Combined Pre-Treatment Technologies for Cleaning Biogas before Its Upgrading to Biomethane: An Italian Full-Scale Anaerobic Digester Case Study

Abstract

1. Introduction

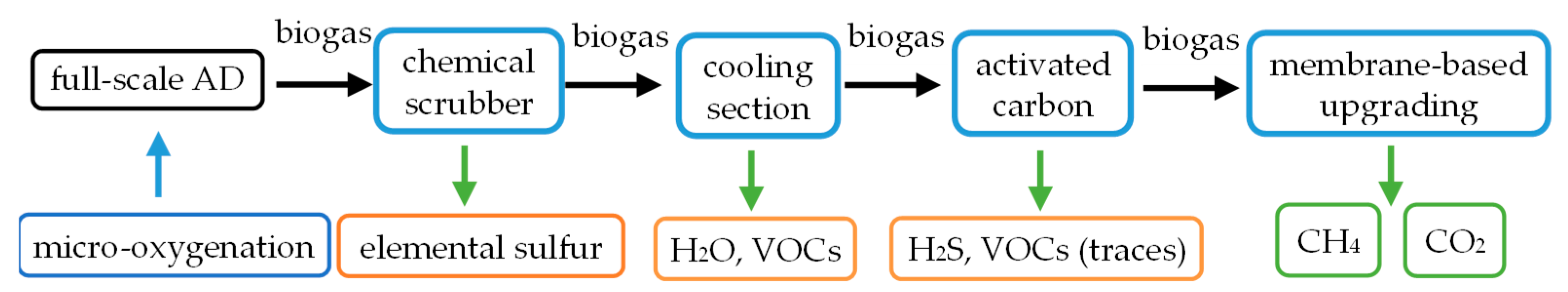

2. Materials and Methods

3. Results and Discussion

3.1. Trace Compounds in Biogas

3.2. Micro-Oxygenation

3.3. Chemical Scrubber

3.4. Cooling Section

3.5. Activated Carbon and Biogas Upgrading

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hoang, A.T.; Varbanov, P.S.; Nižetić, S.; Sirohi, R.; Pandey, A.; Luque, R.; Ng, K.H.; Pham, V.V. Perspective review on Municipal Solid Waste-to-energy route: Characteristics, management strategy, and role in circular economy. J. Cleaner Product. 2022, 359, 131897. [Google Scholar] [CrossRef]

- Sridhar, A.; Kapoor, A.; Kumar, P.S.; Ponnuchamy, M.; Balasubramanian, S.; Prabhakar, S. Conversion of food waste to energy: A focus on sustainability and life cycle assessment. Fuel 2021, 302, 121069. [Google Scholar] [CrossRef]

- Rafiee, A.; Khalilpour, K.R.; Prest, J.; Skryabin, I. Biogas as an energy vector. Biomass Bioener. 2021, 144, 105935. [Google Scholar] [CrossRef]

- Mondello, G.; Salomone, R.; Ioppolo, G.; Saija, G.; Sparacia, S.; Lucchetti, M.C. Comparative LCA of alternative scenarios for waste treatment: The case of food waste production by the mass-retail sector. Sustainability 2017, 9, 827. [Google Scholar] [CrossRef]

- Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. Available online: https://eur-lex.europa.eu/eli/dir/2018/851/oj?locale=en (accessed on 12 February 2024).

- EPA—United States Environmental Protection Agency. Food Recovery Hierarchy. Available online: https://www.epa.gov/sustainable-management-food/food-recovery-hierarchy (accessed on 12 February 2024).

- Calbry-Muzyka, A.; Madi, H.; Rüsch-Pfund, F.; Gandiglio, M.; Biollaz, S. Biogas composition from agricultural sources and organic fraction of municipal solid waste. Renew. Energ. 2022, 181, 1000–1007. [Google Scholar] [CrossRef]

- Stolecka, K.; Rusin, A. Potential hazards posed by biogas plants. Renew. Sust. Energ. Rev. 2021, 135, 110225. [Google Scholar] [CrossRef]

- Abanades, S.; Abbaspour, H.; Ahmadi, A.; Das, B.; Ehyaei, M.A.; Esmaeilion, F.; El Haj Assad, M.; Hajilounezhad, T.; Jamali, D.H.; Hmida, A.; et al. A critical review of biogas production and usage with legislations framework across the globe. Int. J. Environ. Sci. Technol. 2022, 19, 3377–3400. [Google Scholar] [CrossRef]

- Aghel, B.; Behaein, S.; Wongwises, S.; Shadloo, M.S. A review of recent progress in biogas upgrading: With emphasis on carbon capture. Biomass Bioener. 2022, 160, 106422. [Google Scholar] [CrossRef]

- Haldar, D.; Bhattacharjee, N.A.; Shabbirahmed, M.A.; Anisha, G.S.; Kumar Patel, A.; Chang, J.-S.; Dong, C.-D.; Singhania, R.R. Purification of biogas for methane enrichment using biomass-based adsorbents: A review. Biomass Bioener. 2023, 173, 106804. [Google Scholar] [CrossRef]

- Pasini, G.; Baccioli, A.; Ferrari, L.; Antonelli, M.; Frigo, S.; Desideri, U. Biomethane grid injection or biomethane liquefaction: A technical-economic analysis. Biomass Bioener. 2019, 127, 105264. [Google Scholar] [CrossRef]

- Ardolino, F.; Parrillo, F.; Arena, U. Biowaste-to-biomethane or biowaste-to energy? An LCA study on anaerobic digestion of organic waste. J. Clean. Product. 2018, 174, 462–476. [Google Scholar] [CrossRef]

- Bragança, I.; Sánchez-Soberón, F.; Pantuzza, G.F.; Alves, A.; Ratola, N. Impurities in biogas: Analytical strategies, occurrence, effects and removal technologies. Biomass Bioener. 2020, 143, 105878. [Google Scholar] [CrossRef]

- Macor, A.; Benato, A. Regulated emissions of biogas engines—On site experimental measurements and damage assessment on human health. Energies 2020, 13, 1044. [Google Scholar] [CrossRef]

- Werkneh, A.A. Biogas impurities: Environmental and health implications, removal technologies and future perspectives. Heliyon 2022, 8, e10929. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Alaimo, C.P.; Kim, M.; Kado, N.Y.; Peppers, J.; Xue, J.; Wan, C.; Green, P.G.; Zhang, R.; Jenkins, B.M.; et al. Composition and toxicity of biogas produced from different feedstocks in California. Environ. Sci. Technol. 2019, 53, 11569–11579. [Google Scholar] [CrossRef] [PubMed]

- Giordano, A.; Di Capua, F.; Esposito, G.; Pirozzi, F. Long-term biogas desulfurization under different microaerobic conditions in full-scale thermophilic digesters co-digesting high-solid sewage sludge. Int. Biodeter. Biodegr. 2019, 142, 131–136. [Google Scholar] [CrossRef]

- UNI EN 16723-2:2017; Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural Gas Network—Part 2: Automotive Fuels Specification. Available online: https://store.uni.com/uni-en-16723-2-2017 (accessed on 12 February 2024).

- UNI EN 16723-1:2016; Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural gas Network—Part 1: Specifications for Biomethane for Injection in the Natural Gas Network. Available online: https://store.uni.com/uni-en-16723-1-2016 (accessed on 12 February 2024).

- Vu, H.P.; Nguyen, L.N.; Wang, Q.; Ngo, H.H.; Liu, Q.; Zhang, X.; Nghiem, L.D. Hydrogen sulphide management in anaerobic digestion: A critical review on input control, process regulation, and post-treatment. Bioresour. Technol. 2022, 346, 126634. [Google Scholar] [CrossRef]

- Tian, G.; Xi, J.; Yeung, M.; Ren, G. Characteristics and mechanisms of H2S production in anaerobic digestion of food waste. Sci. Total Environ. 2020, 724, 137977. [Google Scholar] [CrossRef]

- Paglini, R.; Gandiglio, M.; Lanzini, A. technologies for deep biogas purification and use in zero-emission fuel cells systems. Energies 2022, 15, 3551. [Google Scholar] [CrossRef]

- Pudi, A.; Rezaei, M.; Signorini, V.; Andersson, M.P.; Baschetti, M.G.; Mansouri, S.S. Hydrogen sulfide capture and removal technologies: A comprehensive review of recent developments and emerging trends. Sep. Purif. Technol. 2022, 298, 121448. [Google Scholar] [CrossRef]

- Azizi, S.M.M.; Zakaria, B.S.; Haffiez, N.; Niknejad, P.; Dhar, B.R. A critical review of prospects and operational challenges of microaeration and iron dosing for in-situ biogas desulfurization. Bioresour. Technol. Rep. 2022, 20, 101265. [Google Scholar] [CrossRef]

- Okoro, O.V.; Sun, Z. Desulphurisation of biogas: A systematic qualitative and economic-based quantitative review of alternative strategies. Chem. Eng. 2019, 3, 76. [Google Scholar] [CrossRef]

- Zheng, G.; Liu, J.; Shao, Z.; Chen, T. Emission characteristics and health risk assessment of VOCs from a food waste anaerobic digestion plant: A case study of Suzhou, China. Environ. Pollut. 2020, 257, 113546. [Google Scholar] [CrossRef]

- Pascual, C.; Cantera, S.; Lebrero, R. Volatile siloxanes emissions: Impact and sustainable abatement perspectives. Trends Biotechnol. 2021, 39, 1245–1248. [Google Scholar] [CrossRef]

- Li, C.; He, L.; Yao, X.; Yao, Z. Recent advances in the chemical oxidation of gaseous volatile organic compounds (VOCs) in liquid phase. Chemosphere 2022, 295, 133868. [Google Scholar] [CrossRef]

- Villarim, P.; Genty, E.; Zemmouri, J.; Fourmentin, S. Deep eutectic solvents and conventional solvents as VOC absorbents for biogas upgrading: A comparative study. Chem. Eng. J. 2022, 446 Pt 1, 136875. [Google Scholar] [CrossRef]

- Esposito, E.; Dellamuzia, L.; Moretti, U.; Fuoco, A.; Giorno, L.; Jansen, J.C. Simultaneous production of biomethane and food grade CO2 from biogas: An industrial case study. Energy Environ. Sci. 2019, 12, 281–289. [Google Scholar] [CrossRef]

- Le Pera, A.; Sellaro, M.; Migliori, M.; Bianco, M.; Zanardi, G. Dry mesophilic anaerobic digestion of separately collected organic fraction of municipal solid waste: Two-year experience in an industrial-scale plant. Processes 2021, 9, 213. [Google Scholar] [CrossRef]

- Ministry of Economic Development, Technical Rule Update. 2018. Available online: https://www.mise.gov.it/images/stories/normativa/decreto_ministeriale_18_maggio_2018_gas_aggiornamento_%20regola_tecnica.pdf (accessed on 12 February 2024).

- Brunetti, A.; Barbieri, G. Membrane engineering for biogas valorization. Front. Chem. Eng. 2021, 3, 775788. [Google Scholar] [CrossRef]

- Marín, D.; Méndez, L.; Suero, I.; Díaz, I.; Blanco, S.; Fdz-Polanco, M.; Muñoz, R. Anaerobic digestion of food waste coupled with biogas upgrading in an outdoors algal-bacterial photobioreactor at pilot scale. Fuel 2022, 324, 124554. [Google Scholar] [CrossRef]

- Muller, C.; Guevarra, K.; Summers, A.; Pierce, L.; Shahbaz, P.; Zemke, P.E.; Woodland, K.; Hollingsworth, V.; Nakhla, G.; Bell, K.; et al. A review of the practical application of micro-aeration and oxygenation for hydrogen sulfide management in anaerobic digesters. Process Saf. Environ. Prot. 2022, 165, 126–137. [Google Scholar] [CrossRef]

- Díaz, I.; Ramos, I.; Fdz-Polanco, M. Economic analysis of microaerobic removal of H2S from biogas in full-scale sludge digesters. Bioresour. Technol. 2015, 192, 280–286. [Google Scholar] [CrossRef]

- Díaz, I.; Lopes, A.C.; Pérez, S.I.; Fdz-Polanco, M. Performance evaluation of oxygen, air and nitrate for the microaerobic removal of hydrogen sulphide in biogas from sludge digestion. Bioresour. Technol. 2010, 101, 7724–7730. [Google Scholar] [CrossRef]

- Katariya, H.G.; Patolia, H.P. Methane enrichment in biogas by using aqueous solutions of alkaline salts. Biomass Conv. Bioref. 2021, 13, 7947–7953. [Google Scholar] [CrossRef]

- Gao, S.; Bo, C.; Li, J.; Niu, C.; Lu, X. Multi-objective optimization and dynamic control of biogas pressurized water scrubbing process. Renew. Energ. 2020, 147 Pt 1, 2335–2344. [Google Scholar] [CrossRef]

- Castrillon, M.C.; Moura, K.O.; Alves, C.A.; Bastos-Neto, M.; Azevedo, D.C.S.; Hofmann, J.; Möllmer, J.; Einicke, W.-D.; Gläser, R. CO2 and H2S removal from CH4-rich streams by adsorption on activated carbons modified with K2CO3, NaOH, or Fe2O3. Energy Fuels 2016, 30, 9596–9604. [Google Scholar] [CrossRef]

| Mean a | SD b | Min | Max | |

|---|---|---|---|---|

| CH4 (%vol) | 59.4 | 1.0 | 58.1 | 60.5 |

| CO2 (%vol) | 40.1 | 0.9 | 39.2 | 40.8 |

| H2S (ppmv) | 1207 | 421 | 613 | 1740 |

| VOCs (mg/Nm3) | 895 | 304 | 432 | 1425 |

| H2O (%vol) | 0.3 | 0.2 | 0.1 | 0.6 |

| N2 (%vol) | 0.2 | 0.1 | 0.1 | 0.3 |

| HCl (mg/Nm3) | 17 | 4 | 12 | 20 |

| NH3 (mg/Nm3) | 36 | 7 | 30 | 46 |

| Siloxanes (mg Si/Nm3) | 0.6 | 0.2 | 0.2 | 0.8 |

| Compound (mg/Nm3) | December–May | June–November | Annual | ||||

|---|---|---|---|---|---|---|---|

| Min | Max | Mean | Min | Max | Mean | Mean | |

| Total VOCs | 582 | 1425 | 1149 | 432 | 746 | 661 | 895 |

| limonene | 199 | 670 | 449 | 58 | 128 | 94 | 272 |

| α-pinene | 113 | 237 | 173 | 26 | 71 | 42 | 108 |

| β-pinene | 118 | 218 | 152 | 37 | 80 | 44 | 98 |

| p-cymene | 89 | 262 | 178 | 14 | 85 | 38 | 108 |

| γ-terpinene | 0 | 1 | 0 | 0 | 15 | 4 | 2 |

| myrcene | 0 | 0 | 0 | 0 | 4 | 1 | <1 |

| Δ-3-carene | 0 | 1 | 0 | 0 | 10 | 3 | 1 |

| propane | 0 | 8 | 2 | 6 | 40 | 27 | 15 |

| butane | 0 | 10 | 3 | 3 | 45 | 28 | 15 |

| pentane | 0 | 2 | 1 | 0 | 5 | 2 | 1 |

| hexane | 0 | 6 | 1 | 8 | 25 | 17 | 9 |

| heptane | 0 | 7 | 2 | 10 | 32 | 24 | 13 |

| 2-methyl-pentane | 0 | 1 | 0 | 0 | 3 | 1 | <1 |

| benzene | 2 | 32 | 23 | 26 | 112 | 42 | 33 |

| toluene | 1 | 24 | 17 | 22 | 34 | 25 | 21 |

| ethyl-benzene | 1 | 26 | 22 | 22 | 39 | 26 | 24 |

| xylene a | 7 | 41 | 26 | 37 | 82 | 51 | 39 |

| mesitylene | 0 | 5 | 1 | 0 | 1 | 0 | 1 |

| cumene | 3 | 40 | 28 | 34 | 72 | 43 | 36 |

| acetone | 5 | 14 | 9 | 32 | 64 | 35 | 22 |

| methyl-ethyl-ketone | 18 | 38 | 32 | 79 | 147 | 122 | 77 |

| hexanal | 1 | 12 | 8 | 0 | 3 | 1 | 3 |

| heptanal | 1 | 10 | 4 | 0 | 1 | 0 | 1 |

| octamethylcyclotetrasiloxane | 0 | 1 | 0 | 0 | 2 | 1 | <1 |

| decamethylcyclopentasiloxane | 0 | 2 | 0 | 0 | 3 | 1 | <1 |

| Entry | O2 (%vol ± 0.01) | H2S (ppmv) | H2S Removal (%) |

|---|---|---|---|

| 1 | 0.0 | 860 | // |

| 2 | 0.1 | 506 | 41.2 |

| 3 | 0.2 | 319 | 62.9 |

| 4 | 0.3 | 264 | 69.3 |

| 5 | 0.4 | 268 | 68.8 |

| 6 | 0.5 | 262 | 69.5 |

| 7 | 0.6 | 268 | 68.8 |

| 8 a | 0.3 | 161 | 81.3 |

| 9 a | 0.4 | 137 | 84.1 |

| 10 a | 0.5 | 135 | 84.3 |

| Entry | 40% FeCl3 (L/h) | H2Sin (ppmv) | H2Sout (ppmv) | H2S Removal (%) | pH |

|---|---|---|---|---|---|

| 1 | 0.5 | 260 | 96 | 63.1 | 8.6 |

| 2 | 0.8 | 255 | 65 | 74.5 | 8.6 |

| 3 | 1.0 | 257 | 52 | 79.8 | 8.6 |

| 4 | 1.5 | 252 | 33 | 86.9 | 8.6 |

| 5 | 2.0 | 263 | 34 | 87.1 | 8.6 |

| 6 | 3.0 | 261 | 32 | 87.7 | 8.6 |

| 7 | 1.5 | 270 | 52 | 80.7 | 8.3 |

| 8 | 1.5 | 259 | 25 | 90.3 | 9.0 |

| Compound (mg/Nm3) | December–May | June–November | Annual | ||||

|---|---|---|---|---|---|---|---|

| Min | Max | Mean | Min | Max | Mean | Mean | |

| Total VOCs | 532 | 1246 | 1022 | 306 | 584 | 422 | 722 |

| limonene | 185 | 648 | 442 | 50 | 96 | 72 | 251 |

| α-pinene | 101 | 213 | 159 | 17 | 62 | 33 | 96 |

| β-pinene | 117 | 215 | 137 | 34 | 77 | 40 | 89 |

| p-cymene | 84 | 241 | 162 | 14 | 74 | 28 | 95 |

| γ-terpinene | 0 | 1 | 0 | 0 | 6 | 2 | 1 |

| myrcene | 0 | 0 | 0 | 0 | 3 | 1 | <1 |

| Δ-3-carene | 0 | 0 | 0 | 0 | 5 | 2 | 1 |

| propane | 0 | 8 | 1 | 2 | 33 | 23 | 12 |

| butane | 0 | 11 | 2 | 1 | 35 | 24 | 12 |

| pentane | 0 | 1 | 0 | 0 | 1 | 0 | <1 |

| hexane | 0 | 6 | 1 | 6 | 24 | 15 | 8 |

| heptane | 0 | 6 | 2 | 7 | 26 | 20 | 11 |

| 2-methyl-pentane | 0 | 0 | 0 | 0 | 2 | 1 | <1 |

| benzene | 2 | 32 | 21 | 24 | 110 | 38 | 34 |

| toluene | 0 | 21 | 16 | 22 | 31 | 24 | 20 |

| ethyl-benzene | 0 | 23 | 21 | 20 | 34 | 24 | 22 |

| xylene a | 5 | 37 | 24 | 28 | 69 | 36 | 34 |

| mesitylene | 0 | 3 | 1 | 0 | 0 | 0 | <1 |

| cumene | 2 | 35 | 26 | 30 | 68 | 33 | 31 |

| acetone | 0 | 1 | 0 | 0 | 4 | 2 | 1 |

| methyl-ethyl-ketone | 0 | 2 | 1 | 0 | 6 | 2 | 2 |

| hexanal | 0 | 2 | 0 | 0 | 0 | 0 | 0 |

| heptanal | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| octamethylcyclotetrasiloxane | 0 | 1 | 0 | 0 | 1 | 0 | <1 |

| decamethylcyclopentasiloxane | 0 | 1 | 0 | 0 | 2 | 0 | <1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le Pera, A.; Sellaro, M.; Pellegrino, C.; Limonti, C.; Siciliano, A. Combined Pre-Treatment Technologies for Cleaning Biogas before Its Upgrading to Biomethane: An Italian Full-Scale Anaerobic Digester Case Study. Appl. Sci. 2024, 14, 2053. https://doi.org/10.3390/app14052053

Le Pera A, Sellaro M, Pellegrino C, Limonti C, Siciliano A. Combined Pre-Treatment Technologies for Cleaning Biogas before Its Upgrading to Biomethane: An Italian Full-Scale Anaerobic Digester Case Study. Applied Sciences. 2024; 14(5):2053. https://doi.org/10.3390/app14052053

Chicago/Turabian StyleLe Pera, Adolfo, Miriam Sellaro, Crescenzo Pellegrino, Carlo Limonti, and Alessio Siciliano. 2024. "Combined Pre-Treatment Technologies for Cleaning Biogas before Its Upgrading to Biomethane: An Italian Full-Scale Anaerobic Digester Case Study" Applied Sciences 14, no. 5: 2053. https://doi.org/10.3390/app14052053

APA StyleLe Pera, A., Sellaro, M., Pellegrino, C., Limonti, C., & Siciliano, A. (2024). Combined Pre-Treatment Technologies for Cleaning Biogas before Its Upgrading to Biomethane: An Italian Full-Scale Anaerobic Digester Case Study. Applied Sciences, 14(5), 2053. https://doi.org/10.3390/app14052053