Analysis of Tangential Leakage Flow Characteristics in a Variable Diameter Dual Circular Arc Vortex Compressor

Abstract

1. Introduction

2. Mathematical Model of Vortex Compressor Profile

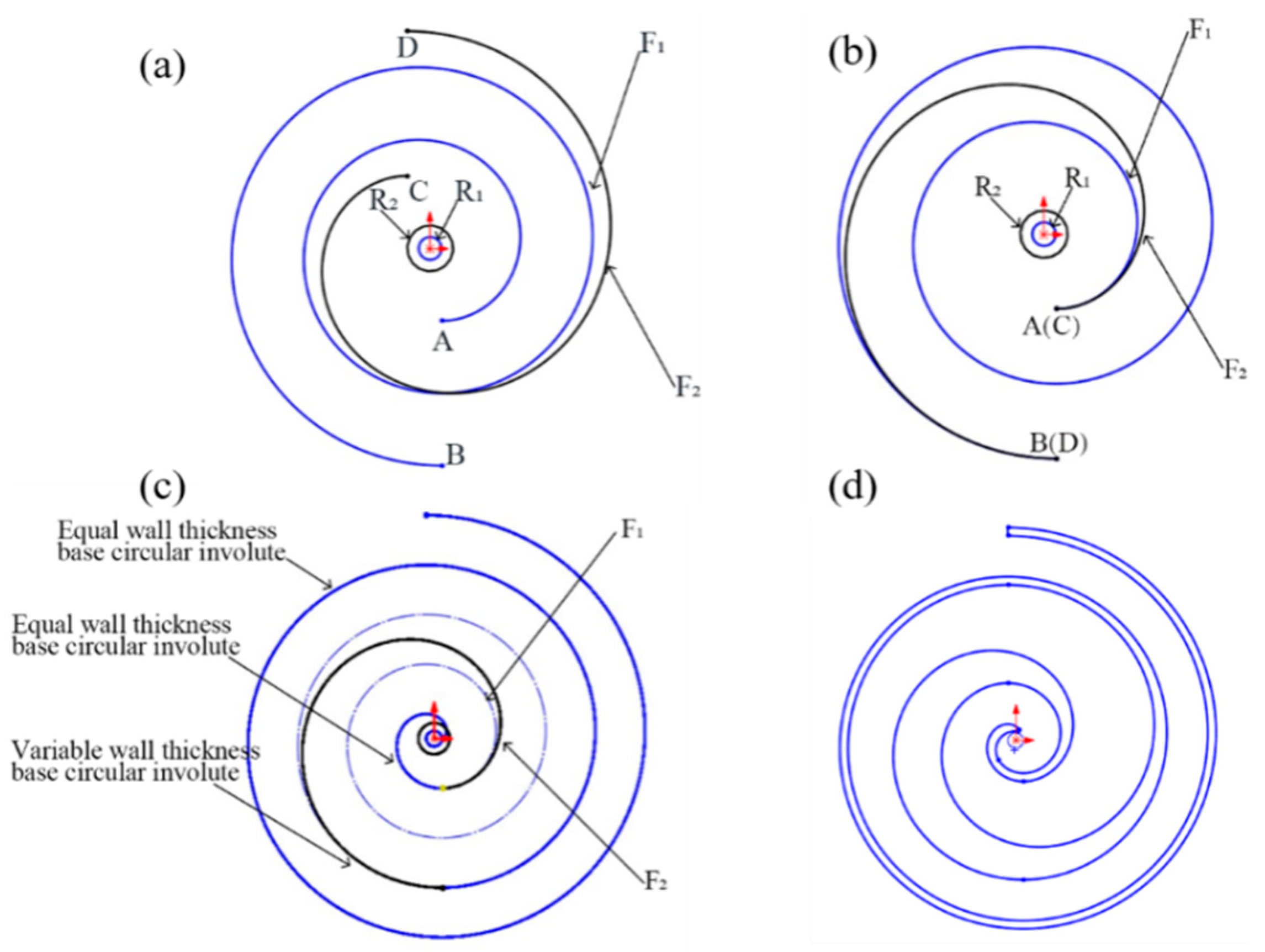

2.1. General Control Equation of the New Variable Diameter Dual Circular Arc Combined Profile

2.2. Formation Process of the New Variable Diameter Dual Circular Arc Combined Profile

2.3. Performance Analysis of the Working Chamber

3. Establishment of the Fluid Domain Model

4. Finite Element Preprocessing

4.1. Structured Grid Division

4.2. Boundary Conditions

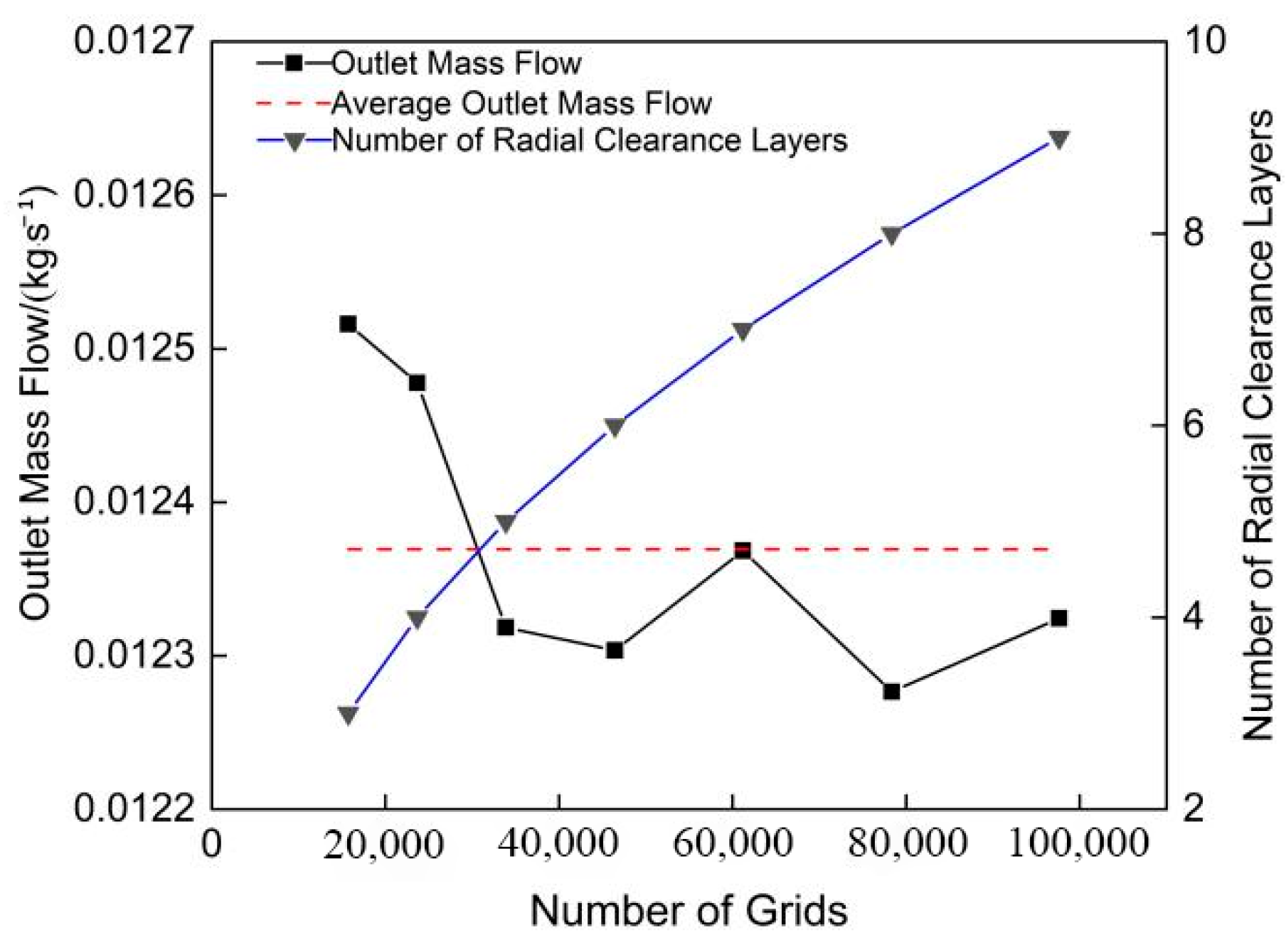

4.3. Grid Sensitivity Test

5. Simulation Results and Analysis

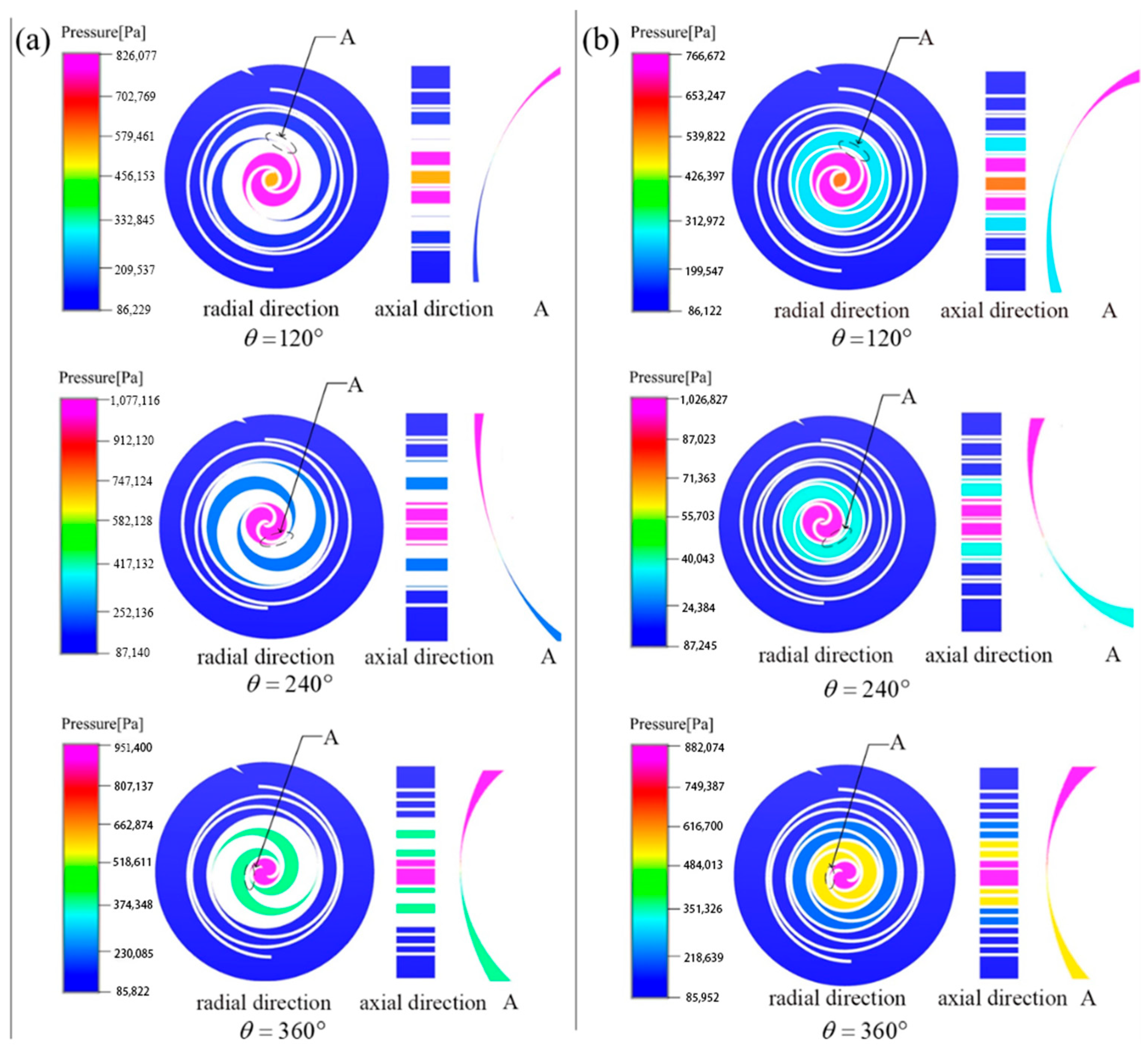

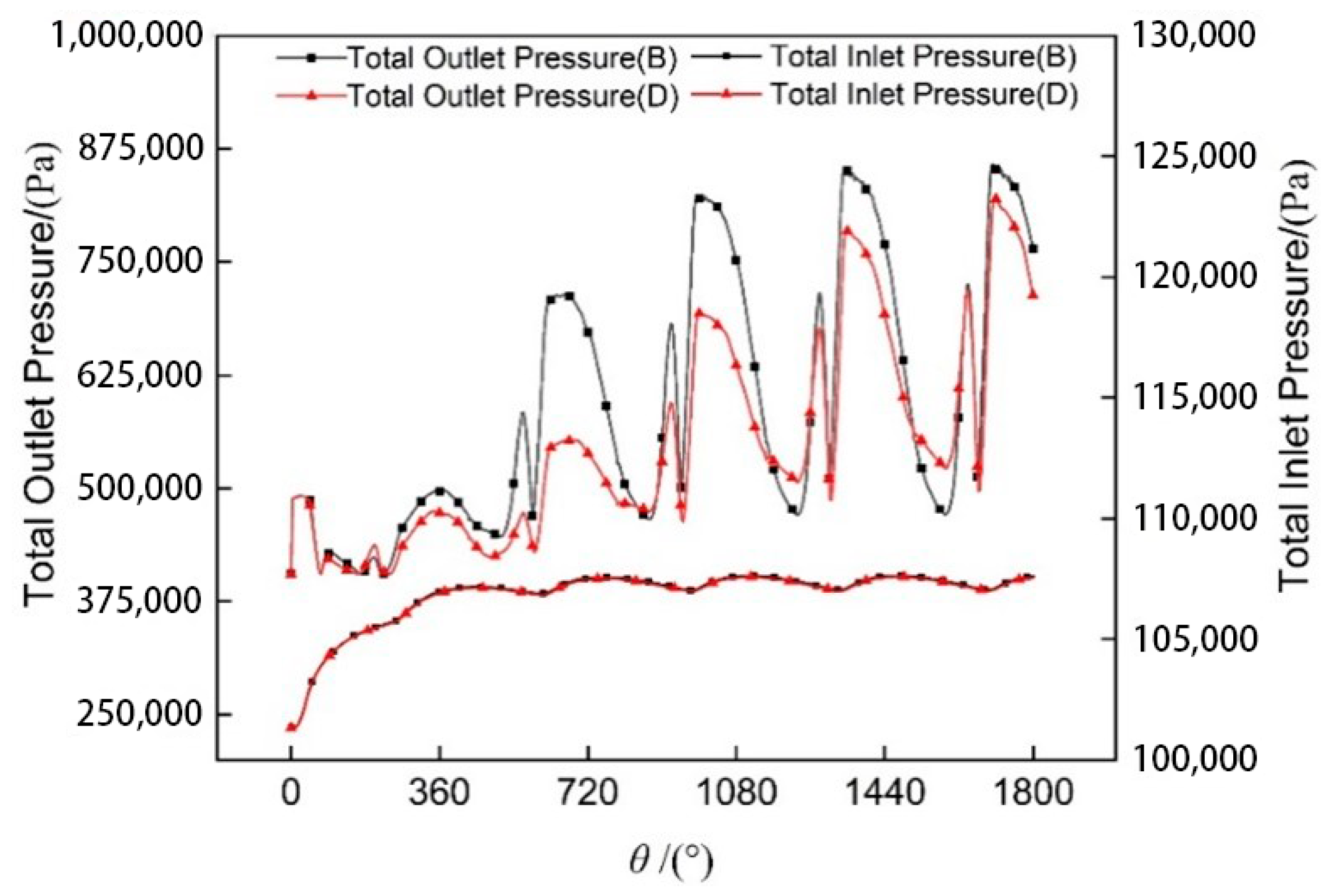

5.1. Pressure Field

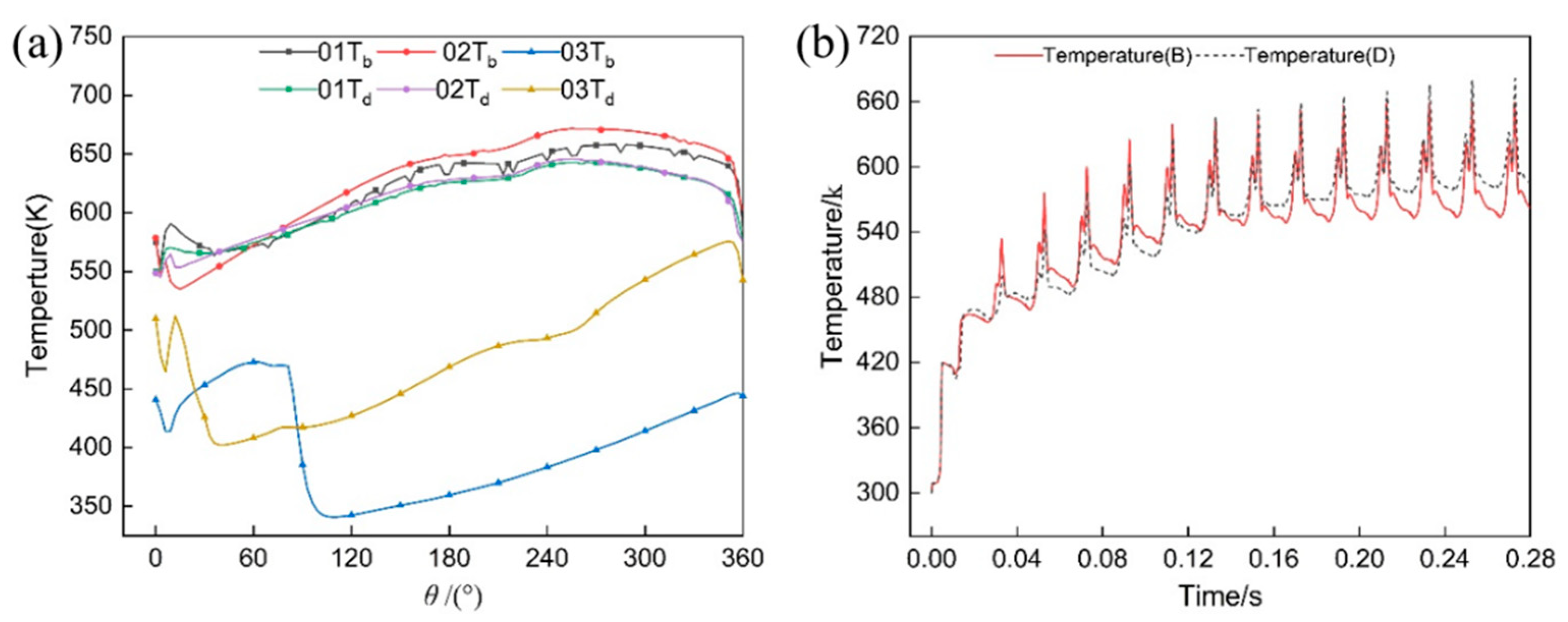

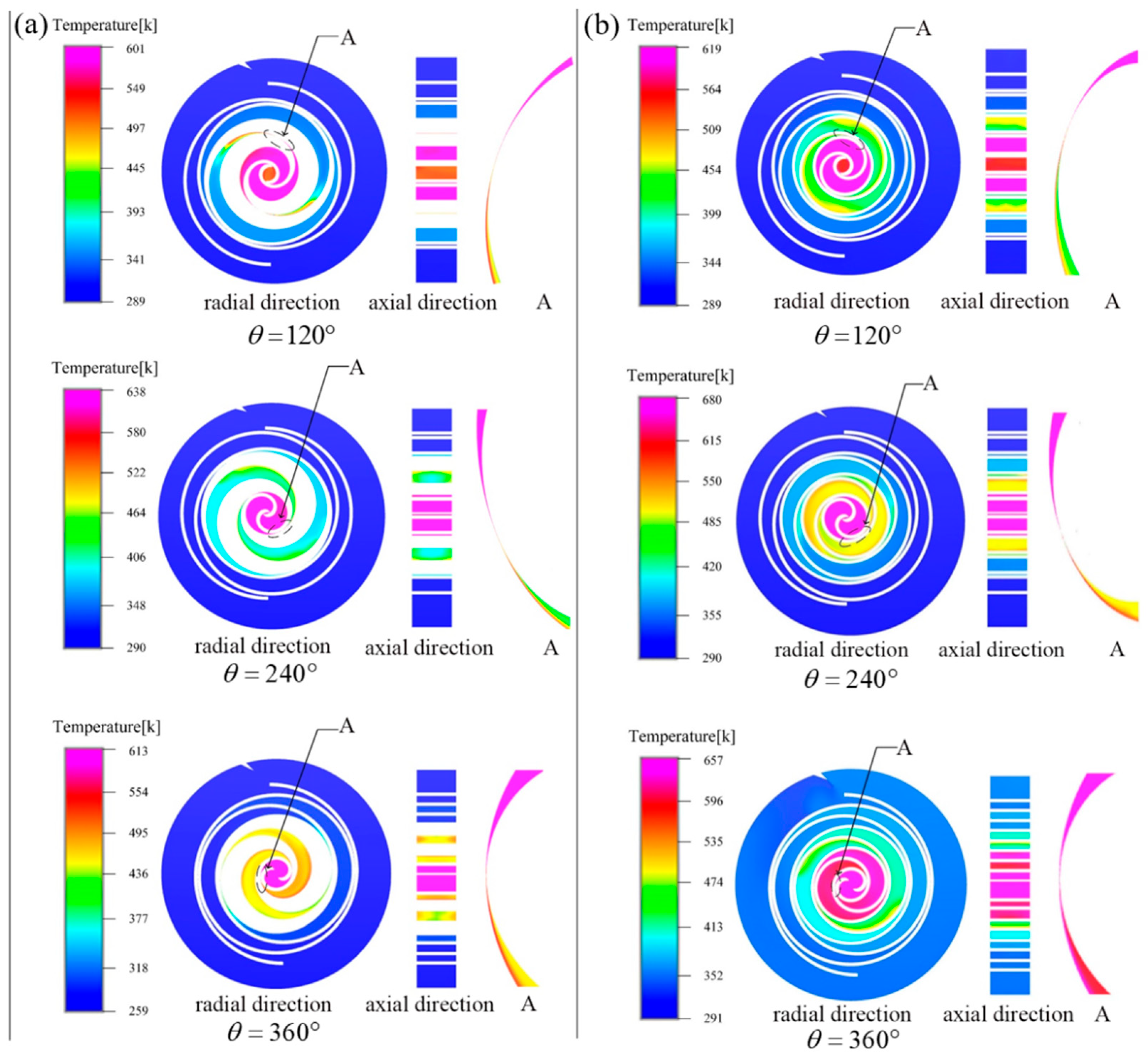

5.2. Temperature Field

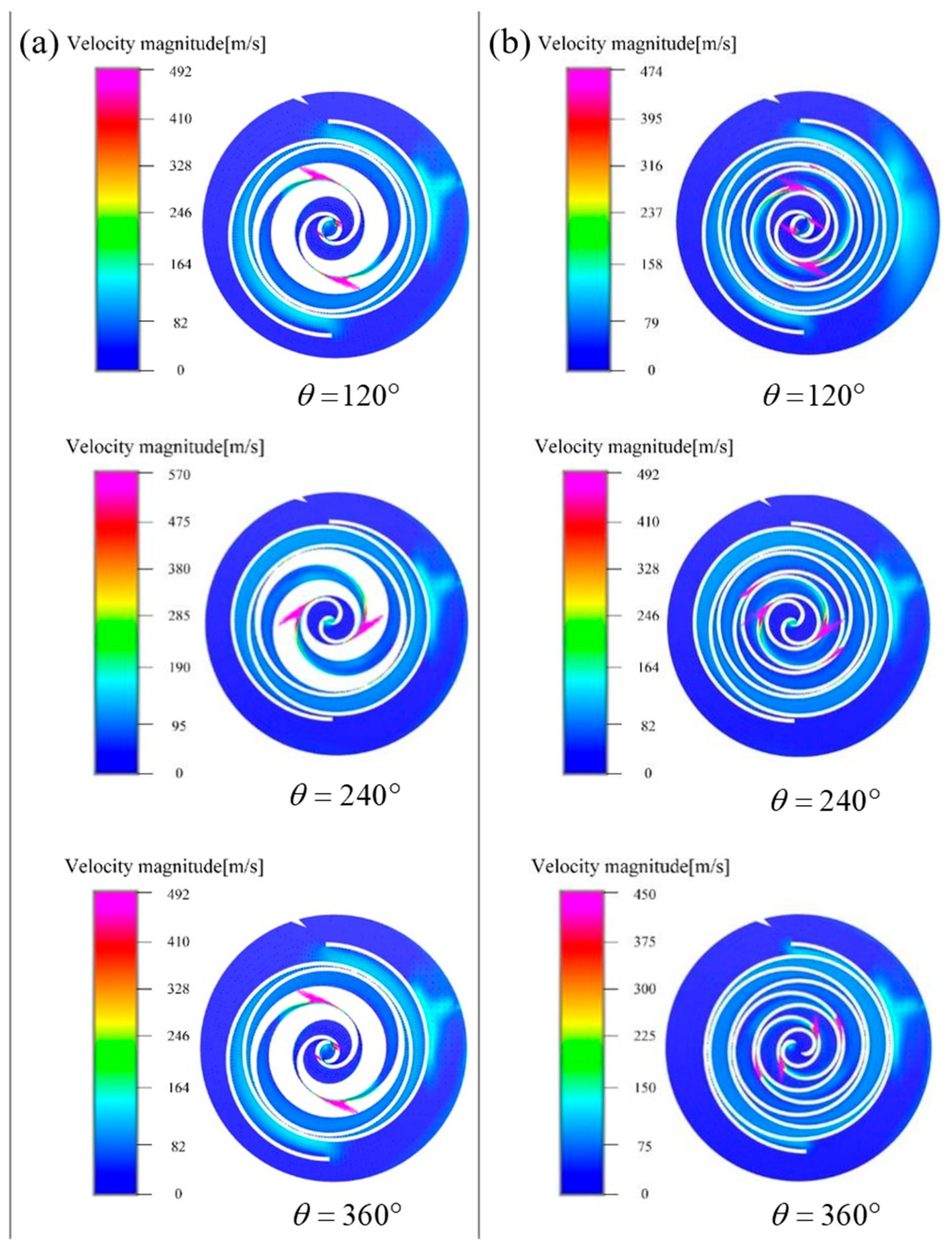

5.3. Velocity Field

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Emhardt, S.; Tian, G.; Song, P.; Chew, J.; Wei, M. CFD analysis of the influence of variable wall thickness on the aerodynamic performance of small-scale ORC scroll expanders. Energy 2022, 244, 122586. [Google Scholar] [CrossRef]

- Zhu, Y.; Yuan, W.; Guo, Q.; Wang, W.; Zhang, L.; Zhu, S. Kinematic Characteristics Analysis of Orbiting Scroll and Structural Optimization of Oldham’s Coupling in Scroll Compression. Machines 2022, 10, 623. [Google Scholar] [CrossRef]

- Cardone, M.; Gargiulo, B. Numerical simulation and experimental validation of an oil free scroll compressor. Energies 2020, 13, 5863. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, B.; Cao, J.; Su, L.; Li, K. Numerical investigation on the performance and vapor injection process of a scroll compressor with different injection features. Appl. Therm. Eng. 2022, 217, 119061. [Google Scholar] [CrossRef]

- Peng, B.; Liu, H.; Zhang, P.; Tao, Y.; Qi, T. Construction and Analysis of Variable Wall Thickness Profile of Double Scroll Teeth of Scroll Compressor. E3S Web Conf. 2021, 267, 02062. [Google Scholar] [CrossRef]

- Cheng, S.; Feng, Y.; Wang, K.; Meng, X. Tribo-dynamics modeling and analysis of key friction pairs in scroll compressor with floating fixed scroll design. Eng. Appl. Comput. Fluid Mech. 2022, 16, 2270–2285. [Google Scholar] [CrossRef]

- Pereira, E.L.; Deschamps, C.J. Numerical analysis and correlations for radial and tangential leakage of gas in scroll compressors. Int. J. Refrig. 2020, 110, 239–247. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, X.M. Transient flow analysis for multi-state automotive scroll compressors. J. Phys. Conf. Ser. 2020, 1601, 042006. [Google Scholar] [CrossRef]

- Wei, M.; Song, P.; Zhao, B.; Shi, L.; Wang, Z.; Ma, C. Unsteady flow in the suction process of a scroll expander for an ORC waste heat recovery system. Appl. Therm. Eng. 2015, 78, 460–470. [Google Scholar] [CrossRef]

- Cui, M.M. Numerical Study of Unsteady Flows in a Scroll Compressor. J. Fluids Eng. 2006, 128, 947–955. [Google Scholar] [CrossRef]

- Li, H.-S.; Wu, K.-B.; Wang, J.-S.; Chen, Y.-H.; Wu, T. Finite Element Analysis of Oil-free Scroll Compressor Seal Element. Fluid Mach. 2015, 43, 19–23. [Google Scholar]

- Sung, J.P.; Boo, J.H.; Jung, E.G. Transient Thermodynamic Modeling of a Scroll Compressor Using R22 Refrigerant. Energies 2020, 13, 3911. [Google Scholar] [CrossRef]

- Wang, B.; Li, X.; Shi, W. A general geometrical model of scroll compressors based on discretional initial angles of involute. Int. J. Refrig. 2005, 28, 958–966. [Google Scholar] [CrossRef]

- Stevanovic, V.D.; Petrovic, M.M.; Cucuz, S.; Milivojevic, S.; Ilic, M. Numerical Prediction of Refrigerant Oil Two-Phase Flow from Scroll Compressor Discharge to the Suction Side via Back Pressure Chamber. Processes 2023, 12, 6. [Google Scholar] [CrossRef]

- Li, X.; Wu, W.; Zhang, J.; Guo, C.; Ke, F.; Jiang, F. Analysis of 3D Transient Flow in a High-Speed Scroll Refrigeration Compressor. Energies 2023, 16, 3089. [Google Scholar] [CrossRef]

- Fang, J.; Xu, Y.; Zhang, H.; Yang, Z.; Wan, J.; Liu, Z. Experimental Research on the Output Performance of Scroll Compressor for Micro Scale Compressed Air Energy Storage System. Sustainability 2023, 15, 15665. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, S.; Lei, B.; Cheng, J.; Wu, J. Analysis on influence factors of back pressure in an asymmetrical algebraic scroll compressor. Int. J. Refrig. 2022, 138, 97–107. [Google Scholar] [CrossRef]

- Wang, L.C.; Chen, J.; Zhao, Y.Y.; Hussain, S.H. Research on the natural meshing mechanism and testing analysis of scroll profiles for refrigeration scroll compressor. Sci. China Technol. Sci. 2010, 53, 2783–2791. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, C.; Li, K. Hybrid Modeling and Efficiency Analysis of the Scroll Compressor Used in Micro Compressed Air Energy Storage System. Appl. Therm. Eng. 2019, 161, 114139. [Google Scholar] [CrossRef]

- Zheng, S.; Wei, M.; Song, P.; Hu, C.; Tian, R. Thermodynamics and flow unsteadiness analysis of trans-critical CO2 in a scroll compressor for mobile heat pump air-conditioning system. Appl. Therm. Eng. 2020, 175, 115368. [Google Scholar] [CrossRef]

- Du, Y.; Pekris, M.; Tian, G. CFD analysis of flank clearance sizes on micro-scale transcritical CO2 scroll expander. Appl. Therm. Eng. 2023, 232, 120980. [Google Scholar] [CrossRef]

- Rak, J.; Pietrowicz, S. Internal flow field and heat transfer investigation inside the working chamber of a scroll compressor. Energy 2020, 202, 117700. [Google Scholar] [CrossRef]

- Cavazzini, G.; Giacomel, F.; Benato, A.; Nascimben, F.; Ardizzon, G. Analysis of the inner fluid-dynamics of scroll compressors and comparison between CFD numerical and modelling approaches. Energies 2021, 14, 1158. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Z.; Xie, D.; Wu, H. Unsteady characteristic and flow mechanism of a scroll compressor in small-scale compressed air energy storage system. J. Energy Storage 2022, 51, 104368. [Google Scholar] [CrossRef]

- Song, P.; Wu, D.; Lu, Z.; Zheng, S.; Wei, M.; Zhuge, W.; Zhang, Y. An Improved Geometric Theoretical Model and Throughflow Prediction Method for a CO2 Scroll Compressor of Automotive Air Conditioning System. Int. J. Energy Res. 2023, 2023, 9382690. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Base circle radius R1/mm | 3.2 |

| Base circle radius R2/mm | 6.4 |

| Number of turns n1 | 2 |

| Number of turns n1 | 1 |

| Override Start involute Angle φ1 | 2π |

| Override Start involute Angle φ2 | π |

| Rotation angle θ | π |

| Involute termination angle φe | 8π |

| Parameters | Leakage Line Length/mm | Stroke Volume | Radial Engagement Points |

|---|---|---|---|

| Numerical value(D) | 1010.65 | 236,756.6 | 6 |

| Numerical value(B) | 757.99 | 236,756.6 | 8 |

| Parameters | Numerical Value (D) | Numerical Value (B) |

|---|---|---|

| Base circle/mm | R1 = 3.2 | R1 = 3.2, R2 = 6.4 |

| Rotation radius/mm | 6.67706433 | 6.67706433 |

| Radial clearance/um | 25 | 25 |

| Tooth height/mm | 40 | 40 |

| Inlet pressure/Pa | 101,325 | 101,325 |

| Inlet temperature/k | 300 | 300 |

| Outlet pressure/Pa | 101,325 × 4 | 101,325 × 4 |

| Speed/r·min−1 | 3000 | 3000 |

| Parameters | Numerical Value (B) | Numerical Value (D) |

|---|---|---|

| Maximum total outlet pressure/pa | 857,706 | 822,064 |

| Average total outlet pressure/pa | 663,460 | 648,044 |

| Average total inlet pressure/pa | 107,405 | 107,362 |

| Parameters | Numerical Value (B) | Numerical Value (D) | Percentage Increase |

|---|---|---|---|

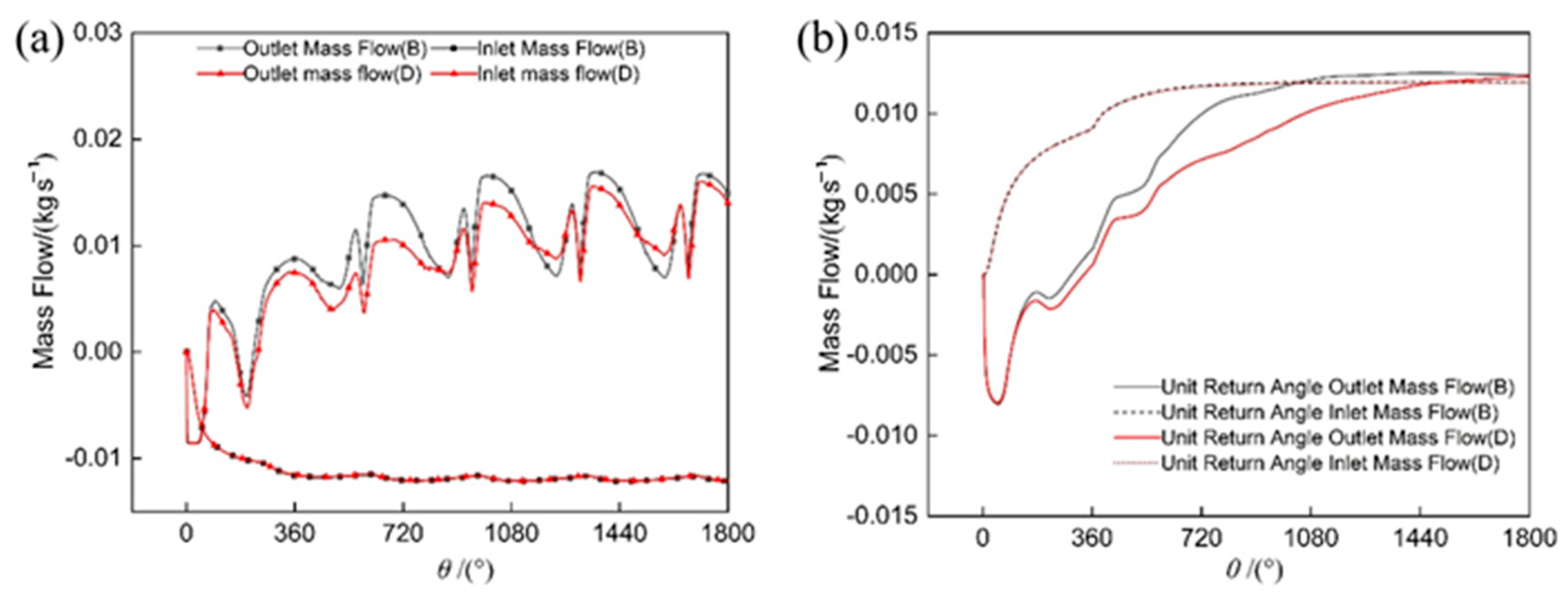

| Maximum outlet mass flow/kg∙s−1 | 0.016757900 | 0.016058100 | 4.4 |

| Maximum inlet mass flow/kg∙s−1 | 0.012135500 | 0.012110800 | 0.2 |

| Average outlet mass flow/kg∙s−1 | 0.012394011 | 0.012302680 | 0.74 |

| Average inlet mass flow/kg∙s−1 | 0.011951788 | 0.011916169 | 0.2 |

| Unit return angle outlet mass flow/kg∙s−1 | 0.012462031 | 0.012078838 | 3.2 |

| Unit return angle inlet mass flow/kg∙s−1 | 0.011949693 | 0.011913969 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Qiu, C.; Wang, Y.; Wu, M.; Ren, S.; Miao, C. Analysis of Tangential Leakage Flow Characteristics in a Variable Diameter Dual Circular Arc Vortex Compressor. Appl. Sci. 2024, 14, 2262. https://doi.org/10.3390/app14062262

Huang L, Qiu C, Wang Y, Wu M, Ren S, Miao C. Analysis of Tangential Leakage Flow Characteristics in a Variable Diameter Dual Circular Arc Vortex Compressor. Applied Sciences. 2024; 14(6):2262. https://doi.org/10.3390/app14062262

Chicago/Turabian StyleHuang, Lei, Changming Qiu, Yu Wang, Mengqi Wu, Shuai Ren, and Changdong Miao. 2024. "Analysis of Tangential Leakage Flow Characteristics in a Variable Diameter Dual Circular Arc Vortex Compressor" Applied Sciences 14, no. 6: 2262. https://doi.org/10.3390/app14062262

APA StyleHuang, L., Qiu, C., Wang, Y., Wu, M., Ren, S., & Miao, C. (2024). Analysis of Tangential Leakage Flow Characteristics in a Variable Diameter Dual Circular Arc Vortex Compressor. Applied Sciences, 14(6), 2262. https://doi.org/10.3390/app14062262