Abstract

The necessity to move to sustainable energy solutions has inspired an investigation of innovative technologies for satisfying educational institutions’ sustainable energy needs. The possibility of a solar-hydrogen storage system and its integration into university energy management is investigated in this article. The study opens by providing context, noting the growing relevance of renewable energy in universities as well as the necessity for effective energy storage systems. The goal is to delve into solar-hydrogen technology, outlining its components, operating mechanism, and benefits over typical storage systems. The chapter on Integration Design examines current university energy infrastructure, identifies problems, and provides ways for integrating solar-hydrogen systems seamlessly. This integration relies heavily on technological and economic considerations, such as a cost-benefit analysis and scalability studies. Case studies include real-world examples, performance measurements, and significant insights learned from successful implementations. The chapter Future Prospects investigates new trends in solar-hydrogen technology as well as the impact of government legislation, providing a forward-looking viewpoint for colleges considering adoption. The report concludes with a summary of significant findings, emphasizing the benefits of solar-hydrogen integration and making recommendations for future implementations. The limitation of this research is that it only focuses on design and simulation as a phase of preliminary study.

1. Introduction

The global shift toward sustainable and renewable energy sources has acquired tremendous traction in recent years [1]. Universities, as centers of research and learning, increasingly understand the importance of embracing environmentally sustainable energy solutions [2]. This paradigm shift is motivated not only by environmental concerns but also by the possibility for educational institutions to serve as models for sustainable practices [3]. In today’s energy consumption situation, the need to shift toward more sustainable methods is becoming increasingly clear [4]. Traditional reliance on nonrenewable energy sources has exacerbated environmental challenges, demanding a rethinking of energy management practices [5,6]. In this perspective, the integration of solar-hydrogen storage systems appears to be a promising answer to universities’ energy concerns. Several strong reasons motivate us to conduct research into the integration of solar-hydrogen storage devices into university energy management (Table 1) [7,8,9].

Table 1.

The Implementation of Solar-Hydrogen Energy in Universities.

In essence, research into the integration of solar-hydrogen storage systems is consistent with a broader commitment to environmental stewardship, fiscal restraint, and the instructional purpose of institutions [10]. It positions institutions as innovators in the adoption of revolutionary technologies that not only meet their energy requirements but also contribute to a more sustainable and resilient future [11].

The development of solar-hydrogen energy presents a viable and sustainable approach to address the negative environmental effects associated with traditional energy sources. This method encourages the production of carbon-neutral energy by using solar electricity to produce hydrogen via electrolysis of water. When operating, solar-hydrogen systems emit no greenhouse gases, in contrast to fossil fuels, which helps to reduce air pollution and mitigate climate change. Additionally, by providing a flexible and environmentally benign substitute in industries like transportation, manufacturing, and power generation, hydrogen as a clean energy carrier aids in the shift to a low-carbon economy. Adopting solar-hydrogen energy supports a cleaner and more sustainable energy future and is in line with international efforts to stop environmental damage [12].

Solar-hydrogen energy combines solar power with electrolysis to produce hydrogen, thereby emulating a clean and sustainable energy paradigm. Sunlight is captured by solar panels and transformed into electricity, which is then used to split water molecules to produce hydrogen, an environmentally friendly fuel. This technology offers a carbon-neutral substitute for traditional energy sources because it produces no emissions at all. The intermittent nature of solar electricity can be mitigated with hydrogen, an energy carrier that is both flexible and storable. Furthermore, hydrogen only produces water vapor when it is burned or used in fuel cells, confirming its status as a clean and sustainable energy source. This novel combination of solar and hydrogen technologies not only lessens their negative effects on the environment but also establishes solar-hydrogen energy as a key participant in the shift to a more sustainable and environmentally friendly energy landscape [13].

Numerous advantages arise from using electrolytic systems in universities to produce hydrogen, supporting both sustainability and academic goals. Universities can achieve environmental stewardship and lower their carbon footprint by producing clean hydrogen on-site through the use of electrolyzers driven by renewable energy sources like solar or wind. Furthermore, incorporating electrolytic systems into academic environments provides a useful and instructive example of cutting-edge sustainable technology. In order to promote an innovative and environmentally conscious culture, staff and students get personal experience with hydrogen production methods and applications of renewable energy. Moreover, the hydrogen generated may be used as a flexible energy source for a range of campus uses, such as hydrogen fuel for automobiles, offering a real-world illustration of how sustainable energy solutions can be incorporated into regular operations [14].

The current study examines the scientific and financial feasibility of powering Delhi Technological University’s Science Block in Delhi, India, utilizing solar photovoltaic energy sources. In a hybrid energy system, the intermittent solar energy is stabilized by using hydrogen energy storage to produce a steady electrical current. The most ideal design, with a net current cost of $1,030,406, has been simulated by HOMER software. With a rated capacity of 240 kW and a mean output of 44.5 kW—or 1068 kWh/day—solar photovoltaic generates 389.865 MWh of energy every year. When operating for 4344 h a year, the PV system can produce up to 253 kW, with a PV penetration of 358% [15].

The major goal of this research is to offer a thorough examination of the solar-hydrogen storage system. Universities can make informed decisions about adopting and integrating this technology into their energy infrastructure if they grasp its complexities. The research intends to go into the practical issues of integrating solar-hydrogen systems into university energy management, in addition to the theoretical ones. This entails investigating universities’ existing energy infrastructure, identifying potential obstacles, and suggesting effective integration options.

Because colleges shape future leaders and decision-makers, their dedication to sustainable energy practices can have a significant impact on societal norms and practices. We hope to contribute to the discussion of sustainable energy in educational institutions with this study, which focuses on the architecture and integration design of solar-hydrogen storage systems.

2. Solar-Hydrogen Storage System

2.1. Solar-Hydrogen Technologies and Storage System

The solar-hydrogen storage system is an innovative technique for capturing and storing renewable energy [16]. This section presents a comprehensive review of the technology, focusing on the synergy between solar power and hydrogen as an energy carrier. This technology solves the intermittent nature of solar power and promotes efficient energy storage by turning solar energy into electricity and then using electrolysis to make hydrogen [17].

This section examines the unique advantages afforded by solar-hydrogen technology, highlighting the limits of typical energy storage technologies. These benefits include increased storage capacity, scalability, and the ability to store energy for long periods of time. Furthermore, the system’s ability to generate a clean energy carrier (hydrogen) makes it an appealing approach to lowering carbon emissions.

Solar-hydrogen technologies cover a wide range of approaches for harnessing solar energy and converting it to hydrogen for storage. Typically, numerous critical components are involved in the integration of various technologies (Table 2) [18,19,20].

Table 2.

Key Components of Solar-Hydrogen Technologies.

2.2. Components

2.2.1. Solar Panel

This section looks at how solar panels capture sunlight and transform it into electrical energy. It discusses advances in solar panel technology and its effectiveness in producing clean electricity. The photovoltaic effect describes the method by which solar panels catch sunlight and convert it into electrical energy (Table 3) [21,22,23].

Table 3.

The Process of Solar Panels Capturing Sunlight and Transforming it into Electrical Energy.

The photovoltaic effect is a key phenomenon that enables solar panels to capture sunlight and transform it into a clean, renewable source of electricity [24,25]. Photovoltaic cells made of semiconductor materials like silicon capture incoming photons from sunlight in this complicated operation. This absorption energizes electrons, causing them to be liberated from their typical locations and the formation of electron-hole pairs. The flow of these liberated electrons creates an electric current, which results in a voltage potential across the solar cell [26]. This resulting electrical energy, primarily in the form of direct current (DC), is immediately collected and used to power devices linked to the solar panel system. In grid-connected systems, an inverter may convert direct current (DC) to alternating current (AC) for more versatile uses [27]. Notably, the photovoltaic effect highlights the sustainable nature of solar energy by emitting no emissions and employing a plentiful and renewable resource—sunlight—for a cleaner and more ecologically friendly power generation process [28].

2.2.2. Electrolyzer

An electrolyzer is a critical component in the process of producing hydrogen via electrolysis, which uses electrical energy to divide water molecules into hydrogen and oxygen [29]. These devices, which include Proton Exchange Membrane (PEM), alkaline, and solid oxide electrolyzers, are critical in the production of clean and renewable hydrogen [30]. During operation, an electrolyzer receives an electric current, which is often derived from renewable energy sources such as solar or wind power, and applies it to water (H2O). Within the electrolyzer, the electrical energy causes a chemical process that causes water molecules to separate. During the process, one electrode (cathode) releases hydrogen gas, while the other electrode (anode) releases oxygen gas. The split hydrogen can be stored for subsequent use as a versatile and environmentally beneficial energy carrier, thereby advancing green energy technology and lowering carbon emissions [31].

Factors influencing electrolyzer efficiency and performance include the type of electrolyzer technology used, the cleanliness of the water source, and the overall system design [32]. Technological advancements in electrolyzers continue to improve efficiency, lower prices, and broaden the possibility of large-scale hydrogen generation, establishing electrolysis as a vital actor in the transition to a sustainable and hydrogen-based energy economy [33].

Several factors influence electrolyzer performance and efficiency (Table 4), affecting their capacity to effectively create hydrogen through water electrolysis. Here are some important variables to consider [34,35,36]:

Table 4.

Factors influencing electrolyzer performance and efficiency.

As electrolyzer technology advances, addressing these contributing elements becomes critical for increasing efficiency, lowering costs, and fulfilling the potential of hydrogen as a clean and adaptable energy carrier [37].

2.2.3. Electrolyzer Hydrogen Storage Tanks

Efficient hydrogen storage is critical for using hydrogen as a versatile energy carrier, allowing it to be integrated into a variety of applications ranging from fuel cells to industrial processes. Several methods and technologies have been developed to securely and efficiently store hydrogen [38,39,40]:

- Compressed Hydrogen Storage: gaseous hydrogen is compressed at high pressures, typically ranging from 350 to 700 bar, in compressed hydrogen storage to reduce volume and increase storage density. The compressed hydrogen is kept in high-strength containers made of materials that can resist the pressures involved. While this approach is well-established and very easy, the energy required for compression and the need for durable storage materials are factors in its efficiency. Advanced composite materials and metal hydrides are being investigated to improve the performance of compressed hydrogen storage systems.

- Liquid Hydrogen Storage: liquid hydrogen storage entails chilling gaseous hydrogen to extremely low temperatures (about −253 degrees Celsius) in order to convert it to a liquid state. This considerably reduces the volume occupied by hydrogen, allowing for increased storage density. Cryogenic storage tanks, sometimes double-walled with vacuum insulation, are used to hold liquid hydrogen. The high energy density achieved by this technology is efficient, but the energy-intensive liquefaction process and the difficulty involved with maintaining low temperatures are aspects to consider.

- Metal Hydride Storage: metal hydride storage involves the absorption and desorption of hydrogen by specific metal alloys. During absorption, hydrogen is chemically bonded to the metal, and during desorption, hydrogen is liberated. This approach has a distinct benefit in that it provides for safe and compact storage at moderate pressures and temperatures. The effectiveness of metal hydride storage is governed by parameters such as metal alloy selection, operating circumstances, and hydrogen absorption and release kinetics. Ongoing research focuses on building high-capacity, reversible metal hydrides for increased performance.

- Underground Storage: underground storage, which is commonly found in depleted natural gas reservoirs or salt caverns, makes use of natural geology to store hydrogen. Gaseous hydrogen is injected and stored in subsurface formations, taking advantage of the geological structure’s permeability and porosity. This approach offers large-scale storage capacity and is especially well-suited for seasonal storage requirements. Underground storage efficiency is determined by elements such as geological conditions, injection and extraction rates, and safety concerns.

Each storage method has advantages and disadvantages, and the decision is influenced by factors such as the intended application, storage scale, and safety concerns [41]. Ongoing research and development aims to improve the efficiency, safety, and economic viability of hydrogen storage systems, thereby contributing to the wider adoption of hydrogen as a sustainable energy solution [42].

2.2.4. Fuel Cells

Fuel cells serve an important role in completing the energy cycle while providing significant efficiency and environmental benefits. These electrochemical systems transform hydrogen’s chemical energy directly into electricity, with only water vapor and heat as byproducts. Fuel cell efficiency is a significant advantage over traditional combustion-based energy conversion technologies [43]. Traditional power production systems, such as internal combustion engines, sometimes entail many energy conversion processes, each of which results in energy losses. Fuel cells, on the other hand, are more efficient, turning more than 50% of the energy content in hydrogen into electricity. This simpler energy conversion process improves overall system efficiency by minimizing energy waste and boosting the energy cycle’s sustainability [44].

Furthermore, the environmental benefits of fuel cells derive from their clean and emission-free operation. Unlike combustion-based power generation, which emits pollutants and greenhouse gasses, fuel cells generate energy via an electrochemical reaction that does not involve combustion [45]. The principal byproduct of fuel cell operation is water vapor, making them an environmentally favorable option for power generation. This quality is especially important in the context of mitigating climate change and lowering air pollution [46]. As the demand for clean energy solutions grows, fuel cells emerge as a potential technology to address both efficiency difficulties and the environmental consequences associated with traditional energy cycles. Fuel cells’ adaptability, from small-scale applications like portable electronics to larger-scale deployments in cars and stationary power systems, positions them as a crucial element in developing a sustainable and low-emission energy future [47].

2.3. Working Mechanism

The importance of this painstakingly developed operating mechanism resides in its transformational potential for the energy environment. Converting solar energy to electricity is the first step toward harnessing an abundant and renewable resource, providing a clean and sustainable alternative to traditional power generation [48]. The ensuing electrolysis process for hydrogen generation not only takes advantage of solar-generated electricity, but also creates a green channel for hydrogen—a versatile and efficient energy carrier [49]. The critical role of hydrogen storage and retrieval addresses the intermittent nature of solar energy by allowing excess energy to be stored for later use. Finally, fuel cell energy generation completes the cycle by transforming stored hydrogen into electricity with unparalleled efficiency and with the least possible environmental impact [50]. This entire working mechanism not only propels us toward a more sustainable and resilient energy paradigm, but it also highlights the possibility for integrated, closed-loop systems that align with the principles of environmental stewardship and green energy advancement [51,52,53]:

- Solar Energy Conversion to Electricity: the process begins with the conversion of solar energy into electricity via photovoltaic (PV) cells. These cells, which are typically composed of semiconductor materials such as silicon, absorb photons from the sun. The energy from the absorbed photons stimulates electrons in the semiconductor, resulting in an electric current. This direct conversion of sunlight into electricity, known as the photovoltaic effect, is the first step in harvesting solar energy for later stages in the energy cycle.

- Electrolysis Process for Hydrogen Production: the power generated by solar panels is then routed to an electrolyzer for electrolysis, which creates hydrogen from water (H2O). Electrical energy is used in the electrolyzer to break water molecules into hydrogen and oxygen. The electrolysis is facilitated by two electrodes, one connected to the positive terminal (anode) and the other to the negative terminal (cathode). The liberated hydrogen gas is collected, and as a byproduct, oxygen is emitted. The use of solar-generated electricity for electrolysis assures a sustainable and environmentally benign technique of producing hydrogen.

- Hydrogen Storage and Retrieval: once created, hydrogen is efficiently stored for subsequent use. Compression, liquefaction, metal hydrides, and underground storage are all means of storage. The storage mechanism chosen is determined by considerations like scale, application, and accessibility. These hydrogen stores serve as a versatile energy transporter, ready to be retrieved when needed. The ability to store hydrogen allows for greater flexibility in energy distribution and consumption, addressing the intermittent nature of solar energy production.

- Fuel Cell Electricity Generation: the final stage of the energy cycle involves the utilization of hydrogen in fuel cells to generate electricity. Fuel cells work by using an electrochemical reaction between hydrogen and oxygen. In a typical Proton Exchange Membrane (PEM) fuel cell, hydrogen is delivered to the anode, and oxygen from the air is fed to the cathode. Hydrogen molecules are divided into protons and electrons at the anode. Protons pass through a membrane, while electrons generate an electric current. Protons, electrons, and oxygen mix at the cathode to form water and heat as byproducts. This electrochemical technique directly turns the chemical energy of stored hydrogen into electrical energy, completing the energy cycle with high efficiency and low environmental impact. Thus, fuel cells play an important role in delivering a clean and sustainable source of electricity for a range of applications.

The coordinated working mechanisms of solar energy conversion, electrolysis for hydrogen synthesis, hydrogen storage, and fuel cell power generation provide a convincing model for a sustainable and closed-loop energy system. Beginning with the direct conversion of solar energy into electricity via photovoltaic cells, the cycle effortlessly advances to the electrolysis stage, where solar-generated electricity supports the environmentally friendly generation of hydrogen from water [54]. The subsequent storage of hydrogen, using various and effective methods, overcomes the temporal variability inherent in solar energy harvesting. Finally, fuel cell electricity generation completes the cycle by efficiently transforming the chemical energy of stored hydrogen into electricity with low environmental impact. This integrated process not only uses renewable resources to meet energy needs, but it also shows a harmonious interplay of technology, providing a viable path toward a resilient, low-emission, and sustainable energy future [55].

3. Research Approach and Integration Design

3.1. Research Approach

The research strategy for this study is extensive and interdisciplinary, including theoretical frameworks, empirical studies, and practical applications. The methodology is designed to evaluate the integration of a solar-hydrogen storage system into a university’s energy management system, taking into account a variety of factors ranging from technological feasibility to environmental impact.

- Literature Review: the investigation begins with a thorough assessment of the available literature on solar-hydrogen systems, university energy management, and associated technologies. This phase lays the theoretical groundwork by synthesizing essential concepts, best practices, and field difficulties. It also identifies knowledge gaps, which informs research questions and objectives.

- Case Studies and Interviews: analyzing real-world case studies where solar-hydrogen systems have been integrated into university energy management is a critical component. In addition, interviews with experts, stakeholders, and professionals in the industry provide useful insights into practical issues, accomplishments, and lessons gained from previous projects. These qualitative data help to provide a more sophisticated view of the integration process.

- Technology Assessment: the study includes a full evaluation of the technological aspects, including the efficiency, scalability, and economic viability, of solar-hydrogen storage systems. This includes a thorough analysis of several types of solar panels, electrolyzers, storage systems, and fuel cell technologies to decide which are most suited for academic applications.

- Simulation and Modeling: the study evaluates the potential energy generation, storage capacity, and overall system performance under varied situations using simulation tools and modeling approaches. This step tries to provide predicted insights into the system’s behavior by taking into account elements such as solar irradiation, swings in energy consumption, and the university’s specific energy needs.

- Environmental Impact Analysis: an environmental impact assessment is carried out to determine the integrated system’s ecological footprint. Analyzing life cycle evaluations, carbon emissions reductions, and overall sustainability measures is part of this process. It looks at the broader environmental effects of switching to a solar-hydrogen energy system at a university.

- Integration Design and Feasibility Analysis: the study synthesizes findings into a holistic integration design, defining the step-by-step procedure for integrating the solar-hydrogen storage system into the university’s existing energy infrastructure. A feasibility analysis looks at the economics, potential obstacles, and overall feasibility of adopting the suggested design.

This interdisciplinary study strategy ensures a comprehensive understanding of the integration process, taking into account technical, economic, and environmental factors. The integration of theoretical concepts, empirical facts, and practical considerations results in a solid and well-informed examination of solar-hydrogen integration within the particular setting of university energy management.

3.2. Integration Design

3.2.1. Existing Energy Infrastructure

Energy sustainability takes center stage at this forward-thinking university, which harnesses the power of four separate sources spread over its campus. A diverse energy portfolio includes solar panels, wind turbines, combined heat and power systems, and a grid link. Sources of Energy at Kangwon National University Samcheok Campus (Figure 1):

Figure 1.

Sources of Energy from Kangwon National University Samcheok Campus.

- Joint Laboratory and Practice Building (Building 123);

- Engineering Building V (Building 120);

- Engineering Building IV (Building 118);

- Engineering Building II (Building 122).

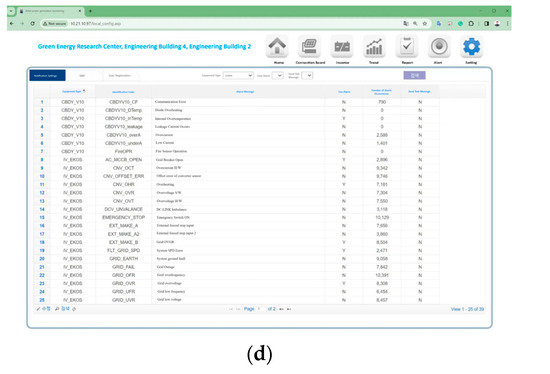

3.2.2. Solar Generation Monitoring System

The university receives unique real-time insights into its energy dynamics. This system is distinguished by its integration with a cutting-edge online monitoring platform (Figure 2). This not only allows for more effective management, but also gives stakeholders the option to remotely monitor and alter energy consumption, responding quickly to demand variations or any unforeseen concerns. The web-based monitoring system serves as a transparent lighthouse, enabling administrators and facility managers to make informed decisions, enhance energy efficiency, and demonstrate a commitment to sustainable practices.

Figure 2.

Elements of Solar Generation Monitoring System: (a) Inverter; (b) Home Dashboard; (c) Report; (d) Settings.

This holistic approach to energy management is consistent with the university’s commitment to environmental responsibility and technical innovation. By seamlessly integrating renewable energy sources and providing a user-friendly interface for monitoring and control, the institution not only decreases its carbon footprint but also establishes a precedent for using innovative technology in pursuit of a greener and more efficient campus. The synergy between various energy sources and the web monitoring system presents a picture of a university at the vanguard of sustainable energy practices, producing a campus climate where cutting-edge technology meets environmental care.

4. Modeling a Solar-Hydrogen System in the University

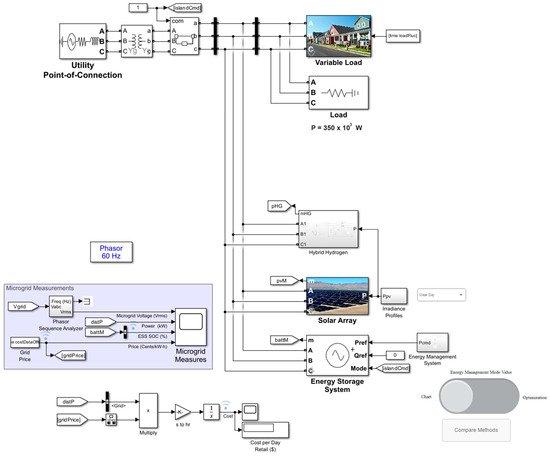

4.1. Energy Management System Model

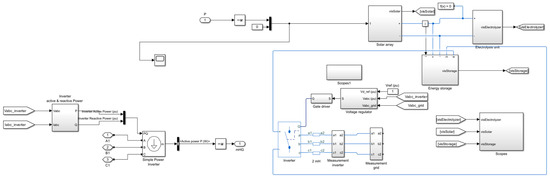

The goal of creating the Microgrid EMS (Energy Management System) Optimization for Solar-Hydrogen (Figure 3) comprises a broad set of goals targeted at tackling current energy concerns and advancing sustainable solutions. The major goal is to incorporate solar and hydrogen technologies into a microgrid context. This integration (Figure 4) intends to maximize energy capture and storage by leveraging the complementary nature of these renewable sources. By maximizing energy storage, the concept attempts to improve the dependability and resilience of microgrid systems. The microgrid becomes more resilient in the face of external disruptions or variations by efficiently controlling the storage and delivery of solar and hydrogen-derived electricity.

Figure 3.

Microgrid with EMS Optimization for Solar-Hydrogen.

Figure 4.

Hybrid Solar-Hydrogen.

Designing a Hybrid Solar-Hydrogen model in Simulink that depicts the interactions between an electrolyzer, energy storage components, and solar photovoltaic (PV) system is the first step in designing a hybrid solar-hydrogen system. The PV system, including the panels, inverters, and controllers, can be represented using Simulink’s graphical user interface. The electrolyzer stack and hydrogen storage can also be dynamically modeled. The integration of control systems and power electronics enhances system performance, and time-domain simulations evaluate the system’s capabilities under different scenarios. Performance metrics and sensitivity analyses are used to assess overall system behavior, efficiency, and hydrogen generation rates. Results can be analyzed with the help of Simulink’s visualization tools, and the best operating conditions can be found by applying optimization techniques.

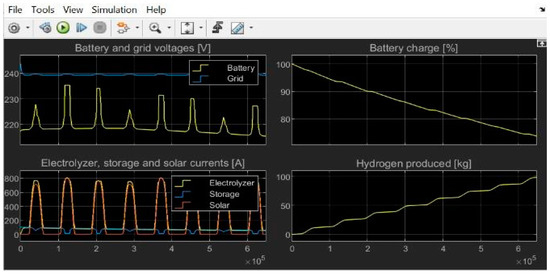

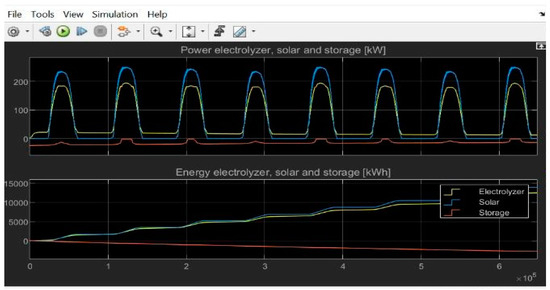

4.2. Performance Result

The system’s effectiveness and efficiency are demonstrated by the performance data based on the created Microgrid ESS Optimization for the Solar-Hydrogen system. In determining the success of the design, the evaluation takes into account a number of essential factors. The overall energy efficiency of the microgrid is the focus of the performance outcomes (Figure 5 and Figure 6). This includes determining how well the system optimizes solar and hydrogen-derived energy storage, delivery, and consumption, with the goal of minimizing energy waste. The microgrid’s performance is measured in terms of reliability and resilience. This includes measuring how well the optimized energy storage system responds to changes in energy demand, changes in solar availability, and external interruptions, ensuring a continuous and stable power supply.

Figure 5.

Performance Result 1.

Figure 6.

Performance Result 2.

The battery and grid voltage Simulink chart findings provide important information about the system’s electrical performance (Figure 5). The average grid voltage stabilizes between 239 and 240 volts, indicating a steady and dependable grid power supply. Conversely, the Battery Voltage displays a dynamic range of 218 to 235 volts, indicating the battery’s charge-discharge cycles. A discharge phase is indicated by the lowest recorded voltage of 218 and a charging phase or high battery capacity is indicated by the maximum voltage of 235. The system’s adaptive nature is reflected in the battery’s variability, which enables it to manage demand fluctuations and intermittent renewable energy inputs while efficiently using the grid as a reliable power source. The Simulink diagram highlights how the grid and battery components work well together to provide a dependable and flexible energy source that stays within the designated voltage range.

The findings of the Simulink chart that shows the solar currents, storage, and electrolyzer give a thorough picture of the system’s energy dynamics (Figure 5). The Electrolyzer and Solar Currents are noteworthy for their synchronized patterns, which frequently peak together. A maximum recorded score of 800 amperes was achieved. This coherence implies that the solar panels maximize the production of hydrogen by contributing significantly to the electrolysis process under ideal solar conditions. On the other hand, the storage system’s charging and discharging actions are indicated by the Storage Current, which has a maximum score of 100 amperes. The comparatively smaller magnitude when contrasted with the Electrolyzer and Solar Currents suggests that the energy storage and retrieval system is functioning effectively, guaranteeing a consistent and balanced supply of electricity. All things considered, these Simulink chart results highlight how well electrolysis, solar power generation, and energy storage are coordinated, presenting a system that makes the best use of renewable energy sources while preserving a steady and flexible energy supply.

The Battery Charge Percentage Simulink chart result offers important insights into the energy storage system’s dynamic behavior (Figure 5). When the battery reaches its maximum performance result of 100%, it indicates that it is fully charged, that available energy sources are being used efficiently, or that there may be a period of low energy demand. On the other hand, the drop to the lowest recorded figure of 30% indicates a situation in which the battery has experienced significant discharge, either during a time of increased energy consumption or restricted production of renewable energy. This variation in the battery charge percentage highlights how adaptable the system is, skillfully controlling the amount of energy stored to satisfy changing needs. The battery’s robust functionality is demonstrated by the Simulink chart, which also shows how well it can store and release energy while adapting to the dynamic nature of energy supply and consumption within the given parameters.

The system’s impressive ability in producing hydrogen by electrolysis is shown in the Simulink chart result for Hydrogen Production in kilos, where the highest score was 98 (Figure 5). This peak value suggests that the energy resources were used efficiently, most likely when solar power input was at its best and the grid was stable. The system’s ability to capture renewable energy sources and transform them into a clean, sustainable energy source is demonstrated by the significant hydrogen generation. As the Simulink chart illustrates, reaching a high level of hydrogen production means that solar power and electrolysis processes have been successfully integrated, which is in line with the system’s goals of encouraging green hydrogen generation. This result highlights the system’s potential as a dependable and environmentally beneficial part of the larger energy landscape and supports its ability to considerably contribute to the creation of a clean energy source.

The power results for the Electrolyzer, Solar, and Storage systems in kilowatts on the Simulink chart provide important information on the energy dynamics of the system (Figure 6). The Electrolyzer’s range is 170 to 190 kW, and the highest score denotes maximal electrolysis activity, perhaps at times when solar power output is abundant. Interestingly, the Solar Power exhibits a steady and coordinated growth with the Electrolyzer, ranging from 220 to 260 kW. According to this alignment, the electrolyzer reacts proportionately to an increase in solar power input, optimizing the production of hydrogen. Nonetheless, the Storage electricity continuously shows less than 0 kW, suggesting that the storage system is more often discharging than producing electricity. This scenario demonstrates the system’s skillful control of power flow and storage discharge by implying a planned use of stored energy, possibly during times of decreased solar input or increasing demand. All things considered, the Simulink diagram highlights how the Electrolyzer, Solar, and Storage components are interdependent and work together to create a dynamic and effective energy balance in the system.

The energy performance of the system is shown dynamically by the Simulink chart results for Energy in kilowatt-hours (kWh) for the Electrolyzer, Solar, and Storage (Figure 6). From 0 to 14,000 kWh, the electrolyzer’s energy output increases gradually, suggesting a steady and significant production of hydrogen over time. Notably, the Solar Energy exhibits a coordinated performance pattern with the Electrolyzer, ranging from 0 to 12,000 kWh. The concurrent rise in Electrolyzer and Solar performance scores points to a balanced reaction to ideal solar power conditions, which increases the production of hydrogen. The Energy stored in the Storage component, on the other hand, indicates that stored energy is primarily being used rather than accumulating, as it displays a downward trend from 0 kWh. This use is consistent with efficient energy management; it might even direct stored energy to adjust to changing grid conditions or demand variations. Thus, the Simulink diagram illustrates a flexible and integrated system in which the Solar and Electrolyzer components work together to promote the generation of hydrogen, while the Storage element dynamically controls energy storage and release in response to the system’s actual needs.

5. Future Prospects

5.1. The Development of AIoT (Artificial Intelligence of Things)

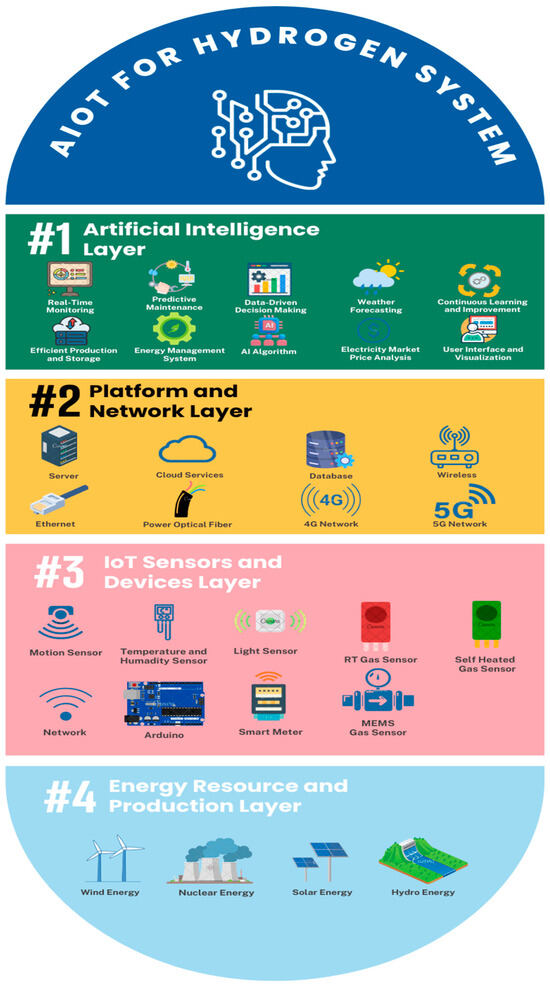

The Internet of Things (IoT) for Hydrogen Systems is a layered architecture that integrates AI and the Internet of Things (IoT) to improve the efficiency and efficacy of hydrogen energy systems. Each layer helps to optimize hydrogen production, distribution, and utilization. Table 5 describes in detail the four basic layers of this design.

Table 5.

Architecture of AIoT for Hydrogen Energy Systems.

By integrating these four layers, AIoT for Hydrogen Systems increases the efficiency, safety, and sustainability of hydrogen energy operations, making them more adaptive to dynamic conditions and contributing to the spread of clean hydrogen technologies (Figure 7).

Figure 7.

The Architecture of AIoT for Hydrogen Energy Systems.

5.2. AIoT for Hydrogen Energy Systems

Incorporating artificial intelligence (AI) into hydrogen energy systems (AIoT) is a crucial step toward generating cleaner, more effective, and safer energy solutions. By combining the power of AI algorithms with the interconnection of IoT devices, AIoT technology advances every stage of the hydrogen energy lifecycle, from production and storage to distribution and usage (Figure 8).

Figure 8.

Mind Map of AIoT for Hydrogen Energy System.

Because of the AIoT’s real-time monitoring and prediction capabilities, proactive maintenance is possible, minimizing risks and downtime while providing rapid responses to safety hazards. Real-time data from renewable sources is used to optimize hydrogen manufacturing operations, resulting in more efficient energy consumption and reduced environmental impact. Furthermore, the AIoT systems’ adaptability to changing conditions assures that hydrogen energy systems may evolve in parallel with improvements in technology and energy demand.

6. Conclusions

This research explores the unknown field of integrating a solar-hydrogen storage system into the energy management framework of a university. We investigated the theoretical foundations, empirical case studies, and practical implementations of this unique energy solution using a thorough research strategy. The literature assessment illuminated the current knowledge landscape, highlighting gaps and laying the groundwork for our investigation. Real-world case studies and expert interviews provided essential insights into the challenges, achievements, and lessons learned from comparable undertakings, rooting our research in the reality of implementation.

The technological evaluation examined solar-hydrogen system components, evaluating their efficiency, scalability, and economic viability. We projected the system’s performance under various scenarios using simulation tools and modeling methodologies, providing a predictive peek into its behavior. Our environmental impact analysis examined the ecological footprint, life cycle evaluations, and carbon emission reductions to ensure that the proposed integration complies with the university’s greater goal of sustainability.

These varied ideas were distilled into a workable plan through integration design and feasibility research. We laid out a step-by-step plan for seamlessly integrating the solar-hydrogen storage system into the university’s existing energy infrastructure. This design takes into account not only technical complexities but also economic aspects and prospective problems, providing a comprehensive view of the viability and practicality of our suggested solution. Our research contributes to the expanding landscape of sustainable energy solutions in educational institutions and beyond as we envision the adoption of this solar-hydrogen integration. Finally, this investigation goes beyond theoretical principles by providing a concrete pathway to a greener and more resilient energy future for universities and other organizations seeking to embrace cutting-edge technologies and environmental stewardship.

Author Contributions

S.R.J.: project evaluation, methodology, investigation, resources, supervision, modeling, simulation S.P.: software development, functionality evaluation. K.K.: conceptualization, funding acquisition, resources, supervision, writing—original draft, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by “Regional Innovation Strategy (RIS)” through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (MOE) (2022RIS-005).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bernhard, T.; Stefan, P.; Andreas, W.; Gerhard, P. Hybrid model predictive control of renewable microgrids and seasonal hydrogen storage. Int. J. Hydrogen Energy 2023, 48, 38125–38142. [Google Scholar]

- Albert, H.S.; Arjen, A.T.V.; Michiel, A.J.U.H.B.; Evrim, U. A Green Hydrogen Energy System: Optimal control strategies for integrated hydrogen storage and power generation with wind energy. Renew. Sustain. Energy Rev. 2022, 168, 112744. [Google Scholar]

- Vincent, K.; Veronika, E.; Kerstin, A.; Stefan, R.; Andrea, H. Decentral Production of Green Hydrogen for Energy Systems: An Economically and Environmentally Viable Solution for Surplus Self-Generated Energy in Manufacturing Companies? Sustainability 2023, 15, 2994. [Google Scholar]

- Wadim, S.; Lubomir, C.; Elena, T.; Manuela, T.; Yelena, P. Renewable Energy in the Sustainable Development of Electrical Power Sector: A Review. Energies 2021, 14, 8240. [Google Scholar]

- Ismail, M.; Tawfik, G.; Badr, M.A.; Khalid, A.; Ahmed, A.; Mansor, A.; Hsan, H.A. Integration of Renewable-Energy-Based Green Hydrogen into the Energy Future. Processes 2023, 11, 2685. [Google Scholar]

- Babangida, M.; Abdullah, M.P.; Abba, L.B.; Mukhtar, F.H. A systematic review of hybrid renewable energy systems with hydrogen storage: Sizing, optimization, and energy management strategy. Int. J. Hydrogen Energy 2023, 48, 38354–38373. [Google Scholar]

- Torbjørn, E.E.; Amin, H.; Sabrina, S. Hydrogen-based systems for integration of renewable energy in power systems: Achievements and perspectives. Int. J. Hydrogen Energy 2021, 46, 31963–31983. [Google Scholar]

- Wilson, F.E.; Joseph, T.A.; Martins, C.O.; Philemon, C.U. A Solar Energy System Design for Green Hydrogen Production in South-Western Nigeria, Lagos State, Using HOMER & ASPEN. Open J. Optim. 2023, 12, 72–97. [Google Scholar]

- Zheng, L.; Wenda, Z.; Rui, Z.; Hexu, S. Development of renewable energy multi-energy complementary hydrogen energy system (A Case Study in China): A review. Energy Explor. Exploit. 2020, 38, 2099–2127. [Google Scholar]

- Vincent, A.A. Development of an Intelligent Power Management System for Solar PV-Wind-Battery-Fuel-Cell Integrated System. Front. Energy Res. 2021, 9, 613958. [Google Scholar]

- Hui, S.; Shunqin, L.; Hengming, H.; Bowen, D.; Jinhua, Y. Solar-Driven Hydrogen Production: Recent Advances, Challenges, and Future Perspectives. Am. Chem. Soc. Energy Lett. 2022, 7, 1043–1065. [Google Scholar]

- Troy, S. South Korean efforts to transition to a hydrogen economy. Clean Technol. Environ. Policy 2021, 23, 509–516. [Google Scholar]

- Layth, H.M.; Hamid, H.M.; Hussein, F.H. Analysis of Renewable Energy Sources, Aspects of Sustainability and Attempts of Climate Change. Am. Sci. Res. J. Eng. Technol. Sci. (ASRJETS) 2018, 43, 22–32. [Google Scholar]

- Tadeusz, C. Wind and solar energy technologies of hydrogen production—A review of issues. Polityka Energetyczna Energy Policy J. 2019, 22, 5–20. [Google Scholar]

- Alfred, J.; Srijit, B.; Akshay; Anil, K. Design and evaluation of stand-alone solar-hydrogen energy storage system for academic institute: A case study. Mater. Proc. 2021, 47, 5918–5922. [Google Scholar]

- Jun, M.; Mustafa, B. Online Energy Management Strategy Based on Adaptive Model Predictive Control for Microgrid with Hydrogen Storage. Int. J. Renew. Energy Res. 2018, 8, 861–870. [Google Scholar]

- Ayodelea, T.R.; Yusuffa, A.A.; Mosetlhea, T.C.; Ntombela, M. Hydrogen production using solar energy resources for the South African transport sector. Int. J. Sustain. Eng. 2021, 14, 1843–1857. [Google Scholar] [CrossRef]

- Azmi, M.S.F.M.; Husain, M.H.; Rahim, S.R.A.; Mid, E.C.; Shaari, A.S.; Hashim, N.; Husky, N.; Ahmad, M.F. Hybrid Cooling System for Solar Photovoltaic Panel. J. Phys. Conf. Ser. 2023, 2550, 012004. [Google Scholar] [CrossRef]

- Sahil, O.; Mumtaz, A.Q.; Basit, S.M.; Ahmed, N.; Sana, U.S.M.; Sana, U.; Muhammad, U.F.; Fang, J. Potential Assessment and Economic Analysis of Concentrated Solar Power against Solar Photovoltaic Technology. Int. J. Energy Res. 2023, 2023, 3611318. [Google Scholar]

- Bahman, H. Renewable Solar Energy Resources Potential and Strategy in Azerbaijan. Int. J. Energy Econ. Policy 2023, 13, 31–38. [Google Scholar]

- Quoc, N.N.; Van, N.M.; Thi, H.L.H. Acceptance of Solar Technology by Farmers in Vietnam. Int. J. Energy Econ. Policy 2023, 3, 93–101. [Google Scholar]

- Erwan, H.; Raden, A.W.; Adiarso, A.; Ermawan, D.S.; Nur, A.H.; Sigit, S.; Hari, S.; Ayu, L.F.; Yanti, R.D.; Ontin, F. Solar Cell Manufacturing Cost Analysis and Its Impact to Solar Power Electricity Price in Indonesia. Int. J. Energy Econ. Policy 2023, 13, 244–258. [Google Scholar]

- Saulesh, M.; Ruslan, A.; Timur, S.; Amangeldy, B.; Bolat, K.; Manuela, T. A Review on Solar Energy Policy and Current Status: Top 5 Countries and Kazakhstan. Energies 2023, 16, 4370. [Google Scholar]

- Modupeola, D.; Patricia, P. Recent advances in solar photovoltaic materials and systems for energy storage applications: A review. Beni-Suef Univ. J. Basic Appl. Sci. 2023, 12, 66. [Google Scholar]

- Sai, N.V.; Mohd, H.A. A Comprehensive Review of Solar Photovoltaic (PV) Technologies, Architecture, and Its Applications to Improved Efficiency. Energies 2023, 16, 319. [Google Scholar]

- Marta, V.; Nancy, H.; Ian, M.P.; Ron, S.; Arnulf, J.W.; Carlos, D.C.; Christian, B.; Matthew, S.; Andrew, B.; Izumi, K.; et al. Solar photovoltaics is ready to power a sustainable future. Joule 2021, 5, 1041–1056. [Google Scholar]

- Nabil, B.; Mohammad, A.M.; Nasser, A.; Sameh, A.; Sultan, T.; Ala, H.J.; Artur, A.; Moh’d, A.; Gabriel, B.; Ali, A.; et al. Effect of the Residential Photovoltaic Systems Evolution on Electricity and Thermal Energy Usage in Jordan. Adv. Sci. Technol. Res. J. 2023, 17, 79–87. [Google Scholar]

- Rahul, R.U.; Muhammad, S.; Ahmad, M.; Ameena, A.S. Technoeconomic Assessment of Various Configurations Photovoltaic Systems for Energy and Hydrogen Production. Int. J. Energy Res. 2023, 2023, 1612600. [Google Scholar]

- Ahmed, M.A.O.; Mohamed, G.O.; Bishoy, E.S. Evaluation of green hydrogen production using solar, wind, and hybrid technologies under various technical and financial scenarios for multi-sites in Egypt. Int. J. Hydrogen Energy 2023, 48, 38535–38556. [Google Scholar]

- Yihao, Z.; Ming, M.; Huaiyu, S. Recent advances in efficient and scalable solar hydrogen production through water splitting. Carbon Neutrality 2023, 2, 23. [Google Scholar]

- Mingjian, X.; Haocheng, W.; Qian, S.; Jiaqi, S.; Jiajun, L. Multi-objective optimization configuration of wind-solar coupling hydrogen production system. J. Phys. Conf. Ser. 2023, 2488, 012001. [Google Scholar]

- Till, W.; Victor, T.; Gonzalo, G.G. Environmental sustainability assessment of large-scale hydrogen production using prospective life cycle analysis. Int. J. Hydrogen Energy 2023, 48, 8310–8327. [Google Scholar]

- Barış, A.; Muhammed, B.A. Hydrogen Production and Storage Methods. Int. J. Adv. Nat. Sci. Eng. Res. 2023, 7, 179–185. [Google Scholar]

- Ibrahim, O. Trend analysis and evaluation of hydrogen energy and hydrogen storage research. Energy Storage 2023, 5, e471. [Google Scholar]

- Kang, P.; Gary, M.; Zhang, X.; Wang, T.; Zhongfu, T.; Jayant, A. Systematic comparison of hydrogen production from fossil fuels and biomass resources. Int. J. Agric. Biol. Eng. 2017, 10, 192–200. [Google Scholar]

- Nima, N. Future of Hydrogen in Energy Transition and Reform. J. Chem. Lett. 2021, 2, 64–72. [Google Scholar]

- Thirugnanasambandham, K. A Review On Hydrogen Energy Production from Electrochemical System: Benefits and Challenges. Energy Sources 2018, 41, 902–909. [Google Scholar]

- Ziyi, L.; Xinyi, Y.; Yingxue, W.; Weidi, L.; Siliang, L.; Yuankun, Z.; Zihan, H.; Hong, Z.; Shuming, D.; Jie, X.; et al. A Survey of Artificial Intelligence Techniques Applied in Energy Storage Materials R&D. Front. Energy Res. 2020, 8, 116. [Google Scholar]

- Song-Jeng, H.; Matoke, P.M.; Sathiyalingam, K. Artificial Intelligence Application in Solid State Mg-Based Hydrogen Energy Storage. J. Compos. Sci. 2021, 5, 145. [Google Scholar]

- Abdulrahman, M.; Abomazid; Nader, A.E.T.; Hany, E.Z.F. Optimal Energy Management of Hydrogen Energy Facility Using Integrated Battery Energy Storage and Solar Photovoltaic Systems. IEEE Trans. Sustain. Energy 2022, 13, 1457–1468. [Google Scholar]

- Eman, H.B.; Hazem, A.; Mahmoud, E. Novel optimization technique of isolated microgrid with hydrogen energy storage. PLoS ONE 2018, 13, e0193224. [Google Scholar]

- Syed, U.A.; Asad, W.; Muhammad, A.; Saeed, M.Q.; Jamshed, I. Model Predictive Control of Consensus-Based Energy Management System for DC Microgrid. PLoS ONE 2023, 18, e0278110. [Google Scholar]

- Sonam; Prateek, M. An Improvised modelling of hybrid power system in atlab using solar power and fuel cell with internet of things implementation. Int. Res. J. Mod. Eng. Technol. Sci. 2023, 5, 167–174. [Google Scholar]

- Mojgan, F.; Paramjotsingh, S.; Sumit, I.T.; Roonak, D.; Ali, J.; Thomas, E.; Hans, K.; Reza, L.; Hamid, K. Artificial Intelligence/Machine Learning in Energy Management Systems, Control, and Optimization of Hydrogen Fuel Cell Vehicles. Sustainability 2023, 15, 5249. [Google Scholar]

- Danqi, S.; Jiayang, Z.; Junjie, M.; Zizhe, D.; Zhangjie, C.; Yanzhou, Q. Application of Machine Learning in Fuel Cell Research. Energies 2023, 16, 4390. [Google Scholar]

- Yang, S.; Jiaming, Z.; Jinming, Z.; Fengyan, Y.; Guofeng, W.; Chaofeng, P.; Wei, G.; Xing, S. Research on Energy Management of Hydrogen Fuel Cell Bus Based on Deep Reinforcement Learning Considering Velocity Control. Sustainability 2023, 15, 12488. [Google Scholar]

- Zhongliang, L.; Zhixue, Z.; Liangfei, X.; Xiaonan, L. A review of the applications of fuel cells in microgrids: Opportunities and challenges. BMC Energy 2019, 1, 8. [Google Scholar]

- Aiman, A.; Ade, J.; Mustafa, J.; Francisco, M.A. Future of Electric and Hydrogen Cars and Trucks: An Overview. Energies 2023, 16, 3230. [Google Scholar]

- Ali, R.B.; Burak, T. Real-time energy management in an off-grid smart home: Flexible demand side control with electric vehicle and green hydrogen production. Int. J. Hydrogen Energy 2023, 48, 23146–23155. [Google Scholar]

- Jiayi, H.; Jianxiao, W.; Zhihao, H.; Qi, A.; Yiyang, S.; Asad, M.; Chin, W.T.; Feng, G. Hydrogen-powered smart grid resilience. IET Energy Convers. Econ. 2023, 4, 89–104. [Google Scholar]

- Seyed, E.H.; Mazlan, A.W. Hydrogen from solar energy, a clean energy carrier from a sustainable source of energy. Int. J. Energy Res. 2020, 44, 4110–4131. [Google Scholar]

- Shan, W.; Aolin, L.; Chuan-Jian, Z. Hydrogen production from water electrolysis: Role of catalysts. Nano Converg. 2021, 8, 4. [Google Scholar]

- Sergey, K.; Yi, Z.; Shi, Y.; Henrik, W.B. Optimal operation of the hydrogen-based energy management system with P2X demand response and ammonia plant. Appl. Energy 2021, 304, 117559. [Google Scholar]

- Tao, Z.; Bruno, F. Modeling and control design of hydrogen production process for an active hydrogen/wind hybrid power system. Int. J. Hydrogen Energy 2009, 34, 21–30. [Google Scholar]

- Canan, A.; Ercan, E.; Irem, F.E. Performance analysis of a stand-alone integrated solar hydrogen energy system for zero energy buildings. Int. J. Hydrogen Energy 2023, 48, 1664–1684. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).