Critical Study Quality Management for the Anti-Seepage System in Macau’s Landfill Area

Abstract

1. Introduction

1.1. Introduction to the Background and Importance of the Macau Landfill Anti-Seepage System Project

1.2. Elaborating the Role of Anti-Seepage Systems in Environmental Protection and Sustainable Development

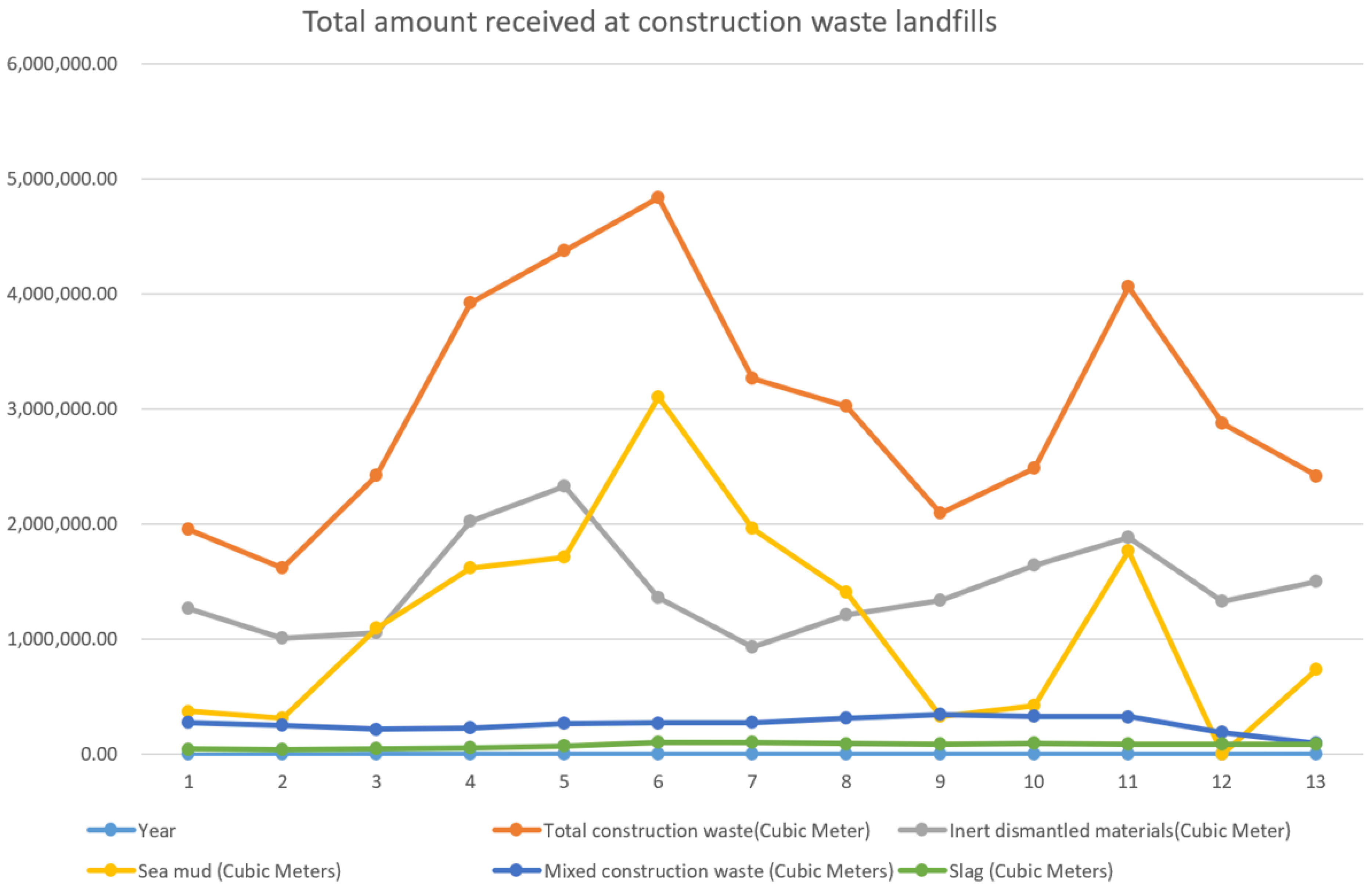

- Fluctuation in total construction waste: From 2010 to 2022, there is an overall upward trend in total construction waste. Particularly, a sharp increase is observed between 2013 and 2015, suggesting a possible surge in construction activities or demolitions during that period. However, after 2016, the total amount decreases, with a peak again in 2020. This fluctuation may be related to economic activities in the construction industry, policy changes, or other external factors, such as natural disasters;

- Changes in proportions of different types of construction waste: The proportions of different types of construction waste (inert dismantled materials, sea mud, mixed construction waste, slag) vary in the total amount and fluctuate over time. For instance, the proportion of inert dismantled materials in total construction waste is constantly changing, reflecting potential shifts in construction material usage and methods. Similarly, the quantities of sea mud and mixed construction waste show significant differences in different years;

- Dramatic fluctuation in sea mud quantity: The quantity of sea mud peaks in 2015 and rapidly declines afterward. This may be related to specific construction projects or environmental policies;

- Yearly reduction in mixed construction waste: Starting from 2016, the quantity of mixed construction waste decreases annually, indicating an improvement in the efficiency of construction waste classification and processing;

- Stable trend in slag production: Compared to other types of construction waste, slag production remains relatively stable with minimal fluctuations.

- Building waste types and material selection for landfills: The data show variations in the quantity of different types of construction waste, impacting the selection of materials for landfills. For example, the composition and stability of inert dismantled materials and mixed construction waste determine their suitability as landfill materials and the need for specific impermeable measures;

- Special considerations for sea mud: Due to its unique properties (high moisture content, high fluidity), special attention is needed when using sea mud in landfills to mitigate its impact on impermeable systems. Sea mud may require special treatment or mixing with other materials to ensure the effectiveness of impermeable systems;

- Design and material selection for impermeable layers: The design of impermeable systems should be based on the characteristics of the materials being landfilled. Considerations should include the chemical properties, stability, and permeability of different construction wastes to choose suitable materials and structures for impermeable layers;

- Monitoring and management: Establishing an effective monitoring system to continuously monitor leakage in landfills is crucial. This includes regular inspections of the integrity and functionality of impermeable layers, as well as monitoring potential pollution of groundwater and the surrounding environment.

1.3. Synthesis of Domestic and International Research

1.4. Basic Theory of Project Management

1.4.1. Explaining the Basic Concepts and Principles of Project Management

1.4.2. Introducing Project Management Theories Relevant to Landfill Anti-Seepage System Projects

2. Overview of the Landfill Containment System Project

2.1. Describing the Scale, Objectives, and Key Components of the Macau Landfill Anti-Seepage System Project

2.2. Emphasizing the Project’s Complexity and Risk Factors

3. Study of Construction Impact Factors

3.1. Exploring Factors Affecting the Construction Quality of Landfill Anti-Seepage Systems, Such as Geological Conditions and Material Selection

3.2. Analyzing the Impact of These Factors on Project Progress and Quality

4. Quality Control Plan

4.1. Proposing a Comprehensive Quality Control Plan, including Quality Objectives, Standards, and Processes

- Quality objectives

- Quality standards

- Quality processes

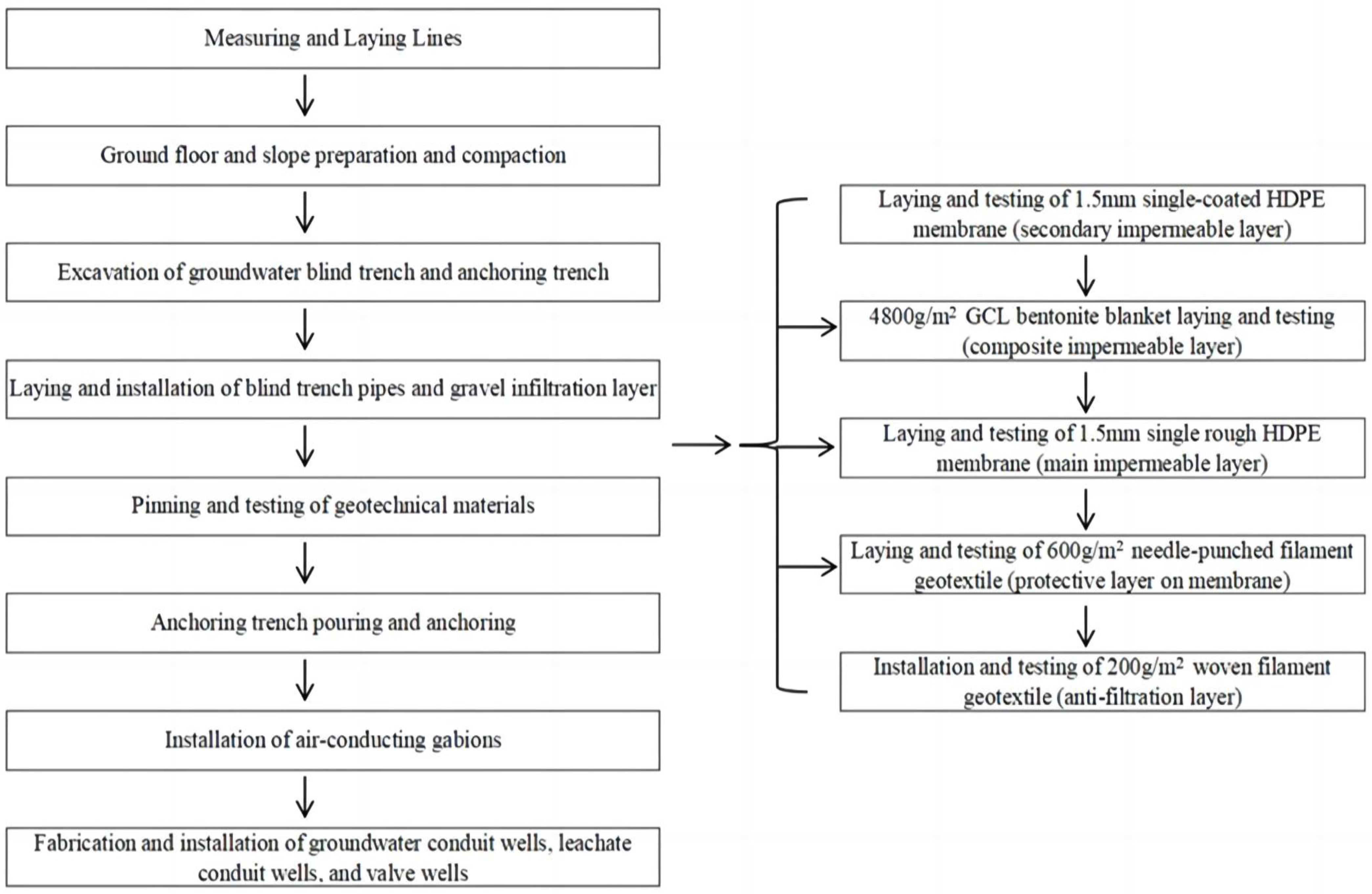

- Initial preparation

- Design phase

- Pre-construction phase

- Construction process

- Quality inspections

- Environmental monitoring

- Quality assessment

4.2. Emphasizing the Importance of Implementing Quality Control in All Project Phases

5. Discussion

5.1. Project Construction Quality and Control

5.1.1. Exploring Quality Management Strategies and Practices during Actual Construction

- Quality assurance plan: Develop a comprehensive quality assurance plan that outlines all the quality measures, procedures, and responsibilities. This plan should also include a systematic documentation process to ensure all quality-related activities are recorded;

- Training and certification: Provide necessary training and certification programs to the construction team members. These programs should focus on enhancing their skills and knowledge related to quality management and construction techniques, ensuring that they are equipped to handle the project requirements effectively;

- Risk assessment and mitigation: Conduct a thorough risk assessment to identify potential risks and hazards that may impact the construction quality. Develop appropriate risk mitigation strategies and implement them throughout the construction process;

- Supplier qualification: Implement a supplier qualification process to ensure that all the materials and equipment used in the construction meet the required standards. This process should involve evaluating suppliers based on their track record, quality control measures, and adherence to industry standards;

- Non-conformance management: Implement a non-conformance management process to address any deviations or non-compliance during the construction process. This process should include formal procedures for documenting, investigating, and resolving non-conformance issues;

- Continual improvement: Establish a culture of continual improvement within the project team by encouraging feedback and suggestions from all stakeholders. Regularly review the construction process and identify areas for improvement to enhance the overall quality of the project;

- Post-construction evaluation: Conduct a post-construction evaluation to assess the effectiveness of the quality management strategies and practices implemented. This evaluation should involve reviewing the construction documentation, conducting site inspections, and gathering feedback from stakeholders to identify any lessons learned and areas for further improvement.

5.1.2. Emphasizing the Importance of Monitoring, Evaluating, and Adjusting Quality Control Measures

5.2. Quality Control and Assessment

5.2.1. Introducing Quality Inspection Methods and Tools, including Non-Destructive Testing and Sampling

5.2.2. Discussing How to Evaluate Project Quality and Progress to Ensure Meeting Expected Objectives

6. Conclusions

6.1. Summarizing the Main Findings and Contributions of the Research

6.2. Emphasizing the Key Role of Quality Management in Landfill Anti-Seepage System Projects

7. Research Outlook

7.1. Proposing Future Research Directions and Possibilities

7.2. Exploring Methods and Strategies for Continuous Improvement of Anti-Seepage System Project Quality Management in a Changing Environment

- Learning from others: A multifaceted approach

- 2.

- Extensive literature review: A knowledge repository

- 3.

- Benchmarking against success stories

- 4.

- Nuanced perspectives: Regional and environmental variables

- 5.

- Customized approaches: Tailoring solutions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.-T.; Ji, L. Evaluation of the Influence of Ningxi Water Supply Project on Economy, Society and Environment of Ningxia. IOP Conf. Ser. Earth Environ. Sci. 2019, 332, 022011. [Google Scholar] [CrossRef]

- Bagheri, M.; Bazvand, A.; Ehteshami, M. Application of artificial intelligence for the management of landfill leachate penetration into groundwater, and assessment of its environmental impacts. J. Clean. Prod. 2017, 149, 784–796. [Google Scholar] [CrossRef]

- Camba, A.; González-García, S.; Bala, A.; Fullana-i-Palmer, P.; Moreira, M.T.; Feijoo, G. Modeling the leachate flow and aggregated emissions from municipal waste landfills under life cycle thinking in the Oceanic region of the Iberian Peninsula. J. Clean. Prod. 2014, 67, 98–106. [Google Scholar] [CrossRef]

- Deng, P.; Xu, K. Anti-seepage for Groundwater Pollution. In The ECPH Encyclopedia of Mining and Metallurgy; Springer Nature: Singapore, 2022; pp. 121–128. [Google Scholar] [CrossRef]

- Sun, J.; Ni, X.; Yang, Y. Innovation and Construction of Practice Teaching for Training Excellent Engineers in Local Colleges and Universities. In Proceedings of the 3rd International Conference on Science and Social Research (ICSSR 2014), Tianjin, China, 14–15 June 2014; Atlantis Press: Amsterdam, The Netherlands, 2014; pp. 284–287. [Google Scholar] [CrossRef]

- Li, B.; Li, T.; Li, B.; Yang, L.; Long, J.; Liu, P.; Li, T. Transport of pollutants in groundwater of domestic waste landfills in karst regions and its engineering control technologies. J. Environ. Manag. 2023, 347, 119245. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, Y. Identification and Assessment of Groundwater and Soil Contamination from an Informal Landfill Site. Sustainability 2022, 14, 16948. [Google Scholar] [CrossRef]

- Nhien, H.T.H.; Giao, N.T. Assessment of pollution levels and ecological potential risk of the soil influenced by landfilling in a Vietnamese Mekong Delta province. Sci. Total Environ. 2022, 845, 157263. [Google Scholar] [CrossRef] [PubMed]

- Qi, C.; Huang, J.; Wang, B.; Deng, S.; Wang, Y.; Yu, G. Contaminants of emerging concern in landfill leachate in China: A review. Emerg. Contam. 2018, 4, 1–10. [Google Scholar] [CrossRef]

- Sun, X.; Jiang, Y.; Huang, Y.; Su, Y.; Miao, K. Modelling Groundwater Flow and Contaminant Migration in Heterogeneous Fractured Media at a Municipal Solid Waste Landfill in Nanjing Lishui, China. Geofluids 2022, 2022, e8391260. [Google Scholar] [CrossRef]

- Tan, W.; Xi, B.; Zhao, X.; Dang, Q. Emerging Views on the Overall Process Treatment of Municipal Domestic Waste for the Sustainable Use of Landfills in China. Engineering 2020, 6, 733–735. [Google Scholar] [CrossRef]

- Wang, S.; Han, Z.; Wang, J.; He, X.; Zhou, Z.; Hu, X. Environmental risk assessment and factors influencing heavy metal concentrations in the soil of municipal solid waste landfills. Waste Manag. 2022, 139, 330–340. [Google Scholar] [CrossRef]

- Xu, X.; Li, G.; Ni, D.; Feng, C.; Xu, S. Laboratory Model Tests of Leachate Drawdown Using Vertical Drainage Wells with Vacuum Pumping in Municipal Solid Waste Landfills with High Leachate Levels. Sustainability 2022, 14, 8101. [Google Scholar] [CrossRef]

- Zeng, D.; Chen, G.; Zhou, P.; Xu, H.; Qiong, A.; Duo, B.; Lu, X.; Wang, Z.; Han, Z. Factors influencing groundwater contamination near municipal solid waste landfill sites in the Qinghai-Tibetan plateau. Ecotoxicol. Environ. Saf. 2021, 211, 111913. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Zhang, X.R.; Jian, Z.; Gong, Y.; Meng, X. Effect of landfill leachate on arsenic migration and transformation in shallow groundwater systems. Environ. Sci. Pollut. Res. 2023, 31, 5032–5042. [Google Scholar] [CrossRef] [PubMed]

- Jing, M.; Kong, J. Discussion of Management Innovation of Green Construction. In Proceedings of the 2016 4th International Education, Economics, Social Science, Arts, Sports and Management Engineering Conference (IEESASM 2016), Yinchuan, China, 13–14 August 2016. [Google Scholar]

- Karimi, N. Assessing Global Waste Management: Alternatives to Landfilling in Different Waste Streams—A Scoping Review. Sustainability 2023, 15, 13290. [Google Scholar] [CrossRef]

- Chandrasekaran, H.; Subramani, S.E.; Partheeban, P.; Sridhar, M. IoT- and GIS-Based Environmental Impact Assessment of Construction and Demolition Waste Dump Yards. Sustainability 2023, 15, 13013. [Google Scholar] [CrossRef]

- Liu, M.; Dong, Y.; Zang, M.; Cai, G.; Lu, H. Experimental Study on Solidified Lake Sediment Based on Industrial Solid Waste and Construction Waste: Stabilization and Mechanism. Buildings 2023, 13, 2053. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. A technical review of bioenergy and resource recovery from municipal solid waste. J. Hazard Mater. 2021, 403, 123970. [Google Scholar] [CrossRef]

- GB 36600-2018; Soil Environmental Quality Soil Contamination Risk Control Standards for Construction Land (Trial). Chinese Standard Press: Beijing, China, 2018.

- GB 14848-2017; Groundwater Quality Standard. Chinese Standard Press: Beijing, China, 2017.

- GB 3838–2002; Environmental Quality Standards for Surface Water. Ministry of Ecology and Environment the People’s Republic of China: Beijing, China, 2002.

- Mohamed, A.K.; Dan, L.; Kai, S.; Hassan, A.; Elubid, B.A.; Aldaw, E. An Optimal Design of Groundwater-Environment Remediation Scheme in Chengdu Plain, China: A Case Study of Huaikou Landfill. In Sustainable Development of Water and Environment; Springer EBooks: Berlin/Heidelberg, Germany, 2019; pp. 127–136. [Google Scholar] [CrossRef]

- Al-Madhlom, Q.; Al-Ansari, N.; Hamza, B.A.; Laue, J.; Hussain, H.M. Seepage Velocity: Large Scale Mapping and the Evaluation of Two Different Aquifer Conditions (Silty Clayey and Sandy). Hydrology 2020, 7, 60. [Google Scholar] [CrossRef]

- Cai, S.; Zhou, S.; Wang, Q.; Cheng, J.; Zeng, B. Assessment of metal pollution and effects of physicochemical factors on soil microbial communities around a landfill. Ecotoxicol. Environ. Saf. 2024, 271, 115968. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, H.; Zhang, W.; Huang, X. Using stress wave technology for leakage detection in a landfill impervious layer. Environ. Sci. Pollut. Res. 2019, 26, 32050–32064. [Google Scholar] [CrossRef]

- Chu, Z.; Wang, W.; Wang, B.; Zhuang, J. Research on Factors Influencing Municipal Household Solid Waste Separate Collection: Bayesian Belief Networks. Sustainability 2016, 8, 152. [Google Scholar] [CrossRef]

- Deng, Q.; Wang, X.F. Analysis of heavy metal pollution prevention, control and management in Nandan County—A case study of Nanfang Non-ferrous Metals Group. In Sustainable Development; World Scientific: Singapore, 2016. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Smirnova, T.S.; Maryev, V.A.; Dineshkumar, M. Remediation Process in Landfill in Arctic Region—A Case of Circular Economy. J. Solid Waste Technol. Manag. 2023, 49, 14–31. [Google Scholar] [CrossRef]

- Huan, H.; Li, X.; Zhou, J.; Liu, W.; Li, J.; Liu, B.; Xi, B.; Jiang, Y. Groundwater pollution early warning based on QTR model for regional risk management: A case study in Luoyang city, China. Environ. Pollut. 2020, 259, 113900. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Huang, C.; Ye, J. Pollutant transport behavior through polymer cutoff wall: Laboratory test and analytical model investigation. J. Hazard. Mater. 2024, 465, 133367. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yang, Y.; Huan, H.; Li, M.; Xi, B.; Lv, N.; Wu, Y.; Xie, Y.; Li, X.; Yang, J. Method for screening prevention and control measures and technologies based on groundwater pollution intensity assessment. Sci. Total Environ. 2016, 551–552, 143–154. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Chen, J.; Huang, Y.; Dou, Z. Experimental investigation and numerical simulation of contaminant migration in the compacted clay containing artificial fractures. Environ. Earth Sci. 2016, 75, 134. [Google Scholar] [CrossRef]

- Li, P.; Wang Ke-hong Meng, L.; Dong, X. An Overview of Municipal Organic Waste Disposal in China. In Energy, Environmental & Sustainable Ecosystem Development; World Scientific: Singapore, 2015. [Google Scholar] [CrossRef]

- Lin, F.-Y.; Liu, P.-G.; Wei, T.; Ren, H.; Wu, D.; Tao, Y. Contamination Prediction and Control of Landfills to Groundwater in Coalmine Subsidence Area. Energy Procedia 2017, 107, 217–221. [Google Scholar] [CrossRef]

- Liu, M.; Lu, H.; Wang, C.; Liu, Y. An experimental study on microanalytical characterizations and service performances of landfill modified municipal sludge liner materials in contact with leachate. Case Stud. Constr. Mater. 2023, 18, e01794. [Google Scholar] [CrossRef]

- Lu, W.; Fu, Z.; Zhao, Y. Combined reticular blind drainage and vertical hierarchical drainage system for landfills located in areas with high rainfall and high groundwater level. Front. Environ. Sci. Eng. 2014, 10, 177–184. [Google Scholar] [CrossRef]

- Demirkol, G.T.; Ozcoban, M.S.; Tufekci, N. Removal rate of compacted clay soil in the batch and continuous reactors and its permeability. J. Adv. Technol. Eng. Res. 2017, 3, 176–183. [Google Scholar] [CrossRef]

- Rong, L.; Zhang, C.; Jin, D.; Dai, Z. Assessment of the potential utilization of municipal solid waste from a closed irregular landfill. J. Clean. Prod. 2017, 142, 413–419. [Google Scholar] [CrossRef]

- Shariatmadari, N.; Askari Lasaki, B.; Eshghinezhad, H.; Alidoust, P. Effects of Landfill Leachate on Mechanical Behaviour of Adjacent Soil: A Case Study of Saravan Landfill, Rasht, Iran. Int. J. Civ. Eng. 2018, 16, 1503–1513. [Google Scholar] [CrossRef]

- Shu, S.; Peng, C.; Liu, H.; Meng, L. Breakthrough times for barrier systems at typical municipal solid waste landfills in China. Environ. Sci. Pollut. Res. 2023, 30, 58773–58782. [Google Scholar] [CrossRef] [PubMed]

- Loushine, T.W.; Hoonakker, P.L.T.; Carayon, P.; Smith, M.J. Quality and Safety Management in Construction. Total Qual. Manag. Bus. Excell. 2006, 17, 1171–1212. [Google Scholar] [CrossRef]

- Xu, Y.; Xue, X.; Dong, L.; Nai, C.; Liu, Y.; Huang, Q. Long-term dynamics of leachate production, leakage from hazardous waste landfill sites and the impact on groundwater quality and human health. Waste Manag. 2018, 82, 156–166. [Google Scholar] [CrossRef] [PubMed]

- Xue, H.; Ma, L.; Gao, C.; Wang, Y.; Zhang, Q. Study on Domestic Waste Treatment of Urban Residents in China. In Proceedings of the 2018 International Conference on Advanced Chemical Engineering and Environmental Sustainability (ICACEES 2018), Guangzhou, China, 15–16 June 2018; pp. 121–126. [Google Scholar] [CrossRef]

- Zhai, Y.; Ma, T.; Zhou, J.; Li, X.; Liu, D.; Wang, Z.; Qin, Y.; Du, Q. Impacts of leachate of landfill on the groundwater hydrochemistry and size distributions and heavy metal components of colloids: A case study in NE China. Environ. Sci. Pollut. Res. 2019, 26, 5713–5723. [Google Scholar] [CrossRef] [PubMed]

- Gurusamy, S.; Thangam, R.S.P. Potential health risk assessment of contaminants in soil-like material recovered from landfill mining. Environ. Monit. Assess. 2023, 195, 330. [Google Scholar] [CrossRef]

| Year | Total Construction Waste (Cubic Meter) | Inert Dismantled Materials (Cubic Meter) | Sea Mud (Cubic Meters) | Mixed Construction Waste (Cubic Meters) | Slag (Cubic Meters) |

|---|---|---|---|---|---|

| 2010 | 1,953,821 | 1,267,569 | 371,536 | 271,088 | 43,628 |

| 2011 | 1,617,836 | 1,007,825 | 315,926 | 252,744 | 41,341 |

| 2012 | 2,420,041 | 1,057,979 | 1,096,303 | 215,644 | 50,115 |

| 2013 | 3,925,068 | 2,025,569 | 1,616,290 | 226,308 | 56,901 |

| 2014 | 4,376,182 | 2,327,819 | 1,708,785 | 269,638 | 69,940 |

| 2015 | 4,834,508 | 1,360,528 | 3,098,966 | 270,182 | 104,832 |

| 2016 | 3,269,101 | 928,382 | 1,964,560 | 272,484 | 103,675 |

| 2017 | 3,023,622 | 1,213,095 | 1,407,575 | 312082 | 90,870 |

| 2018 | 2,095,824 | 1,335,009 | 331,227 | 343,944 | 85,644 |

| 2019 | 2,485,693 | 1,642,316 | 420,173 | 331,294 | 91,910 |

| 2020 | 4,063,306 | 1,883,037 | 1,765,400 | 325,078 | 89,791 |

| 2021 | 2,874,736 | 1,325,103 | 1,278,745 | 184,711 | 86,177 |

| 2022 | 2,417,993 | 1,502,722 | 735,254 | 92,384 | 87,633 |

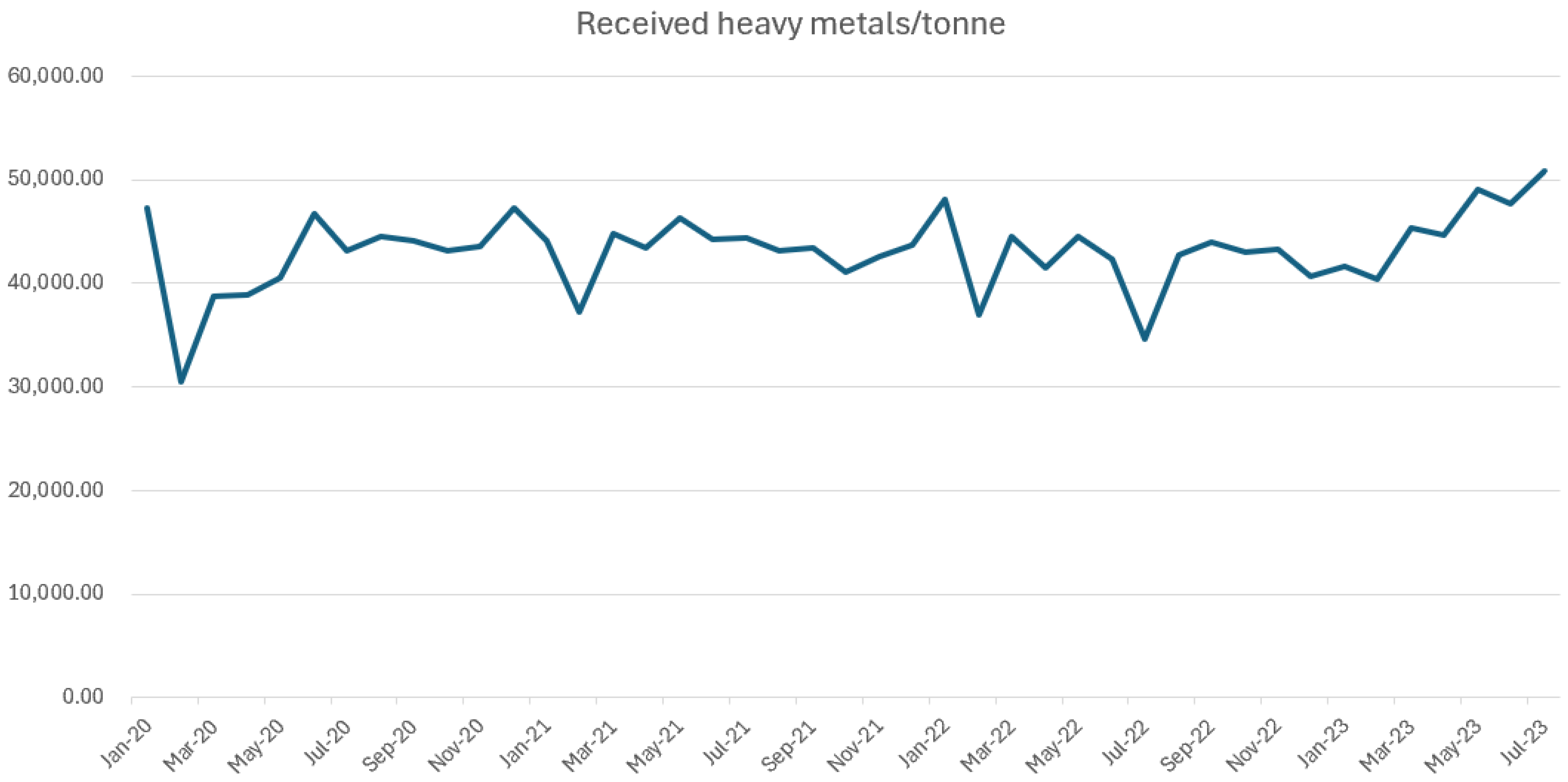

| Date | Received Heavy Metals/Tonne |

|---|---|

| Jul-23 | 50,817.32 |

| Jun-23 | 47,632.67 |

| May-23 | 49,073.93 |

| Apr-23 | 44,609.88 |

| Mar-23 | 45,382.71 |

| Feb-23 | 40,428.64 |

| Jan-23 | 41,607.79 |

| Dec-22 | 40,618.01 |

| Nov-22 | 43,315.88 |

| Oct-22 | 43,008.89 |

| Sep-22 | 43,934.06 |

| Aug-22 | 42,723.89 |

| Jul-22 | 34,550.75 |

| Jun-22 | 42,297.18 |

| May-22 | 44,462.98 |

| Apr-22 | 41,511.53 |

| Mar-22 | 44,543.56 |

| Feb-22 | 36,951.66 |

| Jan-22 | 48,480.95 |

| Dec-21 | 43,627.71 |

| Nov-21 | 42,563.15 |

| Oct-21 | 41,098.75 |

| Sep-21 | 43,383.92 |

| Aug-21 | 43,117.45 |

| Jul-21 | 44,311.81 |

| Jun-21 | 44,184.58 |

| May-21 | 46,334.50 |

| Apr-21 | 43,449.80 |

| Mar-21 | 44,846.84 |

| Feb-21 | 37,207.11 |

| Jan-21 | 44,155.58 |

| Dec-20 | 47,263.25 |

| Nov-20 | 43,542.26 |

| Oct-20 | 43,195.08 |

| Sep-20 | 44,124.60 |

| Aug-20 | 44,458.37 |

| Jul-20 | 43,145.58 |

| Jun-20 | 46,733.62 |

| May-20 | 40,505.04 |

| Apr-20 | 38,882.11 |

| Mar-20 | 38,682.82 |

| Feb-20 | 30,461.47 |

| Jan-20 | 47,311.29 |

| No. | Control Items | Main Control Points | Responsible Person for Control | Control Basis | Remarks | |

|---|---|---|---|---|---|---|

| 1 | Groundwater Diversion Project | Depot Site | Levelling longitudinal and transverse slope, compaction, bearing capacity | Surveyor, tester | Construction drawings, work Instructions, technical delivery documents, construction specification | |

| Blind Ditch | Size, spacing, burial depth | Surveyor, quality inspector | ||||

| Gravel deflector layer | Gravel particle size, laying method, Laying thickness, anti-filtration layer thickness | Constructer, quality inspector | ||||

| Drainage wells | Groundwater control, axis and elevation on piles, cement collapse, pouring, maintenance time | Project general engineer, quality inspector, constructor | ||||

| 2 | Horizontal seepage control system project | HDPE membrane | Thickness, verticality of cut edges, laying sequence joint direction location quantity: welding method time between welding machine songs. lap width ambient temperature, leakage detection of welds, weld qualification rate, finished product protection | Constructor, quality inspector | Work instructions, technical delivery documents, construction specifications | |

| Geotextile | Connection method, lap width, appearance | Constructer, quality inspector | ||||

| GCL bentonite Blanket | Paint penetration coefficient method of joining, width of joining, disposition on of joining blanket, sealing material, sealing method, moisture-proof protection measures. protection of finished products | Constructer, quality inspector | ||||

| Composite drainage net | Surface dryness. surface cleanliness. laving method lap joint tensile and compressive strength | Constructer, quality inspector | ||||

| HDPE pip | Cutting length welding method. adjacent pipe center line control, construction temperature, pipe opening plugging measures, welding ring height. welding cooling time | Constructer, quality inspector | ||||

| Anchoring trench | Collapse degree. pouring, maintenance, location of expansion joints | Constructer, quality inspector | ||||

| 3 | Leachate Drainage Engineering | Arti-filtration laver | Gravel particle size, laying method, key thickness | Constructer, quality inspector | Construction drawings. work instructions, technical delivery documents, construction | |

| Drainage shaft | Axis and elevation piles, pipe welding. seepage and anti-corrosion performance | Constructer, quality inspector | ||||

| 4 | Electrical Equipment And Ancillary works | Air-conducting gabions | Opening diameter. reinforcement grid diameter. grid gap Construction drawings | Constructer, quality inspector | technical briefing documents construction specifications | |

| No. | Name of Sub-Works | Work Process | Frequency | Remarks | |

|---|---|---|---|---|---|

| 1 | Groundwater conduction and drainage system | Foundation of reservoir area | Real Time | Monthly | |

| Blind trench | Real Time | ||||

| Groundwater conduit | Real Time | ||||

| Groundwater collection well | Real Time | ||||

| 2 | Horizontal impermeable system | Secondary impermeable layer | Real Time | Monthly | |

| Composite impermeable layer | Real Time | ||||

| Primary impermeable layer | Real Time | ||||

| Protective layer on membrane | Real Time | ||||

| Anchoring trench | Real Time | Monthly | |||

| 3 | Leachate collection and drainage well | Leachate conduit | Real Time | ||

| Leachate conduit well | Real Time | ||||

| Infiltration layer | Real Time | ||||

| Anti-filtration layer | Real Time | Monthly | |||

| 4 | Electrical equipment and ancillary works | Control box | Real Time | ||

| Power cables | Real Time | ||||

| Air-conducting gabions | Real Time | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Tang, W.; Mak, S.; Li, Q.; Chen, H.; Hong, Q. Critical Study Quality Management for the Anti-Seepage System in Macau’s Landfill Area. Appl. Sci. 2024, 14, 1382. https://doi.org/10.3390/app14041382

Li Z, Tang W, Mak S, Li Q, Chen H, Hong Q. Critical Study Quality Management for the Anti-Seepage System in Macau’s Landfill Area. Applied Sciences. 2024; 14(4):1382. https://doi.org/10.3390/app14041382

Chicago/Turabian StyleLi, Zhaobin, Waifan Tang, Shulun Mak, Qingwen Li, Haolin Chen, and Qianqian Hong. 2024. "Critical Study Quality Management for the Anti-Seepage System in Macau’s Landfill Area" Applied Sciences 14, no. 4: 1382. https://doi.org/10.3390/app14041382

APA StyleLi, Z., Tang, W., Mak, S., Li, Q., Chen, H., & Hong, Q. (2024). Critical Study Quality Management for the Anti-Seepage System in Macau’s Landfill Area. Applied Sciences, 14(4), 1382. https://doi.org/10.3390/app14041382