Abstract

Paperboard boxes represent a sought-after class of packaging products, where the use of recycled fibers offers a cost-effective and environmentally friendly alternative to virgin fibers. The presence of a significant proportion of recycled fibers in the paperboard leads to a number of limitations associated with the deterioration of its characteristics. In this study, the properties of coated and uncoated paperboards containing recycled fibers, wood pulp, and virgin cellulose fibers were investigated using a laboratory sample of paperboard produced from 100% recycled fibers without any chemical additives for comparison. Properties such as smoothness, bulk density, absorbency, and tensile strength, as well as colorimetric characteristics, were determined for the recycled paperboards; for the latter test, charts were printed using inkjet printing and UV-curable inks. Whiteness was calculated by three formulae (CIE, Berger, and Stensby), and all the paperboards had a relatively low whiteness (not exceeding 90 CIE), with a yellowish tint due to recycled fibers and mechanical pulp in the composition. The absence of optical brightening agents in the paperboards was experimentally confirmed. The color gamuts of the paperboards were in direct ratio to their whiteness, with the highest ones demonstrated by the coated paperboards. Color reproduction, according to the tone value increase curves, also depended on the whiteness. Uncoated paperboards demonstrated smaller color shifts than the coated ones, with the greatest increase in tone for yellow color. Coated recycled paperboards are suitable for packaging printing under the same conditions as virgin fiber boards, while uncoated boards are the recommended choice for digital printing with UV inks.

1. Introduction

The pulp and paper industry is essential in providing various products for daily life. Despite facing challenges related to sustainable resource management [1], we are confident in the industry abilities to overcome them. The demand for raw materials, such as wood, leads to deforestation, which affects ecosystems and biodiversity. Furthermore, the production process consumes substantial amounts of water and energy, impacting environmental sustainability.

The industry is actively embracing innovation and sustainable approaches by adopting greener practices and implementing more efficient technologies to minimize the carbon footprint according to the principles of circular economy and environmental conservation [2]. The lack of eco-friendly pulpwood prompts consideration of chemical pulp derived from non-wood raw materials [3]. For instance, wheat straw [3], rapeseed [4,5], and corn stalks [6], among the other agricultural waste, have shown potential for the production of bio-based paper and packaging materials. Additionally, the concept of innovation entails organizing the life cycle of materials in a manner that minimizes waste and optimizes the use of natural resources, promoting efficiency throughout the process of the recycling of paper products. This is accomplished by establishing a system where waste fiber-based products serve as the primary raw material for the new production cycle. Recycling paper, carton, fiberboard, and paperboard can significantly reduce the amount of raw wood used in papermaking, potentially up to 100% depending on the paper type. As a result, this process considerably reduces energy consumption, water use, air pollution, and water and soil contamination, in contrast to the traditional paper production process [7].

Packaging materials are among the most demanded applications of paper products. Despite the decline of traditional printed products (books, newspapers, magazines, documentation) due to digitalization, the production of packaging, such as cartons, cardboard, and paperboard, is consistently increasing [8]. Paperboard, a robust and relatively thick type of paper, finds versatile applications in crafting various packaging materials, carriers, folding cartons, and set-up boxes [9]. In addition to virgin cellulosic fibers, the paperboard composition can be supplemented with recovered fibers obtained by the recycling of wastepaper (recycled paperboard).

Recycled paperboard typically contains approximately 80–100% recovered fibers in the composition; it can have a craft, gray, or white reverse side. Paperboard usually consists of several plies: the top ply determines the whiteness and smoothness of the surface, while the middle ply (or plies) is responsible for the bulk density and firmness. The coating can significantly enhance print quality by improving image resolution. The coated surface of the cardboard becomes smoother, absorbs printing inks, and exhibits increased whiteness [10].

Paperboard is the ideal choice for the packaging of a wide range of goods due to its beneficial functional properties (protection from contamination and damage) and printability (has an advertising function, increasing the attractiveness of the goods). Among the main characteristics of paperboard are firmness, tensile strength, resistance to abrasion and plucking, barrier properties, absorbency, smoothness, whiteness, brightness, gloss, etc. The listed properties must correspond to both the printing method and the nature of the product.

Despite the fact that recycled paperboard is a promising alternative to traditional virgin fibers, offering both environmental and economic benefits, the industry is distrustful of this material and prefers to use it in the simplest types of packaging. There are numerous publications regarding the properties of recycled boards. Paperboard with the addition of recovered fibers generally has lower performance than one with corresponding mass produced from virgin fibers, e.g., it has higher strength, but the density is lower. Powers et al. compared the relative strengths of virgin and recycled paperboards. The results showed that both materials exceeded industry specifications at standard conditions; however, they severely degraded at extreme conditions, with the recycled material showing the greatest degradation [11].

Other disadvantages of recycled paperboard include high absorbency, which affects the quality of printing, and the presence of impurities—such materials cannot be used for packaging in direct contact with food. The quality of inkjet imprints on recycled corrugated boards was studied in order to increase the productivity of the technological process of manufacturing containers and to stabilize the quality of printing [12]. The authors revealed that the color gamuts of the corrugated boards corresponded to the indicators of the reference imprint; however, for some samples the characteristics were twice as low. It was found that due to the discrepancy between the color characteristics of the corrugated board surface to the standard, the color distortion of inkjet imprints occurs for all shades [12].

These studies confirm that while there are restrictions on the use of recycled paperboards, their application can be expanded, since a number of properties of recycled paperboard are not inferior to virgin ones. The aim of this study was the evaluation of the properties of coated and uncoated recycled paperboards, as well as the colorimetric testing of the imprints obtained by inkjet digital printing. Based on the findings, recommendations for printing can be made with confidence.

2. Materials and Methods

2.1. Recycled Paperboards

Seven recycled paperboards were studied—three uncoated and four coated samples. The composition of the paperboards provided by producers is presented in Table 1. Commercial paperboard samples have imprecise composition, which complicates the understanding of the cause-and-effect relationships between the fibrous composition, the additive content, and the properties of the paperboard. Therefore, a laboratory sample obtained using a Rapid-Köthen KWT sheet casting machine (Frank-PTI GMBH, Birkenau, Germany) was used as a reference point for a more correct comparison of the properties of recycled paperboards; it will be called Sample hereinafter in the text. The composition of this paperboard is precisely known; it contains only recycled paper (matte book and magazine paper with a high content of mechanical pulp) without any auxiliary substances, fillers, or brightening agents in it. Forming test handsheets were produced according to TAPPI 205 sp-12 standard (similar to ISO 5269) [13,14].

Table 1.

Composition of the paperboards.

The exact composition of the coating used in the samples listed in Table 1 is not disclosed by the manufacturers. Typically, coating paste consists of pigments (such as chalk, kaolin, blancfix, titanium dioxide, satinweiss, etc.), binders (such as sodium carboxymethylcellulose, starch, latex, etc.), and auxiliary additives (including dispersing agents, substances influencing hydrophilicity, antifoaming agents, optical brighteners, etc.) [10].

2.2. Determination of Functional Properties of Paperboards

The thickness of paperboards was determined with a thickness gauge tool (TIB-1, Russia) for paperboard samples of 10 × 10 cm at five points (ISO 534) [15]. The mass per square meter was calculated gravimetrically by weighing a 10 × 10 cm paperboard sample with a certified quadrant scales (ISO 536) [16]. The bulk density (b) characterizes the presence of interfiber spaces filled with air; it was calculated by the formula:

where m is the weight of a square meter of paperboard, g, and V is volume, cm3 (ISO 536) [16]. The bulk volume (V) was calculated by the formula:

where hav is the average thickness of the paperboard, cm, and S is sheet area, cm2 (ISO 534) [15].

The direction of the paperboard fibers was determined by folding the sheet in mutually perpendicular directions. The machine direction (MD) of the paperboard corresponds to a neater fold without creases running along the fibers (TAPPI/ANSI T 409 sp-23) [17].

The smoothness according to the Bekk method was calculated by measuring the time required for the passage of 10 mL of air in vacuum between the surface of the paperboard sample and the polished glass plate using a pneumatic smoothness meter (Russia) (ISO 5627) [18]. The obtained smoothness values do not take into account the micro- and macro-roughness of the surface, but they do allow one to determine the nature of the finish of the paperboard: machine smoothness (30–100 s), calendered (150–250 s), highly calendered (350–400 s), and coated (more than 500 s), according to the standard.

Determination of paperboard surface absorption (to xylene) was conducted using a drop method, where the absorption time of a solvent drop by the paperboard surface was measured until complete absorption and gloss disappearance. The test was performed on PVB equipment (Russia) from both sides of the material (GOST 12603-67, Russian standard) [19].

Surface absorption (K) at one-sided wetting (Cobb method) indicates the water resistance of the paperboard. The increase in mass of the sample was measured after one-sided contact of its surface with water for a fixed time (ISO 535) [20]. The duration of the test was 60 s; the calculation was carried out according to the formula:

where M1 is the mass of the sample before testing, g, and M2 is the mass of the sample after wetting, g.

The tensile properties of paperboard were tested by a loading method with an FG-100 tensile machine (Russia), for which two strips of paperboard of 150 × 240 mm, cut in the machine and transverse directions, were used for every sample (ISO 1924-1) [21].

2.3. Colorimetric Evaluation of Recycled Paperboard

All colorimetric measurements were carried out using a Eye-One Pro spectrophotometer (GretagMacbeth AG, Regensdorf, Switzerland). The number of measurements for each parameter was at least five; the experimental data were processed statistically by single-factor analysis of variance (ANOVA) (p = 0.05) using the Data Analysis package of Microsoft Excel.

The properties of paperboards were evaluated according to the following stages:

- whiteness determination;

- measurement of the colorimetric values of the test charts printed on the paperboard samples;

- visualization of the obtained values in the CIE La*b* color space;

- estimation of tone value increase (TVI) of printed samples.

There is a wide variety of whiteness indices available, and different formulae are used for different materials and applications [22]. The determination of the whiteness of the paperboards in this study was carried out with a D65 standard illuminant using three methods: CIE index; Berger formula, which is based on the XYZ system; and Stensby formula, which fits the La*b* color model.

The whiteness index CIE (WCIE) was calculated using the formula (ISO 11475) [23]:

where xn and yn are the tristimulus values of the D65 light source, xn = 0.313, yn = 0.329; x and y are the tristimulus values of the sample; and Y is a coordinate from the XYZ system.

The Berger formula for whiteness (WB) was as follows:

where X, Y, and Z are the tristimulus values of the sample and X0 and Z0 are the tristimulus values of the C light source and 2° standard observer [22].

The Stensby formula for calculating whiteness (WS)was as follows:

where L is lightness values and a and b are the red-green and yellow-blue colorimetric coordinates, respectively [22,24].

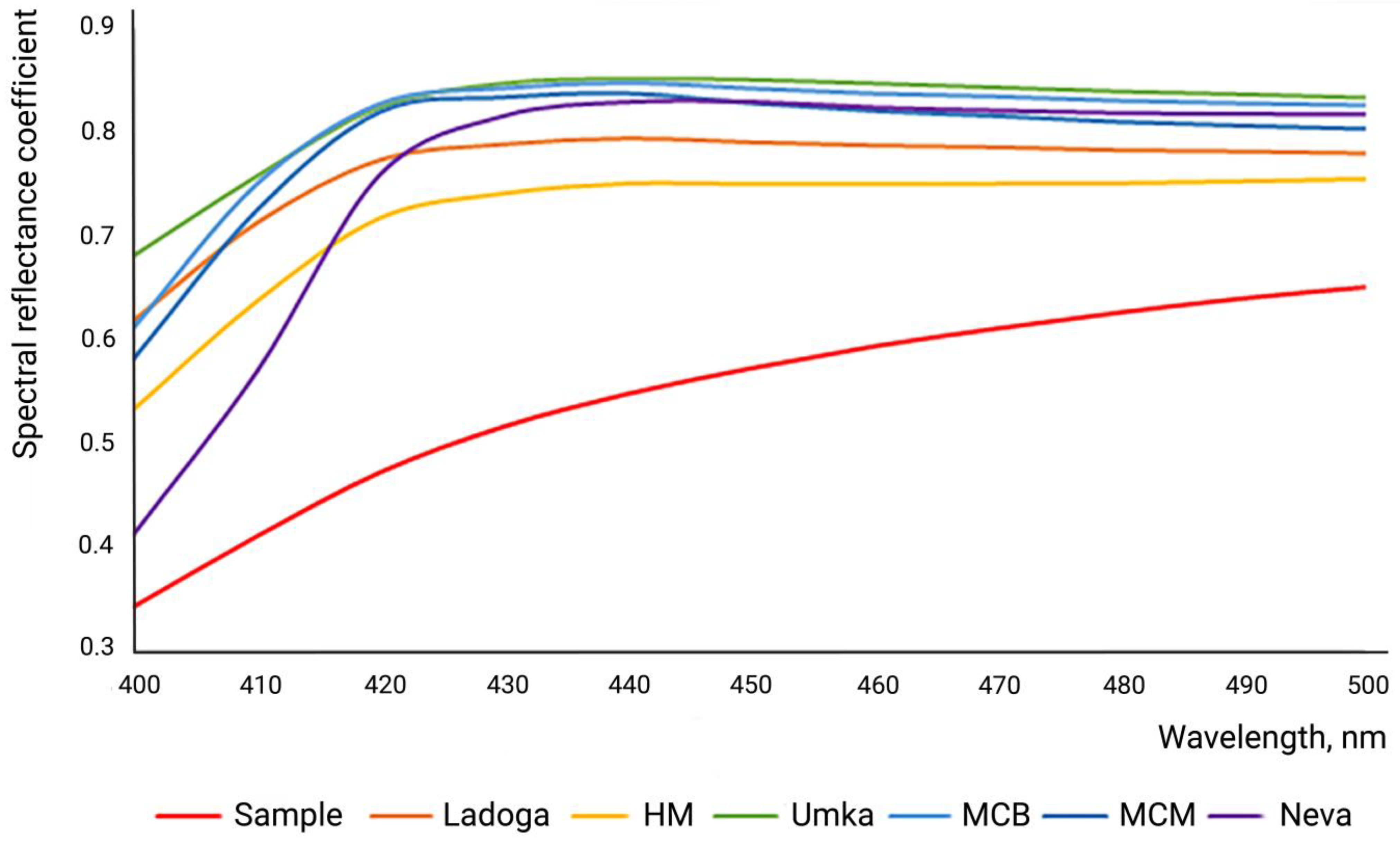

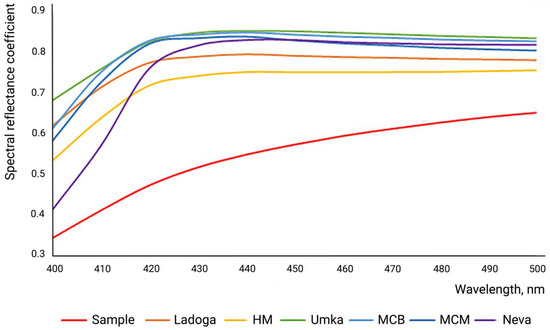

To experimentally determine the presence of optical brightening agents (OBAs) in the paperboards, the values of the spectral reflectance coefficient were measured.

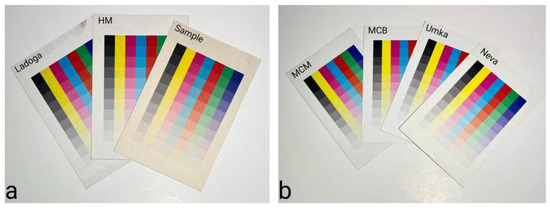

To assess the quality of printing, test charts were printed on the recycled paperboards (Figure 1) using a Mimaki UJF-3042 MkII inkjet flatbed printer (Nagano, Japan) with UV curing technology. The tristimulus values on the test charts were determined towards a white standard under the following conditions: D50 standard illuminant; standard observer, 2°; instrument geometry, 0/45°. The color gamuts were visualized as hexagon areas on a* and b* axes of the chromaticity diagram of the CIE La*b* colorimetric system, where L is lightness (L = 0—absolute black, and L = 100—reference white), the a* and b* coordinates characterize saturation and hue, respectively. The a* axis is represented by values from −120 to +120 of the red to green distribution, and the b* axis represents the color distribution from blue to yellow, with a = 0 and b = 0 corresponding to neutral gray.

Figure 1.

Samples of (a) uncoated and (b) coated paperboards with printed test charts.

Tone value increase was determined according to ISO 12647-1 [25].

3. Results and Discussion

3.1. Functional Properties of Recycled Paperboard

The properties of a material are usually indicated in its specification; however, some manufacturers allow fluctuations in the values in a wide range, which is why we controlled the main properties of the recycled paperboards in this study; the mean values are provided in Table 2. Whenever feasible, standard deviations are incorporated. Within both the coated and uncoated paperboard groups, the disparities among the acquired property values were statistically significant (p < 0.05). Additionally, a pairwise ANOVA analysis (p = 0.05) for close values was conducted, revealing that, for some samples, the differences in properties were not statistically significant.

Table 2.

Properties of recycled paperboards.

The mass per square meter of the studied paperboards ranges from 310.9 to 424.0 g/m2, while their thickness is comparable, namely from 483.2 to 554.6 µm; the latter characteristic is more important for printing. It should be noted that there was the biggest variation in thickness in the laboratory Sample, which is typical for such materials. Another distinctive feature of the Sample is the bigger bulk density compared to other paperboards. Bulk density characterizes compaction of matter, influenced by the specific type of raw material and binders employed in the production of paperboard. The Sample was obtained without additives; as a result, the bulk value outperforms the corresponding values of the other paperboards. The high bulk property can provide a paperboard with increased firmness, which affects the efficiency of many technological operations, such as embossing and folding. If the paperboard is intended for printing packaging, then, due to its firmness, the contents of the package are physically protected during transportation and storage. Usually, recycled paperboards demonstrate comparatively low firmness values.

Smoothness is a surface characteristic that affects the quality of printing, the gloss of the printed and varnished surface, lamination, and foil stamping. The microrelief of the surface allows reproduction of images with high resolution. Smoothness can be significantly improved by applying surface sizing or coating (a mixture of plasticizers, adhesives, clay, or kaolin). Additionally, the purpose of the coating is to reduce deformation when the paperboard contacts with moisture, ensuring accurate color matching during multi-color printing. Coated virgin fiber paperboards are highly smooth materials (more than 500 s); however, achieving the same level of smoothness for recycled paperboards is impossible. In this study, the smoothness values of the recycled paperboards range from 4.0 to 5.5 s for uncoated samples and from 38 to 76 s for coated samples (Table 2). These values correspond more to machine smoothness (30–100 s) than to coating smoothness. The reason for this difference is that the microrelief of the surface is often affected by the ingress of uncooked paper pulp during the production of recycled paperboard.

Deformation properties characterize the response of a material to external forces, which may cause degradation of its shape or volume. The tensile strength of paperboard is an important characteristic, not only for printing and post-processing but also for the protective function of packaging. Paperboard is an anisotropic material, so tensile strength is higher in the machine direction because of the orientation of the fibers. Paperboards containing secondary fibers are characterized by reduced tensile strength, in contrast to virgin fiber ones (up to 3 times). The addition of auxiliary chemicals to the composition of recycled paperboards, as well as controlling the physicochemical and electrokinetic parameters of pulp, can enhance the tensile strength by 15–20% [26]. Neva, Ladoga, and Umka paperboards showed higher tensile strength (MD) compared to the other samples. This seems unrelated to their thickness but can be attributed to sizing (Table 2). The laboratory single-plied paperboard sample does not have fiber directions; this is why its tensile strength corresponds to the values of the transverse (CD) direction of the industrial samples.

Sizing and coating strongly affect the absorption properties of paperboards, minimizing it. For example, Neva paperboard was the only one with a surface absorptiveness (to water) of 48 g/m2, with the norm being 20–60 g/m2 for paperboards without barrier properties. The uncoated paperboards, namely Ladoga and NM, as well as the laboratory Sample, showed unsatisfactory results for both xylene and water absorption. The absorption process depends on the structure of the material; thus, macroporous boards, including uncoated materials from recycled fibers, absorb ink quickly and deeply. As a result, macroporous paperboards are undesirable for illustrative printing, as they may cause loss of color saturation in the image. Microporous paperboards with coating and various fillers are characterized by the “selective absorption” mechanism, where the solvent is mainly absorbed into the micropores of the surface ply under the force of capillary pressure, while the pigment and binder remain on the surface. This is exactly what is needed to obtain a clear image. In general, the performance of recycled fiber paperboards is lower compared to the standards for virgin fiber ones. Accordingly, these materials may show unsatisfactory results in printing.

3.2. Colorimetric Characteristics of Recycled Paperboards

As revealed above, recycled fiber paperboards have high absorbency; therefore, it is necessary to choose a printing method that does not involve moisture. The inkjet digital printing method is suitable for this purpose because it has a number of advantages:

- low cost and simplicity, with the possibility of easily changing the press parameters;

- the nature of multi-color reproduction is similar to other printing methods;

- does not require printing forms, which is environmentally beneficial;

- high speed of the printing process and the possibility of producing small circulations;

- any kind of paper and paperboard can be used;

- no intermediate image information carrier is needed, allowing ink to be applied directly to the material.

For printing on recycled paperboard, UV-curable inks are the best choice because they dry quickly, have a high gloss, and are solvent-free, making them more environmentally friendly. In addition, UV inks have a high viscosity suitable for fast absorption by macroporous recycled paperboards.

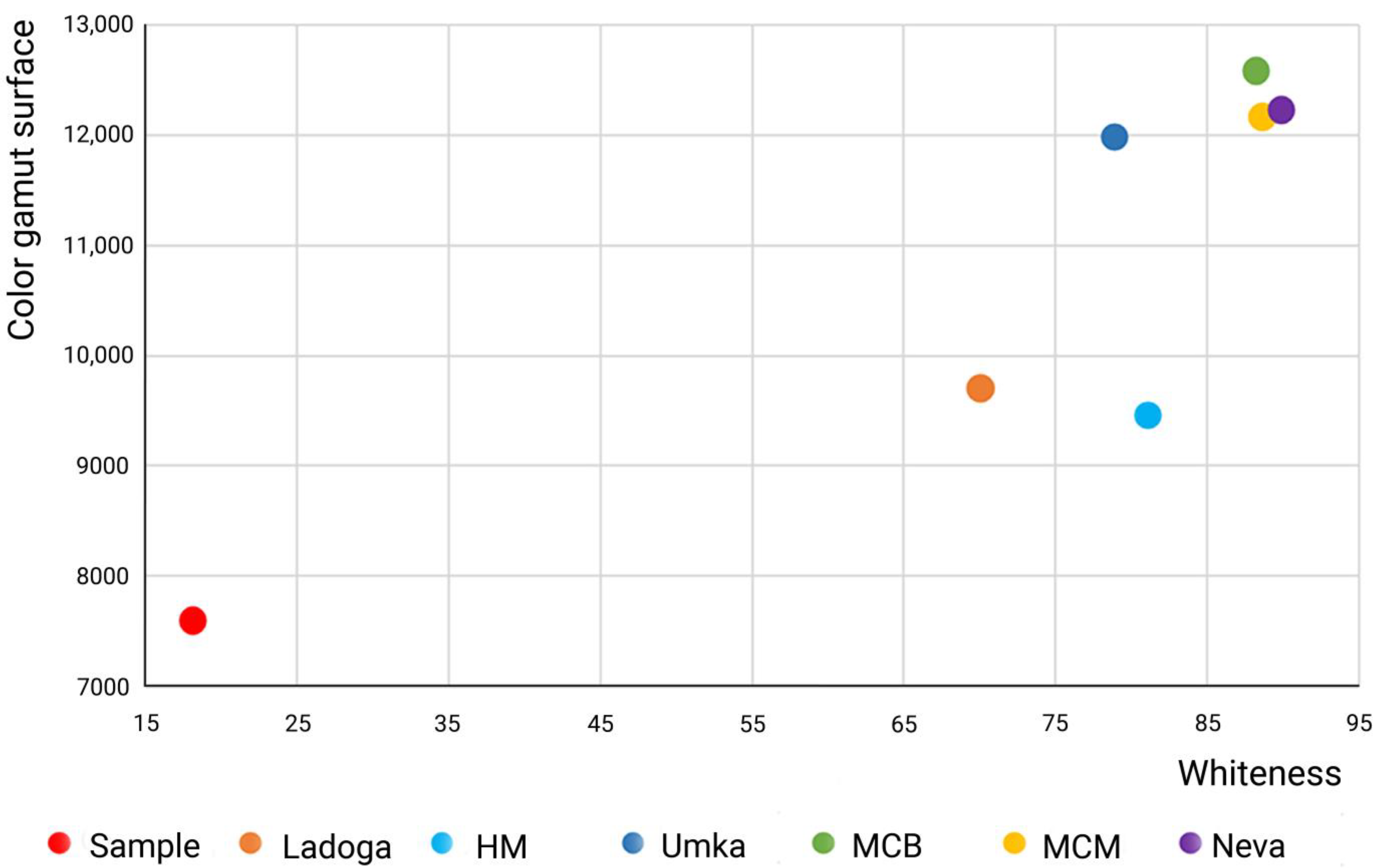

Color gamut is defined as all the colors that can be reproduced by the inks used. In addition to inks, the whiteness of the paperboard affects the color gamut. Therefore, before giving a colorimetric evaluation of imprints, it is necessary to compare the parameters of the whiteness of the samples. The average whiteness values of the recycled paperboards were calculated according to the CIE, Berger, and Stensby formulae; the results are presented in Table 3.

Table 3.

Average whiteness values of the recycled paperboards calculated by CIE, Berger, and Stensby formulae.

In all three groups, namely WCIE, WB, and WS, as well as within the groups of uncoated and coated paperboards, the differences between the obtained values of whiteness were statistically significant (p < 0.05). Pairwise comparisons of whiteness values within the groups (each type of whiteness separately for coated and uncoated cardboards) were assessed using the Tukey test (Table 3). An insignificant difference in whiteness was detected for paperboards Umka, MCB, and MCM from the coated group. Each of them had a multiple pigment coating (Table 1), which led to increased whiteness. Neva also had a coating on the top, but only double-layered. As a result, the whiteness values for this sample were the lowest in the group of uncoated paperboards.

Expectedly, the paperboards with a coated ply demonstrate a greater whiteness than uncoated ones. However, all samples have a yellow tint of different intensity due to the presence of secondary fibers in their composition. A comparative study demonstrates that the addition of bleached pulp to the top ply of recycled paperboards significantly increased (by four times) the whiteness compared to the unbleached laboratory Sample, while coating improved the whiteness of the paperboard by almost five times compared to the Sample.

The human eye tends to describe materials with a slightly bluish tint as “whiter”. This is why the compensation of yellowish colors of raw materials with the help of blue colorants or OBAs became a common practice. OBAs absorb the energy of the electromagnetic spectrum in the invisible ultraviolet region and emit it in the visible range of 430–470 nm. As a result, the material appears slightly bluish [26]. Usually, the manufacturer does not indicate whether OBAs have been used in the paperboard composition. This can be determined experimentally by measuring the values of the spectral reflectance at the wavelength 400–500 nm. The spectral curves indicate the absence of OBAs in the composition of materials (Figure 2). Neva demonstrates the sharpest rise at 410–430 nm; however, this sample has the lowest whiteness index in its group (Table 3). The shape of the curves of the other paperboards is smoother; they repeat the pattern of the laboratory sample, though they demonstrate a higher spectral reflectance coefficient.

Figure 2.

Spectral curves of the recycled paperboards.

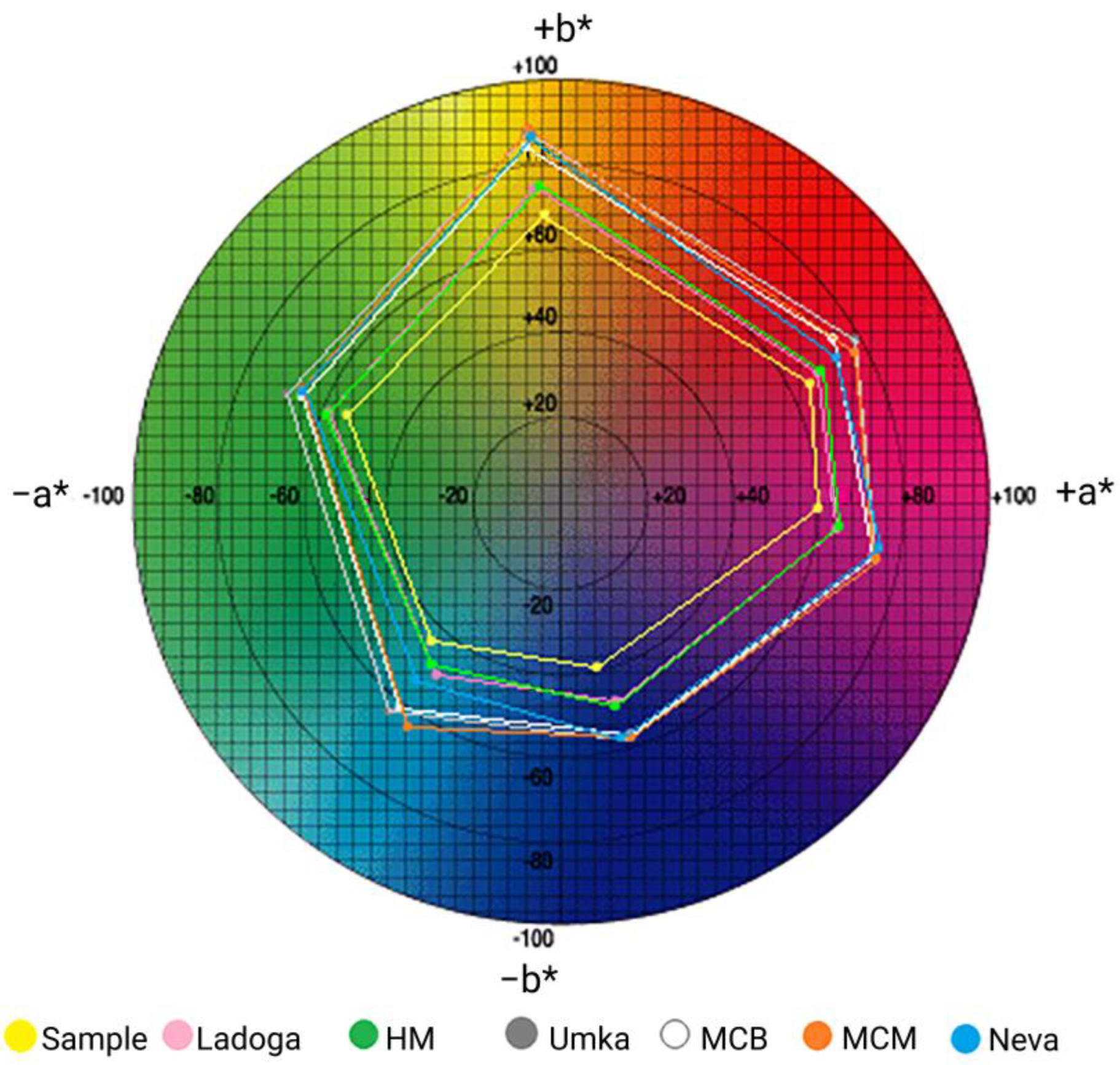

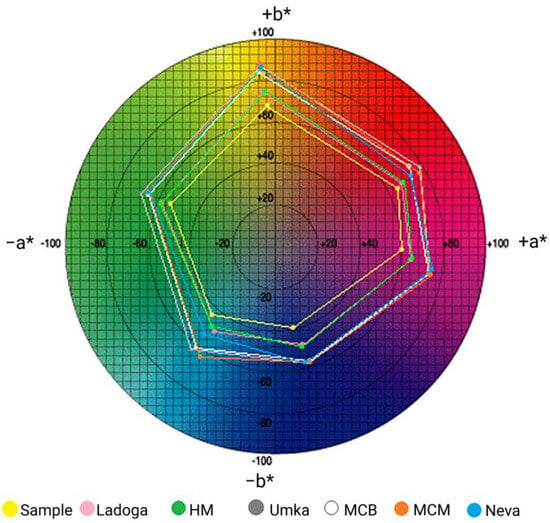

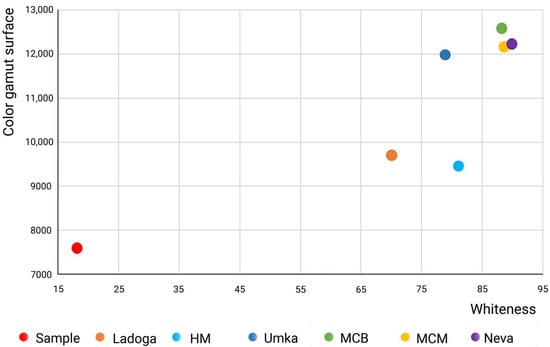

After the evaluation of whiteness of the paperboard samples, a qualitative colorimetric assessment of the printed paperboard was carried out. The tristimulus values of the imprints were measured on the test charts. The color gamuts of the samples were displayed on the a*b* chromaticity diagram of the CIE La*b* colorimetric system (Figure 3). After that, the areas of hexagons were calculated (Table 4). The vertices of the hexagons are the coordinates of the primary colors of subtractive synthesis (cyan, magenta, yellow) and the colors obtained by superimposing them in pairs (red, green, blue).

Figure 3.

Chromaticity diagrams of imprints for recycled paperboards.

Table 4.

Color gamut areas for recycled paperboards.

As mentioned above, the color gamut of any material depends on the whiteness, as clearly visible in Figure 4, where the areas of the color gamut for each paperboard were matched to its CIE whiteness index. The color gamuts of the samples increase with the improving whiteness values of the paperboards, with the best results corresponding to the coated materials. Neva steps out of the trend, which is explained by the coarse fiber composition and the initially low values of whiteness and smoothness. Consequently, the coated ply emphasizes the texture of the fibers and does not provide proper whiteness. The uncoated paperboard samples (NM, Ladoga) have lower whiteness values, and therefore a smaller color gamut. On the other hand, for samples with bleached fibers in the top ply, it is much higher than for a laboratory sample obtained from 100% wastepaper.

Figure 4.

Correlation between color gamut and paperboard whiteness (CIE).

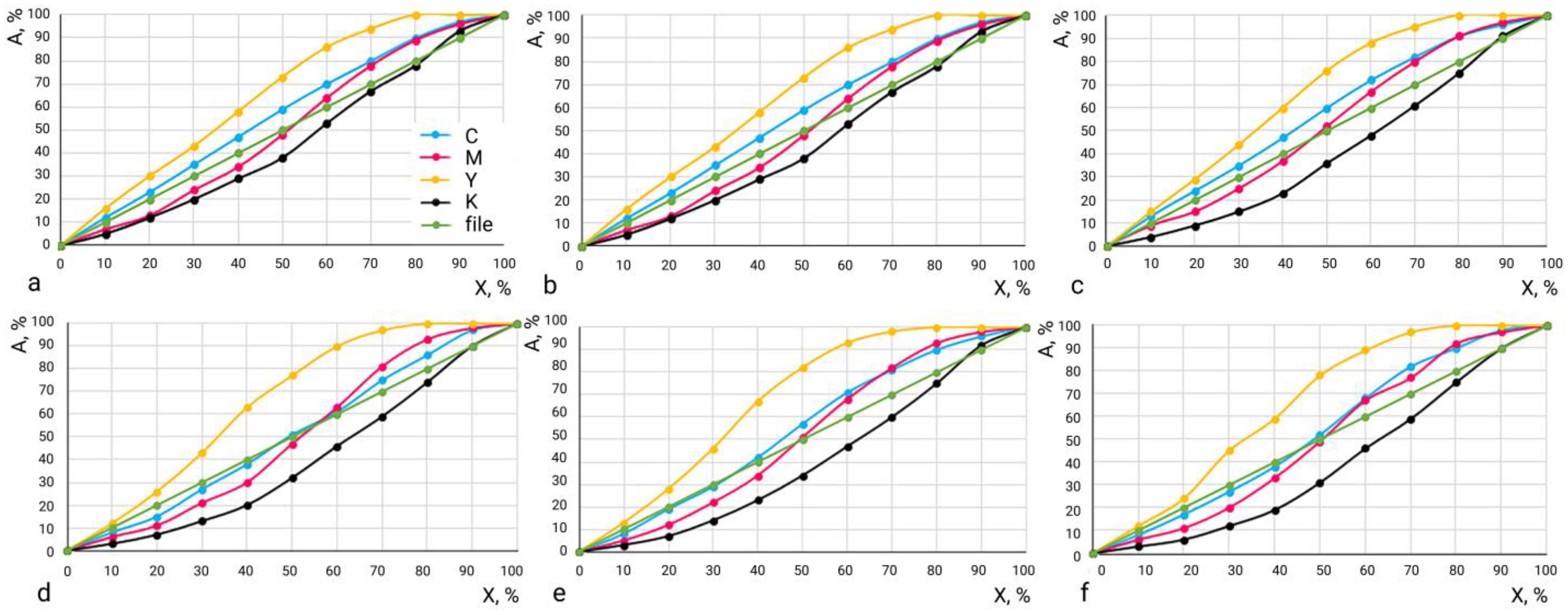

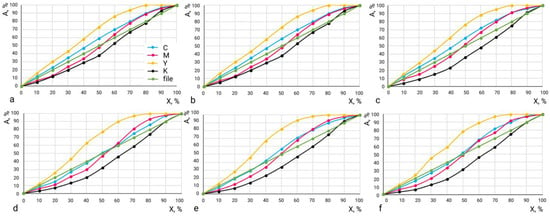

Tone value increase is the apparent relative increment of a raster element on an imprint to its values on a printing form or in a digital file (ISO 12647-1) [25]. In order to determine the amount of tone enhancement, it is necessary to find the difference between the tone-transmitting characteristic of the imprint and those of the file. In Figure 5, the TVI curves for color increments in the recycled cardboard imprints are presented.

Figure 5.

TVI curves for a laboratory Sample (a); uncoated paperboards Ladoga (b) and NM (c); and coated paperboards Umka (d), MCB (e), and Neva (f). Axes: X—tone value in file; A—total dot area in imprint.

The increase in tone is mainly due to the enlargement of the area of the printed elements. Since inkjet printing sprays ink, this is not a result of mechanical action on the ink layer, but rather the consequence of material absorbency. Recycled paperboards, especially those without a surface coating, absorb ink well due to their macroporosity, as discussed above. The highest tone increase among all samples is observed in the yellow color (Figure 5), which can be explained by the yellowish tone of the paperboards. However, the laboratory sample does not have the biggest TVI among the samples. On the contrary, uncoated paperboards demonstrate narrower curves for the C, M, Y, and K (cyan, magenta, yellow, and key, black) colors than the coated ones. In general, the smaller the difference between the imprint and the file, the more accurate the color reproduction. However, since all paperboard samples have different whiteness values, depending on their fibrous composition and surface coating, color accuracy also varies.

After the comparative study of the material properties of the recycled paperboards and the colorimetric evaluation of the imprint’s quality, it can be concluded that paperboards containing recycled fibers are suitable for inkjet UV printing. Due to instant fixing, the ink is not absorbed into the macroporous material, providing a good level of brightness and gloss for the image, especially noticeable on coated paperboards. Uncoated recycled paperboards have lower whiteness and smoothness and, accordingly, smaller color gamuts, which means they are not suitable for UV printing of illustrations with a large number of halftones, as they cannot provide smooth gradation transitions. However, they can be used for packaging printing with text or monochrome designs.

3.3. Recommendations for the Use of Recycled Paperboards for Packaging Production

Recycled paperboards may have relatively low printing and performance characteristics, such as smoothness, whiteness, and tensile strength. However, these shortcomings can be mitigated during the production stage through coating and/or by selecting an appropriate printing method and post-printing processing of the material. Firmness and tensile strength can be enhanced by introducing additives during production, as well as by increasing the thickness and density of the paperboard. Smoothness can be improved through calendering and coating, which improves color accuracy.

Paperboards containing recycled fibers may have a pronounced texture, but this can be concealed using UV inks or UV varnish, providing a thicker layer of ink through instant curing. Due to the yellow tint of recycled fiber paperboards, they are well-suited for packaging designed with a warm color palette.

Despite the identified drawbacks, recycled paperboards are an economically viable alternative to virgin fiber paperboards, and they demonstrate reasonably good printing results. While they may not be suitable for premium product packaging requiring precise color reproduction, they are well-suited for printing packaging for consumer goods, such as stationery and non-food products, alongside traditional paperboards.

4. Conclusions

When it comes to paperboards, there is a common misconception that recycled ones are of lower quality than virgin fiber paperboards. However, it is important to note that recycled paperboards can meet the same standards as virgin fiber paperboards. While the CIE whiteness for coated recycled paperboards ranges from 78.94 to 89.99, and for uncoated ones it ranges from 18.22 to 81.19, it is worth noting that higher quality printing can be achieved by choosing paperboards with the presence of optical brightening agents and/or a coated ply, rather than with a ply of bleached pulp.

Coated paperboards exhibit the greatest color gamuts, ranging from 7590 to 12,574, due to their increased whiteness. Uncoated paperboards, while still viable for printing, have shown lower tone enhancement values for inkjet UV curing compared to coated materials.

This study confirms the suitability of using secondary fiber paperboards for packaging printing. Coated recycled paperboards containing special additives can confidently be recommended for printing under the same conditions as virgin fiber paperboards. Uncoated paperboards may also be suitable for printing with UV curing inks. These materials are ideal for printing eco-design solutions, and interesting color solutions can be achieved for creating unique designs due to their low whiteness.

Author Contributions

Conceptualization, D.A., B.-M.T. and A.M.; methodology, D.A., B.-M.T. and A.M.; software, E.T. and D.A.; validation, D.A., B.-M.T. and A.M.; formal analysis, E.T., D.A., B.-M.T. and A.M.; investigation, E.T.; resources, D.A. and B.-M.T.; data curation, E.T., D.A. and A.M.; writing—original draft preparation, E.T. and A.M.; writing—review and editing, D.A., B.-M.T. and A.M.; visualization, E.T. and A.M.; supervision, A.M.; project administration, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to express gratitude to Irina G. Gruzdeva (Saint-Petersburg State University of Industrial Technologies and Design) for her generous assistance in planning and conducting the experiment on the functional properties of the paperboards, as well as for valuable advice in discussing the results. Additionally, we fondly recall the cozy streets of Karlstad, where the idea for this research was conceived during the Workshop on Cellulose.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Qi, J.; Zhao, J.; Li, W.; Peng, X.; Wu, B.; Wang, H. The Circular Economy-Oriented Practice in the Papermaking Industry. In Development of Circular Economy in China; Research Series on the Chinese Dream and China’s Development Path; Springer: Singapore, 2016; pp. 183–200. [Google Scholar] [CrossRef]

- Mikhailidi, A.M.; Kotelnikova, N.E. Horizons for Future Sustainability. From Trash to Functional Cellulose Fibres. In Sustainability of Biomass through Bio-Based Chemistry; Popa, V.I., Ed.; CRC: Boca Raton, FL, USA; Taylor and Francis: Abingdon, UK, 2021; pp. 91–130. ISBN 978-0-429-34799-3. [Google Scholar] [CrossRef]

- Moisei, N.; Puitel, A.C.; Tofanica, B.M.; Gavrilescu, D. Turning wheat straw in a sustainable raw material for paper industry. Environ. Eng. Manag. J. 2017, 16, 1027–1032. [Google Scholar] [CrossRef]

- Tofanica, B.M.; Gavrilescu, D. Alkaline pulping of rapeseed (Brassica napus) stalks in sulfate and soda-AQ processes. Bull. Polytech. Inst. Iasi Sect. Chem. Chem. Eng. 2011, 57, 51–58. [Google Scholar]

- Tofanica, B.M.; Puitel, A.C. Optimization and design of alkaline pulping of rapeseed (Brassica napus) stalks. Chem. Eng. Commun. 2019, 206, 378–386. [Google Scholar] [CrossRef]

- Chesca, A.M.; Nicu, R.; Tofănică, B.M.; Puiţel, A.C.; Vlase, R.; Gavrilescu, D. Pulping of Corn Stalks—Assessment in Bio-Based Packaging Materials. Cellul. Chem. Technol. 2018, 52, 645–653. [Google Scholar]

- Laurijssen, J.; Marsidi, M.; Westenbroek, A.; Worrell, E.; Faaij, A. Paper and Biomass for Energy?: The Impact of Paper Recycling on Energy and CO2 Emissions. Resour. Conserv. Recycl. 2010, 54, 1208–1218. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Panjagari, N.R.; Alam, T. An Overview of Paper and Paper Based Food Packaging Materials: Health Safety and Environmental Concerns. J. Food Sci. Technol. 2019, 56, 4391–4403. [Google Scholar] [CrossRef] [PubMed]

- Robertson, G.L. Food Packaging: Principles and Practice, 3rd ed.; CRC: Boca Raton, FL, USA; Taylor and Francis: Abingdon, UK, 2012; ISBN 978-1-4398-6241-4. [Google Scholar] [CrossRef]

- Popenya, T.V.; Chornaya, N.V.; Zholnerovich, N.V. Influence of the Composition of Coating Paste on the Properties of Printing Paper. Proc. BSTU 2011, 4, 152–154. (In Russian) [Google Scholar]

- Powers, K.; Warren, M.; Brown, R.W. Recycled Cardboard Comparison. Int. J. Adv. Packag. Technol. 2013, 1, 22–29. [Google Scholar] [CrossRef][Green Version]

- Zorenko, O.; Zorenko, Y.; Kupalkina-Luhova, I.; Skyba, V.; Khokhlova, R. Influence of the Surface Characteristics of Corrugated Cardboard on the Quality of Inkjet Printing. East.-Eur. J. Enterp. Technol. 2021, 6, 47–55. [Google Scholar] [CrossRef]

- TAPPI 205 sp-02; Forming Handsheets for Physical Tests of Pulp. Technical Association of Pulp and Paper Industry: Atlanta, GA, USA, 2006. Available online: https://www.tappi.org/content/sarg/t205.pdf (accessed on 31 January 2024).

- ISO 5269-1:2005; Pulps. Preparation of Laboratory Sheets for Physical Testing. International Organization for Standardization: Geneva, Switzerland, 2005. Available online: https://www.iso.org/standard/39340.html (accessed on 31 January 2024).

- ISO 534:2011; Paper and Board. Determination of Thickness, Density and Specific Volume. International Organization for Standardization: Geneva, Switzerland, 2011. Available online: https://www.iso.org/standard/53060.html (accessed on 31 January 2024).

- ISO 536:2019; Paper and Board. Determination of Grammage. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/77583.html (accessed on 31 January 2024).

- TAPPI/ANSI Test Method T 409 sp-23; Machine Direction of Paper and Paperboard. Technical Association of Pulp and Paper Industry: Atlanta, GA, USA, 1952. Available online: https://webstore.ansi.org/standards/tappi/ansitappi409sp23 (accessed on 31 January 2024).

- ISO 5627:1995; Paper and Board. Determination of Smoothness (Bekk Method). International Organization for Standardization: Geneva, Switzerland, 1995. Available online: https://www.iso.org/standard/20129.html (accessed on 31 January 2024).

- GOST 12603-67; Paper and Cardboard. Method for Determining Surface Absorption by Drop Method. IPK Izdatel’stvo Standartov: Moscow, Russia, 1967. Available online: https://docs.cntd.ru/document/1200018179 (accessed on 31 January 2024). (In Russian)

- ISO 535:2023; Paper and Board. Determination of Water Absorptiveness. Cobb Method. International Organization for Standardization: Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/80320.html (accessed on 31 January 2024).

- ISO 1924-1:1983; Paper and Board. Determination of Tensile Properties. International Organization for Standardization: Geneva, Switzerland, 1983. Available online: https://www.iso.org/ru/standard/6615.html (accessed on 31 January 2024).

- Katayama, I. Performance Comparison of Various Whiteness Formulas Based on Visual Evaluation Experiments. J. Sci. Technol. Light. 2019, 43, 7–17. [Google Scholar] [CrossRef]

- ISO 11475:2017; Paper and Board. Determination of CIE Whiteness, D65/10 Degrees (Outdoor Daylight). International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/63614.html (accessed on 31 January 2024).

- Grum, F.; Witzel, R.F.; Stensby, P. Evaluation of Whiteness. J. Opt. Soc. Am. JOSA 1974, 64, 210–215. [Google Scholar] [CrossRef] [PubMed]

- ISO 12647-1:2013; Graphic Technology. Process Control for the Production of Half-Tone Colour Separations, Proof and Production Prints. International Organization for Standardization: Geneva, Switzerland, 2013. Available online: https://www.iso.org/standard/57816.html (accessed on 31 January 2024).

- Slautin, D.; Teploukhova, M.; Andrakovski, R. Improving the Strength of Paper from Waste Paper. PNRPU Bull. Chem. Technol. Biotechnol. 2018, 1, 113–135. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).