Surface Roughness of Polyetheretherketone Printed by Fused Deposition Modeling: A Pilot Study Investigating the Impact of Print Layer Thickness and Polishing Method

Abstract

1. Introduction

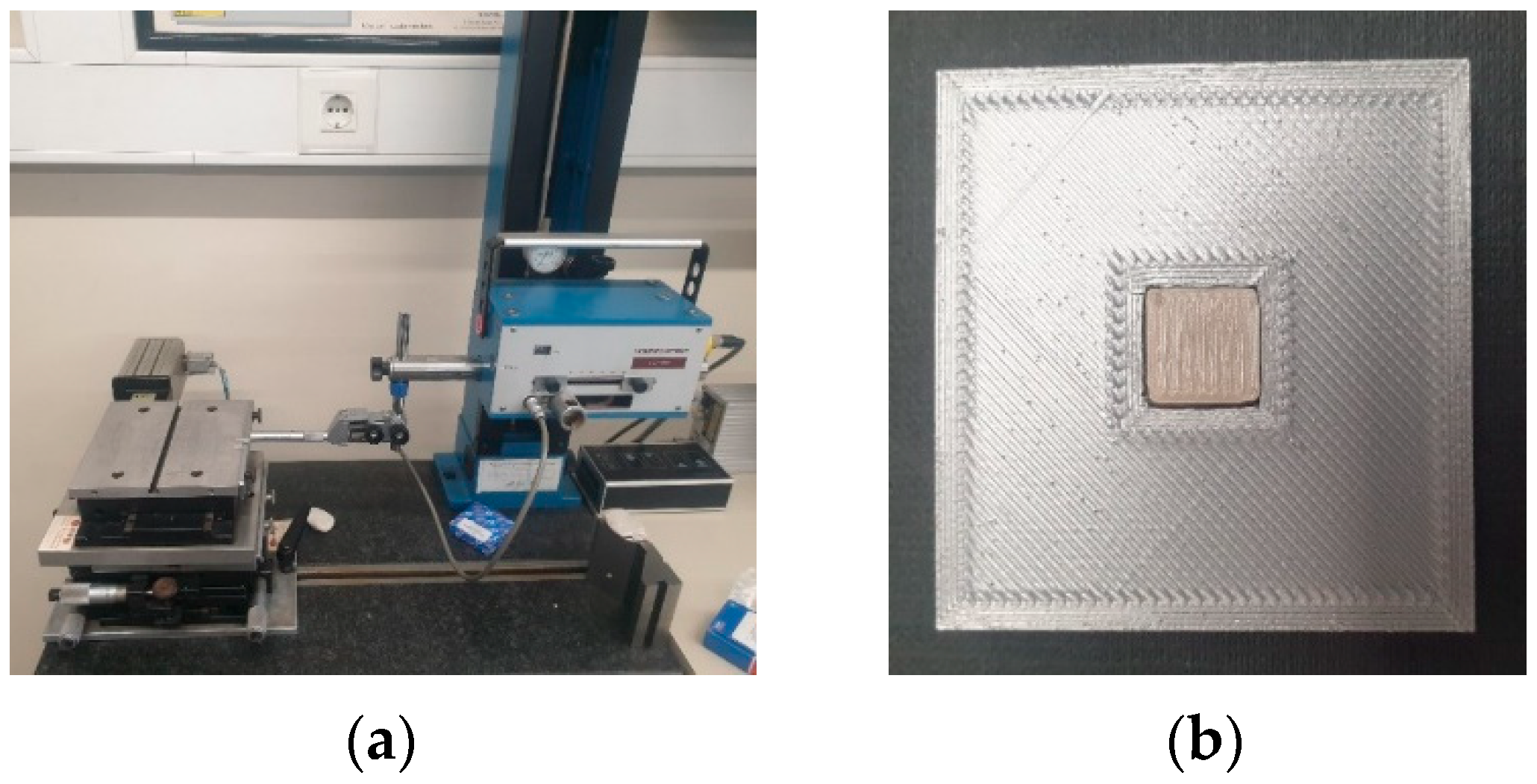

2. Materials and Methods

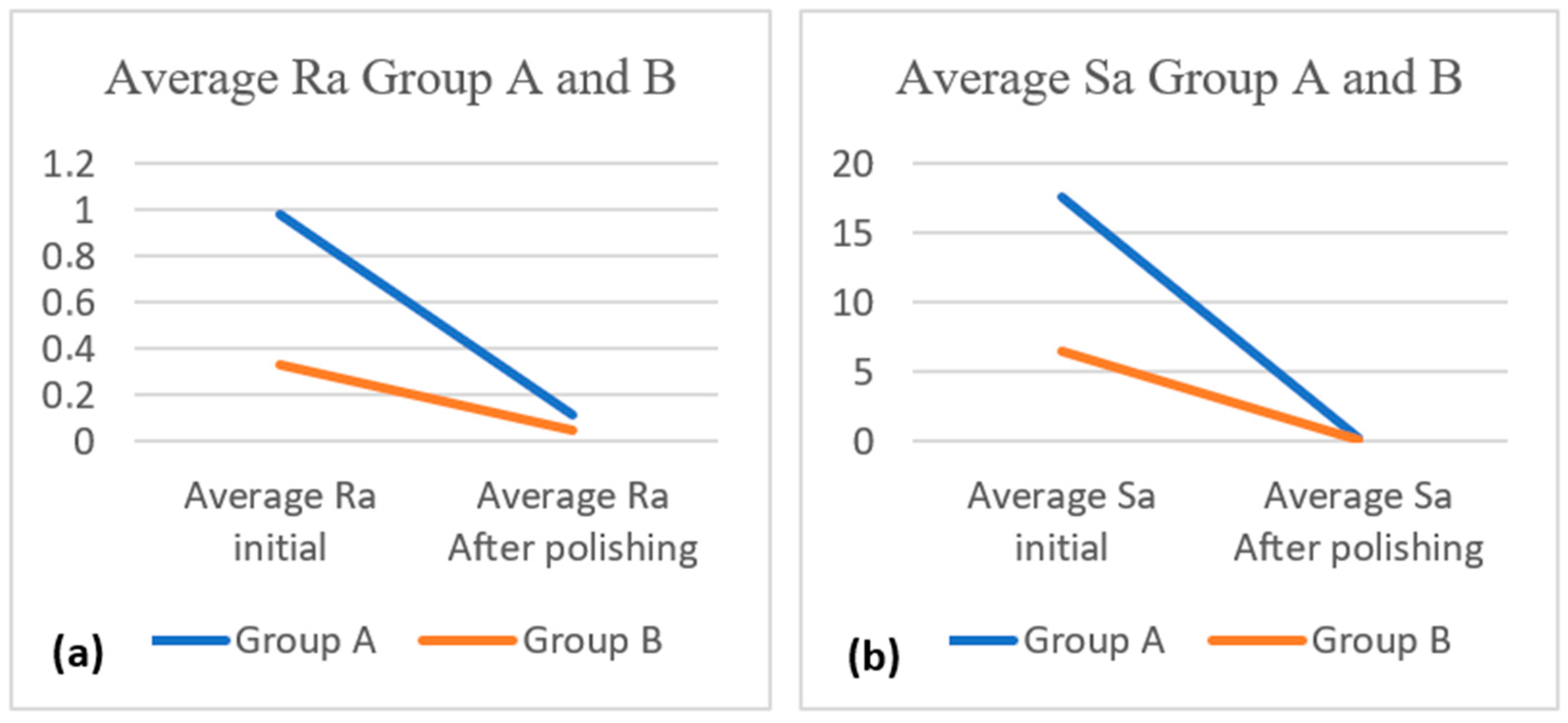

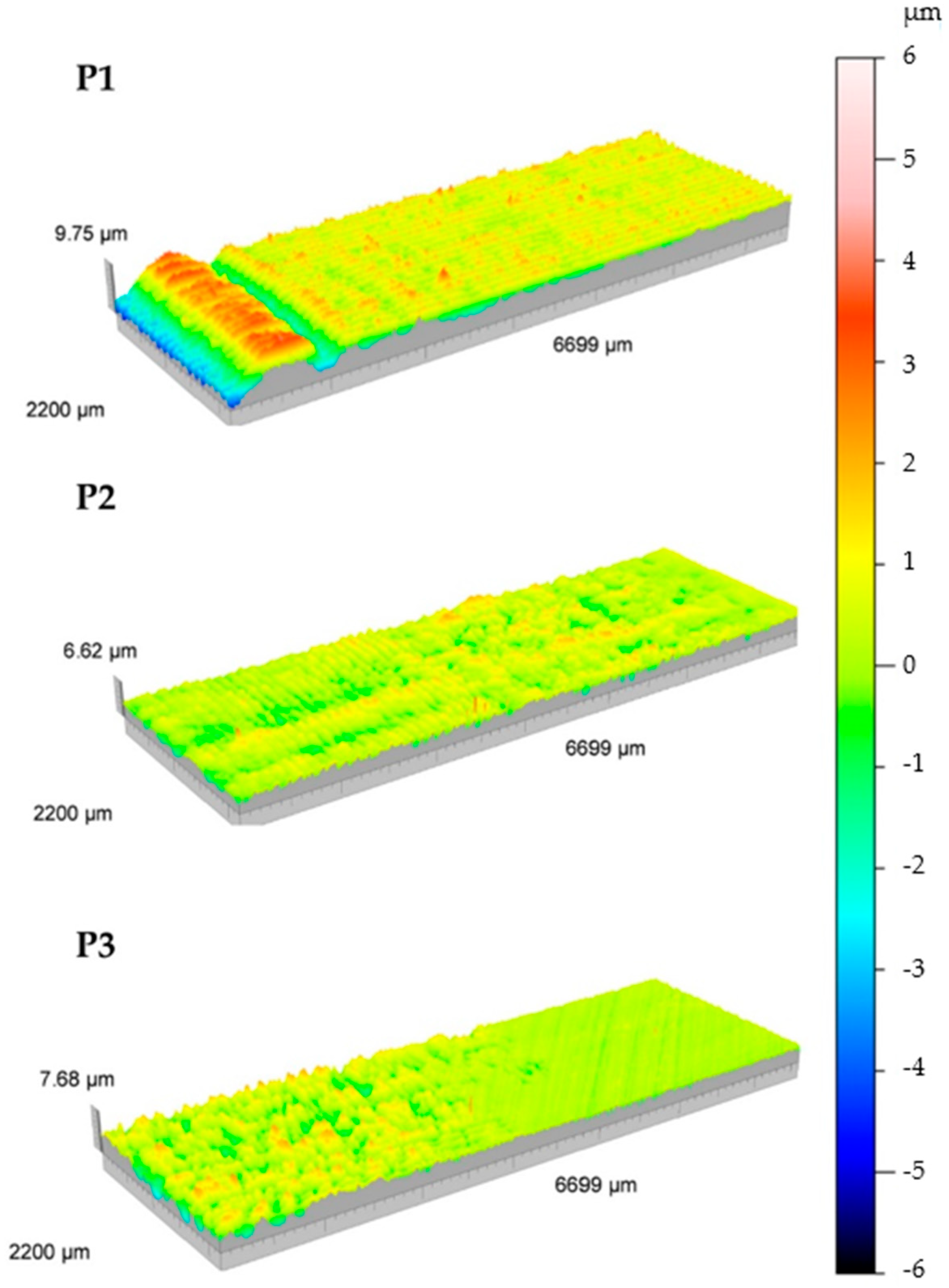

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Czyzewski, W.; Jachimczyk, J.; Hoffman, Z.; Szymoniuk, M.; Litak, J.; Maciejewski, M.; Kura, K.; Rola, R.; Torres, K. Low-Cost Cranioplasty-A Systematic Review of 3D Printing in Medicine. Materials 2022, 15, 4731. [Google Scholar] [CrossRef] [PubMed]

- Papathanasiou, I.; Kamposiora, P.; Papavasiliou, G.; Ferrari, M. The use of PEEK in digital prosthodontics: A narrative review. BMC Oral Health 2020, 20, 217. [Google Scholar] [CrossRef] [PubMed]

- Elfahl, B.N.; Mostafa, T.M.N. Polyetheretherketone custom CAD-CAM splint for treatment of periodontally affected mobile anterior teeth. J. Prosthet. Dent. 2020, 127, 210–212. [Google Scholar] [CrossRef] [PubMed]

- Skirbutis, G.; Dzingute, A.; Masiliunaite, V.; Sulcaite, G.; Zilinskas, J. A review of PEEK polymer’s properties and its use in prosthodontics. Stomatol. Balt. Dent. Maxillofac. J. 2017, 19, 19–23. [Google Scholar]

- Shrivastava, S.P.; Dable, R.; Nirmal Raj, A.P.; Mutneja, P.; Srivastava, S.B.; Haque, M. Comparison of Mechanical Properties of PEEK and PMMA: An In Vitro Study. J. Contemp. Dent. Pract. 2021, 22, 179–183. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Liu, Y.; Peng, B.; Chen, M.; Liu, Z.; Li, Z.; Kuang, H.; Gong, B.; Li, Z.; Sun, H. PEEK for Oral Applications: Recent Advances in Mechanical and Adhesive Properties. Polymers 2023, 15, 386. [Google Scholar] [CrossRef]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Schonhoff, L.M.; Mayinger, F.; Eichberger, M.; Reznikova, E.; Stawarczyk, B. 3D printing of dental restorations: Mechanical properties of thermoplastic polymer materials. J. Mech. Behav. Biomed. Mater. 2021, 119, 104544. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. Polyether ether ketone (PEEK) and its manufacturing of customised 3D printed dentistry parts using additive manufacturing. Clin. Epidemiol. Glob. Health 2019, 7, 654–660. [Google Scholar] [CrossRef]

- Li, H.; Xiao, X.; Liao, W.; Liu, T.; Li, G. Numerical Simulation and Experimental Study Regarding the Cross-Sectional Morphology of PEEK Monofilament Deposition During FDM-Based 3D Printing. Langmuir 2023, 39, 13287–13295. [Google Scholar] [CrossRef]

- Wang, Y.; Muller, W.D.; Rumjahn, A.; Schwitalla, A. Parameters Influencing the Outcome of Additive Manufacturing of Tiny Medical Devices Based on PEEK. Materials 2020, 13, 466. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Li, Z.; Ye, H.; Zhao, W.; Liu, Y.; Zhou, Y. Preliminary clinical evaluation of traditional and a new digital PEEK occlusal splints for the management of sleep bruxism. J. Oral. Rehabil. 2020, 47, 1530–1537. [Google Scholar] [CrossRef]

- Bathala, L.; Majeti, V.; Rachuri, N.; Singh, N.; Gedela, S. The Role of Polyether Ether Ketone (Peek) in Dentistry—A Review. J. Med. Life 2019, 12, 5–9. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wang, F.; Sun, F.; Zhang, L.; Wu, G. Digital fabrication of an adult speech aid prosthesis by using a 3-dimensionally printed polyetheretherketone framework. J. Prosthet. Dent. 2022, 127, 358–361. [Google Scholar] [CrossRef] [PubMed]

- Moby, V.; Dupagne, L.; Fouquet, V.; Attal, J.P.; Francois, P.; Dursun, E. Mechanical Properties of Fused Deposition Modeling of Polyetheretherketone (PEEK) and Interest for Dental Restorations: A Systematic Review. Materials 2022, 15, 6801. [Google Scholar] [CrossRef] [PubMed]

- Kessler, A.; Hickel, R.; Reymus, M. 3D Printing in Dentistry-State of the Art. Oper. Dent. 2020, 45, 30–40. [Google Scholar] [CrossRef]

- Han, X.; Yang, D.; Yang, C.; Spintzyk, S.; Scheideler, L.; Li, P.; Li, D.; Geis-Gerstorfer, J.; Rupp, F. Carbon Fiber Reinforced PEEK Composites Based on 3D-Printing Technology for Orthopedic and Dental Applications. J. Clin. Med. 2019, 8, 240. [Google Scholar] [CrossRef]

- Baek, I.; Kwon, O.; Lim, C.M.; Park, K.Y.; Bae, C.J. 3D PEEK Objects Fabricated by Fused Filament Fabrication (FFF). Materials 2022, 15, 898. [Google Scholar] [CrossRef]

- Rodzeń, K.; Harkin-Jones, E.; Wegrzyn, M.; Sharma, P.K.; Zhigunov, A. Improvement of the layer-layer adhesion in FFF 3D printed PEEK/carbon fibre composites. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106532. [Google Scholar] [CrossRef]

- Gao, S.; Liu, R.; Xin, H.; Liang, H.; Wang, Y.; Jia, J. The Surface Characteristics, Microstructure and Mechanical Properties of PEEK Printed by Fused Deposition Modeling with Different Raster Angles. Polymers 2021, 14, 77. [Google Scholar] [CrossRef] [PubMed]

- Limaye, N.; Veschini, L.; Coward, T. Assessing biocompatibility & mechanical testing of 3D-printed PEEK versus milled PEEK. Heliyon 2022, 8, e12314. [Google Scholar] [CrossRef]

- Kurahashi, K.; Matsuda, T.; Ishida, Y.; Ichikawa, T. Effect of polishing protocols on the surface roughness of polyetheretherketone. J. Oral Sci. 2020, 62, 40–42. [Google Scholar] [CrossRef] [PubMed]

- Heimer, S.; Schmidlin, P.R.; Roos, M.; Stawarczyk, B. Surface properties of polyetheretherketone after different laboratory and chairside polishing protocols. J. Prosthet. Dent. 2017, 117, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Liu, X.; Liu, G. Surface Finishing of FDM-Fabricated Amorphous Polyetheretherketone and Its Carbon-Fiber-Reinforced Composite by Dry Milling. Polymers 2021, 13, 2175. [Google Scholar] [CrossRef] [PubMed]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Grymak, A.; Waddell, J.N.; Aarts, J.M.; Ma, S.; Choi, J.J.E. Evaluation of wear behaviour of various occlusal splint materials and manufacturing processes. J. Mech. Behav. Biomed. Mater. 2022, 126, 105053. [Google Scholar] [CrossRef]

- Perea-Lowery, L.; Vallittu, P.K. Resin adjustment of three-dimensional printed thermoset occlusal splints: Bonding properties—Short communication. J. Mech. Behav. Biomed. Mater. 2019, 95, 215–219. [Google Scholar] [CrossRef] [PubMed]

- Gibreel, M.; Perea-Lowery, L.; Vallittu, P.K.; Lassila, L. Characterization of occlusal splint materials: CAD-CAM versus conventional resins. J. Mech. Behav. Biomed. Mater. 2021, 124, 104813. [Google Scholar] [CrossRef]

- Quezada, M.M.; Salgado, H.; Correia, A.; Fernandes, C.; Fonseca, P. Investigation of the Effect of the Same Polishing Protocol on the Surface Roughness of Denture Base Acrylic Resins. Biomedicines 2022, 10, 1971. [Google Scholar] [CrossRef]

- Tasin, S.; Ismatullaev, A.; Usumez, A. Comparison of surface roughness and color stainability of 3-dimensionally printed interim prosthodontic material with conventionally fabricated and CAD-CAM milled materials. J. Prosthet. Dent. 2022, 128, 1094–1101. [Google Scholar] [CrossRef] [PubMed]

- Myagmar, G.; Lee, J.H.; Ahn, J.S.; Yeo, I.L.; Yoon, H.I.; Han, J.S. Wear of 3D printed and CAD/CAM milled interim resin materials after chewing simulation. J. Adv. Prosthodont. 2021, 13, 144–151. [Google Scholar] [CrossRef] [PubMed]

- FILAMENT2PRINT. Available online: https://filament2print.com/pt/avancados/1794-peek-ketaspire.html (accessed on 7 February 2024).

- Ozdogan, A.; Tosun, B. Effects of Different Polishing Procedures on the Surface Roughness and Hardness of Polyether Ether Ketone (PEEK). Odovtos—Int. J. Dent. Sci. 2020, 23, 219–227. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Beuer, F.; Wimmer, T.; Jahn, D.; Sener, B.; Roos, M.; Schmidlin, P.R. Polyetheretherketone-a suitable material for fixed dental prostheses? J. Biomed. Mater. Res. B Appl. Biomater. 2013, 101, 1209–1216. [Google Scholar] [CrossRef]

- Culhaoglu, A.K.; Ozkir, S.E.; Sahin, V.; Yilmaz, B.; Kilicarslan, M.A. Effect of Various Treatment Modalities on Surface Characteristics and Shear Bond Strengths of Polyetheretherketone-Based Core Materials. J. Prosthodont. 2020, 29, 136–141. [Google Scholar] [CrossRef] [PubMed]

- Prechtel, A.; Stawarczyk, B.; Hickel, R.; Edelhoff, D.; Reymus, M. Fracture load of 3D printed PEEK inlays compared with milled ones, direct resin composite fillings, and sound teeth. Clin. Oral Investig. 2020, 24, 3457–3466. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Zou, B.; Xiao, H.; Ding, S.; Huang, C. Effects of printing parameters of fused deposition modeling on mechanical properties, surface quality, and microstructure of PEEK. J. Mater. Process. Technol. 2019, 271, 62–74. [Google Scholar] [CrossRef]

- Erdağ, Ü.H.; Şahin, O.; Köroğlu, A.; Özdemir, T.; Dede, D.Ö. Performance of polyether ether ketone (peek) for dental applications: Surface roughness and color stability. Polym. Bull. 2022, 80, 6819–6834. [Google Scholar] [CrossRef]

- Koroglu, A.; Sahin, O.; Dede, D.O.; Yilmaz, B. Effect of different surface treatment methods on the surface roughness and color stability of interim prosthodontic materials. J. Prosthet. Dent. 2016, 115, 447–455. [Google Scholar] [CrossRef]

- Bollen, C.M.; Papaioanno, W.; Van Eldere, J.; Schepers, E.; Quirynen, M.; van Steenberghe, D. The influence of abutment surface roughness on plaque accumulation and peri-implant mucositis. Clin. Oral Implant. Res. 1996, 7, 201–211. [Google Scholar] [CrossRef]

- Alp, G.; Johnston, W.M.; Yilmaz, B. Optical properties and surface roughness of prepolymerized poly(methyl methacrylate) denture base materials. J. Prosthet. Dent. 2019, 121, 347–352. [Google Scholar] [CrossRef] [PubMed]

- Kaplan, B.; Goldstein, G.; Vijayaraghavan, T.; Nelson, I. The effect of three polishing systems on the surface roughness of four hybrid composites: A profilometric and scanning electron microscopy study. J. Prosthet. Dent. 1996, 76, 34–38. [Google Scholar] [CrossRef] [PubMed]

- Elawadly, T.; Radi, I.A.W.; El Khadem, A.; Osman, R.B. Can PEEK Be an Implant Material? Evaluation of Surface Topography and Wettability of Filled Versus Unfilled PEEK With Different Surface Roughness. J. Oral Implantol. 2017, 43, 456–461. [Google Scholar] [CrossRef] [PubMed]

- Batak, B.; Cakmak, G.; Johnston, W.M.; Yilmaz, B. Surface roughness of high-performance polymers used for fixed implant-supported prostheses. J. Prosthet. Dent. 2021, 126, 254.e1. [Google Scholar] [CrossRef] [PubMed]

- Kuhar, M.; Funduk, N. Effects of polishing techniques on the surface roughness of acrylic denture base resins. J. Prosthet. Dent. 2005, 93, 76–85. [Google Scholar] [CrossRef]

- Cakmak, G.; Donmez, M.B.; Atalay, S.; de Paula, M.S.; Fonseca, M.; Schimmel, M.; Yilmaz, B. Surface roughness and stainability of CAD-CAM denture base materials after simulated brushing and coffee thermocycling. J. Prosthet. Dent. 2022. online ahead of print. [Google Scholar] [CrossRef]

| Parameters | Technical Specifications |

|---|---|

| Extruder diameter | 0.6 mm |

| Printing layer thickness | 0.1 mm or 0.3 mm |

| Print speed | 10 mm/s |

| Printing table temperature | 160 °C |

| Chamber temperature | 100 °C |

| Extruder temperature | 380 °C |

| Specimens | Roughness Parameters | Before Polishing (μm) | After Polishing (μm) |

|---|---|---|---|

| A1 | Sa | 17.3 | 0.19 |

| Ra | 0.91 | 0.12 | |

| St | 124 | 7.64 | |

| A2 | Sa | 18 | 0.15 |

| Ra | 1.05 | 0.09 | |

| St | 123 | 10.2 | |

| B1 | Sa | 0.09 | |

| Ra | 0.05 | ||

| St | 26 | ||

| B2 | Sa | 6.51 | 0.1 |

| Ra | 0.33 | 0.05 | |

| St | 118 | 27.5 |

| Group | Group Average Ra (μm) | Group Average Sa (μm) | ||

|---|---|---|---|---|

| Before polishing | After polishing | Before polishing | After polishing | |

| A (A1 and A2) | 0.98 | 0.11 | 17.65 | 0.17 |

| B (B1 and B2) | 0.33 | 0.05 | 6.51 | 0.09 |

| Specimens | P1 (Unfinished Specimen) | P2 Polished with SiC Sandpaper) | P3 (Conventional Finish) | |

|---|---|---|---|---|

| Roughness Parameters | Sa | 0.74 | 0.4 | 0.49 |

| Ra | 0.26 | 0.11 | 0.11 | |

| St | 9.75 | 7.68 | 6.62 | |

| Specimens | Arithmetic Mean Roughness (Ra) before Polishing ± SD (μm) | Arithmetic Mean Roughness (Ra) after Polishing ± SD (μm) |

|---|---|---|

| PEEK—Group A | 0.98 ± 0.07 | 0.11 ± 0.02 |

| PEEK—Group B | 0.33 ± * | 0.04 ± 0 |

| PMMA | 0.26 ± * | 0.11 ± * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soares, T.; Fernandes, C.; Barbosa, C.; Vaz, M.A.P.; Reis, T.; Figueiral, M.H. Surface Roughness of Polyetheretherketone Printed by Fused Deposition Modeling: A Pilot Study Investigating the Impact of Print Layer Thickness and Polishing Method. Appl. Sci. 2024, 14, 3096. https://doi.org/10.3390/app14073096

Soares T, Fernandes C, Barbosa C, Vaz MAP, Reis T, Figueiral MH. Surface Roughness of Polyetheretherketone Printed by Fused Deposition Modeling: A Pilot Study Investigating the Impact of Print Layer Thickness and Polishing Method. Applied Sciences. 2024; 14(7):3096. https://doi.org/10.3390/app14073096

Chicago/Turabian StyleSoares, Tânia, Carlos Fernandes, Cláudia Barbosa, Mário A. P. Vaz, Tiago Reis, and Maria Helena Figueiral. 2024. "Surface Roughness of Polyetheretherketone Printed by Fused Deposition Modeling: A Pilot Study Investigating the Impact of Print Layer Thickness and Polishing Method" Applied Sciences 14, no. 7: 3096. https://doi.org/10.3390/app14073096

APA StyleSoares, T., Fernandes, C., Barbosa, C., Vaz, M. A. P., Reis, T., & Figueiral, M. H. (2024). Surface Roughness of Polyetheretherketone Printed by Fused Deposition Modeling: A Pilot Study Investigating the Impact of Print Layer Thickness and Polishing Method. Applied Sciences, 14(7), 3096. https://doi.org/10.3390/app14073096