Featured Application

Development of novel and green technologies to produce biochemicals, especially biodiesel and biolubricants from municipal sewage sludge.

Abstract

In this work, a detailed analysis of the lipid component in primary sludge and sewage scum up-taken from several wastewater treatment plants located in southern Italy was carried out. Lipids in the primary sludge accounted for 200–250 mg/g of the total solids (TS), with calcium soaps as a main component (70–82%), while total lipids made up about 350–500 mg/gTS in the sewage scum and consisted mainly of FFAs (45–60%) and calcium soaps (27–35%). In addition, estolides and 10-hydroxystearic acid were also quantified. A specific valorization process was then developed and tested for either primary sludge or sewage scum. In detail, lipids were first recovered, chemically activated by the addition of acids (calcium soaps were converted to free fatty acids) and finally reacted with methanol to obtain methyl esters. The lipid recovery from primary sludge and sewage scum was particularly efficient (recoverability of 92–99%). The conversion of the starting acids into FAMEs (yield > 98%) was achieved under very mild conditions (70 °C, 2 h) with AlCl3·6H2O as a catalyst. Biodiesel (according to EN14214), methyl 10-hydroxystearate and methyl estolides were efficiently isolated by distillation under vacuum. Finally, a feasibility study of the proposed processes was carried out to evaluate their possible integration into a wastewater treatment plant, critically analyzing both the positive aspects and the relative limitations.

1. Introduction

Urbanization is increasing rapidly worldwide: in 2018, 55% of the world’s population lived in urban areas, and it is predicted that this proportion will reach 68% by 2050 [1]. Two issues are directly related: the ever-increasing environmental impact of industrialization with the resulting use of fossil fuels and the global scarcity of resources. With the growing world population, the demand for resources is expected to increase rapidly, indicating an increasing consumption of natural resources. The total global material consumption is forecasted to reach around 90 billion tons by 2050 [2,3]. As planet Earth’s resources are limited, exponential economic and population growth demands cannot be met [4,5]. Rapid urbanization and the depletion of resources have led to the traditional linear system of take–produce–use–dispose evolving into a circular system of resource conservation and reuse. The circular economy is a sustainable development approach based on a waste management strategy of reducing, recycling and recovering waste [6,7,8,9,10]. It could increasingly solve several problems, such as resource scarcity and waste generation, generating sustainable economic benefits towards a resource-efficient and environmentally friendly society [11,12]. In this way, significant benefits can be achieved as waste-derived energy and fuels can replace fossil resources, limiting carbon dioxide (CO2) emissions and providing economic, social and environmental benefits. Considerable efforts have been made worldwide in various sectors, such as waste management, food production, the electronics industry, the construction sector, the automotive sector, etc., to achieve the objectives of the circular economy. Utilizing municipal wastewater’s chemical and energetic potential is a topic of great interest. In industrialized countries, wastewater treatment plants (WWTPs) account for more than 1% of municipal electricity consumption [13,14]. However, the energy content of incoming municipal wastewater is usually more than ten times higher than the energy required to operate the treatment plants [15,16,17]. This energetic evaluation clearly shows that raw wastewater should be regarded as a valuable resource and not as waste to be disposed of. Potentially, WWTPs could not only be energy self-sufficient but also act as net energy suppliers. Half of this energy is due to suspended biodegradable solids [18,19], which can be easily recovered through inexpensive and simple physical separation. In this scenario, the recovery of valuable streams from raw wastewater can be achieved by utilizing the potential of the sludge in which most of the suspended solids have been concentrated. The management of sewage sludge according to the circular economy concept would be beneficial from several points of view. Firstly, sustainable energy or valuable products could be generated to replace an equivalent amount of materials/energy that would otherwise have to be produced from non-renewable resources with significant environmental impacts [20,21,22,23]. It could also reduce the overall cost of sludge treatment, which accounts for about 50% of the total operating cost of wastewater treatment plants (WWTPs) [24,25]. Finally, the environmental impact could also be reduced, as sludge disposal is responsible for 40% of total greenhouse gas emissions from WWTPs [26,27,28]. Different types of sludge are produced in a municipal WWTP, depending on the treatment stage. Primary sludge, which contains 2–9% by weight (%wt) of solids [29,30], is produced during primary treatment (precipitation and sedimentation) to remove heavy solids and fats from raw wastewater [31,32,33]. It has a higher content of total and volatile solids than secondary biological sludge and is theoretically suitable for energy and materials recovery [34]. Sewage scum is a special waste produced in wastewater treatment plants. It is listed under the European Waste Code (EWC) 190809 and can be easily separated from incoming municipal sewage by flotation in the pretreatment stage. Nowadays, sewage sludge is disposed of as wet material in landfills (total solids content 20–30%wt at approx. 200–300 € ton−1). Several physical, chemical and biological processes have been developed to minimize sludge production [35,36,37]. The most common methods for disposing sewage sludge are incineration, landfilling [38,39] or reuse in agriculture [40,41]. Recently, new technologies have been developed for their utilization, with particular attention paid to the lipid component, which can produce biodiesel. Biodiesel is a mixture of fatty acid methyl esters (FAMEs) produced mainly by the transesterification of refined vegetable oils in the presence of alkaline catalysts [42,43]. To reduce the use of renewable energy sources and the cost of biodiesel production, alternative, less expensive feedstocks have been used, such as waste oils [44,45], animal fats [46,47] and oils from macro- and microalgae [48,49]. In this context, sewage sludge represents a possible alternative source of lipids that meets sustainability criteria [50,51]. In this work, a detailed analysis of the lipid component in primary sludge and sewage scum samples up-taken from several wastewater treatment plants (WWTPs) in southern Italy was carried out to achieve an optimal synthetic process for extracting raw lipids and producing biodiesel following European standards (EN14214 [52]). Lipids in the primary sludge accounted for 200–250 mg/g of the total solids (TS), with calcium soaps being the main component (70–82%). In contrast, the total lipids in the sewage sludge amounted to about 350–500 mg/gTS and consisted mainly of FFAs (45–60%) and calcium soaps (27–35%). In addition, estolides and 10-hydroxystearic acid were found in considerable amounts, with (R)-10-hydroxystearic as the most abundant enantiomer. Subsequently, a novel strategy for the extraction and chemical upgrading of primary sludge and sewage scum was proposed and experimentally tested in order to obtain biodiesel, methyl estolides and methyl 10-hydroxystearate efficiently. Finally, a feasibility study of the proposed processes was carried out to evaluate the possible integration into a wastewater treatment plant, taking a critical look at the positive aspects and the associated limitations.

2. Materials and Methods

2.1. Primary Sludge and Sewage Scum

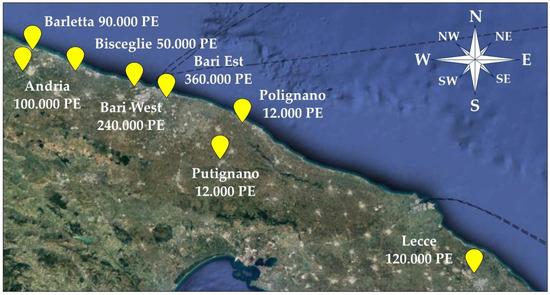

Sewage sludge samples were collected from several WWTPs located in the Apulia region, southern Italy (Figure 1). Primary sludge samples were taken from municipal WWTPs of Bari Est (360.000 Population Equivalent, PE), Bari West (240.000 PE), Putignano (12.000 PE) and Lecce (120.000 PE). Sewage scum was taken from Bari West (240.000 PE), Andria (100.000 PE), Barletta (90.000 PE), Bisceglie (50.000 PE), Putignano (12.000 PE) and Polignano a Mare (12.000 PE). The samples were immediately processed to avoid a long storage time (4 °C) and chemically characterized according to the experimental procedure described in Supplementary Material (Section S.1).

Figure 1.

Geolocation of WWTPs located in the Apulia region, southern Italy.

2.2. Valorization of Lipids of Primary Sludge and Sewage Scum

2.2.1. Recovery of Lipids

Primary sludge was centrifuged (4000 rpm, 3 min) to obtain a total solids (TS) value of about 10%wt. Then, 2 mL of H2SO4 (96%) and 150 mL of hexane (3 times × 50 mL) were added to 150 g centrifuged sludge and stirred for 4 h at 25 °C. The hexane was easily separated from the exhausted slurry and recovered using rotavapor (80 °C, 500 ± 5 mmHg) [53]. The residual oil was weighed and used directly for the esterification process. Sewage scum was heated to 80 °C in a thermostatic bath and then rapidly centrifuged (4000 rpm, 3 min). A three-phase system was obtained: (i) an upper oily phase of lipids, (ii) an intermediate aqueous phase and (iii) a lower phase of residual wet solids. The oily phase was collected, and the stoichiometric amount of HCOOH (4.3–5.5 g per 100 g of fats) was then added with respect to calcium soaps, to obtain a final product consisting mainly of FFAs [54]. Finally, activated oils were obtained by directly separating the clear oily phase after centrifugation (4000 rpm, 80 °C, 1 min).

2.2.2. Direct Esterification of FFAs into Methyl Esters with AlCl3·6H2O and Purification of Biodiesel Produced by Distillation

Lipids obtained from sewage sludge samples were efficiently converted to methyl esters under optimized conditions of direct esterification with AlCl3·6H2O as a catalyst [55,56,57]. The reaction was carried out at 70 °C for 2 h with a molar ratio of MeOH:FFAs:catalyst = 10:1:0.02. The reagent mixture was then cooled to 25 °C, separating (i) a methanol layer in which the catalyst was dissolved and (ii) a lower oily phase consisting mainly of methyl esters. The lower layer was separated, the residual methanol evaporated and the pure FAMEs (>99%) were isolated by vacuum distillation (165–180 °C, 50 ± 5 mmHg). The distillation residue (21–25%wt) was then either purified by chromatography to separate and characterize the different components or transferred into smaller units for further distillation. 10-hydroxystearic acid methyl ester with a purity of 80–85%wt was obtained at 180–200 °C, 50 ± 5 mmHg. The enantiomeric excess was determined by gas chromatographic analysis of the corresponding diastereoisomers obtained with (S)-1-phenylpropyl isocyanate (>96%) and/or (R)-1-phenyl methyl isocyanate, as recently described [58]. Methyl estolides remained as distillation residue (purity 83–85%wt).

3. Results and Discussion

3.1. Chemical Characterization of Raw Lipids and Optimization of Extraction Process

Primary sludge and sewage scum were taken from several WWTPs in the Apulia region of southern Italy. After a preliminary determination of TS content, raw lipids were extracted from sewage sludge samples, quantified and chemically characterized (see Supplementary Materials of Section S.2). The results obtained are shown in Table 1.

Table 1.

Chemical characterization of raw lipids extracted from primary sludge and sewage scum samples up-taken from WWTPs of Apulia region, southern Italy.

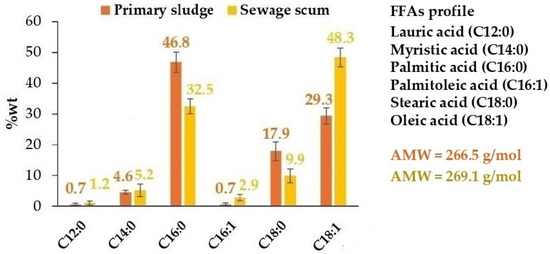

In primary sludge samples (E1–3), TS content was about 4%wt with a lipid content between 202.4 ± 6.1 mg/gTS and 244.3 ± 9.3 mg/gTS. Soaps were found to be the main component of the lipids isolated. In contrast, TS content in sewage scum samples (E4–9) ranged from 19.3 ± 0.5%wt to 32.0 ± 0.5%wt with a significantly higher lipid content of 350.1 ± 8.4 mg/gTS–502.4 ± 1.5 mg/gTS. Lipids consisted mainly of FFAs (47.5 ± 0.8%–59.5 ± 1.9%) and soaps (27.3 ± 1.9%–34.5 ± 1.0%). The different chemical nature of the lipids in primary sludge and sewage scum made it necessary to optimize the lipid recovery for each feedstock typology. The recovery of lipids from primary sludge, consisting mainly of calcium soaps (>70%), was achieved by extraction with hexane from acidified wet primary sludge with a recovery rate of 99% [53]. In the case of sewage scum, heating wet biomass at 80 °C and directly centrifuging it (4000 rpm, 3 min) allowed the extraction of lipid components with a recovery of 92–99%, without the addition of solvents or acids [54]. Subsequently, recovered lipids were activated by adding the stoichiometric amount of HCOOH to calcium soaps, thus obtaining their conversion into FFAs. The chemical composition of FFAs extracted from primary sludge and sewage scum is shown in Figure 2.

Figure 2.

Chemical composition of FFAs extracted from primary sludge and sewage scum and determination of Average Molecular Weight (AMW).

3.2. Esterification of Extracted Lipids with Methanol and Characterization of Chemical Products

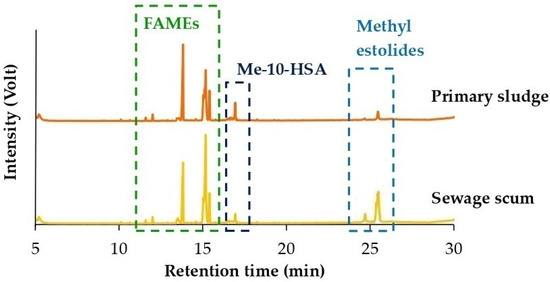

After the extraction process, both lipids derived from primary sludge and sewage scum (composed mainly of FFAs, 72–89%) were efficiently converted by direct esterification with methanol by using AlCl3·6H2O [55,56,57] with a yield of 98.2 ± 0.6% and 99.1 ± 0.4%, respectively. The use of AlCl3·6H2O promoted the production of FAMEs and a favorable phase separation of the products in a single step. Most of the water formed during the reaction, and the remaining FFAs were selectively dissolved in the upper methanol layer, while the methyl esters were in the lower oily phase. The remaining methanol was then evaporated from the oily layer, yielding crude products that were quantified and analyzed (Figure 3).

Figure 3.

Gas chromatogram of crude products obtained from the esterification of lipids extracted from primary sludge and sewage scum.

According to the data reported in Table 2, FAMEs, Me-10-HSA and methyl estolides (preferentially 10-(palmitoyloxy) and 10-(oleyloyloxy) stearic acid methyl esters) were detected as main reaction products (see Supplementary Materials of Section S.2) with a very low FFA content (less than 0.5%wt). At the end of the vacuum distillation, three different fractions were then separated: pure FAMEs 98.5–99%wt (according to EN14214) were distilled at 165–180 °C, 50 ± 5 mmHg, Me-10-HSA with a purity of 80–85%wt was obtained at 180–200 °C, 50 ± 5 mmHg, while methyl estolides remained as distillation residue (final purity of 85–88%wt).

Table 2.

Chemical characterization of esterified lipids extracted from primary sludge and sewage scum.

3.3. Feasibility Study of Sewage Sludge Valorization

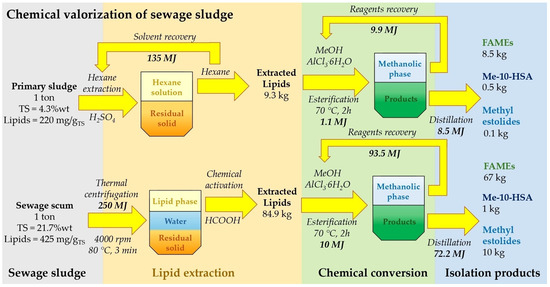

Based on these laboratory-scale experiments, the preliminary feasibility of the overall process can be calculated by considering the costs of the chemicals required, the different steps for processing the individual starting materials, and the corresponding energy supply (Figure 4).

Figure 4.

Scheme of processes for the valorization of primary sludge and sewage scum.

For this preliminary study, the average composition of samples analyzed in Table 1 was considered: 4.3%wt and 21.7%wt were the initial TS content of primary sludge and sewage scum, while the lipid content was 220 mg/gTS and 425 mg/gTS of TS, respectively (Table 3). Additional information about the estimated costs can be found in Supplementary Materials of Section S.3. Taking into account the reagents consumed during the process and, in the case of primary sludge, the hexane lost during the recovery (approx. 2% by weight), the net cost of the reagents required to process 1 ton of primary sludge is 3.4 €, compared to 7.4 € for sewage scum. The total energetic demand was approximately 154.5 MJ and 425.7 MJ. Providing this energy by burning methane (efficiency = 80%, [59]), 0.8 € and 2.1 € would entail associated costs. Under these conditions, the costs for carrying out these procedures were 4.2 € and 9.5 €. Based on 1 ton of initial primary sludge or sewage scum, after the extraction step, 9.3 kg and 84.9 kg of raw lipids were obtained, respectively. Considering that 8.5 kg and 67 kg of biodiesel would be obtained from the two different feedstocks, already yielding a profit of 6.8 € and 53.6 €, respectively, both processes seem very feasible, especially considering that Me-10-HSA and methyl estolides could be concomitantly produced. From 1 ton of settled primary sludge, 0.5 kg of Me-10-HSA and 0.1 kg of methyl estolides can be recovered, while from 1 ton of sewage scum, 1 kg of Me-10-HSA and 10 kg methyl estolides were recovered. By applying this strategy, the value of these by-products contributed considerably to improving the overall profits (4.4 € and 76.5 €, respectively). Furthermore, the residual sludge produced at the end of the extraction process can be anaerobically digested to produce biogas, which could be used to fully cover the total energy costs [23] without producing more sludge than the conventional digestion of the starting sludge [60,61]. As a result, the estimated cost of producing biodiesel from primary sludge and sewage scum would be lower, leading to a further increase in profits. The proposed system of using lipids from primary sludge and sewage scum to produce biodiesel and biolubricants could have a significant impact. If this approach were applied in Europe, more than 2.5 Mton of biodiesel and 0.3 Mton of biolubricants could be produced annually, corresponding to a quarter and a fifth of the current total demand, respectively. However, there are some critical points that need to be discussed. Lipid extraction from primary sludge is the most crucial part of the entire technology, and improvements to this process would be helpful in constantly reducing the energy and environmental impact. Extraction with organic solvents is harmful to the environment. For this reason, further experimental studies are currently being conducted by using both bioderived solvents (e.g., volatile fatty acid esters [62]) and solvent-free technologies [54,56] to minimize the environmental impact of lipid extraction according to green chemistry principles. Sewage scum, for which the proposed strategy promises the greatest benefit, is hardly ever collected. Some WWTPs do not separate it at all, preferring a problematic treatment in the water line (biological oxidation), which is negatively affected by the presence of this floating material. The spread of floats which separate floating sludge directly from raw sewage would bring significant economic value and other operational benefits to wastewater treatment.

Table 3.

Analysis of manufacturing costs, energy demand and product revenues derived from chemical conversion of primary sludge and sewage scum in biochemicals.

4. Conclusions

The concept of the circular economy for the treatment of sewage sludge generated in WWTPs is a topic of great interest as it offers a variety of benefits on social, environmental, and economic levels. Currently, sewage sludge is considered a waste that requires special treatment before disposal and generates the highest costs in the management of wastewater treatment plants. These conditions are exacerbated by the increasing expansion of residential and industrial areas, creating more significant quantities of sewage sludge yearly. However, sewage sludge can be considered a relatively cheap, readily available and abundant raw material for producing energy and recyclable materials. Among the possible alternatives which utilize the surplus sewage sludge, the production of biodiesel could be profitable given the high lipid content of the specific sewage sludge, namely sewage scum and primary sludge. In this work, a process for the utilization of lipids in sewage scum and primary sludge was proposed and investigated. The utilization strategy consisted of first extracting the lipids from these two raw materials and then converting them into biodiesel and fine chemicals through sustainable chemical processes. In addition to free fatty acids, (R)-10-hydroxystearic acid and estolides were detected and quantified in the extracted lipids. The direct esterification of the two extracted lipids with methanol was successfully carried out under mild conditions. Finally, the high-quality compounds can be purified and recovered by distillation in a vacuum. The extraction of biodiesel and the simultaneous recovery of (R)-10-hydroxystearic acid methyl esters and methyl estolides from sewage sludge could significantly impact the current scenario of sewage sludge treatment. It would promote a change in perspective and transform sewage sludge from waste to be disposed of into a new raw material with valuable resources.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/app14124974/s1, S.1 Materials and methods; S.2 Characterization of reaction products obtained from esterification process, S.3 Estimation costs of biodiesel production from primary sludge and sewage scum, S.4 Analysis of biodiesel isolated by distillation process. References [63,64,65,66,67] are cited in the Supplementary Materials.

Author Contributions

Conceptualization, C.P. and L.d.B.; methodology, L.d.B., C.P. and A.A.; validation, L.d.B., C.P. and A.A.; formal analysis, L.d.B. and C.P.; investigation, L.d.B., C.P. and A.A.; resources C.P.; data curation, L.d.B. and C.P.; writing—original draft preparation, L.d.B., C.P. and A.A.; writing—review and editing, C.P., L.d.B. and A.A.; supervision, C.P.; project administration, C.P.; funding acquisition, C.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by European Union—FESR “PON Ricerca e Innovazione 2014–2020. Progetto: Energie per l’Ambiente TARANTO—Cod. ARS01_00637”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

All authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Chen, G.; Li, X.; Liu, X.; Chen, Y.; Liang, X.; Leng, J.; Xu, X.; Liao, W.; Qiu, Y.; Wu, Q.; et al. Global projections of future urban land expansion under shared socioeconomic pathways. Nat. Commun. 2020, 11, 537. [Google Scholar] [CrossRef] [PubMed]

- Guerra, B.C.; Shahi, S.; Mollaei, A.; Skaf, N.; Weber, O.; Leite, F.; Haas, C. Circular economy applications in the construction industry: A global scan of trends and opportunities. J. Clean. Prod. 2021, 324, 129125. [Google Scholar] [CrossRef]

- Swilling, M.; Hajer, M.; Baynes, T.; Bergesen, J.; Labbè, F.; Musango, J.K.; Ramaswami, A.; Robinson, B.; Salat, S.; Suh, S.; et al. The Weight of Cities: Resource Requirements of Future Urbanization. UN Environment—International Resource Panel. 2018. Available online: https://wedocs.unep.org/20.500.11822/31624 (accessed on 2 February 2024).

- Jie, H.; Khan, I.; Alharthi, M.; Zafar, M.W.; Saeed, A. Sustainable energy policy, socio-economic development, and ecological footprint: The economic significance of natural resources, population growth, and industrial development. Util. Policy 2023, 81, 101490. [Google Scholar] [CrossRef]

- Batrancea, L.; Pop, M.C.; Rathnaswamy, M.M.; Batrancea, I.; Rus, M.I. An empirical investigation on the transition process toward a green economy. Sustainability 2021, 13, 13151. [Google Scholar] [CrossRef]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; Johns Hopkins University Press: Baltimore, MD, USA, 1990. [Google Scholar]

- Czekała, W.; Drozdowski, J.; Łabiak, P. Modern technologies for waste management: A review. Appl. Sci. 2023, 13, 8847. [Google Scholar] [CrossRef]

- Mandpe, A.; Paliya, S.; Gedam, V.V.; Patel, S.; Tyagi, L.; Kumar, S. Circular economy approach for sustainable solid waste management: A developing economy perspective. Waste Manag. Res. 2023, 41, 499–511. [Google Scholar] [CrossRef] [PubMed]

- Araujo-Morera, J.; Verdejo, R.; López-Manchado, M.A.; Santana, M.H. Sustainable mobility: The route of tires through the circular economy model. Waste Manag. 2021, 126, 309–322. [Google Scholar] [CrossRef] [PubMed]

- di Bitonto, L.; Scelsi, E.; Reynel-Ávila, H.E.; Mendoza-Castillo, D.I.; Bonilla-Petriciolet, A.; Hájek, M.; Mustafa, A.; Pastore, C. A Closed-Loop Biorefinery Approach for the Valorization of Winery Waste: The Production of Iron-Sulfonated Magnetic Biochar Catalysts and 5-Hydroxymethyl Furfural from Grape Pomace and Stalks. Catalysts 2024, 14, 185. [Google Scholar] [CrossRef]

- Xia, Y.; Zuo, H.; Lv, J.; Wei, S.; Yao, Y.; Liu, Z.; Lin, Q.; Yu, Y.; Yu, W.; Huang, Y. Preparation of multi-layered microcapsule-shaped activated biomass carbon with ultrahigh surface area from bamboo parenchyma cells for energy storage and cationic dyes removal. J. Clean. Prod. 2023, 396, 136517. [Google Scholar] [CrossRef]

- Shi, S.; Zhou, D.; Jiang, Y.; Cheng, F.; Sun, J.; Guo, Q.; Luo, Y.; Chen, Y.; Liu, W. Lightweight Zn-Philic 3D-Cu Scaffold for Customizable Zinc Ion Batteries. Adv. Funct. Mater. 2024, 2312664. [Google Scholar] [CrossRef]

- Kehrein, P.; Van Loosdrecht, M.; Osseweijer, P.; Garfí, M.; Dewulf, J.; Posada, J. A critical review of resource recovery from municipal wastewater treatment plants–market supply potentials, technologies and bottlenecks. Environ. Sci. Water Res. Technol. 2020, 6, 877–910. [Google Scholar] [CrossRef]

- Longo, S.; d’Antoni, B.M.; Bongards, M.; Chaparro, A.; Cronrath, A.; Fatone, F.; Hospido, A. Monitoring and diagnosis of energy consumption in wastewater treatment plants. A state of the art and proposals for improvement. Appl. Energ. 2016, 179, 1251–1268. [Google Scholar] [CrossRef]

- Guven, H.; Ersahin, M.E.; Ozgun, H.; Ozturk, I.; Koyuncu, I. Energy and material refineries of future: Wastewater treatment plants. J. Environ. Manag. 2023, 329, 117130. [Google Scholar] [CrossRef] [PubMed]

- Hao, X.; Li, J.; van Loosdrecht, M.C.; Jiang, H.; Liu, R. Energy recovery from wastewater: Heat over organics. Water Res. 2019, 161, 74–77. [Google Scholar] [CrossRef] [PubMed]

- Junior, I.V.; de Almeida, R.; Cammarota, M.C. A review of sludge pretreatment methods and co-digestion to boost biogas production and energy self-sufficiency in wastewater treatment plants. J. Water Proc. Eng. 2021, 40, 101857. [Google Scholar] [CrossRef]

- Di Capua, F.; Spasiano, D.; Giordano, A.; Adani, F.; Fratino, U.; Pirozzi, F.; Esposito, G. High-solid anaerobic digestion of sewage sludge: Challenges and opportunities. Appl. Energy 2020, 278, 115608. [Google Scholar] [CrossRef]

- D’Ambrosio, V.; di Bitonto, L.; Angelini, A.; Gallipoli, A.; Braguglia, C.M.; Pastore, C. Lipid extraction from sewage sludge using green biosolvent for sustainable biodiesel production. J. Clean. Prod. 2021, 329, 129643. [Google Scholar] [CrossRef]

- Domini, M.; Bertanza, G.; Vahidzadeh, R.; Pedrazzani, R. Sewage sludge quality and management for circular economy opportunities in Lombardy. Appl. Sci. 2022, 12, 10391. [Google Scholar] [CrossRef]

- Fijalkowski, K.; Rorat, A.; Grobelak, A.; Kacprzak, M.J. The presence of contaminations in sewage sludge e the current situation. J. Environ. Manag. 2017, 203, 1126e1136. [Google Scholar] [CrossRef]

- Parajuli, R.; Dalgaard, T.; Jørgensen, U.; Adamsen, A.P.S.; Knudsen, M.T.; Birkved, M.; Gylling, M.; Schjørring, J.K. Biorefining in the prevailing energy and materials crisis: A review of sustainable pathways for biorefinery value chains and sustainability assessment methodologies. Renew. Sustain. Energy Rev. 2015, 43, 244–263. [Google Scholar] [CrossRef]

- di Bitonto, L.; Scelsi, E.; Locaputo, V.; Mustafa, A.; Pastore, C. Enhancing biodiesel production from urban sewage sludge: A novel industrial configuration and optimization model. Sustain. Energy Technol. Assess. 2023, 60, 103567. [Google Scholar] [CrossRef]

- Qian, L.; Wang, S.; Xu, D.; Guo, Y.; Tang, X.; Wang, L. Treatment of municipal sewage sludge in supercritical water: A review. Water Res. 2016, 89, 118–131. [Google Scholar] [CrossRef] [PubMed]

- Collivignarelli, M.C.; Castagnola, F.; Sordi, M.; Bertanza, G. Treatment of sewage sludge in a thermophilic membrane reactor (TMR) with alternate aeration cycles. J. Environ. Manag. 2015, 162, 132–138. [Google Scholar] [CrossRef] [PubMed]

- Pilli, S.; Yan, S.; Tyagi, R.D.; Surampall, R.Y. Overview of Fenton pretreatment of sludge aiming to enhance anaerobic digestion. Rev. Environ. Sci. Biotechnol. 2015, 14, 453–472. [Google Scholar] [CrossRef]

- Brown, S.; Beecher, N.; Carpenter, A. Calculator tool for determining greenhouse gas emissions for biosolids processing and end use. Environ. Sci. Technol. 2010, 44, 9509–9515. [Google Scholar] [CrossRef] [PubMed]

- Masuda, S.; Sano, I.; Hojo, T.; Li, Y.Y.; Nishimura, O. The comparison of greenhouse gas emissions in sewage treatment plants with different treatment processes. Chemosphere 2018, 193, 581–590. [Google Scholar] [CrossRef] [PubMed]

- Goldan, E.; Nedeff, V.; Barsan, N.; Culea, M.; Tomozei, C.; Panainte-Lehadus, M.; Mosnegutu, E. Evaluation of the use of sewage sludge biochar as a soil amendment—A review. Sustainability 2022, 14, 5309. [Google Scholar] [CrossRef]

- Flores-Alsina, X.; Ramin, E.; Ikumi, D.; Harding, T.; Batstone, D.; Brouckaert, C.; Sotemann, S.; Gernaey, K.V. Assessment of sludge management strategies in wastewater treatment systems using a plant-wide approach. Water Res. 2021, 190, 116714. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Wang, Z.; Yang, Y.; Liu, H.; Fang, S.; Liu, S. Research status and development trend of wastewater treatment technology and its low carbonization. Appl. Sci. 2023, 13, 1400. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Mofijur, M.; Nuzhat, S.; Chowdhury, A.T.; Rafa, N.; Uddin, M.A.; Inayat, A.; Mahlia, T.M.I.; Ong, H.C.; Show, P.L. Recent developments in physical, biological, chemical, and hybrid treatment techniques for removing emerging contaminants from wastewater. J. Hazard. Mater. 2021, 416, 125912. [Google Scholar] [CrossRef] [PubMed]

- Gherghel, A.; Teodosiu, C.; De Gisi, S. A review on wastewater sludge valorization and its challenges in the context of circular economy. J. Clean. Prod. 2019, 228, 244–263. [Google Scholar] [CrossRef]

- Zhu, F.; Wu, X.; Zhao, L.; Liu, X.; Qi, J.; Wang, X.; Wang, J. Lipid profiling in sewage sludge. Water Res. 2017, 116, 149–158. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.; Arkatkar, A.; Singh, S.; Rabbani, A.; Medina, J.D.S.; Ong, E.S.; Habashy, M.M.; Jadhav, D.A.; Rene, E.R.; Mungray, A.A.; et al. Physico-chemical and biological treatment strategies for converting municipal wastewater and its residue to resources. Chemosphere 2021, 282, 130881. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Hu, J.; Lee, D.J.; Chang, Y.; Lee, Y.J. Sludge treatment: Current research trends. Bioresour. Technol. 2017, 243, 1159–1172. [Google Scholar] [CrossRef] [PubMed]

- Praspaliauskas, M.; Pedisius, N. A review of sludge characteristics in Lithuania’s wastewater treatment plants and perspectives of its usage in thermal processes. Renew. Sustain. Energy Rev. 2017, 67, 899–907. [Google Scholar] [CrossRef]

- Anjum, M.; Al-Makishah, N.A.; Barakat, M.A. Wastewater sludge stabilization using pretreatment methods. Process Saf. Environ. 2016, 102, 615–632. [Google Scholar] [CrossRef]

- Ferrentino, R.; Langone, M.; Fiori, L.; Andreottola, G. Full-scale sewage sludge reduction technologies: A review with a focus on energy consumption. Water 2023, 15, 615. [Google Scholar] [CrossRef]

- Wydro, U.; Jankowska, M.; Wołejko, E.; Kondzior, P.; Łozowicka, B.; Kaczyński, P.; Rodziewicz, J.; Janczukowicz, W.; Pietryczuk, A.; Cudowski, A.; et al. Changes in soil biological properties after sewage sludge and pesticide application in wheat cultivation. Appl. Sci. 2022, 12, 11452. [Google Scholar] [CrossRef]

- Sugurbekova, G.; Nagyzbekkyzy, E.; Sarsenova, A.; Danlybayeva, G.; Anuarbekova, S.; Kudaibergenova, R.; Frochot, C.; Acherar, S.; Zhatkanbayev, Y.; Moldagulova, N. Sewage sludge management and application in the form of sustainable fertilizer. Sustainability 2023, 15, 6112. [Google Scholar] [CrossRef]

- Belousov, A.S.; Esipovich, A.L.; Kanakov, E.A.; Otopkova, K.V. Recent advances in sustainable production and catalytic transformations of fatty acid methyl esters. Sustain. Energ. Fuels 2021, 5, 4512–4545. [Google Scholar] [CrossRef]

- Alsultan, A.G.; Asikin-Mijan, N.; Ibrahim, Z.; Yunus, R.; Razali, S.Z.; Mansir, N.; Islam, A.; Seenivasagam, S.; Taufiq-Yap, Y.H. A short review on catalyst, feedstock, modernized process, current state and challenges on biodiesel production. Catalysts 2021, 11, 1261. [Google Scholar] [CrossRef]

- Grosmann, M.T.; Andrade, T.A.; di Bitonto, L.; Pastore, C.; Corazza, M.L.; Tronci, S.; Errico, M. Hydrated metal salt pretreatment and alkali catalyzed reactive distillation: A two-step production of waste cooking oil biodiesel. Chem. Eng. Process. Process Intensif. 2022, 176, 108980. [Google Scholar] [CrossRef]

- Goh, B.H.H.; Chong, C.T.; Ge, Y.; Ong, H.C.; Ng, J.H.; Tian, B.; Ashokkumar, V.; Lim, S.; Seljak, T.; Józsa, V. Progress in utilization of waste cooking oil for sustainable biodiesel and biojet fuel production. Energy Convers. Manag. 2020, 223, 113296. [Google Scholar] [CrossRef]

- Tracey, C.T.; Shavronskaya, D.O.; Yang, H.; Krivoshapkin, P.V.; Krivoshapkina, E.F. Heterogeneous carbon dot catalysts for biodiesel production: A mini review. Fuel 2024, 362, 130882. [Google Scholar] [CrossRef]

- Toldrá-Reig, F.; Mora, L.; Toldrá, F. Trends in biodiesel production from animal fat waste. Appl. Sci. 2020, 10, 3644. [Google Scholar] [CrossRef]

- Jeyakumar, N.; Hoang, A.T.; Nižetić, S.; Balasubramanian, D.; Kamaraj, S.; Pandian, P.L.; Sirohi, R.; Nguyen, P.Q.P.; Nguyen, X.P. Experimental investigation on simultaneous production of bioethanol and biodiesel from macro-algae. Fuel 2022, 329, 125362. [Google Scholar] [CrossRef]

- Anto, S.; Mukherjee, S.S.; Muthappa, R.; Mathimani, T.; Deviram, G.; Kumar, S.S.; Verma, T.N.; Pugazhendhi, A. Algae as green energy reserve: Technological outlook on biofuel production. Chemosphere 2020, 242, 125079. [Google Scholar] [CrossRef] [PubMed]

- Bora, A.P.; Gupta, D.P.; Durbha, K.S. Sewage sludge to bio-fuel: A review on the sustainable approach of transforming sewage waste to alternative fuel. Fuel 2020, 259, 116262. [Google Scholar] [CrossRef]

- di Bitonto, L.; Locaputo, V.; D’Ambrosio, V.; Pastore, C. Direct Lewis-Brønsted acid ethanolysis of sewage sludge for production of liquid fuels. Appl. Energy 2020, 259, 114163. [Google Scholar] [CrossRef]

- EN 14214:2020; Liquid Petroleum Products—Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications—Requirements and Test Methods. Available online: https://standards.iteh.ai/catalog/standards/cen/0a2c5899-c226-479c-b277-5322cc71395d/en-14214-2012a2-2019 (accessed on 30 April 2024).

- Pastore, C.; Lopez, A.; Lotito, V.; Mascolo, G. Biodiesel from dewatered wastewater sludge: A two-step process for a more advantageous production. Chemosphere 2013, 92, 667–673. [Google Scholar] [CrossRef] [PubMed]

- di Bitonto, L.; Lopez, A.; Mascolo, G.; Mininni, G.; Pastore, C. Efficient solvent-less separation of lipids from municipal wet sewage scum and their sustainable conversion into biodiesel. Renew. Energ. 2016, 90, 55–61. [Google Scholar] [CrossRef]

- Pastore, C.; Lopez, A.; Mascolo, G. Efficient conversion of brown grease produced by municipal wastewater treatment plant into biofuel using aluminium chloride hexahydrate under very mild conditions. Bioresour. Technol. 2014, 155, 91–97. [Google Scholar] [CrossRef]

- di Bitonto, L.; Pastore, C. Metal hydrated-salts as efficient and reusable catalysts for pre-treating waste cooking oils and animal fats for an effective production of biodiesel. Renew. Energy 2019, 143, 1193–1200. [Google Scholar] [CrossRef]

- Pastore, C.; Barca, E.; Del Moro, G.; Lopez, A.; Mininni, G.; Mascolo, G. Recoverable and reusable aluminium solvated species used as a homogeneous catalyst for biodiesel production from brown grease. Appl. Catal. A Gen. 2015, 501, 48–55. [Google Scholar] [CrossRef]

- di Bitonto, L.; Todisco, S.; Gallo, V.; Pastore, C. Urban sewage scum and primary sludge as profitable sources of biodiesel and biolubricants of new generation. Biores. Technol. Rep. 2020, 9, 100382. [Google Scholar] [CrossRef]

- Leal Silva, J.F.; Grekin, R.; Mariano, A.P.; Maciel Filho, R. Making levulinic acid and ethyl levulinate economically viable: A worldwide technoeconomic and environmental assessment of possible routes. Energy Technol. 2018, 6, 613–639. [Google Scholar] [CrossRef]

- Halaby, A.; Ghoneim, W.; Helal, A. Sensitivity analysis and comparative studies for energy sustainability in sewage treatment. Sustain. Energy Technol. Assess. 2017, 19, 42–50. [Google Scholar] [CrossRef]

- Demirbas, A.; Taylan, O.; Kaya, D. Biogas production from municipal sewage sludge (MSS). Energ. Sources Part A 2016, 38, 3027–3033. [Google Scholar] [CrossRef]

- Villalobos-Delgado, F.J.; di Bitonto, L.; Reynel-Avila, H.E.; Mendoza-Castillo, D.I.; Bonilla-Petriciolet, A.; Pastore, C. Efficient and sustainable recovery of lipids from sewage sludge using ethyl esters of volatile fatty acids as sustainable extracting solvent. Fuel 2021, 295, 120630. [Google Scholar] [CrossRef]

- de Jesus, S.S.; Ferreira, G.F.; Maciel, M.R.W.; Maciel Filho, R. Biodiesel purification by column chromatography and liquid-liquid extraction using green solvents. Fuel 2019, 235, 1123–1130. [Google Scholar] [CrossRef]

- Spurgeon, J.M.; Kumar, B. A comparative technoeconomic analysis of pathways for electrochemical CO2 reduction to liquid products. Energy Environ. Sci. 2018, 11, 1536–1551. [Google Scholar] [CrossRef]

- Brigagão, G.V.; Araújo, O.D.Q.F.; de Medeiros, J.L.; Mikulcic, H.; Duic, N. A techno-economic analysis of thermochemical pathways for corncob-to-energy: Fast pyrolysis to bio-oil, gasification to methanol and combustion to electricity. Fuel Process. Technol. 2019, 193, 102–113. [Google Scholar] [CrossRef]

- Schwiderski, M.; Kruse, A. Process design and economics of an aluminium chloride catalysed organosolv process. Biomass Conv. Bioref. 2016, 6, 335–345. [Google Scholar] [CrossRef]

- de Haro, J.C.; del Prado Garrido, M.; Pérez, Á.; Carmona, M.; Rodríguez, J.F. Full conversion of oleic acid to estolides esters, biodiesel and choline carboxylates in three easy steps. J. Clean. Prod. 2018, 184, 579–585. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).