Abstract

Molecular hydrogen (H2) is a low-molecular-weight, non-polar and electrochemically neutral substance that acts as an effective antioxidant and cytoprotective agent, with research into the effects of H2 incorporation into the food chain, at various stages, rapidly gaining momentum. H2 can be delivered throughout the food growth, production, delivery and storage systems in numerous ways, including as a gas, as hydrogen-rich water (HRW), or with hydrogen-donating food supplements such as calcium (Ca) or magnesium (Mg). In plants, H2 can be exploited as a seed-priming agent, during seed germination and planting, during the latter stages of plant development and reproduction, as a post-harvest treatment and as a food additive. Adding H2 during plant growth and developmental stages is noted to improve the yield and quality of plant produce, through modulating antioxidant pathways and stimulating tolerance to such environmental stress factors as drought stress, enhanced tolerance to herbicides (paraquat), and increased salinity and metal toxicity. The benefits of pre- and post-harvest application of H2 include reductions in natural senescence and microbial spoilage, which contribute to extending the shelf-life of animal products, fruits, grains and vegetables. This review collates empirical findings pertaining to the use of H2 in the agri-food industry and evaluates the potential impact of this emerging technology.

1. Introduction

As the global population increases, so do the obligations to provide nutritious sustenance to an ageing population. For this to be achieved, the preservation of fresh produce is critical. Due to such contemporary issues as climate change, chemical pollution, loss of biodiversity and soil erosion, the production, preservation, and distribution of quality foods becomes ever more challenging [1]. Currently, such preservation processes as cooking, drying, pasteurization, refrigeration and sterilisation can make food products more resistant to microbial spoilage and attenuate lipid oxidation, thereby decelerating the natural decomposition and rancidification of produce over time [2]. Although effective, such techniques can be expensive to implement and maintain; there is, therefore, a requirement to develop alternative, ecologically responsible, low cost and sustainable methods of preserving natural produce.

Molecular hydrogen (H2) is classified as a ‘generally regarded as safe’ (GRAS) product by the U.S. Food and Drug Administration [3] and is regarded as a food supplement (E949) under part C group I of regulation 1129/2011 in the European Union [4] and U.K [5]. H2 technologies are at the forefront of modern research, due in part to it being trialled as an efficient and sustainable source of energy [6] and in part to its recognition as an effective antioxidant and cytoprotective compound in health and agricultural science [7,8]. In this regard, H2 could provide the increased energy required for sustainable food production, storage and distribution while enhancing food security through maintaining the nutritional value and prolonging the shelf-life of produce.

Oxidative stress and subsequent cellular and tissue damage can be caused by numerous factors, including environmental challenges (e.g., drought, pollution, increased soil salinity), human intervention (e.g., fertilisers, insecticides, paraquat) and natural senescence (e.g., cellular deterioration, microbial spoilage). These factors can affect the growth, yield and nutritional content of food [8]. Furthermore, oxidative damage can lead to the rapid deterioration of food quality, resulting in lipid oxidation, discolouration and alterations to both the nutritional profile and flavour of foods [8]. Lipid oxidation, in particular, is a primary consideration for the meat, fish and dairy industries as it affects the sensory attributes and shelf-life of produce [9].

Antioxidants neutralise reactive oxygen and reactive nitrogen species (ROS/RNS, respectively), which can cause oxidative stress and damage to cells and tissues and disrupt essential functional physiological processes, including energy metabolism and the biosynthesis of proteins and peptides [10]. As an antioxidant, H2 is demonstrated to quench cytotoxic free radicals, enhance endogenous antioxidant capacity and modulate both inflammatory responses (in animals) [11,12] and stress responses (in animals and in plants) [11,13]. Oxidation of biomolecules can also be inhibited with the post-harvest treatment of plant products (e.g., exposure to H2 gas or treatment with hydrogen-rich water (HRW)). Additionally, exposing dairy products such as butter to H2 during processing is shown to prevent biogenic amine formation due to microbial spoilage, a phenomenon attributed to the reducing effect of H2 [14]. The ability of H2 to traverse biological boundaries is likely to be highly influential, affecting fundamental organelle biochemistry as well as cytosolic reactions, a possible explanation as to why the application of H2 has been demonstrated to have positive effects in numerous disease models in both plants and animals.

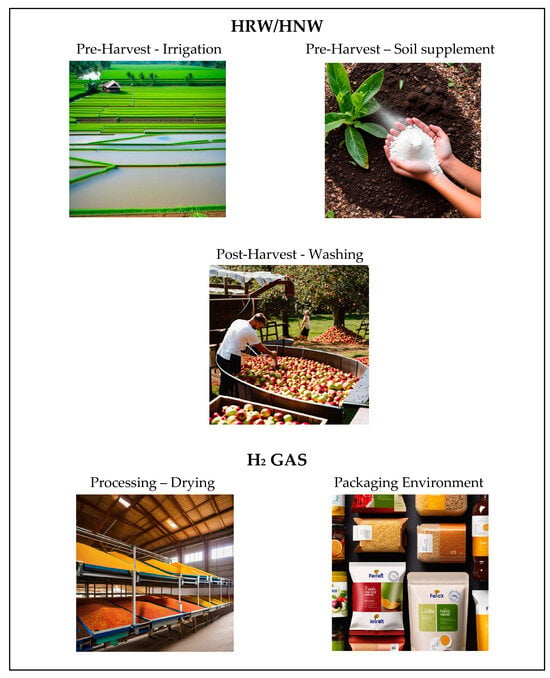

When growing plants or rearing animals, H2 can be used as an additive to water in the form of HRW or hydrogen-rich nanobubble water (HNW), or as a food or soil supplement in the form of hydrogen-forming magnesium (Mg) or calcium (Ca) powders. Additionally, HRW, HNW and H2 gas can also be used as a topical preparation on fruits and foliage (Figure 1).

Figure 1.

Potential methods of utilizing hydrogen in the agri-food industry. Images created by the author using an artificial intelligence platform (wonderai.app). Mode: Photo. Prompts: HRW/HNW Pre-Harvest Irrigation ‘Rice field irrigation’. Soil supplement ‘Adding calcium powder to soil’. Post-Harvest ‘Washing apples on farm’. H2 Gas. Drying ‘Drying fruit industry’. Packaging ‘Dry packaging of food for retail’.

As a gas, H2 can be used during the dehydration processes of fruits and pulses, for example, and as hydrogen-infused packaging films in modified packaging atmospheres (Figure 1). Such processes are likely to reduce the oxidation of produce and prolong the shelf-life of foods [10]. Furthermore, foodborne pathogens also pose a significant risk to food security; here, H2 is documented to inhibit the growth of such bacteria as Escherichia coli, Salmonella listeriosis and moulds [15], potentially reducing the risk of spoilage and foodborne illnesses.

2. H2 Use on the Farm

Global losses of food productivity as a result of increasing burdens (e.g., climate change, pollution and soil erosion) are estimated to be in the region of USD 170 billion annually [16]. Ergo, there is a pressing requirement for additional, effective, means of preserving the nutritional content, preventing the spoilage and prolonging the shelf-life of fresh produce. In this regard, there is an extensive body of research attesting to the benefits of adding H2 into the feedwater of seeds, seedlings and maturing plants, wherein H2, supplied as HRW, is demonstrated to improve crop viability and yield [17,18]. The antioxidant activity of H2 is proposed to be the primary mode of action, involving the upregulation of glutathione and sulphur metabolism [19], enhanced antioxidant gene expression [18] and promoting hormone synthesis [20]. Such cytoprotective actions proffer resistance to both biotic and abiotic stressors, including drought [21], heavy metal toxicity [17,22], increased salinity [23], temperature variation [18,24] and viral infection [25].

A wealth of academic studies show that exposing plants to H2 during the germination, plantation and growth phases can enhance root establishment, increase disease resistance and promote the growth and development of leaves, fruits and seeds. Incorporating H2 into the feedwater of plant crops is a relatively simple process which can be implemented in various ways. For example, HRW and H2 gas can also be used as a topical application. However, atmospheric losses due to evaporation make it difficult to envisage how practical this application method would be at scale. HRW and HNW can also be obtained by diffusing H2 gas (formed through water electrolysis) into nutrient solutions and irrigation systems and by dissolving Mg or H2 donors (e.g., ammonia borane hollow mesoporous silica nanoparticles (AB@hMSN)) in aqueous solutions. Such methods are already being implemented academically [18,20,26] and are beginning to be rolled out commercially.

The addition of H2 into soil environments is also noted to improve soil quality through increasing H2-oxidising microbial activity and promoting carbon fixation [27,28,29], a term referred to as hydrogen fertilisation, although the process is somewhat complex, which may rule out its application in an agricultural setting. Whether this type of application would provide a large-scale, long-term solution to replenishing nutrient-deficient soils will need to be explored.

3. H2 in the Storage and Distribution Chain

The distribution and storage of fresh produce are paramount to ensuring food security with many aspects (e.g., transportation, warehouse and vendor) reliant on controlling the temperature at which foods are stored. The refrigeration process is not only energy-intensive, costly and environmentally taxing [30], but using this preservation method does not prevent, but mitigates, losses of perishable foods. Therefore, to ensure future food security, it is pertinent to consider novel approaches that can further reduce the deterioration rate of valuable produce.

A broad range of research in animals [11,31,32] and plants [33,34,35] identifies H2 as having noticeable reducing properties, which are relevant to the preservation of food products as such redox poise favours a reducing environment, attenuating the accumulative oxidation of lipid components. Lipid oxidation is instrumental in the deterioration of biological substances as it can diminish cell membrane integrity, resulting in ion leakage, dysfunctional organelle activity and aberrant cellular cohesion [36,37]. Preventing lipid oxidation is a leading consideration for increasing the longevity and nutritional value of food products [9,10].

To date, research into H2 describes the molecule as an effective mediator of cellular homeostasis, albeit the precise mode of action has yet to be delineated. Many reports highlight a direct scavenging effect of such ROS/RNS as the hydroxyl radical (•OH) and peroxynitrite ion (ONOO−) [38,39,40], both significant contributors to lipid oxidation. However, considering the spatial and temporal distribution, and the kinetics of these highly reactive molecules, whether such reactions occur in vivo is questioned [41,42]. Alternative mechanisms of action involving the partial reduction in Fe3+ moieties [43] and protein stabilisation [44] have been proposed, and whilst the modality of H2 is currently a matter of academic debate, what is clear is that implementation of HRW and H2 gas to post-harvest produce consistently demonstrates an increased resistance to ripening, senescence and spoilage in fruits, herbs and vegetables (Table 1).

Table 1.

Identifies the benefits of H2 application to animal and plant products, noting the mechanism of action and overall effects on fresh produce. APx—ascorbate peroxidase; β-Gal—β-galactosidase; CAT—catalase; Cx—connexin; GR—glutathione reductase; GSH—glutathione; PG—peptidoglycan hydrolase; PL—pectate lyase; PME—pectin methylesterase; POD—peroxidase; SOD—superoxide dismutase.

In addition to postharvest treatments, preharvest irrigation with HRW has also been demonstrated to protect natural produce against storage-related chilling injury [52]. This indicates that the application of H2 has long-lasting, positive effects on plant biochemistry. As is shown in Table 1, H2 has pleiotropic effects in plants, from regulating the activity of endogenous antioxidants including ascorbate peroxidase (APx), catalase (CAT), peroxidase (POD) and superoxide dismutase (SOD) [34], to reducing biomarkers of senescence β-Galactosidase (β-Gal), peptidoglycan hydrolase (PG) and pectin methylesterase (PME) [47] and increasing the biosynthesis of such polysaccharides as cellulose and pectin [49]. It is conceivable that, together, these cytoprotective qualities can further prevent the deterioration of fresh produce in storage and transit.

Incorporation of H2-producing technologies into established storage and distribution chains will require careful consideration due, in part, to the possibility of igniting H2 [53], a highly explosive gas, and to the time involved in washing and subsequently drying produce. Additionally, although the preparation of HRW baths is a relatively simplistic process [45,50], with a large volume of produce the process could become labour-intensive. Therefore, it may be prudent to focus on the pre-harvest and processing/packaging applications of H2.

4. H2 in Food Processing

A more practical and viable way of treating plant and animal produce can be envisaged during the packaging and processing stages, where H2 can be applied without much adaptation to current preservation methods. H2 gas can be easily incorporated into numerous preservation techniques, including drying, fermentation, extraction and preparation of foods (Table 2).

Table 2.

The benefits of H2 addition in the processing of food products. Ca—calcium; K—potassium; Mg—magnesium; Na—sodium. Ile—isoleucine; Leu—leucine; Met—methionine.

Dairy products are particularly susceptible to oxidation-related spoilage which can shorten the shelf-life. For example, oxidative reactions in butter lead to the destruction of essential fatty acids and vitamins. The foremost oxidative decomposition products formed in animal-derived produce such as butter are unstable hydroperoxides (R-OOH), molecules which are further decomposed into rancidity-inducing compounds (e.g., aldehydes (R-CH=O), ketones (R-C=O), alcohols (R-C-OH)) [61]. Introducing H2 in the form of HRW when washing raw butter [58,60] was demonstrated to improve the quality attributes (e.g., acidity, colour), decrease the accumulation of heavy metals, prevent spoilage by inhibiting microbial decarboxylase activity, and retard the growth of yeasts and moulds, prolonging the shelf-life.

Adding H2 into the preparation stages of such dairy products as butter and yoghurt is shown to inhibit microbial spoilage whilst also promoting microbial fermentation. Similarly, dissolving H2 gas into the pickling media of vegetable produce was noted to enhance the fermentation process and reduce lactic-acid-bacteria-associated biogenic amine formation. The authors demonstrated that using HRW during the fermentation phase and replacing the medium with freshly infused H2-enriched brine before pasteurisation was most effective in reducing levels of such biogenic amines as 2-phenylethylamine, putrescine and tryptamine [55]. Dissolving H2 into solvent fluids used for the extraction of phytochemicals can increase the yields of anthocyanins, flavonoids and polyphenolic substances, whilst in the preparation of rice milk, an alternative to dairy, replacing pure water with HRW increased essential mineral and amino acid content [59].

The use of 4% H2 gas in the fruit-drying process has also shown an increased potential to maintain the nutritional and sensorial notes of dried fruits [54]. Here, instead of infusing liquids with H2 generated on demand, a mixture of gases (typically, CO2, N2 and H2) into the drying apparatus is regulated via instrumentation. As such apparatuses utilise gas canisters, and since H2 is explosive above concentrations of 75% (v/v) [62], increased storage and safety protocols may be required if this mechanism of application is to be exploited in the food preservation industry.

5. Incorporating H2 in the Packaging Environment of Food

Historically, the packaging of food had the sole intention of providing a physical barrier between the environment and the contents to prevent external contamination. Innovation in the food packaging industry is broadly focused on the incorporation of active components such as ethylene scavengers (e.g., potassium permanganate) into the package, which can maintain, or extend, product quality, sensory attributes and shelf-life [63].

Currently, to improve the quality and longevity of produce, many fresh products are distributed and displayed in plastic packages containing a modified atmosphere composed of carbon dioxide (CO2) and Nitrogen (N2) [9]. This O2-depleted environment inhibits cellular oxidative mechanisms and microbial activity, restricting senescent processes and preserving the contents. However, with compounding stresses on food security and distribution networks, any improvements which can enhance the longevity of fresh produce will be highly valued.

As with the utilisation of H2 gas in thermal drying discussed previously, incorporating H2 into the packaging atmosphere should be relatively simple. Nevertheless, unless the gas is used as it is produced, through water electrolysis, for example, the same safety concerns over the storage of pressurised gas and flammability apply. Therefore, stringent safety procedures in food processing and manufacturing environments will be necessary. On the other hand, the benefits of introducing non-explosive (<4% v/v) amounts of H2 into packaging atmospheres may well outweigh any required investment in safety measures.

Although the precise mechanisms behind H2 activity in cells have yet to be elucidated, the ability of H2 to act as an effective antioxidant in plants and produce is now well-documented [8,64,65,66]. One of the primary functions of H2 utilization in both agricultural and clinical settings is as an antioxidant, first demonstrated by Ohsawa et al. (2007), in a rodent model of ischemia/reperfusion injury [38]. The highly influential study describes the selective reduction in the highly reactive •OH radical and ONOO− molecules, but no reduction in the important signalling molecules hydrogen peroxide (H2O2) and nitric oxide (NO•). Either as a result of, or in addition to, selectively neutralising the most detrimental reactive oxygen/nitrogen species, the upregulation and increased expression of such antioxidant proteins and peptides CAT, nuclear erythroid factor-2 (Nrf-2) and SOD are often reported [34]. Upregulation of such endogenous antioxidants is known to enhance tolerance to such environmental stressors as diseases, salinity, drought and temperature stress, and to confer a level of microbial resistance [23,24,25]. Such antioxidant activity is also demonstrated when H2 is incorporated into the packaging atmosphere. Recently, several studies have identified that adding up to 4% H2 gas into such packaging environments can markedly improve both the sensory qualities and shelf-life of fresh produce (Table 3).

Table 3.

Identifies the benefits of H2 application in the processing and packaging of fresh produce.

It can be seen from Table 3 that the addition of H2 in the packaging atmosphere of animal and animal-derived products, including cheese, eggs and fish, was able to inhibit both lipid oxidation and the decomposition of amino acids by decarboxylase enzymes, whilst concomitantly reducing microbial growth and spoilage. As with the pre-harvest and processing applications of H2 (Table 1 and Table 2, respectively), the preservation of endogenous antioxidant activity may account for many of the effects noted in Table 3. Furthermore, in addition to being utilised as a preservative gas, H2 gas can be used to detect flaws in food packages such as mis-sealing, tears, and small holes [71]. Here, the gas is used during the sealing process, before the packet passes through a sensor; if the sensor detects H2, an alarm is activated, allowing for the damaged packet to be removed from the production chain and repackaged before wastage occurs.

Although supplementary research into the use of H2 gas in the packaging environments of perishable goods is warranted, the initial findings strongly suggest that such reducing-atmosphere packaging environments can impede the natural deterioration of fresh produce. However, before this method of preservation can be adopted by the agri-food industry, detailed cost-benefit analyses, assessments of the practical incorporation into working spaces (e.g., safety, storage, transportation) and the effects of H2 on other food products will be required.

6. Safety

Using H2 safely will require proper handling precautions and procedures due to its flammability and potential for explosive reactions. For example, during storage, H2 will need to be contained in appropriate cylinders in well-ventilated areas away from heat sources, ignition and direct sunlight [72], a factor that is likely to pose an issue towards comprehensive use, particularly in countries such as the UK and USA which have stringent safety policies. Cylinders should also be regularly checked for damage to reduce the potential of leakage. Additionally, as H2 is lighter than air, proper airflow and ventilation are also necessary to prevent the accumulation of H2. Equipment, fittings and connections of any apparatus using H2 will also require detectors/monitors, which can provide early warning of malfunction and H2 leakage. Pressure regulators and flow meters can detect sudden pressure changes and may well be instrumental in preventing harm from faults in H2-associated equipment. It will be prudent to ensure individuals working with H2 are adequately trained in the safe handling, storage and emergency procedures, with training to include recognizing the potential hazards and how to respond to incidences that may involve H2 (e.g., evacuation, fires, leaks, etc.).

7. Future Perspectives and Conclusions

Reducing food waste and cutting costs is a primary concern for food security and the agri-food industry [73,74]. To better assess the potential for H2 to support food growth, distribution and production industries, large-scale, in-field research, along with further empirical investigations into the primary, secondary and, perhaps, tertiary effects of H2 applications will be advantageous. It may also be prudent to analyse whether heritable traits are affected by long-term H2 usage. This could involve understanding the epigenetic context, hormone regulation, and resistance to biotic and abiotic stressors.

Recent studies, such as the one conducted by Cheng et al. (2021), have identified that HNW is suitable for irrigating crops [17]; therefore, it may be propitious to focus on this aspect of H2 production when considering pre-harvest administration. For post-harvest applications, comparative analyses of whether treatment with HRW/HNW or H2 gas, and at what stage in the distribution chain application is most effective, would be beneficial.

It is not only the efficacy of hydrogen treatments that must be scrutinised, but the cost-effectiveness, sustainability and long-term benefits of treatment must also be assessed. The cost of established ‘green’ hydrogen production technologies has been estimated to be 0.7–1.4 GBP/W for alkaline water electrolysis and 0.8–2.2 GBP/W for proton exchange membrane (PEM) electrolysis [75,76]. However, as such production costs are influenced by commercial innovation and investment, and the interest in H2-producing technologies is growing internationally, it is likely such costs will be reduced as H2 technology becomes more efficient over time. In addition to the purchase and maintenance costs, an assessment of the durability and longevity of commercial units versus conventional treatments and processes will also need to be considered.

To summarise both the risks and benefits of commercial H2 usage in the agri-food industry, Table 4 provides an analysis of the strengths, weaknesses, opportunities and threats (SWOT) for incorporating H2 into the agri-food chain.

Table 4.

A SWOT analysis of strengths, weaknesses, opportunities and threats to incorporating H2 into the agri-food chain.

In conclusion, via regulating antioxidant, hormonal and microbial activity, a wealth of evidence is accumulating strongly indicating that H2 may be an effective fertiliser, microbial deterrent and preserving agent for edible produce (Table 1, Table 2 and Table 3). The application of H2, whether as an atmospheric gas or in solution, into the agri-food industry may help to support the healthy growth of plant produce, increasing biomass, resistance to stress and yield (Table 1). Adopting the hydrogen strategy in various stages of the food production chain can decrease the heavy metal content, limit the biogenic amine formation of food products, preserve the nutritional and sensory properties, and extend the product’s shelf-life [4,6,17,22]. Furthermore, reduction in both animal-derived and plant-derived food wastage can be achieved through H2-induced inhibition of endogenous senescent processes (Table 2 and Table 3). Moreover, as a sustainable, non-toxic and non-polluting agent, the future of H2 application in the agri-food industry could help to reduce the carbon footprint, from the field to the table, of such a demanding supply chain.

Author Contributions

Conceptualization, G.R. and J.T.H.; writing—G.R.; writing—review and editing, G.R., J.T.H. and A.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was co-funded by Water Fuel Engineering and the University of the West of England. Funding identification number 7096050. Project code: RDAS0184.

Conflicts of Interest

Author Alexander Nenov was employed by the company Water Fuel Engineering. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

APx—Ascorbate peroxidase; β-Gal—β-Galactosidase; CAT—Catalase; Cx—Connexin; GR—Glutathione reductase; GSH—Glutathione; GRAS—Generally regarded as safe; HNW—Hydrogen-rich nanobubble water; HRS—Hydrogen-rich saline; HRW—Hydrogen-rich water; Nrf2—Nuclear erythroid factor-2; PEM—Proton exchange membrane; PG—Peptidoglycan hydrolase; PL—Pectate lyase; PME—Pectin methylesterase; POD—Peroxidase; RNS—Reactive nitrogen species; ROS—Reactive oxygen species; SOD—Superoxide dismutase; USD—United States dollar.

References

- King, T.; Cole, M.; Farber, J.M.; Eisenbrand, G.; Zabaras, D.; Fox, E.M.; Hill, J.P. Food safety for food security: Relationship between global megatrends and developments in food safety. Trends Food Sci. Technol. 2017, 68, 160–175. [Google Scholar] [CrossRef]

- Amit, S.K.; Uddin, M.; Rahman, R.; Islam, S.M.R.; Khan, M.S. A review on mechanisms and commercial aspects of food preservation and processing. Agric. Food Secur. 2017, 6, 51. [Google Scholar] [CrossRef]

- Food and Drug Administration. GRASNotices. 2014. Available online: https://www.cfsanappsexternal.fda.gov/scripts/fdcc/?set=GRASNotices&id=520&sort=GRN_No&order=DESC&startrow=1&type=basic&search=hydrogen (accessed on 14 January 2024).

- EU Commission Regulation. No 1129/2011 of 11 November 2011 Amending Annex II to Regulation (EC) No 1333/2008 of the European Parliament and of the Council by Establishing a Union List of Food Additives Text with EEA Relevance. Document Number: 32011R1129. Available online: https://eur-lex.europa.eu/legalcontent/EN/ALL/?uri=CELEX%3A32011R1129 (accessed on 14 July 2022).

- Food Standards Agency. Approved Additives and E Numbers. 2018. Available online: https://www.food.gov.uk/businessguidance/approved-additives-and-e-numbers (accessed on 14 January 2024).

- Singla, M.K.; Nijhawan, P.; Oberoi, A.S. Hydrogen fuel and fuel cell technology for cleaner future: A review. Environ. Sci. Pollut. Res. 2021, 28, 15607–15626. [Google Scholar] [CrossRef]

- Ohta, S. Molecular hydrogen as a novel antioxidant: Overview of the advantages of hydrogen for medical applications. Methods Enzymol. 2015, 555, 289–317. [Google Scholar] [PubMed]

- Alwazeer, D.; Çiğdem, A. Use of the molecular hydrogen in agriculture field. Turk. J. Agri-Food Sci. Tech. 2022, 10, 14–20. [Google Scholar]

- Adegoke, G.O.; Kumar, M.V.; Krishna, A.G.; Varadaraj, M.C.; Sambaiah, K.; Lokesh, B.R. Antioxidants and lipid oxidation in foods-A critical appraisal. J. Food Sci. Tech. 1998, 35, 283–298. [Google Scholar]

- Sezer, Y.; Bulut, M.; Boran, G.; Alwazeer, D. The effects of hydrogen incorporation in modified atmosphere packaging on the formation of biogenic amines in cold stored rainbow trout and horse mackerel. J. Food Compos. Anal. 2022, 112, 104688. [Google Scholar] [CrossRef]

- Li, J.; Ge, Z.; Fan, L.; Wang, K. Protective effects of molecular hydrogen on steroid-induced osteonecrosis in rabbits via reducing oxidative stress and apoptosis. BMC Musculoskelet. Disord. 2017, 18, 58. [Google Scholar] [CrossRef]

- Qi, D.-D.; Ding, M.-Y.; Wang, T.; Hayat, M.A.; Liu, T.; Zhang, J.-T. The therapeutic effects of oral intake of hydrogen rich water on cutaneous wound healing in dogs. Vet. Sci. 2021, 8, 264. [Google Scholar] [CrossRef]

- Hancock, J.T. Editorial for Special Issue: “Production and Role of Molecular Hydrogen in Plants”. Plants 2022, 11, 2047. [Google Scholar] [CrossRef]

- Bulut, M.; Sezer, Y.Ç.; Ceylan, M.M.; Alwazeer, D.; Koyuncu, M. Hydrogen-rich water can reduce the formation of biogenic amines in butter. Food Chem. 2022, 384, 132613. [Google Scholar] [CrossRef] [PubMed]

- George, S.M.; Richardson, L.C.; Pol, I.; Peck, M.W. Effect of oxygen concentration and redox potential on recovery of sublethally heat-damaged cells of Escherichia coli O157:H7, Salmonella enteritidis and Listeria monocytogenes. J. Appl. Microbiol. 1998, 84, 903–909. [Google Scholar] [CrossRef] [PubMed]

- Razzaq, A.; Wani, S.H.; Saleem, F.; Yu, M.; Zhou, M.; Shabala, S. Rewilding crops for climate resilience: Economic analysis and de novo domestication strategies. J. Exp. Bot. 2021, 72, 6123–6139. [Google Scholar] [CrossRef] [PubMed]

- Cheng, P.; Wang, J.; Zhao, Z.; Kong, L.; Lou, W.; Zhang, T.; Jing, D.; Yu, J.; Shu, Z.; Huang, L.; et al. Molecular hydrogen increases quantitative and qualitative traits of rice grain in field trials. Plants 2021, 10, 2331. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; An, Z.; Liao, J.; Ran, N.; Zhu, Y.; Ren, S.; Meng, X.; Cui, N.; Yu, Y.; Fan, H. The role and mechanism of hydrogen-rich water in the Cucumis sativus response to chilling stress. Int. J. Mol. Sci. 2023, 24, 6702. [Google Scholar] [CrossRef]

- Cui, W.; Yao, P.; Pan, J.; Dai, C.; Cao, H.; Chen, Z.; Zhang, S.; Xu, S.; Shen, W. Transcriptome analysis reveals insight into molecular hydrogen-induced cadmium tolerance in alfalfa: The prominent role of sulfur and (homo)glutathione metabolism. BMC Plant Biol. 2020, 20, 58. [Google Scholar] [CrossRef]

- Felix, K.; Su, J.; Lu, R.; Zhao, G.; Cui, W.; Wang, R.; Mu, H.; Cui, J.; Shen, W. Hydrogen-induced tolerance against osmotic stress in alfalfa seedlings involves ABA signaling. Plant Soil 2019, 445, 409–423. [Google Scholar] [CrossRef]

- Yan, M.; Yao, Y.; Mou, K.; Dan, Y.; Li, W.; Wang, C.; Liao, W. The involvement of abscisic acid in hydrogen gas-enhanced drought resistance in tomato seedlings. Sci. Hortic. 2021, 292, 110631. [Google Scholar] [CrossRef]

- Zhang, J.; Hao, H.; Chen, M.; Wang, H.; Feng, Z.; Chen, H. Hydrogen-rich water alleviates the toxicities of different stresses to mycelial growth in Hypsizygus marmoreus. AMB Express 2017, 7, 107. [Google Scholar] [CrossRef]

- Wu, Q.; Su, N.; Shabala, L.; Huang, L.; Yu, M.; Shabala, S. Understanding the mechanistic basis of ameliorating effects of hydrogen rich water on salinity tolerance in barley. Environ. Exp. Bot. 2020, 177, 104136. [Google Scholar] [CrossRef]

- Guan, Q.; Ding, X.-W.; Jiang, R.; Ouyang, P.-L.; Gui, J.; Feng, L.; Yang, L.; Song, L.-H. Effects of hydrogen-rich water on the nutrient composition and antioxidative characteristics of sprouted black barley. Food Chem. 2019, 299, 125095. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Lin, F.; Wang, Y.; Cheng, P.; Lou, W.; Wang, Z.; Liu, Z.; Chen, D.; Guo, W.; Lan, Y.; et al. Molecular Hydrogen Confers Resistance to Rice Stripe Virus. Microbiol. Spectr. 2023, 11, e0441722. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Lv, P.; Kong, L.; Shen, W.; He, Q. Nanomaterial-mediated sustainable hydrogen supply induces lateral root formation via nitrate reductase-dependent nitric oxide. Chem. Eng. J. 2020, 405, 126905. [Google Scholar] [CrossRef]

- Stein, S.; Selesi, D.; Schilling, R.; Pattis, I.; Schmid, M.; Hartmann, A. Microbial activity and bacterial composition of H2-treated soils with net CO2 fixation. Soil Biol. Biochem. 2005, 37, 1938–1945. [Google Scholar] [CrossRef]

- Piché-Choquette, S.; Constant, P. Molecular hydrogen, a neglected key driver of soil biogeochemical processes. Appl. Environ. Microbiol. 2019, 85, 02418-18. [Google Scholar] [CrossRef] [PubMed]

- Islam, Z.F.; Greening, C.; Hu, H.W. Microbial hydrogen cycling in agricultural systems–plant beneficial or detrimental? Micro Biotech 2023, 16, 1623–1628. [Google Scholar] [CrossRef] [PubMed]

- Adekomaya, O.; Jamiru, T.; Sadiku, R.; Huan, Z. Sustaining the shelf life of fresh food in cold chain–A burden on the environment. Alex. Eng. J. 2016, 55, 1359–1365. [Google Scholar] [CrossRef]

- Diao, M.; Zhang, S.; Wu, L.; Huan, L.; Huang, F.; Cui, Y.; Lin, Z. Hydrogen gas inhalation attenuates seawater instillation-induced acute lung injury via the Nrf2 pathway in rabbits. Inflammation 2016, 39, 2029–2039. [Google Scholar] [CrossRef] [PubMed]

- Kalocayova, B.; Kura, B.; Vlkovicova, J.; Snurikova, D.; Vrbjar, N.; Frimmel, K.; Hudec, V.; Ondrusek, M.; Gasparovic, I.; Sramaty, R.; et al. Molecular hydrogen: Prospective treatment strategy of kidney damage after cardiac surgery. Can. J. Physiol. Pharmacol. 2023, 101, 502–508. [Google Scholar] [CrossRef]

- Zeng, J.; Zhang, M.; Sun, X. Molecular hydrogen is involved in phytohormone signaling and stress responses in plants. PLoS ONE 2013, 8, e71038. [Google Scholar] [CrossRef]

- Jiang, K.; Kuang, Y.; Feng, L.; Liu, Y.; Wang, S.; Du, H.; Shen, W. Molecular hydrogen maintains the storage quality of Chinese chive through improving antioxidant capacity. Plants 2021, 10, 1095. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Duan, Y.; Chi, Q.; Wang, R.; Yin, Y.; Cui, D.; Li, S.; Wang, A.; Ma, R.; Li, B.; et al. The role of reactive oxygen species in plant response to radiation. Int. J. Mol. Sci. 2023, 24, 3346. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A comprehensive review on lipid oxidation in meat and meat products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [PubMed]

- Sachdev, S.; Ansari, S.A.; Ansari, M.I. ROS Production and function at plasma membrane and apoplast. In Reactive Oxygen Species in Plants: The Right Balance; Springer Nature: Singapore, 2023; pp. 125–142. [Google Scholar]

- Ohsawa, I.; Ishikawa, M.; Takahashi, K.; Watanabe, M.; Nishimaki, K.; Yamagata, K.; Katsura, K.-I.; Katayama, Y.; Asoh, S.; Ohta, S. Hydrogen acts as a therapeutic antioxidant by selectively reducing cytotoxic oxygen radicals. Nat. Med. 2007, 13, 688–694. [Google Scholar] [CrossRef] [PubMed]

- Hanaoka, T.; Kamimura, N.; Yokota, T.; Takai, S.; Ohta, S. Molecular hydrogen protects chondrocytes from oxidative stress and indirectly alters gene expressions through reducing peroxynitrite derived from nitric oxide. Med. Gas Res. 2011, 1, 18. [Google Scholar] [CrossRef] [PubMed]

- Kong, L.; Chen, C.; Mou, F.; Feng, Y.; You, M.; Yin, Y.; Guan, J. Magnesium particles coated with mesoporous nanoshells as sustainable therapeutic-hydrogen suppliers to scavenge continuously generated hydroxyl radicals in long term. Part. Part. Syst. Charact. 2019, 36, 1800424. [Google Scholar] [CrossRef]

- Penders, J.; Kissner, R.; Koppenol, W.H. ONOOH does not react with H2: Potential beneficial effects of H2 as an antioxidant by selective reaction with hydroxyl radicals and peroxynitrite. Free Radic. Biol. Med. 2014, 75, 191–194. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Xie, F.; Yi, Y.; Zhao, P.; Zhang, X.; Zhang, X.; Zhang, X.; Ma, X. Hydroxyl-radical scavenging activity of hydrogen does not significantly contribute to its biological function. BioRxiv 2021. [Google Scholar] [CrossRef]

- Hancock, J.T.; LeBaron, T.W.; Russell, G. Molecular hydrogen: Redox reactions and possible biological interactions. React. Oxyg. Species 2021, 11, 17–25. [Google Scholar] [CrossRef]

- Hancock, J.T.; Russell, G.; Craig, T.J.; May, J.; Morse, H.R.; Stamler, J.S. Understanding Hydrogen: Lessons to Be Learned from Physical Interactions between the Inert Gases and the Globin Superfamily. Oxygen 2022, 2, 578–590. [Google Scholar] [CrossRef]

- Yun, Z.; Gao, H.; Chen, X.; Duan, X.; Jiang, Y. The role of hydrogen water in delaying ripening of banana fruit during postharvest storage. Food Chem. 2022, 373, 131590. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Li, P.; Wang, Y.; Gu, R. Hydrogen-rich water delays postharvest ripening and senescence of kiwifruit. Food Chem. 2014, 156, 100–109. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Qiu, W.; Fang, X.; Zhao, X.; Xu, X.; Li, W. Hydrogen-rich water treatment of fresh-cut kiwifruit with slightly acidic electrolytic water: Influence on antioxidant metabolism and cell wall stability. Foods 2023, 12, 426. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhang, J.; Hao, H.; Feng, Z.; Chen, M.; Wang, H.; Ye, M. Hydrogen-rich water increases postharvest quality by enhancing antioxidant capacity in Hypsizygus marmoreus. AMB Express 2017, 7, 221. [Google Scholar] [CrossRef] [PubMed]

- Dong, W.; Shi, L.; Li, S.; Xu, F.; Yang, Z.; Cao, S. Hydrogen-rich water delays fruit softening and prolongs shelf life of postharvest okras. Food Chem. 2023, 399, 133997. [Google Scholar] [CrossRef] [PubMed]

- An, R.; Luo, S.; Zhou, H.; Zhang, Y.; Zhang, L.; Hu, H.; Li, P. Effects of hydrogen-rich water combined with vacuum precooling on the senescence and antioxidant capacity of pakchoi (Brassica rapa subsp. Chinensis). Sci. Hortic. 2021, 289, 110469. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, G.; Cheng, P.; Yan, X.; Li, Y.; Cheng, D.; Wang, R.; Chen, J.; Shen, W. Nitrite accumulation during storage of tomato fruit as prevented by hydrogen gas. Int. J. Food Prop. 2019, 22, 1425–1438. [Google Scholar] [CrossRef]

- Hu, H.; Li, P.; Shen, W. Preharvest application of hydrogen-rich water not only affects daylily bud yield but also contributes to the alleviation of bud browning. Sci. Hortic. 2021, 287, 110267. [Google Scholar] [CrossRef]

- Yang, F.; Wang, T.; Deng, X.; Dang, J.; Huang, Z.; Hu, S.; Li, Y.; Ouyang, M. Review on hydrogen safety issues: Incident statistics, hydrogen diffusion, and detonation process. Int. J. Hydrogen Energy 2021, 46, 31467–31488. [Google Scholar] [CrossRef]

- Alwazeer, D. Reducing atmosphere drying as a new technique for the preservation of the color of dried foods. J. Inst. Sci. Tech. 2018, 8, 125–131. [Google Scholar]

- Alwazeer, D.; Bulut, M.; Çelebi, Y. Hydrogen-rich water can restrict the formation of biogenic amines in red beet pickles. Fermentation 2022, 8, 741. [Google Scholar] [CrossRef]

- Alwazeer, D.; Elnasanelkasim, M.A.; Çiğdem, A.; Engin, T.; Kanmaz, H.; Hayaloglu, A.A.; Russell, G.; Hancock, J.T. Hydrogen incorporation into solvents can improve the extraction of phenolics, flavonoids, anthocyanins, and antioxidants: A case-study using red beetroot. Ind. Crop. Prod. 2023, 202, 117005. [Google Scholar] [CrossRef]

- Alwazeer, D.; Elnasanelkasim, M.A.; Çiğdem, A.; Engin, T.; LeBaron, T.W. Incorporation of molecular hydrogen into solvents increases the extraction efficiency of phenolics, flavonoids, anthocyanins, and antioxidants: The case of lemon peels. Front. Sustain. Food Syst. 2023, 7, 1223027. [Google Scholar] [CrossRef]

- Ceylan, M.M.; Bulut, M.; Alwazeer, D.; Koyuncu, M. Evaluation of the impact of hydrogen-rich water on the quality attribute notes of butter. J. Dairy Res. 2022, 89, 431–439. [Google Scholar] [CrossRef] [PubMed]

- Zor, M.; Bulut, M.; Karagöz, S.G.; Çetintaş, Y.; Alwazeer, D. Use of Hydrogen-Rich water in rice milk preparation improves the nutritional and sensory properties of product. Food Chem. 2024, 437, 137821. [Google Scholar] [CrossRef] [PubMed]

- Bulut, M.; Alwazeer, D.; Tunçtürk, Y. Effects of the incorporation of hydrogen and nitrogen into milk on the reducing and acidification capacities of yoghurt bacteria. J. Food Process. Preserv. 2023, 2023, 7462909. [Google Scholar] [CrossRef]

- Zamuz, S.; Bohrer, B.M.; Campagnol, P.C.B.; Domínguez, R.; Pateiro, M.; Santos, E.M.; Lorenzo, J.M. Lipid oxidation of animal fat. In Food Lipids; Academic Press: Cambridge, MA, USA, 2022; pp. 89–103. [Google Scholar]

- Luo, J.; Liu, S.; Chen, P.; Lu, S.; Zhang, Q.; Chen, Y.; Du, B.; Tang, J.; He, J.; Liao, C.; et al. Fiber optic hydrogen sensor based on a Fabry–Perot interferometer with a fiber Bragg grating and a nanofilm. Lab A Chip 2021, 21, 1752–1758. [Google Scholar] [CrossRef]

- Drago, E.; Campardelli, R.; Pettinato, M.; Perego, P. Innovations in smart packaging concepts for food: An extensive review. Foods 2020, 9, 1628. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, X.; Wang, Z.; Shen, W.; Xu, X. Protective effects of hydrogen-rich water on the photosynthetic apparatus of maize seedlings (Zea mays L.) as a result of an increase in antioxidant enzyme activities under high light stress. Plant Growth Regul. 2015, 77, 43–56. [Google Scholar] [CrossRef]

- Dai, C.; Cui, W.; Pan, J.; Xie, Y.; Wang, J.; Shen, W. Proteomic analysis provides insights into the molecular bases of hydrogen gas-induced cadmium resistance in Medicago sativa. J. Proteom. 2017, 152, 109–120. [Google Scholar] [CrossRef]

- Liu, S.; Zha, Z.; Chen, S.; Tang, R.; Zhao, Y.; Lin, Q.; Duan, Y.; Wang, K. Hydrogen-rich water alleviates chilling injury-induced lignification of kiwifruit by inhibiting peroxidase activity and improving antioxidant system. J. Sci. Food Agric. 2022, 103, 2675–2680. [Google Scholar] [CrossRef]

- Alwazeer, D.; Tan, K.; Örs, B. Reducing atmosphere packaging as a novel alternative technique for extending shelf life of fresh cheese. J. Food Sci. Technol. 2020, 57, 3013–3023. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, J.; Kuang, Y.; Shen, W. Packaging with hydrogen gas modified atmosphere can extend chicken egg storage. J. Sci. Food Agric. 2021, 102, 976–983. [Google Scholar] [CrossRef] [PubMed]

- Jiang, K.; Zhang, Y.; Cai, C.; Lin, W.; Li, L.; Shen, W. Hydrogen-based modified atmosphere packaging delays the deterioration of dried shrimp (Fenneropenaeus chinensis) during accelerated storage. Food Control. 2023, 152, 109897. [Google Scholar] [CrossRef]

- Alwazeer, D.; Özkan, N. Incorporation of hydrogen into the packaging atmosphere protects the nutritional, textural and sensorial freshness notes of strawberries and extends shelf life. J. Food Sci. Technol. 2022, 59, 3951–3964. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Ruiz-Garcia, L.; Qian, J.; Yang, X. Food packaging: A comprehensive review and future trends. Compr. Rev. Food Sci. Food Saf. 2018, 17, 860–877. [Google Scholar] [CrossRef]

- Abohamzeh, E.; Salehi, F.; Sheikholeslami, M.; Abbassi, R.; Khan, F. Review of hydrogen safety during storage, transmission, and applications processes. J. Loss Prev. Process Ind. 2021, 72, 104569. [Google Scholar] [CrossRef]

- Britz, W.; Dudu, H.; Fusacchia, I.; Jafari, Y.; Roson, R.; Salvatici, L.; Sartori, M. Economy-Wide Analysis of Food Waste Reductions and Related Costs; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Bajželj, B.; Quested, T.E.; Röös, E.; Swannell, R.P. The role of reducing food waste for resilient food systems. Ecosyst. Serv. 2020, 45, 101140. [Google Scholar] [CrossRef]

- Younas, M.; Shafique, S.; Hafeez, A.; Javed, F.; Rehman, F. An overview of hydrogen production: Current status, potential, and challenges. Fuel 2022, 316, 123317. [Google Scholar] [CrossRef]

- Finke, C.E.; Leandri, H.F.; Karumb, E.T.; Zheng, D.; Hoffmann, M.R.; Fromer, N.A. Economically advantageous pathways for reducing greenhouse gas emissions from industrial hydrogen under common, current economic conditions. Energy Environ. Sci. 2021, 14, 1517–1529. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).