Selection of the Processing Method for Green Banana Chips from Barraganete and Dominico Varieties Using Multivariate Techniques

Abstract

1. Introduction

Related Works

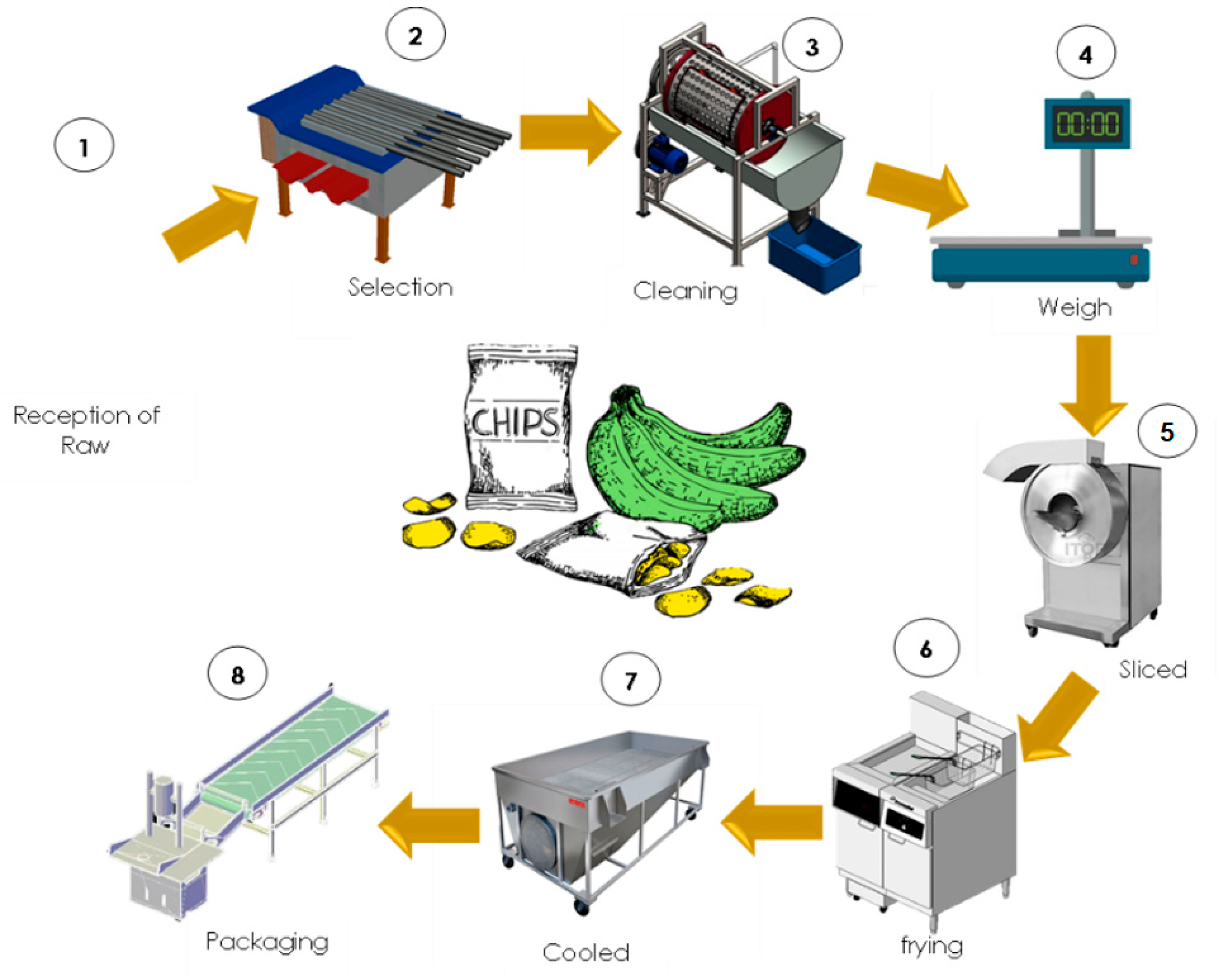

2. Materials and Methods

2.1. Sample

2.2. Determination of Starch, Moisture, Fat, Fiber, Ash, Protein, and Sodium

2.3. Statistical Analysis

3. Results

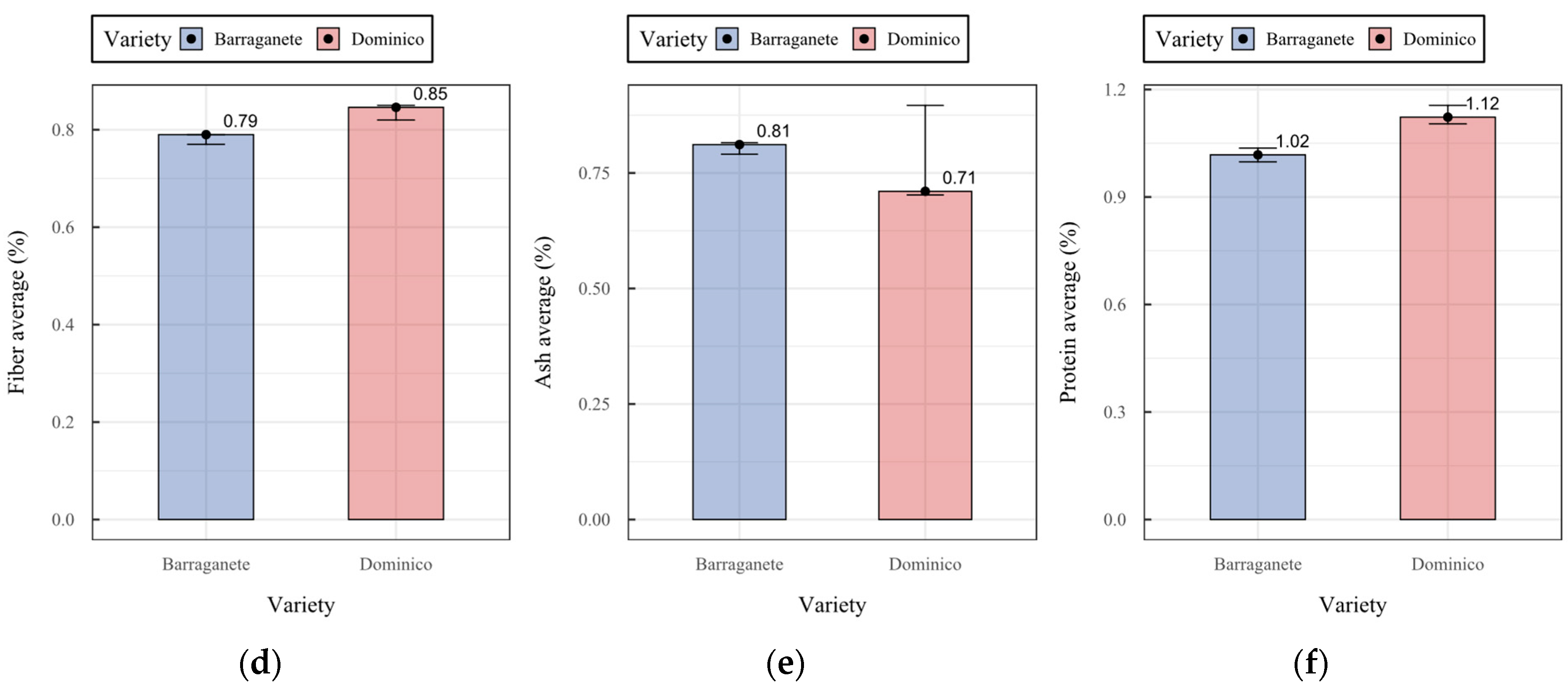

3.1. Raw Material Analysis

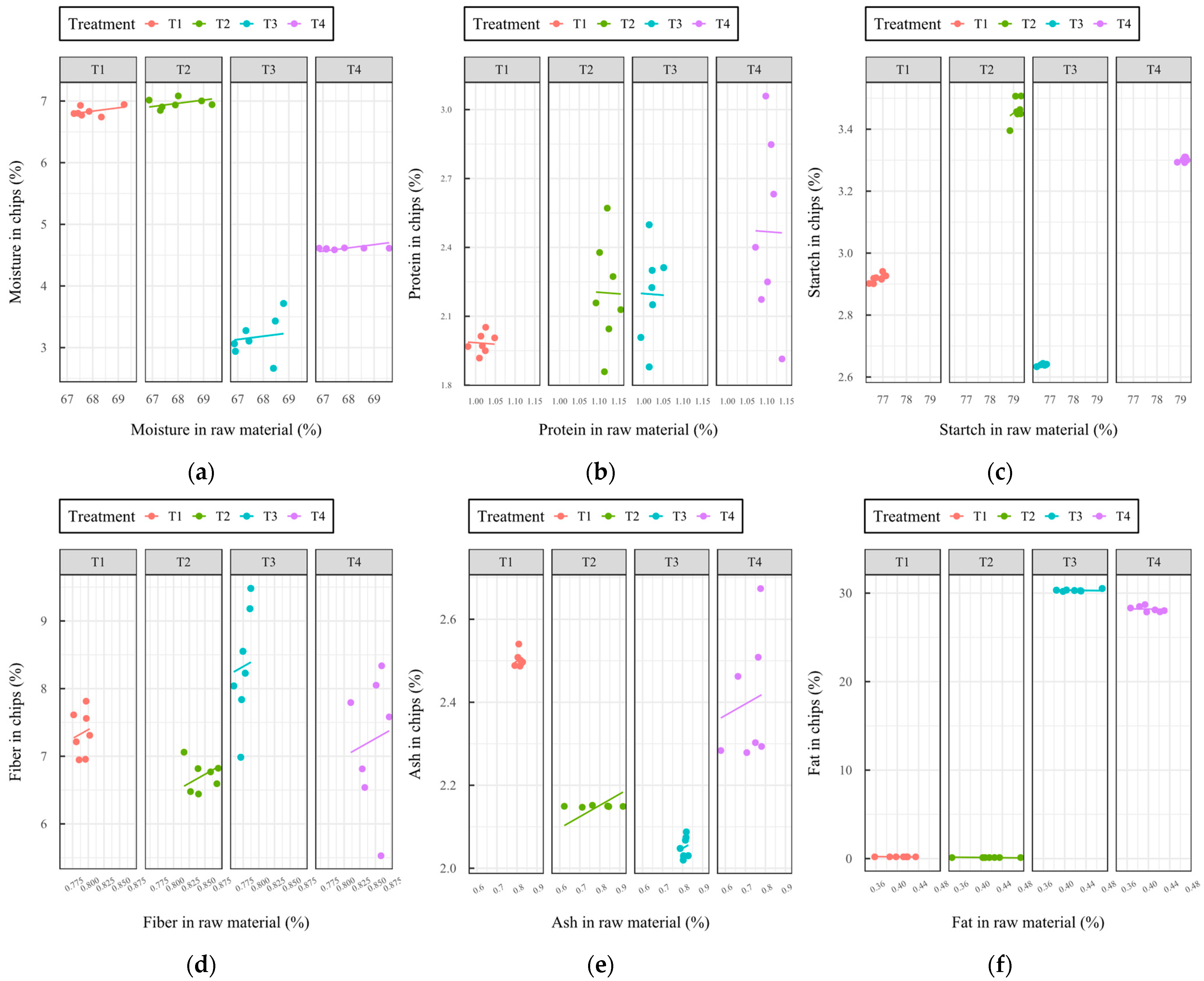

3.2. Analysis of Covariance

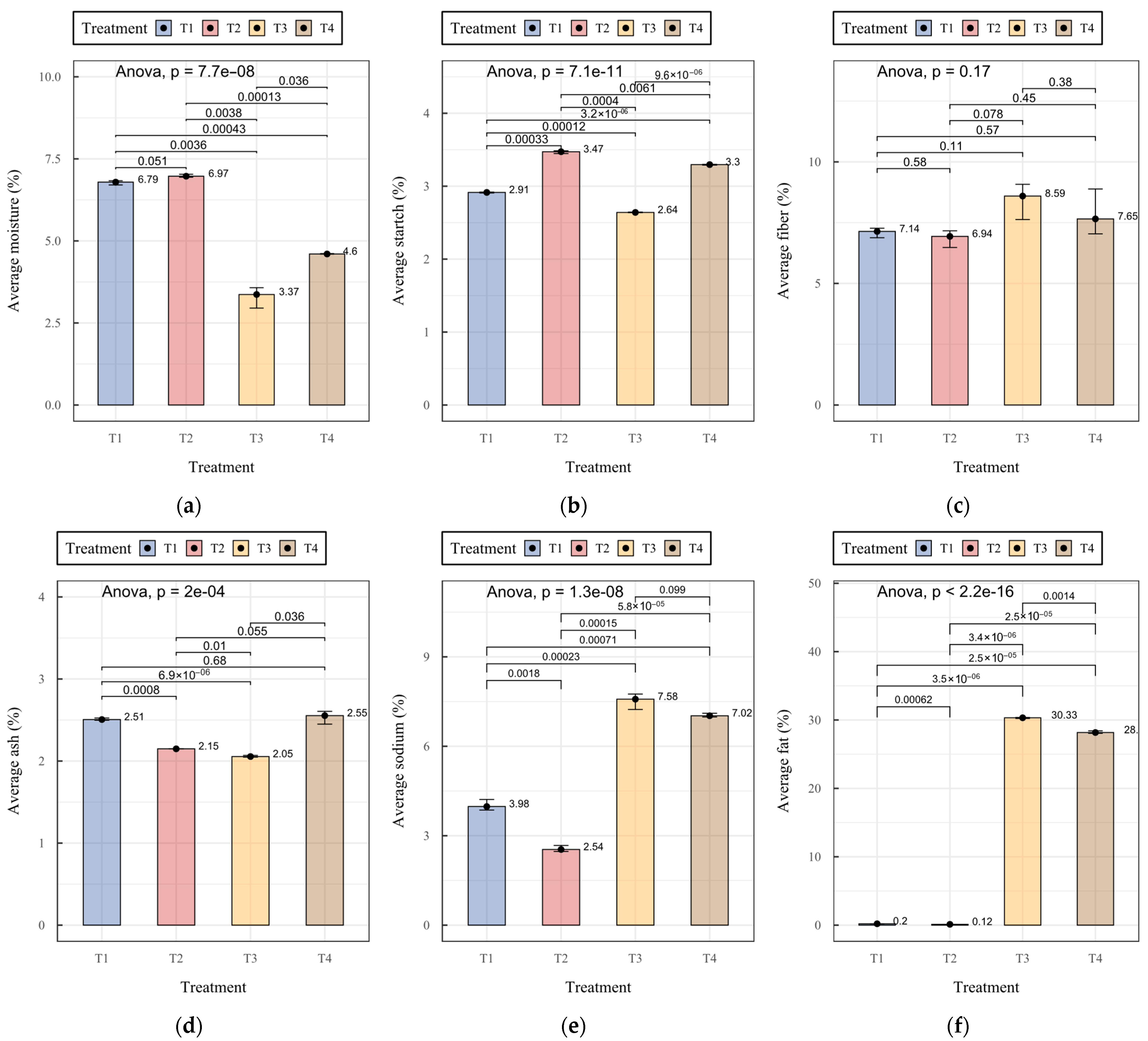

3.3. Analysis of Variance

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aksoy, N.C.; Kabadayi, E.T.; Alan, A.K. An unintended consequence of COVID-19: Healthy nutrition. Appetite 2021, 166, 105430. [Google Scholar] [CrossRef]

- Rizwana, R.; Rao, E.S.; Sondhi, A.; Agarwal, A.; Verma, A.; Kant, K.; Kumar, D. Consumer’s attitude and awareness towards functional foods during COVID-19. Ann. Phytomed. Int. J. 2021, 10, S56–S62. [Google Scholar] [CrossRef]

- Kennedy, E.T.; Ohls, J.; Carlson, S.; Fleming, K.; Kennedy, E.T.; Ohls, J.; Carlson, S.; Fleming, K. The Healthy Eating Index: Design and Applications. J. Am. Diet. Assoc. 1995, 95, 1103–1108. [Google Scholar] [CrossRef]

- Asmalovskij, A.; Sadílek, T. Food quality perception in the Czech Republic: Trial study results. Ukr. Food J. 2016, 5, 186–194. Available online: http://nbuv.gov.ua/UJRN/UFJ_2016_5_1_21 (accessed on 2 December 2023).

- Kowalska, A.; Ratajczyk, M.; Manning, L.; Bieniek, M.; Mącik, R. “Young and Green” a Study of Consumers’ Perceptions and Reported Purchasing Behaviour towards Organic Food in Poland and the United Kingdom. Sustainability 2021, 13, 13022. [Google Scholar] [CrossRef]

- Sobaih, A.E.E. Excessive Food Buying in Saudi Arabia Amid COVID-19: Examining the Effects of Perceived Severity, Religiosity, Consumption Culture and Attitude toward Behavior. Int. J. Environ. Res. Public Health 2023, 20, 3126. [Google Scholar] [CrossRef]

- Oke, E.K.; Idowu, M.A.; Sobukola, O.P.; Adeyeye, S.A.O.; Akinsola, A.O. Frying of Food: A Critical Review. J. Culin. Sci. Technol. 2017, 16, 107–127. [Google Scholar] [CrossRef]

- Garmakhany, A.D.; Mirzaei, H.O.; Maghsudlo, Y.; Kashaninejad, M.; Jafari, S.M. Production of low fat french-fries with single and multi-layer hydrocolloid coatings. J. Food Sci. Technol. 2012, 51, 1334–1341. [Google Scholar] [CrossRef]

- Panang, C.; Thikeaw, K.; Soubsub, K.; Olanwanit, W.; Phahom, T. A correlation between oil measurement methods and the application of principal component analysis for selecting the best pre-frying treatment of reduced-fat banana chips. J. Food Meas. Charact. 2023, 17, 5402–5411. [Google Scholar] [CrossRef]

- Yamsaengsung, R.; Ariyapuchai, T.; Prasertsit, K. Effects of vacuum frying on structural changes of bananas. J. Food Eng. 2011, 106, 298–305. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Lenart, A. Freeze-Drying—Application in Food Processing and Biotechnology—A Review. Pol. J. Food Nutr. Sci. 2011, 61, 165–171. [Google Scholar] [CrossRef]

- Njike, V.Y.; Smith, T.M.; Shuval, O.; Shuval, K.; Edshteyn, I.; Kalantari, V.; Yaroch, A.L. Snack food, satiety, and weight. Adv. Nutr. 2016, 7, 866–878. [Google Scholar] [CrossRef]

- ElAlfy, A.; Palaschuk, N.; El-Bassiouny, D.; Wilson, J.; Weber, O. Scoping the Evolution of Corporate Social Responsibility (CSR) Research in the Sustainable Development Goals (SDGs) Era. Sustainability 2020, 12, 5544. [Google Scholar] [CrossRef]

- Wichaphon, J.; Judphol, J.; Tochampa, W.; Singanusong, R. Effect of frying conditions on properties of vacuum fried banana bracts. LWT 2023, 184, 115022. [Google Scholar] [CrossRef]

- Sapei, L. Proximate composition and functional properties of banana flour at different ripening stages. J. Litbang Ind. 2023, 13, 41–49. [Google Scholar] [CrossRef]

- Martínez, S.; Roman-Chipantiza, A.; Boubertakh, A.; Carballo, J. Banana Drying: A Review on Methods and Advances. Food Rev. Int. 2023, 1–39. [Google Scholar] [CrossRef]

- Murillo, V.Á.; Tamayo, J.C.; Cárdenas, L.M.; León, J.L.; Pájaro, N.M. Ecuador: Diagnosis of the banana export agri-food chain. Rev. Espac. 2021, 42, 1–12. [Google Scholar]

- Hu, S.; Wang, M.; Zhang, X.; Chen, W.; Song, X.; Fu, X.; Fang, H.; Xu, J.; Xiao, Y.; Li, Y.; et al. Genetic basis of kernel starch content decoded in a maize multi-parent population. Plant Biotechnol. J. 2021, 19, 2192–2205. [Google Scholar] [CrossRef]

- Damto, T.; Chala, G. Effect of Blanching and Frying Time on the Sensory Quality of Fried Sweet Potato Chips. Food Nutr. Sci. An Int. J. 2019, 3, 1–17. [Google Scholar] [CrossRef]

- Saguy, I.; Dana, D. Integrated approach to deep fat frying: Engineering, nutrition, health and consumer aspects. J. Food Eng. 2003, 56, 143–152. [Google Scholar] [CrossRef]

- Gupta, P. Physico-chemical changes of fried products during oil and vacuum frying. Pharma Innov. 2023, 12, 1582–1586. [Google Scholar] [CrossRef]

- Ammawath, W.; Man, Y.B.C.; Yusof, S.; A Rahman, R. Effects of variety and stage of fruit ripeness on the physicochemical and sensory characteristics of deep-fat-fried banana chips. J. Sci. Food Agric. 2001, 81, 1166–1171. [Google Scholar] [CrossRef]

- Dueik, V.; Bouchon, P. Development of Healthy Low-Fat Snacks: Understanding the Mechanisms of Quality Changes During Atmospheric and Vacuum Frying. Food Rev. Int. 2011, 27, 408–432. [Google Scholar] [CrossRef]

- Valdiviezo, Y. Análisis del Tipo de aceite y Tiempo de fritura en la Vida Útil del Snack de Malanga (Xanthosoma sagittifolium) Procedente del Tena. Bachelor Thesis, Universidad Técnica de Ambato, Ambato, Ecuador, 2014. [Google Scholar]

- Teruel, M.d.R.; Gordon, M.; Linares, M.B.; Garrido, M.D.; Ahromrit, A.; Niranjan, K. A Comparative Study of the Characteristics of French Fries Produced by Deep Fat Frying and Air Frying. J. Food Sci. 2015, 80, E349–E358. [Google Scholar] [CrossRef]

- Restrepo, S.; Castellanos, F.; Leyton, D. Efecto de la presión sobre los parámetros de calidad (color-textura) de chips de plátano verde durante la fritura por inmersión. Vitae 2016, 23, 283–287. [Google Scholar]

- Gárcia, G.; Duarte, H.; Moncada, L. Determinación del tiempo de cocción en los procesos de freido y horneado de tres alimentos de consumo masiuo en Colombia. Épsilon 2005, 1, 7–18. [Google Scholar]

- Pantoja, D.F.M.; Castaño, M.A.; Barreto, C.I.A.; Galeano, F.J.C. Fritura por inmersión al vacío de rodajas de plátano verde con recubrimientos comestibles. Ing. Compet. 2022, 25, 14. [Google Scholar] [CrossRef]

- Torres, J.; Alvis, A.; Gallo, L.; Acevedo, D.; Montero, P.; Castellanos, F. Optimization of the deep fat frying process of arepa con huevo using response surface methodology. Rev. Chil. Nutr. 2018, 45, 50–59. [Google Scholar] [CrossRef]

- Gómez, M.d.J.G.; Coutiño, L.P.R. Potencial del plátano macho verde para la elaboración de botanas saludables/Potential green plantain to prepare healthy snacks. RIDE Rev. Iberoam. Para Investig. Desarro. Educ. 2015, 3, 20–30. [Google Scholar] [CrossRef]

- Velázquez, M. Elaboración de Botanas de Platano Horneado Enriquecido con Proteina Vegetal. Reporte previo [Instituto Tecnologico de Tuxtla Gutierrez]. 2013. Available online: http://repositoriodigital.tuxtla.tecnm.mx/xmlui/handle/123456789/3082 (accessed on 20 December 2023).

- Montes, N.; Millar, I.; Martínez, N.; Fernández, D.; Morales, G.; Valenzuela, R. Absorción de aceite en alimentos fritos Oil absorption in fried foods. Rev. Chil. Nutr. 2015, 43, 87–91. [Google Scholar] [CrossRef]

- Tejedor, G.; Segalàs, J.; Barrón, Á.; Fernández-Morilla, M.; Fuertes, M.T.; Ruiz-Morales, J.; Gutiérrez, I.; García-González, E.; Aramburuzabala, P.; Hernández, À. Didactic Strategies to Promote Competencies in Sustainability. Sustainability 2019, 11, 2086. [Google Scholar] [CrossRef]

- Erdfelder, E.; Faul, F.; Buchner, A. GPOWER: A general power analysis program. Behav. Res. Methods Instrum. Comput. 1996, 28, 1–11. [Google Scholar] [CrossRef]

- De Normalización, I.E. NTE INEN 2561 (2010) (Spanish): Bocaditos de Productos Vegetales. Requisitos. Instituto Ecuatoriano de Normalización: Quito, 2010; pp. 1–8. Available online: https://www.fao.org/faolex/results/details/es/c/LEX-FAOC098206/ (accessed on 1 December 2023).

- Villamizar, R.H.; Quinceno, M.C.; Giraldo, G.A. Comparación de la fritura al vacío y atmosférica en la obtención de pasabocas de mango (Manguifera indica L.). Temas Agrar. 2011, 16, 64–74. [Google Scholar] [CrossRef]

- Chong, M.; Mazzitelli, G.; Quintero, R. Efecto de los métodos de cocción por fritura en las propiedades fisicoquímicas y sensoriales de chips de taro (Colocasia esculenta). I+ D Tecnol. 2019, 15, 30–37. [Google Scholar] [CrossRef]

- Lucas, J.C.; Quintero, V.D.; Vasco, J.F.; Mosquera, J.D. Evaluación de los parámetros de calidad de chips en relación con diferentes variedades de plátano (Musa paradisiaca L.). Rev. Lasallista Investig. 2012, 9, 65–74. Available online: https://www.redalyc.org/pdf/695/69525875009.pdf (accessed on 2 December 2023).

| Variety | % Starch | % Moisture | % Fat | % Fiber | % Ash | % Protein |

|---|---|---|---|---|---|---|

| t-Statistic | −16.679 | 0.16554 | −15.245 | −4.8 | 0.56665 | −5.8846 |

| 3.9841 | 3.9251 | 3.9862 | 3.6048 | 2.059 | 3.6845 | |

| p-value | 7.784 × 10−5 * | 0.8767 | 4.374 × 10−5 * | 0.01117 * | 0.6266 | 0.005373 |

| Barraganete | 76.702 ± 0.185 a | 67.902 ± 0.803 a | 0.408 ± 0.025 a | 0.783 ± 0.012 a | 0.806 ± 0.013 a | 1.017 ± 0.019 a |

| Domínico | 79.152 ± 0.174 b | 67.785 ± 0.923 a | 0.364 ± 0.049 b | 0.839± 0.016 b | 0.77 ± 0.109 a | 1.128 ± 0.026 b |

| Variety | % Moisture | % Protein | % Starch | % Fiber | % Ash | % Fat |

|---|---|---|---|---|---|---|

| SSn | 0.012 | 0.283 | 0.000287 | 0.298 | 0.006 | 0.017 |

| SSd | 0.359 | 0.205 | 0.003 | 5.671 | 0.054 | 0.119 |

| F-Statistics | 0.229 | 9.672 | 0.756 | 0.368 | 0.793 | 1.028 |

| p-value | 0.647 | 0.017 * | 0.414 | 0.563 | 0.403 | 0.344 |

| ANCOVA Test: Protein ~Protein + treatment | |||

| SSn: 0.283 | SSd: 0.205 | F: 9.672 | 0.017 * |

| Estimated Marginal Means test: Protein ~ treatment; covariate: Protein | |||

| Treatment * | T1 | T2 | T3 |

| T2 | * Significant | ||

| T3 | Not significant | Not significant | |

| T4 | * Significant | Not significant | Not significant |

| MANOVA: Moisture + Protein + Fiber + Ash + Sodium + Fat ~ Treatment | ||||

|---|---|---|---|---|

| Multivariate Test | Df | Test Stat. | Aprox. F | Pr(>F) |

| Pillai | 3 | 3 | 133.6 | 3.6651 × 10−11 * Significant |

| Wilks | 3 | 0 | 2364.9 | 1.6592 × 10−10 * Significant |

| Hotelings–Lawley | 3 | 1,054,353 | 33,471.5 | 2.9876 × 10−5 * Significant |

| Roy | 3 | 1,052,471 | 601,412.2 | 7.1093 × 10−12 * Significant |

| Variable | Moisture (%) | Starch (%) | Fiber (%) | Ash (%) | Sodium (%) | Fat (%) |

|---|---|---|---|---|---|---|

| ANOVAgeneral test | * Significant | * Significant | Not significant | * Significant | * Significant | * Significant |

| Levene’s TestHomogeneity | ||||||

| T1 | 6.7905 a | 2.9148 a | 7.1402 a | 2.5060 a | 3.9794 a | 0.2011 a |

| T2 | 6.9709 a | 3.4728 b | 6.9361 a | 2.1489 b | 2.5383 b | 0.1184 a |

| T3 | 3.3672 b | 2.6403 c | 8.5946 a | 2.0549 b | 7.5799 c | 30.3272 b |

| T4 | 4.6014 c | 3.2960 d | 7.6547 a | 2.5534 a | 7.0242 c | 28.1730 c |

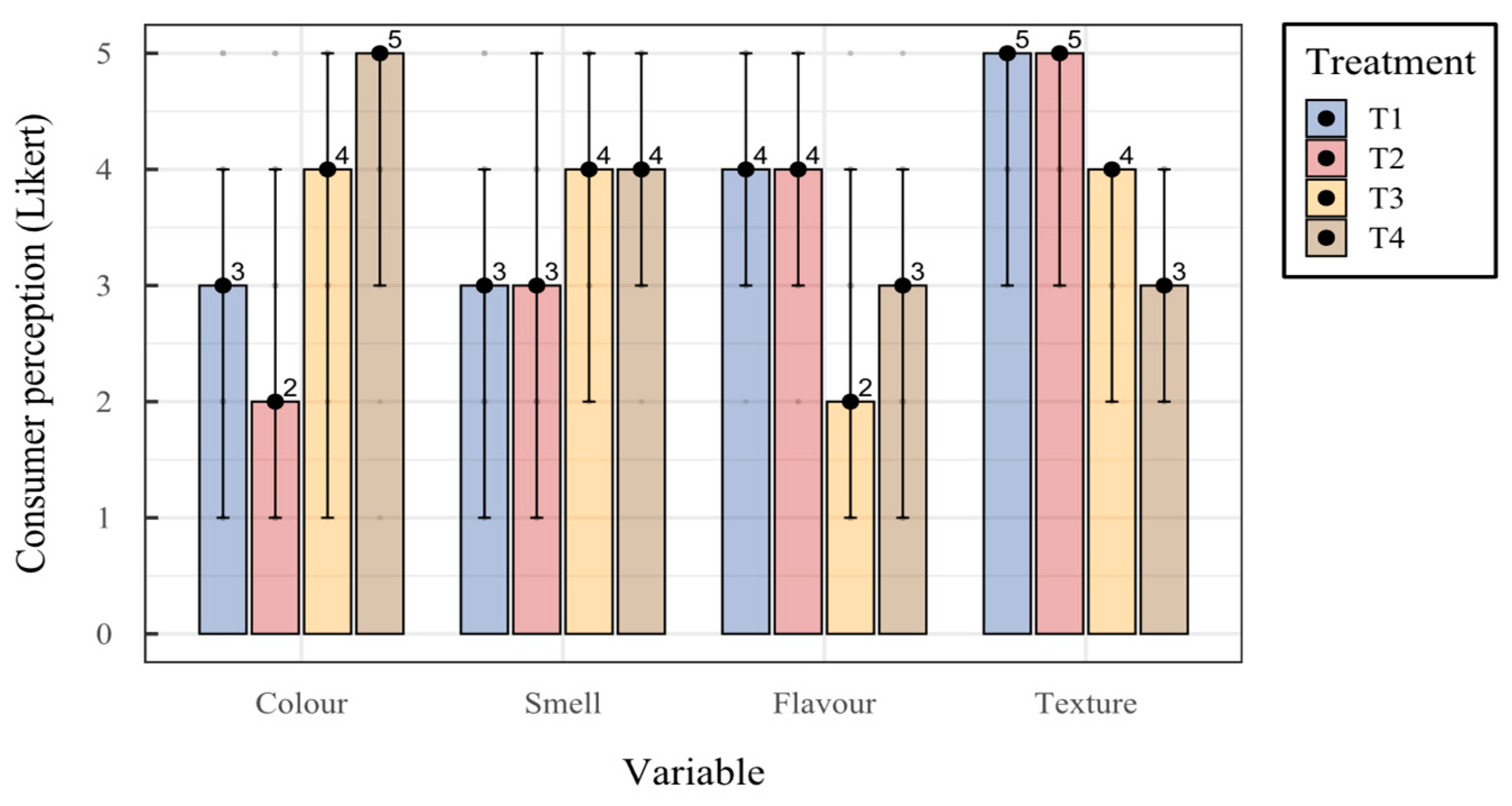

| Method | Color | Smell | Flavor | Texture |

|---|---|---|---|---|

| Kruskal–Wallis general test | ||||

| T1 | 3 a | 3 a | 4 a | 5 a |

| T2 | 2 a | 3 a | 4 a | 5 a |

| T3 | 4 b | 4 b | 2 b | 4 b |

| T4 | 5 c | 4 b | 3 b | 3 c |

| Treatment | Advantages | Limitations |

|---|---|---|

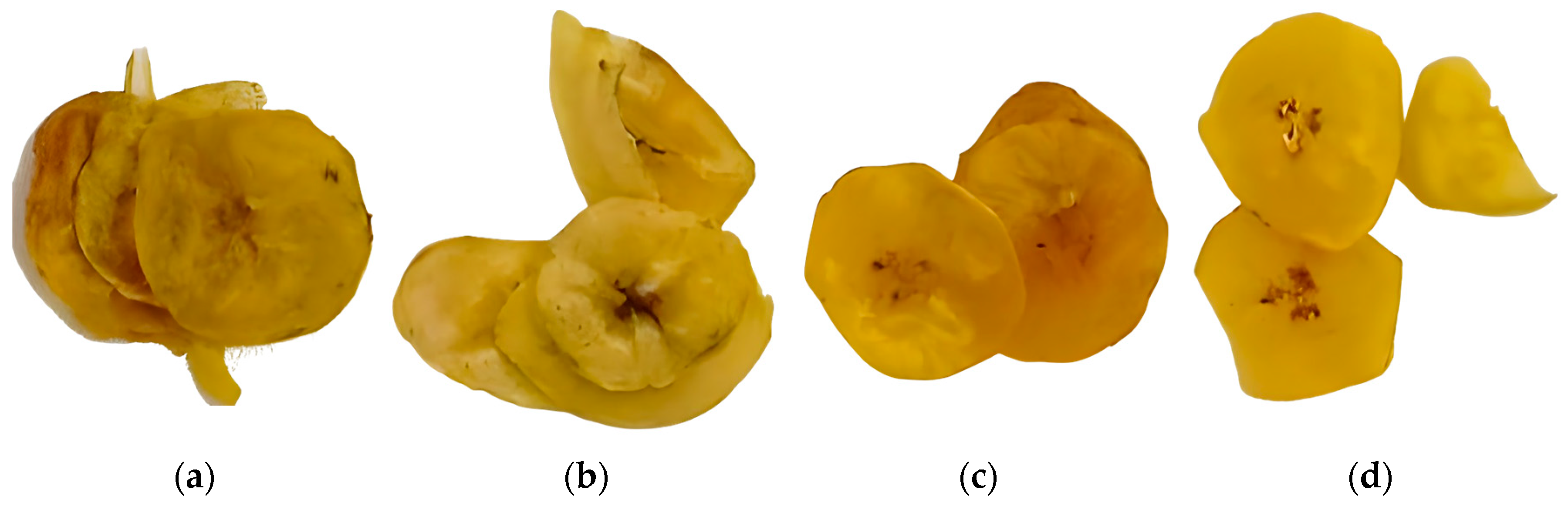

| T1 = Barraganete + Baked | Low levels of sodium and fat. Showed a high but not significant level of fiber. Significantly lower fat content than frying treatments. | Has a high moisture level, exceeding the 5% required by the NTE INEN 2561 standard. |

| T2 = Dominico + Baked | Higher protein content. Higher starch content. Lower sodium content. Lower fat content. | Has a high moisture level, exceeding the 5% required by the NTE INEN 2561 standard. |

| T3 = Barraganete + Fried | Lowest moisture content among all treatments. | Had the highest percentage of sodium and fat among all treatments. |

| T4 = Dominico + Fried | Highest ash content among all treatments. | Ranked second for the highest percentages of sodium and fat. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chamorro-Hernandez, L.M.; Herrera-Granda, E.P.; Rivas-Rosero, C. Selection of the Processing Method for Green Banana Chips from Barraganete and Dominico Varieties Using Multivariate Techniques. Appl. Sci. 2024, 14, 2682. https://doi.org/10.3390/app14072682

Chamorro-Hernandez LM, Herrera-Granda EP, Rivas-Rosero C. Selection of the Processing Method for Green Banana Chips from Barraganete and Dominico Varieties Using Multivariate Techniques. Applied Sciences. 2024; 14(7):2682. https://doi.org/10.3390/app14072682

Chicago/Turabian StyleChamorro-Hernandez, Liliana M., Erick P. Herrera-Granda, and Carlos Rivas-Rosero. 2024. "Selection of the Processing Method for Green Banana Chips from Barraganete and Dominico Varieties Using Multivariate Techniques" Applied Sciences 14, no. 7: 2682. https://doi.org/10.3390/app14072682

APA StyleChamorro-Hernandez, L. M., Herrera-Granda, E. P., & Rivas-Rosero, C. (2024). Selection of the Processing Method for Green Banana Chips from Barraganete and Dominico Varieties Using Multivariate Techniques. Applied Sciences, 14(7), 2682. https://doi.org/10.3390/app14072682