Investigation of Cement and Fly Ash on the Improvement of Fine Sand Soil

Abstract

1. Introduction

2. Materials and Methods

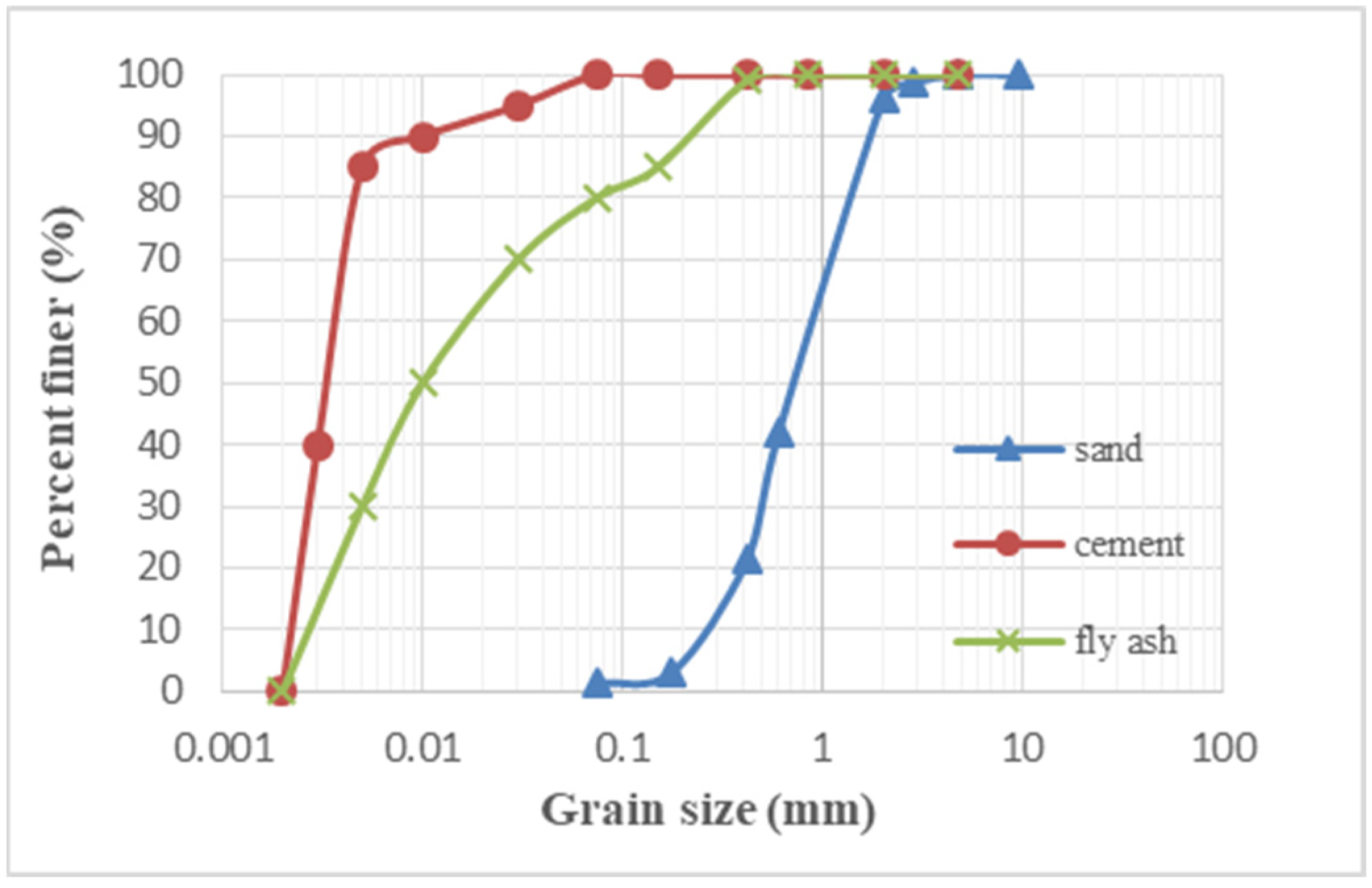

2.1. Materials

2.2. Method

3. Results

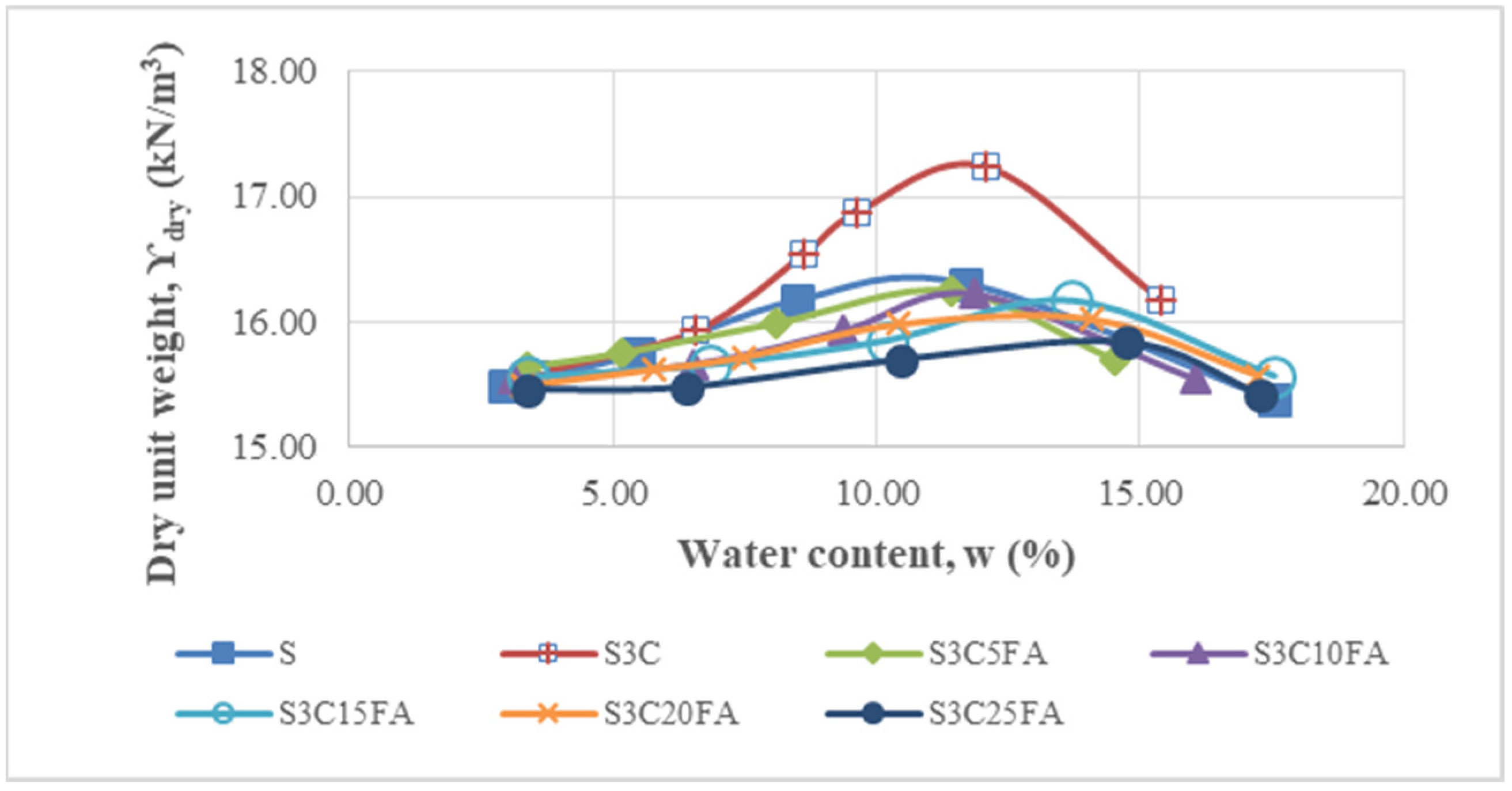

3.1. Standard Proctor Test

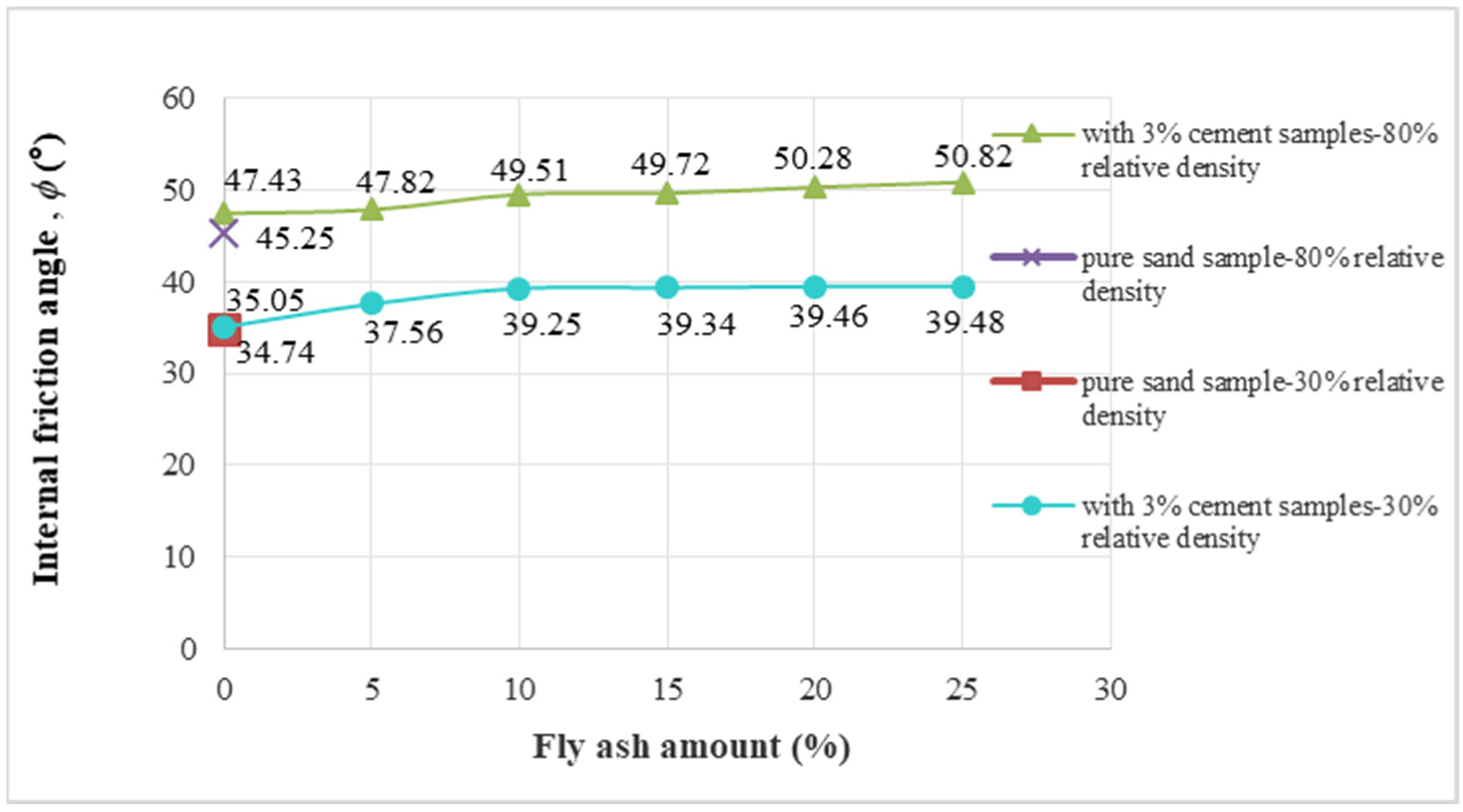

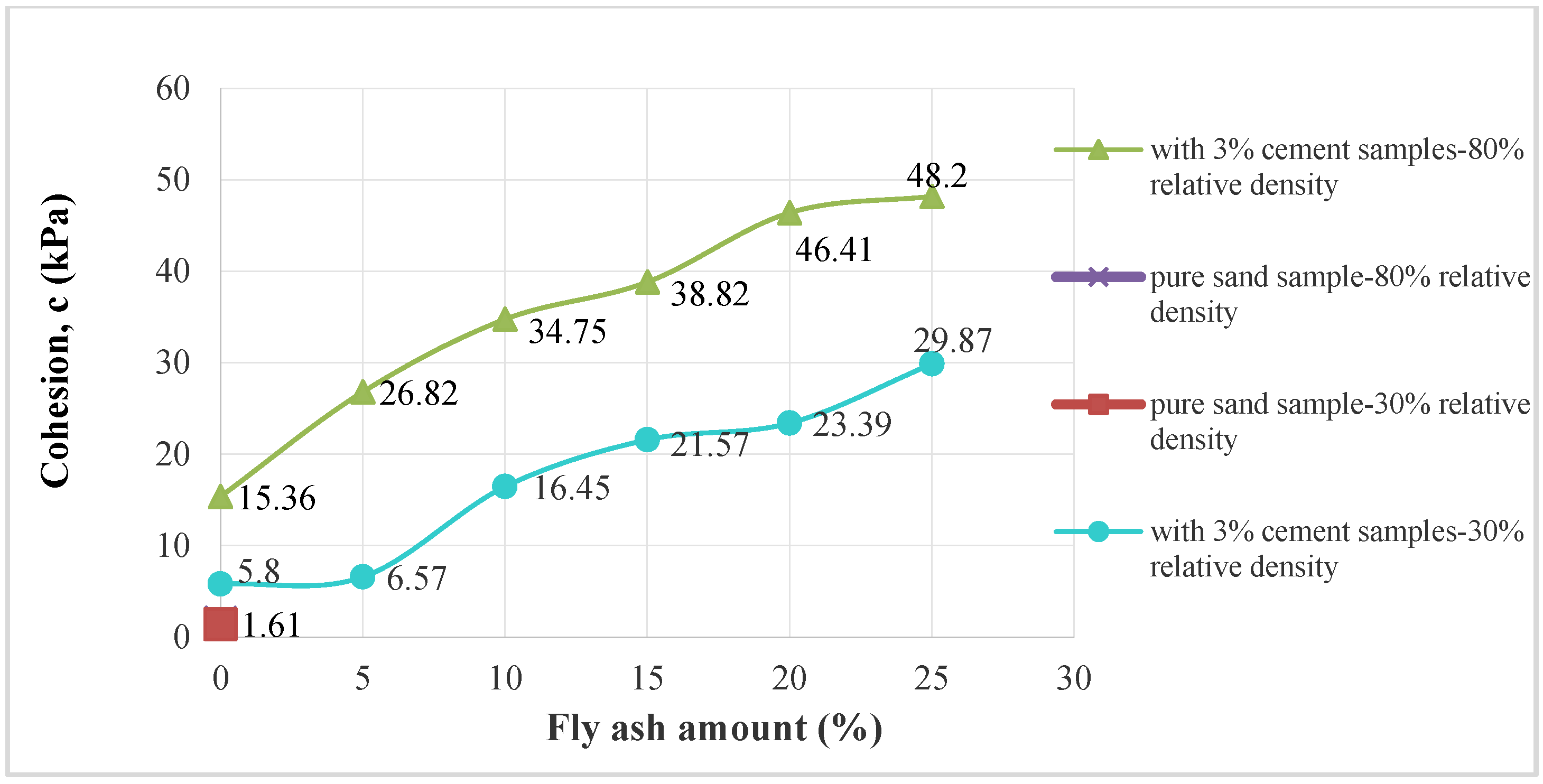

3.2. Direct Shear Box Test

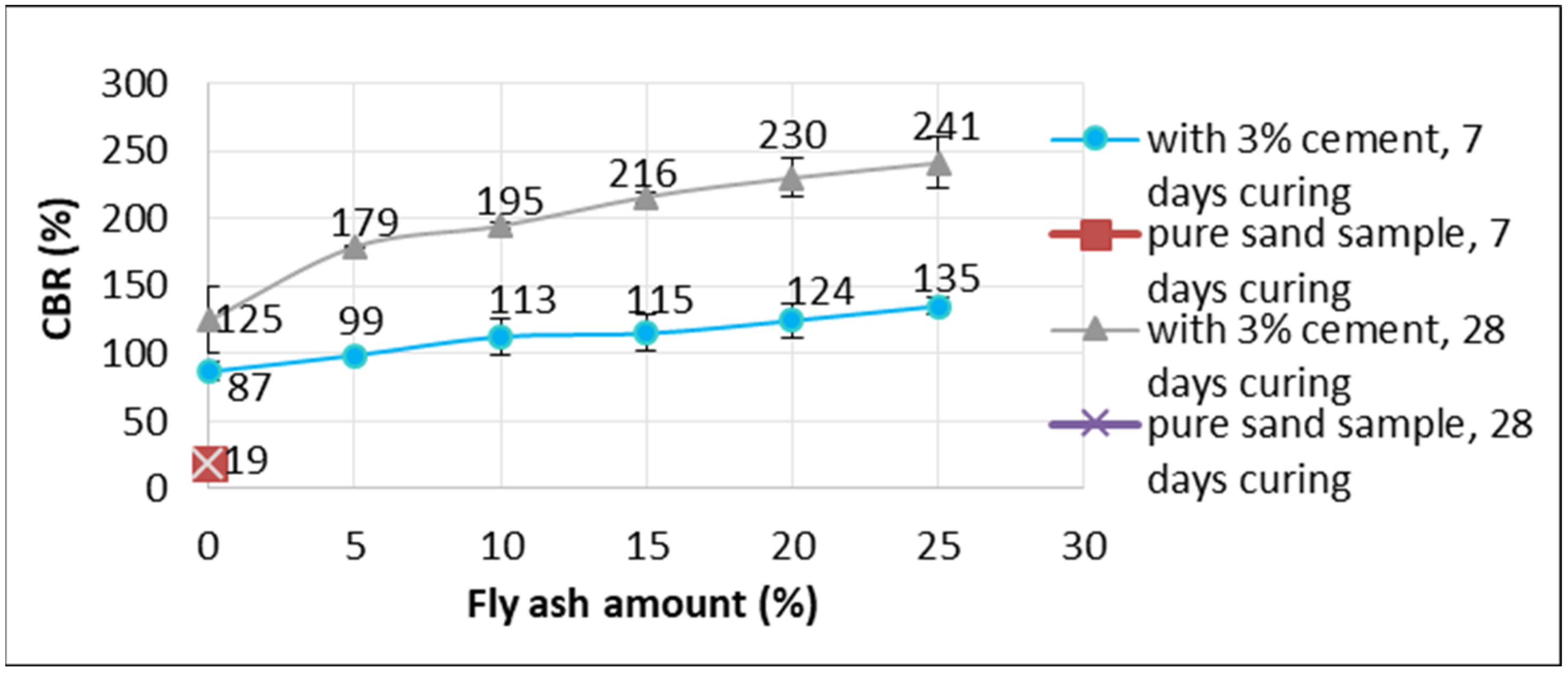

3.3. California Bearing Ratio Test (CBR Test)

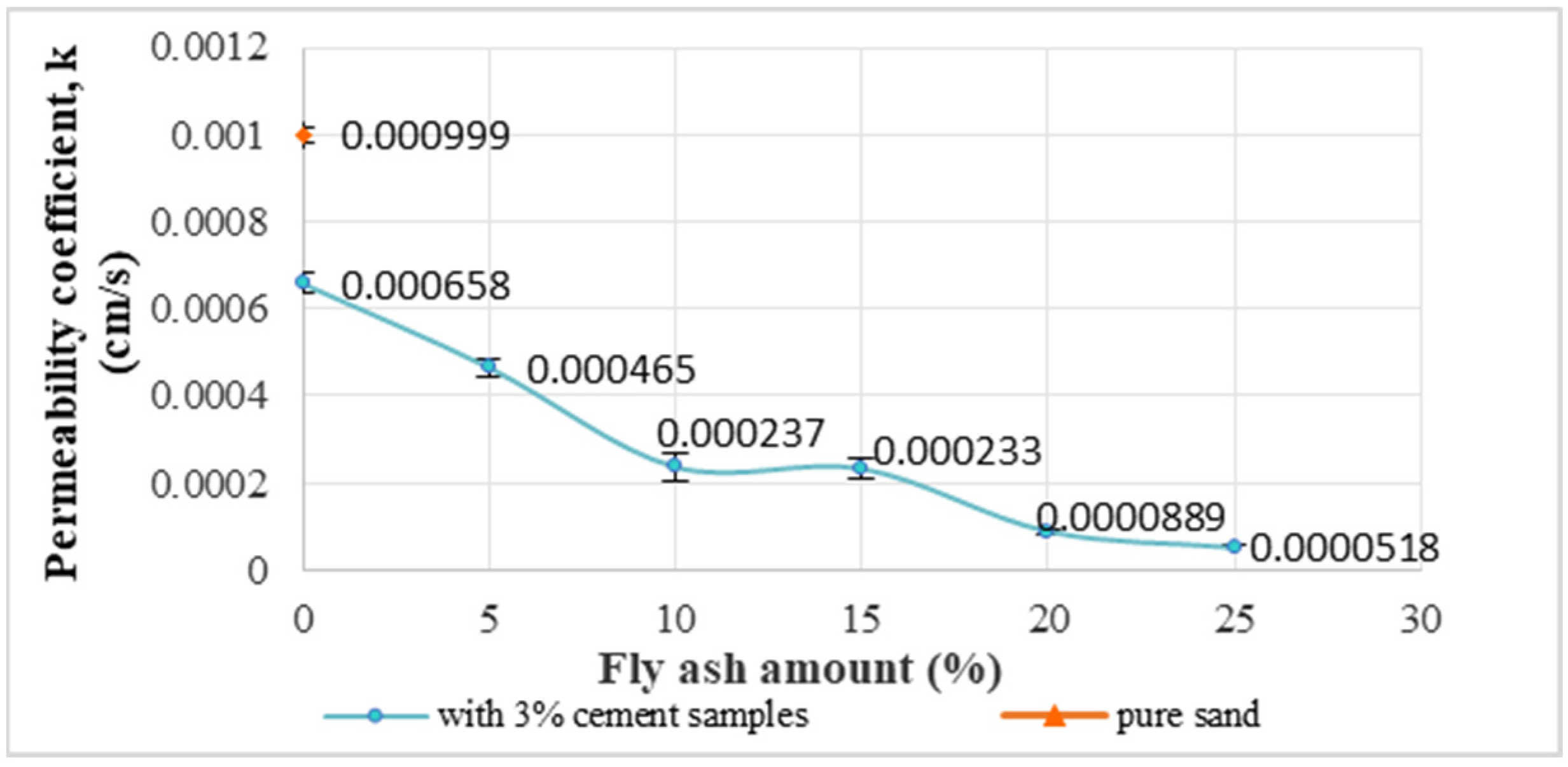

3.4. Falling Head Permeability Test

4. Conclusions

- The optimum water contents of treated soils increases continuously with the increase in fly ash amount. However, the dry unit weight of the samples decreases with the addition of fly ash, contrary to the addition of cement.

- Fly ash and cement additives improve the internal friction angle, cohesion and CBR value of the fine sand soil in the experiments. A 28 day curing period results in nearly a two-fold increase in the CBR ratio compared to a 7 day curing period. The relative density of the sand influences both the increase in the friction angle and cohesion. The friction angle shows a greater increase in loose sand, while the cohesion exhibits a larger increment in dense sand compared to loose sand.

- The permeability coefficient of the sand decreases with the addition of fly ash and cement at all percentages of additives.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Little, D.N.; Nair, S. NCHRP 20-07 Recommended Practice for Stabilization of Subgrade Soils and Base Materials; Texas Transportation Institute: Bryan, TX, USA, 2009; ISBN 978-0-309-43562-8. [Google Scholar] [CrossRef]

- Correa-Silva, M.; Rouainia, M.; Miranda, T.; Cristelo, N. Predicting the mechanical behaviour of a sandy clay stabilised with an alkali-activated binder. Eng. Geol. 2021, 292, 106260. [Google Scholar] [CrossRef]

- Zahmak, A.; Abdallah, M.; Jarah, B.; Arab, M.G. Environmental performance of alkali-activated binders for ground improvement. Transp. Geotech. 2021, 31, 100631. [Google Scholar] [CrossRef]

- Komaei, A.; Noorzad, A.; Ghadir, P. Stabilization and solidification of arsenic contaminated silty sand using alkaline activated slag. J. Environ. Manag. 2023, 344, 118395. [Google Scholar] [CrossRef] [PubMed]

- Turan, C.; Javadi, A.A.; Vinai, R.; Beig Zali, R. Geotechnical Characteristics of Fine-Grained Soils Stabilized with Fly Ash, a Review. Sustainability 2022, 14, 16710. [Google Scholar] [CrossRef]

- Kaniraj, S.R.; Havanagi, V.G. Compressive strength of cement stabilized fly ash-soil mixtures. Cem. Concr. Res. 1999, 29, 673–677. [Google Scholar] [CrossRef]

- Sahu, B.K. Improvement in California bearing ratio of various soils in Botswana by fly ash. In Proceedings of the International Ash Utilization Symposium, Lexington, KY, USA, 22–24 October 2001; University of Kentucky: Lexington, KY, USA, 2001. [Google Scholar]

- Sumesh, M.; Kalita, A.; Singh, B. An experimental investigation on strength properties of fly ash blended soils treated with cement. J. Environ. Res. Dev. 2010, 5, 322–329. [Google Scholar]

- Saha, S.; Pal, S.K. Influence of fly ash on unconfined compressive strength of soil and fly ash layers placed successively. Electron. J. Geotech. Eng. 2013, 18, 1593–1602. [Google Scholar]

- Ige, J.A.; Ajamu, S.O. Unconfined compressive strength test of a fly ash stabilized sandy soil. Int. J. Latest Res. Eng. Technol. 2015, 1, 1–11. [Google Scholar]

- Motamedi, S.; Song, K.I.; Hashim, R. Prediction of unconfined compressive strength of pulverized fuel ash–cement–sand mixture. Mater. Struct. 2015, 48, 1061–1073. [Google Scholar] [CrossRef]

- Mahvash, S.; López-Querol, S.; Bahadori-Jahromi, A. Effect of class F fly ash on fine sand compaction through soil stabilization. Heliyon 2017, 3, e00274. [Google Scholar] [CrossRef]

- Mahvash, S.; López-Querol, S.; Bahadori-Jahromi, A. Effect of fly ash on the bearing capacity of stabilised fine sand. Proc. Inst. Civ. Eng.-Ground Improv. 2018, 171, 82–95. [Google Scholar] [CrossRef]

- Simatupang, M.; Mangalla, L.K.; Edwin, R.S.; Putra, A.A.; Azikin, M.T.; Aswad, N.H.; Mustika, W. The mechanical properties of fly-ash-stabilized sands. Geosciences 2020, 10, 132. [Google Scholar] [CrossRef]

- Azaiez, H.; Cherif Taiba, A.; Mahmoudi, Y.; Belkhatir, M. Shear characteristics of fly ash improved sand as an embankment material for road infrastructure purpose. Innov. Infrastruct. Solut. 2021, 6, 148. [Google Scholar] [CrossRef]

- Ghadir, P.; Razeghi, H.R. Effects of sodium chloride on the mechanical strength of alkali activated volcanic ash and slag pastes under room and elevated temperatures. Constr. Build. Mater. 2022, 344, 128113. [Google Scholar] [CrossRef]

- Samadi, P.; Ghodrati, A.; Ghadir, P.; Javadi, A.A. Effect of seawater on the mechanical strength of geopolymer/cement stabilized sandy soils. In Proceedings of the TMIC 2022 Slope Stability Conference (TMIC 2022), Dordrecht, The Netherlands, 10–13 December 2022; Atlantis Press: Dordrecht, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Zumrawi, M.E.M. Stabilization of pavement subgrade by using fly ash activated cement. Am. J. Civ. Eng. Archit. 2015, 3, 218–224. [Google Scholar] [CrossRef]

- Kolias, S.; Kasselouri-Rigopoulou, V.; Karahalios, A. Stabilization of clayey soils with high calcium fly ash and cement. Cem. Concr. Compos. 2005, 27, 301–313. [Google Scholar] [CrossRef]

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2003.

- ASTM D698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D3080; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2011.

- Chegenizadeh, A.; Nikraz, H. Shear Test on Reinforced Clay. Adv. Mater. Res. 2011, 250–253, 3223–3227. [Google Scholar] [CrossRef]

- Stacho, J.; Sulovska, M.; Slavik, I. Determining the shear strength properties of a soil-geogrid interface using a large-scale direct shear test apparatus. Period. Polytech. Civ. Eng. 2020, 64, 989–998. [Google Scholar] [CrossRef]

- ASTM D1883; Standard Test Method for California Bearing Ratio (cbr) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D5856; Standard Test Method for Measurement of Hydraulic Conductivity of Porous Material Using a Rigid-Wall Compaction Mold Permeameter. ASTM International: West Conshohocken, PA, USA, 2015.

- Nithin, S.; Sayida, M.K. Stabilization of silty sand using fly ash and coir fiber. In Proceedings of the Recent Advances in Civil Engineering, Delhi, India, 28–29 December 2012; CUSAT Cochin: Kerala, India, 2012. [Google Scholar]

- Prabakar, J.; Dendorkar, N.; Morchhale, R.K. Influence of fly ash on strength behavior of typical soils. Constr. Build. Mater. 2004, 18, 263–267. [Google Scholar] [CrossRef]

- Amadi, A.A. Enhancing durability of quarry fines modified black cotton soil subgrade with cement kiln dust stabilization. Transp. Geotech. 2014, 1, 55–61. [Google Scholar] [CrossRef]

- Harichane, K.; Ghrici, M.; Kenai, S. Effect of curing time on shear strength of cohesive soils stabilized with combination of lime and natural pozzolana. Int. J. Civ. Eng. 2011, 9, 90–96. [Google Scholar]

- Zhou, Y.; Wang, X.; Liang, J. State of the art of fly ash engineering property. J. Civ. Eng. Constr. 2016, 5, 56–73. [Google Scholar]

| Soil Classification (USCS) | SP |

|---|---|

| Specific Gravity, Gs | 2.78 |

| Max. void ratio, emax | 1.190 |

| Min. void ratio, emin | 0.626 |

| Max. dry unit weight, γd,max (kN/m3) | 16.76 |

| Min. dry unit weight, γd,min (kN/m3) | 12.44 |

| Uniformity coefficient, Cu | 2.50 |

| Coefficient of curvature, Cc | 1.20 |

| Effective particle size, D10 (mm) | 0.52 |

| Physical Properties | Chemical Properties | ||||

|---|---|---|---|---|---|

| Cement | Fly Ash | Chemical Compounds | Cement (%) | Fly Ash (%) | |

| Specific Gravity | 3.04 | 2.46 | SiO2 | 25.08 | 29.88 |

| Specific surface (cm2/g) | 4260 | 2380 | Al2O3 | 6.24 | 15.03 |

| Fe2O3 | 2.90 | 6.01 | |||

| CaO | 56.44 | 29.28 | |||

| MgO | 0.88 | 2.27 | |||

| SO3 | 2.34 | 13.34 | |||

| Na2O | 0.73 | 0.13 | |||

| K2O | 0.96 | 1.71 | |||

| Code | S. Proctor Test | Direct Shear Test | CBR Test | Permeability Test | |

|---|---|---|---|---|---|

| Sand | S | 6 | 6 | 6 | 2 |

| Sand + 3% Cement | S3C | 6 | 6 | 4 | 2 |

| Sand + 3% Cement + 5% FA | S3C5FA | 6 | 6 | 4 | 2 |

| Sand + 3% Cement + 10% FA | S3C10FA | 6 | 6 | 4 | 2 |

| Sand + 3% Cement + 15% FA | S3C15FA | 6 | 6 | 4 | 2 |

| Sand + 3% Cement+20% FA | S3C20FA | 6 | 6 | 4 | 2 |

| Sand + 3% Cement + 25% FA | S3C25FA | 6 | 6 | 4 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yazıcı, E.; Unsever, Y.S. Investigation of Cement and Fly Ash on the Improvement of Fine Sand Soil. Appl. Sci. 2024, 14, 2908. https://doi.org/10.3390/app14072908

Yazıcı E, Unsever YS. Investigation of Cement and Fly Ash on the Improvement of Fine Sand Soil. Applied Sciences. 2024; 14(7):2908. https://doi.org/10.3390/app14072908

Chicago/Turabian StyleYazıcı, Elanur, and Yesim S. Unsever. 2024. "Investigation of Cement and Fly Ash on the Improvement of Fine Sand Soil" Applied Sciences 14, no. 7: 2908. https://doi.org/10.3390/app14072908

APA StyleYazıcı, E., & Unsever, Y. S. (2024). Investigation of Cement and Fly Ash on the Improvement of Fine Sand Soil. Applied Sciences, 14(7), 2908. https://doi.org/10.3390/app14072908