Abstract

The main purpose of this study is to research the literature and examine how logistics companies can effectively integrate modern digital technologies of Industry 4.0 internally and then present the most critical steps and conditions that determine the successful operation of an innovative business model in logistics, as well as the expected benefits of this process. This study was written entirely as a literature review. Four steps of literature review research were completed: (a) initial formulation of the problem, (b) search of literature sources, (c) selection and evaluation of articles, and d) final classification and presentation of data. The results show that the most critical steps and conditions that contribute to the successful adoption of new Industry 4.0 technologies in the business models of logistics companies are Business Model Innovation, Digital Transformation, Quality 4.0, Human Resource Management, and Logistics 4.0. These critical prerequisites and Industry 4.0 architecture are now at the forefront of logistics, proving the key role they play in modernizing a business and gaining competitive advantage, and to fully reap these benefits, businesses must be prepared to adapt their organizational culture, embrace change, and invest in the necessary resources.

1. Introduction

Industry 4.0 is a concept that is becoming more and more familiar these days and concerns further activities and sectors. Industry 4.0 is no longer a future fad, but something that is emerging at a dizzying pace, radically changing the way we deal with established processes and bringing the concept of “innovation” to the fore. The aspects of Industry 4.0 not only refer to manufacturers and factories but also even more so to the customers themselves, as the whole approach is based on the ever-increasing and changing demands of customers.

In short, the term “Industry 4.0” was originally adopted by a German strategic program, in an attempt to capture the relationship between many different elements of the manufacturing sector and the innovative technologies that now compose the new industrial [1].

Of course, for the concept of “Industry 4.0” to have an impact on the processes and overall functioning of a company, it should first include technological, procedural, organizational, and digital transformation [2]. Creating an innovative business model is a big challenge for every business and organization. This is mainly due to the ever-changing environment, intense competition, globalization, crisis situations, etc. [3,4,5].

The modern customer is now more informed and demands more immediate and efficient results from the market, and it is imperative for every organization to develop a new business structure that includes the methodical use of available information and the automation of processes [6,7].

A business model is influenced by several factors that ultimately determine its success. The two main factors that influence a business model are employee skills and organizational culture. Industry 4.0 is a collective concept that describes the technique of innovation and the organization of the value chain, thus offering a revolution in the manufacturing industry [8,9]. Although it is directly linked to mechanical equipment and modern technologies, it also includes its humanitarian side and the role that people play. Employees should be fit and able to continuously develop the ability to learn [10,11].

The terms Industry 4.0 and Logistics 4.0 are becoming more and more congruent as a result of the technological revolution. One of the industries affected by Industry 4.0 is most likely the supply chain. Fulfilling customer demands in an effective and efficient manner is the main goal of supply chain and logistics. Increasing speed, productivity, flexibility, and transparency, lowering prices, and eliminating waste are basic goals of logistics [12,13].

The main objective of this paper is to outline and examine the fundamental steps and conditions that evolve into a cutting-edge Logistics 4.0 business model. Then the question raised to facilitate this work is: How can a company in the logistics industry successfully assimilate the Industry 4.0 architecture and ultimately gain a competitive advantage?

The work is divided into five sections. Section 2 refers to a brief literature review of the critical steps and conditions that determine the effectiveness of a business model, with extensive references to innovative business models, digital transformation, Quality 4.0, human resources, and Logistics 4.0. This was followed by Section 3 on the research methodology for the preparation and the final result of the study. Section 4 presents the results of the bibliographic research. In Section 5, a discussion of the results is presented, while Section 6 concerns the final outcome of the conclusions.

2. Theoretical Background

2.1. Innovative Business Models in Industry 4.0

Today’s frenetic pace of technological innovation has created a business environment more complex and ambiguous than ever before. These developments significantly prevent traditional business models from maintaining their competitive advantage, as flexibility and speed come to the fore in new markets, which in turn require new forms of organizing value creation [14]. Thus, although technological innovation itself is critical to meeting the demands of today’s markets, it must be accompanied by a sound innovative business model structure and enable businesses to compete successfully. The relationship between technological innovation and innovative business models is actually much more complex and multifaceted, and it is far more than necessary for the competitive advantage of businesses [15,16].

It was clarified that the right business models improve the capabilities of companies to respond effectively and immediately to the intense changes in the modern business environment [17]. Business models essentially mediate the commercialization of new technologies and they can be a source of innovation in themselves and also help other types of innovation by promoting technological innovation, harnessing it, eliciting it, and further encouraging the element of innovation, including cross-industry technology, leading to the merging of previously separate technologies into new business applications [18,19]. Therefore, in the age of Industry 4.0, the competitive advantage of businesses depends on more than only the technology itself, but rather also how it is “transformed” into business models [20,21].

Typically, a business model can be seen as a system of directing resources, including social, through interdependent activities focused on value creation and the delivery and capture of value [22,23]. The enterprise value architecture and the tools that support the development of value propositions are considered to be the first dimension of value creation. They usually have to do with how resources and processes are set up. The second most important element of a business strategy is giving value to the customer, as expressed through utility, emotional value, and social value. The third dimension examines how an organizational strategy generates income and profits for the company by converting the value supplied to customers [24,25]. It should be noted at this point that Industry 4.0 aims to innovate primarily because doing so enables the production, delivery, and acquisition of distinctive value and competitive advantage. Innovations aim to benefit both consumers (new goods, new customer service techniques, etc.) and businesses (environmental protection, new technology, new value chains, greater productivity, etc.). Comparable business models could be an indicator of organizational innovation, which is crucial for competitiveness [20,26].

The implementation of Industry 4.0 has resulted in the identification of four stages of strategies for innovation-based business models. According to [27,28,29], the following stages of these models are mentioned:

- Process optimization, both internal and external: This shift placed a heavy focus on incremental innovation, which enhances a company without necessitating major changes. New technologies are only implemented when the architecture of value creation (key resources and activities) is optimized to boost performance and productivity (lower costs, time and failure rates, train personnel, etc.) without taking significant risks.

- This specific incremental innovation focuses on improving value delivery (value proposition through product and service offerings, customer segment, channels, and customer interactions) in order to improve the user experience.

- Based on the core principles of sharing uncertainty with other actors, focusing on the primary activity (core or unique company activities), and obtaining new critical skills and resources from partners, the real business model that this model presents offers radical innovation. Utilizing this idea is now feasible thanks to technologies like Big Data, Cloud Computing, Augmented Reality, and Virtual Reality. This strategy establishes a close relationship between the business’s value-creation process and that of the other stakeholders.

- A brand-new business model based on cutting-edge technologies and emphasizes, among other things, big data, cloud computing, etc., in order to provide cutting-edge and intelligent products and services, is introduced in new business models that focus on intelligent products and services. Therefore, it is required to make a major innovation that modifies almost every aspect of the business model.

In general, the main purpose of the business model is to fulfill its strategic objectives concerning the flow of production and added value. The notion of added value is essential to the total effectiveness of the business model; thus, it should be built on the tripartite “technological changes-process changes-social changes” [30].

In this case, the question that arises is what are the critical conditions that frame the strategic objectives of a business model that is able to highlight added value as a tool of differentiation? There is no clear answer to this question because each company has identified different conditions related to the production process; the only thing that is certain is that the key to all of them is the vertical processes in the value chain, and according to [28,31] are as follows:

- Integration of planning and programming processes.

- Digitized process automation.

- Real-time quality control.

- Structured processes and activities in real time and end-to-end.

- Personalized and online organized procedures.

- Customer-centric online ordering system.

- Maintaining core technologies oriented towards online principles.

- Personalized and online organized planning, control, and production improvement.

2.2. Digital Transformation

Logistics 4.0 is the evolution of logistics with the ultimate goal of increasing customer satisfaction, based on their requirements and in combination with reducing overall costs [32]. A company should be able to provide what customers want and need as a result of the digital transformation it has undergone, as well as address supply chain issues with regard to inventory control and boost internal productivity [33]. Due to this fact, customer service standards can be raised, production can be optimized, and production and storage expenses can be decreased [34].

Logistics 4.0 is heavily influenced by digital technologies, especially in terms of Mobile Services, the Internet of Things (IoT), Augmented Reality (AR), and Cloud and Big Data [35]. Digital technology in turn brings about changes in the consumer behavior of the customer and the market, so companies need to transform their business model and the set of processes they follow, through digitization, in order to finally achieve an effective response [36,37].

Digital transformation is based on how companies innovate their business model. New digitally transformed companies enter the market with an innovative business model, while incumbents still rely on the existing business model as part of their business, and while the market and customers change, incumbents need to develop new skills and innovate the business model they apply [7]. Therefore, company digitalization encourages changes in sociocultural (i.e., attitudes, beliefs, and behaviors) and technical aspects (i.e., material elements like processes and goods) [38,39]. In this sense, strong leadership behaviors are needed for the digitization projects that Industry 4.0 supports. In a similar vein, some significant obstacles to the digitization of businesses include poor change management, a deficiency of digital culture and strategy, and developing nations in particular, where the socioeconomic climate creates extra challenges for deeper digitization [40,41].

The significance of leadership in digitizing companies highlights the need for them to consider leadership development in their strategies for digitization. Businesses that can identify issues with these leadership traits early on may have an advantage over competitors because changing behavior takes time and effort, and outcomes are frequently observed over a long period of time. Furthermore, this can help companies avoid wasting resources and educate and grow their executives in the wrong ways, allowing processes to be prioritized [42,43].

There are many potential uses of digital transformation for Industry 4.0 and the degree to which they manifest may depend on the interactions of many elements, such as [39,44]:

- Top management involvement and commitment.

- Organizational strategy.

- Digitization of the supply chain.

- Smart products and services.

- Digitization of the organization.

- Adaptation of workers in Industry 4.0.

In summary, digitization has an impact on every industry, whether it is through the replacement of old products with digital ones or the addition of new digital features to existing items. In any instance, businesses should first take into account the needs of their customers before implementing the necessary adjustments within the organization. The most uncertain challenge is this one [45,46].

2.3. Quality 4.0 and Logistics

The establishment of Industry 4.0, technological progress, and digitization have created significant transformation opportunities in manufacturing, technical practices, and systems in several businesses [47]. Quality as a concept in manufacturing industries and service organizations mainly refers to conformance to product design and customer requirements. Quality is the main means of attracting customers and enhancing their satisfaction, which has a leading role in the viability of businesses in a competitive environment [48].

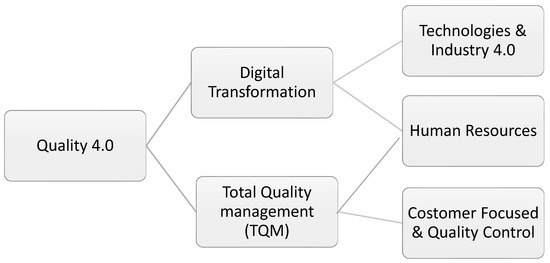

The utilization of contemporary technology developed from Industry 4.0 and digital transformation is primarily what is meant by the phrase “Quality 4.0”. Quality is now depicted as a strategy in a company and is now considered an integral part of a business model, driven by the active involvement of executives and employees [49,50]. Within the scope of Total Quality Management (TQM), Industry 4.0 components are blended with traditional quality management approaches with the ultimate goal of creating new, optimum conditions for the quality of goods and services. This integration is referred to as “Quality 4.0” [51]. Quality 4.0 also explores the role of quality at a time of increasing automation and digitization of employment [52]. Digital tools are used for quality management in Quality 4.0. These cutting-edge tools make it possible to offer clients high-quality goods and services, giving businesses a much-needed competitive advantage. These tools increase operational effectiveness inside a company, lower nonconformance and defect rates, and guarantee on-time deliveries, manufacturing output, and supply chain adaptability [53,54]. In a nutshell, Quality 4.0 is a branch of Industry 4.0 that aims to improve quality through clever solutions and algorithms. Quality 4.0 does not in any way replace or degrade the present quality management methodologies; rather, it augments them with Industry 4.0 Technologies [55,56]. The basic architecture of Quality 4.0 is given in Figure 1.

Figure 1.

The basic Architecture of Quality 4.0.

Quality 4.0 in logistics refers to the application of Industrial Transformation (IX) methodologies and emerging digital technologies to transform quality management and achieve step-change improvements in the value chain across product development, suppliers, operations, logistics, and customer experience [57].

In the context of logistics, Quality 4.0 involves leveraging digital advancements to enhance quality processes and outcomes. For example, it can lead to better tracking, real-time monitoring, and optimization of logistics operations, ultimately improving overall supply chain efficiency and customer satisfaction. Emerging digital technologies are transforming logistics processes on a large scale. Despite a growing body of knowledge about individual use cases ranging from collaborative robots to platform-based programming systems at the forefront of Logistics 4.0 industrial development, organizations lack a systematic understanding of the opportunities that digital technologies bring to quality control [57,58].

At the forefront of Logistics 4.0 industrial development, digital technologies such as artificial intelligence (AI), blockchain, cloud computing, and the Internet of Things (IoT) are driving automation and planning from performing planned quality control tasks to a level where functions are (partially) performed autonomously and information is shared in an inter-organizational environment of physical processes in cyberspace [59].

In recent years, the Quality 4.0 paradigm has slowly begun to expand into the logistics sector. However, Logistics 4.0 is still at an early stage of adoption: some sectors, such as warehousing, are still exploring its applicability, and the technological implementation of this paradigm may become unclear. A company’s digital awareness and readiness is a major influencer, while the barriers and critical points are primarily technological, safety and security, and financial in nature [58,59].

2.4. Human Resources and Logistics 4.0

The pace of change brought about by Industry 4.0 in regard to how work is organized is unprecedented, as was to be expected. Industry 4.0, as it is commonly known, involves cutting-edge technologies that encourage the interconnection of people, processes, products, and services (e.g., Internet of Things (IoT), Big Data, etc.) [30,60].

The digitization of processes, the influx of massive amounts of data, and the adoption of Industry 4.0 technologies (such as simulation, cloud computing, autonomous robots, the Internet of Things (IoT), additive manufacturing, etc.) led to the creation of new data in processes for production and logistics, as was already mentioned. Smart processes and smart goods are two categories of innovations produced by these criteria [61,62]. One of the main problems of Industry 4.0 today is the need for changes in the workforce, which will need to be trained and qualified to be able to develop high problem-solving and decision-making skills in an environment of extreme complexity [63].

New standards for employee talent and skill are set by Industry 4.0 and Logistics 4.0. According to numerous studies, Industry 4.0 has resulted in a 6% rise in employment overall, but automation has also led to the displacement of low-skilled manual laborers and increased demand for software and IT technologies, which has led to an increase in the need for professional developers. Additionally, businesses need to implement fresh approaches to the development and management of their people resources. However, the workforce distribution—that is, the number of employees with each set of skills—should be in accordance with the coverage of consumer demand [64].

In the context of Industry 4.0, a variety of talents for employees is crucial. Collaboration skills amongst various corporate divisions, strategic thinking, computer proficiency, general work aptitude, leadership, culture protection, and information security are a few of these [65].

The human aspect in Logistics 4.0 is proving to be one of the most critical to address. People in the supply chain can be divided into two stations based on the variety of functions they perform [66,67]:

- Role replacement by technology.

- Technology support and performance enhancement.

The phrase “Logistics 4.0” is frequently used to describe logistics systems that take full advantage of employee skill sets and are adaptable to changing market conditions and consumer demands. The Logistics in Industry 4.0 aims are as follows [47]:

- Decision-making and support in the dualities of big data analytics to automate decision-making processes or assist human decisions based on data.

- The identification of unique materials and linkage to IoT technologies and smart sensors that can do so will improve product tracking and tracing in and out of plants.

- Real-time access to data and information from many sources is made possible by the information flow that occurs as a result of its systems integration, which also makes use of cloud computing.

- Automation, robots, and new manufacturing techniques will bring about new products and intelligent/smart transportation systems that can support or replace manual labor in manual jobs.

In any case, it is clear that Logistics 4.0 can successfully support both physical processes related to, for example, material handling, storage, or transport, as well as management processes mainly related to resource planning.

However, it is evident that a new scenario requiring close collaboration between humans and machines is emerging in modern logistics. Within this framework, responsibilities pertaining to internal and external logistics fall into two areas of support for new technologies. The first relates to internal concerns [68,69,70]:

- Known as material flow handling technologies, these technologies include external human augmentation to improve human performance, prevent workplace injuries, and facilitate the lifting and moving of heavy objects. They also include assistive wheeled robots that transport materials to assembly stations. Logistics operators may now use data analysis tools thanks to the Visual Analytics solution, which transforms data into reliable knowledge.

- Information flow management technologies include hands-free workstations with better facility signage and navigation, video conferencing between staff members for group problem-solving, and mobile devices that allow users to access digital dashboards and related data while taking inventory.

Finally, with regard to external logistics, the following observations are made [67,70,71]:

- Material flow management technologies, which mostly refer to intelligent cargo handling tools (like trucks, cranes, and forklifts) and share real-time data about their location and status to help logistics operators with management tasks and equipment control (like identifying idle time and bottlenecks, keeping track of maintenance status, etc.), are also covered in this section. Also included are smart containers that can exchange real-time data about various characteristics such as location, temperature, humidity, CO2 level, and vibra-tactile level.

3. Materials and Methods

The successful operation of a business model in logistics with the contribution of Industry 4.0 technologies involves a multifaceted approach that is highly dependent on many critical steps and conditions. Contributing knowledge about these steps and conditions can significantly promote the successful implementation and establishment of logistics business models incorporating Industry 4.0 technologies, enhancing efficiency, competitiveness, and sustainability in the logistics industry. In this particular research field, previous studies have extensively reported a wide range of prerequisite functions that determine the successful implementation of a business model in Industry 4.0, but what is observed is that there are many conflicting goals from researcher to researcher. Many aspects are presented as critical steps and conditions, but without elucidating in the literature the basic central body of the most critical steps in a business model, with the greatest concern for the new technologies adopted from the Industry 4.0 side. Therefore, this paper aims to shed light on this complexity by providing a brief literature review on new trends in business models based on Industry 4.0 technologies, as well as identifying the most critical prerequisite steps and conditions at the core of a business logistics model.

In this study, the literature review follows the guidelines set by the systematic literature review (SLR) standard. The SLR methodology technique is particularly useful as it meticulously summarizes the available research in response to research questions [72]. In addition, the inclusion and exclusion criteria are visible, with two attempts to reduce the papers, and according to this technique, we can obtain a more targeted list of papers [73]. In this paper, this review technique has been of great help in exploring the various steps and conditions that play a catalytic role in the business models of logistics companies and then in narrowing down the options to the most critical ones that have the greatest relevance to the new digital age of Industry. 4.0.

The SLR is of scientific major importance as it derives from its emphasis on the systematic identification and collection of all available information on a particular subject. Based on this information, it is possible to identify a specific trend for the topic or field of study. This literature review is designed in a structured way that can be updated in the future with the findings of the latest developments, making further study relatively easy. In addition to data analysis, the methodology was further supported by content analysis. Content analysis can be described as a systematic technique in which certain words (codes) in a text are summarized into categories [74]. Similarly, for this review, research thematic areas were constructed based on a combination of quantitative and qualitative content analysis.

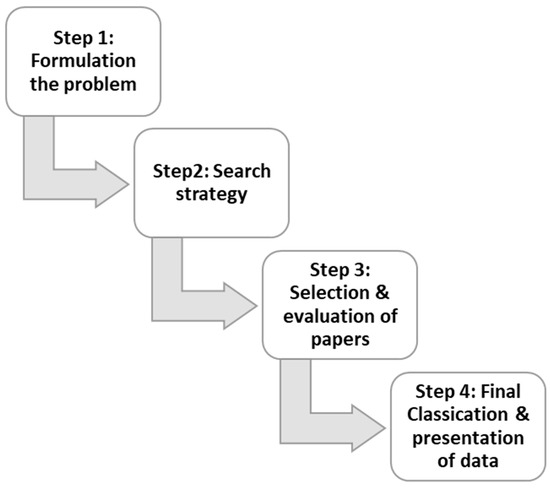

The procedure for the literature review was conducted in 4 main steps. These steps are (1) problem formulation, (2) search strategy, (3) task selection and evaluation, and (4) final classification and presentation of data. Figure 2 shows the stages of the work methodology followed.

Figure 2.

The steps of the bibliographic review process.

- Step 1:

- Formulation of the problem

Like any research, the starting point here is the initial formulation of the problem. First, an initial literature survey was conducted to clarify the dominant trends concerning business models in the Industry 4.0 era, and then we combined these dominant trends with their application in the field of logistics. In the second stage, after evaluating the framework and the different research methods, it was found that in addition to the new technologies of Industry 4.0 and the challenges, benefits, obstacles, and future prospects, the most important is the stage concerning the functions that must take place in a business model in order to successfully adapt to the architecture and philosophy of Industry 4.0. Therefore, this research is based on this framework and the trends of the literature that have emerged in recent years, with an extensive effort to identify the gaps and problems related to critical operational conditions.

In order to facilitate problem identification and research directions, the following questions were asked:

RQ1.

How can logistics companies effectively integrate Industry 4.0 technologies with existing systems and ensure interoperability?

RQ2.

What are the critical steps and conditions required for the successful implementation of a business model in logistics?

RQ3.

What are the potential financial and competitive advantages for organizations that successfully implement Industry 4.0 applications in their logistics operations?

- Step 2:

- Search strategy

When searching for literature sources, what must be determined from the beginning is what search strategy will be used and how the research questions will be converted into keywords. In this case, research questions RQ1, RQ2, and RQ3 have been formulated based on our own research rationale for the research topic in the corresponding literature survey, which aimed to clarify the dominant trends regarding what prevails in logistics business models, in line with data from the Industry 4.0 era. The variety of relevant keywords was firstly identified and recorded, and secondly, search strings were developed from identified keywords, which dominate the concept of trends concerning a business model in logistics in the respective search channels. Google Scholar and Academia were used as search channels in the international literature. The selection was based on the fact that these two search engines provided the most results with the greatest relevance to the research topic and methodology.

The next step was to clearly define the search strings from the identified bibliography keywords drawn from the search. To select the appropriate strings, we filtered the data collected from the initial literature search and came up with the concepts that have the most relevance to the objective of our study, which is to investigate the critical steps and assumptions that take place in a logistics business model, always combined with the concept of Industry 4.0. The search strings used in the search bases were “Innovative Business Models in Industry 4.0”. Terms with various variations were then used, such as “Logistics 4.0”, “Digital Transformation in Industry 4.0”, “Human Resources in Industry 4.0”, and “Quality in Industry 4.0”. By applying the search strings to Google Scholar and Academia online search databases, the total number of papers retrieved was 684. After studying these 684 papers, we ended up including those most relevant to the Industry 4.0 era and that are also included in our research philosophy. The total number of papers included in this methodological step amounts to 213.

- Step 3:

- Selection and evaluation of papers

After searching for bibliographic sources in the aforementioned search engines, the process of selecting and evaluating the works was carried out, with the primary objective of excluding duplicates and works of low quality or relevance to the topic. Then, to determine the theme of the papers, their abstract and keywords were thoroughly read. In order to make the results more targeted in the search for the problem under consideration, some restrictions such as journal publishers, publication dates, and language were set. In this context, it was decided to consider papers only from reputable publishing houses of well-known journals (a high index of academic and research credibility) such as MDPI, Elsevier, Taylor & Francis, Emerald, IEEE Advancing Technology for Humanity, etc. At the same time, because the topic is still in an early research stage, most of the works on the critical conditions and functions for the implementation of Industry 4.0 in logistics enterprises are reported from 2019 onwards. Therefore, we made a selection mainly with studies referring to the last 2–3 years in order to be closer to the observed future trends. Regarding the publication language, English was chosen due to the volume of publications and the cut.

- Step 4:

- Final classification and presentation of data

After the completion of the selection and evaluation of the works, a categorization of the works was created according to the subject under consideration and the type of research referred to. The categories created based on this list are Business Model Innovation, Digital Transformation, Quality 4.0, Human Resource Management, and Logistics 4.0 in the era of Industry 4.0. This process is vital for any researcher to make the literature management and data presentation process as easy as possible. To better serve this purpose, the online bibliography management application Mendeley 2.84.0 was used, which provides the ability to organize the bibliography with the ability to easily read the abstract and categorize the papers.

The findings collected from the literature were examined for their thematic unit and content and were presented in the form of descriptive statistics through visual diagrams and written comments.

4. Results

Through descriptive analysis, it is possible to identify trends and the big picture in a set of data. In this paper, there is a series of analyses concerning the whole of the bibliographic research and specifically the papers of the research journals that were collected. For this purpose, specific guidance variables were used, e.g., the year of publication, the source of the paper, the subject area of the papers, and the keywords used.

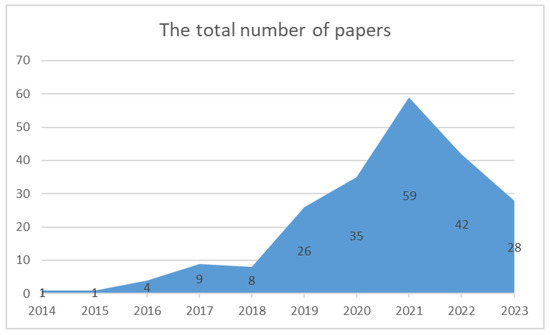

First, the total number of papers after using all of the aforementioned keywords used in academic research search engines is presented. From what can be seen, the research field around the concept of Industry 4.0 is quite new, especially regarding the critical processes in business models in the logistics industry, and this can be seen from the fact that the trend from 2019 onwards until the end of 2023 seems to trend upward with a peak in 2021 (see Figure 3). At the same time, it seems that before 2019, the number of research papers on the subject under consideration was very small, which is because the term Industry 4.0 was introduced in mid-2011 and references in the literature were mainly about the innovative technologies introduced in modern industry without giving too much weight to the research foreground of critical conditions and functions, while in recent years, several research parameters of the term Industry 4.0 have been added to many fields, with many future visions.

Figure 3.

The total number of papers found in the search process.

As mentioned, this research examines research papers from reputable academic and research journals in the English language. Table 1 lists the scientific journals found to have the greatest contribution to the topic of critical processes in business models based on the concept of Industry 4.0 and critical business processes (i.e., they have presented more than five bibliographic references within the study).

Table 1.

Journals with the greatest contribution to the study.

From the table above, it can be seen that most of the papers come from ‘Sustainability’, a journal with a very large number of papers dealing with the topic of sustainable development in many research fields. Next, most journals correspond to the field of manufacturing technology management, with an emphasis on industrial applications (Journal of Manufacturing Technology Management, Procedia Manufacturing, and Procedia CIRP), which is to be expected due to the industry-first nature of the subject matter. Equally important is the contribution of The TQM Journal and International Journal of Quality & Reliability Management, two journals with a very large contribution of theoretical and practical knowledge in the quality and reliability process, as in the last 2 years, it has been observed that the terms Industry 4.0 and quality are closely related, especially when it comes to critical processes. Nevertheless, the rest of the works should not be omitted, which investigate a variety of research fields related to applied sciences (Applied Sciences) from each research field of Industry 4.0. Meanwhile, the fact that papers on specific fields have also been reported in journals that involve computer science, mathematics, social sciences, etc., shows that the research field around Industry 4.0 has expanded to many scientific fields in recent years.

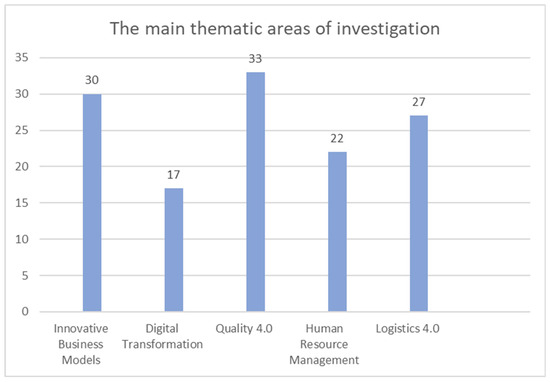

The keywords used to search for substantive data represent the thematic areas identified for conducting the present research (i.e., the identification of critical conditions and functions for the successful implementation of an innovative business model in logistics with the contribution of Industry 4.0). The thematic areas identified during the research process, always guided by the concepts of Industry 4.0 and Logistics, are Innovative Business Models, Digital Transformation, Quality 4.0, Human Resource Management, and Logistics 4.0. After applying the restrictions and final ranking of the papers, a total of 129 papers were selected for detailed investigation. Figure 4 shows the main research topic areas, with all papers classified for review.

Figure 4.

The subject areas of investigation and the final sets of papers selected for review.

In addition, as shown in Figure 4, the largest number of works concerns the thematic area of Quality 4.0, followed by Innovative Business Models and Logistics 4.0. This is mainly due to the fact that the specific thematic sections include works that have been published with great frequency in the last 2–3 years and are currently in the spotlight, which does not imply that the rest are lagging behind but rather that these are the main activities of intense interest with a greater future orientation. In the discussion of the results that follows, reference is made to the dominant trends arising from the above thematic areas, as well as to the main concerns that arise.

5. Discussion

5.1. Main Trends and Concerns

Using a literature review, we had the opportunity to highlight the evolutionary future elements of a specific field regarding the critical steps and conditions in an Industry 4.0 business model in logistics, at the same time bringing to the surface emerging trends and concerns in the respective field of study.

In the first phase, the most dominant trend concerning the logistics industry is the Application of Industry 4.0 Technologies and how they can be integrated into the operations of the business to improve performance and efficiency. The Internet of Things (IoT), Cloud Services, and Big Data Analytics are the technologies with the biggest impact on the way logistics businesses operate in comparison to other Industry 4.0 technologies [75]. Of course, in this case, the importance of digital transformation should be emphasized, as it is the basis for the integration of Industry 4.0 technologies in all aspects of business, fundamentally changing the way it operates and providing value to customers. At the same time, digital transformation strongly emphasizes the importance of business model innovation in logistics companies that want to make the most of Industry 4.0 technologies [8]. At the same time, it should be noted that logistics companies should also focus on developing smart products that communicate with each other as well as with the existing system. This relationship is equally important to the literature as it highlights the development of new Industry 4.0 technologies while examining their impact on business models [76].

Another trend that has recently come to the fore is the strengths and skills SMEs need to successfully implement Industry 4.0. In this case, it is emphasized that it is not necessary for SMEs to use all the resources and capabilities of Industry 4.0 but rather to focus on identifying and prioritizing the main skills and resources needed to effectively exploit the benefits of Industry 4.0. In this regard, SMEs can develop these key resources and capabilities both internally (through process and product innovation focused on digital technologies, human resource management practices, and top management commitment) and externally (through the recruitment of skilled workers and through networks of creative collaboration). In this case, the key to this venture is change management, which in turn determines the successful implementation of new technologies and business models [13,77]. The only thing that is certain is that change management starts with learning and training programs to help staff members acquire new skills required by Industry 4.0. On the other hand, the concept of training in the light of Industry 4.0 is somewhat complicated, especially for SMEs, as it requires a significant change in training and work design, especially for qualitative elements of work organization and the human–computer interface, and it is one of the biggest challenges faced by businesses in the era of Industry 4.0 [64]. In addition, typical industrial personnel lack the necessary digital proficiency to handle the complexity of Industry 4.0 technologies. In the end, staff training practices and risk management are highly interrelated skills in trying to establish an effective operating model with a well-developed culture that minimizes the possibility of crises within companies or possible “embarrassment” in external events [78].

A distinct trend that has become increasingly identified with Industry 4.0 and logistics is the early stages of Quality 4.0 and its accompanying processes. These accompanying processes include the assessment of readiness for an organization. Generally, in the literature, such tools are observed that can classify an organization according to how prepared it is to implement Quality 4.0 and the vestibule of the Industry 4.0 architecture [55]. These readiness tools are mainly the preliminary stage of exploring the key aspects required to move from traditional quality methods such as total quality management, quality assurance, and quality control to a new quality approach closely related to the era of Industry 4.0 and its technologies. In this case, several factors influencing readiness for the transition to Quality 4.0 are mentioned, such as leveraged technology adoption, training, new skills, infrastructure, government service, top management support, strategy and vision, collaboration, awareness, knowledge, customer and supplier focus, and organizational culture. All of these in turn have the basic purpose of automating processes in a business, improving the quality, efficiency, accuracy, and speed of business operations, and thus capturing the concept of business model innovation [54].

The implementation of new business models in logistics companies is not at all an easy task, and it can lead to various challenges and concerns, but at the same time, it offers opportunities for improvement and development. The main concern for logistics companies is that they need to consider how Industry 4.0 technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and robotic solutions, can be directly integrated into their business models. These technologies, as mentioned earlier, if implemented correctly can improve the efficiency of logistics businesses by increasing the accuracy of inventory tracking, improving the efficiency of storage and distribution processes, and enabling more efficient supply chain management; however, the application of these technologies requires significant investment, both in terms of capital and training and skills development. In addition, companies must address data security and privacy issues, as well as adapt to new legislative and regulatory requirements [63].

As can be seen from the literature, this concern is even greater for small and medium-sized enterprises (SMEs), which find it difficult to implement a comprehensive digital strategy, as large internal upheavals and significant investments are required, while the lack of a culture for change, the inability to undertake significant risks, and the lack of digital skills create significant barriers to innovation and digital transformation. This is especially relevant in countries that show a great lack of background for the adoption of Industry 4.0 technologies, such as Greece, where, in fact, companies have very low investments in innovation and technological development, which also contributes to their low digital maturity [79]. Also, a necessary condition is the creation of complex forms of cooperation and collaborations between the private sector, the state, innovation ecosystems, and the education system. Despite the challenges and concerns, the implementation of new innovative business models in the field of logistics can provide significant benefits, such as improved efficiency, reduced costs, and increased customer satisfaction.

5.2. Main Trends and Concerns

Through a review of the literature, critical answers were given regarding the initial research questions posed and are presented in detail below:

RQ1.

How can logistics companies effectively integrate Industry 4.0 technologies with existing systems and ensure interoperability?

Integrating Industry 4.0 technologies, as has been achieved before, into logistics companies can be a complex process, but it is certainly possible and can bring significant improvements to the supply chain. Here are some key steps to consider [80]:

- Understanding the opportunities: Industry 4.0 technologies provide opportunities to improve the financial performance, environmental performance, and social impact of logistics sectors. It is important to give special consideration to these opportunities and how they align with the company’s goals.

- System Integration and Digital Twin: Focus on system integration and digital twin technologies. These can help with a virtual representation of physical assets, enabling better planning and decision making.

- Human-Centered Technological Transformation: In any case, technological transformation is human-centered. This means that the technology should be designed to work seamlessly with the existing workforce.

- Collaboration and integration: Logistics 4.0 is able to collaborate and integrate with Industry 4.0 processes and systems. This integration can create a common and synergistic relationship between shippers, manufacturers, and end users.

- Addressing challenges: The challenges in this case do not stop, as more and more emerge. In addition to the main ones mentioned above, there are also those related to different sustainability indicators, unclear benefits, environmental impacts in the life cycle, issues of inequality and technological maturity, etc.

Certainly, understanding the opportunities presented by the new technologies of Industry 4.0 is crucial for logistics companies that want to take full advantage of these possibilities and integrate them internally. When it comes to improving financial performance, cost reduction is certainly a primary goal, where Industry 4.0 technologies such as IoT sensors, AI-based analytics, and automation can optimize business processes, reduce inefficiencies, and minimize costs associated with transportation, inventory management, and labor. At the same time, improved marketability, forecasting accuracy, and customer satisfaction enabled by Industry 4.0 technologies can lead to increased sales, improved offers, and new revenue streams [80,81].

In terms of environmental performance, the integration of IoT-enabled smart devices and sensors can monitor energy consumption and optimize resource use, leading to reduced carbon emissions and energy costs. In addition, optimization algorithms and route planning tools can minimize fuel consumption and carbon footprint by optimizing transport routes, load consolidation, and vehicle scheduling, which can, in combination with advanced technologies such as RFID and blockchain, enable end-to-end traceability and authentication, facilitating the adoption of sustainable packaging practices and circular supply chain models [80,82].

In terms of societal impact, robotics and automation can reduce the risk of workplace accidents and injuries by automating hazardous tasks and enhancing workplace safety protocols. At the same time, Industry 4.0 technologies can improve employee productivity, job satisfaction, and skill development by automating repetitive tasks, providing real-time feedback and enabling remote collaboration [81].

System integration facilitates the seamless exchange of data between various hardware and software components within the logistics ecosystem. It enables real-time visibility into critical operational metrics such as inventory levels, shipment statuses, and vehicle locations. By integrating different systems such as TMS, WMS, ERP, and IoT platforms, logistics companies can streamline workflows, automate manual tasks, and optimize resource allocation [83].

Also, integrated systems provide decision makers with access to accurate, timely, and actionable information derived from centralized data sources. This enables informed decision-making at all levels of the organization, from strategic planning to day-to-day operations [80].

On the other hand, a digital twin is a virtual representation of physical assets, processes, or systems that reflect their behavior and characteristics in the real world. In logistics, digital twins can model warehouses, distribution centers, transportation networks, and even individual products or vehicles. Digital twins allow logistics companies to simulate and model different scenarios, such as changes in demand, disruptions in supply chains, or modifications to operational processes. This allows organizations to anticipate potential challenges, evaluate alternative strategies, and optimize the use of resources. By combining real-time data from IoT sensors with digital twin models, logistics companies can leverage predictive analytics to predict future trends, identify emerging risks, and proactively address potential issues. This proactive approach enhances resilience, flexibility, and responsiveness in the face of dynamic market conditions [84].

Absolutely, the concept of Human-Centered Technological Transformation emphasizes that technology should be designed and implemented in a way that complements and enhances human skills and capabilities. It is not just about introducing new technologies into the workplace but also about ensuring that these technologies are user-friendly and intuitive and add value to the tasks and processes they are designed to support. This approach recognizes that the success of technological transformation depends largely on its acceptance by the people who will use it. Therefore, understanding the needs, preferences, and limitations of the workforce is crucial. This can be achieved through methods such as user research, usability testing, and iterative design. Moreover, training and support should be provided to help the workforce adapt to new technologies. This can help to alleviate any fears or resistance that may arise due to the introduction of new technologies and can also help to ensure that the workforce is able to use the technology effectively and efficiently [85].

The integration of Logistics 4.0 with Industry 4.0 processes and systems can lead to significant benefits. This collaboration can create a synergistic relationship between shippers, manufacturers, and end users, leading to improved efficiency, transparency, and customer satisfaction because both Logistics 4.0 and Industry 4.0 are heavily data-driven. By sharing data between systems, organizations can gain a more complete understanding of their operations and make more informed decisions. At the same time, Logistics 4.0 technologies can provide real-time tracking of goods. When integrated with Industry 4.0 systems, this can enable real-time visibility of the entire supply chain, from production to delivery [86].

It should be noted that the journey towards Industry 4.0 and Logistics 4.0 is fraught with challenges that extend beyond the technical and operational aspects. Therefore, by addressing these challenges proactively and holistically, logistics companies can navigate the complexities of technological transformation while promoting sustainability, equity, and innovation in their industry [86].

In summary, there are three key challenges that logistics companies need to consider, according to the literature. The first is related to the development and training of human resources. Training workers and developing their skills to meet the changing needs of new types of work developed by the industry is always a major challenge in human resource development. As with all previous “revolutions” in industrial activity, Industry 4.0 involves complex interactions between humans and machines and leads to the creation of new industries, professions, and forms of employment. The day-to-day responsibilities faced by logistics workers are becoming more difficult as this revolution takes shape [87]. They must become extremely flexible and show adaptive skills in a highly dynamic work environment in order to handle this complexity. As a result, in the near future, the logistics workforce’s skills and capabilities must be developed in order to keep up with Industry 4.0 innovations [88]. Four workforce competencies, namely personal, social/interpersonal, action-related, and domain-related, are recognized. Regarding personal skills, there will be a greater need for a workforce that is creative, imaginative, and communicative as a result of a shift away from tedious, taxing, and somewhat “isolated” occupations. Employees in this interpersonal setting will be in charge of a greater number of processes; thus, in order to handle any disruptions and come up with solutions, they must be able to comprehend the connections between various processes, information flows, and technological specifics. It takes a more active and domain-relevant set of skills to accomplish this effectively. The workforce of the future will require highly developed analytical abilities, a foundational understanding of statistics and data analysis techniques, and the capacity to evaluate whether systems and subsystems are operating as intended while interacting with them via suitable interfaces [89].

The second challenge is creating the infrastructure required to integrate Industry 4.0 technology into contemporary logistics. Logistics procedures, which may involve transportation outside the confines of a manufacturing or storage site, require an infrastructure that is both adaptable and scalable and offers the networking and communication tools required [90]. Even though sensors and actuators are relatively simple hardware components, creating a cooperative and fully functional Industry 4.0 ecosystem is a challenging task, particularly when it comes to autonomous logistics and visibility, network node interoperability, successful integration that is free from errors and conflicts in the logistics business environment, and processing the information gathered to create useful decision support. Cloud computing, which provides the required level of flexibility and scalability to any installation, is by definition the technological foundation of all Logistics 4.0 installations, even though it is not usually stated as such in the literature. When demand grows and additional processing power is needed, a well-planned cloud-based solution along with a well-thought-out growth strategy from a technological and financial standpoint could avoid needless turbulence and delays. Simultaneously, if well-engineered, it may ensure seamless and economical integration with recently introduced devices and applications, as well as excellent data flow management and analysis.

The third challenge concerns the adoption and development of technology, which is currently hindered or postponed due to insufficient legislative frameworks, insufficient standardization initiatives, and a lack of a comprehensive security strategy for Industry 4.0 facilities [91]. Logistics systems face an extremely difficult task as a result of the security concerns of Industry 4.0. A hostile third party can use the several hundred access points found in even the most typical smart distribution center to pose a serious threat. In addition to causing financial damage and consumer misery, a basic malware attack can also cause accidents or even deaths if it targets large automation. A solid basis for future standardization efforts for security in the Industry 4.0 era is provided by established standards like ISO/IEC 27000 [92] for information security and IEC-62443 [93] for cybersecurity [94]. To address the security concerns that have an impact on the technology’s global adoption and application rates, further work must be conducted. One may argue that the industrial community is far from accomplishing standardized goals if they were to deviate from the norm regarding security in technical implementation, management, and interoperability standards. Industry 4.0 is now in terrible shape, and individual efforts, even those that rely on best practices, fail to produce implemented solutions that are resilient, scalable, and reliable.

In any case, it is always true that the integration of Industry 4.0 technologies in logistics is not only about adopting new technologies but also about transforming the way your company operates. It requires a strategic approach and a clear understanding of the company’s needs and capabilities.

RQ2.

What are the critical steps and conditions required for the successful implementation of a business model in logistics?

As mentioned in the theoretical background of this paper, the most critical steps and conditions for the effective operation of business models in logistics are (1) business model innovation, (2) digital transformation, (3) Quality 4.0, (4) human resources management practices, and (5) Logistics 4.0.

The key points about how Industry 4.0 affects business model innovation in logistics are mainly about the digitization of supply chains, which in turn enables companies to address new customer demands, challenges on the supply side, and expectations for improved efficiency. This includes putting sensors on everything, building networks everywhere, automating everything, and analyzing everything to significantly improve performance and customer satisfaction [95]. On top of that, the online trend of recent years has led to increased service expectations combined with a much stronger distribution of orders. There is also a very clear trend towards further personalization and customization that is driving strong growth and constant change in a business’s portfolio. In addition to the need to adapt, supply chains also have the opportunity to reach the next horizon of operational efficiency, take advantage of emerging digital supply chain business models, and integrate their business into the new digital supply chain. Moreover, the application of Industry 4.0 technologies in logistics is not only about survival in today’s competitive market but also about prosperity through the improvement of logistics performance. It requires companies to rethink their business models and adapt to the changing landscape [96].

Digital transformation is playing a dominant role in reshaping industrial logistics. The rapid advancement of digital technologies has fundamentally changed the competitive dynamics of the logistics industry, forcing logistics service providers (LSPs) to go digital. This includes using digital platforms to integrate businesses and create single interfaces for contracts and customer service. The main digital innovation that is strongly observed in the industry is the development of autonomous vehicles, where the largest logistics companies such as DHL and UPS are investing in research to develop autonomous delivery vehicles [97]. They see it as a way to reduce costs and increase efficiency by automating parcel delivery. Another important example of digital innovation is automation. By automating tasks, internal operations can save manual labor and lower logistics costs. It allows more time for the logistics team to find ways to optimize workflows using automation [98]. These innovative actions and the shift to the digital age are transforming the logistics industry, making it more flexible. Companies can now manage supply chain operations more efficiently with elastic logistics [99].

Quality 4.0 is indeed a critical aspect of the Industry 4.0 revolution, especially in the field of logistics. It represents the application of digital technologies to improve quality management systems, making them more efficient and effective. This transformation can lead to improved product quality, reduced defects, and increased customer satisfaction. A primary role in this is played by IoT devices that can monitor and collect data on product quality in real time, enabling immediate feedback and rapid response to any issues [100]. In addition, advanced data analytics and machine learning algorithms can predict quality issues before they occur, enabling proactive quality control. Ultimately, cloud-based quality management systems enable seamless integration and real-time collaboration across an organization, and automating quality controls can lead to increased efficiency and consistency in maintaining high-quality standards. By embracing Quality 4.0, logistics companies can not only improve existing quality processes but also innovate new ways to ensure quality in their products and services. It is a transformative approach that aligns with the broader goals of Industry 4.0 [101].

Human Resource Management (HRM) practices play an important role in the logistics sector. HRM practices can be used to encourage supply chain partners to develop valuable inter-firm relationships and establish knowledge-sharing routines. Properly understanding the workforce and its management and making strategic decisions about training and improving them are important issues for supply chain companies [102]. Then to harness the potential of the people in the industry more effectively, it is of the utmost importance to ensure that the right HR strategy is in place to recruit, train, retain, and optimize the workforce. This strategy will depend on the company’s business goals and culture. In any case, technology is a key factor in the success of an innovative business model in logistics, but on the other hand, the best IT applications are incapable without a logistics workforce to manage and operate them. Therefore, investing in HRM practices is crucial to the success of logistics companies [103].

Logistics 4.0 is a key element of Industry 4.0 and is transforming the logistics industry by integrating digital technologies into logistics processes. “Logistics 4.0” specifically refers to the use of Industry 4.0 innovations and technology in modern logistics. Intelligent warehouse management systems, advanced transport management systems, intelligent transport systems, and information security systems are the four technological applications that must be used and built upon in a successful and robust Logistics 4.0 project. According to the recent literature, the increased reliance on technology in Logistics 4.0 makes this a critical and demanding necessity. It is clear that the core value of the Industry 4.0 era is intelligence [104]. The strategic goals of enterprises include the terms “Smart Logistics”, “Smart Products”, and “Smart Services” in this context. According to an operational definition of smart logistics, these are systems that increase flexibility and can adapt to changes in the market, bringing the company closer to the needs of its customers [89].

In addition, Logistics 4.0 enables the immediate exchange of information and the analysis of big data in real time, which are vital for new business models. Digital technologies such as artificial intelligence (AI), blockchain, cloud computing, and the Internet of Things (IoT) are driving automation in logistics. This leads to operations that run (partially) autonomously and share information in a cross-organizational environment of physical processes in cyberspace. At the same time, the demand for sustainability in business creates new demands for production and logistics activities. Logistics 4.0 can help address these sustainability challenges. To also provide opportunities offered by digital technologies for logistics processes, etc., the transition to Logistics 4.0 provides possibilities for new business models. In conclusion, Logistics 4.0 is reshaping the logistics industry by leveraging digital technologies, promoting sustainability, and enabling new business models. It is an important step towards the successful implementation of a business model in logistics [105].

RQ3.

What are the potential financial and competitive advantages for organizations that successfully implement Industry 4.0 applications in their logistics operations?

Industry 4.0 applications can bring significant economic and competitive advantages to organizations in their logistics operations, with the main advantages being [35,106,107,108]:

- Cost reduction: Industry 4.0 technologies such as IoT sensors, predictive analytics, and automation can optimize various aspects of logistics, leading to cost savings through improved efficiency in inventory management, order processing, and transportation.

- Resource optimization: Real-time data from connected devices enables better resource allocation, reducing waste and minimizing excess inventory or underutilized assets.

- Real-time tracking: IoT devices and sensors facilitate real-time tracking of goods throughout the supply chain, providing improved visibility. This can lead to better decision making and more accurate demand forecasting.

- Data-driven Insights: Advanced analytics and machine-learning algorithms can turn collected data into actionable insights, enabling organizations to make informed decisions and quickly adapt to market changes.

- Demand forecasting: Industry 4.0 applications can improve the accuracy of demand forecasting, reducing the risk of overstock or inventory and helping organizations maintain optimal inventory levels.

- Supplier collaboration: Improved communication and data sharing with suppliers through Industry 4.0 technologies can lead to better coordination, faster response times, and improved overall supply chain performance.

- Faster response times: Improved visibility and streamlined processes enable faster response times to customer requirements, leading to higher levels of customer satisfaction.

- Accurate Order Fulfillment: Automation and real-time tracking help ensure accurate and timely order fulfillment, enhancing the overall customer experience.

- Predictive maintenance: IoT-enabled predictive maintenance can reduce the risk of equipment failures, minimizing downtime and potential disruptions to logistics operations.

- Compliance and security: Industry 4.0 applications can improve regulatory compliance and enhance security measures, reducing the risk of legal issues and protecting the supply chain from potential threats.

- Innovation leadership: Organizations that successfully implement Industry 4.0 applications demonstrate leadership in innovation, positioning themselves as forward-thinking and adaptable in a competitive marketplace.

- Flexibility and Agility: The ability to quickly adapt to market changes, demand, or disruptions gives organizations a competitive advantage over those with traditional logistics systems.

- Energy efficiency: Smart, connected systems can contribute to energy efficiency, leading to long-term cost savings and environmental sustainability.

In short, the integration of new Industry 4.0 technologies, which include features such as flexibility, global connectivity, real-time communication, transparency, intelligence, and innovation, contribute more to the context of digital supply chains. The ability to adapt quickly to changing conditions and be operationally flexible is implied by flexibility. The ability to rapidly transport goods and services around the world while maintaining local responsiveness is known as global connectivity. Businesses that lack real-time communication and openness are less prepared for disruptions and are unable to predict and immediately adapt their supply chain to changing conditions [109]. Enhanced capture and automated execution are enabled by intelligence through smart devices that have sufficient processing power to enable autonomous capture and self-learning based on predefined algorithms [110]. Finally, innovation is the characteristic of digital supply chains that makes them almost constantly open to change.

Order fulfillment and transport logistics are the areas of logistics that Industry 4.0 will have the biggest impact on. According to recent research, the use of particular technologies, such as virtual and augmented reality (VR/AR), can significantly increase productivity and enhance the quality of work. In fact, AR applications that let users model, simulate, and analyze 3D environments are already starting to find their way into actual industrial settings. These applications help businesses make better decisions, enhance product flows, and keep a close eye on processes. Simulated processes and 3D printing have also demonstrated benefits for logistical operations, such as improved productivity, efficiency, flexibility, and quality standards [111]. The paradigm changes in modern manufacturing, which is attempting to keep up with the rise in product customization and the enormous expansion in the diversity of variations that businesses are forced to offer, further amplifies the influence of these technologies. Furthermore, shorter cycles of production and distribution have resulted from shorter product life cycles. This is mostly because of the rise in e-commerce, which is currently at an all-time high due to the recent pandemic and is placing pressure on all parties involved in the supply chain. This kind of setting is ideal for additive manufacturing since it does not require sophisticated numerical control (NC) programming or pricey equipment [27]. When additive manufacturing technologies reach a certain level of maturity, they have the potential to completely change supply chains and logistics as they currently exist by doing away with stock availability and travel distances.

Furthermore, the literature [44] also mentions the transportation and storage industries as being heavily impacted by digitization and Industry 4.0 technology. Real-time systems that use auto-identification and sensor technologies to record events and states will allow transportation to respond quickly by allowing for the immediate detection and localization of any disturbance in the system. The primary driver of change in the storage space will be robotic automation and physical systems in cyberspace [112]. Nowadays, robotic technologies are rapidly replacing human labor as a viable economic option, particularly in high-wage industrial economies. The availability and cost of robotics will continue to decrease drastically in the future, significantly affecting the economics of important strategic options such as distribution and manufacturing facilities. If labor costs or other costs of production continue to rise in developing countries, this could be the beginning of a major resumption of activity towards countries with advanced economies.

By realizing these advantages, organizations can significantly improve their financial performance and competitive position in the market. However, it is important to note that the successful implementation of Industry 4.0 requires a clear strategy, investment in technology and skills, and a willingness to embrace new ways of working.

6. Conclusions

As observed by the current study, the application of advanced technologies (IoT, Cloud Systems, Big Data, robotics, etc.), should focus on critical conditions and operations, collaboration, and talent development. This allows logistics companies to streamline their operations, reduce costs, improve overall performance, and ultimately gain the coveted competitive advantage. An approach based on critical business conditions and steps is necessary, and enterprises must prioritize the preliminary stage and the overall readiness perfectly captured through these critical stages in order to successfully enter the Industry 4.0 era and build trust with customers, employees, and partners. As found by the literature research, all the activity of the transition to the era of Industry 4.0 mainly goes through the philosophy of business model innovation, digital transformation, Quality 4.0, human resource management, and the shift to the new generation of logistics—Logistics 4.0.

However, the journey towards innovation is by no means an easy task. Industry 4.0 technologies create, in addition to significant development opportunities, several concerns and challenges for logistics companies. In this context, innovation is more about steps and business conditions and not so much about technologies or manufacturing innovative products. For businesses to fully realize these benefits. they must be prepared to adapt their organizational culture, embrace change, and invest in the necessary resources.

As can be seen, the present research is not exempt from limitations. Starting from the first limitation identified in the creation of the search strings, after the preliminary research of the literature and the search of the functions in business models based on Industry 4.0 in the logistics industry, the search strings that prevailed were “Innovative business models in Industry 4.0”, “Digital Transformation in Industry 4.0”, “Human Resources in Industry 4.0”, “Quality in Industry 4.0”, and “Logistics 4.0”. At the same time, the second limitation is found in the selection of journal publishers, dates of publication, and the language of publication in which English prevails, excluding papers that were in other languages. In this context, it was decided to consider only papers from reputable publishing houses of well-known journals with a high index of academic and research credibility.

The main contribution of the present study concerns the identification of the research direction captured by the literature review process. Business-critical requirements and Industry 4.0 architecture are now at the forefront of logistics, proving the key role they play in modernizing an organization and gaining a competitive advantage in today’s globalized environment. At the same time, the present study provides a framework for practical and theoretical contributions. The practical contribution concerns logistics companies, as it indicates a structure in which they should clarify that it is not enough to only invest in technologies derived from Industry 4.0 to bring them to the fore, but they should first identify the concerns—obstacles that concern both the internal and external environment—and then invest significantly in the critical conditions to finally take full advantage of the advantages of these technologies. The theoretical contribution offers a comprehensive analysis of the existing literature on the research field under study, indicating the importance and necessity of the critical steps and conditions in the field of logistics and the general presentation of the most critical decisions to be taken into account during the introduction phase of the Industrial age 4.0, in a consolidated bibliographic context, as well as with reference to the main concerns and reflections.

Future research in this area should focus on addressing the challenges and opportunities identified in this study. In particular, how logistics companies are redesigning their business models towards the Industry 4.0 philosophy, thus leading to more efficient logistics operations. At the same time, it should be explored in depth how Industry 4.0 can contribute to sustainable logistics practices, including optimizing routes for reduced emissions, better allocation of resources, and reducing waste in the supply chain. In addition, more extensive research should be conducted on the strategies used to develop and adapt business models so that they are flexible enough to thrive in a rapidly changing landscape. In any case, this study encourages logistics companies not to hesitate to continuously innovate their business models, emphasizing critical conditions, and urges researchers to conduct studies based on the main body of critical steps and conditions in various industries and add other critical steps and conditions or data in those arising, depending on the case.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Miqueo, A.; Torralba, M.; Yagüe-Fabra, J. Lean Manual Assembly 4.0: A Systematic Review. Appl. Sci. 2020, 10, 8555. [Google Scholar] [CrossRef]

- Dobrowolska, M.; Knop, L. Fit to Work in the Business Models of the Industry 4.0 Age. Sustainability 2020, 12, 4854. [Google Scholar] [CrossRef]

- Vu, O.T.K.; Duarte Alonso, A.; Buitrago Solis, M.A.; Goyzueta, S.; Nguyen, T.; McClelland, R.; Tran, T.D.; Nguyen, N.; Huynh, H.T.N.; Atay, E. A dynamic capabilities approach of Industry 4.0: The experiences of managers operating in two emerging economies. Eur. Bus. Rev. 2023, 35, 137–160. [Google Scholar] [CrossRef]

- Richard, S.; Pellerin, R.; Bellemare, J.; Perrier, N. A business process and portfolio management approach for Industry 4.0 transformation. Bus. Process Manag. J. 2021, 27, 505–528. [Google Scholar] [CrossRef]

- Varela, L.; Araújo, A.; Ávila, P.; Castro, H.; Putnik, G. Evaluation of the Relation between Lean Manufacturing, Industry 4.0, and Sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef]

- Naeem, H.M.; Di Maria, E. Customer participation in new product development: An Industry 4.0 perspective. Eur. J. Innov. Manag. 2022, 25, 637–655. [Google Scholar] [CrossRef]

- Veile, J.; Schmidt, M.; Voigt, K. Toward a new era of cooperation: How industrial digital platforms transform business models in Industry 4.0. J. Bus. Res. 2022, 143, 387–405. [Google Scholar] [CrossRef]

- Ferrigno, G.; Del Sarto, N.; Piccaluga, A.; Baroncelli, A. Industry 4.0 base technologies and business models: A bibliometric analysis. Eur. J. Innov. Manag. 2023, 26, 502–526. [Google Scholar] [CrossRef]

- Resende, C.; Geraldes, C.; Rodrigues Lima Junior, F. Decision Models for Supplier Selection in Industry 4.0 Era: A Systematic Literature Review. Procedia Manuf. 2021, 55, 492–499. [Google Scholar] [CrossRef]

- Saha, P.; Talapatra, S.; Belal, H.; Jackson, V. Unleashing the Potential of the TQM and Industry 4.0 to Achieve Sustainability Performance in the Context of a Developing Country. Glob. J. Flex. Syst. Manag. 2022, 23, 495–513. [Google Scholar] [CrossRef]

- Agostini, L.; Filippini, R. Organizational and managerial challenges in the path toward Industry 4.0. Eur. J. Innov. Manag. 2019, 22, 406–421. [Google Scholar] [CrossRef]