Abstract

In Italy, the use of chainsaws for field operations such as Felling (FE), Delimbing (DE), and Bucking (BU) is widespread due to the topography, the medium–small size of farms, and the predominant presence of broad-leaved forests managed through coppicing. However, this has led to an increase in injuries and illnesses due to exposure to physical factors (e.g., noise, dust, and vibrations) and chemical agents (e.g., various volatile compounds). Occupational health and safety legislation in Italy has undergone several phases, including the approval of U.T. 81/2008. The present study aims to evaluate the noise generated by chainsaws and the concentration of pollutants (CO, VOC, and C6H6) present in chainsaw exhaust gases during interventions in a chestnut coppice in relation to the limits set by current legislation. The analysis of the noise generated by chainsaws during chestnut cutting operations showed that it exceeded the legal noise limits during all chainsaw activities, with peak levels of about 110 dB. The detected noise could cause important critical issues in relation to the health and safety of specialized operators. Furthermore, the correlation between the specific work (FE, DE, and BU) and the ratio between maximum and average values of CO and VOC emissions was evaluated. Notably, comparable levels of maximum VOC emissions were observed during the FE and BU phases. However, the average emission values during these phases exhibited significant differences, suggesting higher VOC production when the engine was running but not actively engaged in cutting. The highest emissions were recorded during the FE phase (CO = 135 ppm, VOC = 17.28 ppm, and C6H6 = 2.13 ppm).

1. Introduction

The proliferation of portable equipment for urban green care, maintenance, and recreational activities has engendered significant challenges concerning operator safety and ergonomics [1]. These tools are frequently acquired online without the provision of any training prior to their utilization. Furthermore, in the forestry sector, despite the introduction of cutting-edge machinery and systems, the chainsaw remains unequivocally the primary apparatus employed for felling operations, delimbing logs, and segmenting timber into diverse assortments. The rationale behind this lies in the intricate topography of the Italian terrain. It is distinguished by a notable slope, which is even more pronounced within wooded regions, as lowland and hillside forests have long since relinquished their existence to agricultural land. Additionally, the majority of Italian forestry companies fall into the medium- or small-scale category, thereby often lacking the financial capacity to procure, depreciate, and manage state-of-the-art machinery. Another influential factor contributing to the presence of inadequate machinery fleets [2] is the organizational structure and composition of the forestry companies’ wood capital. According to data derived from the RAF Italy 2017–2018 report, approximately 66% of forests nationwide are privately owned, while the remaining 34% are under public ownership. As far as private companies, there exists a marked fragmentation of land ownership, compounded by the prevalence of broadleaf forests frequently subject to coppice management practices, thereby rendering the implementation of Harvester and analogous techniques rather arduous. Often, the presence of low-value woody capital results in management strategies that further increase the phenomena of soil degradation [3]. Moreover, Italian silviculture is primarily geared towards the production of low-value timber or, in some cases, biomass for energy purposes [4]. Consequently, the yield that can be extracted from the majority of Italian forests is not particularly lucrative, rendering it incompatible with management models predicated on advanced mechanization [5].

From the literature analysis, exponential growth in the number of publications in this area over the past five years is notable, indicating a significant level of interest within the scientific community regarding the discussed topic. Specifically, the issue of safety on forestry sites, which was previously predominantly regulated and monitored by public agencies, has now become a subject of research and experimentation, making it highly relevant.

The topic of chainsaw emissions, in particular, has historically received limited attention, at least until 2000. This partly explains the scarcity of available literature on the subject and the absence of standardized operating procedures for evaluating emissions in open-field conditions. Furthermore, a considerable proportion (~44%) of the specific contributions analysed pertain to the field of medicine rather than agricultural engineering.

Greater involvement of agricultural engineering in this field would obviously be desirable to integrate medical knowledge with the design and development of safer, more efficient, and ecologically sustainable chainsaws. Multidisciplinary collaboration between medicine, agricultural engineering, and other relevant disciplines could lead to more comprehensive and cutting-edge solutions to address the challenges associated with chainsaws.

The main objective of our research was the analysis of data on airborne pollutant and noise emissions during work activities conducted on forestry sites, with a focus on the respiratory safety of operators. This study aims to provide accurate information regarding the potential health risks and safety considerations for workers using chainsaws, contributing to informed decision-making and the development of appropriate safety measures and guidelines.

The specific objectives of the present work are as follows:

- To assess the concentration of pollutants present in the exhaust gases of chainsaws with internal combustion engines, focusing on their impact on the respiratory health and safety of workers;

- To evaluate the noise emitted by chainsaws with internal combustion engines during different activities involved in chestnut coppice utilization, with a particular emphasis on its impact on the respiratory health and safety of workers.

2. Material and Methods

2.1. Study Sites

The experiments were conducted within a chestnut coppice managed by the clear-cutting method. The experimental area was located in southern Italy, in Basilicata, in the municipality of Sassano (‘Gravola’), at an altitude between 900 and 1000 m above sea level. The investigated silvicultural operations were as follows: felling (FE), delimbing (DE), and bucking (BU). All tests were conducted under clear weather conditions with light wind and an average temperature of 9 ± 3 °C. Experimental trials were conducted in accordance with current safety protocols and regulations. The sampling analysis lasted 8 working days. The measurements were conducted on 25 contiguous sample sites belonging to the same chestnut coppice forest. All operators had proven experience in site operations. The equipment was in good condition and carefully maintained. Precautions were taken to ensure the safety of researchers and operators involved in silvicultural operations. Attention was paid to the proper use of tools and equipment, as well as to the proper management of waste generated during the experimental activities. In addition, a preliminary analysis of the terrain and surrounding ecosystem was conducted to assess the potential impact of silvicultural operations on the local soil, vegetation, and fauna.

2.2. Equipment

The experimental tests were carried out with a Husqvarna chainsaw model 357xp (Stockholm, Sweden). The instrumentation used was in perfect condition (sharpening, lubrication, etc.) and had 107 working hours prior to the experimental tests conducted for this work. On the market, it is possible to find a wide assortment of chainsaws, distinguished by individual characteristics and nominal powers [6]; the one chosen is designed for demanding cutting tasks and is among the most used in the forestry sites involved in the experimentation. The chainsaw is equipped with a 56.5 cm3 engine with 3.2 kW of power, a recommended bar length of 40 cm, and a weight of 5.5 kg, which make it powerful but versatile for various applications. The chainsaw operates at a maximum speed of 9600 rpm and offers low levels of handle vibration (3.9/4.2 m/s2). It produces sound power levels of 100 dB(A) and pressure levels of 112 dB(A). Additionally, it features a 0.68 L fuel tank and a 0.38 L oil tank, ensuring long-lasting operation without frequent refuelling or oil top-ups.

To evaluate the overall perception arising from complex sound or acoustic emissions, a Noise sensor TES 1355 dosimeter (TES Electrical Electronic Corp., Taipei, Taiwan) was employed, designed to replicate the response characteristics of the human auditory system. This dosimeter measures sound pressure levels and converts sound pressure levels into decibels. The experimental tests incorporated a TES 1355 dosimeter, encompassing a microphone, preamplifier, frequency weighting circuit, third-octave analysis capability, root mean square (RMS) circuit, analogue output, integrator circuit, and a comprehensive display system.

In order to assess the potential exposure of personnel to airborne pollutants emitted by chainsaw exhaust, a MultiRAE PGM-50 plus professional gas monitor (RAE Systems, San Jose, CA, USA) was employed. This programmable multi-gas monitor facilitates continuous real-time monitoring of toxic gases, oxygen levels, and combustible gases. The instrument detects and records the instantaneous concentration of gases in parts per million (ppm) for toxic gases, in percent volume (%vol) for oxygen, and in percent volume relative to the lower explosive limit (%vol of LEL) for combustible gases. The captured data were stored within the integrated data logger for subsequent analysis.

2.3. Data Collection

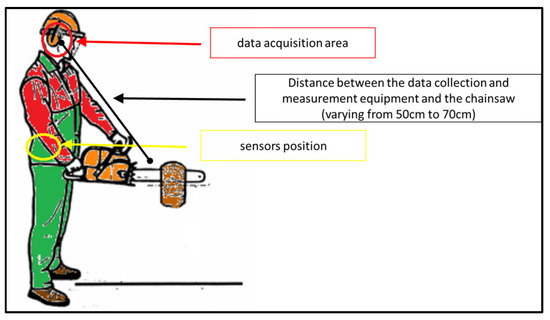

Noise measurements were conducted during the various silvicultural operations (FE, DE, and BU) on a sample of 30 trees. A total of 1260 observations were made, with 420 observations for each silvicultural operation. To capture a comprehensive range of scenarios encountered by operators, individuals with varying diametrical classes were included in the study. The dosimeter was directly affixed to the operator during chainsaw cutting operations to simulate the actual stress experienced by the auditory system (Figure 1). Such positioning ensured that data were acquired at a constant distance of 50 cm to 70 cm.

Figure 1.

Operating scheme of data collection using Noise sensor TES 1355.

Specifically, the index of exceedance of exposure limits was calculated, both based on the recorded average values and the corresponding medians (Table 1). The following formula was employed to determine the indices:

where AV is the average value, MED refers to the median value of the variable, and Lim is the threshold established by law.

Table 1.

Descriptive statistics for each type of machining and in relation to different diametric classes.

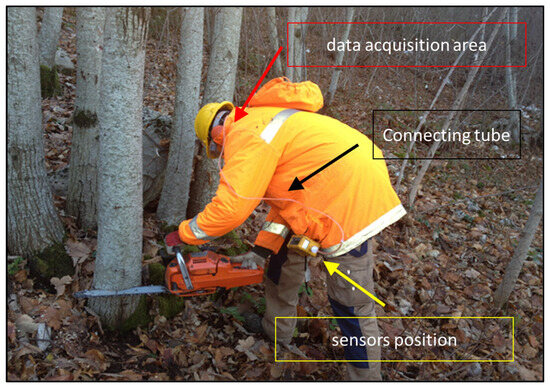

For exhaust gas sampling, including CO, VOC, and C6H6, specialized clips were utilized to securely attach the instrumentation to the operator’s belt (Figure 2). This approach yielded reliable results, as it ensured proximity between the gas analyser and the worker’s mouth, which is a crucial requirement according to standards [7].

Figure 2.

Operating scheme of data collection using gas emission sensor MultiRAE PGM-50.

Pollutants that are close to the operator’s airway access are captured by a gentle current of air generated at the connecting tube port, to be transmitted to the sensor that provides data acquisition.

In this case, 432 measurements were taken on a sample of 30 trees, including 144 for each silvicultural operation. The collected data were clustered into 8 groups (one for each day of data acquisition). Instantaneous measurements of the three gas emission variables were acquired at 15 min intervals throughout each processing phase (FE, DE, and BU).

In both cases, the descriptive statistics were calculated for each dataset, encompassing maximum values (Vmax), minimum values (Vmin), averages, and standard deviations for each time interval and work process. In particular, to estimate the variability of the parameters, the coefficient of variation was computed:

where σ is the standard deviation and μ is the mean value of the variable.

The frequency of exceeding limits is given by the following formula:

where Na are the readings above the threshold and Ntot is the total number of events.

3. Results and discussion

3.1. Noise Exposure

In order to assess the levels of acoustic pressure on the hearing apparatus of operators, a statistical analysis was carried out on a total sample of 1260 observations. For each operation, the three most representative diametric classes were identified:

- Delimbing (DE): 5 cm; 7 cm; 9 cm;

- Bucking (BU): 12 cm; 16 cm; 18 cm;

- Felling (FE): 10 cm; 15 cm; 20 cm.

It should be noted that according to the current legislation in Italy (D.P.R. 81/2008), which is the Consolidated Law on occupational health and safety, the following weighted limits of exposure are set for workers operating on construction sites:

- Lim1—80 dB (below this limit, there is no risk to the health of workers);

- Lim2—85 dB (between 80 and 85 dB, the employer provides PPE, trains operators, and appoints a competent physician);

- Lim3—87 dB (between 85 and 87 dB, workers are required to use PPE, health surveillance is activated, and workplaces must be properly cordoned off and marked).

Above 87 dB, measures are required to bring exposure below the limit value. Consolidation Act 81/2008 also sets peak values, that is, the maximum value of instantaneous sound pressure. These limits are as follows:

- Lim1_peak: 135 dB;

- Lim2_peak: 137 dB;

- Lim3_peak: 140 dB.

For each diametric class related to a specific silvicultural operation, the following noise emission values (dB) were identified:

- Average of the sound emission values;

- Median of the sound emission values;

- Maximum sound emission value recorded;

- Standard deviation;

- Coefficient of variability.

The analysis of the data from the various samples revealed coefficients of variation (CVs) below 15 percent. This indicates moderate relative variability from the mean, suggesting a good quality of the data acquisition methodology. Consequently, the mean and median values can serve as reliable indicators for conducting further analyses. Table 1 presents the descriptive statistics for each silvicultural operation and for each diametric class.

It is evident from Table 2 that the legal limits are consistently exceeded, and this situation is further exacerbated by the lack of proper personal protective equipment at forestry sites [8]. However, it is worth noting that the recorded values do not come close to the peak values mandated by law.

Table 2.

Exceedance rates of noise thresholds stipulated by current Italian regulations.

Further investigations have been conducted to provide a more detailed understanding of the dynamics present in these contexts.

Values exceeding 1 indicate the surpassing of the analysed critical threshold, along with a percentage indicator relative to the threshold itself. For instance, in the case of felling operations on logs with a diameter falling within the 7 cm class, an exceedance of 10% for Lim1 is reported. The percentage of exceedance ranges from 8% to 27%, with an average of 11% for DE, 19% for FE, and 16% for BU, in relation to Lim1. It is important to emphasize that even small differences of a few dB in noise levels can result in a significant increase in perceived noise intensity. Noise is measured on a logarithmic scale, where a 3 dB increase corresponds to a doubling of perceived noise intensity.

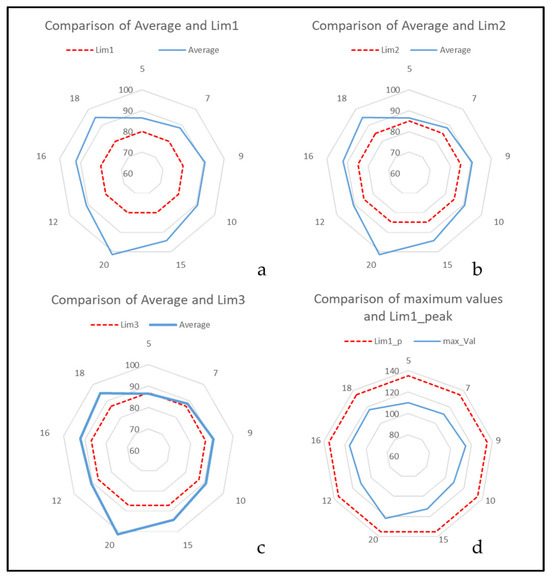

Figure 3 shows the comparison between the average values of sound emissions detected for each diametric class, along with the respective legal limits (a–c). Additionally, it presents the maximum recorded values for each diametric class, along with the corresponding peak limit set by law (d).

Figure 3.

Comparisons between the average noise values measured for each diametric class and the relevant legal limits (a–c). Comparisons between the maximum values recorded for each diametric class and the relevant peak limits set by law (d).

The analysis also confirms that in at least 50 percent of the activities the limits imposed by current regulations are exceeded. The rate at which the thresholds, set by current regulations, are exceeded for each individual operation and for each diametric class were calculated; the results are shown below, in Table 3.

Table 3.

Frequencies of exceeding legal limits for each type of processing and for each diametric class.

In relation to Lim1, during DE operations, the exceedance rate varies from 57% for the smallest diameter trees to 69% for the largest diameters. Similarly, for FE and BU operations, the rates vary from 65% to 83% and 69% to 77%, respectively. Even considering the other statutory limits (Lim2 and Lim3, where operators should wear hearing protectors), the recorded rates show major criticalities for workers’ health and safety, being on average at 48% and 47% for DE, 67% and 65% for FE, and 61% and 58% for BU. The analysis highlights not only that the thresholds are regularly disregarded, but that this dynamic is prevalent during the majority of construction operations.

3.2. Exposure to Airborne Pollutants

Table 4 shows the average values of the maximum detections obtained in each of the eight repeated measurements, along with the corresponding mean values of the same measurements. The table also includes the relative standard deviations (SDs) and coefficients of variation (CVs) for the measurements.

Table 4.

Gas emissions detected during the different cutting operations.

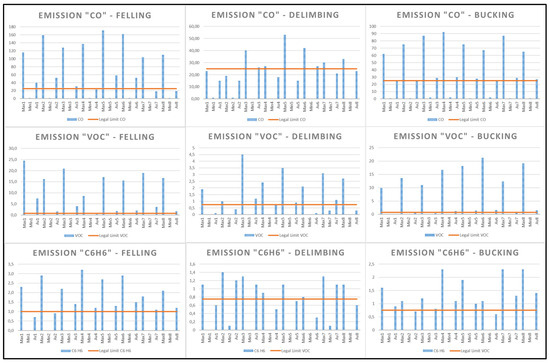

Figure 4 shows the average concentrations of CO, VOC, and C6H6 detected during each of the eight time intervals monitored for each process by using the Multi-RAE PGM-50 plus professional gas detector. The graphs also display the legally established emission limits. The graphical representations reveal noticeable changes in the measured variables, particularly in the emissions observed during the FE phase.

Figure 4.

Average CO, VOC, and C6H6 (ppm) emissions detected in each reference interval. The red line represents the legal limits for each machining operation.

To assess the variability of the data, the average of the maximum values was considered more reliable, despite the potential presence of momentary peaks. This choice is justified because during the period of 15 min of constant detection, the chainsaw engine often remains running without actively cutting. In line with this rationale, the coefficients of variation calculated on the maximum values were relatively low, whereas those calculated on the averages exhibited higher values (as shown in Table 5). The coefficients of variation were particularly higher for delimbing operations compared to other cases. This variability can be attributed to the significant diameter variations observed among branches of the same tree. The coefficients of variation computed on the average values were generally high, except for CO emissions during BU (bucking) operations, which showed a CV value of 7%.

Table 5.

Comparison between gaseous emissions measured in the field during wood processing and the imposed thresholds.

Table 5 shows that the maximum values observed during the three different interventions significantly exceeded the thresholds established by international regulations. However, observing the average values, the situation appears less critical. It should be highlighted that maximum emission values are rarely reached in the experimental time intervals during the various operations. Bucking operations (BU) showed average emissions lower than the threshold, and DE operations recorded values slightly higher and close to the limits. The most critical scenario occurred during Forest Extraction (FE) operations, with emissions exceeding the permitted threshold, in particular for volatile organic compounds (VOCs). These results highlight the greater need to use personal protective equipment (PPE) to safeguard the respiratory system, especially during the FE phase. During this phase, in fact, a significant risk emerged for operators’ health and safety.

A comparison between the average of the maximum values and the average values obtained during field operations is shown in Table 5. The presence of consistent peaks in VOC emissions for all three operations is evident. In particular, during FE operations, the maximum values recorded were approximately 16 times higher than the corresponding average values.

The results found in the present work are in accordance with those of Neri et al. [9]. Indeed, work operations, from the point of view of the chainsaw required effort, can be characterized differently depending on the emissions of CO and C6H6. During felling, the high emissions of CO and C6H6 are linked to the greater efforts of the chainsaw. However, important intervals of inactivity are recorded in the sampling interval of 15 min, and this depends both on the technical/operational characteristics linked to the particular activity (FE, DE, and BU) and on the specific fatigue of the operator. During cutting, the chainsaw is subjected to medium efforts; the high CO and C6H6 emissions are probably due to the shorter time intervals in which the chainsaw is on but not cutting than the previous operation (FE). During delimbing, the chainsaw makes small efforts, releasing moderate quantities of CO and C6H6 into the environment; furthermore, the intervals in which the engine is on but not running during the 15 min of detection are extremely reduced compared to previous operations. The chainsaw, in accordance with Kováč et al. [10], produces high VOC emissions when it is switched on but not operating at the cut. During the logging operations, the following can be observed:

- The maximum emissions recorded, 17.28 ppm for FE and 15.24 ppm for BU, are similar, and higher in the abatement phase;

- The average emissions recorded during FE (2.81 ppm) and BU (0.96 ppm) operations are very different, 2.9 times higher in the abatement phase;

- The high risk of exposure occurs in the abatement phase, when VOC emissions are particularly higher than the threshold;

- The lowest-risk situation, on the other hand, occurs during delimbing operations when the chainsaw’s non-working intervals are minimal.

3.3. Health Implications

The chainsaw is currently the predominant machine used in the forestry sector. Workers engaged in moto-manual chainsaw operations face unfavourable environmental conditions that may adversely affect their long-term occupational health [11]. Both professional and consumer chainsaws are equipped with two-stroke engines, which have distinct advantages over four-stroke engines. This technology, although simpler and less expensive to produce than the other, offers a lower weight/power ratio and can be used in various positions, such as vertical, horizontal, or lateral [12]. Extensive investigations carried out systematically since the 1960s have unveiled numerous critical concerns associated with the persistent and continuous use of such portable equipment. In addition, concerning the results of the present study, motorized and manual forestry operations are intrinsically characterized by elevated hazard rates [13]. The analyses indeed highlight significant exceeding of the thresholds set by law in terms of both noise and gaseous emissions. Prolonged exposure to these physical and chemical agents [14] is the main cause of various occupational diseases.

Furthermore, our analysis conforms to numerous studies showing that chainsaws can emit noise levels above 90 dB(A) [15], thus posing a significant risk of hearing damage to operators [16]. The vibrations transmitted to the hand–arm system, in turn, cause irreversible damage to the peripheral circulatory system of the hands, leading to capillary rupture and the onset of Raynaud’s syndrome, or ‘white fingers’ disease [17]. Despite the critical nature of these issues, there is extremely limited scientific literature explicitly addressing airborne pollutant emissions from machinery such as chainsaws [9] and specifically forestry operator exposure to BTEX and PAHs [18]. Both temporary and chronic harm, resulting from the inhalation of exhaust gases emitted by chainsaws and brush-cutters, have been hitherto considered in broad and generalized terms, often compared to those encountered in other contexts involving the use of hand-guided power tools such as lawnmowers and motor-hoes. The literature on exhaust emissions during harvesting has often focused on laboratory tests. Field operational tests are a recently developed approach, but they are essential for determining emissions based on actual engine or vehicle conditions [19]. Several studies have explored related issues, albeit with different methodologies. Ref. [20] undertook an examination of the composition of chainsaw engine exhaust emissions, concentrating on the chemical constituents present. However, the monitoring of operators’ exposure to emissions and therefore the assessment of the actual implications and risks linked to the health of the operators have been neglected. Baldauf et al. [21] conducted an assessment of the occupational exposure to airborne contaminants experienced by operators engaged in activities within urban and peri-urban green areas. However, their study did not explicitly differentiate between different tools employed, including brush-cutters and chainsaws. Dimou et al. [22] proposed a comparison of the exhaust emissions of nitrogen monoxide and methane produced by the engines of two conventional chainsaws (one professional and one amateur) with those produced by a catalytic one. Other authors [23] adopted a distinct approach by monitoring the occupational exposure of loggers to chainsaw exhaust emissions. In [24], the measurement of carboxyhemoglobin levels was utilized as an indicator of exposure to exhaust emissions. Other elements, such as the demanding nature of chainsaw tasks, contribute significantly to operator fatigue [25], increasing the heart rate and consequently accelerating breathing, potentially leading to a respiratory rate above 60 litres per minute. This further aggravates the operator’s exposure to airborne pollutants, comprising both combustion gases and the non-combusted fraction expelled along with residual residues (approximately 30% of the initial mixture utilized in two-stroke engines). Several combustion products, including BTEX (benzene, toluene, ethylbenzene, and total xylenes), have negative impacts on the lower respiratory system [26] and central nervous system [27]. Studies by [28,29] showed that PAHs (polycyclic aromatic hydrocarbons) can be present either in the particulate form or associated with the gas phase in diluted exhaust gases. The present study analyses the emissions of a chainsaw in relation to work-site safety during forestry activity in a chestnut coppice. To address these critical concerns, a series of national and EU legislative measures have been implemented over the past few decades to regulate permissible exposure levels and prescribe preventive measures to be employed accordingly. One of the most pivotal and current Italian regulations in the occupational health and safety domain is Legislative Decree No. 81 of 9 April 2008, commonly referred to as the ‘Consolidation Act on Health and Safety in the Workplace’. This innovative and continually updated legislation aims to restructure and integrate all pertinent regulations in a comprehensive manner, reflecting the progressive nature of the field.

4. Conclusions

In the present study, we proposed a comprehensive analysis of noise and gaseous emissions from a chainsaw during silvicultural operations on a chestnut coppice. The analysis of worker exposure to the noise produced by the chainsaw in the different operational phases (FE, DE, and BU) and for the different diametric classes showed strong criticalities for health and safety. The exposure limits set by the Italian regulations are almost never respected. The issue becomes more complex considering the low propensity of operators and employers in the training, use, and maintenance of PPE. The noise emission levels, despite the use of PPE contributing considerably to mitigating the acoustic pressure on workers’ hearing apparatus, were higher than the specific thresholds (Lim2 and Lim3) in at least 50% of cases.

The risk assessment of workers’ exposure to airborne pollutants is alarming. The computation of individual exposure based on measurements obtained during the sampling process showed, according to current regulations, that few operational situations reveal a moderate limit for carbon monoxide (CO) emissions. In all other samplings, the chemical risk associated with CO, VOC (volatile organic compound), and benzene inhalation was found to be non-moderate. The felling operation (FE) proved to be the most critical activity for carbon monoxide emissions.

Author Contributions

Conceptualization, P.D., F.T. N.M. and C.F.; methodology, F.T. and C.F.; software, F.T.; validation, C.F. and P.D.; formal analysis, F.T., N.D.I. and P.D.; investigation, F.T.; resources, P.D. and F.T.; data curation, F.T. and C.F.; writing—original draft preparation, P.D., F.T. and C.F.; writing—review and editing, P.D. and F.T.; visualization, C.F.; supervision, P.D. and C.F.; project administration, P.D. and C.F.; funding acquisition, P.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This work was realized as part of a collaboration between the University of Basilicata and ‘Casa delle Tecnologie Emergenti di Matera, Laboratorio del Giardino delle tecnologie emergenti—CTEMT’. Activities were conducted in the framework of the PSR 16.2 ‘SMART IRRIFERT’ project CUP: G19J21004870006.

Conflicts of Interest

The authors would like to hereby certify that there are no conflicts of interest in the data collection, analyses, and interpretation in the writing of the manuscript, or in the decision to publish the results. The authors would also like to declare that the funding of the study has been supported by the authors’ institutions.

Abbreviations

| FE | Felling |

| DE | Delimbing |

| BU | Bucking |

| CO | Carbon monoxide |

| VOC | Volatile organic compounds |

| C6H6 | Benzene |

| AV | Average noise |

| MED | Median |

| Lim | Law Limit |

| iAV | Average index |

| iMED | Median index |

| σ or SD | Standard deviation |

| µ | Average pollutants |

| CV | Coefficient of variation |

| BTEX | Benzene, toluene, ethylbenzene, and Xylenes |

| PAHs | Polycyclic aromatic hydrocarbons |

| PPE | Personal protective equipment |

References

- Toscano, F.; D’Antonio, P.; D’Antonio, C.; De Iorio, N.; Modugno, F.; Fiorentino, C. Experimental Analysis of Chainsaw Emissions in Chestnut Wood Operations. Lect. Notes Civ. Eng. 2023, 337, 957–965. [Google Scholar]

- Fiorentino, C.; Crimaldi, M.; Libergoli, P.; D’Antonio, P.; Scalcione, V. Farm Management Information Systems: Digital Register of Farm Management in Southern Italy. Lect. Notes Civ. Eng. 2022, 252, 337–354. [Google Scholar]

- AbdelRahman, M.A.E.; Metwalli, M.R.; Gao, M.; Toscano, F.; Fiorentino, C.; Scopa, A.; D’Antonio, P. Determining the Extent of Soil Degradation Processes Using Trend Analyses at a Regional Multispectral Scale. Land 2023, 12, 855. [Google Scholar] [CrossRef]

- D’Antonio, P.; D’Antonio, C.; Evangelista, C.; Doddato, V. The assessment of the sawmill noise. J. Agric. Eng. 2013, 44. [Google Scholar] [CrossRef][Green Version]

- Di Marzio, N. An Overview of Forest Cover and Management in Italy. Nova Meh. Šumarstva 2020, 41, 63–71. [Google Scholar] [CrossRef]

- Dąbrowski, A. Analysis and Laboratory Testing of Technical Injury Prevention Measures for Portable Combustion Chainsaws. Forests 2020, 11, 276. [Google Scholar] [CrossRef]

- Dimou, V.; Anezakis, V.D.; Demertzis, K. Comparative analysis of exhaust emissions caused by chainsaws with soft computing and statistical approaches. Int. J. Environ. Sci. Technol. 2018, 15, 1597–1608. [Google Scholar] [CrossRef]

- Albizu-Urionabarrenetxea, P.; Tolosana-Esteban, E.; Roman-Jordan, E. Safety and health in forest harvesting operations. Diagnosis and preventive actions. A review. For. Syst. 2013, 22, 392–400. [Google Scholar] [CrossRef]

- Neri, F.C.; Foderi, A.; Laschi, F.; Fabiano, M.; Cambi, G.; Sciarra, M.C.; Aprea, A.; Cenni, E.; Marchi, M. Determining exhaust fumes exposure in chainsaw operations. Environ. Pollut. 2016, 218, 1162–1169. [Google Scholar] [CrossRef]

- Kováč, J.; Krilek, J.; Dado, M.; Beno, P. Investigating the influence of design factors on noise and vibrations in the case of chain-saws for forestry work. FME Trans. 2018, 46, 513–519. [Google Scholar] [CrossRef]

- Ålander, T.; Antikainen, E.; Raunemaa, T.; Elonen, E.; Rautiola, A.; Torkkell, K. Particle Emissions from a Small Two-Stroke Engine: Effects of Fuel, Lubricating Oil, and Exhaust Aftertreatment on Particle Characteristics. Aerosol Sci. Technol. 2005, 39, 151–161. [Google Scholar] [CrossRef]

- Nuti, M. A Variable Timing Electronically Controlled High Pressure Injection System for 2T S.I. Engines; SAE Technical Paper 900799; SAE International: Warrendale, PA, USA, 1990. [Google Scholar] [CrossRef]

- Micheletti Cremasco, M.; Giustetto, A.; Caffaro, F.; Colantoni, A.; Cavallo, E.; Grigolato, S. Risk Assessment for Musculoskeletal Disorders in Forestry: A Comparison between RULA and REBA in the Manual Feeding of a Wood-Chipper. Int. J. Environ. Res. Public Health 2019, 16, 793. [Google Scholar] [CrossRef] [PubMed]

- Rukat, W.; Barczewski, R.; Jakubek, B.; Wróbel, M. The comparison of vibro-acoustic impact of chainsaws with electric and combustion drives. In Proceedings of the 17th International Conference Diagnostics of Machines and Vehicles, MATEC Web of Conferences, Bydgoszcz, Poland, 30 July 2018; p. 02020. [Google Scholar] [CrossRef][Green Version]

- Neri, F.; Laschi, A.; Bertuzzi, L.; Galipò, G.; Frassinelli, N.; Fabiano, F.; Marchi, E.; Foderi, C.; Marra, E. A Comparison between the Latest Models of Li-Ion Batteries and Petrol Chainsaws Assessing Noise and Vibration Exposure in Cross-Cutting. Forests 2023, 14, 898. [Google Scholar] [CrossRef]

- Iftime, M.D.; Dumitrascu, A.E.; Ciobanu, V.D. Chainsaw operators’ exposure to occupational risk factors and incidence of professional diseases specific to the forestry field. Int. J. Occup. Saf. Ergon. 2022, 28, 8–19. [Google Scholar] [CrossRef] [PubMed]

- Tavares Jesus, A.; Fiedler, N.C.; de Assis do Carmo, F.C.; Silva Juvanhol, R. Exposure of operators to chainsaw vibration in forest harvesting. Floresta 2020, 50, 1653–1659. [Google Scholar] [CrossRef]

- Magagnotti, N. Exposure of Mobile Chipper Operators to Diesel Exhaust. Ann. Occup. Hyg. March 2014, 58, 217–226. [Google Scholar] [CrossRef][Green Version]

- Lijewski, P.; Merkisz, J.; Fuć, P. Research of exhaust emissions from a harvester diesel engine with the use of portable emission measurement system. Croat. J. Eng. 2013, 34, 113–122. [Google Scholar]

- Magnusson, R.; Nilsson, C.; Andersson, K.; Andersson, B.; Gieling, R.; Wiberg, K.; Östman, C.; Rannug, U. Determination of Chemical Composition and Mutagenicity in Particles from Chainsaw Exhaust. Experimental Set-Up, Stability and Results from Two Different Fuels. Environ. Technol. 2000, 21, 819–829. [Google Scholar] [CrossRef]

- Baldauf, R.; Fortune, C.; Weinstein, J. Air contaminant exposures during the operation of lawn and garden equipment. J. Expo. Sci. Environ. Epidemiol. 2006, 16, 362–370. [Google Scholar] [CrossRef]

- Dimou, V.; Kantartzis, A.; Malesios, C.; Kasampalis, E. Research of exhaust emissions by chainsaws with the use of a portable emission measurement system. Int. J. For. Eng. 2019, 30, 228–239. [Google Scholar] [CrossRef]

- Bünger, J.; Bombosch, F.; Mesecke, U.; Hallier, E. Monitoring and Analysis of Occupational Exposure to Chain Saw Exhausts. Am. Ind. Hyg. Assoc. J. 1997, 58, 747–751. [Google Scholar] [CrossRef] [PubMed]

- Hooper, B.; Parker, R.; Todoroki, C. Exploring chainsaw operator occupational exposure to carbon monoxide in forestry. J. Occup. Environ. Hyg. 2017, 14, D1–D12. [Google Scholar] [CrossRef] [PubMed]

- Hinze, A.; König, J.L.; Bowen, J. Worker-fatigue contributing to workplace incidents in New Zealand Forestry. J. Saf. Res. 2021, 79, 304–320. [Google Scholar] [CrossRef] [PubMed]

- Moskal, A.; Makowski, L.; Sosnowski, T.R.; Gradoń, L. Deposition of Fractal-Like Aerosol Aggregates in a Model of Human Nasal Cavity. Inhal. Toxicol. 2006, 18, 725–731. [Google Scholar] [CrossRef]

- Oberdörster, G.; Sharp, Z.; Atudorei, V.; Elder, A.; Gelein, R.; Kreyling, W.; Cox, C. Translocation of Inhaled Ultrafine Particles to the Brain. Inhal. Toxicol. 2004, 16, 437–445. [Google Scholar] [CrossRef]

- Westerholm, R.N.; Alsberg, T.E.; Frommelin, A.B.; Strandell, M.E.; Rannug, J.U.; Winquist, L.; Grigoriadis, V.; Egebaeck, E.K. Effect of fuel polycyclic aromatic hydrocarbon content on the emissions of polycyclic aromatic hydrocarbons and other mutagenic substances from a gasoline-fuelled automobile. Environ. Sci. Technol. 1988, 22, 925–930. [Google Scholar] [CrossRef]

- Westerholm, R.N.; Almen, J.; Li, H.; Rannug, J.U.; Egebaeck, K.E.; Graegg, K. Chemical and biological characterization of particulate-, semivolatile-, and gas-phase-associated compounds in diluted heavy-duty diesel exhausts: A comparison of three different semivolatile-phase samplers. Environ. Sci. Technol. 1991, 25, 332–338. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).