Testing of Indoor Obstacle-Detection Prototypes Designed for Visually Impaired Persons

Abstract

1. Introduction

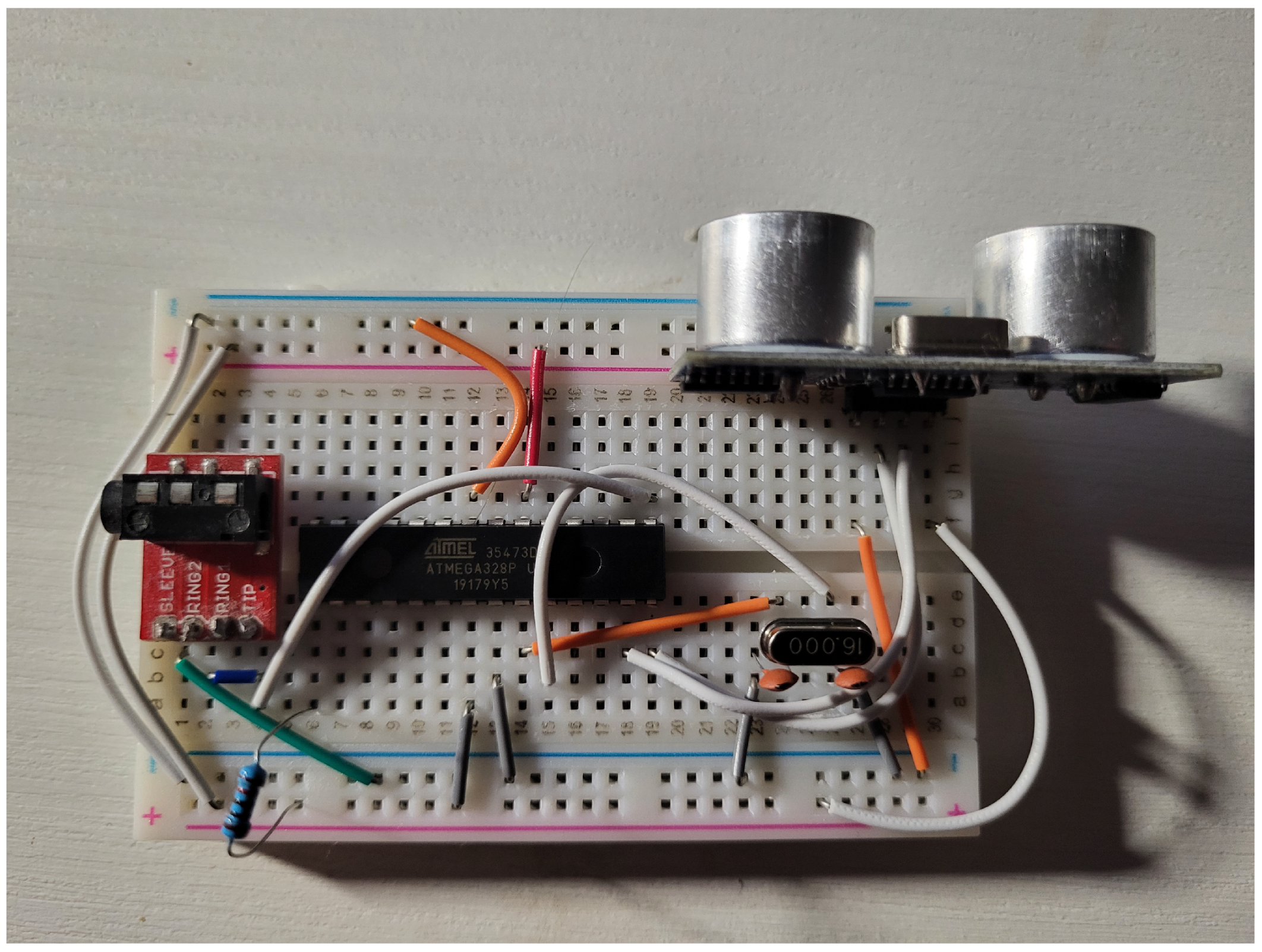

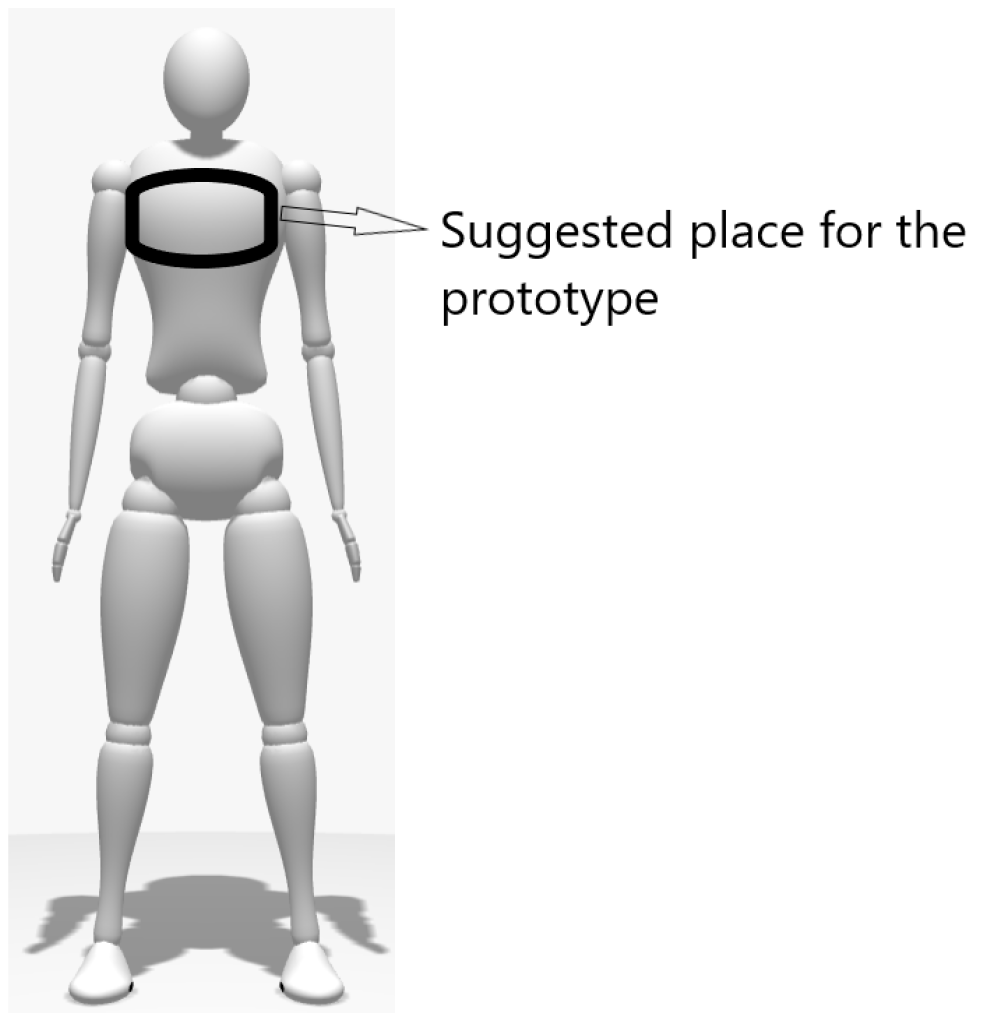

2. Materials and Methods

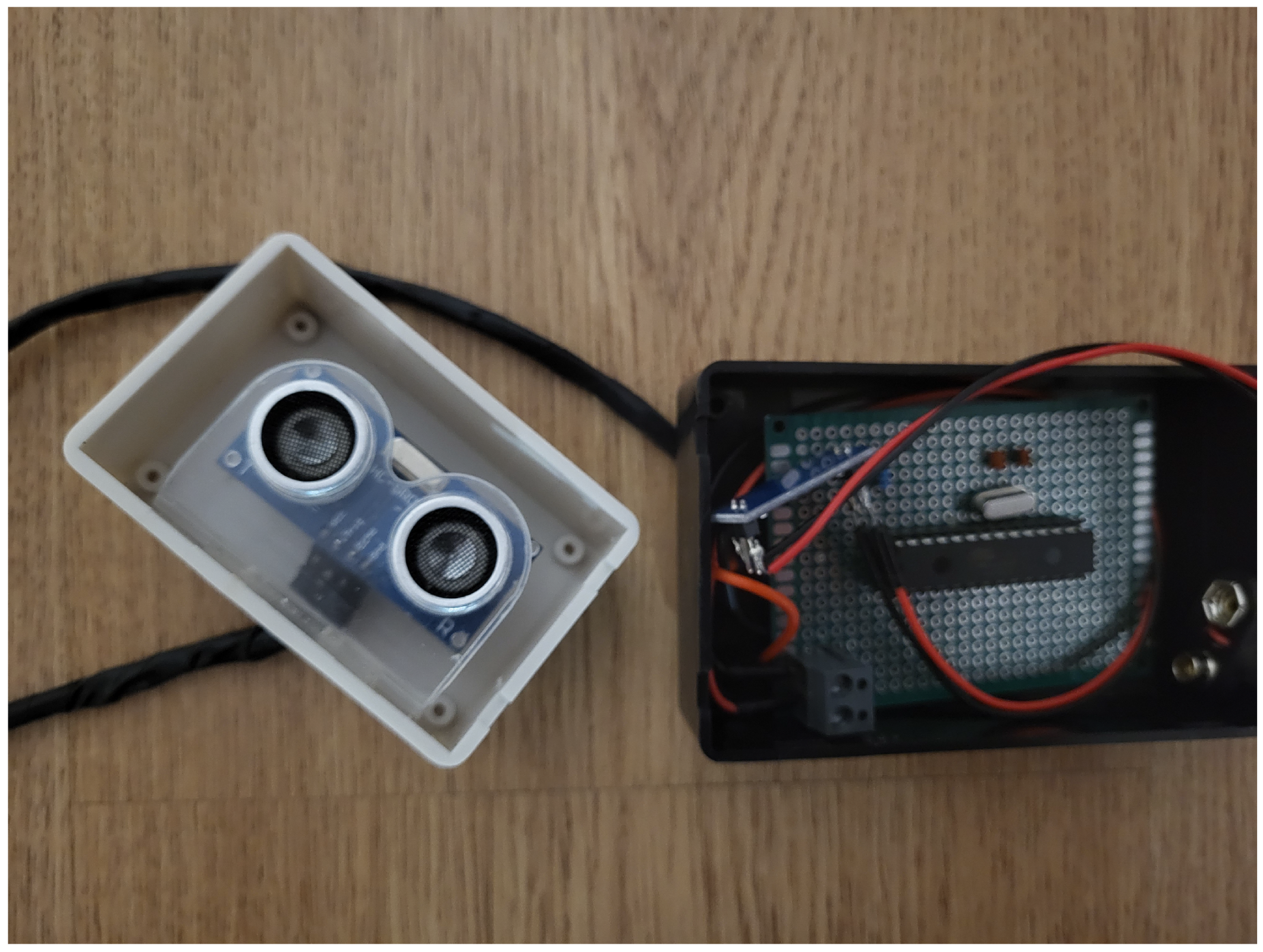

2.1. Prototypes Modules Material and Software

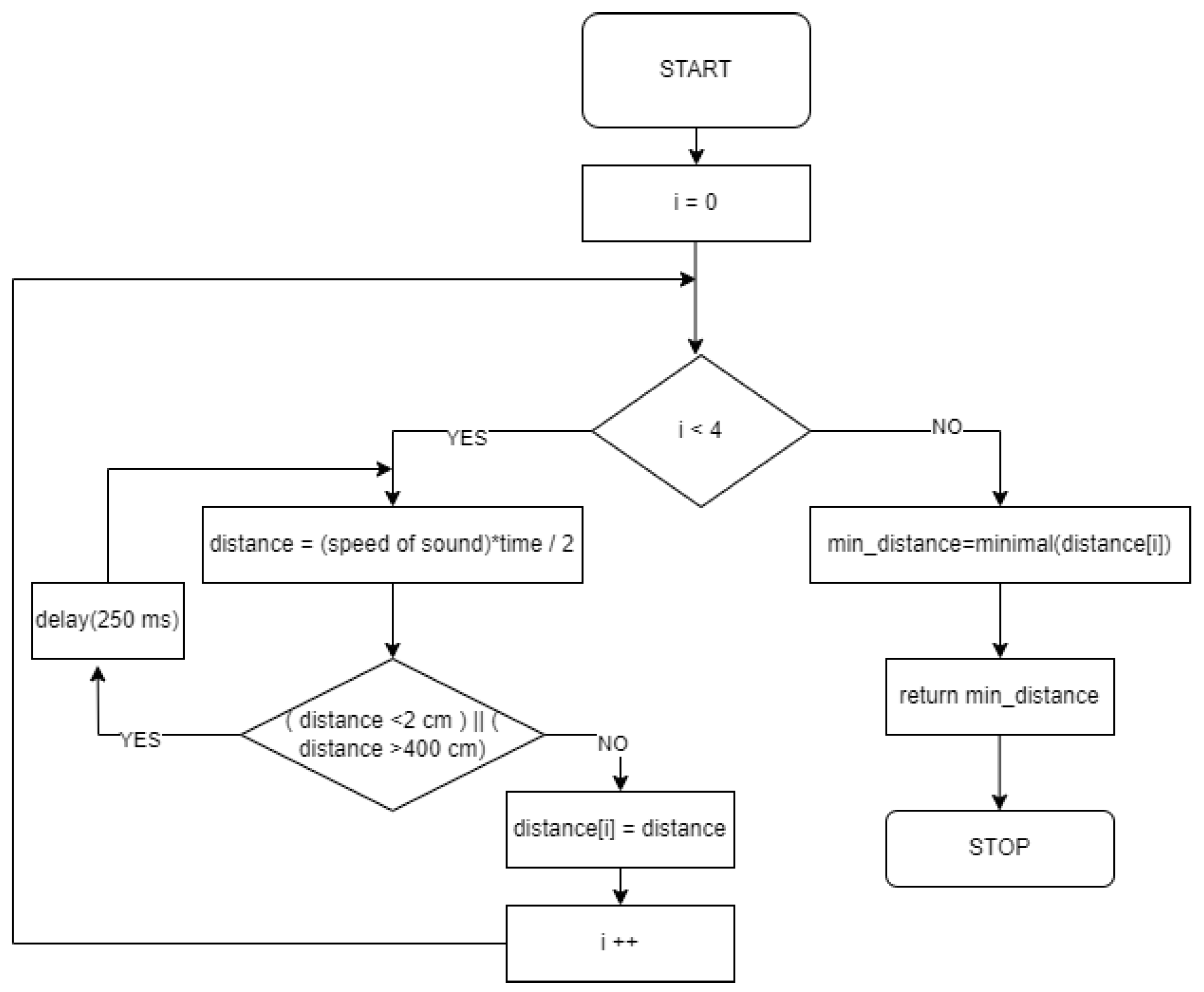

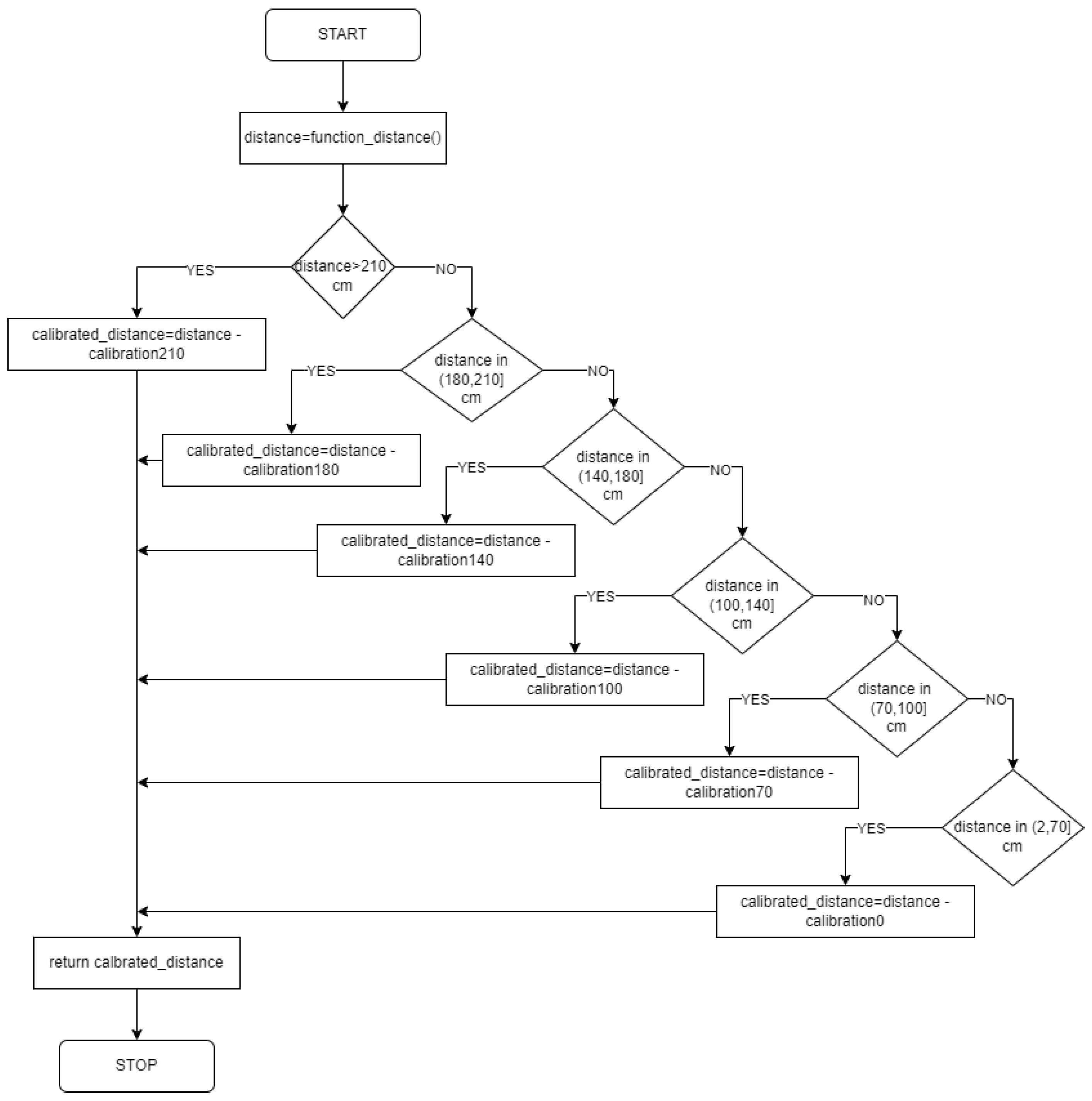

2.1.1. Functionality Module

2.1.2. User Interface Module

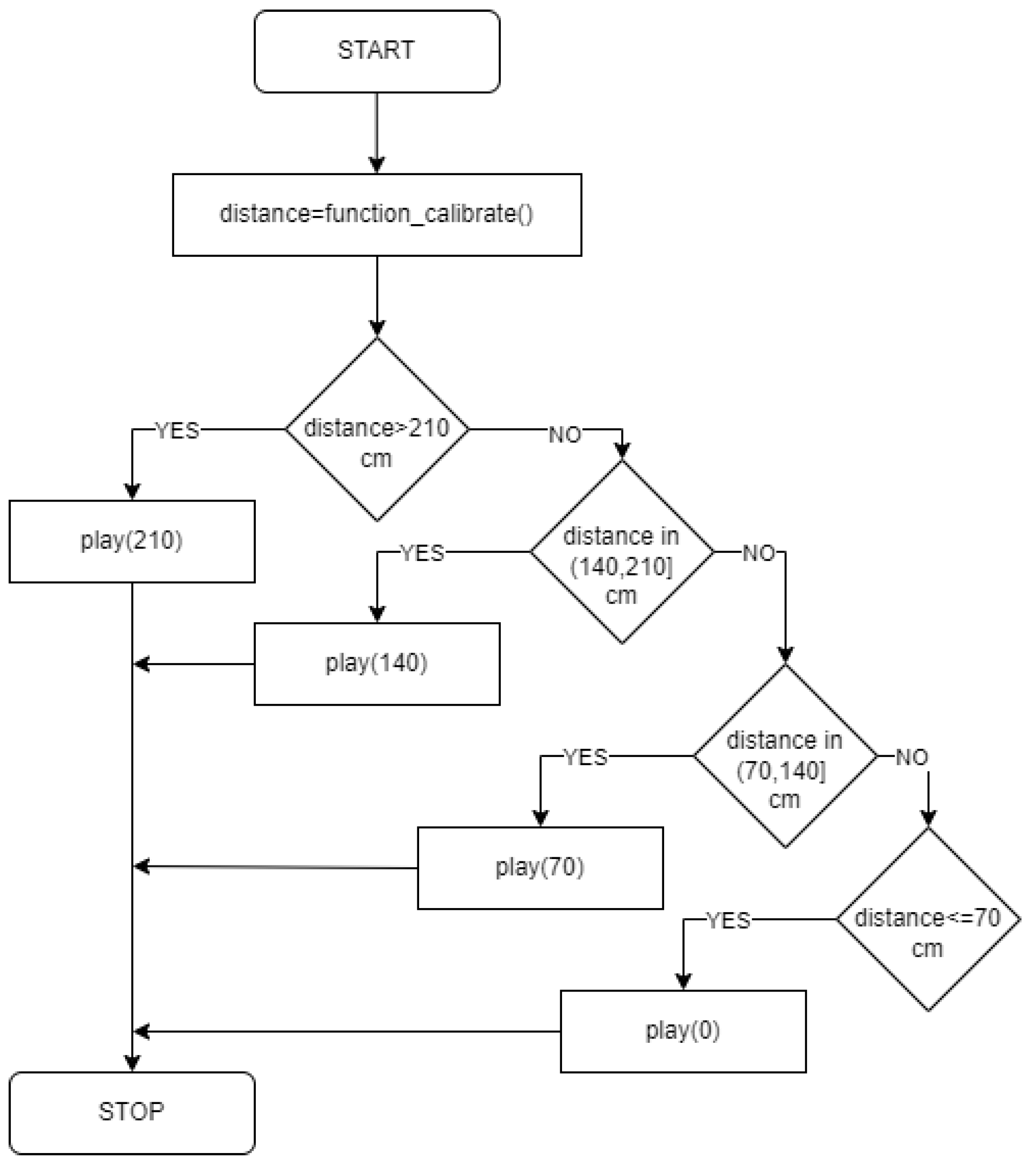

2.2. Audio Conversion

2.2.1. PCM Audio Conversion

- Sample per second: 16 kHz

- Channel: Mono

- Format: 16-bit PCM

2.2.2. WAVE Audio Conversion

- Bit resolution: 8 bits.

- Audio frequency: 16 kHz.

- Audio channel: Mono.

- PCM format: U8.

- The STOP message corresponds to the file named 0.

- The DANGER message corresponds to the file named 70.

- The CAUTION message corresponds to the file named 140.

- The CLEAR message corresponds to the file named 210.

2.3. Testing Environment and Methods

2.3.1. Test Environment

- An unfurnished room that is wide enough to enable the prototypes to be placed at different distances without other interference.

- On the floor, different positions are marked for the obstacles (both square and cylinder).

- From each obstacle position, markers (blue tape) are placed on the floor at the following distances: 50, 70, 100, 140, 180, 210 and 230/250 cm.

- The prototype and a laptop that will collect the log files is placed on a table with wheels so it can be easily moved to any marker.

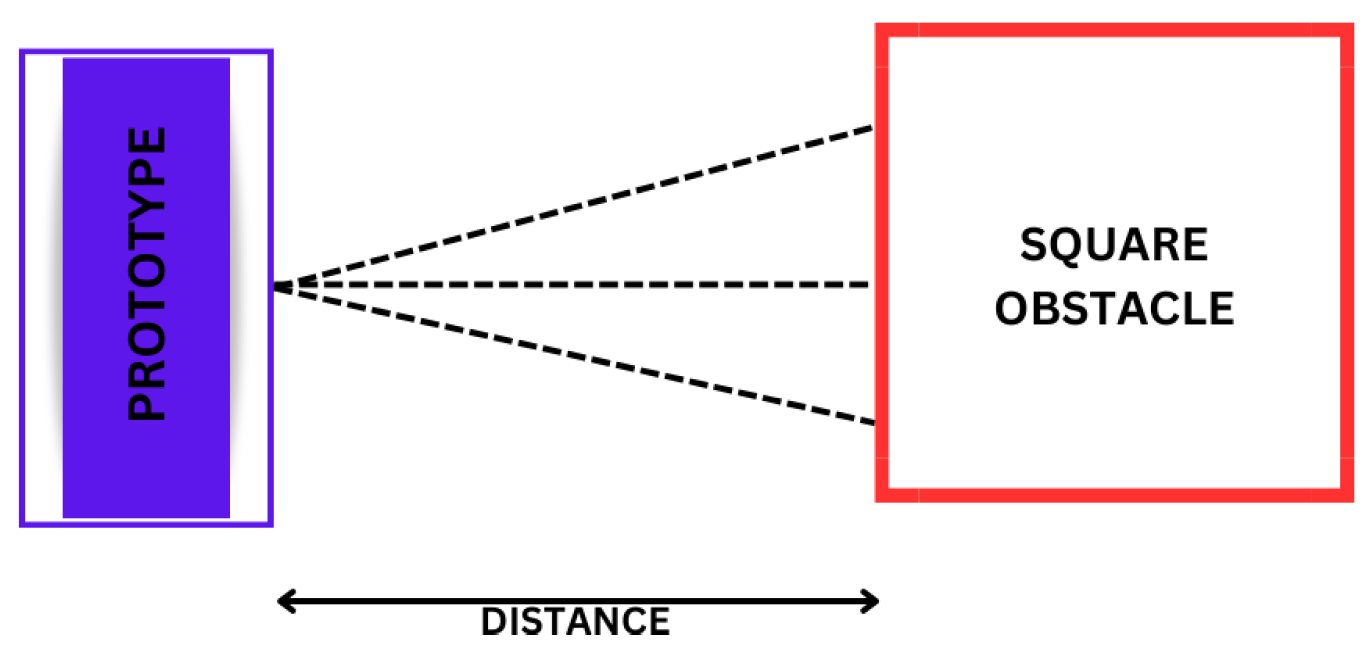

- The square obstacle is simulated with a cardboard box with sides measuring 40 cm.

- The cylinder obstacle is simulated using a 38 cm diameter cardboard box.

- For a specific test: a PVC pipe with a 2 cm diameter and a matchbox.

- Different types of materials used to simulate obstacles: cardboard, concrete, slicker, glass, mirror, MDF, paper, iron, plastic, wood, PAL, jeans, cotton, leather, linen. As a note, these materials will be tested under only one condition: in the full path of the sensor. Tor the confusion matrix results, the readings will take place for 10 min.

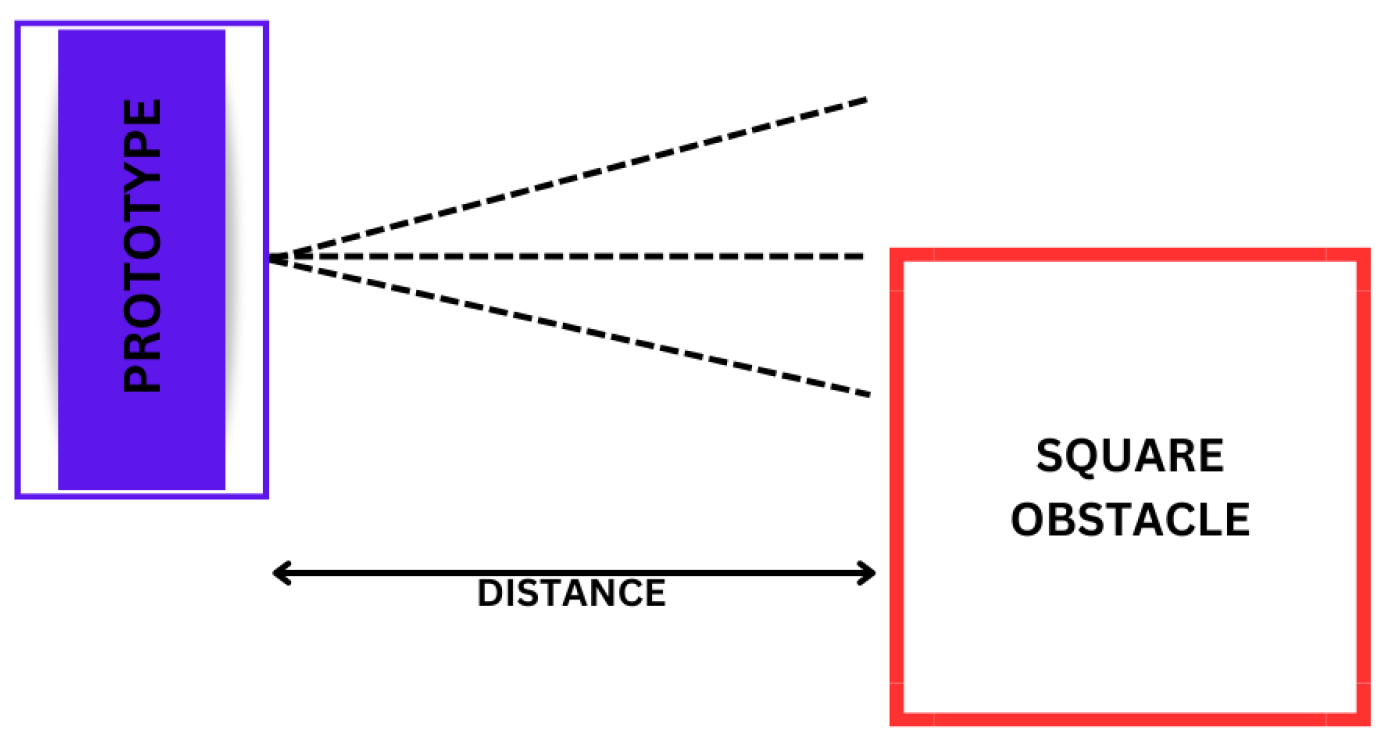

- In the full path of the sensor’s directivity, as shown in Figure 4—the sensor has a 15 degree measuring angle.

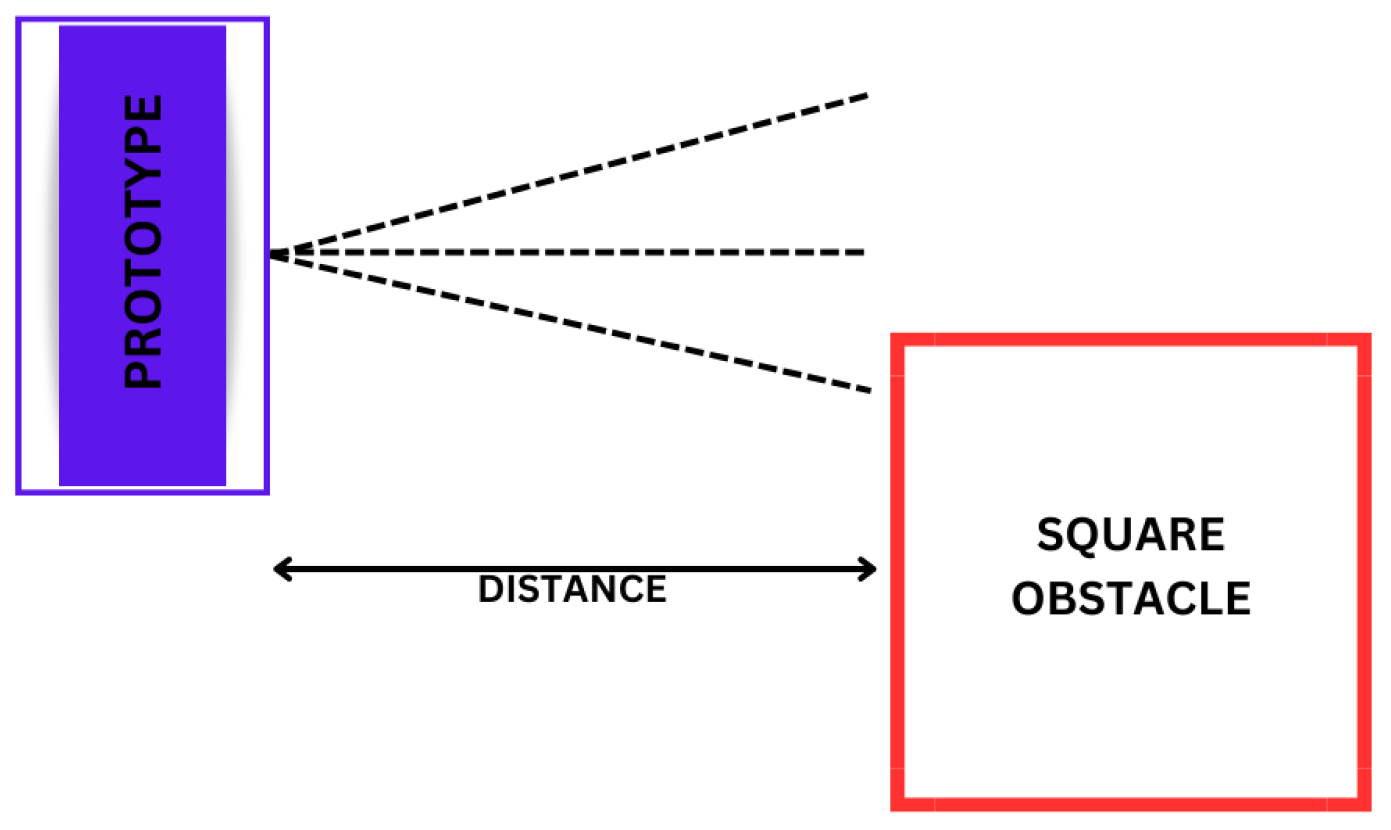

- The obstacle is placed so it covers only half of the measuring angle of the sensor, as shown in Figure 5.

- The obstacle is placed so it covers only a quarter of the measuring angle of the sensor, as shown in Figure 6.

2.3.2. Testing Methods

- For static obstacle testing:

- The obstacle (square or cylinder) is placed on a designated marker for position on the floor (completely in front of the sensor directivity, so it covers only half of the sensor directivity and so it covers only a quarter of the sensor directivity).

- The prototype and the laptop are placed on a specific distance marker.

- The test for each distance and position is conducted for 30 min, so the log file will have sufficient entries to create a confusion matrix

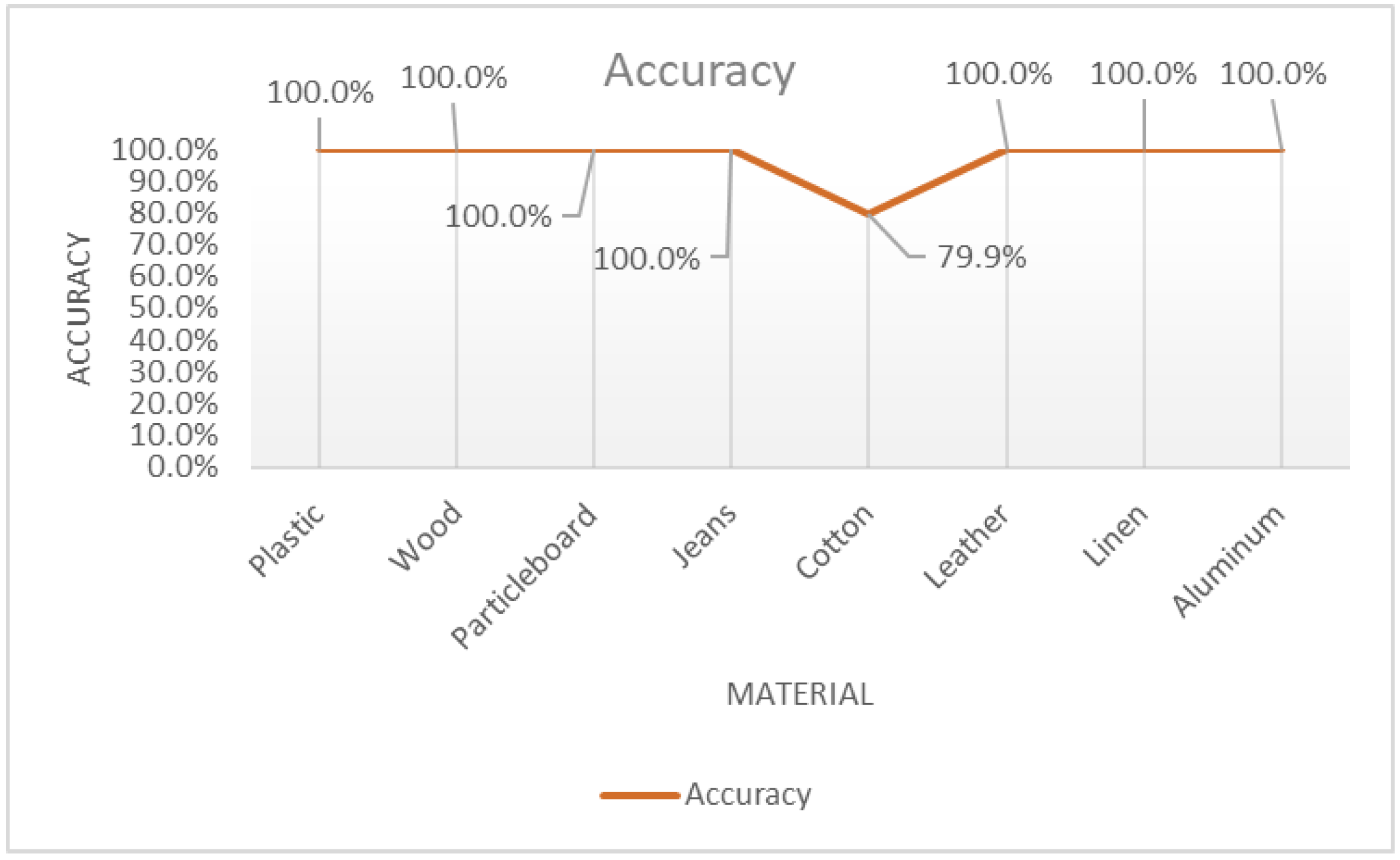

- For different materials testing:

- Each of the materials is placed completely in front of the sensor.

- The WAVE prototype and laptop are placed on the 50 cm marker.

- The test will be conducted for each of the materials for 10 min.

- The confusion matrix predictions—as a graphic and a table in the appendix.

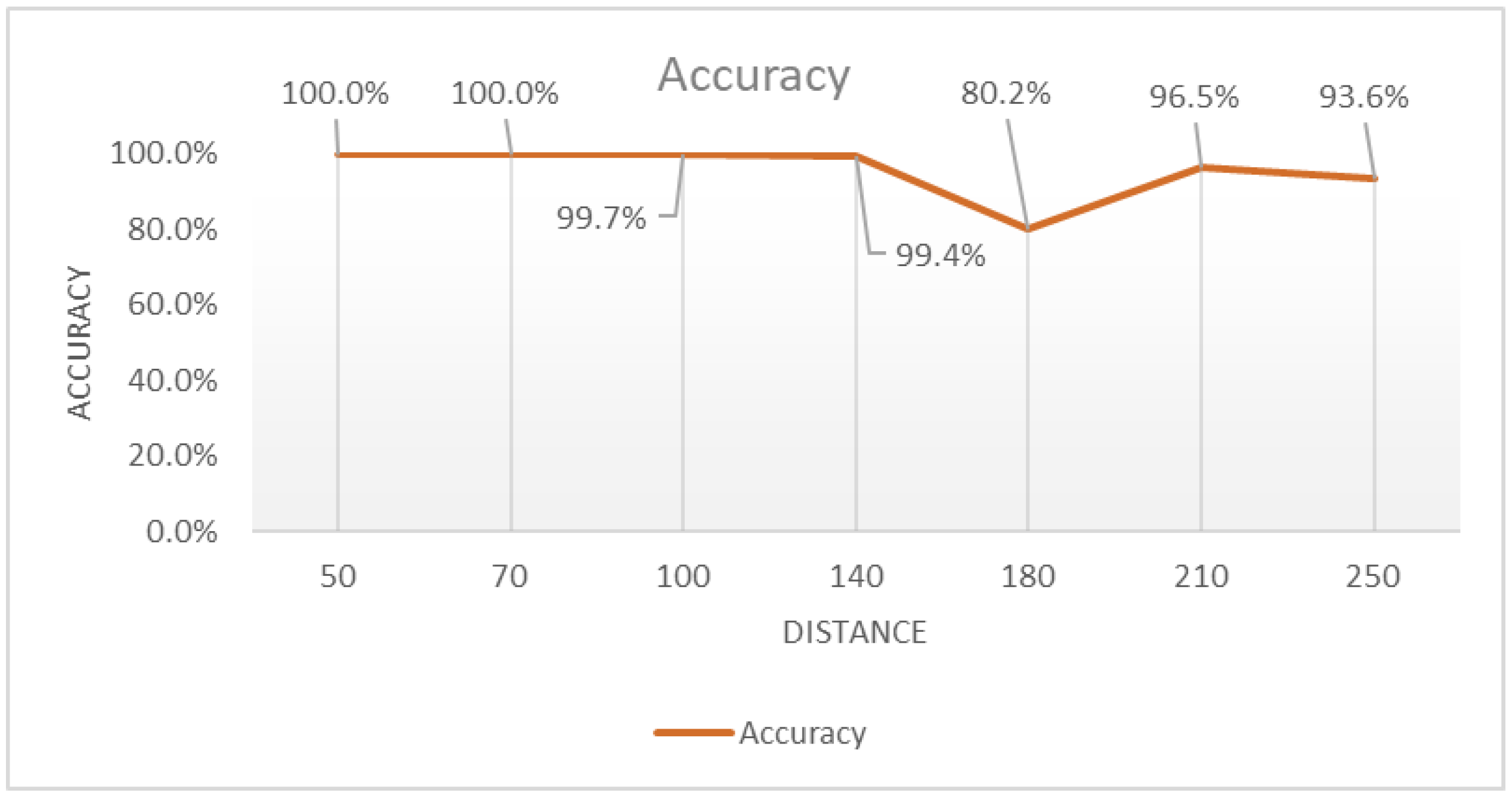

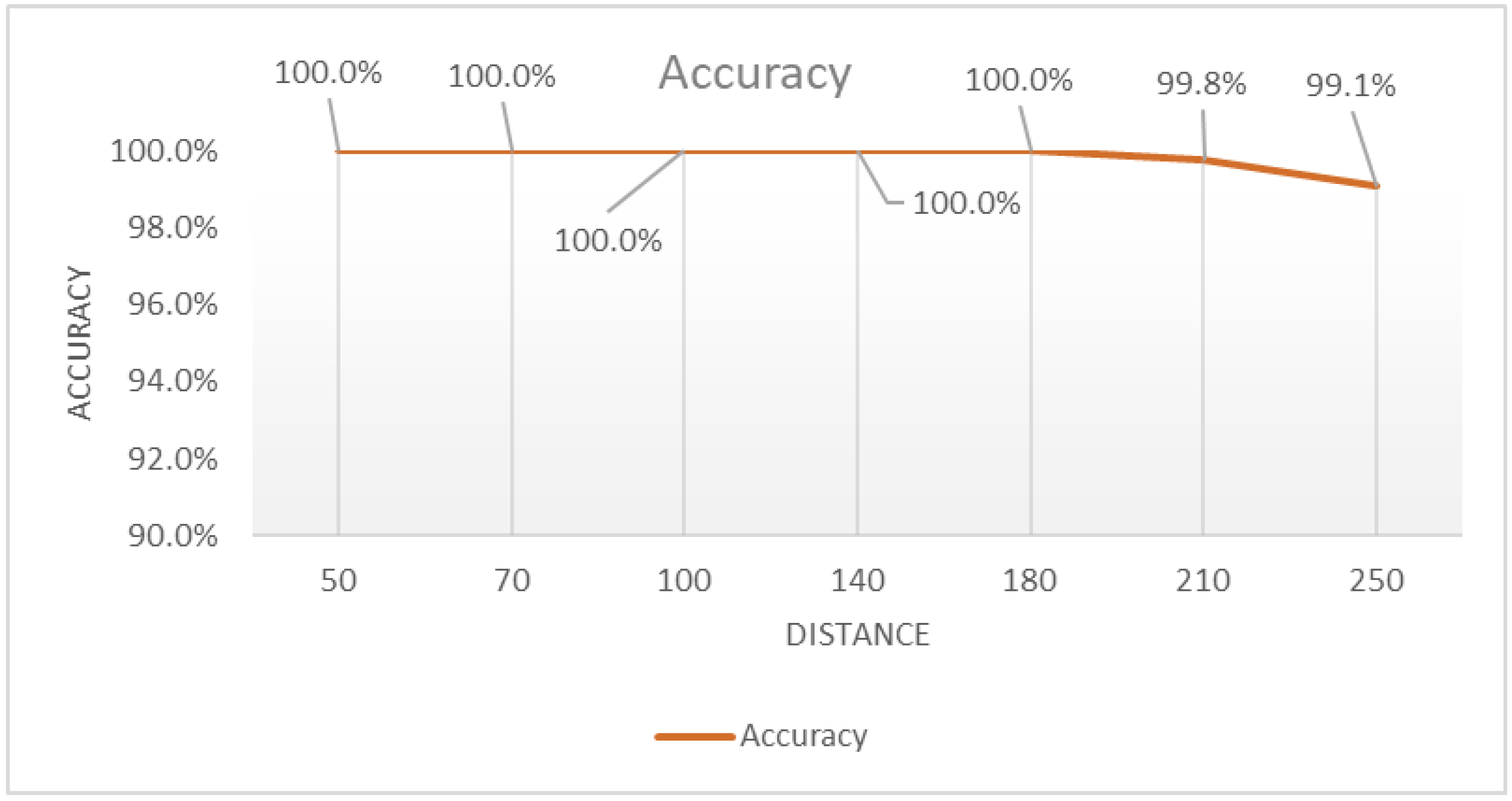

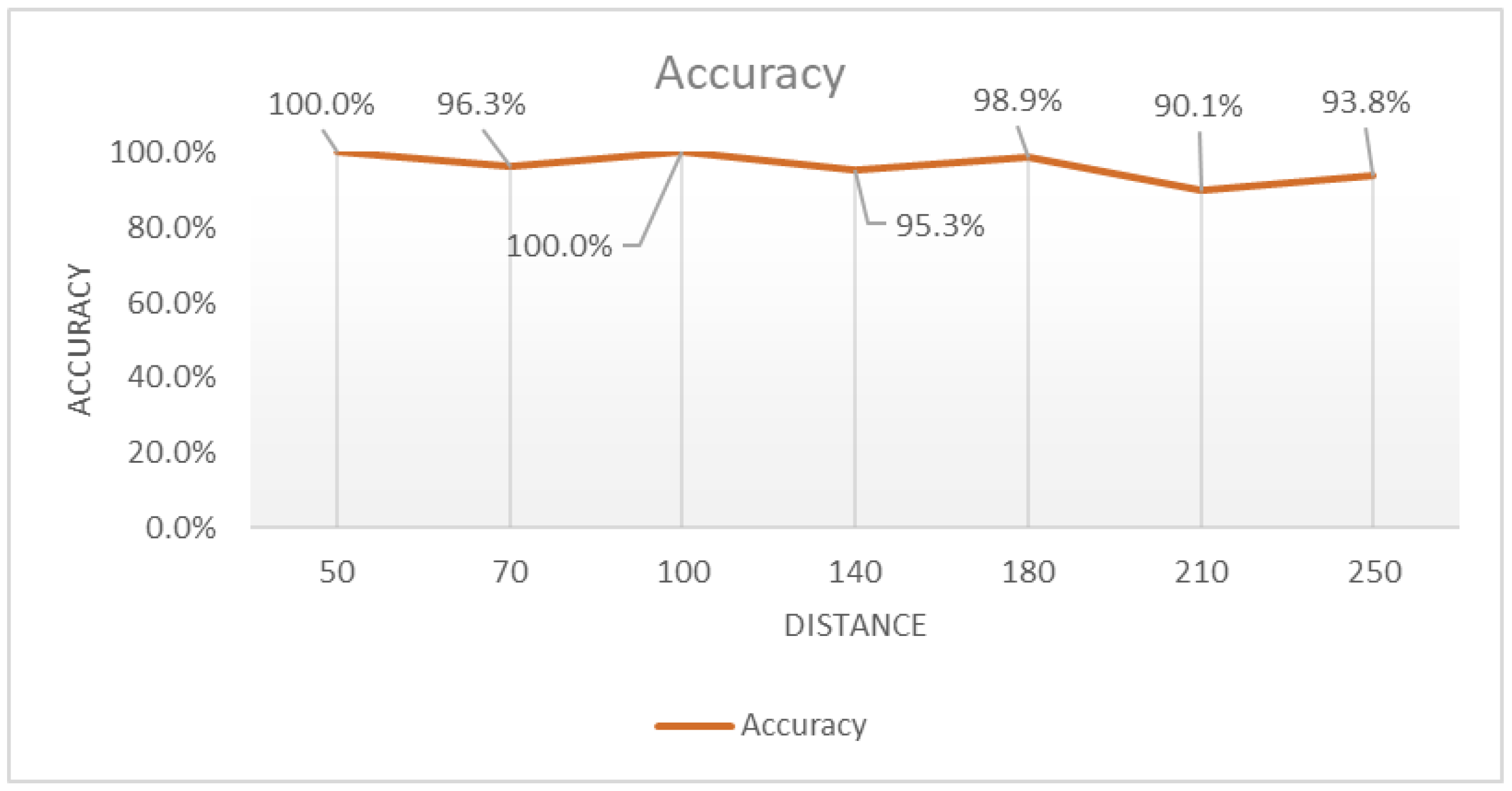

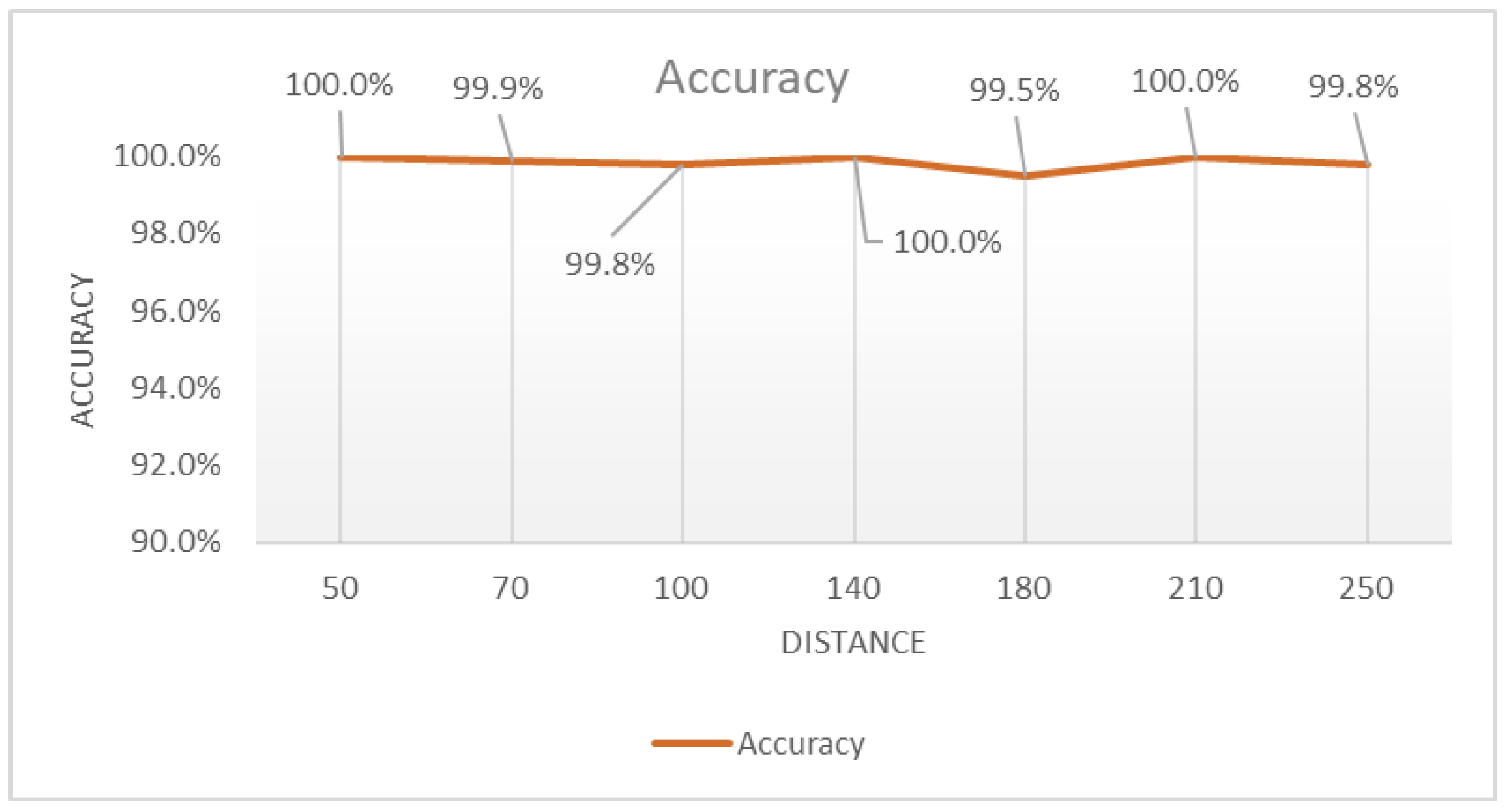

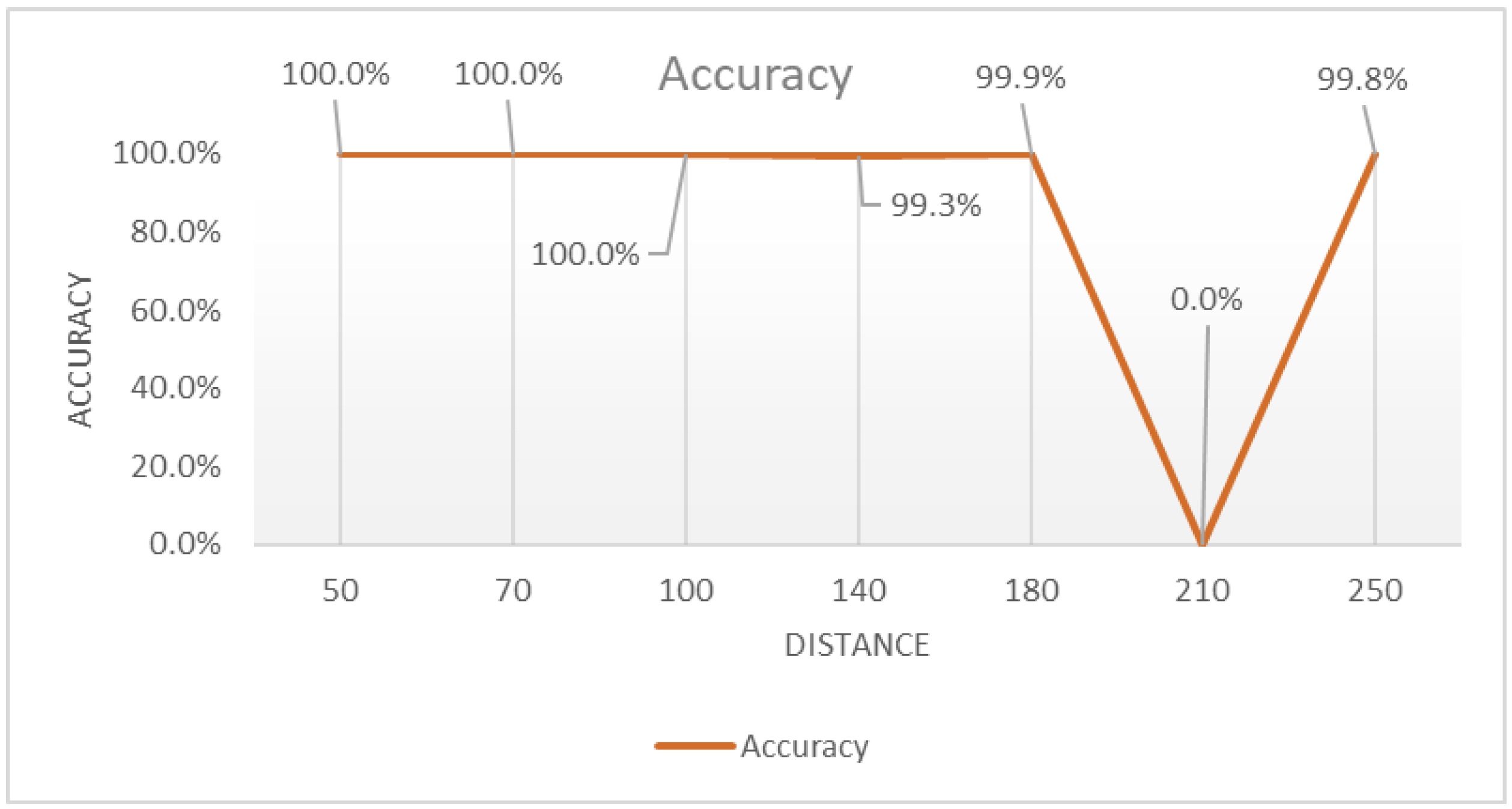

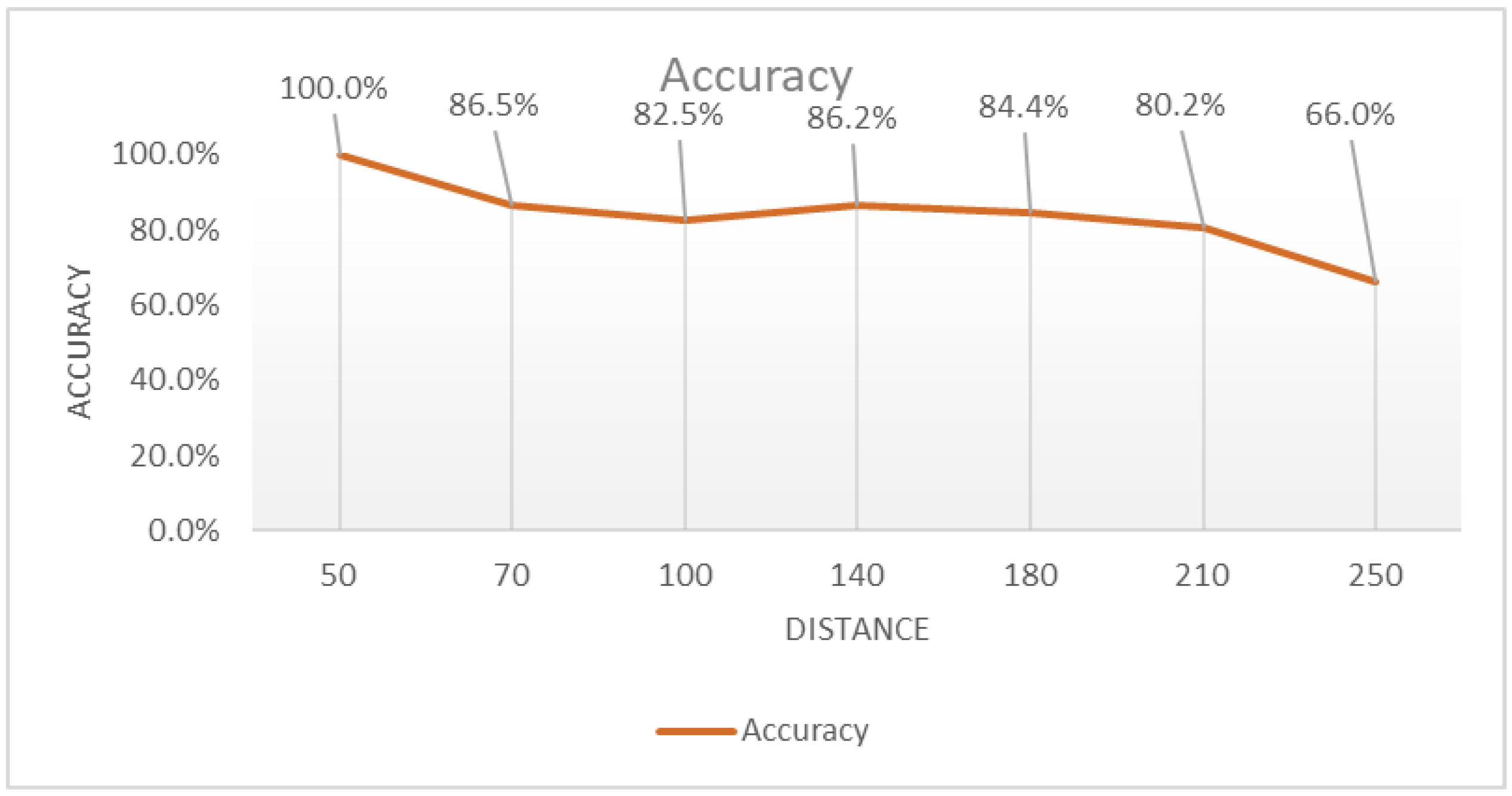

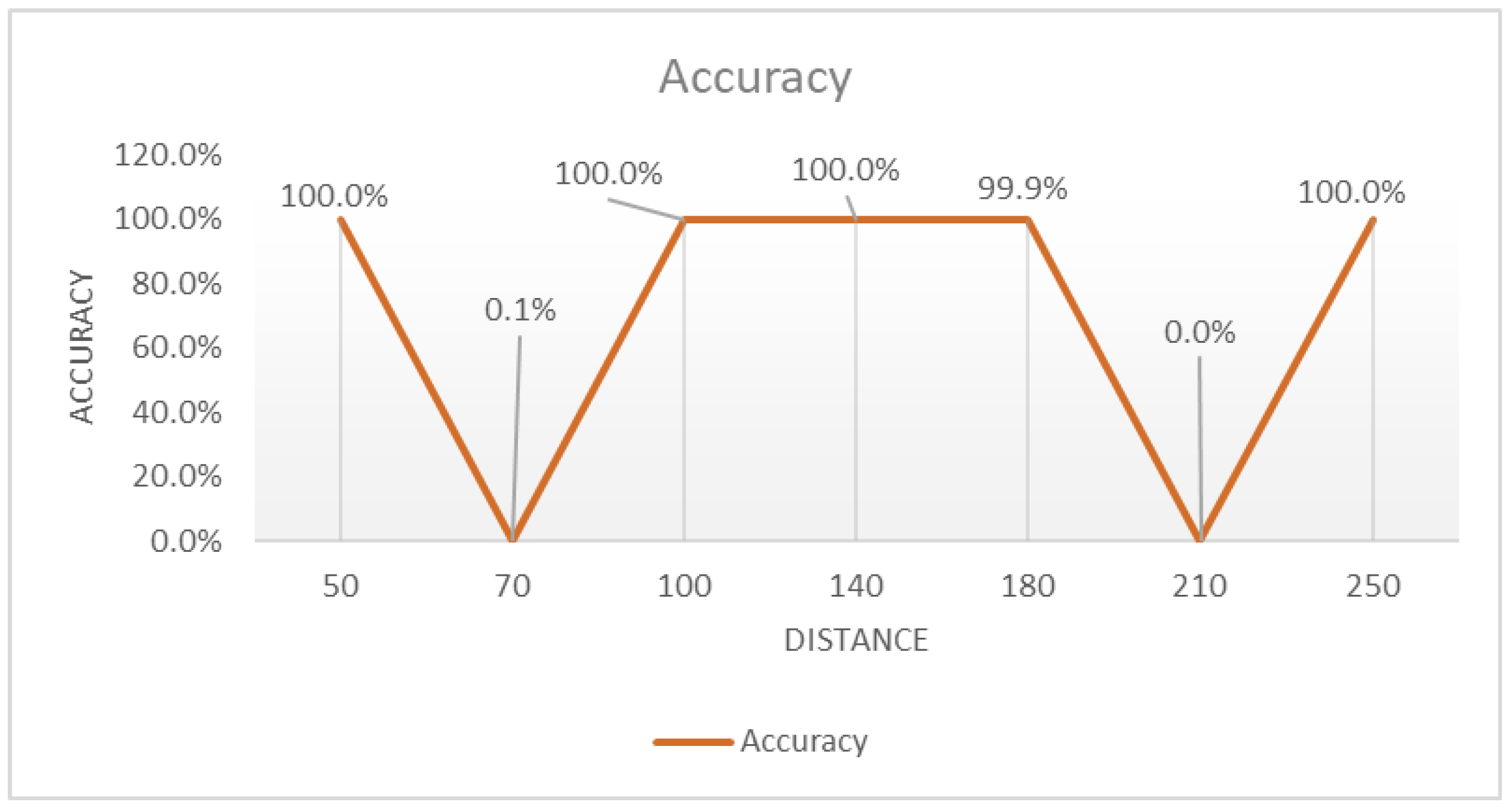

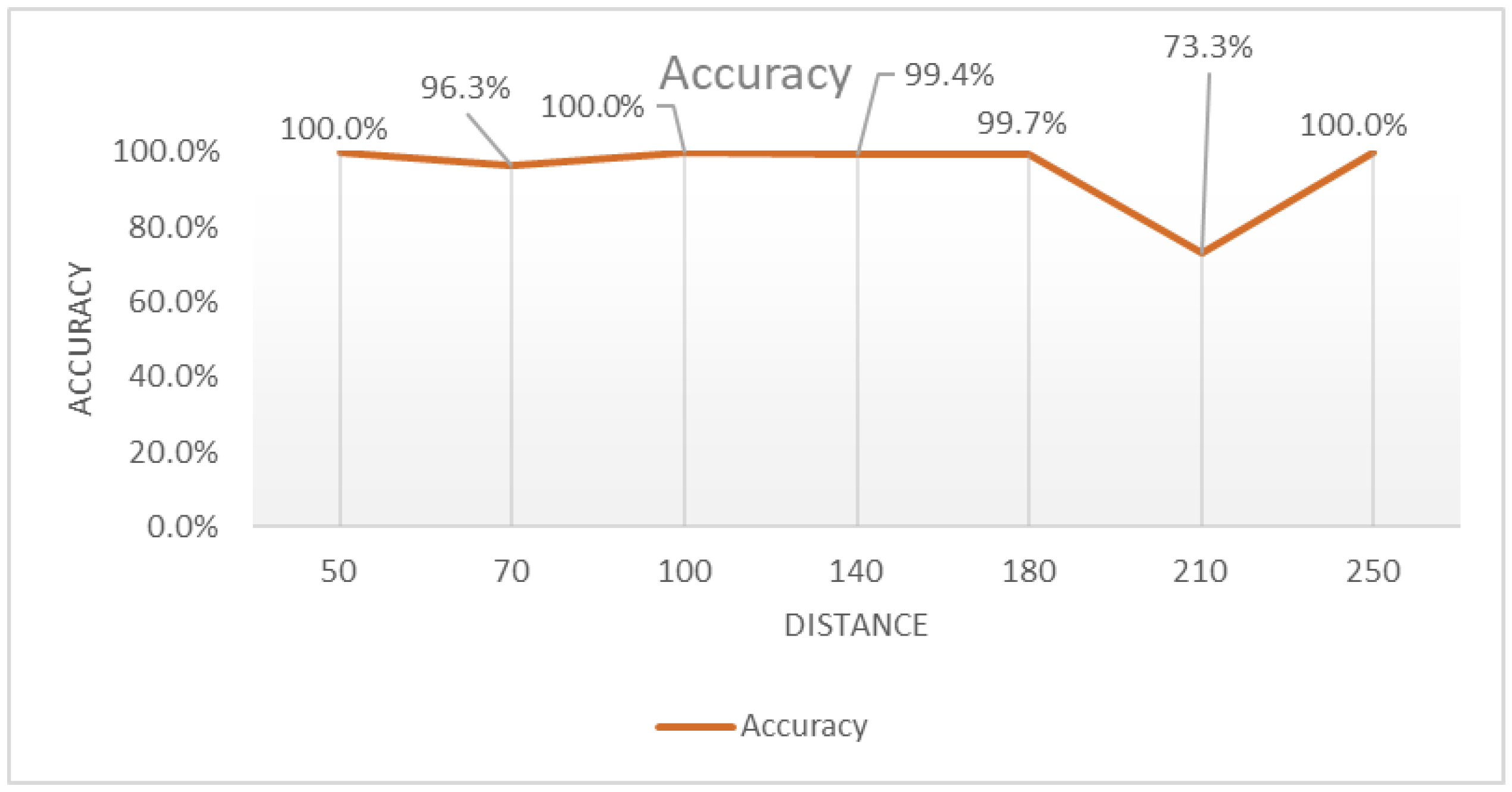

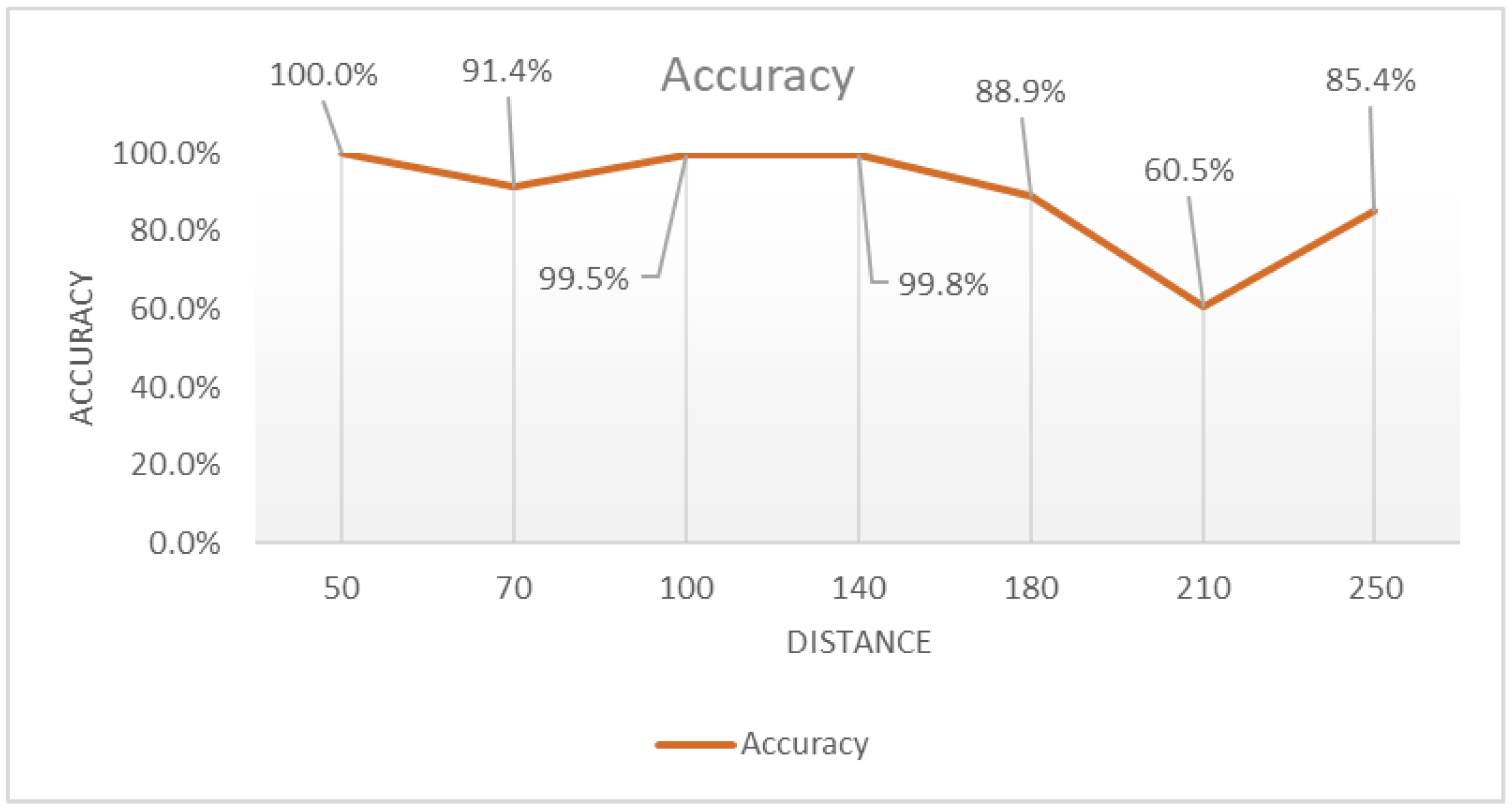

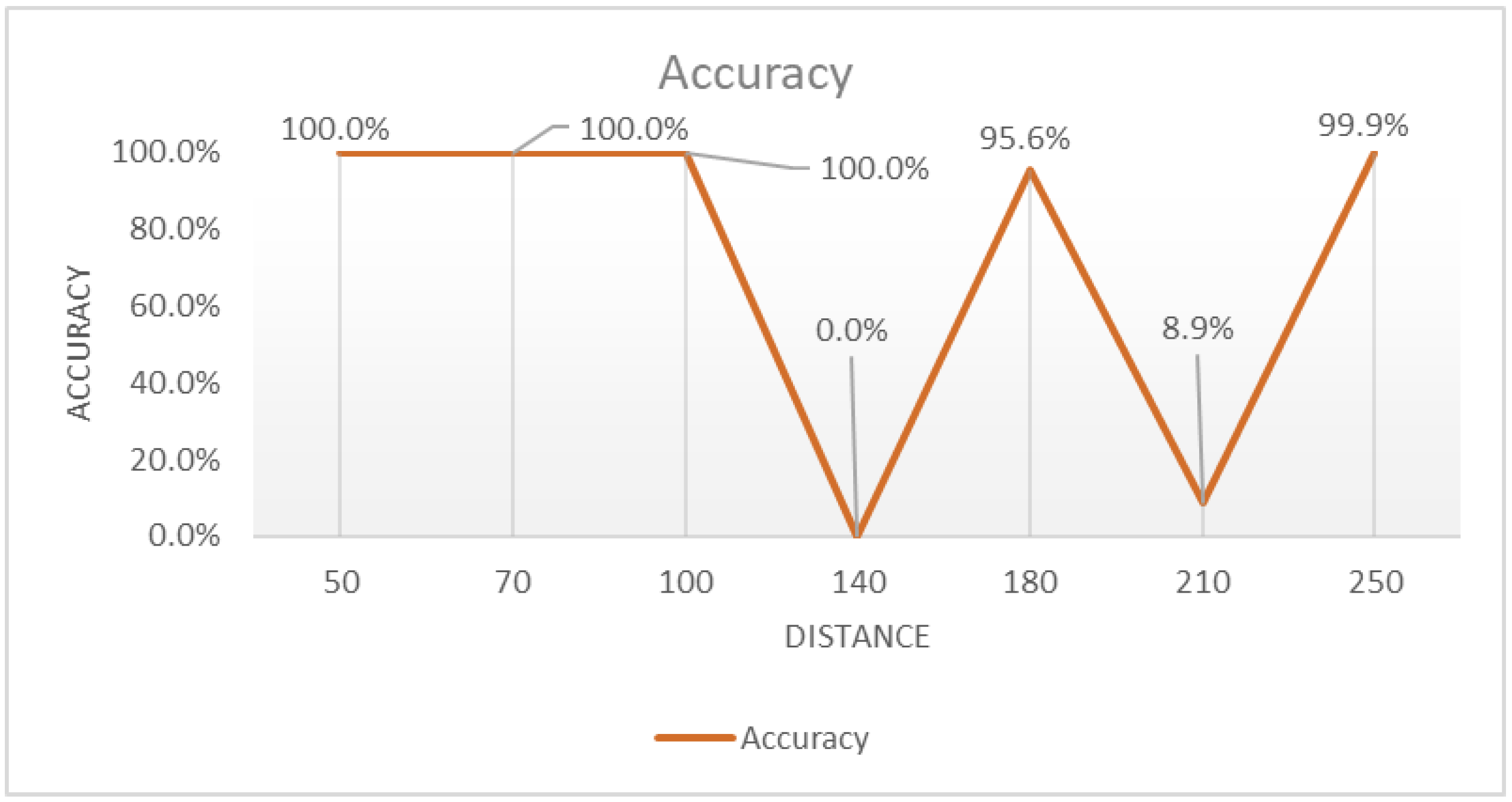

- The accuracy for each distance—as a graphical representation—calculated using the following formula:

- The overall accuracy of each of the prototype calculated using the following formula:

- The critical accuracy (for the 50, 70, 100, and 140 cm distances) of each of the prototype calculated using the following formula:

2.4. Interpretation of Results

- True positive (TP): Instances that were correctly predicted as positive.

- True negative (TN): Instances that were correctly predicted as negative.

- False positive (FP): Instances that were incorrectly predicted as positive.

- False negative (FN): Instances that were incorrectly predicted as negative.

- —indicator function that returns 1 if the condition is met and 0 in all the other cases;

- model—the measured distance by the prototype;

- reality—the real distance measured using a measuring tape.

- TP: results ∈ [realDistance− 2 cm, realDistance].

- FP: results ∈ [realDistance− 5 cm, realDistance− 2 cm].

- FN: results ∈ [realDistance + 1 cm, realDistance + 5 cm].

- TN: any other result.

- TP: if the prototype reading is between 68 and 70 cm and the user hears a “STOP” message;

- FP: if the prototype reading is between 65 and 67 cm and the user hears the “STOP” message;

- FN: if the prototype reading is between 71 and 75 cm and the user hears the “DANGER” message;

- TN: any other prototype reading.

3. Results

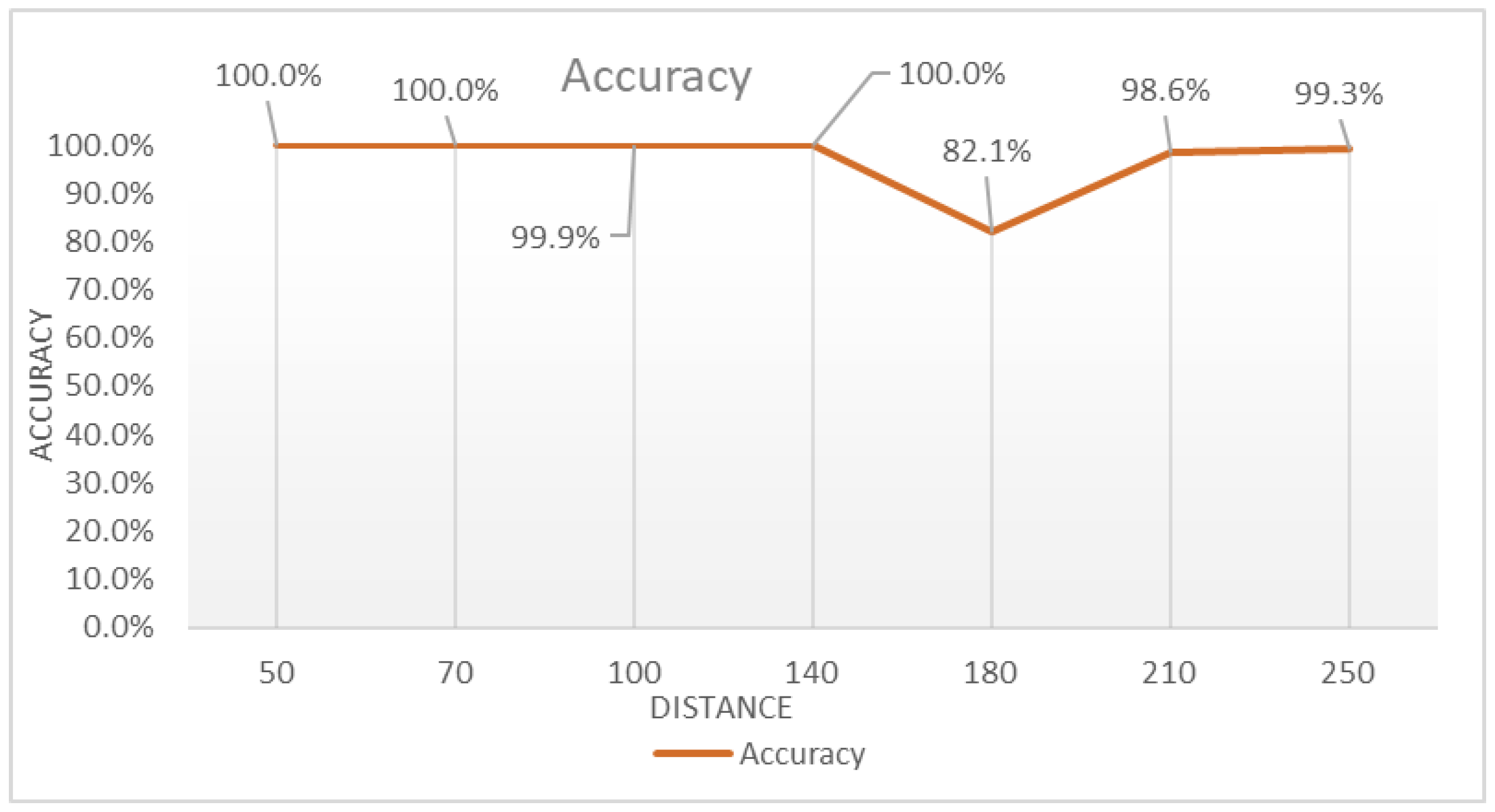

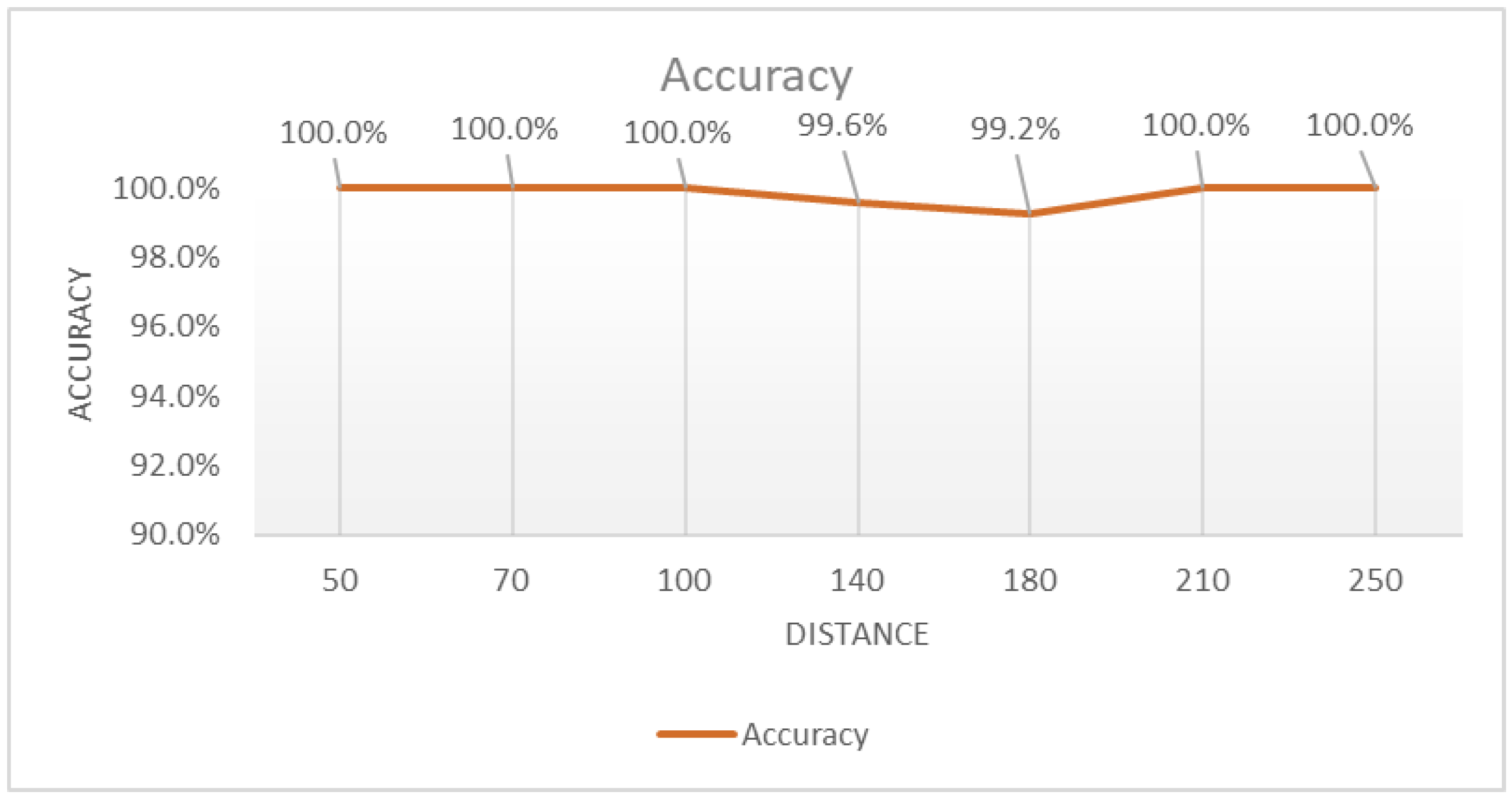

3.1. Square Static Obstacle Placed in Front of the Prototypes

3.2. Square Static Obstacle Placed So It Covers Half of the Prototype’s Detection Cone

3.3. Square Static Obstacle Placed So It Covers a Quarter of the Prototype’s Detection Cone

3.4. Round Static Obstacle Placed So It Covers the Full Path of the Prototypes Detection Cone

3.5. Round Static Obstacle Placed So It Covers Half the Path of the Prototype’s Detection Cone

3.6. Round Static Obstacle Placed So It Covers a Quarter of the Path of the Prototype’s Detection Cone

3.7. Tests with Various Materials Placed in Front of the Prototype

4. Conclusions

- User-friendliness.

- High autonomy.

- Low manufacturing cost.

- Safety.

- Static obstacles of square or rectangular shape placed in the user’s direction of travel will be detected and, depending on the distance between them and the prototype, will be signaled accordingly.

- The variation in the reading count between the PCM and WAVE prototypes arises from the duration it takes for them to “speak” and the algorithm’s capability to automatically eliminate false readings.

- Static obstacles of cylindrical shape are detected if the user is close to them, but at a greater distance, they may not be detected, or the distance between them and the prototype may be calculated incorrectly, leading to an incorrectly transmitted message.

- Testing with different materials used as obstacles has shown that the 40 kHz sonic wave is not absorbed or reflected in a direction other than the correct one.

- Under the conditions of very long usage of more than 9 h, the prototype can offer false readings due to overheating of the micro-controller. The addition of a radiator will add to the overall weight of the prototype and will create additional problems, so the advice is to power the prototype down after maximum 5 h of usage. This will be transmitted to the user by an alert message. This aspect will receive due attention in further developments of the algorithm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Prototype Test Results for Square Obstacle Placement So It Covers Half of the Prototype’s Detection Cone

| Distance | PCM Prototype Results | WAVE Prototype Results |

|---|---|---|

| 50 | Stop = 1101 | Stop = 996 |

| Danger = 0 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 70 | Stop = 1551 | Stop = 994 |

| Danger = 0 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 100 | Stop = 4 | Stop = 0 |

| Danger = 1462 | Danger = 987 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 140 | Stop = 9 | Stop = 0 |

| Danger = 1598 | Danger = 978 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 180 | Stop = 295 | Stop = 0 |

| Danger = 0 | Danger = 0 | |

| Caution = 1195 | Caution = 947 | |

| Clear = 0 | Clear = 0 | |

| 210 | Stop = 51 | Stop = 0 |

| Danger = 1 | Danger = 2 | |

| Caution = 1435 | Caution = 976 | |

| Clear = 0 | Clear = 0 | |

| 230 | Stop = 90 | Stop = 4 |

| Danger = 0 | Danger = 0 | |

| Caution = 0 | Caution = 5 | |

| Clear = 1321 | Clear = 961 |

Appendix B. Prototype Test Results for Square Obstacle Placement So It Covers a Quarter of the Prototype’s Detection Cone

| Distance | PCM Prototype Results | WAVE Prototype Results |

|---|---|---|

| 50 | Stop = 1692 | Stop = 1029 |

| Danger = 0 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 70 | Stop = 1416 | Stop = 993 |

| Danger = 54 | Danger = 1 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 100 | Stop = 0 | Stop = 2 |

| Danger = 1455 | Danger = 1019 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 140 | Stop = 69 | Stop = 0 |

| Danger = 1413 | Danger = 995 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 180 | Stop = 16 | Stop = 5 |

| Danger = 0 | Danger = 0 | |

| Caution = 1409 | Caution = 1027 | |

| Clear = 0 | Clear = 9 | |

| 210 | Stop = 144 | Stop = 0 |

| Danger = 0 | Danger = 0 | |

| Caution = 1309 | Caution = 998 | |

| Clear = 0 | Clear = 0 | |

| 230 | Stop = 93 | Stop = 0 |

| Danger = 0 | Danger = 2 | |

| Caution = 2 | Caution = 0 | |

| Clear = 1438 | Clear = 952 |

Appendix C. Prototype Test Results for Round Obstacle Placement So It Covers the Full Path of the Prototype’s Detection Cone

| Distance | PCM Prototype Results | WAVE Prototype Results |

|---|---|---|

| 50 | Stop = 1517 | Stop = 835 |

| Danger = 0 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 70 | Stop = 1045 | Stop = 885 |

| Danger = 411 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 100 | Stop = 0 | Stop = 0 |

| Danger = 1268 | Danger = 987 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 140 | Stop = 0 | Stop = 1 |

| Danger = 340 | Danger = 1079 | |

| Caution = 811 | Caution = 7 | |

| Clear = 0 | Clear = 0 | |

| 180 | Stop = 0 | Stop = 0 |

| Danger = 0 | Danger = 1 | |

| Caution = 1258 | Caution = 968 | |

| Clear = 0 | Clear = 0 | |

| 210 | Stop = 0 | Stop = 0 |

| Danger = 0 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 1101 | Clear = 963 | |

| 230 | Stop = 0 | Stop = 1 |

| Danger = 0 | Danger = 1 | |

| Caution = 0 | Caution = 0 | |

| Clear = 1089 | Clear = 979 |

Appendix D. Prototype Test Results for Round Obstacle Placement So It Covers a Half of the Path of the Prototype’s Detection Cone

| Distance | PCM Prototype Results | WAVE Prototype Results |

|---|---|---|

| 50 | Stop = 1476 | Stop = 997 |

| Danger = 0 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 70 | Stop = 1291 | Stop = 1 |

| Danger = 201 | Danger = 1000 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 100 | Stop = 258 | Stop = 0 |

| Danger = 1217 | Danger = 988 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 140 | Stop = 189 | Stop = 0 |

| Danger = 1243 | Danger = 973 | |

| Caution = 10 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 180 | Stop = 221 | Stop = 0 |

| Danger = 0 | Danger = 1 | |

| Caution = 1196 | Caution = 976 | |

| Clear = 0 | Clear = 0 | |

| 210 | Stop = 226 | Stop = 0 |

| Danger = 9 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 47 | Clear = 963 | |

| 230 | Stop = 485 | Stop = 1 |

| Danger = 0 | Danger = 1 | |

| Caution = 0 | Caution = 0 | |

| Clear = 943 | Clear = 957 |

Appendix E. Prototype Test Results for Round Obstacle Placement So It Covers a Quarter of the Path of the Prototype’s Detection Cone

| Distance | PCM Prototype Results | WAVE Prototype Results |

|---|---|---|

| 50 | Stop = 1417 | Stop = 1101 |

| Danger = 0 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 70 | Stop = 1392 | Stop = 998 |

| Danger = 127 | Danger = 0 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 100 | Stop = 8 | Stop = 0 |

| Danger = 1457 | Danger = 1020 | |

| Caution = 0 | Caution = 0 | |

| Clear = 0 | Clear = 0 | |

| 140 | Stop = 3 | Stop = 0 |

| Danger = 1505 | Danger = 0 | |

| Caution = 0 | Caution = 974 | |

| Clear = 0 | Clear = 0 | |

| 180 | Stop = 162 | Stop = 0 |

| Danger = 1 | Danger = 4 | |

| Caution = 1302 | Caution = 931 | |

| Clear = 0 | Clear = 39 | |

| 210 | Stop = 310 | Stop = 0 |

| Danger = 0 | Danger = 0 | |

| Caution = 862 | Caution = 89 | |

| Clear = 252 | Clear = 912 | |

| 230 | Stop = 209 | Stop = 0 |

| Danger = 0 | Danger = 0 | |

| Caution = 0 | Caution = 1 | |

| Clear = 1225 | Clear = 956 |

References

- World Health Organization. Vision Impairment and Blindness. Available online: www.who.int (accessed on 13 October 2022).

- European Blind Union. Available online: www.euroblind.org (accessed on 13 October 2022).

- Siu, Y.T.; Presley, I. Access Technology for Blind and Low Vision Accessibility; Aph Press, American Printing House for the Blind: Louisville, KY, USA, 2020. [Google Scholar]

- Wiener, W.R.; Welsh, R.L.; Blasch, B.B. Foundations of Orientation and Mobility; Afb Press: New York, NY, USA, 2010. [Google Scholar]

- Lancioni, G.E.; Singh, N.N. Assistive Technologies for People with Diverse Abilities; Springer: New York, NY, USA, 2014. [Google Scholar]

- Apostoaie, M.G.; Baritz, M.; Repanovici, A.; Barbu, D.M.; Lazăr, A.M.; Bodi, G. Visual Aid Systems from Smart City to Improve the Life of People with Low Vision. Sustainability 2023, 15, 6852. [Google Scholar] [CrossRef]

- Simões, W.C.; Machado, G.S.; Sales, A.M.; de Lucena, M.M.; Jazdi, N.; de Lucena, V.F., Jr. A Review of Technologies and Techniques for Indoor Navigation Systems for the Visually Impaired. Sensors 2020, 20, 3935. [Google Scholar] [CrossRef] [PubMed]

- Kuriakose, B.; Shrestha, R.; Sandnes, F.E. Tools and Technologies for Blind and Visually Impaired Navigation Support: A Review. IETE Tech. Rev. 2020, 39. [Google Scholar] [CrossRef]

- Ghebali, A. OrCam MyEye—The Best Device for visually impaired Persons. OrCam Techologies. 26 February 2023. Available online: www.orcam.com/ro-ro/orcam-myeye (accessed on 28 August 2023).

- ESight—Electronic Eyewear for the Visually Impaired. ESight Eyewear. Available online: www.esighteyewear.com/ (accessed on 28 August 2023).

- Radu, P.; Loredana, B.; Ramona, G. Ultrasonic indoor navigation prototype for visually impaired users. In Proceedings of the 2021 IEEE 27th International Symposium for Design and Technology in Electronic Packaging (SIITME), Timisoara, Romania, 27–30 October 2021; pp. 254–257. [Google Scholar] [CrossRef]

- Radu, P.; Loredana, B.; Ramona, G. Indoor Obstacle Detector for visually impaired Persons. In Proceedings of the 2023 23rd International Conference on Transparent Optical Networks (ICTON), Bucharest, Romania, 2–6 July 2023. [Google Scholar] [CrossRef]

- Circuitgeeks. Complete Guide for HC-SR04 Ultrasonic Sensor with Arduino. Circuit Geeks. 7 February 2021. Available online: www.circuitgeeks.com/hc-sr04-ultrasonic-sensor-with-arduino/ (accessed on 28 August 2023).

- Graham, D.; Black, R.; Veenendaal, E.V. Foundations of Software Testing: ISTQB Certification; Cengage Learning, EMEA: Andover, UK, 2020. [Google Scholar]

- Géron, A. Hands-On Machine Learning with Scikit-Learn and TensorFlow Concepts, Tools, and Techniques to Build Intelligent Systems, 2nd ed.; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2019. [Google Scholar]

- Lee, W.-M. Python Machine Learning; Wiley: Indianapolis, IN, USA, 2019. [Google Scholar]

- Xu, L.S.; Yang, W.; Tian, H.X. A Channel Estimation Method for Ultrasonic Through-Metal Communication. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2022, 69, 823–832. [Google Scholar] [CrossRef]

| Solution | Advantages | Disadvantages |

|---|---|---|

| Walking stick |

|

|

| Guide dog |

|

|

| Mobile applications |

|

|

| Special lines mounted on the floor |

|

|

| Orcam glasses [9] |

|

|

| eSight glasses [10] |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Păpară, R.; Grec, L.; Potarniche, I.-A.; Voichița, R.G. Testing of Indoor Obstacle-Detection Prototypes Designed for Visually Impaired Persons. Appl. Sci. 2024, 14, 1767. https://doi.org/10.3390/app14051767

Păpară R, Grec L, Potarniche I-A, Voichița RG. Testing of Indoor Obstacle-Detection Prototypes Designed for Visually Impaired Persons. Applied Sciences. 2024; 14(5):1767. https://doi.org/10.3390/app14051767

Chicago/Turabian StylePăpară, Radu, Loredana Grec, Ioana-Adriana Potarniche, and Ramona Gălătuș Voichița. 2024. "Testing of Indoor Obstacle-Detection Prototypes Designed for Visually Impaired Persons" Applied Sciences 14, no. 5: 1767. https://doi.org/10.3390/app14051767

APA StylePăpară, R., Grec, L., Potarniche, I.-A., & Voichița, R. G. (2024). Testing of Indoor Obstacle-Detection Prototypes Designed for Visually Impaired Persons. Applied Sciences, 14(5), 1767. https://doi.org/10.3390/app14051767