Motion Characteristics of Self-Sensing Piezoelectric Actuator for Yarn Micro-Gripper

Abstract

1. Introduction

2. Structure and Modeling of the Self-Sensing Micro-Gripper

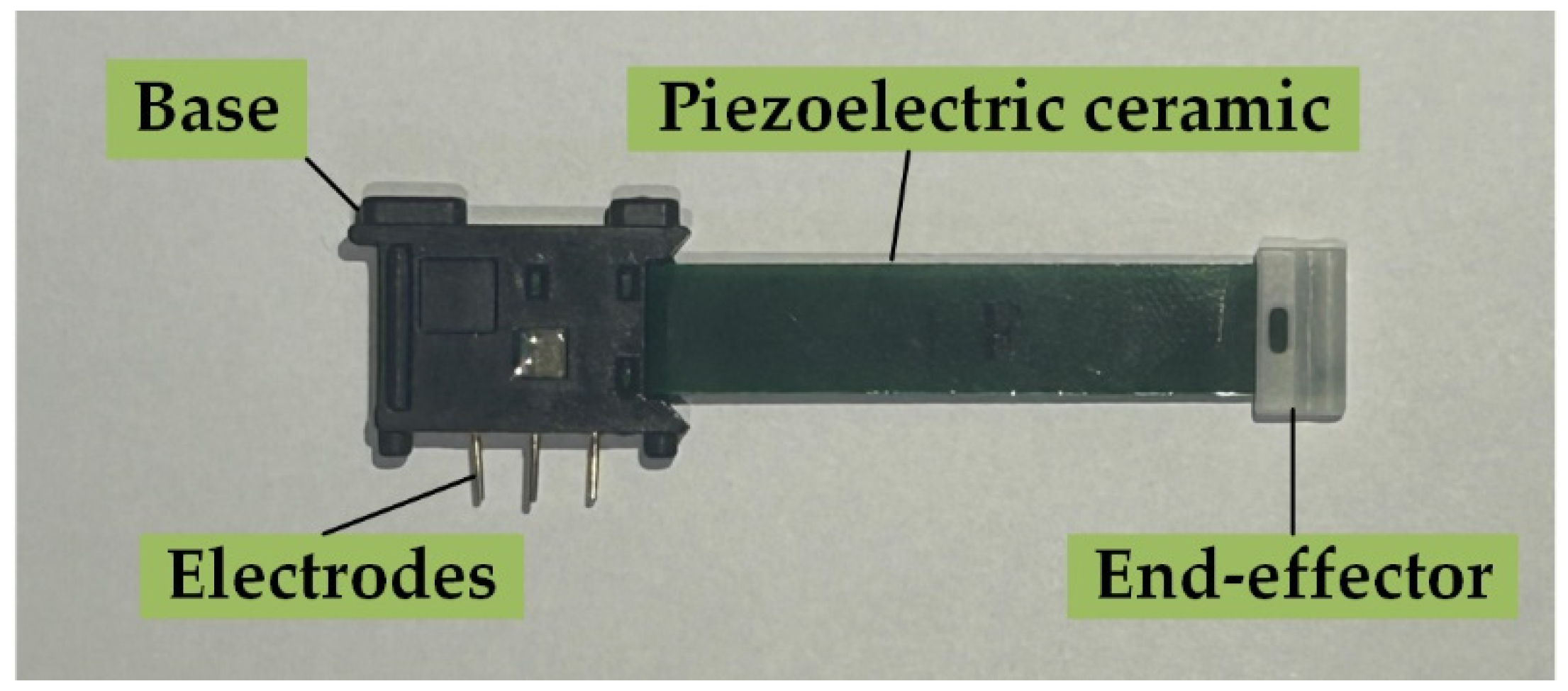

2.1. The Structure of the Self-Sensing Micro-Gripper

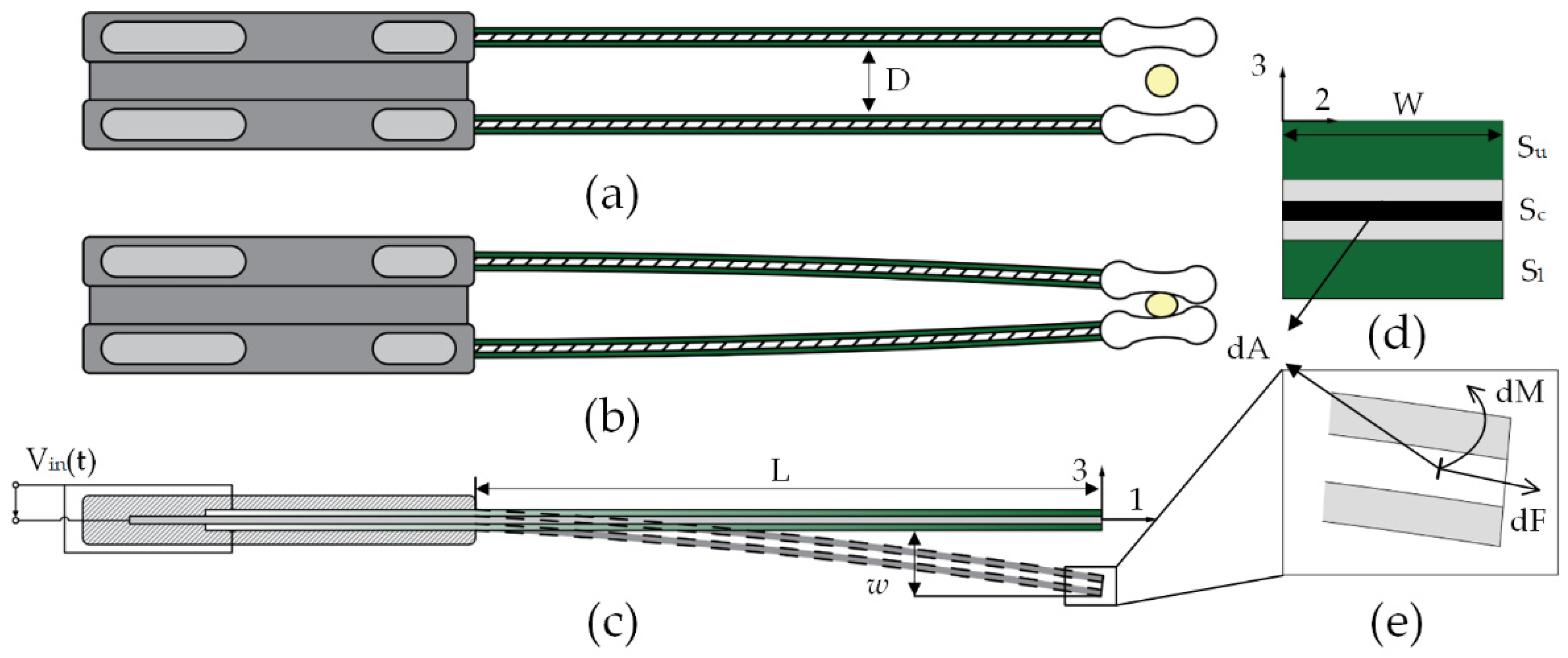

2.2. Model of the BPBA

2.2.1. Mechanical Modeling

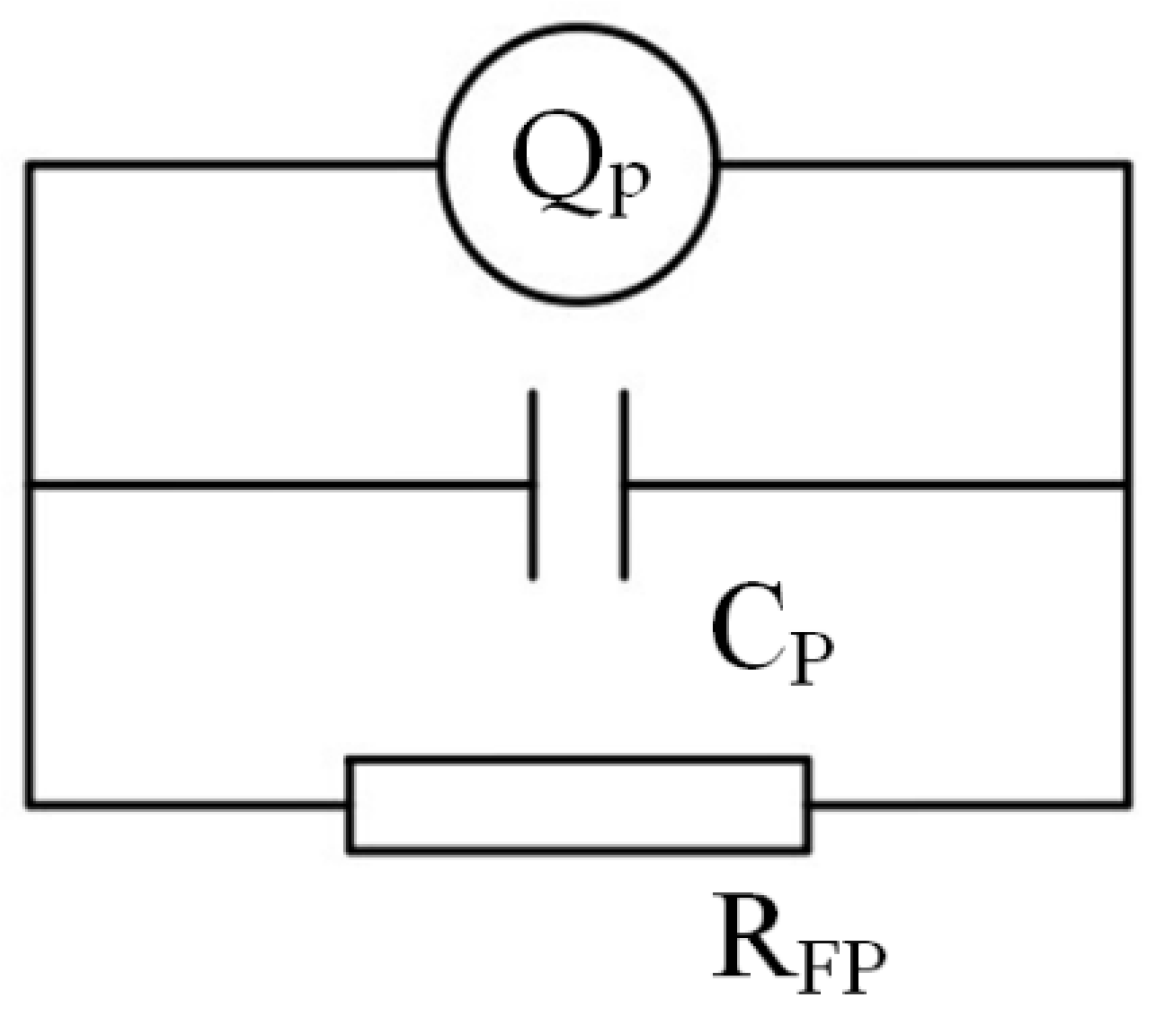

2.2.2. Electrical Modeling of BPBA

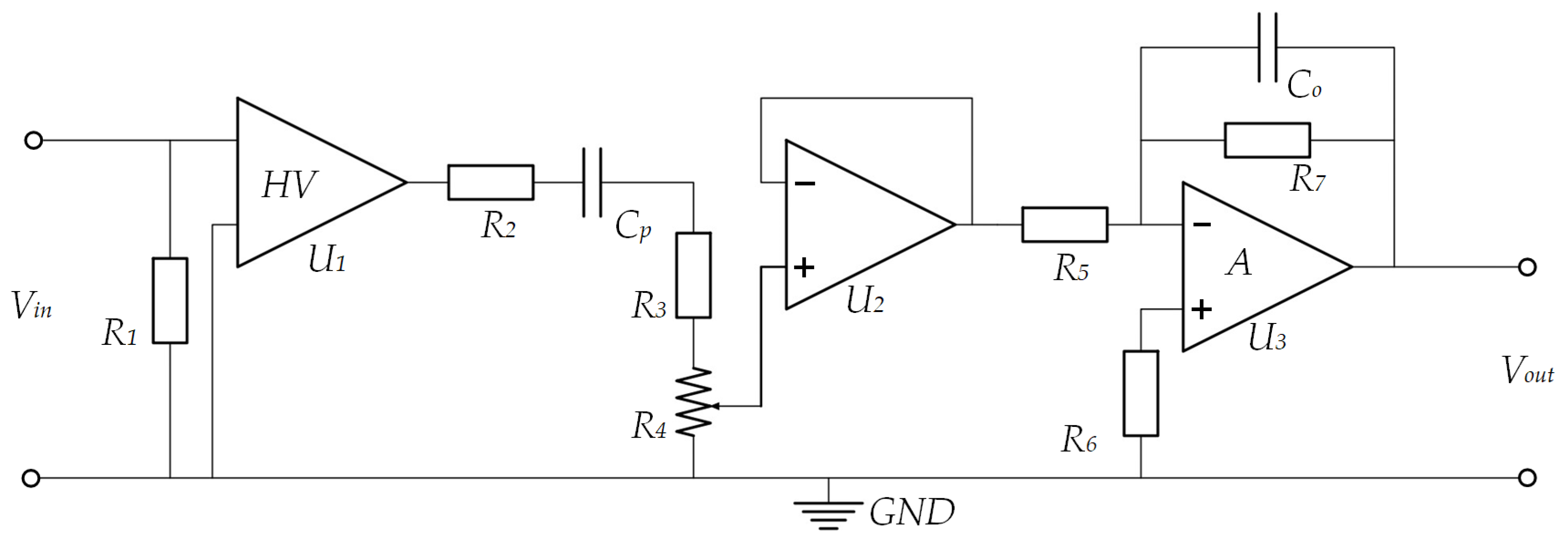

2.3. Design and Modeling of Self-Sensing Circuits

2.3.1. Circuit Design and Modeling

2.3.2. Selection of Electronic Components

2.3.3. Self-Sensing Parameter Identification

3. Performance and Self-Sensing Testing of BPBA

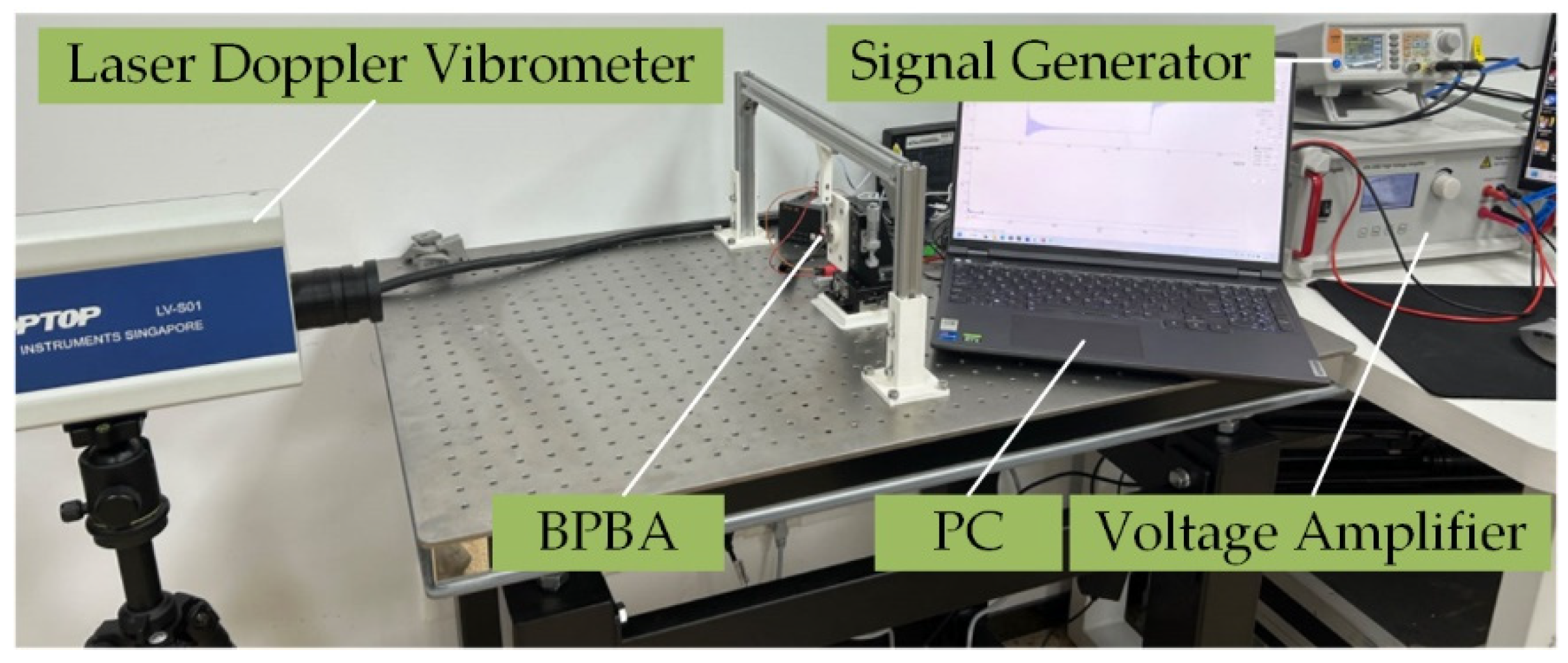

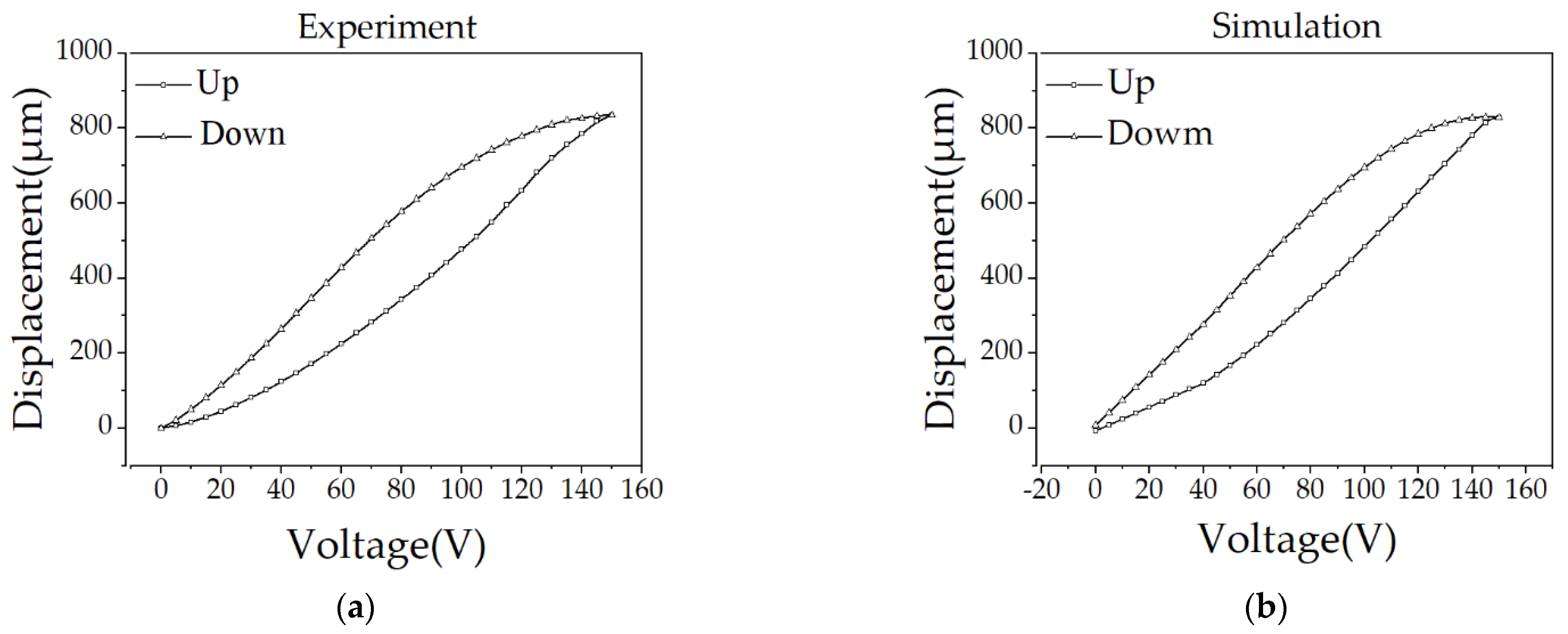

3.1. Static Displacement Test

3.1.1. Test System Composition

3.1.2. Measurement Result

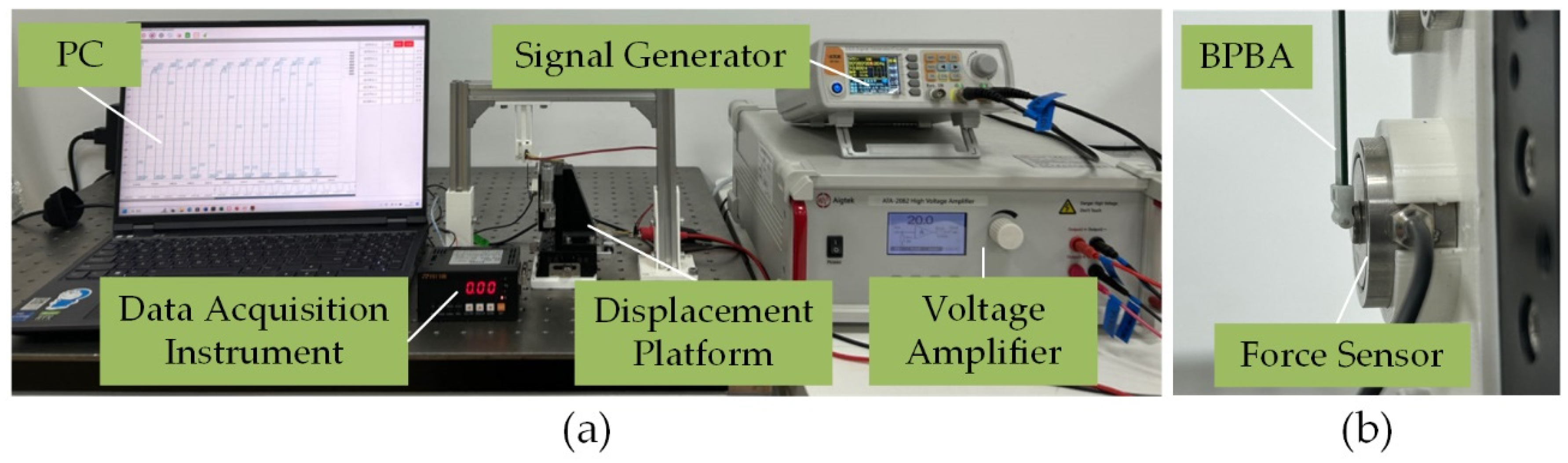

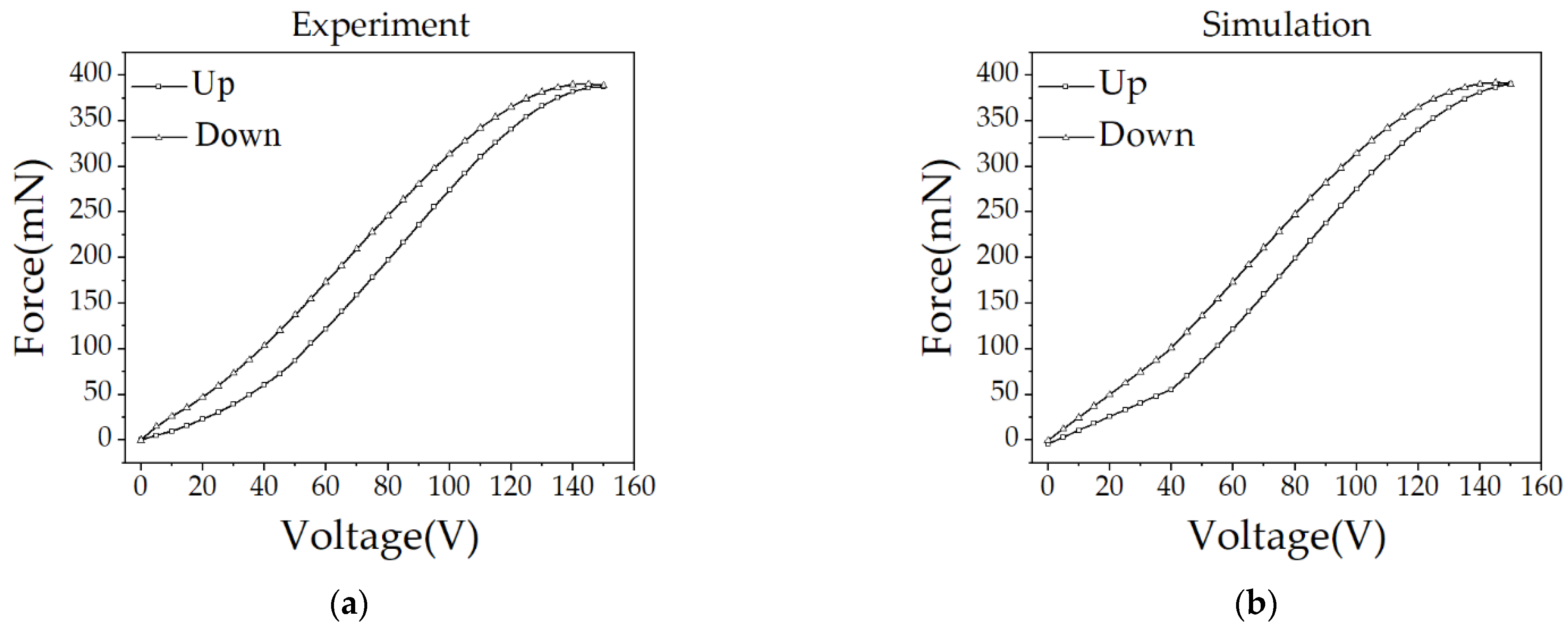

3.2. Output Force Characteristic Test

3.2.1. Composition of the Experimental System

3.2.2. Measurement Result

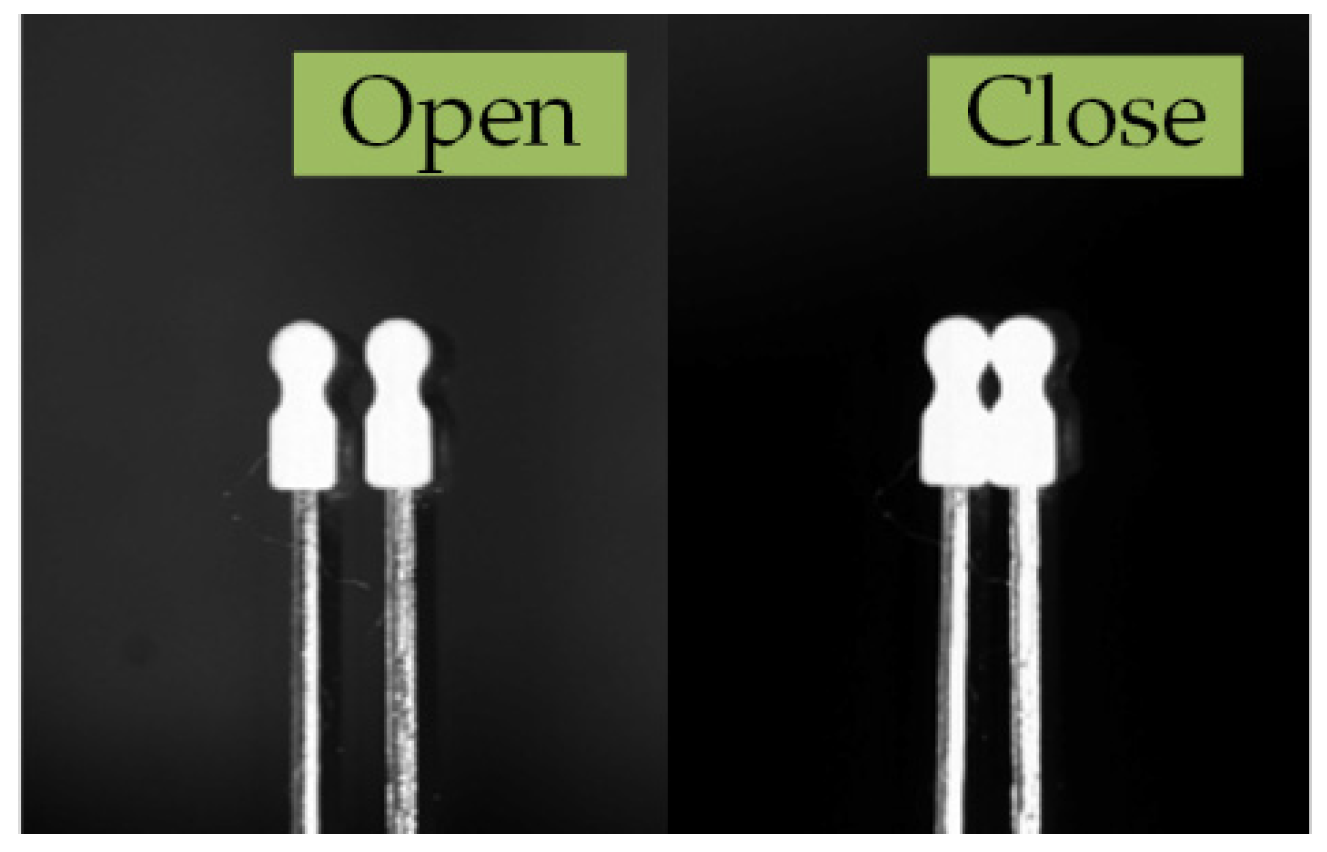

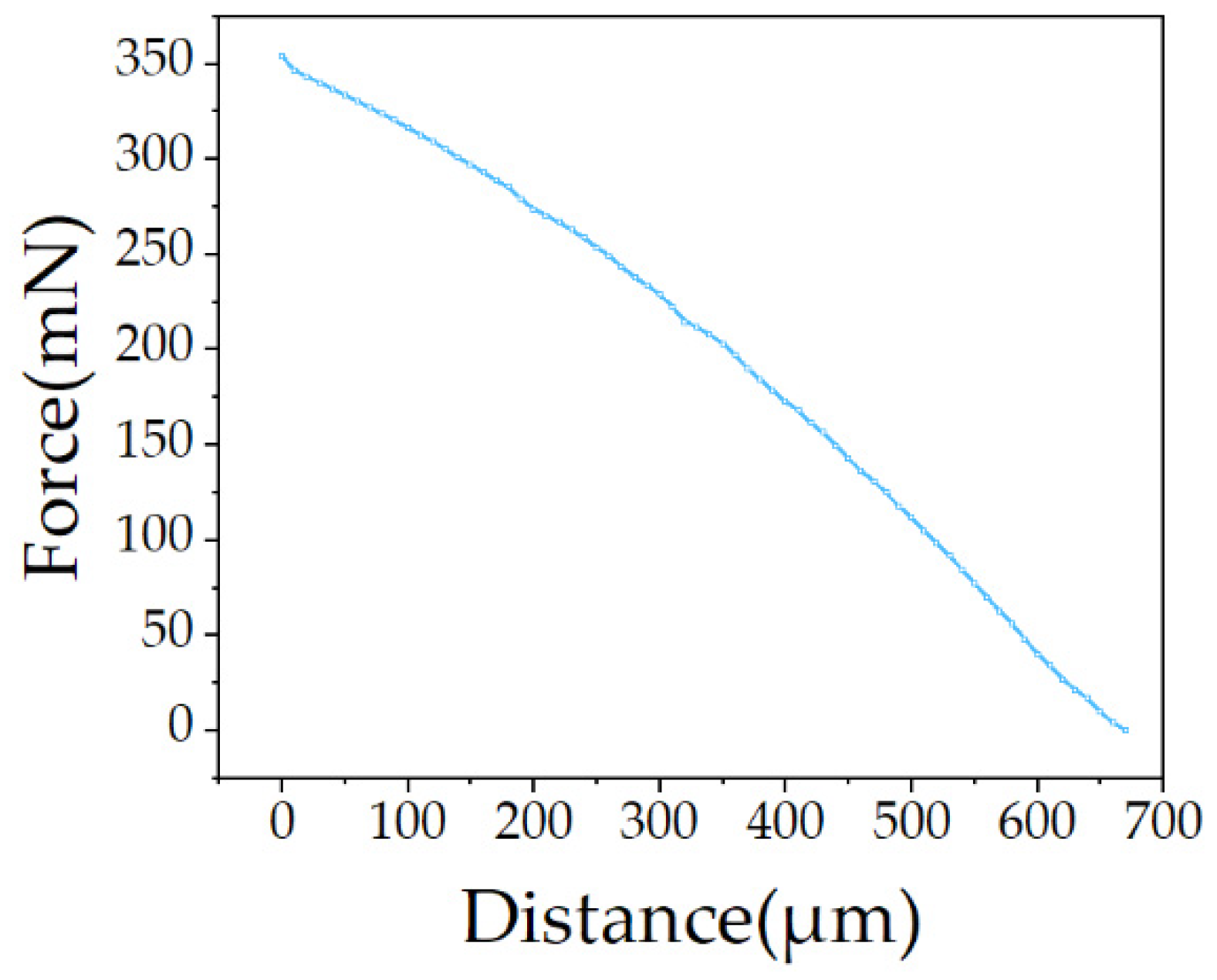

3.3. Clamping Distance Characteristic Test

3.3.1. Test System Composition

3.3.2. Measurement Result

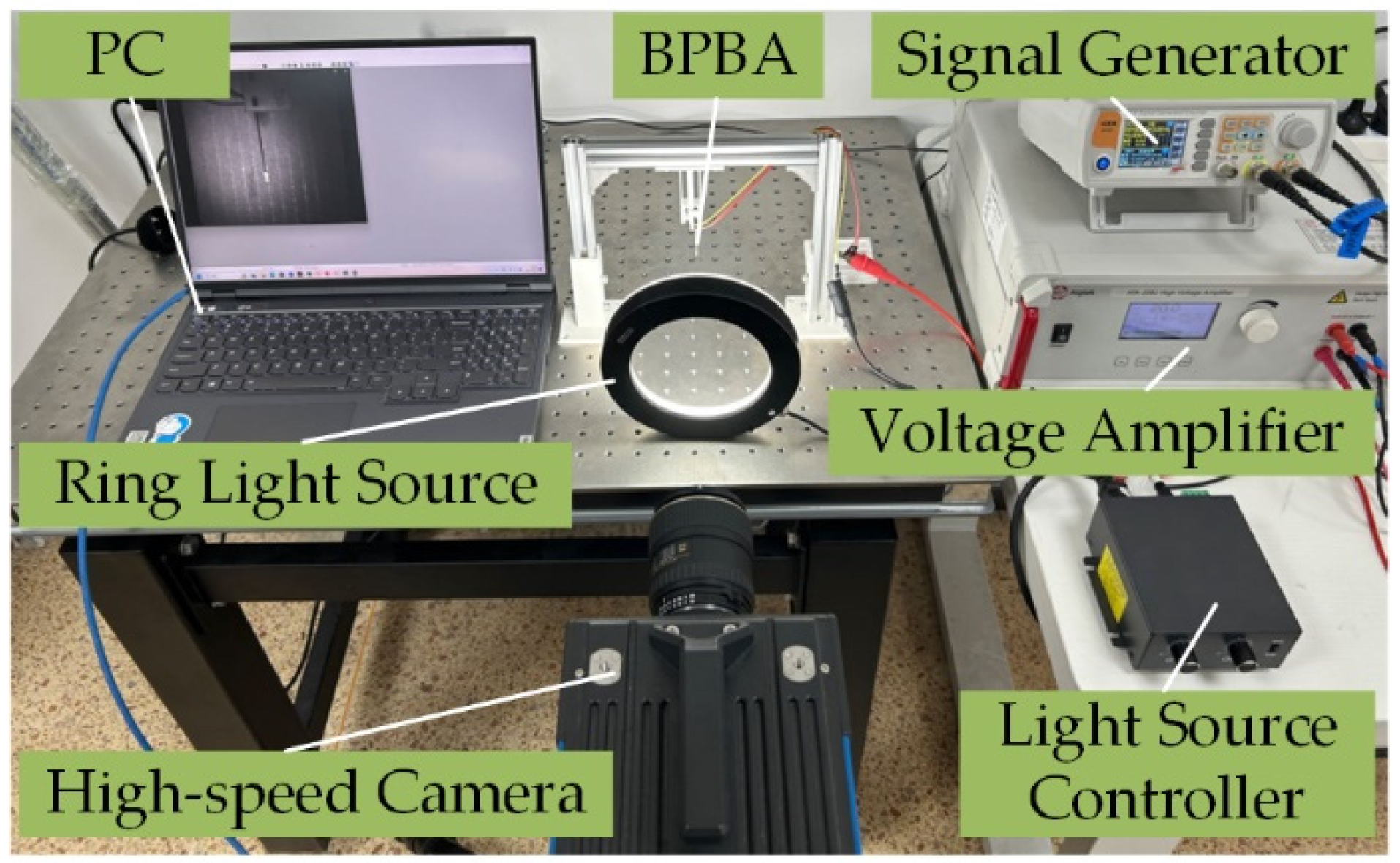

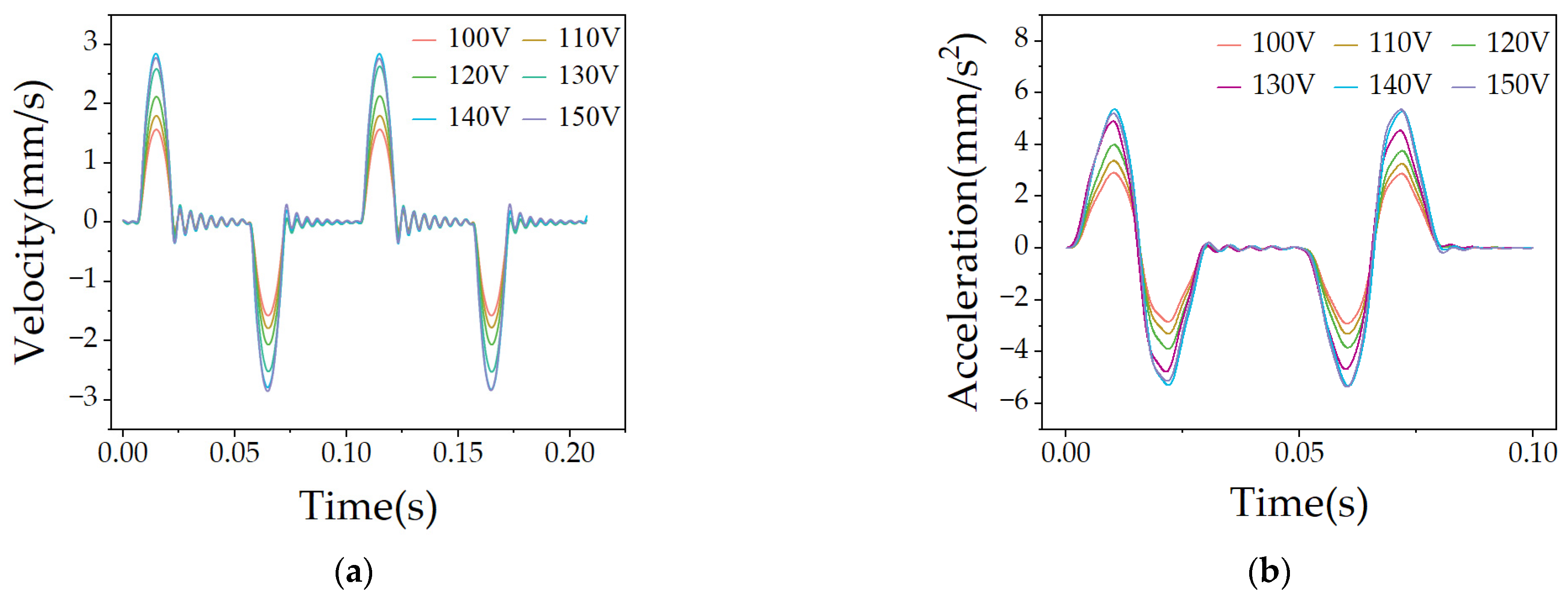

3.4. Study of Bending Motion Characteristics

3.4.1. Composition of the Experimental System

3.4.2. Measurement Result

3.5. Output Force Self-Sensing Test

3.5.1. Composition of the Experimental System

3.5.2. Comparative Analysis

4. Conclusions

- (1)

- The BPBA has a working length of 41 mm and a width of 7.2 mm. Mechanical and electrical modeling is performed according to the structure of the piezoelectric actuator, and the working range of the actuator can be estimated according to the theoretical values, which proves that the piezoelectric actuator of this structure meets the working requirements of yarn clamping. At the same time, the self-sensing circuits based on charge detection are carried out on the basis of the physical model, and the non-zero amplification bias current and driver leakage resistance are further compensated.

- (2)

- The maximum clamping stroke of the clamping device is about 1668 μm, and the maximum output force is about 776 mN, which meet the working requirements of yarn clamping. Compared with domestic and foreign micro-grippers, the clamping range and end clamping force are both improved.

- (3)

- By studying the negative correlation between the clamping distance and the end output force, the clamping distance can be decided according to the size of the target, so as to realize effective clamping for different targets.

- (4)

- The motion characteristics of the BPBA are analyzed by a high-speed camera, which shows a fast response speed and meets the requirements of a high-speed loom of 1000~1200 r/min. At the same time, its high response stability is greatly improved compared with the traditional electromagnetic-type yarn gripper

- (5)

- The maximum relative error between the self-sensing output force and the force measured by the external sensor was found to be 1.6%, and the average relative error was found to be 0.74%. These values are the same as or better than previously reported displacement force self-sensing techniques using charge and voltage measurements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ulkir, O.; Ertugrul, I.; Akkus, N.; Ozer, S. Fabrication and Experimental Study of Micro-gripper with Electrothermal Actuation by Stereolithography Method. J. Mater. Eng. Perform. 2022, 31, 8148–8159. [Google Scholar] [CrossRef]

- Jain, R.K.; Majumder, S.; Ghosh, B.; Saha, S. Design and manufacturing of mobile micro manipulation system with a compliant piezoelectric actuator based micro gripper. J. Manuf. Syst. 2015, 35, 76–91. [Google Scholar] [CrossRef]

- Schröter, F.; Schmidt, E. Micromanipulation of spherical particles during condensation and evaporation of water in an environmental scanning electron microscope. Powder Technol. 2018, 330, 80–92. [Google Scholar] [CrossRef]

- Garcés-Schröder, M.; Leester-Schädel, M.; Schulz, M.; Böl, M.; Dietzel, A. Micro-Gripper: A new concept for a monolithic single-cell manipulation device. Sens. Actuators A Phys. 2015, 236, 130–139. [Google Scholar] [CrossRef]

- Chowdhury, S.; Thakur, A.; Švec, P.; Wang, C.; Losert, W.; Gupta, S.K. Automated Manipulation of Biological Cells Using Gripper Formations Controlled By Optical Tweezers. IEEE Trans. Autom. Sci. Eng. 2014, 11, 338–347. [Google Scholar] [CrossRef]

- Wei, Y.; Xu, Q. A Survey of Force-Assisted Robotic Cell Microinjection Technologies. IEEE Trans. Autom. Sci. Eng. 2019, 16, 931–945. [Google Scholar] [CrossRef]

- Pevec, S.; Donlagic, D. Optically controlled fiber-optic micro-gripper for sub-millimeter objects. Opt. Lett. 2019, 44, 2177–2180. [Google Scholar] [CrossRef]

- Chen, W.H.; Shi, X.H.; Chen, W.J.; Zhang, J.B. A two degree of freedom micro-gripper with grasping and rotating functions for optical fibers assembling. Rev. Sci. Instrum. 2013, 84, 10. [Google Scholar] [CrossRef]

- Liu, H.; Li, J.P. A Piezoelectric Micro-Gripper with Large Working Stroke and Integrated Force Sensor for Optical Fiber Manipulation. In Proceedings of the 16th Symposium on Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), Nanjing Univ Aeronaut & Astronaut, Nanjing, China, 11–14 October 2022; pp. 253–257. [Google Scholar]

- Kuroda, T.; Onoe, H. Pnipam/swcnt-based hydrogel micro-gripper driven by infrared light for intravascular surgery. In Proceedings of the 33rd IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020; pp. 540–541. [Google Scholar]

- Kang, H.-W.; Lee, I.H.; Cho, D.-W. Development of a micro-bellows actuator using micro-stereolithography technology. Microelectron. Eng. 2006, 83, 1201–1204. [Google Scholar] [CrossRef]

- Guo, X.-Y.; Li, W.-B.; Gao, Q.-H.; Yan, H.; Fei, Y.-Q.; Zhang, W.-M. Self-locking mechanism for variable stiffness rigid–soft gripper. Smart Mater. Struct. 2020, 29, 035033. [Google Scholar] [CrossRef]

- Cheng, P.; Ye, Y.; Jia, J.; Wu, C.; Xie, Q. Design of cylindrical soft vacuum actuator for soft robots. Smart Mater. Struct. 2021, 30, 045020. [Google Scholar] [CrossRef]

- Boudaoud, M.; Haddab, Y.; Gorrec, Y.L. Modeling and Optimal Force Control of a Nonlinear Electrostatic Microgripper. IEEE/ASME Trans. Mechatron. 2013, 18, 1130–1139. [Google Scholar] [CrossRef]

- Boudaoud, M.; Gaudenzi De Faria, M.; Le Gorrec, Y.; Haddab, Y.; Lutz, P. An output feedback LPV control strategy of a nonlinear electrostatic microgripper through a singular implicit modeling. Control Eng. Pract. 2014, 28, 97–111. [Google Scholar] [CrossRef]

- Majidi Fard-Vatan, H.; Hamedi, M. Design, analysis and fabrication of a novel hybrid electrothermal microgripper in microassembly cell. Microelectron. Eng. 2020, 231, 111374. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, X.; Chen, X. Design, modeling, and characterization of a MEMS electrothermal microgripper. Microsyst. Technol. 2015, 21, 2307–2314. [Google Scholar] [CrossRef]

- Feng, Y.-Y.; Chen, S.-J.; Hsieh, P.-H.; Chu, W. Fabrication of an electro-thermal micro-gripper with elliptical cross-sections using silver-nickel composite ink. Sens. Actuators A-Phys. 2016, 245, 106–112. [Google Scholar] [CrossRef]

- AbuZaiter, A.; Nafea, M.; Mohamed Ali, M.S. Development of a shape-memory-alloy micromanipulator based on integrated bimorph microactuators. Mechatronics 2016, 38, 16–28. [Google Scholar] [CrossRef]

- Dhanalakshmi, K. Shape memory alloy wire for self-sensing servo actuation. Mech. Syst. Signal Process. 2017, 83, 36–52. [Google Scholar] [CrossRef]

- Mehrabi, H.; Aminzahed, I. Design and testing of a microgripper with SMA actuator for manipulation of micro components. Microsyst. Technol. 2020, 26, 531–536. [Google Scholar] [CrossRef]

- Xu, D.M.; Yang, F.; Yu, S.M.; Xu, C.; Liu, X.L.; Zhao, Z.W.; Zhang, X.H.; Li, S.T.; Yang, H.X.; Lu, Q. A three-stage amplification piezoelectric-actuated micro-gripper with adjustable output displacement: Design, modeling, and experimental evaluation. Smart Mater. Struct. 2023, 32, 11. [Google Scholar] [CrossRef]

- Wang, F.; Shi, B.; Huo, Z.; Tian, Y.; Zhang, D. Control and dynamic releasing method of a piezoelectric actuated microgripper. Precis. Eng. 2021, 68, 1–9. [Google Scholar] [CrossRef]

- Lyu, Z.; Xu, Q. Recent design and development of piezoelectric-actuated compliant microgrippers: A review. Sens. Actuators A Phys. 2021, 331, 113002. [Google Scholar] [CrossRef]

- Sakuragi, Y.; Seki, K.; Iwasaki, M. Contact Force Estimation and Sensorless Force Control in Piezoelectric Bending Actuators. IEEJ J. Ind. Appl. 2022, 11, 555–561. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J.; Jiang, X.; Kim, T.; Gasulla, M. Static Force Measurement Using Piezoelectric Sensors. J. Sens. 2021, 2021, 6664200. [Google Scholar] [CrossRef]

- Abondance, T.; Jayaram, K.; Jafferis, N.T.; Shum, J.; Wood, R.J. Piezoelectric Grippers for Mobile Micromanipulation. IEEE Robot. Autom. Lett. 2020, 5, 4407–4414. [Google Scholar] [CrossRef]

- Masson, L.; Xinchang, L.; Perriard, Y. An optimized self-sensing piezoelectric cantilever for micro-robotic applications. J. Micro-Bio Robot. 2019, 15, 91–103. [Google Scholar] [CrossRef]

- Ivan, I.A.; Rakotondrabe, M.; Lutz, P.; Chaillet, N. Quasistatic displacement self-sensing method for cantilevered piezoelectric actuators. Rev. Sci. Instrum. 2009, 80, 065102. [Google Scholar] [CrossRef]

- Jain, R.K.; Majumder, S.; Ghosh, B. Design and analysis of piezoelectric actuator for micro gripper. Int. J. Mech. Mater. Des. 2014, 11, 253–276. [Google Scholar] [CrossRef]

- Liu, Y.; Zhong, Y.; Wang, C. Recent advances in self-actuation and self-sensing materials: State of the art and future perspectives. Talanta 2020, 212, 120808. [Google Scholar] [CrossRef]

- Mansour, S.Z.; Seethaler, R.J. Simultaneous Displacement and Force Estimation of Piezoelectric Stack Actuators Using Charge and Voltage Measurements. IEEE/ASME Trans. Mechatron. 2017, 22, 2619–2624. [Google Scholar] [CrossRef]

- Apicella, V.; Clemente, C.S.; Davino, D.; Leone, D.; Visone, C. Stress self-sensing in Amplified Piezoelectric Actuators through a fully-coupled model of hysteresis. Phys. B Condens. Matter 2020, 579, 411894. [Google Scholar] [CrossRef]

- Yang, C.; Verbeek, N.; Xia, F.; Wang, Y.; Youcef-Toumi, K. Statically Stable Charge Sensing Method for Precise Displacement Estimation of Piezoelectric Stack-Based Nanopositioning. IEEE Trans. Ind. Electron. 2021, 68, 8550–8560. [Google Scholar] [CrossRef]

- Masson, L.; Civet, Y.; Germano, P.; Perriard, Y. Design of a generalised charge-based self-sensing model for quasi-static piezoelectric actuators. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017; pp. 1–6. [Google Scholar]

- Ivan, I.A.; Rakotondrabe, M.; Lutz, P.; Chaillet, N. Current integration force and displacement self-sensing method for cantilevered piezoelectric actuators. Rev. Sci. Instrum. 2009, 80, 126103. [Google Scholar] [CrossRef]

- Rakotondrabe, M.; Ivan, I.A.; Khadraoui, S.; Lutz, P.; Chaillet, N. Simultaneous Displacement/Force Self-Sensing in Piezoelectric Actuators and Applications to Robust Control. IEEE/ASME Trans. Mechatron. 2015, 20, 519–531. [Google Scholar] [CrossRef]

- Saigusa, K.; Morita, T. Self-sensing control of piezoelectric positioning stage by detecting permittivity. Sens. Actuators A Phys. 2015, 226, 76–80. [Google Scholar] [CrossRef]

- Kawamata, A.; Kadota, Y.; Hosaka, H.; Morita, T. Self-Sensing Piezoelectric Actuator using Permittivity Detection. Ferroelectrics 2010, 368, 194–201. [Google Scholar] [CrossRef]

- Ishikiriyama, Y.; Morita, T. Improvement of Self-sensing Piezoelectric Actuator Control Using Permittivity Change Detection. J. Adv. Mech. Des. Syst. Manuf. 2010, 4, 143–149. [Google Scholar] [CrossRef]

- Zarif Mansour, S.; Seethaler, R. Simultaneous quasi-static displacement and force self-sensing of piezoelectric actuators by detecting impedance. Sens. Actuators A Phys. 2018, 274, 272–277. [Google Scholar] [CrossRef]

- Joël, B.L.; Sepehr, Z.M.; Rudolf, S.; Joël, A.; Philippe, L.; Micky, R. Piezoelectric Actuators Characterization for Simultaneous Force and Displacement Self-Sensing by detecting Impedance. IFAC-PapersOnLine 2019, 52, 501–506. [Google Scholar] [CrossRef]

- Lei, B.; Lu, W.; Mian, Z.; Bao, W. Effect of IDT position parameters on SAW yarn tension sensor sensitivity. Meas. Control 2020, 53, 2055–2062. [Google Scholar] [CrossRef]

| Micro-Gripper | Size /mm | Clamping Stroke /μm | Clamping Force /mN | Response Speed /ms | Force Sensing Relative Error |

|---|---|---|---|---|---|

| Target | - | 560 | 500 | 50 | 1% |

| Layers | Length/mm | Width/mm | Thickness/mm |

|---|---|---|---|

| Piezoelectric layer | 41 | 7.2 | 0.245 |

| Base layer | 41 | 7.2 | 0.3 |

| Materials | Density ) | Young’s Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| PZT-5H | 7500 | 56 | 0.36 |

| carbon fiber | 1800 | 250 | 0.28 |

| Micro-Gripper | Size /mm | Clamping Stroke /μm | Clamping Force /mN | Response Speed /ms | Force Sensing Relative Error |

|---|---|---|---|---|---|

| Target | - | 560 | 500 | 50 | 1% |

| BPBA in this paper | 41 × 7.2 × 0.79 | 1668 | 776 | 24 | 0.74% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, L.; Sun, Y.; Qi, Y.; Ru, X. Motion Characteristics of Self-Sensing Piezoelectric Actuator for Yarn Micro-Gripper. Appl. Sci. 2024, 14, 2620. https://doi.org/10.3390/app14062620

Peng L, Sun Y, Qi Y, Ru X. Motion Characteristics of Self-Sensing Piezoelectric Actuator for Yarn Micro-Gripper. Applied Sciences. 2024; 14(6):2620. https://doi.org/10.3390/app14062620

Chicago/Turabian StylePeng, Laihu, Yuan Sun, Yubao Qi, and Xin Ru. 2024. "Motion Characteristics of Self-Sensing Piezoelectric Actuator for Yarn Micro-Gripper" Applied Sciences 14, no. 6: 2620. https://doi.org/10.3390/app14062620

APA StylePeng, L., Sun, Y., Qi, Y., & Ru, X. (2024). Motion Characteristics of Self-Sensing Piezoelectric Actuator for Yarn Micro-Gripper. Applied Sciences, 14(6), 2620. https://doi.org/10.3390/app14062620