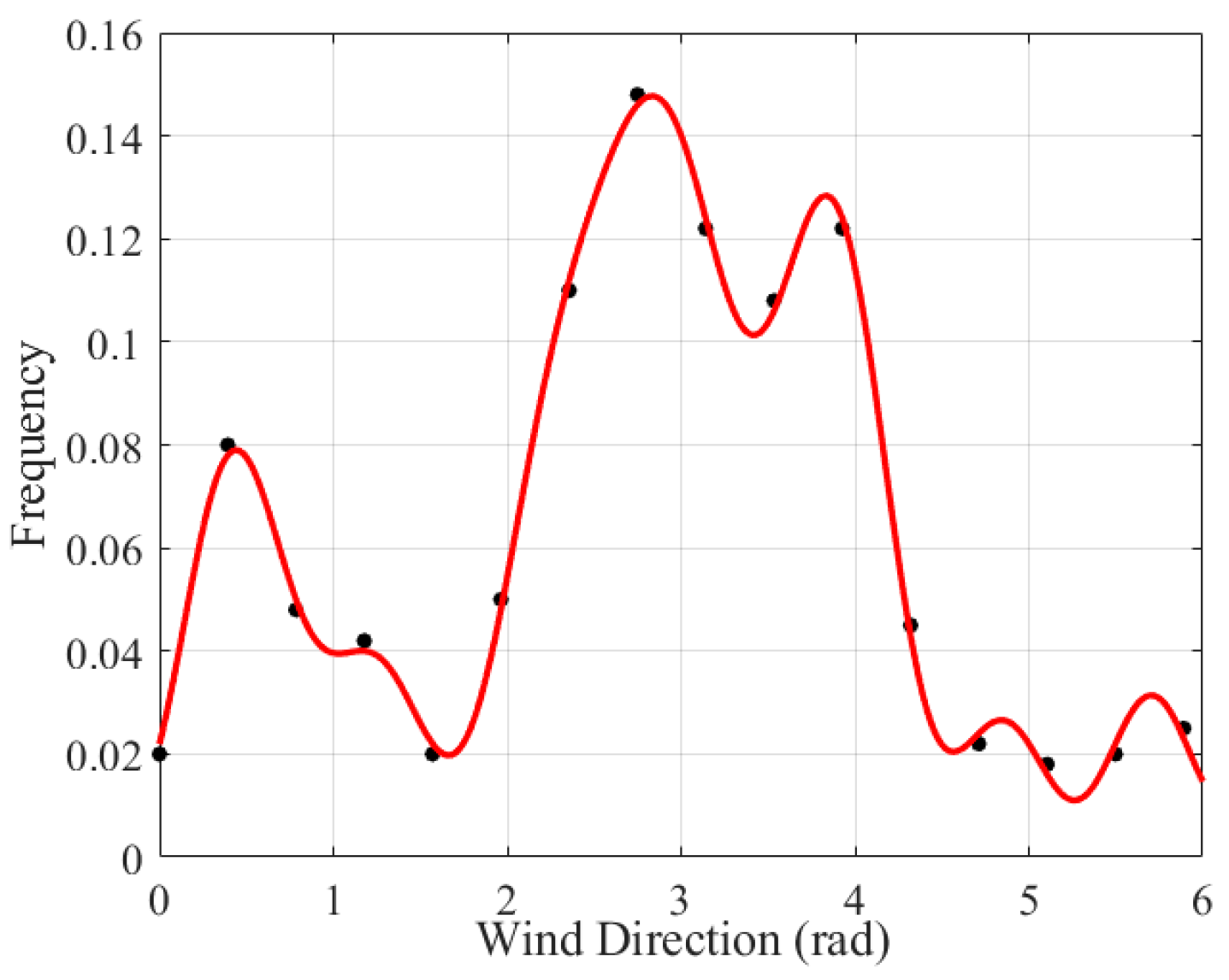

2.3.2. Sampling and Fitting of Wind Speed and Direction

2.3.3. Basic Wind Speed Calculation and Result Analysis

3. Wind Load Calculation

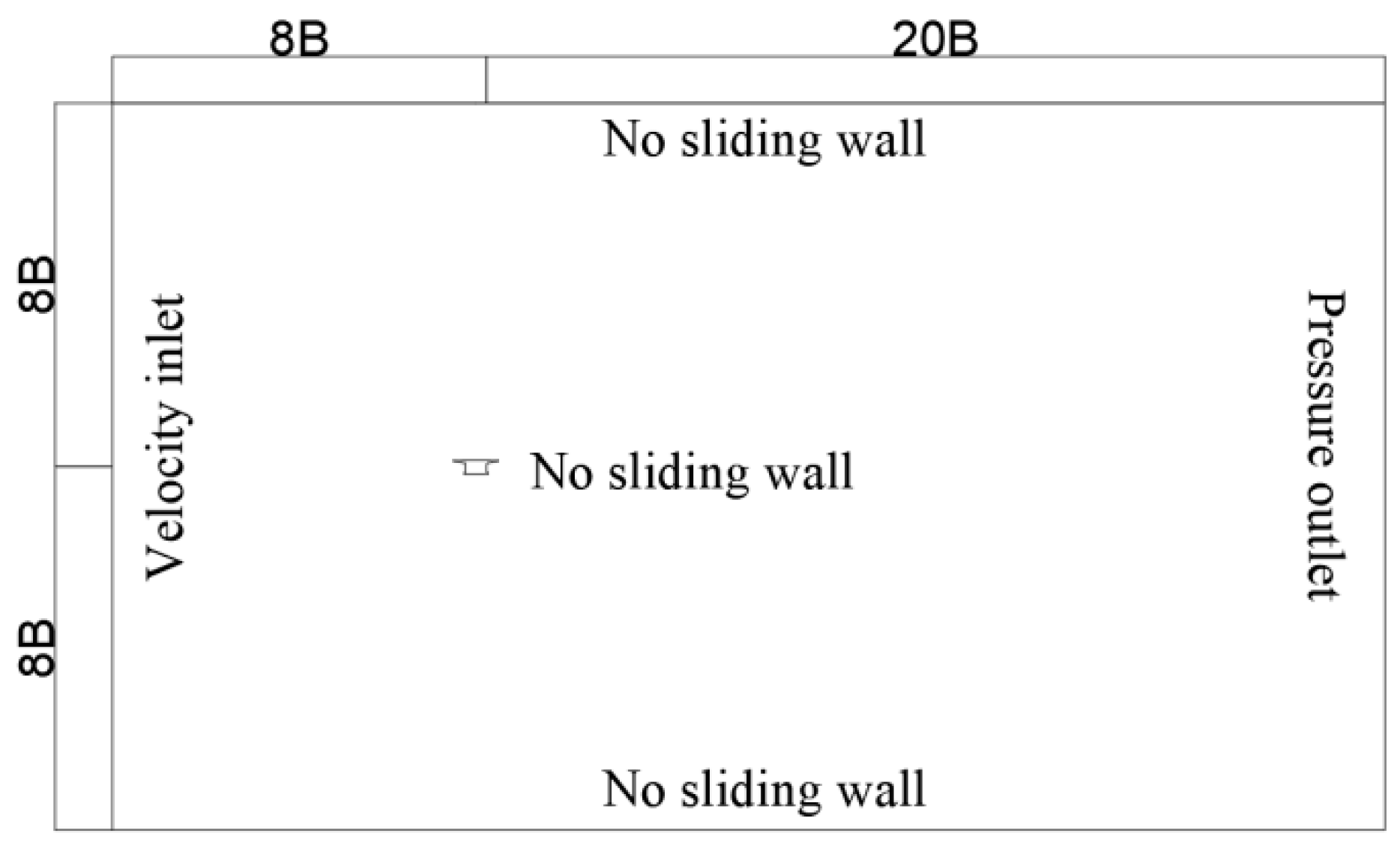

3.1. Principle of Wind Load Calculation

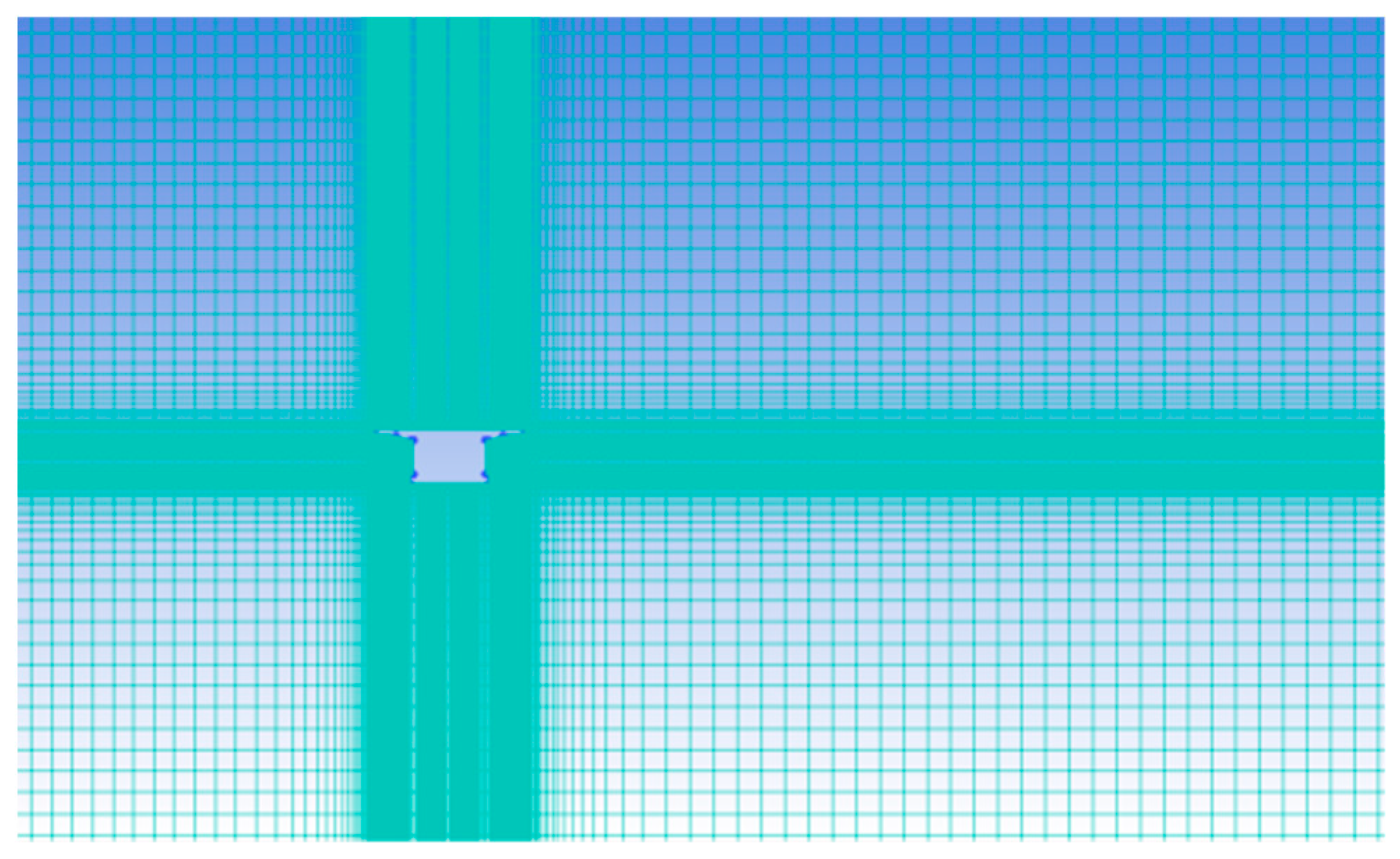

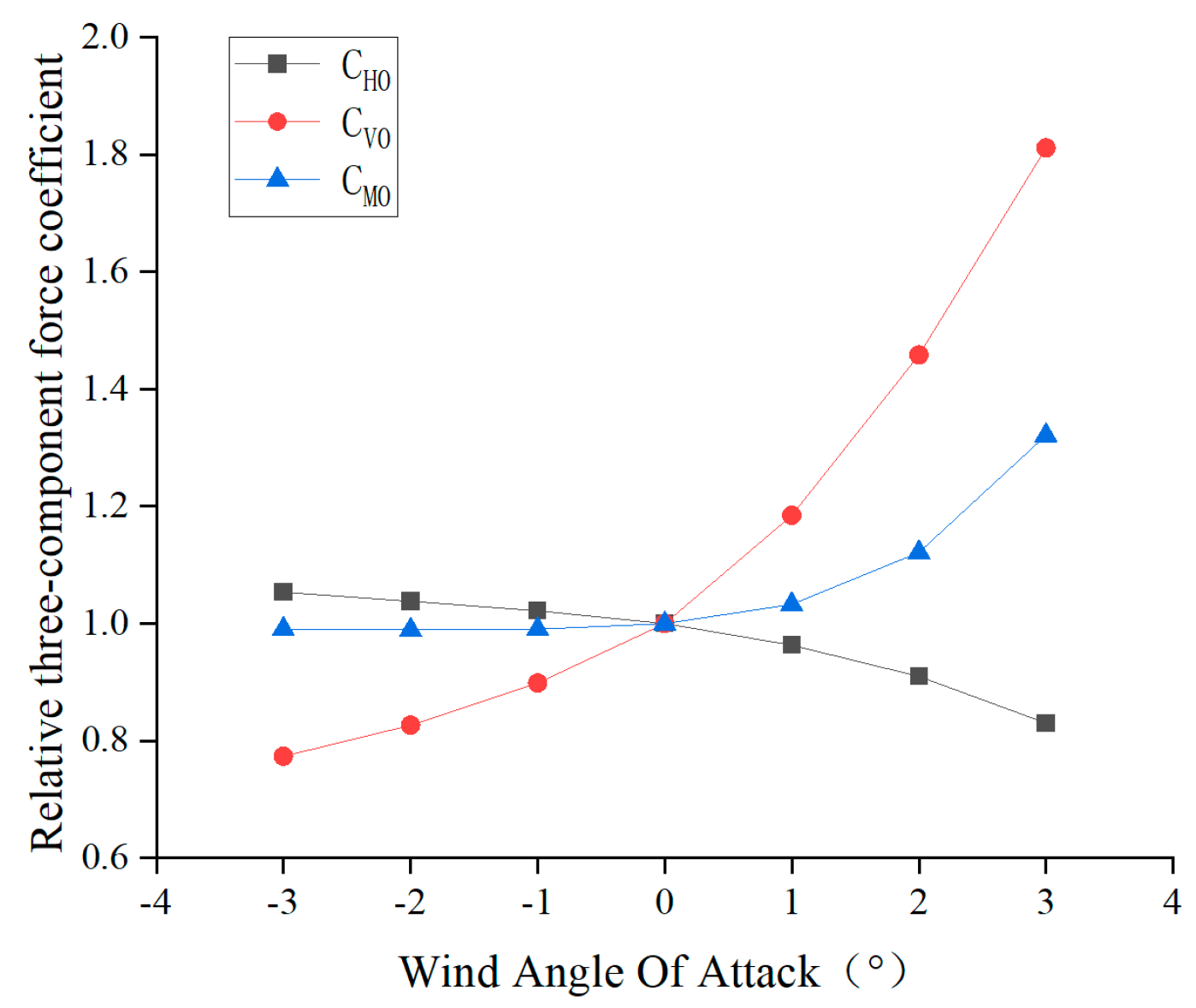

3.2. Model Validation

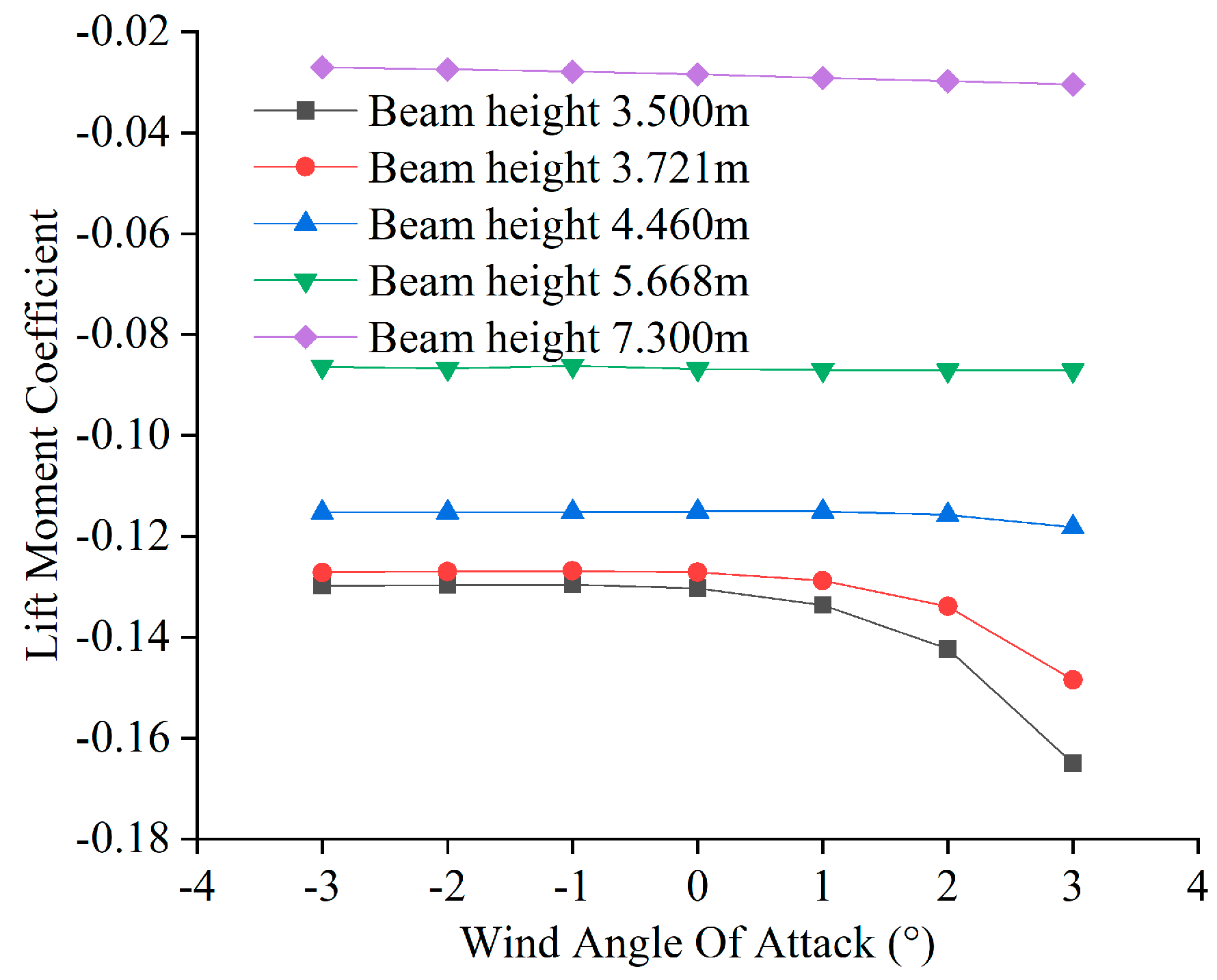

3.3. Three-Component Force Coefficient and Three-Component Force Calculation Results and Analysis

4. Fatigue Life Estimation of PC Composite Box Girder Bridge with Corrugated Steel Webs

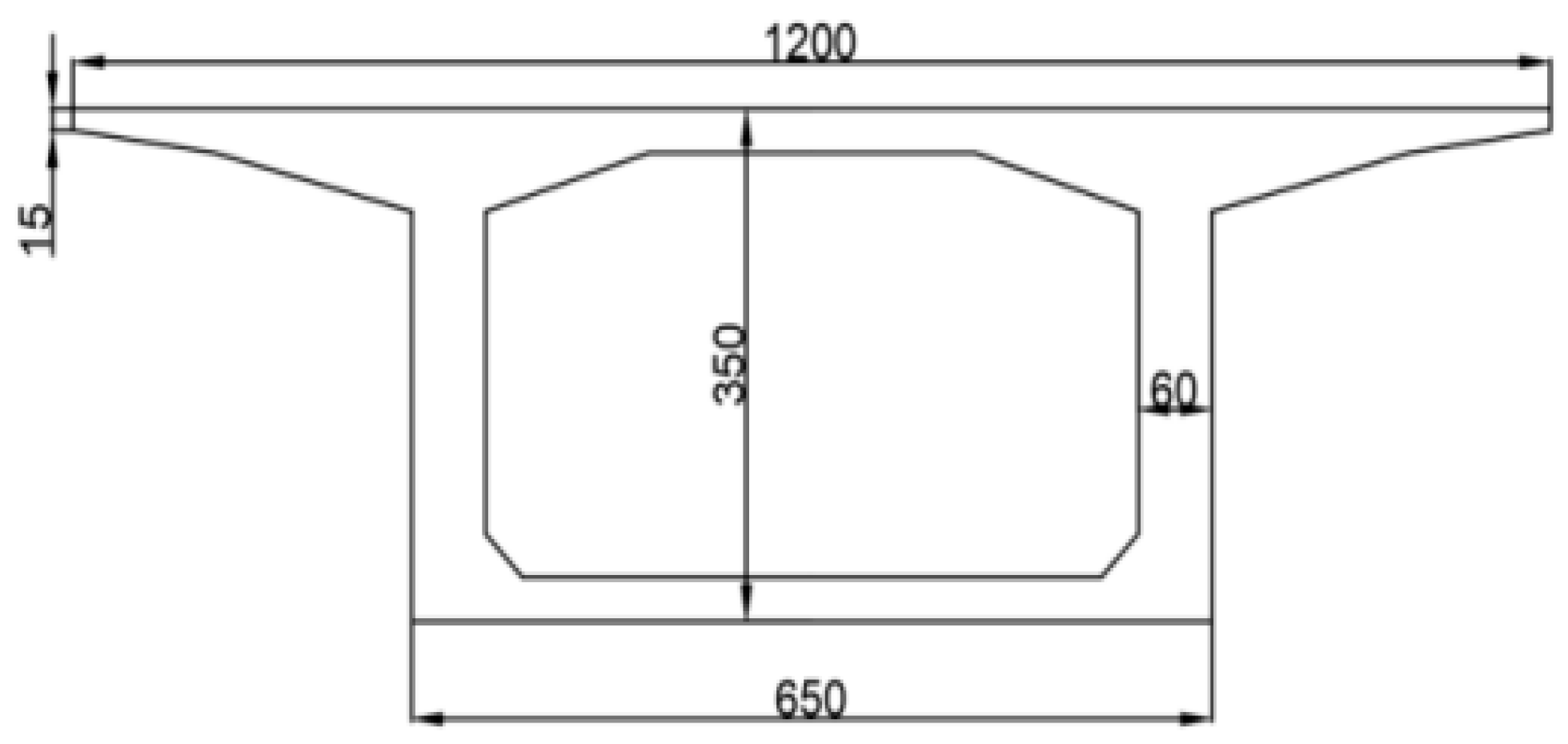

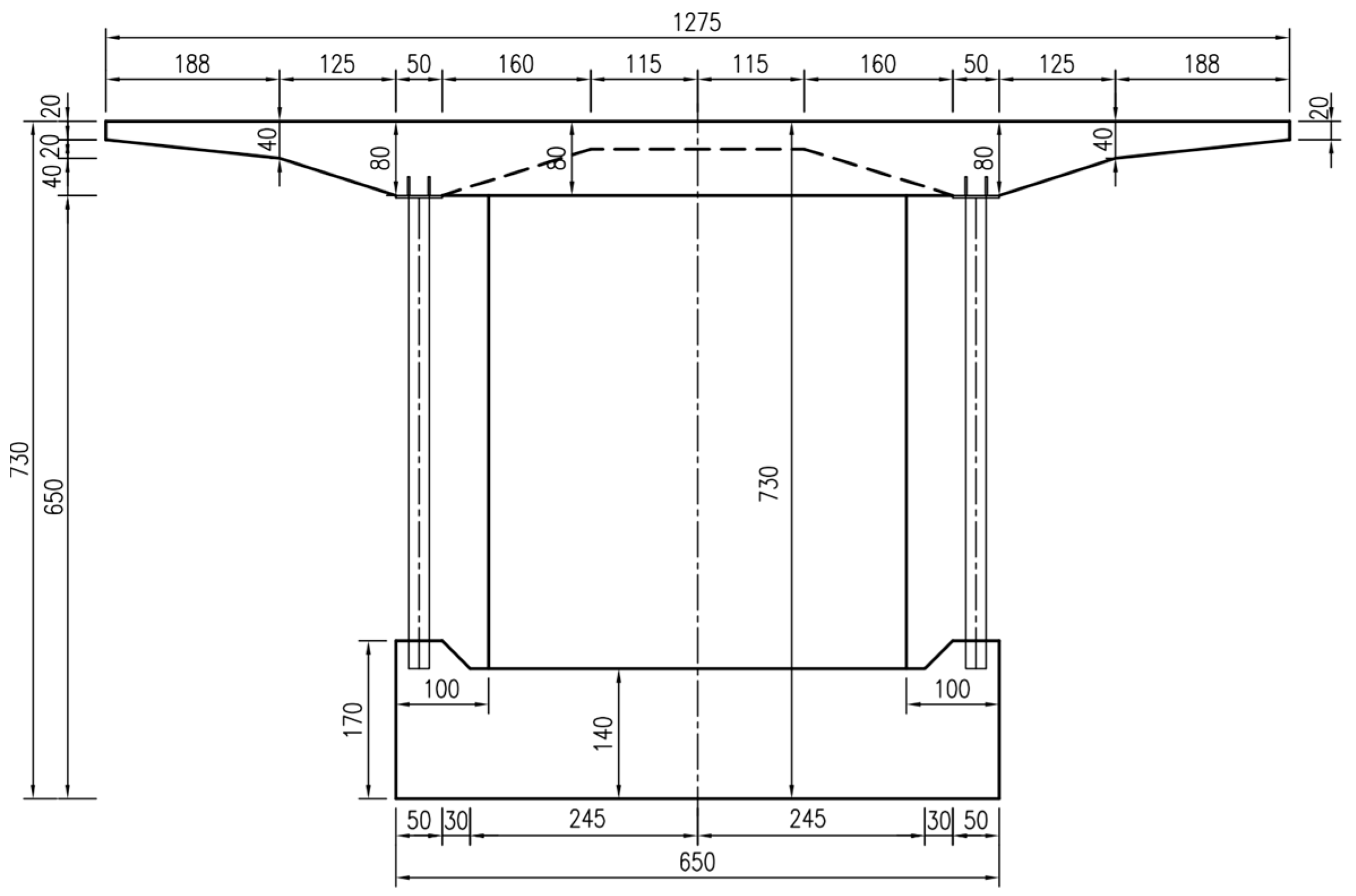

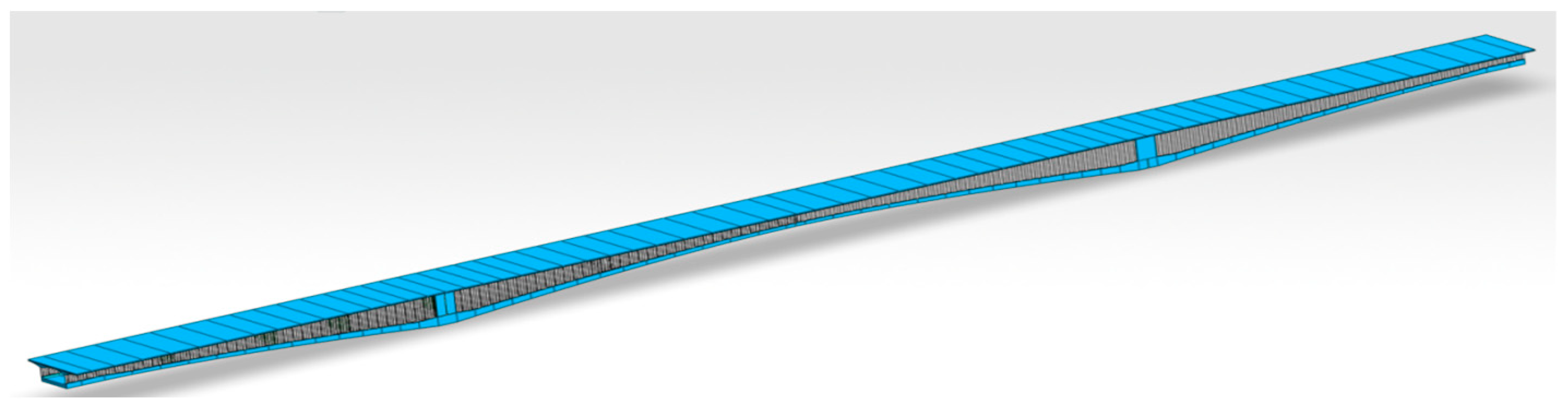

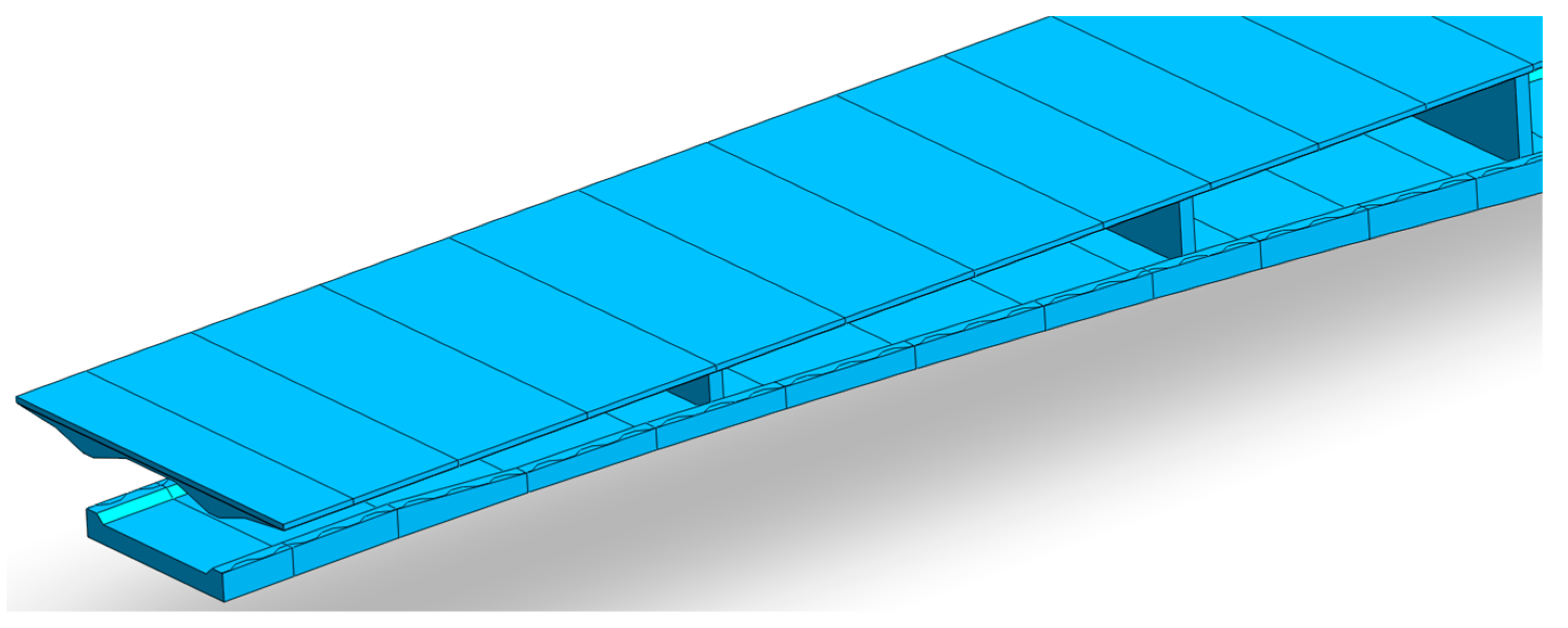

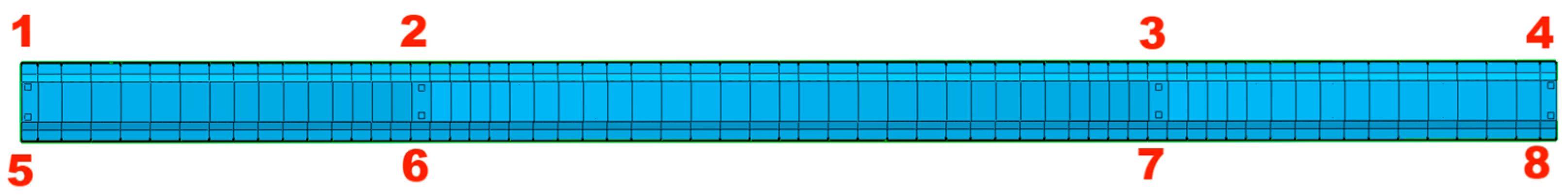

4.1. Finite Element Solid Model

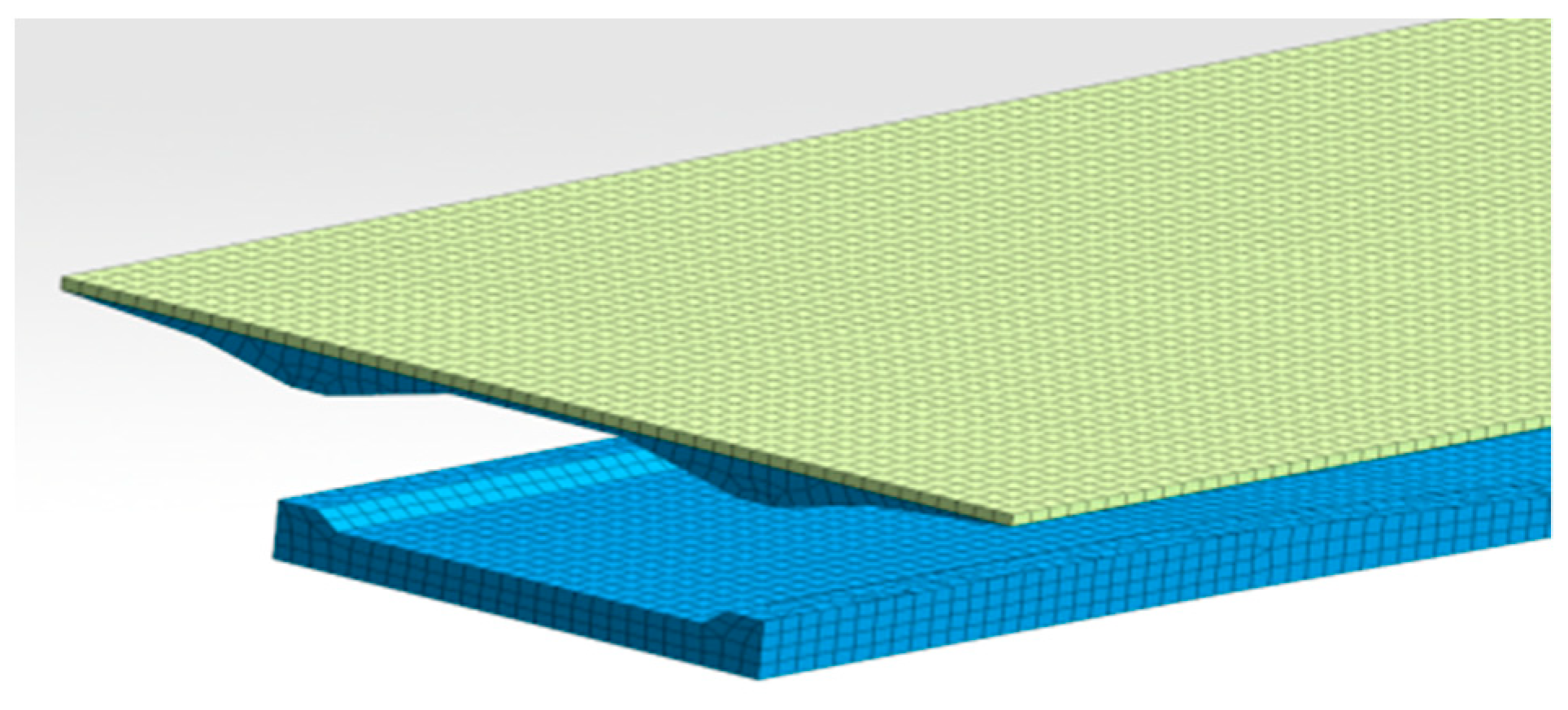

4.1.1. Concrete Roof and Floor Model

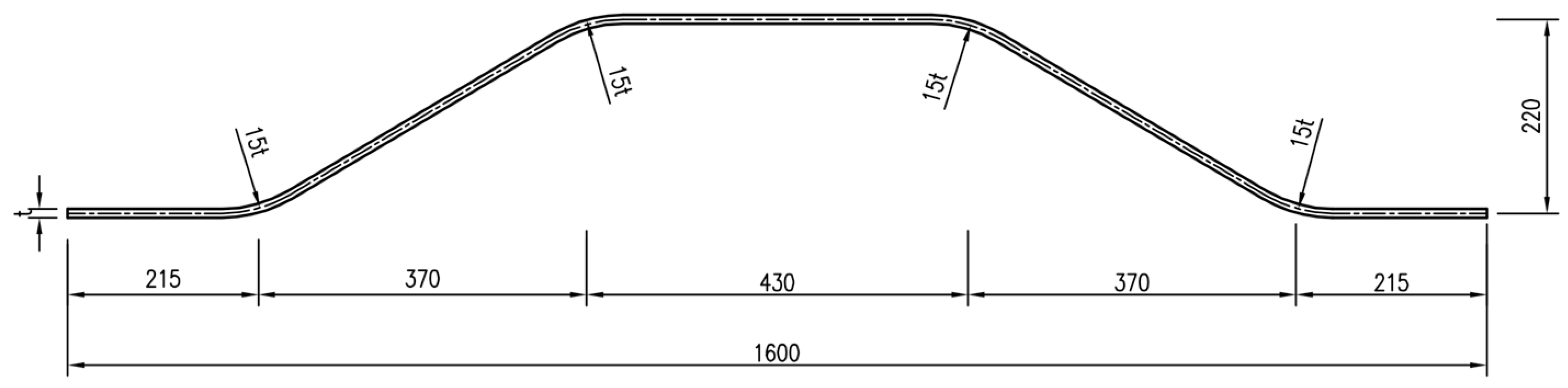

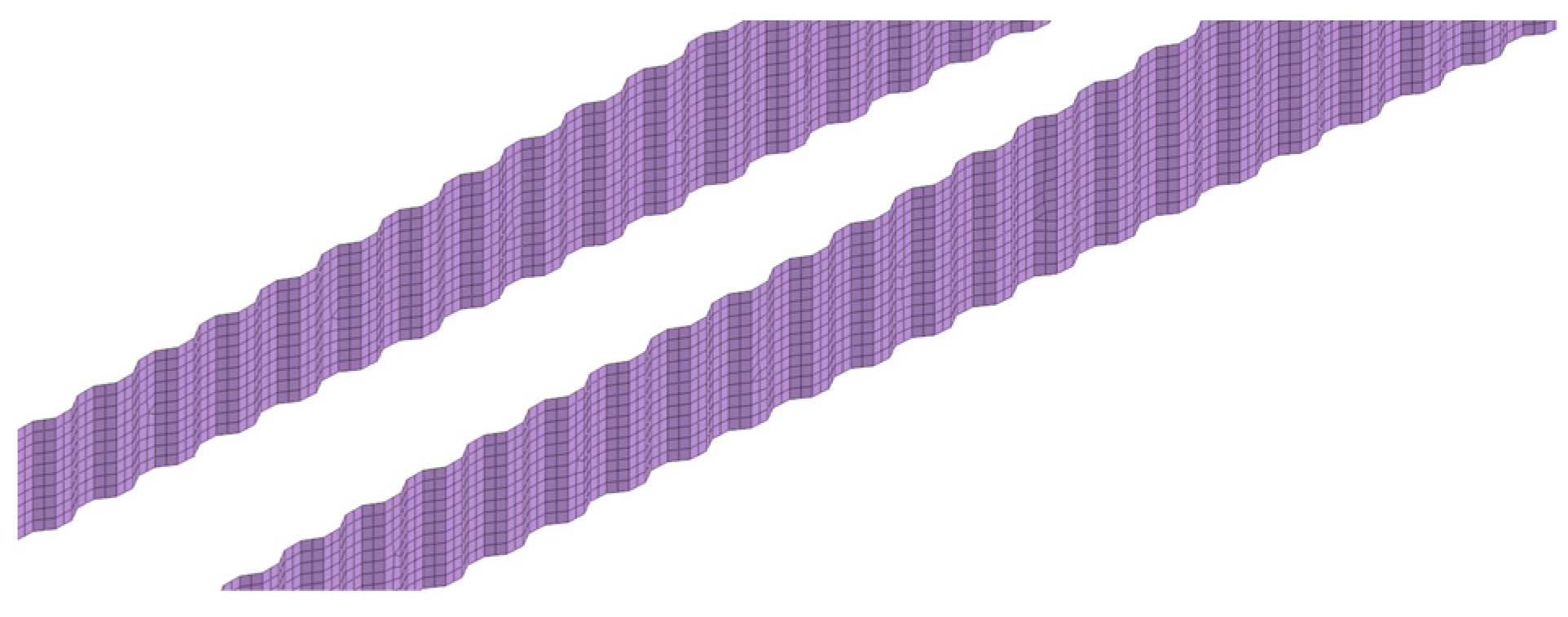

4.1.2. Simulation of Corrugated Steel Web Model

4.1.3. Simulation of Diaphragms

4.1.4. Simulation of Prestressed Steel Bundle

4.1.5. Material Property

4.1.6. Boundary Condition

4.1.7. Load Action Value

- Structural deadweight: automatically taken into account by the program;

- Phase II pavement: 0.1 m thick asphalt concrete × 24 kN/m3 = 2.4 kN/m2; 0.08 m thick reinforced concrete × 26 kN/m3 = 2.08 kN/m2

- Guardrails: 1.1 m × 26 kN/m3 = 28.6 kN/m2;

- Internal tension control stress: 1395 MPa; external tension control stress: 1116 MPa;

- Overall temperature rise: this study considers the overall temperature rise is considered to be 39 °C.

- Temperature gradient: using the values in the General Specification for Design of Highway Bridge and Culverts (JTGD60-2015), consider the thickness of the paving layer is 10 cm asphalt concrete, in which the vertical sunshine positive temperature difference T1 = 14 °C, T2 = 5.5 °C.

- Wind load: take the value of wind load in the most unfavorable wind direction (NNE) and at the most unfavorable wind angle of attack (3°).

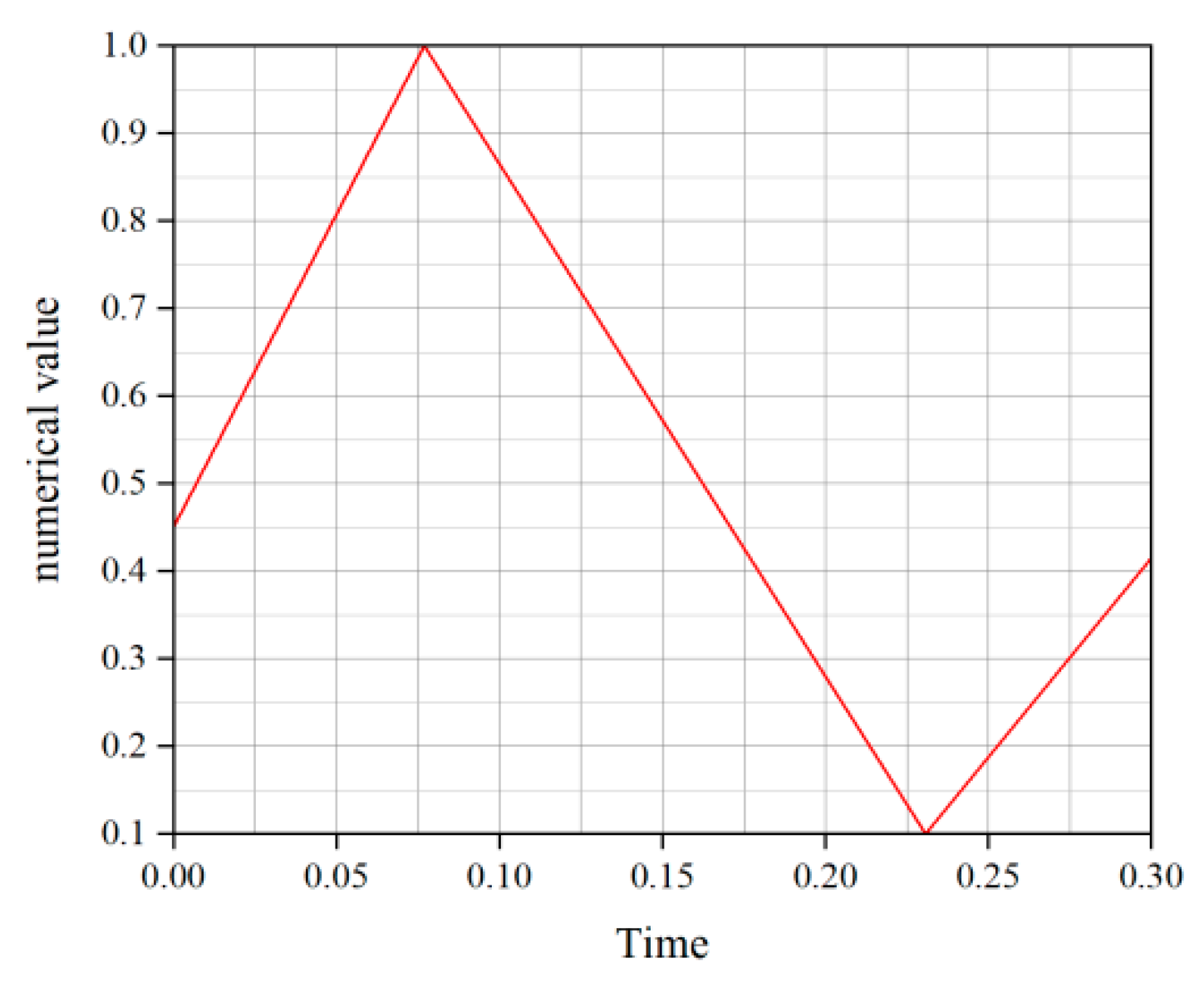

- Vehicle load: according to the fatigue load model I of “Specifications for Design of Highway Steel Bridge” (JTGD64-2015) [28], the moving load condition is added. The longitudinal reduction factor is 0.97, the structural fundamental frequency is 1.04 Hz, and the impact coefficient μ is 0.05.

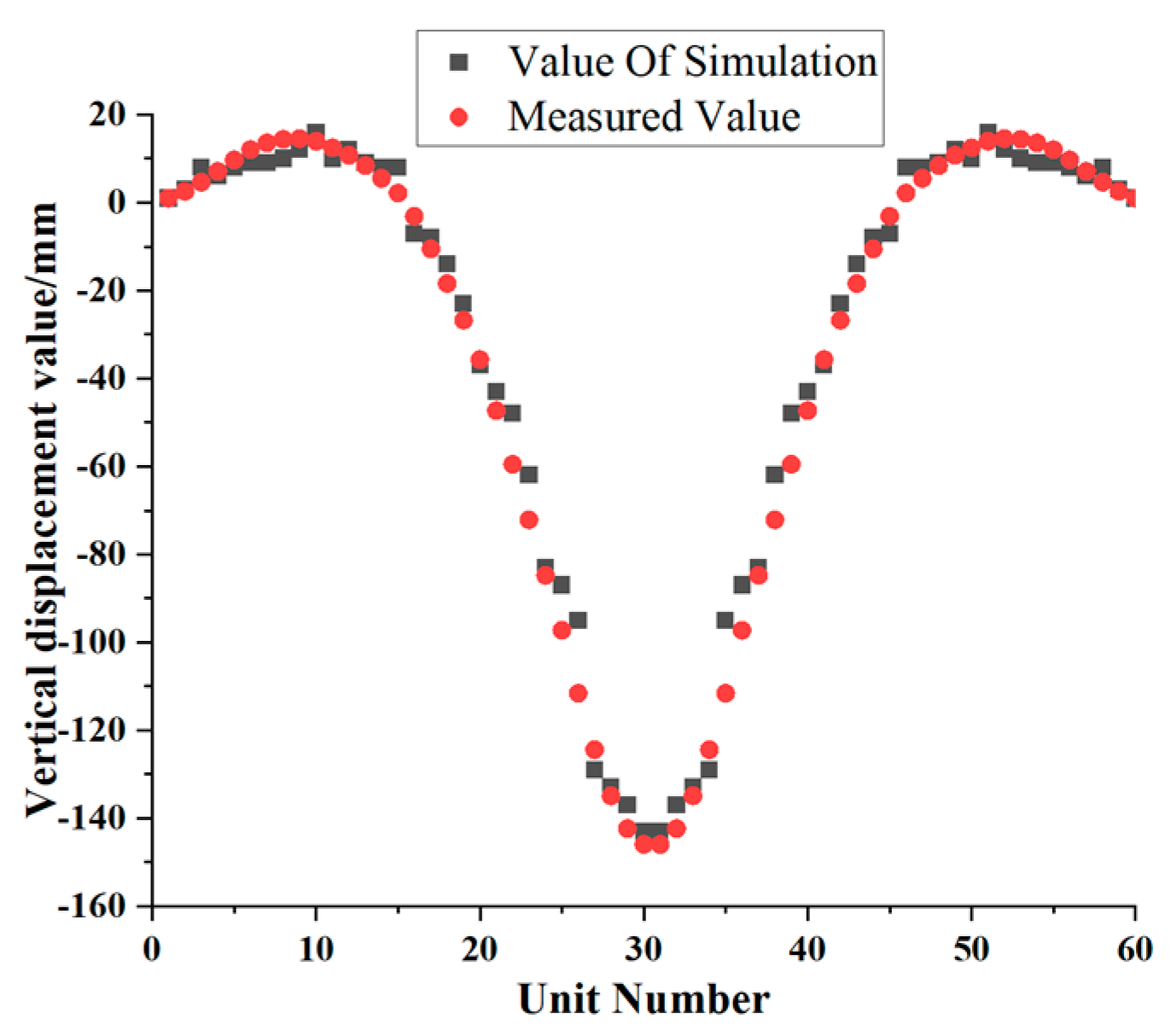

4.1.8. Comparison of Detected and Simulated Values

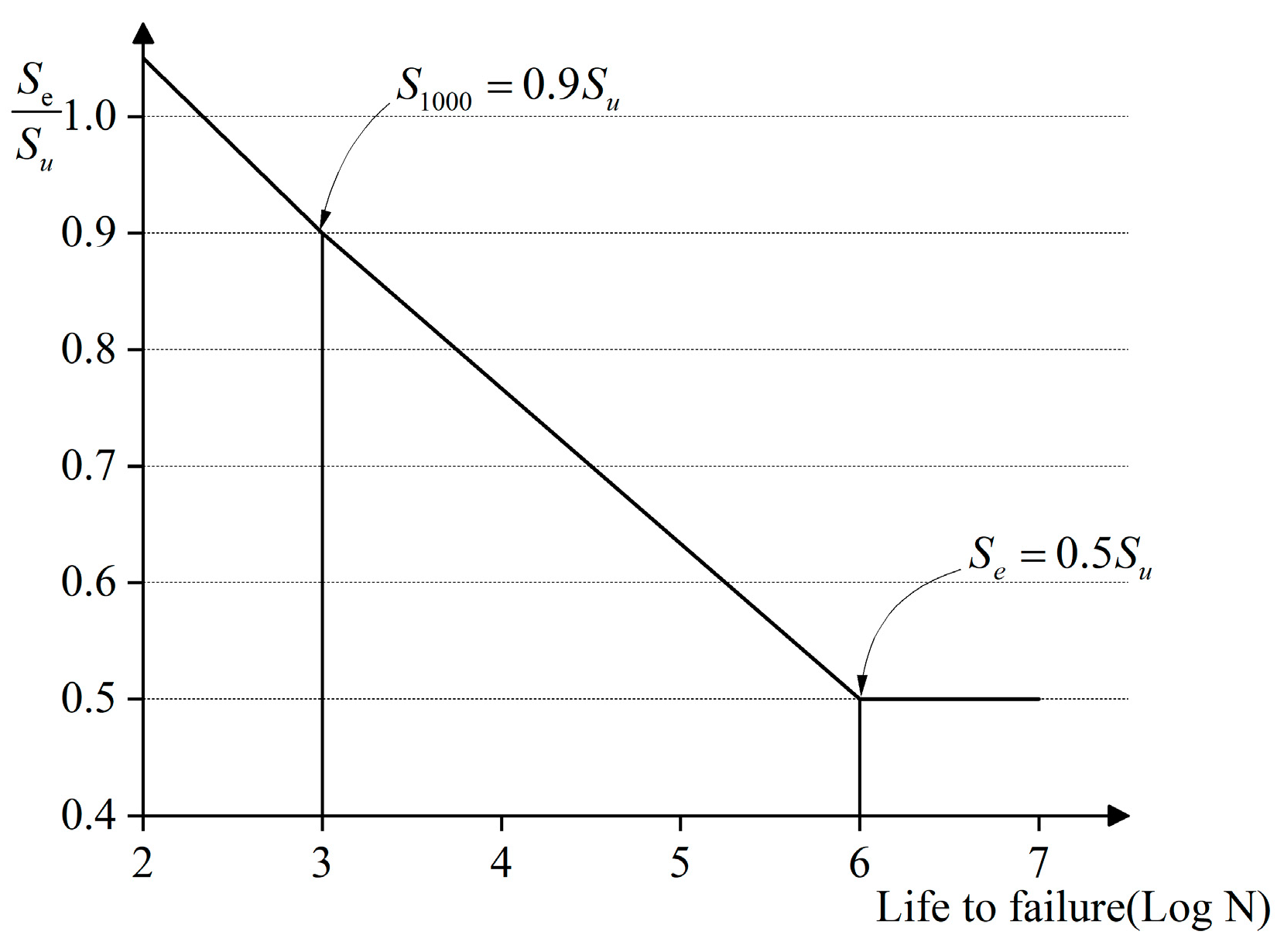

4.2. Fatigue Life Estimation

4.2.1. Lane Loading

4.2.2. Fatigue Simulation Analysis Principle of MIDAS/FEA

4.2.3. Fatigue Calculation Analysis

5. Conclusions

- The temperature difference of PC composite box girder bridge with corrugated steel webs obeys the Weibull distribution of W(15.287, 3.981). The temperature difference of PC composite box girder bridge with corrugated steel webs is 22.33 °C, the average temperature is 17.46 °C, and the extreme maximum temperature is 39 °C. The temperature difference of PC composite box girder bridge with corrugated steel webs obeys the Weibull distribution of W(15.287, 3.981), and the temperature difference of PC composite box girder bridge with corrugated steel webs obeys the Weibull distribution of W(15.287,3.981).

- According to the measured data of wind speed and direction in the area, the statistical method of joint probability distribution of wind speed and direction is adopted, and the extreme value distribution of wind speed at the bridge site is closer to Gumbel distribution; secondly, the harmonic function of Gumbel distribution parameters is fitted to the curve, and the distribution parameters under any wind direction are obtained. Then, the basic wind speed (30.69 m/s) is designed according to the 100-year return period of the most unfavorable wind direction, and it is brought into FLUENT 2022 R1 software. Finally, the most unfavorable wind load direction is NNE, and the most unfavorable wind angle of attack is 3°.

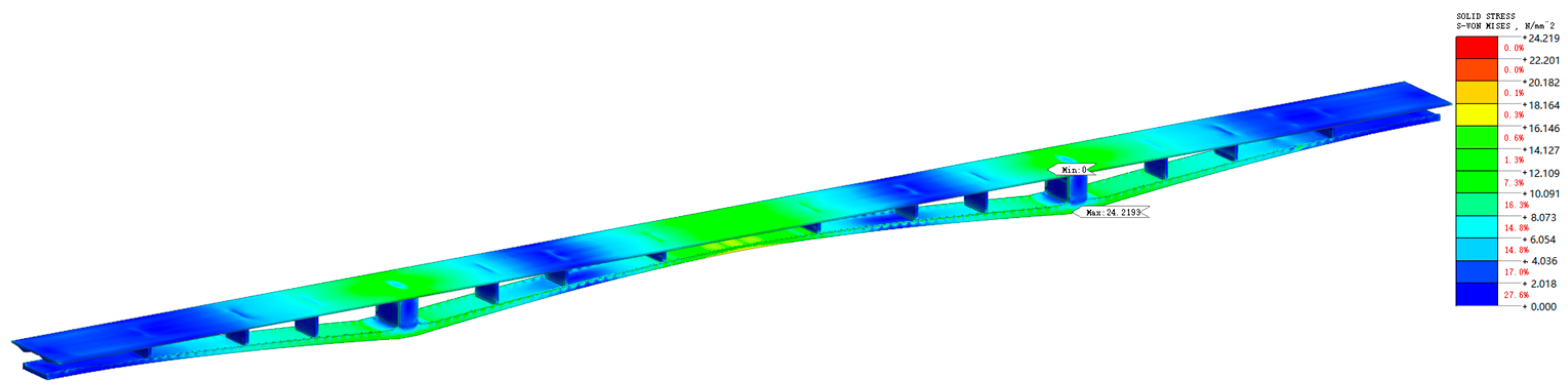

- The MIDAS/FEA NX 2022 finite element model was developed, and it was found that the maximum stresses in both the concrete and the corrugated steel web occurred near block 0#. Estimating the fatigue life of PC composite box girder bridge with corrugated steel webs under the combined effect of temperature and static wind, the fatigue life of the stress concentration location with larger stress amplitude was obtained to be 705,882 times, with a damage level of 1.41 × 10−4%. It can also be seen that the fatigue life of concrete is much smaller than that of the corrugated steel web.

- In summary, fatigue life and the extent of damage when loaded within the allowable stress range need to be analyzed in detail to avoid sudden fatigue damage at locations of stress concentrations and locations subjected to continuous repetitive loading.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Liu, S.Z.; Li, Z.Q.; Huang, J.J.; Ding, W.P. Temperature effect of combined deck slab wave web steel box simply supported combination girder. Eng. Sci. Technol. 2022, 54, 133–140. (In Chinese) [Google Scholar]

- Liu, X.J. Fatigue Performance Analysis of Steel-Mixed Structures with Shear Bond under Different Fatigue Loads. Master’s Thesis, Changsha University of Science and Technology, Changsha, China, 2021. (In Chinese). [Google Scholar]

- Zheng, G. Study on Fatigue Reliability of Tension Cables of Large-Span Cable-Stayed Bridges under the Combined Effect of Random Traffic and Wind Loads. Master’s Thesis, Changsha University of Science and Technology, Changsha, China, 2019. (In Chinese). [Google Scholar]

- Ye, X.W.; Su, Y.H.; Han, J.P. A state-of-the-art review on fatigue life assessment of steel bridges. Math. Probl. Eng. 2014, 2014, 956473. [Google Scholar] [CrossRef]

- Caglayan, B.O.; Ozakgul, K.; Tezer, O. Fatigue life evaluation of a through-girder steel railway bridge. Eng. Fail. Anal. 2009, 16, 765–774. [Google Scholar] [CrossRef]

- HParodi-Figueroa, C.; D’Ayala, D.; Sebastian, W. Fatigue assessment of historic retrofitted through-truss riveted railway bridge. Eng. Struct. 2024, 307, 117812. [Google Scholar] [CrossRef]

- Jiang, H.B.; Chen, Y.H.; Liu, B.; Feng, W.X.; Zhou, C.X. Research on static characteristics of large span wave form steel web PC combined continuous box girder bridge. Guangdong Build. Mater. 2018, 34, 56–58. (In Chinese) [Google Scholar]

- Ibrahim, S.A.; El-Dakhakhni, W.W.; Elgaaly, M. Behavior of Bridge Girders with Corrugated Webs under Monotonic and Cyclic Loading. Eng. Struct. 2006, 28, 1941–1955. [Google Scholar] [CrossRef]

- Kövesdi, B.; Dunai, L. Fatigue Life of Girders with Trapezoidally Corrugated Webs: An Experimental Study. Int. J. Fatigue 2014, 64, 22–32. [Google Scholar] [CrossRef]

- Kövesdi, B.; Jáger, B.; Dunai, L. Bending and Shear Interaction Behavior of Girders with Trapezoidally Corrugated Web. J. Constr. Steel Res. 2016, 121, 383–397. [Google Scholar] [CrossRef]

- Xu, X.F.; Zhang, F.; Liu, J.Q. Temperature distribution of corrugated steel web box girder. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 2018, 37, 1–10. (In Chinese) [Google Scholar]

- Yao, C. Research on Temperature Effect of PC Composite Box Girder with Corrugated Steel Web under Extreme Temperature. Master’s Thesis, Shandong University, Jinan, China, 2017. (In Chinese). [Google Scholar]

- Ning, Z. Study on Temperature Gradient Mode and Its Effect on Corrugated Steel Web Combined Box Girder Bridge. Master’s Thesis, Changsha University of Science and Technology, Changsha, China, 2021. (In Chinese). [Google Scholar]

- Wang, H.; Xu, Z.D.; Tao, T.Y.; Yao, C.Y.; Li, A.Q. Analysis of joint distribution of wind speed and direction at Sutong Bridge based on measured data from 2008–2015. J. Southeast Univ. (Nat. Sci. Ed.) 2016, 46, 836–841. (In Chinese) [Google Scholar]

- Li, W.R.; Zhang, G.L.; Li, L.; Du, Y.F. Analysis of joint probability distribution of wind speed and direction in wind farms in Northwest China based on long-term measured data. J. Lanzhou Univ. Technol. 2022, 48, 115–124. (In Chinese) [Google Scholar]

- Lucas, J.M.; Virlogeux, M.; Louis, C. Temperature in the box girder of the normandy bridge. Struct. Eng. Int. 2005, 15, 156–165. [Google Scholar] [CrossRef]

- JTGD60-2015; General Code for Design of highway Bridges and Culverts. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- Dargahi-Noubary, G.R. New method for prediction of extreme wind speeds. J. Eng. Mech. 1989, 115, 859–866. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, X.D. Study on joint distribution function of wind speed and Wind direction under population sample. In Proceedings of the 13th National Structural Wind Engineering Conference, Dalian, China, 1 October 2007. [Google Scholar]

- Zhang, C.T.; Li, Z.L.; Fan, W.L.; Wang, Z.S. Study on wind vibration fatigue of transmission tower line system considering the joint distribution of wind direction and wind speed. Eng. Mech. 2013, 30, 315–322. (In Chinese) [Google Scholar]

- Zhang, Y.J. Fatigue Reliability Analysis of Large-Span Cable-Stayed Bridges Considering the Combined Effect of Wind and Traffic Vehicles. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2021. (In Chinese). [Google Scholar]

- Wang, Q.H.; Zhang, L.L. Statistical analysis of basic wind speed in Foshan area considering the influence of wind direction. Guangdong Civ. Eng. Constr. 2011, 18, 22–24. (In Chinese) [Google Scholar]

- National Standard GB/T 35227-2017; Specification for Surface Meteorological Observation. Standardization Administration of China: Beijing, China, 2017.

- Yao, L.L.; Liu, Q. Wind load analysis of girder bridge based on joint distribution theory of wind speed and direction. Sichuan Build. Mater. 2022, 48, 161–163. [Google Scholar]

- Simiu, E.; Scanlon, R.H. Wind Effects on Structures—An Introduction to Wind Engineering, 3rd ed.; The Macmillan Company: New York, NY, USA, 1996. [Google Scholar]

- Chen, A.; He, X.; Xiang, H. Identification of 18 flutter derivatives of bridge decks. J. Wind Eng. Ind. Aerodyn. 2002, 90, 2007–2022. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Z.Q.; Zhang, Z.T. CFD numerical simulation of static wind force co-efficient of box girder section. Vib. Shock 2010, 29, 133–137+242. [Google Scholar]

- JTGD64-2015; Code for Design of Highway Steel Bridges. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- Zhou, J. Fatigue Test and Research on Improved Embedded Shear Key of PC Composite Box Girder with Corrugated Steel Web. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2015. (In Chinese). [Google Scholar]

| Wind Direction | Wind Frequency | Gumbel Distribution | Frechet Distribution | Weibull Distribution | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | r | A | C | r | A | C | r | ||

| N | 2.00% | 0.929 | 5.842 | 0.856 | 5.875 | 6.131 | 0.886 | 6.551 | 5.255 | 0.716 |

| NNE | 8.00% | 2.982 | 6.893 | 0.786 | 7.045 | 2.243 | 0.786 | 9.163 | 2.554 | 0.738 |

| NE | 4.75% | 1.101 | 4.895 | 0.849 | 4.968 | 4.152 | 0.834 | 5.349 | 5.846 | 0.844 |

| ENE | 4.25% | 1.129 | 5.224 | 0.920 | 5.323 | 4.528 | 0.938 | 5.850 | 4.739 | 0.859 |

| E | 2.00% | 1.158 | 5.500 | 0.846 | 5.866 | 4.211 | 0.797 | 6.304 | 4.331 | 0.859 |

| ESE | 5.00% | 0.966 | 3.679 | 0.808 | 3.742 | 3.599 | 0.869 | 4.268 | 3.877 | 0.718 |

| SE | 11.00% | 2.667 | 4.475 | 0.636 | 4.379 | 1.797 | 0.715 | 6.891 | 1.983 | 0.634 |

| SSE | 14.75% | 0.585 | 3.284 | 0.793 | 3.240 | 5.851 | 0.851 | 3.728 | 6.583 | 0.725 |

| S | 12.25% | 1.380 | 3.316 | 0.840 | 3.493 | 2.292 | 0.928 | 4.492 | 2.446 | 0.744 |

| SSW | 10.75% | 3.014 | 5.285 | 0.747 | 5.302 | 1.548 | 0.703 | 7.555 | 2.144 | 0.749 |

| SW | 12.25% | 2.827 | 5.379 | 0.711 | 5.314 | 1.881 | 0.717 | 7.610 | 2.306 | 0.713 |

| WSW | 4.50% | 1.212 | 5.942 | 0.740 | 6.035 | 4.771 | 0.726 | 6.308 | 7.286 | 0.742 |

| W | 2.25% | 1.253 | 5.821 | 0.762 | 5.956 | 4.673 | 0.739 | 6.392 | 5.562 | 0.861 |

| WNW | 1.75% | 1.158 | 4.888 | 0.896 | 4.881 | 4.039 | 0.851 | 5.706 | 5.019 | 0.946 |

| NW | 2.00% | 0.694 | 3.398 | 0.932 | 3.345 | 4.959 | 0.924 | 3.878 | 5.889 | 0.937 |

| NNW | 2.50% | 0.343 | 3.021 | 0.882 | 3.053 | 7.774 | 0.877 | 3.591 | 6.297 | 0.818 |

| ∑ | 1 | 2.398 | 5.014 | 0.980 | 5.199 | 1.962 | 0.934 | 6.796 | 2.422 | 0.948 |

| Wind Direction | f(θ) | Gumbel Distribution | ||

|---|---|---|---|---|

| 10 Years (m/s) | 50 Years (m/s) | 100 Years (m/s) | ||

| N | 2.00% | 9.82 | 11.32 | 11.97 |

| NNE | 8.00% | 23.82 | 28.62 | 30.69 |

| NE | 4.75% | 10.58 | 12.35 | 13.12 |

| ENE | 4.25% | 10.90 | 12.72 | 13.50 |

| E | 2.00% | 10.46 | 12.33 | 13.13 |

| ESE | 5.00% | 8.71 | 10.26 | 10.93 |

| SE | 11.00% | 20.46 | 24.76 | 26.60 |

| SSE | 14.75% | 6.96 | 7.91 | 8.31 |

| S | 12.25% | 11.73 | 13.95 | 14.91 |

| SSW | 10.75% | 23.30 | 28.15 | 30.24 |

| SW | 12.25% | 22.62 | 27.17 | 29.13 |

| WSW | 4.50% | 12.12 | 14.07 | 14.92 |

| W | 2.25% | 11.31 | 13.33 | 14.20 |

| WNW | 1.75% | 9.73 | 11.60 | 12.40 |

| NW | 2.00% | 6.37 | 7.49 | 7.97 |

| NNW | 2.50% | 4.57 | 5.12 | 5.36 |

| ∑ | 1 | 24.68 | 28.54 | 30.21 |

| Fifth-Order Fitting Parameters | A(θ) | B(θ) | f(θ) |

|---|---|---|---|

| c | 1.462 | 4.803 | 0.062 |

| d1 | −0.409 | −0.377 | −0.047 |

| e1 | 0.029 | −3.468 | −0.193 |

| d2 | 0.576 | 1.116 | 0.032 |

| e2 | 1.207 | 8.202 | 0.255 |

| d3 | 0.255 | 0.611 | 0.011 |

| e3 | 0.283 | 0.715 | −4.585 |

| d4 | 0.686 | 0.503 | −0.015 |

| e4 | −4.225 | 0.952 | 0.034 |

| d5 | 0.296 | 0.496 | 0.009 |

| e5 | 0.012 | 0.450 | 1.014 |

| d6 | −0.458 | −0.476 | −0.006 |

| e6 | 11.520 | 5.055 | 0.336 |

| d7 | −0.358 | 0.145 | −0.011 |

| e7 | 0.088 | −7.861 | −0.691 |

| Three-Component Force Coefficient | Experimental Result | CFD Simulated Result | Error |

|---|---|---|---|

| CH | 0.370868 | 0.384444 | 3.66% |

| CV | 0.558385 | 0.491538 | 11.9% |

| CM | −0.129795 | −0.135794 | 4.62% |

| Beam Height | Drag Force (N) | Lift Force (N) | Lift Moment (N·mm) |

|---|---|---|---|

| 3.500 m | 2037 | 5496 | −14,789 |

| 3.573 m | 2111 | 5335 | −14,178 |

| 3.721 m | 2251 | 4854 | −13,303 |

| 3.923 m | 2459 | 4181 | −12,188 |

| 4.170 m | 2662 | 3786 | −11,330 |

| 4.460 m | 2885 | 3431 | −10,587 |

| 4.725 m | 3095 | 3219 | −9947 |

| 5.017 m | 3314 | 3078 | −9306 |

| 5.332 m | 3564 | 2984 | −8559 |

| 5.668 m | 3780 | 2927 | −7806 |

| 6.026 m | 4056 | 2905 | −6868 |

| 6.326 m | 4313 | 2913 | −6032 |

| 6.638 m | 4566 | 2915 | −5069 |

| 6.963 m | 4852 | 2931 | −3968 |

| 7.300 m | 5141 | 2950 | −2730 |

| Mean Stress Correction | Cycle Index | Damage |

|---|---|---|

| None | 106 | 0 |

| Goodman | 705,882.31 | 1.41 × 10−6 |

| Gerber | 106 | 0 |

| Mean Stress Correction | Cycle Index | Damage |

|---|---|---|

| None | 106 | 0 |

| Goodman | 106 | 0 |

| Gerber | 106 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Jia, J. Study on Fatigue Life of PC Composite Box Girder Bridge with Corrugated Steel Webs under the Combined Action of Temperature and Static Wind Loads. Appl. Sci. 2024, 14, 3165. https://doi.org/10.3390/app14083165

Wang S, Jia J. Study on Fatigue Life of PC Composite Box Girder Bridge with Corrugated Steel Webs under the Combined Action of Temperature and Static Wind Loads. Applied Sciences. 2024; 14(8):3165. https://doi.org/10.3390/app14083165

Chicago/Turabian StyleWang, Siyu, and Jie Jia. 2024. "Study on Fatigue Life of PC Composite Box Girder Bridge with Corrugated Steel Webs under the Combined Action of Temperature and Static Wind Loads" Applied Sciences 14, no. 8: 3165. https://doi.org/10.3390/app14083165

APA StyleWang, S., & Jia, J. (2024). Study on Fatigue Life of PC Composite Box Girder Bridge with Corrugated Steel Webs under the Combined Action of Temperature and Static Wind Loads. Applied Sciences, 14(8), 3165. https://doi.org/10.3390/app14083165