Abstract

Emulsions have garnered significant attention within a variety of industries, including pharmaceuticals, food production, and cosmetics. The importance of emulsions across these sectors is attributed to their versatility and unique properties, such as increased interfacial area and the ability to deliver compounds insoluble in water or to mask the flavor of unpalatable ingredients. A comprehensive and precise assessment of the physicochemical properties, structural features, and stability of emulsions is an indispensable phase in the pursuit of new formulations and the improvement of manufacturing protocols. The characterization of emulsions encompasses an array of methodologies designed to determine their attributes, such as droplet size, distribution, concentration, surface charge, and others. In this review, we explore the techniques most frequently used to characterize emulsions and critically assess the significance each method holds in understanding the behavior and predicting the stability of emulsions. We elucidate the basic principles of these methods while emphasizing what information can be gathered from them, and how to effectively interpret this information to optimize the properties of emulsions, crucial from the standpoints of food and other industries, such as long-term stability and easy processing.

1. Introduction

Emulsions are systems composed of two immiscible phases: an oil and an aqueous phase, stabilized by an emulsifying agent [1,2,3]. Owing to their unique characteristics, such as the capability to improve the solubility of poorly water-soluble ingredients, increase the absorption of active agents, and prolong their release, emulsions have become inseparable elements in multiple formulations used in the pharmaceutical, food, and cosmetic industries [4,5,6]. Accurate characterization of their physicochemical properties, structure, and stability is a crucial step in understanding their behavior, developing new formulations, and optimizing manufacturing processes.

To fully harness the capabilities of emulsions, their properties have to be carefully scrutinized using a wide range of techniques. A pivotal characteristic of emulsions that determines their stability and physicochemical properties is droplet size [7]. Dynamic light scattering, small-angle X-ray scattering, ultrasonic spectrometry, electrical pulse counting, field-flow fractionation, and capillary hydrodynamic fractionation [8] are key tools used for droplet size analysis. The understanding of emulsion behaviors can be further enhanced by microscopic analysis, which provides fundamental information about the morphology of the droplets, their concentration, and distribution [9,10,11]. Various techniques, such as optical microscopy, atomic force microscopy, transmission, or scanning electron microscopy, enable researchers to assess the structural properties of emulsions [12].

Analysis of rheological properties is another indispensable step in the evaluation of emulsions in terms of their manufacturing efficiency and product performance [13,14]. Determining the optical properties of emulsions, including transparency and turbidity, is crucial for applications requiring optical clarity [15]. Further details of emulsion properties can be revealed by zeta potential analysis, which offers insight into the electrostatic forces governing droplet behavior [16], which are key factors affecting the stability of emulsions [17].

Another crucial aspect of emulsion dynamics is heat exchange during phase transitions and crystalline transformations [18]. These features can be examined by differential scanning calorimetry (DSC). DSC is particularly useful in tracking crystallization and melting processes in emulsions, which are closely linked to their viscosity, droplet size, and density [19].

One of the primary focuses in analyzing the properties of emulsions is their chemical composition. Emulsion composition can be qualitatively and semi-quantitatively assessed by Fourier Transform Infrared (FTIR) spectroscopy [20]. This technique allows the identification of functional and structural groups responsible for both chemical and physical aging, all while preserving the internal equilibrium of the emulsion. FTIR has proven instrumental in examining thermal degradation processes within oils, providing insights into the structural alterations occurring as the emulsion matures [21].

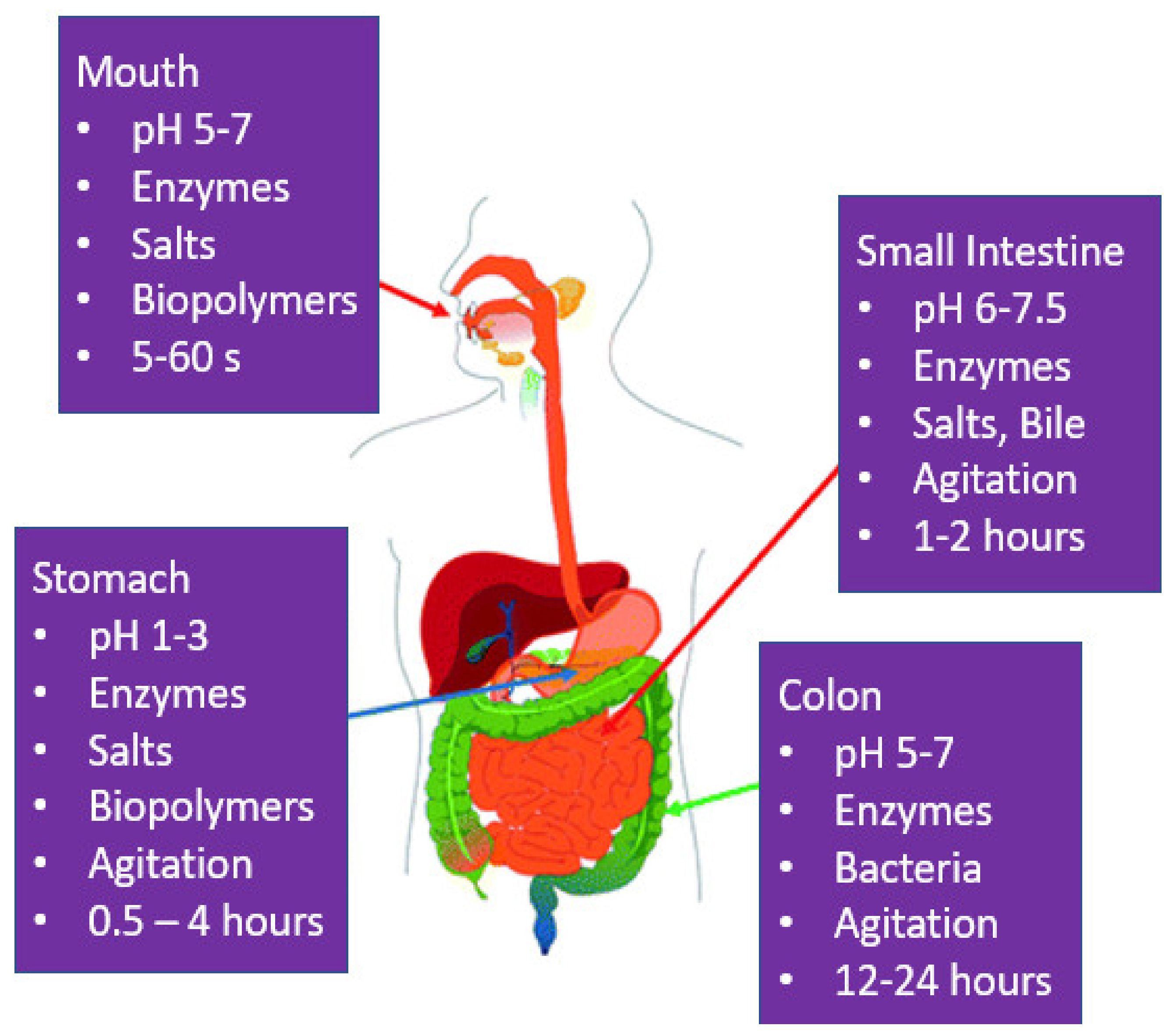

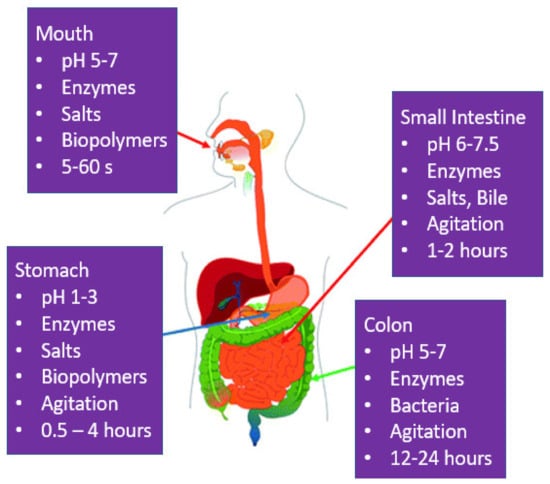

Evaluation of emulsions using in vitro digestion models has become another valuable tool for emulsion characterization, especially in the food and pharmaceutical sectors, where there is a growing interest in understanding and controlling the digestion of emulsified lipids [22]. In vitro models enable the assessment of emulsions as delivery systems for non-polar lipids, vitamins, nutraceuticals, and other therapeutic compounds within specific gastrointestinal tract regions [23,24].

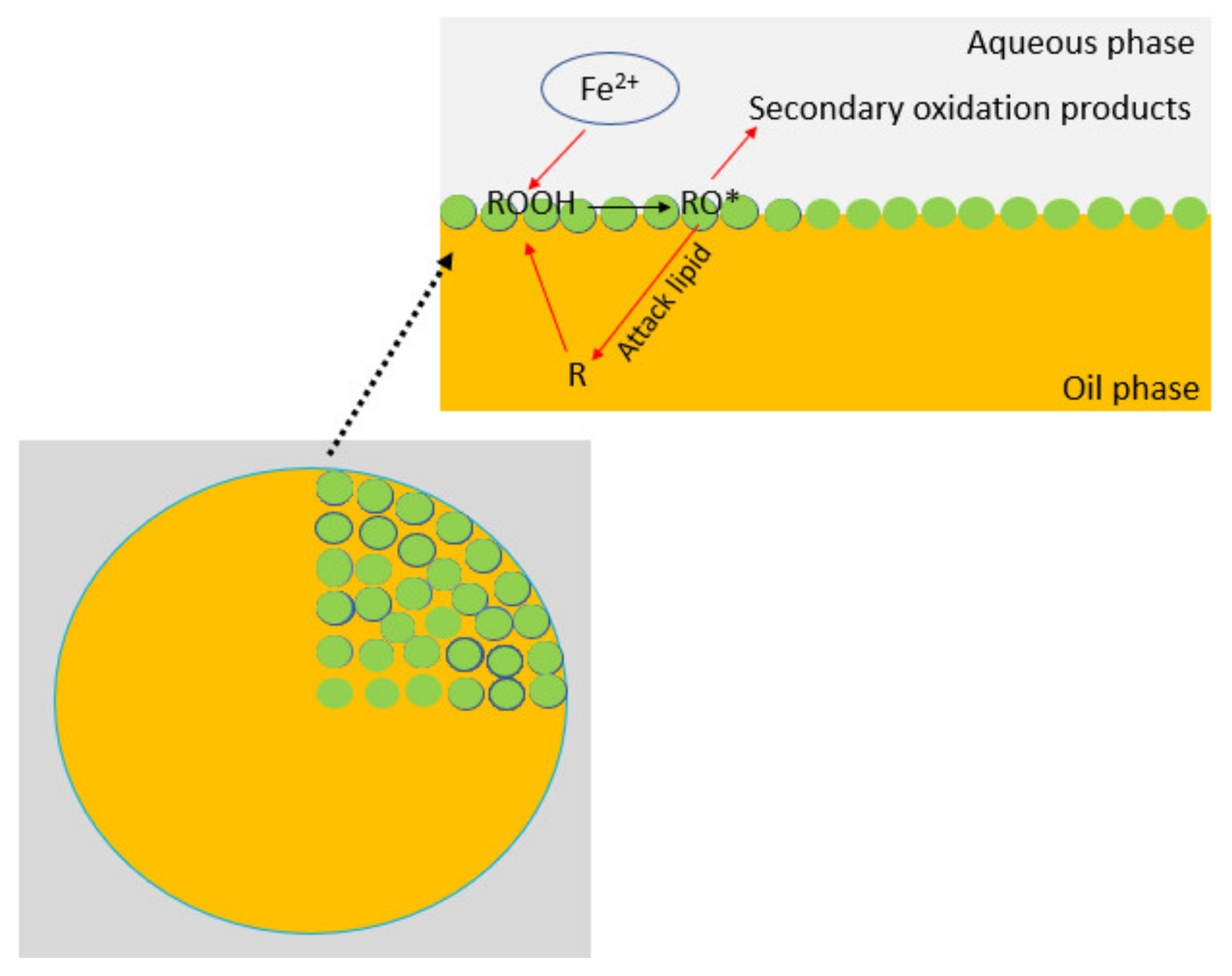

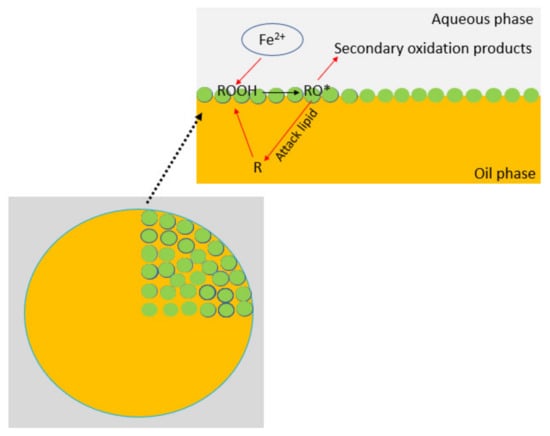

Despite the widespread use of emulsions across different industries, the manufacturing and storage of emulsion-based formulations still face challenges related to lipid oxidation. The susceptibility to oxidation is intensified within emulsions due to their complex composition, increased interfacial area, and potential exposure to oxidative stress during emulsification. Various techniques, including spectrophotometric measurement and wet-chemical methods, are employed to detect both primary and secondary oxidation products in emulsions.

This review offers insight into the emulsion characterization techniques mentioned above and discusses their effectiveness in providing accurate and comprehensive information on emulsion properties. The article elucidates the basic concepts of emulsion characterization methods with particular emphasis on the information that can be obtained using different analytical methods, and how to interpret this data to understand emulsion behavior and stability. By doing so, it equips researchers and formulators with the practical knowledge required to tailor emulsion characteristics to a specific application and maximize their potential across food and other industry sectors.

2. Emulsion Formation and Stability

Emulsions are colloidal dispersions created by mixing two immiscible phases, an oil phase, and an aqueous phase, in the presence of an emulsifying agent. Emulsions consist of liquid droplets (dispersed phase) dispersed in a continuous phase and can be classified into several categories based on their composition: oil-in-water (O/W), water-in-oil (W/O), and oil-in-oil (O/O). An example of the last category is an emulsion comprising a polar oil, such as propylene glycol, that is dispersed in a nonpolar oil, like paraffinic oil, or vice versa [25]. Emulsions can also be categorized based on droplet size, falling into macroemulsions, microemulsions, and nanoemulsions (also known as miniemulsions) [26]. Macroemulsions contain droplets larger than 0.1 µm, microemulsions have droplets ranging from 10 to 100 nm, while nanoemulsion droplets range in size from 20 to 500 nm. The majority of emulsions fall into the macroemulsion category.

Microemulsions are thermodynamically stable due to their low interfacial energy and can spontaneously form, however, they exhibit high sensitivity to changes in temperature and composition [27]. Macroemulsions and nanoemulsions are inherently thermodynamically unstable and exist in a state of non-equilibrium [28]. In these types of emulsions, breaking the dispersed phase into droplets enlarges the interface between the phases, resulting in a significant increase in interfacial area and energy. Hence, forming macro- and nanoemulsions does not occur spontaneously but requires an input of energy [29]. However, due to the very small size of droplets, nanoemulsions can remain kinetically stable over extended periods. It is important to note that this metastability does not result from the equilibrium state, but rather from greatly reduced rates of gravity-related sedimentation-based separation processes [30].

Unstable systems can be stabilized using surface active agents—surfactants (called also emulsifiers). Surfactants can be categorized into: (1) small molecular surfactants, such as sodium lauryl sulfate (SLS), diacetyl tartaric acid ester of mono- and diglycerides (DATEM), citric acid esters of mono and diglycerides (CITREM), Tweens 20 and 80, Spans 20, 40, 60 and 80, and Brij-97 [31]; (2) macromolecular emulsifiers, such as proteins, polysaccharides, phospholipids, and surface-active polymers; and (4) solid particles (known as Pickering particles), such as silica, clay, hydroxyapatite, starch, or chitosan particles [32]. The function of the emulsifier is to decrease the interfacial tension between immiscible phases and the resistance of the droplets to deformation, thereby reducing the shear force needed for breaking up droplets [33]. The resistance of the droplets to deformation is determined by the Laplace pressure, which refers to the difference in pressure inside and outside the droplet. Concurrently, emulsifier molecules adsorb to newly formed droplet surfaces, creating a physical barrier between them, which both stabilizes them and inhibits coalescence [29]. Emulsifiers with low molecular weight adsorb more rapidly to the droplet surface than high molecular weight surfactants and have a tendency to create a single-molecule layer at the interface of oil and water. The adsorption of a single emulsifier molecule at the interface can be described using Gibbs or Langmuir adsorption theorems [34]. In contrast, macromolecular surfactants form thicker layers with more complex morphologies, such as cross-linked multilayers or supramolecular structures [35].

The capacity of emulsifiers to stabilize the droplets arises from their amphiphilic nature [36]. Emulsifier molecules consist of a hydrophilic part (the head) and a hydrophobic segment (the tail). When introduced into an oil-in-water (O/W) emulsion, where oil droplets are dispersed in an aqueous phase, emulsifier molecules spontaneously envelop the oil droplets, with their non-polar tails reaching into the droplet [33]. Meanwhile, their heads point outward toward the continuous phase, forming a protective layer around the droplets. In water-in-oil (W/O) emulsions, where water droplets are dispersed in the oil phase, the orientation of emulsifier molecules is reversed: non-polar tails are oriented outward toward the oil phase, while polar heads are directed inward toward the center of the water droplets. Oil-in-water emulsions are known as standard emulsions [2], while water-in-oil emulsions are termed reverse or inverted emulsions. When an emulsion is additionally dispersed into another continuous phase, it is referred to as a multiple emulsion or an emulsified emulsion. An instance of a multiple emulsion is oil-water-oil (O/W/O), which includes small oil droplets scattered in larger water droplets suspended in the continuous oil phase.

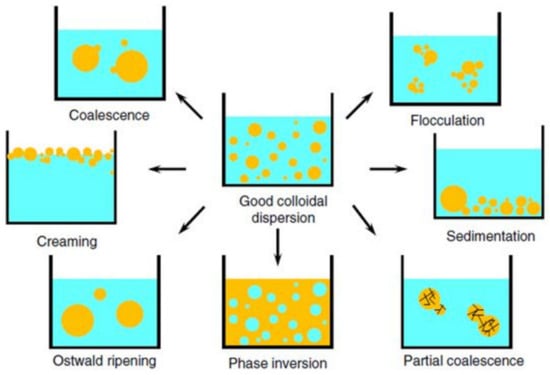

The stability of emulsions refers to their capability to withstand alterations in physicochemical properties and droplet size over time [37]. Emulsion stability is a crucial factor in various applications, including in the food, cosmetic, and pharmaceutical industries, as it ensures the desired physicochemical properties and shelf-life of the product. There are several destabilization mechanisms responsible for the separation of emulsions (Figure 1), including flocculation, coalescence, Ostwald ripening [29], sedimentation, and creaming, which may occur simultaneously or separately [38].

One of the key emulsion destabilization mechanisms is coalescence, which occurs when the droplets of the dispersed phase come into contact and merge to form larger droplets. The fusion of droplets can happen due to Brownian motion, collisions, and attractive forces between the droplets. Coalescence causes the thin liquid layer separating individual droplets to break. As two droplets approach, the layer becomes thinner until it reaches a stable thickness determined by surface forces. The resulting force, known as disjoining pressure, involves different interactions, such as repulsive electrostatic forces, van der Waals interactions, and repulsive steric forces, depending on the properties of the surfaces involved. It is worth noting that, in stable emulsions, as droplets draw closer together, disjoining pressure increases; however, beyond a critical distance and disjoining pressure, the interfacial layer is compromised, and coalescence begins [39]. The interfacial tension between the dispersed and continuous phases and the viscosity of both phases are crucial parameters determining emulsion resistance to coalescence. In emulsions where the dispersed phase is partially crystallized, the droplets can undergo partial coalescence (called also arrested coalescence). During partial coalescence, droplets begin to merge, but before coalescence is completed, a smaller daughter droplet is formed. Partial coalescence may occur again in daughter droplets creating the next generations of daughter droplets.

Another important mechanism in emulsion destabilization is flocculation, where the droplets group together to form larger clusters or flocs due to attractive forces between them, including van der Waals forces [40]. The rate of flocculation is related to the strength of the van der Waals attraction, which depends on the droplet radius and effective Hamaker constant (dictated by the interactive van der Waals energy and the distance of separation between two droplets), as well as the electrostatic or steric repulsion between the droplets. The rate of flocculation can be predicted from a frequency factor that determines how often drops encounter each other, and a probability factor indicating how long they stay together. Usually, flocculation leads to enhanced creaming (i.e., the movement of the dispersed phase to the upper layer of the emulsion), because flocs rise faster than individual drops due to their larger effective radius. However, exceptions occur in concentrated emulsions, where gel-like network structures can have a stabilizing influence. Polydispersity enhances flocculation, as differences in creaming rates between small and large droplets cause them to come into proximity more often compared with monodisperse systems. The cream layer formed towards the end of this process actually constitutes a concentrated floc.

The third process leading to emulsion separation is Ostwald ripening. During Ostwald ripening, smaller droplets are incorporated into larger ones because of pressure differences between the droplets and the continuous phase, as well as differences in the solubility of unevenly sized droplets. In polydisperse emulsions, smaller droplets exhibit higher Laplace pressure compared to larger drops. Small droplets also have higher solubility in the continuous phase and therefore tend to be included in the larger droplets. Ostwald ripening occurs due to the diffusion of the dispersed phase through the continuous phase, involving a continual exchange of matter. As a result, there is a continuous transfer of the dispersed phase from small to large droplets, leading to a gradual growth of larger droplets and the diminishment of smaller ones. This disproportionation leads to a reduction in the total number of droplets within the population. The rate of Ostwald ripening is influenced by the solubility of the dispersed phase in the continuous phase. Higher solubility results in faster Ostwald ripening [41]. Therefore, this separation process can be minimized by selecting a dispersed phase that exhibits low solubility in the continuous phase [42].

Figure 1.

Emulsion destabilization mechanisms. Orange and blue areas represent the oil and water phases, respectively. Reprinted from [43], published under CC license CC BY-NC 3.0. Copyright © 2023 Royal Society of Chemistry.

Figure 1.

Emulsion destabilization mechanisms. Orange and blue areas represent the oil and water phases, respectively. Reprinted from [43], published under CC license CC BY-NC 3.0. Copyright © 2023 Royal Society of Chemistry.

As mentioned above, creaming involves the movement of the dispersed phase to the upper layer of the emulsion. It results from density differences between oil and water phases, leading to droplets rising to the surface. The separation process that occurs through a similar mechanism is sedimentation. Sedimentation is commonly observed in water-in-oil emulsions, where heavier water droplets gather at the bottom. Creaming or sedimentation can be prevented by employing a high-viscosity continuous phase or regulating both particle size distribution and dispersed phase density.

The temporal evolution of emulsion separation is subject to multi-factorial influences, encompassing parameters such as emulsifier type and concentration, water-to-oil volume ratio, the incorporation of additives, like co-surfactants, polydispersity index, and the physicochemical attributes of the mixture constituents (including viscosity, density, and interfacial tension) [44]. Other determinants include polarity, ionic strength, and temperature. Emulsion stability characteristics can vary greatly, with certain emulsions designed for transient stability, while others demonstrate enduring stability, persisting for weeks, months, or even years [45].

The choice of emulsifier can greatly influence the stability and physicochemical properties of emulsions. Emulsifiers can be either ionic (positively or negatively charged), zwitterionic (carrying both positive and negative charges at neutral pH) [46], or nonionic. Ionic emulsifiers form a charged shell around droplets, causing electrostatic repulsion between them. The extent of repulsion depends on the emulsifier surface charge and ionization degree, which are strongly affected by emulsion pH and the presence of other charged species, like electrolytes [44]. This renders them sensitive to composition and pH, limiting their use to specific emulsion types. For instance, cationic emulsifiers perform well in low pH and neutral solutions but not in alkaline solutions, whereas anionic emulsifiers are better suited for alkaline emulsions. Nonionic emulsifiers, which contain large bulky non-charged polar groups in their molecules, are considered more universal as they can effectively stabilize different kinds of emulsions [44]. This is due to steric hindrance, which prevents droplet coalescence without being sensitive to changes in medium pH and composition. Therefore, most emulsions are stabilized by this kind of emulsifier (e.g., Pluronics 70, Tween-80, Span-80, Brij-30) [47]. Surfactant mixtures, including combinations of ionic/nonionic or nonionic/nonionic emulsifiers, can also be employed to enhance emulsification and improve the stability of the formulation.

When selecting the most suitable emulsifier, a key factor to consider is its hydrophilic-lipophilic balance (HLB), which describes the emulsifier affinity for oil and water phases. It is utilized to predict the emulsifier capability to form a specific type of emulsion. HLB is linked to the emulsifier solubility in water and oil, as well as the size and strength of its hydrophilic and lipophilic moieties [48]. HBL is calculated based on the weight percentage of the hydrophilic groups compared to the hydrophobic groups in a molecule and spans from 0 to 20, with an HLB of 10 indicating an equal attraction to both phases. Emulsifiers with a higher HLB value are more inclined towards being hydrophilic and typically form oil-in-water emulsions, while those with lower values tend to be more hydrophobic and favor the formation of water-in-oil emulsions. To achieve maximum stability of emulsions, it is essential to align the HLB value with that of the non-polar oil phase being utilized [49]. For instance, emulsifiers with an HLB ranging from 7 to 8 are generally required for emulsifying vegetable oils, whereas surfactants with a higher HLB of around 14 are better suited for creating castor oil emulsions.

Nevertheless, the hydrophilic-lipophilic balance concept is not without its constraints. Notably, it may fail to accurately predict the resultant emulsion type formed by specific emulsifiers, owing to variables, such as temperature or emulsifier concentration, during the emulsification process [50]. These factors can lead to the same emulsifier giving rise to both water-in-oil (W/O) and oil-in-water (O/W) emulsions. Furthermore, O/W emulsions can be generated using emulsifiers exhibiting HLB values across the entire spectrum, and theoretical HLB calculations prove inadequate for blends comprising diverse emulsifying agents.

In response to these challenges, the hydrophilic-lipophilic difference (HLD) concept has been introduced. HLD offers a more precise characterization of emulsifiers [51] as it takes into account various parameters shaping the emulsion, encompassing surfactant concentration and type, hydrophobicity of the oil phase, salinity, temperature, and the characteristic curvature (Cc) of the emulsifier [52]. The Cc value indicates whether the emulsifier tends to form a curvature around an oil droplet in water (negative Cc) or a water droplet in oil (positive Cc). Typically, hydrophilic emulsifiers exhibit negative Cc values; for example, sodium lauryl sulfate (SLS) possesses a Cc value of −2.3. Conversely, hydrophobic emulsifiers demonstrate positive Cc values; dioctyl sodium sulfosuccinate, for instance, has a Cc value of 2.6.

As previously mentioned, emulsions can also be stabilized with solid particles, known as Pickering particles. Pickering particles accumulate at the water-oil interface and create a steric barrier preventing droplet coalescence. These particles include inorganic particles (e.g., silica, clay, hydroxyapatite particles), organic particles (e.g., starch, ovotransferrin, chitosan particles) [53], and Janus particles (particles whose surfaces have two or more distinct physical properties, e.g., hydrophilic and hydrophobic). They provide stability to emulsions by being partially wetted by both the oil and water phases [54]. The formation of oil-in-water (O/W) Pickering emulsion or water-in-oil (W/O) Pickering emulsion depends on the wettability of solid particles at the interface between oil and water. If one liquid has better wetting properties with solid particles compared to the other, it will become the continuous phase, while the other becomes dispersed. O/W emulsions are created when the phase contact angle θ is less than 90° (e.g., emulsions stabilized with silica or clay particles), whereas W/O emulsions form when θ > 90° (e.g., emulsions stabilized with carbon black). However, for a particle to effectively act as a stabilizer in either case, θ needs to be relatively close to 90°. It is worth noting that Pickering particles attach to the interface irreversibly and thus provide more efficient emulsion stabilization than conventional surfactants that adsorb to the water-oil interface [55].

The stability of emulsions is also significantly affected by emulsifier concentration [56]. While higher emulsifier concentrations generally result in more stable emulsions [57], there are instances where this may not be the case due to different inter-droplet interactions in various emulsion systems. Additionally, there is an emulsifier concentration limit, beyond which the stability of the emulsion may decrease. This is often referred to as “over-emulsification”. Over-emulsification is a phenomenon that occurs when an excessive amount of emulsifier is added to an emulsion, leading to its destabilization. The mechanism of over-emulsification involves an imbalance in the concentration of emulsifier at the interface [58]. When the emulsifier concentration surpasses a certain threshold, there is an excess of emulsifier molecules at the interface, resulting in repulsion between these molecules. This repulsion disrupts the formation of a stable interfacial film, leading to a reduction in the emulsifier’s ability to lower interfacial tension.

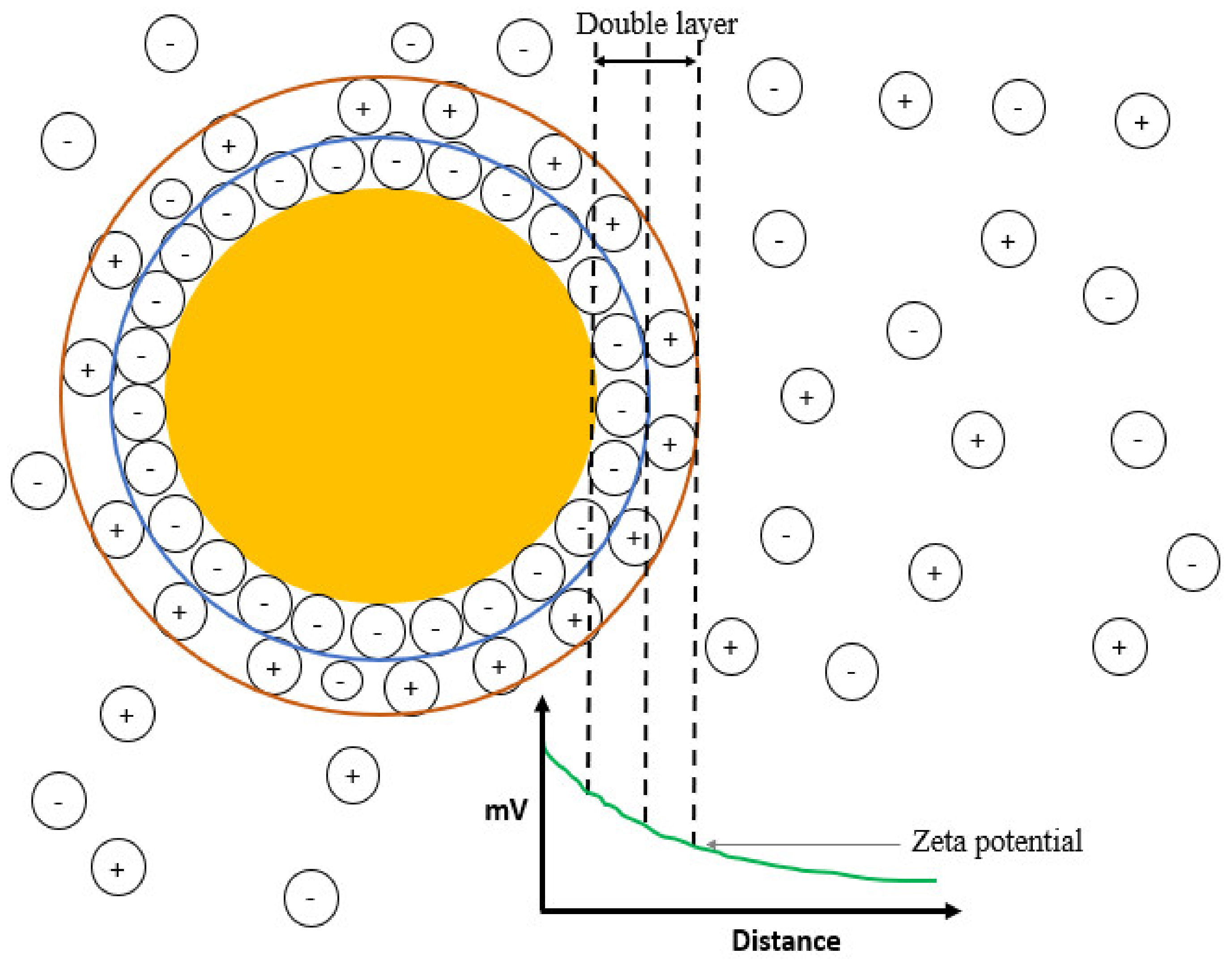

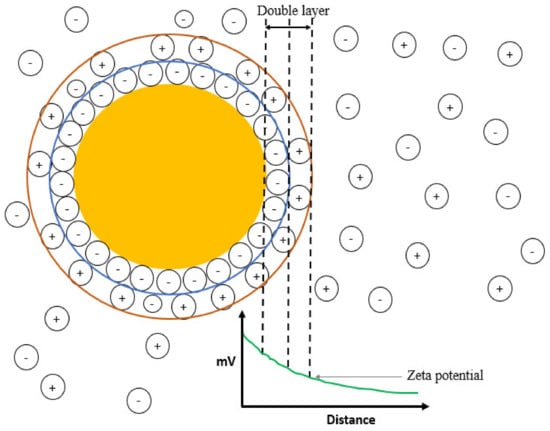

The rate of emulsion destabilization is also influenced by factors such as pH, ionic strength, temperature, and the viscosity of the continuous phase [43,59]. These variables significantly impact electrostatic interactions and the repulsive barrier between droplets [59]. They have a particularly profound effect on emulsions that are stabilized with ionic emulsifiers. In the context of emulsion stability, pH and ionic strength play a critical role in influencing droplet surface charge density, molecular flexibility, and electrostatic and steric interactions [58]. Emulsion droplets acquire their electrical charge primarily through the adsorption of ionized species, such as ionic emulsifiers, polyelectrolytes, or ions, from the surrounding solution onto their surface. The sign and magnitude of droplet surface charge are influenced by the kind and concentration of molecules adsorbed to the surface.

The ionic strength of the solution influences the extent and strength of intra- and intermolecular electrostatic interactions, impacting the interfacial layer structure and thickness, and repulsion between the droplets [2]. An increase in the ionic strength of the continuous phase reduces the electrostatic repulsion between droplets due to the accumulation of counter-ions around their surfaces, consequently increasing the likelihood of the droplets flocculating or coalescing. The magnitude of this phenomenon is influenced by the concentration and valency of the counter-ions present in the solution. Multivalent counter-ions, such as Ca2+, Fe2+, and Fe3+, exert a more significant effect on the electrostatic forces between droplets than monovalent ions, like Na+, Cl−, and K+. To modify droplet surface charge, polyelectrolytes containing weakly acidic or basic ionizable groups can also be added to the emulsions. Negatively charged groups, such as sulfate, phosphate, or carbonate groups with pKa values around 1–2 and 4–5, respectively, can be provided by incorporating anionic polyelectrolytes (e.g., pectin, carrageenan, alginate) in the formulations, whereas positively charged groups, such as amino or imino groups (with pKa values around 7–11), by adding cationic polyelectrolytes. (e.g., chitosan).

Emulsion pH level governs the ionization of surface groups, which impacts the density of droplet surface charge [60]. By adjusting the solution pH, it is possible to tailor the thickness and integrity of the interfacial layer [61] and control how much ionizable molecules adsorb to droplet surfaces. For instance, anionic pectin will not attach to anionic β-lactoglobulin-stabilized droplets at neutral pH (pH = 7) due to electrostatic repulsion between polysaccharide molecules and droplet surfaces but will do so at lower pH levels of around 3 when polysaccharide molecules and droplets are oppositely charged [62] At the same time, pH-driven changes in the thickness of the interfacial layer can strongly impact emulsion stability by altering the strength of steric repulsion and van der Waals attraction between droplets. Protein emulsifiers are particularly effective in manipulating droplet charge by adjusting the pH of the emulsion. Protein molecules have a positive charge below their isoelectric point (pI) and a negative charge above it. By adjusting the solution pH, it becomes possible to tune the electrostatic interactions between droplets. Moreover, since different proteins have varying isoelectric points, selecting proteins with the necessary electrical properties at the desired solution pH allows for altering the magnitude of electrical repulsion between the droplets [58].

The change in temperature impacts various factors, including the viscosity of the phases, interfacial tension, surfactant adsorption to droplets, solubility, and diffusivity of the droplets in the continuous phase [63]. These changes indirectly affect emulsion stability. A rise in temperature decreases interfacial tension and viscosity, facilitating emulsion formation. However, high temperatures can reduce emulsion stability due to increased dispersed phase solubility in the continuous phase and accelerated Ostwald ripening [43]. Sudden temperature variations are particularly detrimental to emulsion stability [63]. Conversely, increasing the viscosity of the continuous phase can enhance emulsion resistance against separation by slowing down gravitational separation processes, like sedimentation, while decreasing droplet collisions and coalescence frequency [59,64].

Emulsion stability can also be enhanced by reducing droplet size and the polydispersity index (PDI). In general, emulsions exhibit greater stability when the droplets and PDI are small, due to diminished attraction between droplets and increased viscosity, resulting in reduced coalescence [37]. In polydisperse systems, smaller droplets show greater solubility in the continuous phase compared to larger ones. With an increase in emulsion polydispersity, differences in solubility and chemical potential between droplets intensify, accelerating Ostwald ripening.

Another crucial factor for emulsion stability is the concentration of droplets. In O/W emulsions, an increase in droplet concentration has been shown to improve their stability and reduce creaming rate, which can be attributed to droplet crowding effects, higher packing density, and stronger inter-droplet interactions [65]. However, the strength of these interactions largely depends on the surface charge of the droplets, since electrically charged droplets cannot get as close to each other as uncharged ones.

Efforts have been made to enhance control over emulsion stability through the use of emulsifiers that respond to specific stimuli, such as light (e.g., azobenzene-modified emulsifiers), pH (e.g., poly(methacrylic acid-co-methyl methacrylate-co-7-(4-vinylbenzyloxyl)-4-methylcoumarin emulsifier), or salts (e.g., zwitterionic emulsifiers) [64]. These stimuli-responsive emulsifiers enable reversible stabilization and destabilization of emulsions in response to physical or chemical changes, offering potential benefits for on-demand site-specific drug delivery.

3. Techniques for Emulsion Characterization

3.1. Microscopic Analysis

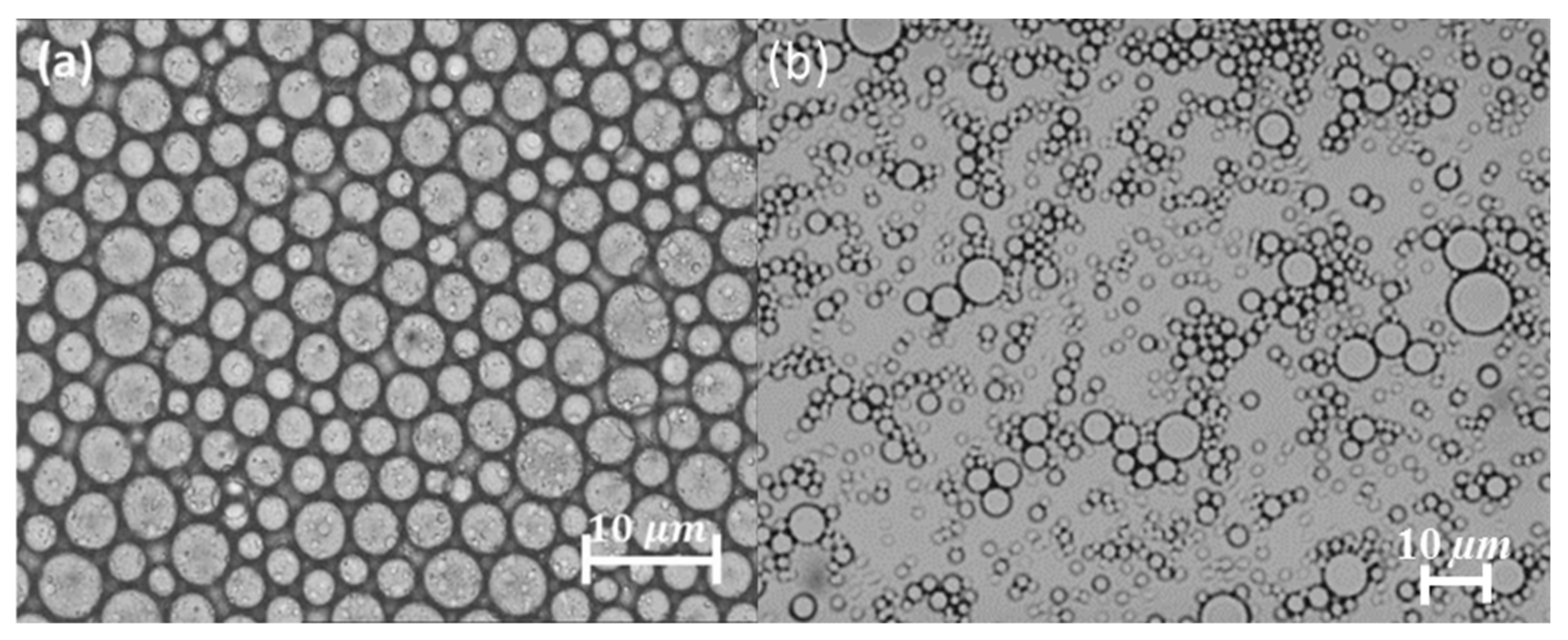

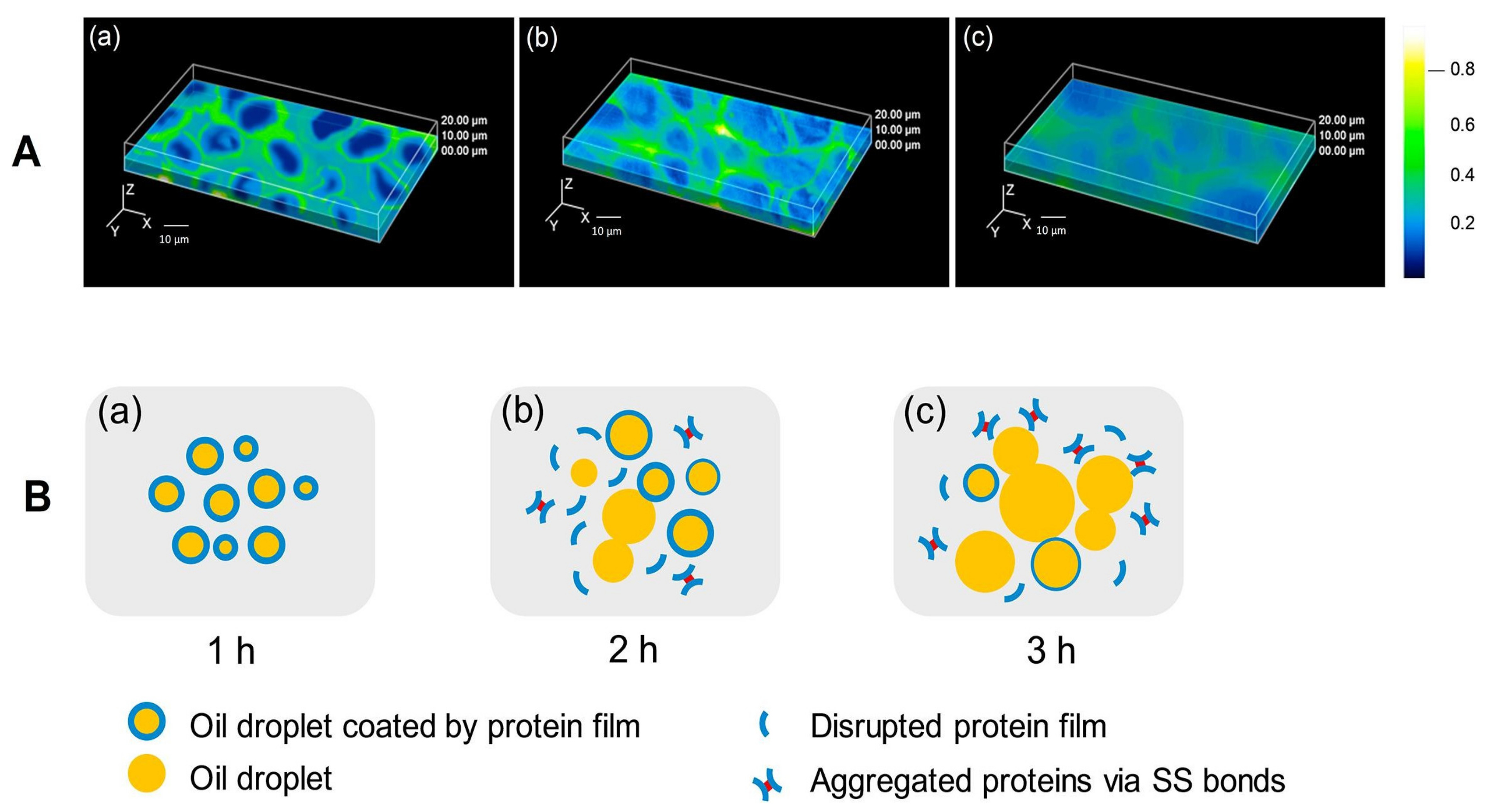

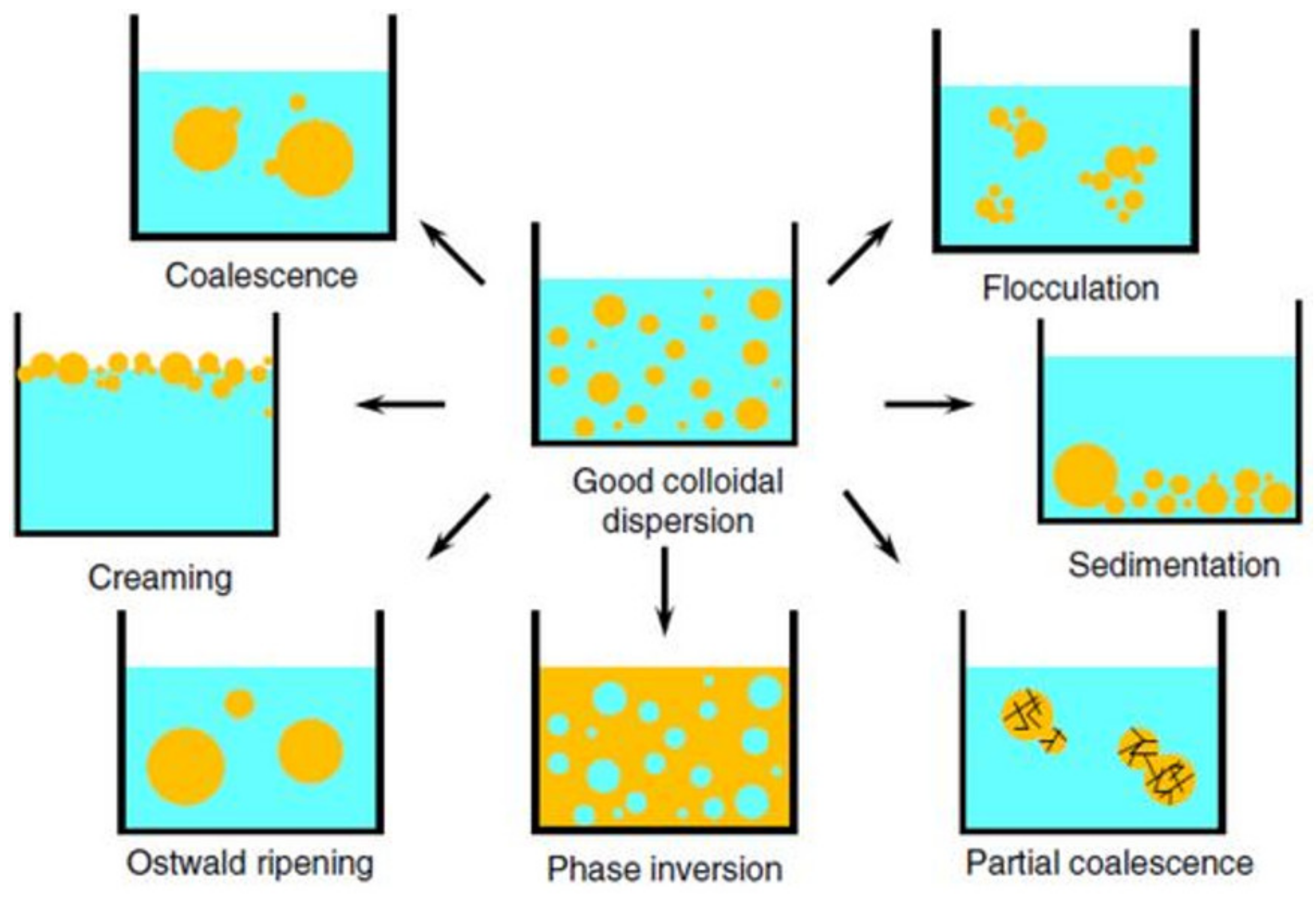

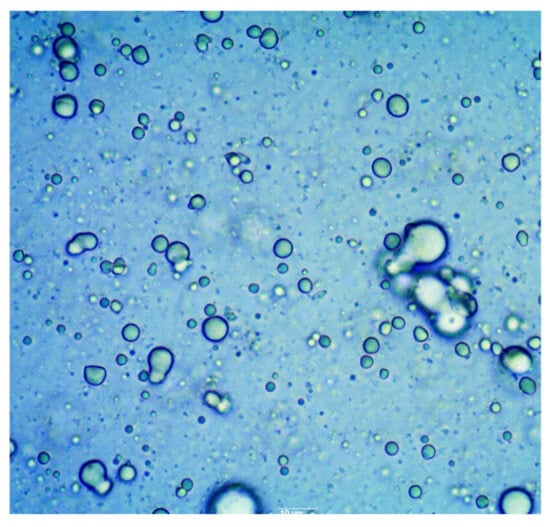

One of the most straightforward and widespread methods for emulsion characterization is microscopic analysis. Microscopic analysis is performed to assess the morphology of the droplets (shape and size), droplet concentration, and distribution throughout the sample [66]. Observing changes in the morphology of the droplets over time can give us valuable information on emulsion stability and the mechanism of phase separation. The image typical for stable emulsion shows small, non-flocculated, homogenously distributed droplets that are relatively uniform in size (Figure 2a). Unstable emulsion separating through flocculation can be recognized by the presence of equally sized droplets that group but maintain their integrity. In the emulsions undergoing separation through coalescence or Ostwald ripening (Figure 2b and Figure 3), small and large droplets are present at the same time [37].

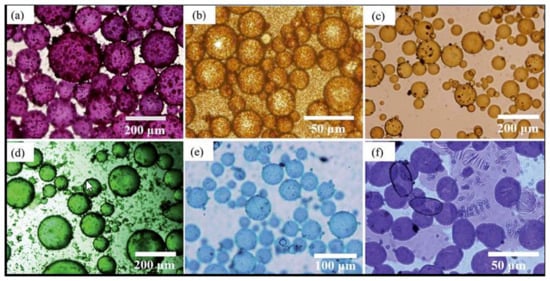

Figure 2.

Optical microscopy images of (a) a stable emulsion, and (b) an unstable emulsion separating through coalescence. Adapted with permission from [66]. Copyright © 2023 Springer Nature.

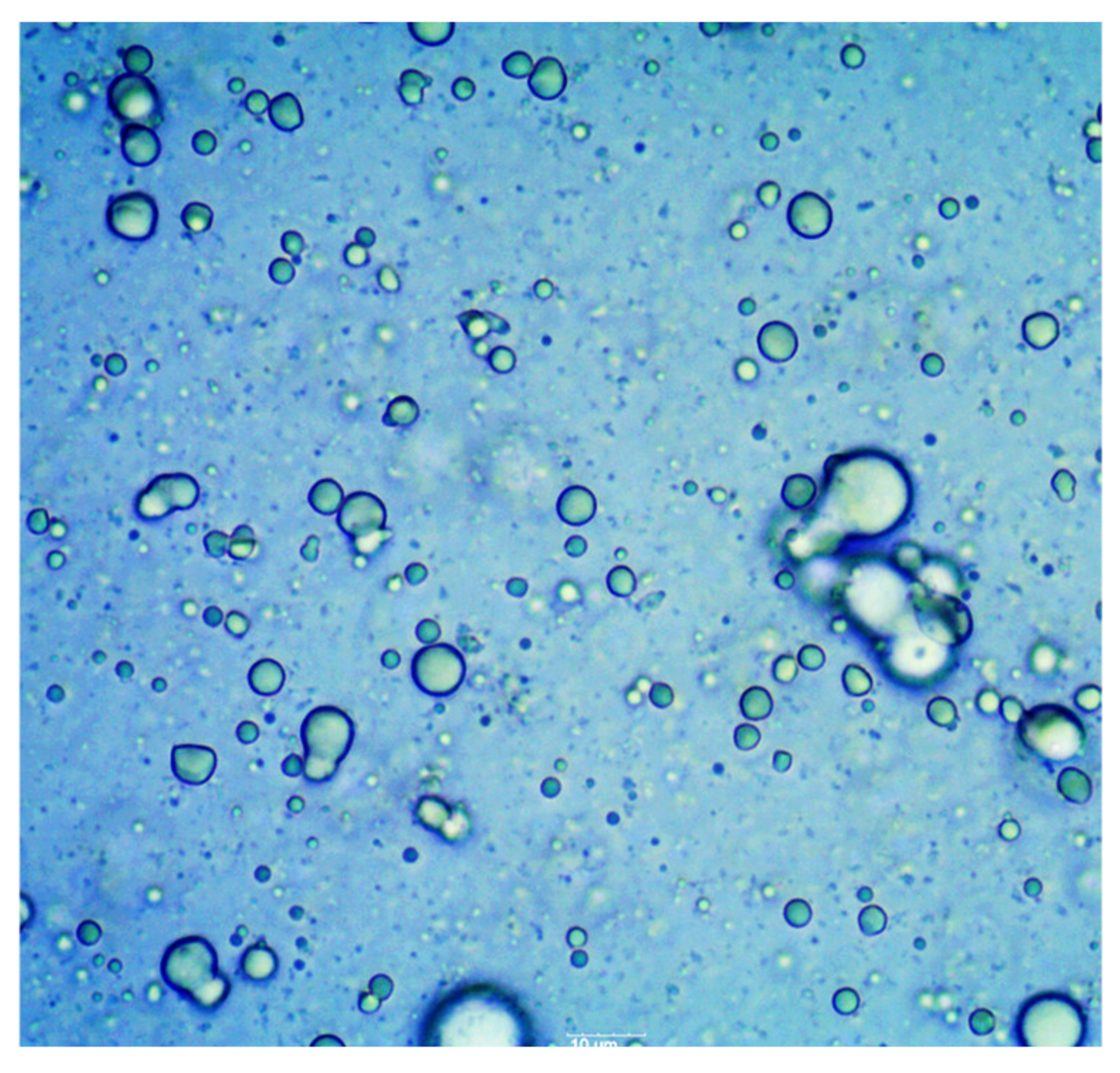

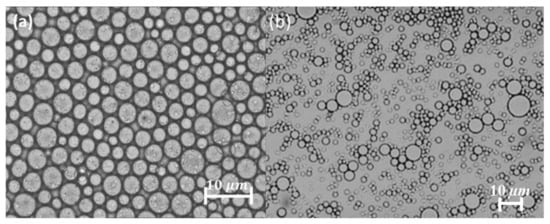

Figure 3.

Optical microscopy image of coalescing emulsion droplets. Two droplets merge and form a larger one.

Microscopic evaluation of emulsions can be performed via several techniques. The most common methods include optical microscopy, fluorescent microscopy, and electron microscopy [67,68]. Optical microscopy is commonly used for the initial assessment of emulsions due to its simplicity, availability, and capability to quickly provide qualitative information about the emulsion. However, with the level of resolution it provides (down to 1–2 μm [69], it is often insufficient for a detailed analysis of the emulsion structure. Optical microscope images of emulsions often suffer from relatively low contrast between the phases, caused by their similar refractive indexes, which makes it difficult to distinguish one phase from the other [70].

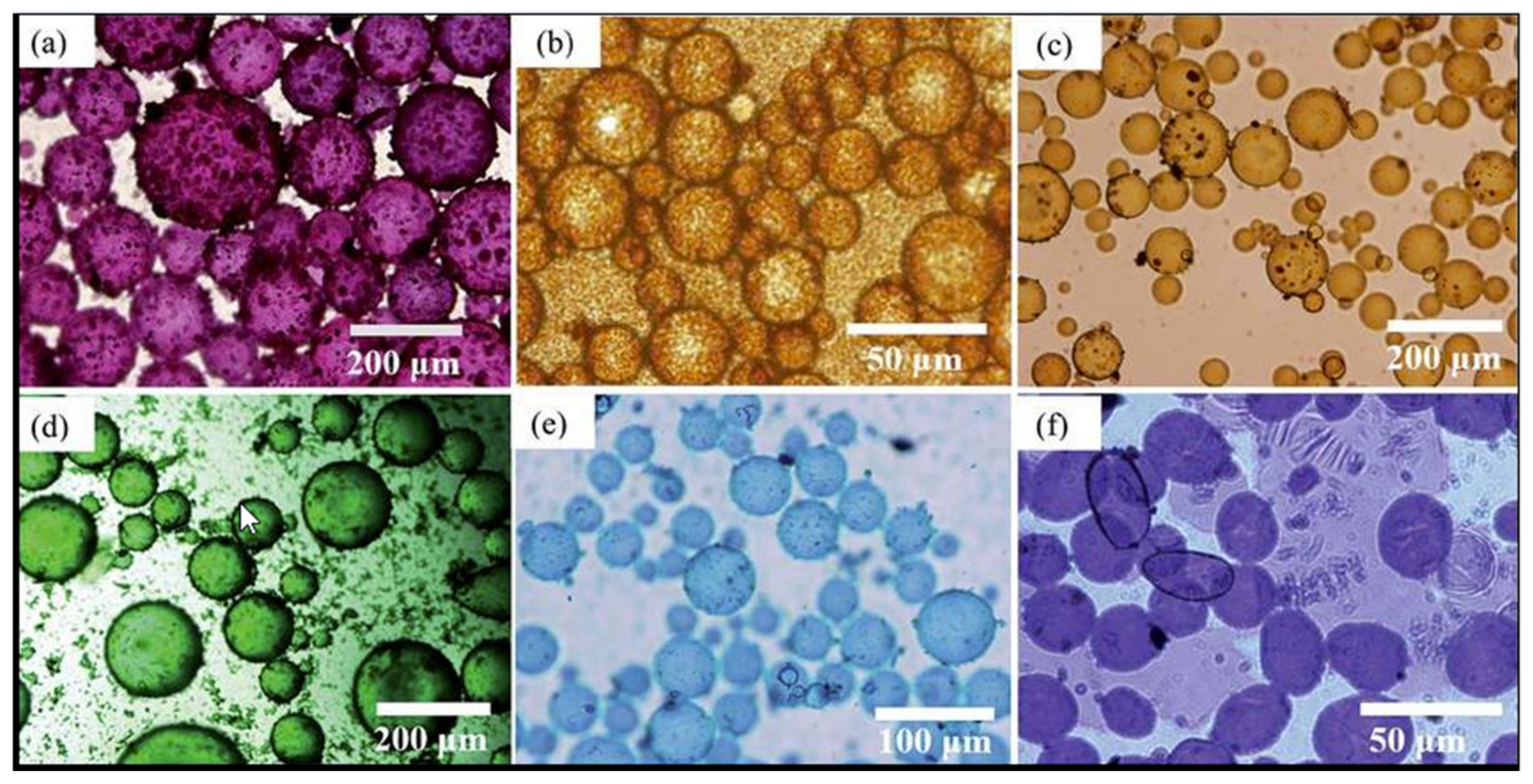

To improve the contrast and visibility of the droplets against the background of the continuous phase, water- or oil-soluble dyes absorbing light in the visible region can be added to the sample [66,71] or emulsion droplets may be stabilized with pigment particles (e.g., Irgalite Red D 3707, Cromophtal Violet D 5700, Paliotol Yellow K 0961) serving simultaneously as a contrast-enhancing agent and a surfactant (Figure 4) [72]. However, the color compounds added to the emulsions have to be carefully selected, as they may induce substantial changes in emulsion structure or interact with some of its components. Enhanced contrast can also be achieved using phase contrast or differential interference contrast microscopy, in which special lenses amplify the small differences in the refractive index into more significant differences in light intensity.

Figure 4.

Optical microscope images of Pickering emulsions stabilized with pigment particles: (a) Irgalite Red D 3707, (b) Cromophtal K 2960, (c) Paliotol Yellow K 0961, (d) Heliogen Grun K 8730, (e) Heliogen Blau K 6907, (f) Cromophtal Violet D 5700. Emulsions depicted in images (a,c–f) are W/O. The emulsion shown in (b) is O/W. Adapted from [73], published under a Creative Commons Attribution 3.0 License. Copyright © 2017 Royal Society of Chemistry.

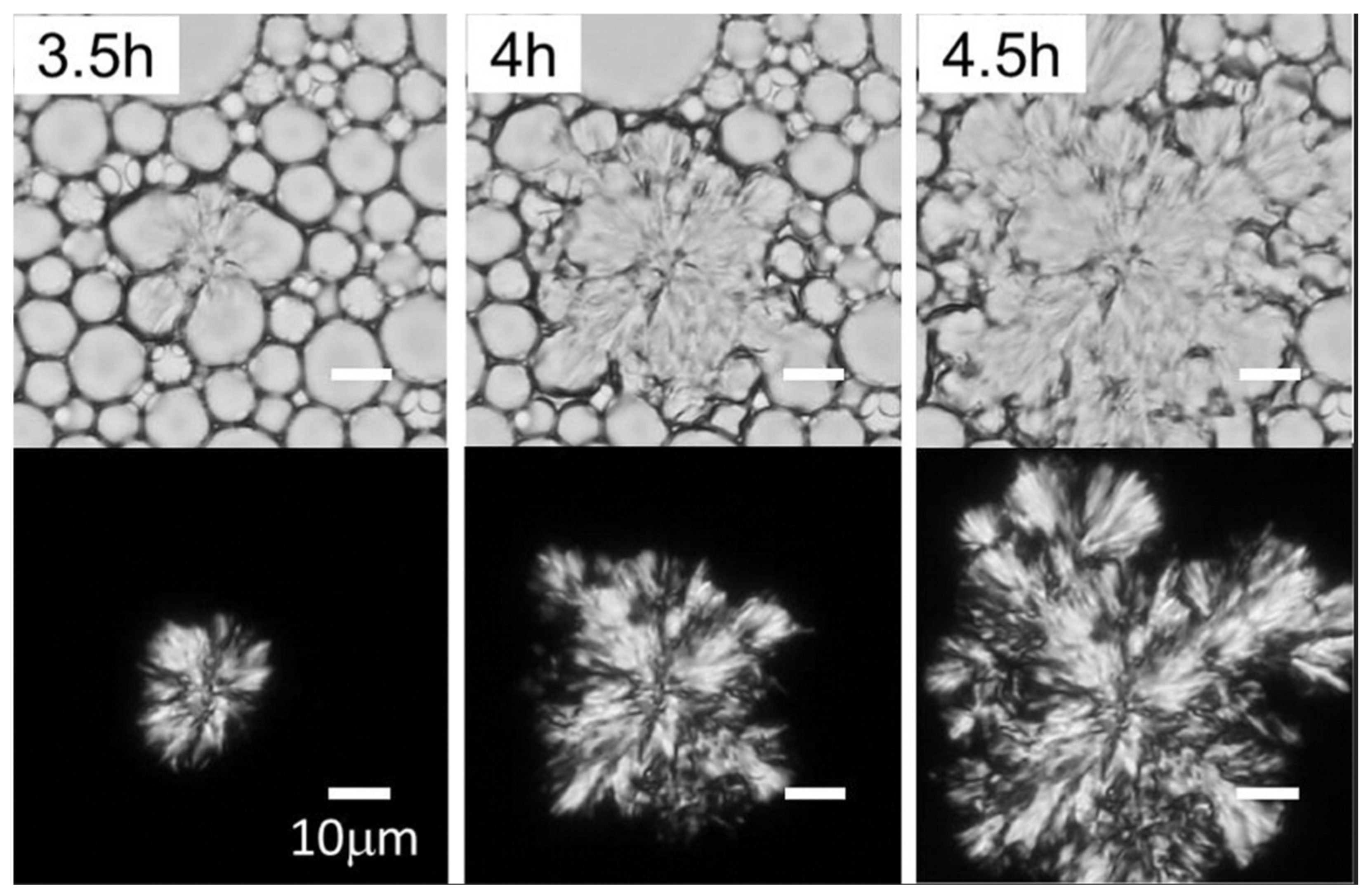

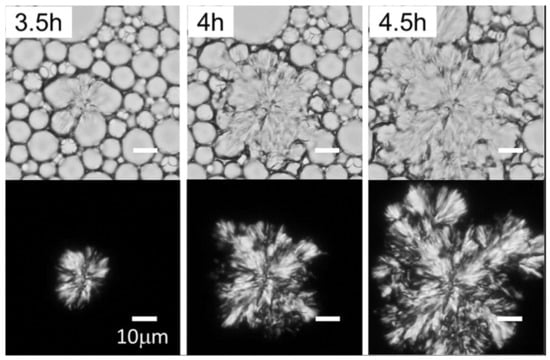

Another limitation of conventional bright field light microscopy is limited imaging capabilities in the case of 3D objects, such as crystals of fat or ice (in frozen emulsions), or air bubbles. Polarization light microscopy is a valuable tool for three-dimensional imaging of such objects. As can be seen in Figure 5 [74], there is a striking difference between images of fat crystals in emulsions observed using a transmitted light microscope and a polarized light microscope. Although conventional transmitted light microscopy allows for the visualization of emulsion droplets, it fails to clearly recognize transparent fat crystals against a bright background. The visibility of fat crystals under polarized light is greatly improved; however, this method fails to show the structure of the emulsion in the background. For this reason, it is advisable to combine several different microscopic techniques to obtain reliable information about emulsion structure.

Figure 5.

Fat crystals formed during the destabilization of canola oil-in-water (O/W) emulsion by freeze-thawing as a result of partial coalescence of canola oil droplets. Adapted with permission from [72]. Copyright © 2016 Elsevier Ltd.

The techniques widely used to complement the information about emulsion structure gathered from white light microscopy are fluorescent microscopy and confocal laser scanning microscopy (CLSM) [75]. These approaches can be applied to assess emulsions containing compounds that display inherent fluorescence when exposed to light (autofluorescence), which is typical for many oils (e.g., aromatic hydrocarbons), vitamins (e.g., A, B2, E, and D), proteins, toxins (e.g., aflatoxin), metabolites, plant pigments (e.g., chlorophyll), and flavoring compounds [76]. Auto-fluorescent compounds can easily be differentiated from other emulsion components, as well as particles and air bubbles that may be present in the sample. The fluorescence of the oil phase can also be enhanced by adding fluorescent oleophilic dyes such as 3-alkoxyflavone or Nile Red [77]. Non-fluorescent compounds present in the emulsions, such as proteins, surfactants, contaminants, etc., can be visualized using fluorescent probes that selectively bind to target molecules. In addition, the fluorescence emitted by these molecules can be utilized for quantitative analysis of their content in the emulsion by fluorescence spectroscopy.

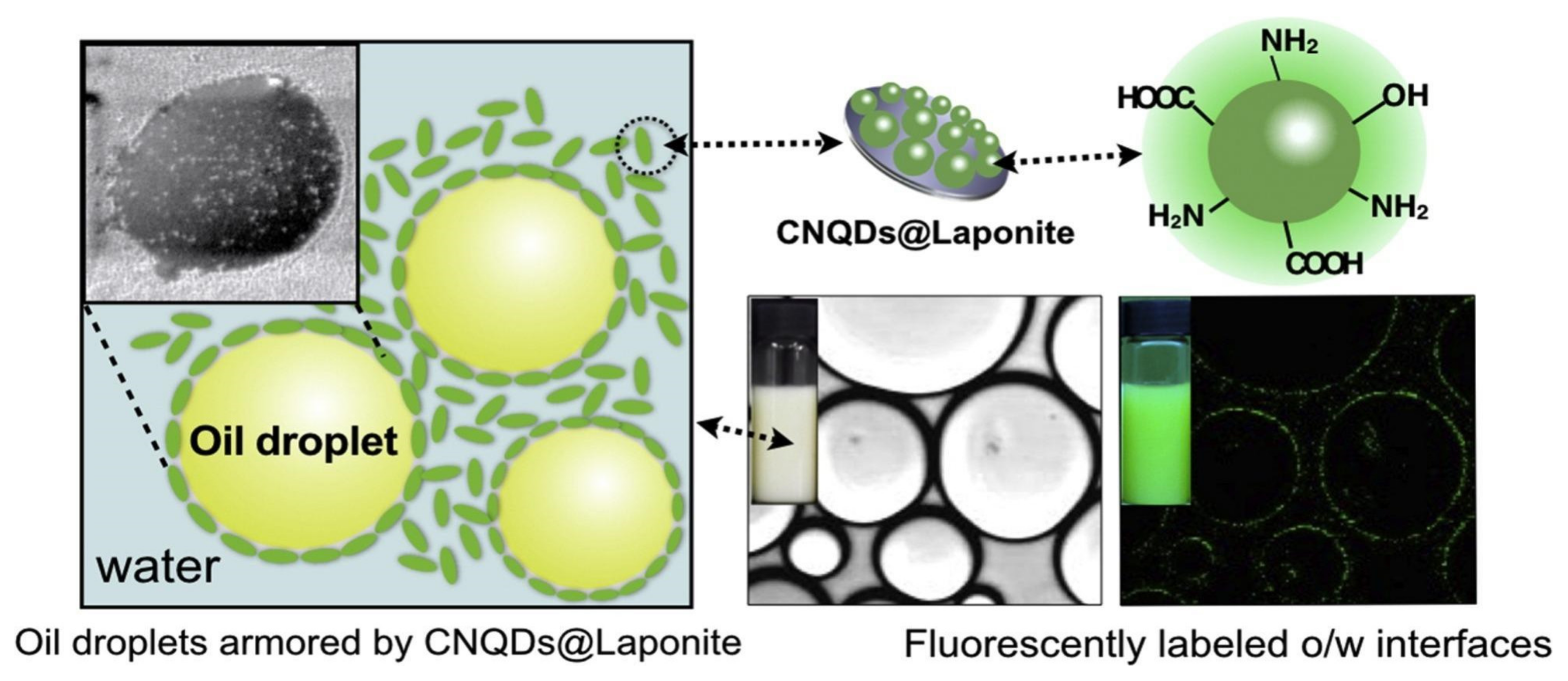

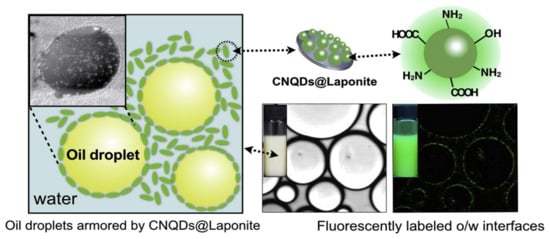

Fluorescent dyes can be used to analyze the structure and stabilization mechanisms of emulsions. High-contrast images of emulsions comprising non-fluorescent oil and water phases can be obtained by labeling the oil-water interface using fluorescent stabilizers, such as carbon nitride quantum dots, combined with solid supports, e.g., laponite nanoparticles (Figure 6) [78] or fluorescent dyes, e.g., NBD [79]. Using fluorescent surfactants to stabilize emulsions can provide information on the localization and behavior of emulsifier molecules at the oil-water interface. Thijssen et al. [78] have demonstrated that NBD, a common fluorescent dye, can effectively act as a surfactant. However, they have also revealed that the dye substantially affected the behavior of other particles adsorbed to the liquid-liquid interface, which altered the interfacial tension and the particle contact angle. This should be taken into account in studies utilizing fluorescent probes for labeling and in situ imaging of emulsion components.

Figure 6.

A Pickering O/W emulsion (paraffin in water) stabilized with highly fluorescent carbon nitride quantum dots combined with solid laponite nanoparticles Adapted with permission from [78]. Copyright © 2018 Elsevier B.V.

Fluorescent microscopy and CLSM are typically employed for the visualization of emulsions containing droplets with sizes down to ~300 nm [69]. Since, over the last few decades, the size of emulsion droplets has reached the lower end of the nanometer scale, visualization by optical microscopy has become insufficient to provide reliable data on nanoemulsion structure. Therefore, optical microscopy has been largely replaced by electron microscopy, which offers much higher resolution and allows imaging structures with sizes down to 0.1 nm [69]. The excellent resolution of electron microscopy allows visualization of multi-lamellar structures, vesicles, micelles, crystals, and liposomes, which remain undetected by both optical microscopy and particle size analyzers [80].

Electron microscopy techniques can be divided into transmission electron microscopy (TEM) and scanning electron microscopy (SEM). The SEM analysis offers the advantage of obtaining topographical information at a significant depth of focus on a 2D image [80]. SEM generates images of a sample by scanning the surface with a focused beam of electrons accelerated under high voltage. The electrons penetrate the specimen and are deflected by elastic scattering. As a result of the interactions between electrons and the specimen, electron signals (backscattered and secondary electrons), and X-rays are generated. Backscattered electrons are high-energy electrons scattered out of the sample that originate from deeper regions of the specimen. They provide valuable information about the composition of the sample. Secondary electrons are low-energy electrons, which have penetrated the surface regions of the sample a few nanometers below its surface. They reveal topographic information about the structure of the specimen surface. X-rays produced when electrons reach the sample give information about its elemental composition. These signals are collected by electron detectors to form a gray-scale image.

The advantages of SEM that have made it one of the most popular tools for the ultrastructural analysis of emulsions include detailed topographical information of the sample surface, which cannot be obtained in two-dimensional projections produced by TEM, and a high depth of focus. The depth of focus at low magnifications can reach a few millimeters. However, preserving the shape and size of emulsion droplets during SEM analysis is challenging, and requires specific SEM fixation protocols [81]. Other limitations include a lack of information on the internal structure of the sample, limited resolution, and the risk of damaging the specimen structure, especially after prolonged exposure to the electron beam [80].

TEM is one of the most powerful methods for the analysis of emulsion structure. The high resolution of TEM has rendered this technique an indispensable tool for imaging emulsions comprising droplets in the nanometer and sub-nanometer size range (down to 0.1 nm) [82,83]. Before TEM analysis, a 2–5 µL sample of emulsion is deposited onto a carbon- or polymer-coated grid and dried for up to several hours. Alternatively, the sample may be cooled to cryogenic temperatures, which allows preservation of its native state. During imaging, a beam of electrons passes through an ultra-thin (<200 nm) sample of emulsion at high (60–200 kV) accelerating voltage. The electrons transmitted through the specimen are cast onto a fluorescent screen producing a high-resolution image. Typically, a bright field TEM imaging combined with diffraction mode is used for the characterization of the size and shape of emulsion droplets [84].

The main limitation of both SEM and TEM techniques is that they require relatively complex preparation of the sample before observation, which often involves dilution, spreading, drying, or freezing and may alter the original emulsion structure [71]. As a result, obtained images are often not representative of the sample in a liquid state [85]. The degree to which the original structure of the emulsion is maintained is highly dependent on the technique applied to fix the sample [80]. For example, chemical fixation with glutaraldehyde is known to distort native emulsion structure by causing the shrinking of oil droplets and is therefore considered unsuitable for emulsions [86]. Among other methods, fixation by cryogenic freezing, in which sample characterization is carried out in a vitreous frozen-hydrated state, has been shown as the most reliable [87]. In this approach, the water contained in the sample is transformed from a liquid to an amorphous solid state by vitrification without the formation of ice crystals. Avoiding the formation of ice crystals within the water phase allows the prevention of structural damage to emulsion droplets [88]. Cryogenic freezing can be used to fix emulsions before observation with both SEM and TEM [87]. However, to account for any changes that may have occurred in the structure of the emulsion during microscopic evaluation, it is necessary to verify the obtained data with other analytical methods such as droplet size analysis.

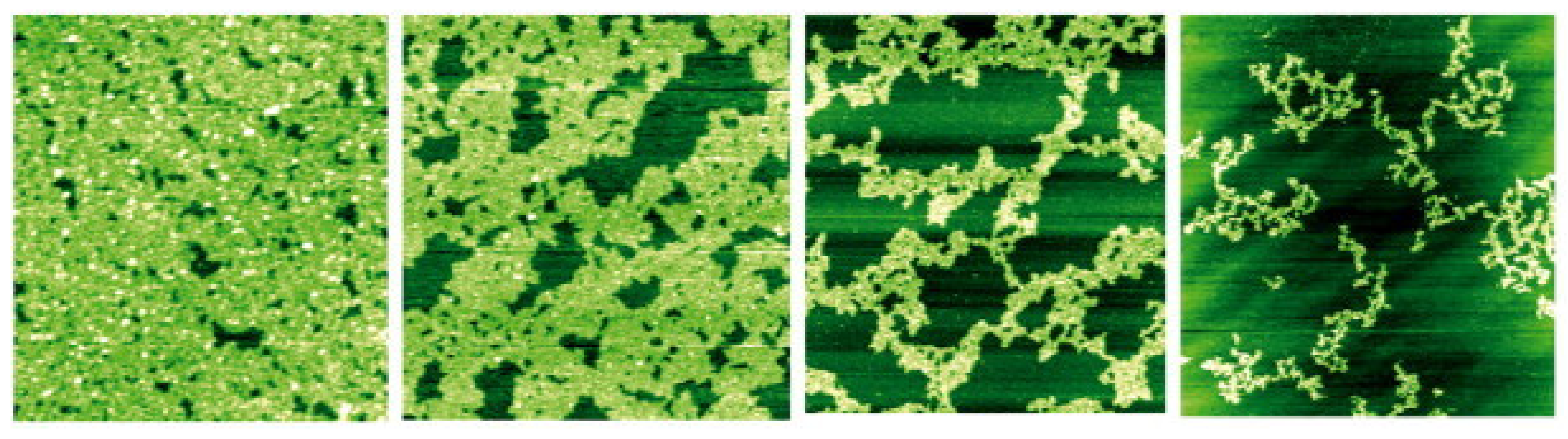

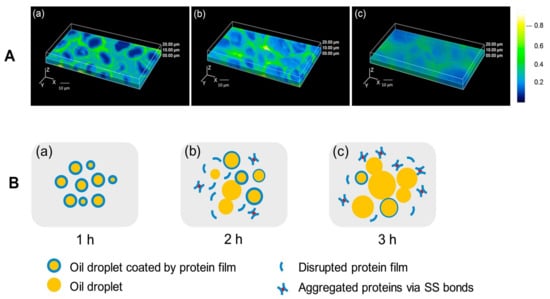

One of the most promising techniques for emulsion imaging that may open new perspectives in understanding the behavior of these complex systems is atomic force microscopy (AFM). This technique allows direct visualization of emulsion interfacial films (Figure 7) and analysis of their tightness, integrity, morphology, and structure. This can provide crucial insights into emulsion stability and separation phenomena, as well as the behavior of molecules at the droplet interfaces [89]. For example, AFM can be utilized to examine the competitive adsorption of various emulsifier molecules at the oil-water interface [90]. Morris et. al. used AFM to visualize the gradual displacement of milk protein β-lactoglobulin from an air-water interface by the water-soluble surfactant Tween 20 [90]. AFM has also been used to study the formation and arrangement of multi-layer films at the oil-water interface, providing a deeper understanding of the stabilization mechanisms in more complex interfacial layers. Recent technological advancements in AFM have allowed the visualization and quantification of interfacial interactions at a nanoscale level [91]. By utilizing nano-structured probes for scanning material surfaces at sub-nanometric and atomic resolution, AFM can provide information on the surface interaction forces as well as micro/nano-structured surface topography [92].

Figure 7.

An interfacial film in emulsion stabilized with β-lactoglobulin visualized by atomic force microscopy (AMF). The images show the gradual displacement of β-lactoglobulin molecules from the interfacial film at an air-water interface by the progressive addition of the water-soluble surfactant Tween 20. The images were obtained by spreading the protein at the interface and then adding the surfactant to the bulk phase. Adapted with permission from [92]. Copyright © 2004 Elsevier Ltd.

One of the significant limitations of AFM analysis of emulsion droplets is that it can be time-consuming and labor-intensive. Since, in most studies on emulsions via AFM, the imaging is performed under dry conditions (in the air mode), the droplets need to be deposited on a solid matrix by the Langmuir–Blodgett technique [93] and dehydrated before observation [88]. The process of depositing air-water or oil-water interfacial films onto a solid matrix is not only highly intricate and difficult but may also alter the native emulsion structure. However, the transfer process of air-water interfacial films is more convenient and operable compared to oil-water interfacial films. This has led to a greater focus on visualization studies of air-water interfacial films, while the oil-water interfaces are less often explored. Therefore, there is an urgent need for new techniques that allow for the direct in situ visualization of nanodroplet interfaces in liquid nanoemulsions. The use of surface force apparatus in conjunction with atomic force microscopy can provide novel insights into the complexities of emulsion stabilization mechanisms [94]. Another downside of AFM lies in the fact that it does not provide information on the internal structure or composition of emulsion droplets, as it primarily focuses on surface topography. AFM measurements on nanodroplets present certain limitations due to their deformable soft surfaces. Such surfaces may present challenges in accurately measuring their mechanical properties and surface roughness and can be easily damaged during the probing process.

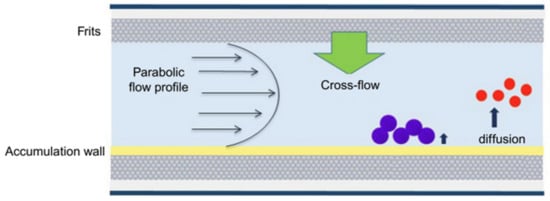

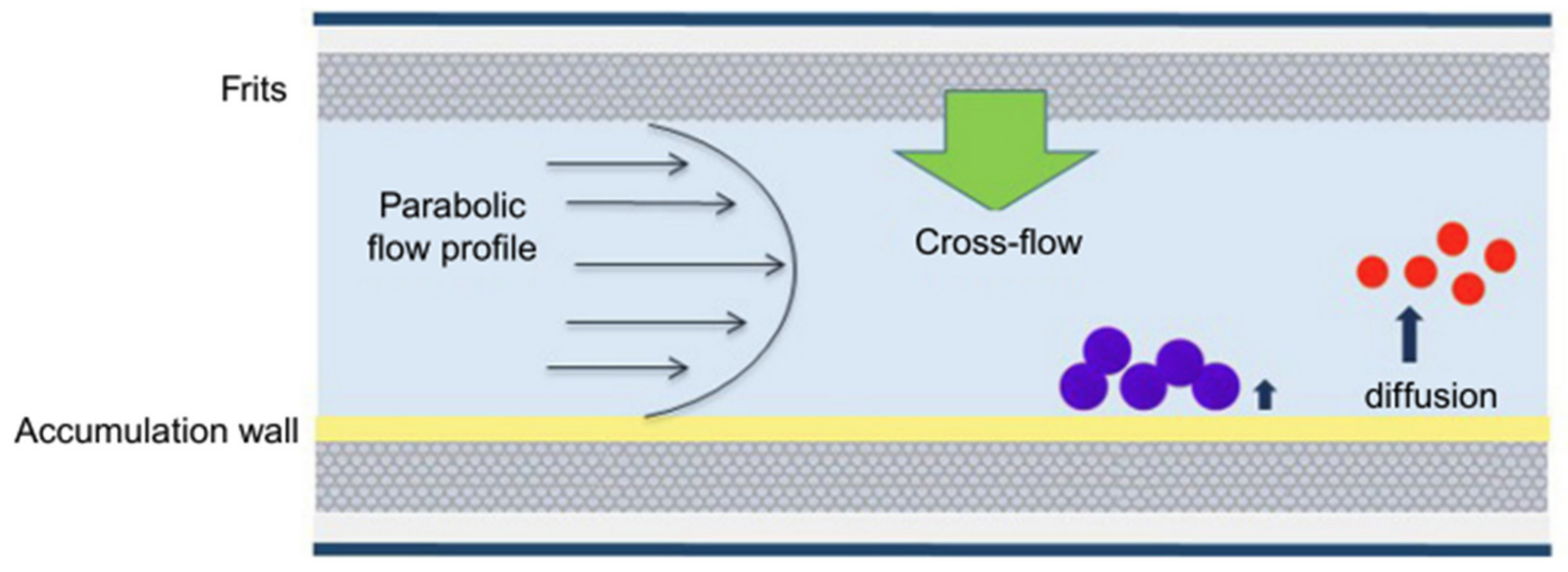

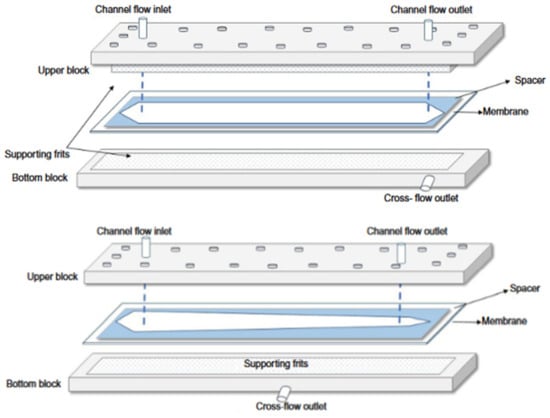

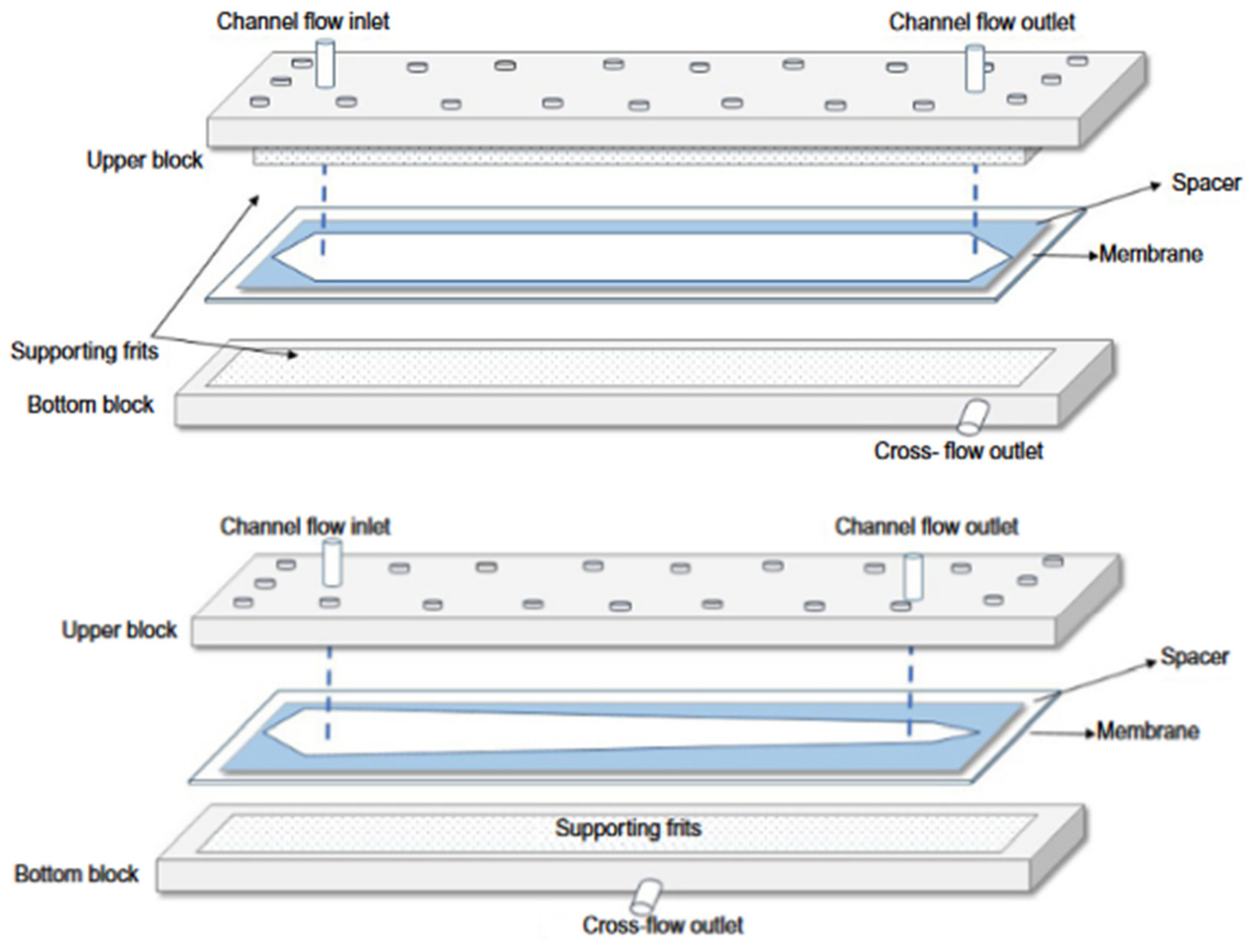

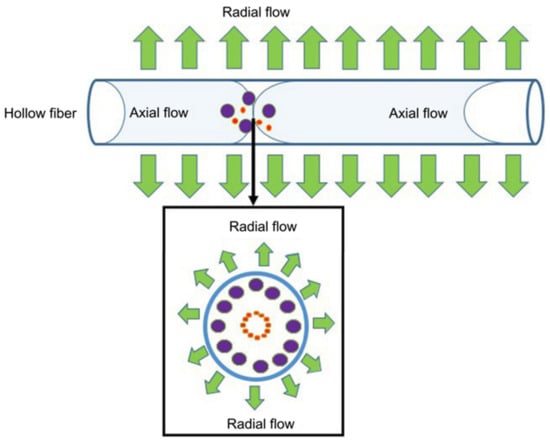

3.2. Droplet Size Analysis

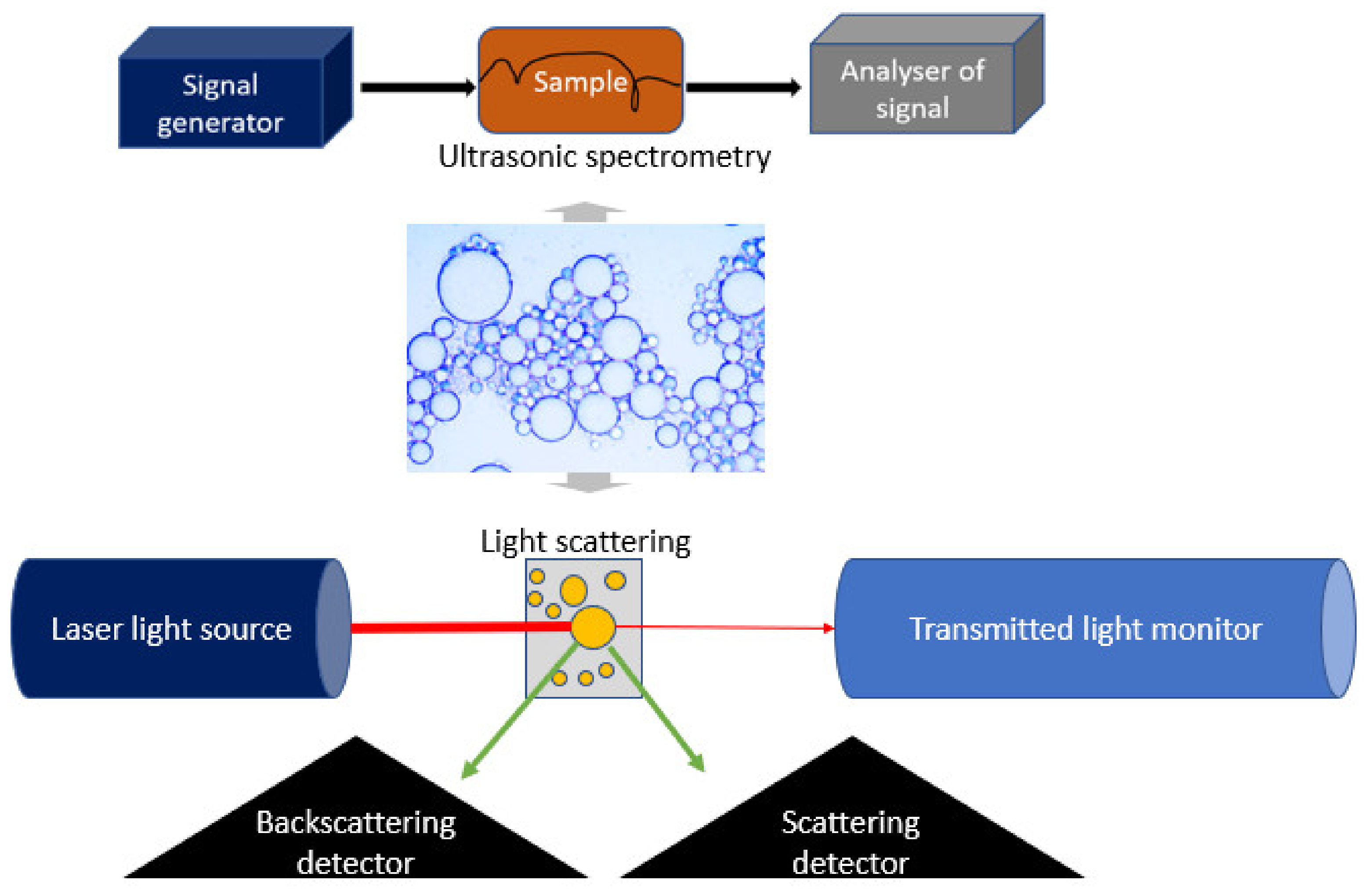

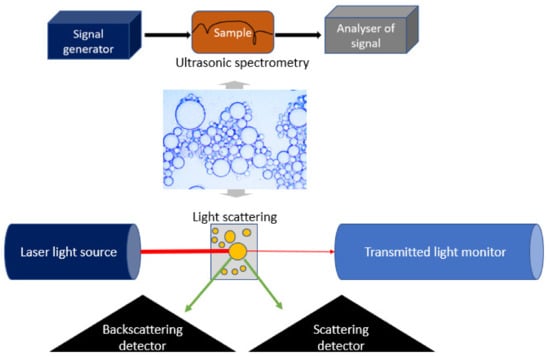

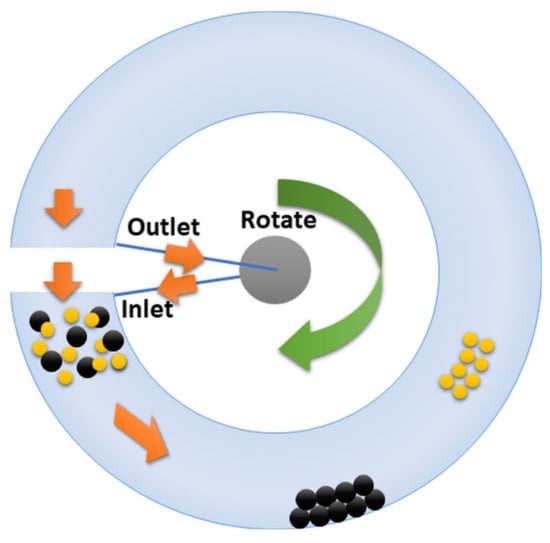

Droplet size is one of the most vital characteristics of emulsions, determining their stability and physicochemical properties. Emulsion droplet size and size distribution are typically analyzed by dynamic light scattering [95], small-angle X-ray scattering, ultrasonic spectrometry, or electrical pulse counting techniques [29,37] (Figure 8).

Figure 8.

Evaluation of emulsion droplet size, size distribution, and stability using ultrasonic spectrometry (upper panel) and light scattering (bottom panel).

The analysis is typically performed using fully automated particle size analyzers, which allow measurements of large numbers of droplets within several minutes or less. There are two main categories of commercially available light scattering instruments for particle size analysis: dynamic and static light scattering devices [96]. Dynamic light scattering (DLS) devices measure the intensity fluctuation of light scattered by the emulsion droplets by assuming that smaller particles move faster than larger ones and create a higher rate of intensity fluctuation. When a monochromatic light beam passes through an emulsion, the light is scattered by the droplets undergoing the Brownian motion at a certain angle [83]. The random movement of emulsion droplets causes rapid fluctuations in the intensity of scattered light, which are dependent on droplet size. The percentage and angle of backscattered light are recorded by a detector [97] and converted into the photocount (intensity)–time correlation, which is further used to calculate droplet size, size distribution, concentration, and polydispersity index (PDI). The polydispersity index describes the uniformity of droplet size and can take values between 0 and 1 with 0 corresponding to completely monodisperse systems [83].

Dynamic light scattering devices generally operate using a specific, fixed, or variable scattering angle and mathematically convert the fluctuation intensity into particle size distribution (PSD). This approach is utilized for particles ranging from 3 nm to 5 μm in size. The static light scattering instruments operate based on Mie’s light scattering theory and utilize parameters, such as particle refractive index and shape, to determine the size of particles measuring from 100 nm to 1000 μm. Small-angle X-ray scattering (SAXS) techniques are based on a similar principle as the DLS method, but instead of a light beam, they use a monochromatic beam of X-rays that are scattered by emulsion droplets in a size-dependent manner.

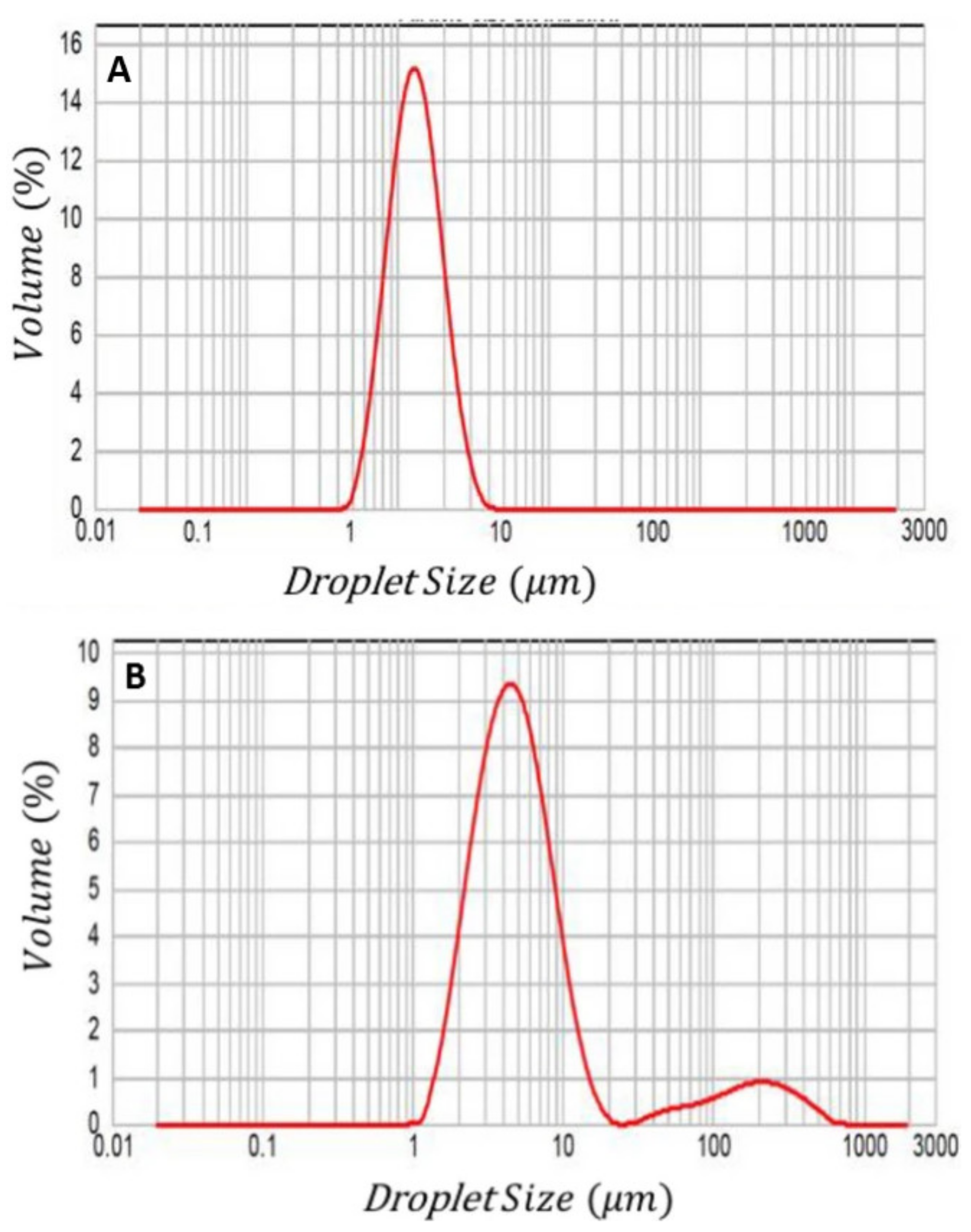

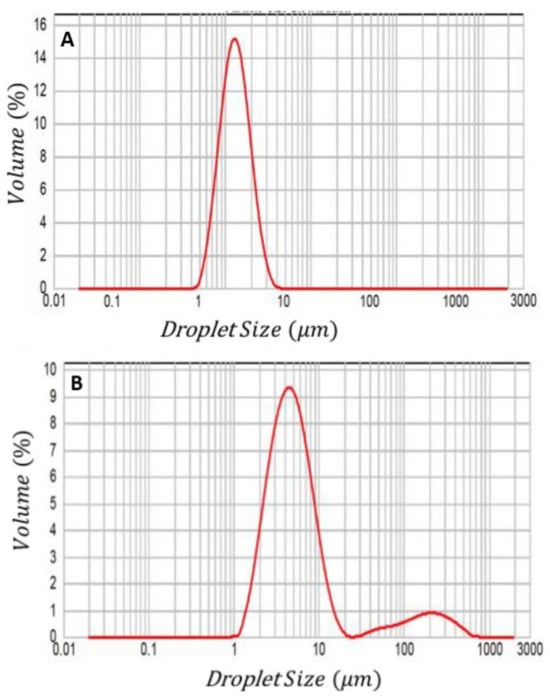

The results from droplet size analysis are typically depicted on histograms (Figure 9). In the case of stable emulsions (Figure 9A), the histogram shows one peak, which represents a population of small droplets that are relatively uniform in size. Droplet sizes remain within a relatively narrow range (1–10 μm). In contrast, in unstable emulsion separating through coalescence (Figure 9B), two populations of droplets, small and large (represented by two peaks on the histogram) are present at the same time. In addition, the uniformity of the droplet size decreases, which is clearly visible on the histogram as the widening of both peaks, corresponding to the range of droplet sizes becoming wider.

Figure 9.

Histograms showing droplet size distribution in stable emulsion (A) and unstable emulsion separating through coalescence (B). Adapted with permission from [66]. Copyright © 2023 Springer Nature.

The polydispersity index serves as a crucial indicator of emulsion stability, as it directly correlates with the uniformity of droplet sizes. A lower PDI value indicates a more uniform distribution of droplet sizes and higher emulsion stability, whereas an increase in PDI reflects destabilization of the emulsion leading to high variation in droplet size. In emulsions where coalescence and flocculation occur, the droplet size varies widely, leading to a higher PDI. Tracking changes in emulsion PDI over time can provide valuable insights into the emulsion’s performance and stability under different manufacturing, processing, and storage conditions.

Although DLS is capable of measuring droplets with sizes down to 3 nm, its reliability in assessing polydisperse samples may be significantly compromised [98,99,100]. This results from the fact that the light scattering intensity fluctuation detected by DLS is theoretically linked to the sixth power of the droplet size According to manufacturers of DLS instruments, a sample is considered monodisperse if its polydispersity index (PDI) is below 0.1, moderately polydisperse within the range of 0.1–0.4, and polydisperse if the PDI exceeds 0.4. When the polydispersity index (PDI) in DLS is elevated, and the direct method indicates a non-normal particle size distribution, the reliability of particle size measurements is significantly diminished. Under such circumstances, it becomes feasible to conduct high-resolution liquid sample measurements using a combination of Multi-Angle Light Scattering (MALS) and DLS with size-exclusion chromatography (SEC) or field flow fractionation (FFF) [101,102]. However, these measurements rely on the assumption that the separation process does not impact the particles of interest. As will be discussed later, FFF necessitates intricate measurement conditions, and particles may potentially interact with the membrane or channel walls.

Some particle size analyzers have the capability of performing automatic analysis of emulsion stability over time [97]. An example of such an instrument is the Turbiscan®, which operates based on the principles of multiple light scattering and permits the assessment of phase separation phenomena, such as creaming or sedimentation [103,104]. The operation of this device relies on vertical scanning of the emulsion, enabling the real-time detection of changes in backscattering (BS) and transmission (T) intensities over time. During static multiple light scattering, a light source with a wavelength of 850 nm is directed onto the emulsion sample, and both backscattering and transmission signals are collected [105]. The acquired signals are associated with droplet concentration and size, as described by the Mie theory [106]. By repeatedly performing these measurements with a suitable frequency, the instrument allows for the continuous monitoring of physical stability, which provides insight into the development of emulsion instabilities.

Despite being some of the most fundamental tools for emulsion characterization and stability assessment, particle size analyzers relying on dynamic light scattering have significant shortcomings. The first is reduced accuracy of measurement at high droplet concentrations, resulting from the occurrence of multiple scattering effects. Multiple scattering is a common problem that causes overestimation of droplet size. As a result, emulsion samples with high droplet concentrations need to be diluted before measurement [21]. However, dilution of emulsions may induce destabilization processes, including flocculation and coalescence, which in turn makes the results unreflective of the original sample.

Furthermore, the calculation of droplet size in these devices is most often based on the assumption that the shape of the droplets is spherical, which in real-life samples may not often be the case. For emulsions containing droplets deviating in shape from the sphere, this assumption may lead to significant under- or overestimation of droplet size. Numerous studies have shown that there are significant discrepancies between data obtained from DLS and microscopic analysis. For instance, Preetz et al. [107] demonstrated that, despite DLS data collected over months of emulsion monitoring indicating excellent emulsion stability, a microscopic analysis of the same sample showed substantial changes in its internal structure. The authors observed that, while the average size of the droplets determined by DLS was 150 nm, droplet size established based on freeze-fracture TEM and confirmed by AFM varied between 50 and 500 nm, with the majority of the droplets measuring around 100 nm. These and similar findings from other studies indicate that DLS data needs to be confirmed by additional analytical methods, including microscopic analysis, field-flow fractionation [108], nuclear magnetic resonance spectroscopy [109], or Fourier transform infrared spectroscopy [110].

Another group of particle size analyzers frequently used for emulsion characterization are devices that utilize electrical pulse counting. The electrical pulse counting is performed in setups comprising a glass tube with two electrodes and a small hole, through which the emulsion sample is drawn. Electrical pulse counting methods rely on the measurement of variations in the electrical conductivity of the sample caused by the passing of the emulsion droplets between two electrodes [111]. Since oils have much lower electrical conductivity than water, droplets passing between the electrodes affect the electrical current flowing through the emulsion, creating electrical pulses. Droplet size is determined based on the assumption that larger particles move more slowly and create larger electrical pulses.

This technique is appropriate for measuring droplets ranging in diameter from 0.4 μm to 1200 μm [28]. The measurement is constrained by the size of the hole in the glass tube, which requires adjustments to accommodate a wide range of droplet sizes. Additionally, similarly to the methods using light scattering, emulsion samples need to be diluted before measurement. High concentrations of droplets in the sample hinder the smooth passage of single droplets into the glass tube. Therefore, while suitable for droplet size analysis, this method is not ideal for studying the flocculation process, as dilution can disrupt the gathered droplets and result in misinterpretation of data on emulsion stability.

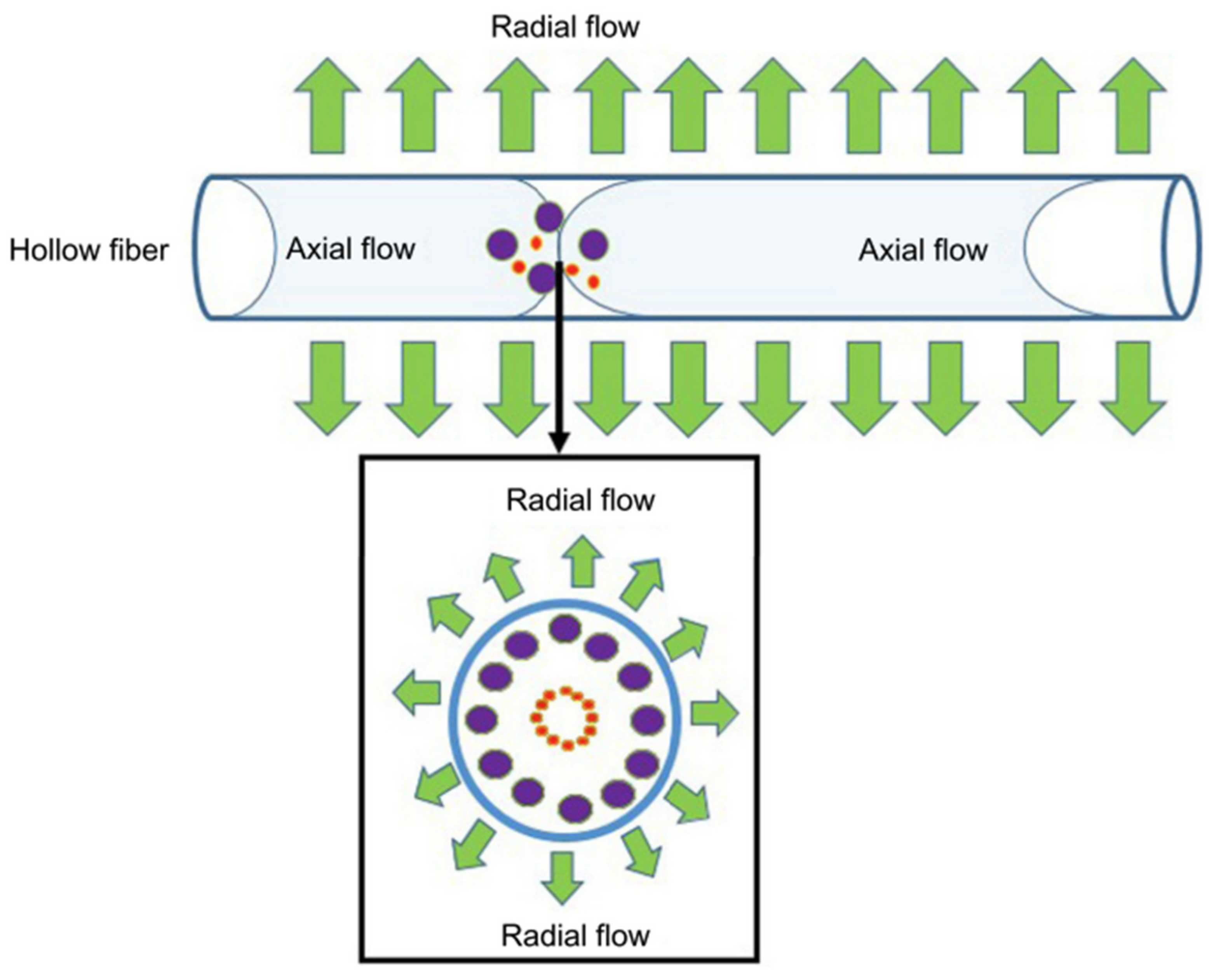

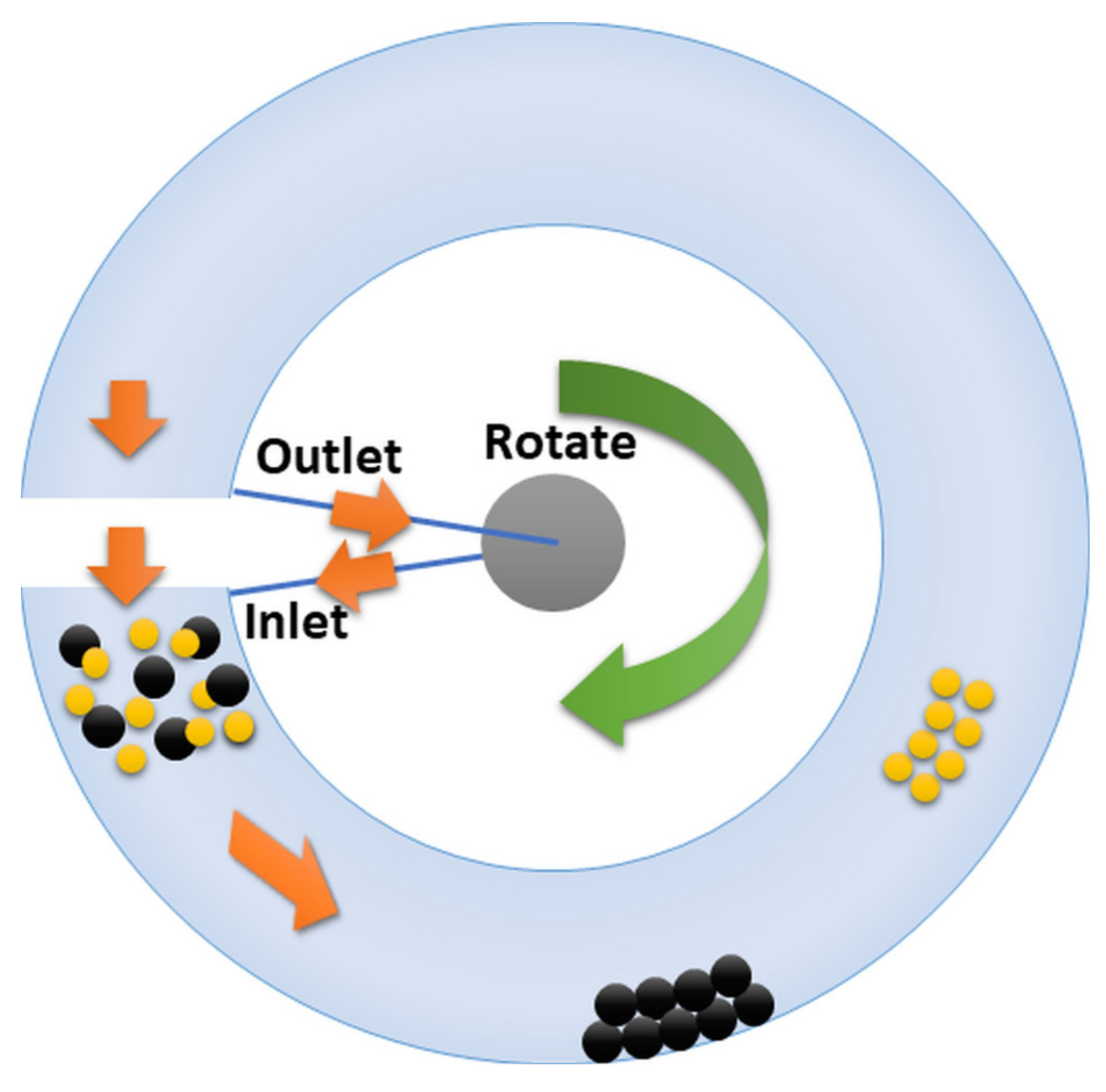

A method enabling the determination of droplet size in emulsions with high droplet concentrations (up to 50%) without dilution is ultrasonic spectrometry [112]. This technique estimates emulsion droplet size and concentration based on the scattering of the ultrasound waves transmitted through the emulsion. Scattering of the ultrasound waves by the droplets leads to a decrease in velocity and an increase in attenuation of the frequency of ultrasonic waves. Ultrasonic spectroscopy can be used to determine droplet sizes ranging from 10 nm to 1000 μm. Its major advantage over other particle size analyzers lies in its ability to characterize not only concentrated but also optically opaque emulsions.

3.3. Determination of Emulsion Optical Properties

Since many applications require that emulsions are optically clear (e.g., eye drop formulations), transparency is an important parameter considered at the product development stage. Optical properties of emulsions, such as transparency, opacity, turbidity, and color, depend on the degree of absorption and scattering of light passing through the sample [41]. The changes in optical properties can be visually observed or quantitatively measured using colorimeters, refractometers, and UV–vis spectrophotometers.

Colorimeters quantify parameters, such as brightness, hue, and saturation, to measure the color and appearance of emulsions, while spectrophotometers measure the absorption and reflection of light by emulsions across a wide range of wavelengths. Spectrophotometers record the emulsion absorbance spectra by detecting the amount of light absorbed while passing through a sample. Refractometers are used to measure the refractive index of emulsions. During measurement, a drop of emulsion is placed onto a slide and introduced into a refractometer. The refractive index describes how fast light travels through the analyzed sample and is expressed as the ratio of the speed of light in a vacuum and the phase velocity of light in the assessed medium. The calculated value is compared to the refractive index of the reference medium, e.g., distilled water, which is considered the most transmittable liquid. If the refractive index of the emulsion is equal to or close to that of water (1.333), the emulsion is considered transparent [67,113].

Analysis of optical properties is non-destructive and can provide real-time monitoring of emulsion stability, making it a valuable tool in quality control and product development. As the appearance of emulsions is strongly influenced by droplet concentration, size, and distribution, measuring the optical properties of emulsions over time can provide valuable information on destabilization processes that may occur in the system [114]. For example, as the emulsion undergoes coalescence, the droplet size distribution changes, leading to alterations in the overall appearance of the emulsion. As larger droplets form due to coalescence, the emulsion becomes less transparent, more opaque, and turbid. Additionally, the color intensity may increase due to the merging of the droplets [77]. When flocculation occurs [115], the formation of flocs or droplet aggregates leads to increased light scattering and reduced transparency of the emulsion. This increase in light scattering contributes to the higher turbidity of the emulsion, making it appear cloudy or hazy. The color intensity of the emulsion may also change due to a different optical density or color of the flocs compared to the individual droplets. Similar changes can be observed when emulsion separates through Ostwald ripening. As Ostwald ripening progresses, the average droplet size in the emulsion increases, leading to changes in light scattering and absorption and a decrease in transparency.

3.4. Rheological Analysis of Emulsions

Investigating the rheological properties of emulsions provides insight into their behavior and stability. The complex interplay between stability and time-dependent changes in the rheological properties of emulsions influences their quality and functionality in various applications [116]. Understanding the thixotropic behavior, viscoelastic properties, and shear thinning behavior of emulsions is essential for product formulation and development, achieving the desired functional attributes, and optimizing emulsion performance at different stages of manufacturing, processing, packing, and storage. Characterization of the rheological properties of emulsions plays a fundamental role in predicting their response to external conditions, such as pressure, temperature, centrifugal force, applied to emulsions during technological operations, such as mixing, pumping, pouring, leveling, etc. [117]. Furthermore, the rheological properties of emulsions allow for monitoring their stability over time, which directly translates to their shelf-life. Quantitative analysis of emulsion rheological properties provides also important information about their visual and sensory properties, such as appearance, texture, creaminess, consistency, and mouthfeel [118], which strongly influence the acceptance of commercial formulations by consumers and their preferences when choosing products.

Rheological analysis of emulsions aims to determine the deformation and flow properties of emulsions under different conditions. The key parameters that determine the rheology of emulsions are the chemical composition and rheological properties of the continuous and dispersed phases, phase volume ratio, the structure of the emulsion including droplet size, concentration and distribution, droplet characteristics, such as deformability, internal viscosity, and inter-droplet interactions (e.g., steric interactions, electrostatic repulsion, and van der Waals attraction) [44], elasticity and composition of the interfacial layer (including concentration and type of the emulsifier), as well other colloidal interactions within the emulsion system.

Emulsions vary greatly in terms of their rheological properties, from low-viscosity Newtonian liquids such as milk, through non-Newtonian, shear-thinning liquids that become less viscous under shear stress [119], to shear-thickening formulations, whose viscosity increases under shear stress, such as salad dressings, mayonnaise or creams. Flow curves offer important insights into the rheological behavior of emulsions. They depict the correlation between shear stress and shear rate, aiding in comprehending the flow characteristics of emulsions and defining their viscosity and shear thinning behavior. Therefore, flow curves can indicate whether the emulsion displays Newtonian or non-Newtonian behavior, Additionally, flow curves help define emulsion resistance to flow, showcasing its capability to maintain structure under varying shear conditions, which is essential for establishing suitable processing conditions [119].

The rheological properties of emulsions are largely dependent on the nature and characteristics of the continuous phase, including its chemical composition, pH, and viscosity [120]. The viscosity of the continuous phase has a major impact on the gravitational separation of the emulsion [121]. For example, a more viscous continuous phase can hinder droplet movement, thereby inhibiting the creaming or sedimentation processes [88]. At the same time, lower mobility of the droplets may promote flocculation or coalescence, leading to increased instability of the emulsion.

The rheological properties of emulsions can be altered by adding polymers or hydrocolloids, such as thickeners and texture modifiers (e.g., pectin, modified cellulose, gum arabic, corn fiber gum, modified starch, polysaccharide-protein complexes, etc.) [122]. Due to their high molecular weight, they exhibit a thickening effect and create a network that enhances emulsion stability by increasing its viscosity and the thickness of interfacial film [123]. As a result, hydrocolloid-stabilized emulsions display improved long-term stability compared to emulsions stabilized with proteins and small molecule surfactants [124]. Texture modifiers also improve the textural and functional attributes of the emulsion, such as gelation mechanism, gel strength, and fracture properties.

Other parameters that significantly impact the rheological behavior of emulsions include the concentration of the dispersed phase, the size, and distribution of the dispersed droplets, as well as the presence of solid particles [125]. At higher volume ratios, emulsions typically exhibit non-Newtonian behavior. Smaller droplets tend to decrease the viscosity of emulsions due to reduced interfacial area and improved packing efficiency. The reduction in viscosity is attributed to the decreased resistance to flow exhibited by the smaller droplets. Conversely, larger droplets lead to increased viscosity due to enhanced droplet interactions and a higher dispersed phase volume. The interactions between larger droplets result in higher resistance to flow, thus increasing the viscosity of the emulsion [126]. Furthermore, the presence of solid particles in particle-stabilized emulsions, also known as Pickering emulsions, such as colloidal particles or nanoparticles, can significantly alter the rheology of the emulsion, influencing its flow behavior and overall texture. These particles can act as fillers or thickeners, contributing to increased emulsion viscosity and improved stability.

The rheology of emulsions is also strongly related to the structure, thickness, and elasticity of the adsorption layer at the interface between the dispersed and the continuous phase. The properties of the interface influence droplet size distribution, coalescence, and flocculation [37]. The interface layer shields the internal liquid from velocity gradients across the continuous phase. A thick and elastic interfacial layer creates strong steric hindrance, which is key for the stability of the emulsion [88]. Studies comparing the thickness of the interfacial films in emulsions stabilized by different types of surfactants revealed that the thickest interfacial layers are formed by hydrocolloids and solid particles (10 nm to several mm and 5–10 nm, respectively) followed by proteins (1–5 nm), while the thinnest layers are generated by low molecular weight surfactants (0.5–1 nm) [123]. Moreover, emulsions stabilized by multilayer adsorption films exhibit greater stability due to higher thickness compared to single-layer films [127]. The interfacial layer thickness is linked also to the concentration of the emulsifying agent. In general, at higher emulsifier concentrations, the adsorption layer at the interface becomes thicker and more rigid, leading to increased viscosity and elastic behavior of the emulsion.

Another crucial aspect affecting emulsion rheological behavior and stability is the elasticity of the interfacial layer. More elastic interfacial films prevent the aggregation and coalescence of the droplets, resulting in improved long-term stability of the emulsion [128]. On the other hand, a less elastic interfacial layer may intensify droplet coalescence and flocculation, thus reducing stability and increasing the viscosity of the emulsion. Higher elasticity of the adsorption layer contributes also to the viscoelastic behavior of emulsions. A more elastic adsorption layer can give the emulsion viscoelastic properties, such as shear-thinning. Conversely, if the relative rigidity of the interface is high, the rheological behavior of the emulsion may mimic a dispersion of solid particles [129].

The flow properties of emulsions can be divided into linear and non-linear [119]. The linear viscoelastic properties are measured within the range of stress, strain, and shear rates, in which the measured properties depend only on frequency and time (as well as temperature and pressure). These properties include the frequency-dependent storage and loss moduli, G’ and G”, the various combinations of these such as complex modulus G*, the phase lag, and the time-dependent creep compliance. The storage modulus G’ serves as an indicator of the elastic component within the viscoelastic behavior, effectively capturing the solid-state characteristics of the sample. In contrast, the loss modulus as G”, delineates the viscous component of the viscoelastic behavior, reflective of the liquid-state properties of the sample. G’ symbolizes the stored deformation energy, while G” characterizes the deformation energy lost (dissipated) through internal friction when flowing. Viscoelastic solids with G’ > G” have a higher storage modulus than loss modulus, whereas viscoelastic liquids with G” > G’ have a higher loss modulus than storage modulus. While, typically, these properties may not apply to high-stress technical applications, they are valuable for evaluating the microstructure and stability of emulsions [119].

The non-linear characteristics of emulsions include properties that are influenced by the applied stress, strain, or shear rate. These properties include the non-linear variations of the moduli and compliances, mentioned above, and viscosity. Viscosity is one of the most basic parameters describing the rheological properties of emulsions, which enables distinction between whether the analyzed sample is a classic (O/W) emulsion or reverse (W/O) emulsion. In general, low viscosity indicates O/W emulsion, while high viscosity indicates W/O emulsion [113].

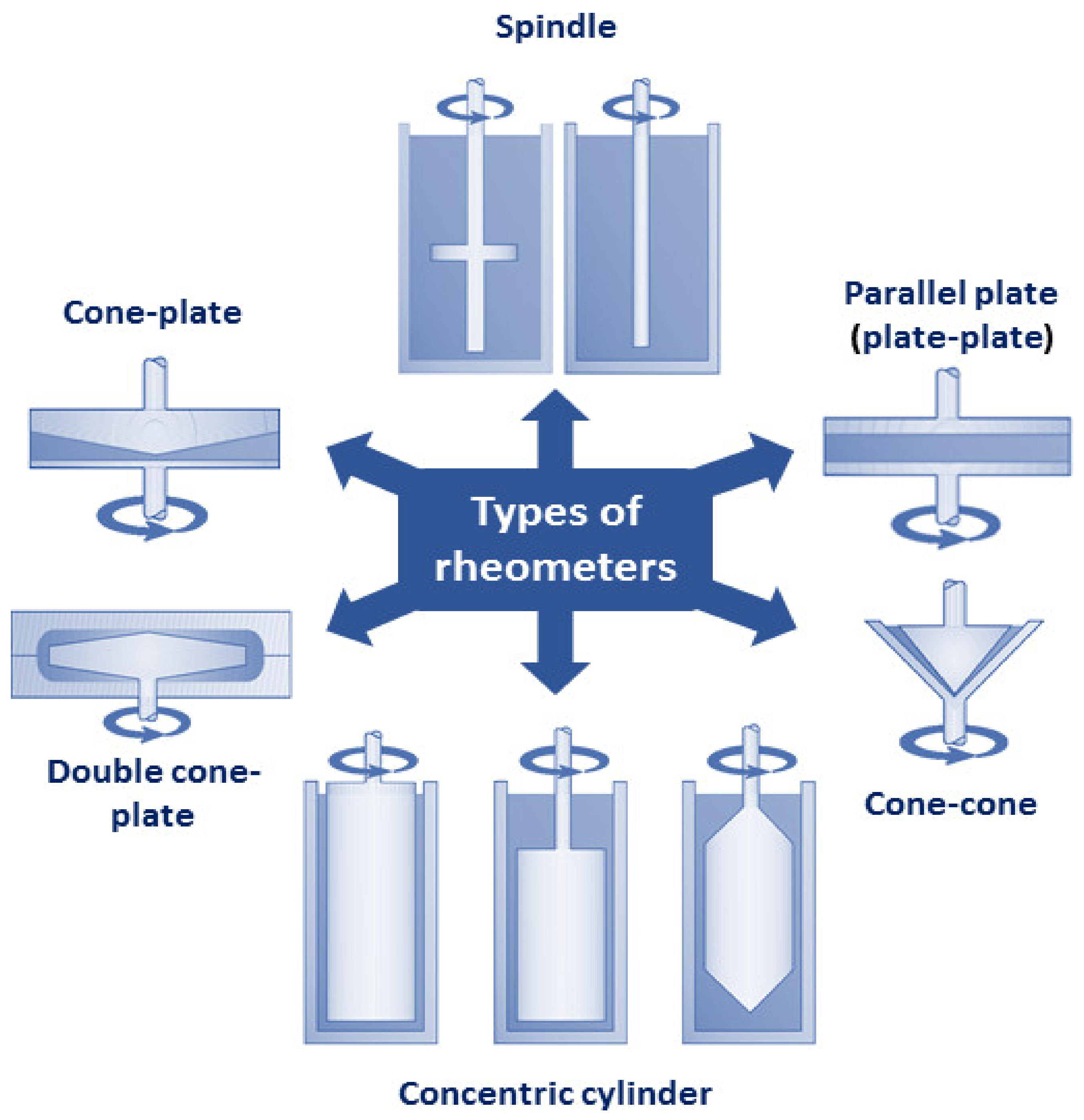

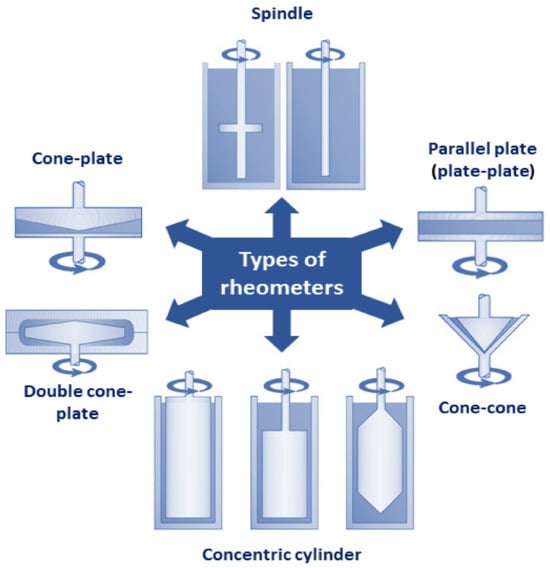

The viscosity of emulsions can be measured with various types of viscometers, such as capillary, rotational, falling-ball, oscillatory, torque, and interfacial viscometers [33]. Based on the geometry of the measurement cell, rheometers can be divided into several categories including spindle, concentric cylinder, parallel plate (plate-plate), cone–cone, cone–plate, and vane spindle apparatuses, depicted in Figure 10 [129]. Dynamic shear rheometers, such as the Brookfield rotational rheometer, are the most frequently used devices for simple single-speed viscosity measurements of emulsions. This type of viscometer applies shearing deformation force and measures viscosity based on the torque required to rotate a spindle immersed in the fluid, which increases proportionally to the viscosity of the analyzed sample.

Figure 10.

Classification of rheometers based on geometry of measurement cell: spindle, concentric cylinder, parallel plate (plate–plate), cone–cone, cone–plate, double cone–plate.

However, single-speed viscosity measurements are not sufficient to characterize the rheology of emulsions, the majority of which are complex non-Newtonian liquids, whose viscosity decreases as the applied shear rate increases or vice versa. As a result, emulsions require a much more thorough rheological analysis, including a comprehensive assessment of their oscillatory shear behavior. Oscillatory shear tests involve subjecting emulsions to alternating shear stresses to study their responses under dynamic conditions [130]. This type of analysis provides valuable insights into the viscoelastic behavior of emulsions, including their ability to deform and flow under various stress conditions.

Dynamic oscillatory shear tests involve subjecting a material to sinusoidal deformation and measuring the resulting mechanical response over time. Most emulsions, when subjected to shear stress, display rheological properties characteristic of both fluids and solids [118]. As a result, during oscillatory shear tests, emulsions typically exhibit a range of dynamic responses, such as elastic (storage) and viscous (loss) moduli, phase shifts, and shear thinning behavior [131]. The elastic modulus represents the stored energy in the emulsion, reflecting its ability to recover after deformation, while the viscous modulus characterizes the energy dissipation and flow resistance. These moduli are crucial in understanding the stability and texture of emulsions, especially in applications where elastic or viscous properties are essential. The phase shift between stress and strain in oscillatory shear tests provides information about the nature of the interactions within the emulsions, such as droplet collisions, interfacial interactions, and structural rearrangements. Understanding these phase shifts helps predict the stability and structural changes of emulsions under different processing and storage conditions. Oscillatory shear behavior can reveal shear-thinning properties in emulsions, where the viscosity decreases under increasing stress amplitudes. This shear sensitivity is vital in industrial applications, such as food and pharmaceutical processing, as it affects the pourability, spreadability, and mouthfeel of emulsion-based products.

Across measurements of oscillatory shear behavior, we could underline the amplitude, frequency, or temperature sweep test. The amplitude sweep test can be performed by varying the oscillatory stress (e.g., in the range of 0.01–100 Pa) at a fixed frequency (e.g., 1 Hz). This measurement can show a linear viscoelastic region (LVR), in which G′ (storage modulus) and G” (viscous modulus) are almost constant and, later, a nonlinear region, in which G′ and G” start to change [132]. The oscillatory stress value, where G′ sharply decreases, is defined as the critical oscillatory stress, also known as the limiting value of oscillatory stress (OSL). Obtaining the OSL value is crucial, as it indicates the maximum deformation that a system can withstand without structural breakdown [133]. Here, we can investigate how the composition or processing of emulsions can impact their strength and rigidity during storage at a defined time, temperature, or other conditions of our choice.

During the frequency sweep test, the viscous and elastic behavior of emulsions can be monitored [133]. During storage, we can test the emulsions within a defined experimental frequency range (e.g., 0.01–10 Hz) and observe if the samples display gel-like behavior, resembling a solid rather than a liquid, or the other way around. Deformation can be interpreted as elastic and recoverable. In order to determine the frequency dependence of the G’ parameter (n’), we can apply a power-law relation. Parameter n’ close to 1 indicates that the system behaves as a viscous gel, whereas a low n’ parameter shows characteristics of elastic gels. To determine the sensitivity of the sample structure to thermal changes, a temperature sweep test can be conducted. In this test, we can observe the changes in the elastic behavior of the emulsion with a temperature increase, such as melting or transformation of the liquid state into a gel state (sol-gel transition), which can be related to the composition of the emulsifier [134,135].

To accurately reflect the rheological behavior of emulsions, their rheological properties should be measured under conditions mimicking real-life environments in terms of temperature, pressure, mechanical stress, shear rate, etc. For example, the assessment of emulsion long-term stability should be performed under creeping flow conditions that simulate storage environments. Creeping flow (also known as Stokes flow) is defined as a non-turbulent flow, in which fluid flow velocity is very low and the Reynolds number is below 1 [136]. Under such conditions, inertial effects are negligible, while the dominant role is played by the viscous forces and viscous resistance.

The viscosity of emulsions stored under creeping flow conditions, at some point, reaches a plateau known as zero-shear viscosity. Zero-shear viscosity describes the mobility of the droplets or droplet flocs/aggregates within the emulsion. An emulsion with a high zero-shear viscosity exhibits low droplet movement, which translates to a limited incidence of interactions between droplets that may lead to coalescence and reduced separation processes. Therefore, a formulation based on such emulsion would be expected to display a prolonged shelf-life.

Zero-shear viscosity of emulsions may be approximated based on Stokes’ Law by calculating the terminal velocity of a droplet (v) moving through the viscous continuous phase. The terminal droplet velocity v is related to the drag force (Fd) acting on the droplet on the interface between the continuous and the dispersed phase (also known as frictional force or Stokes’ drag), continuous phase viscosity (μ), and droplet radius (R), as given in Equation (1):

According to Stoke’s law, the resistance of the emulsion to instabilities caused by droplet flocculation becomes higher as its viscosity increases [37]. Nevertheless, the application of the Stokes equation to real-life emulsions is limited, as it assumes no interactions between droplets moving through the fluid.

Fd = 6πµRv

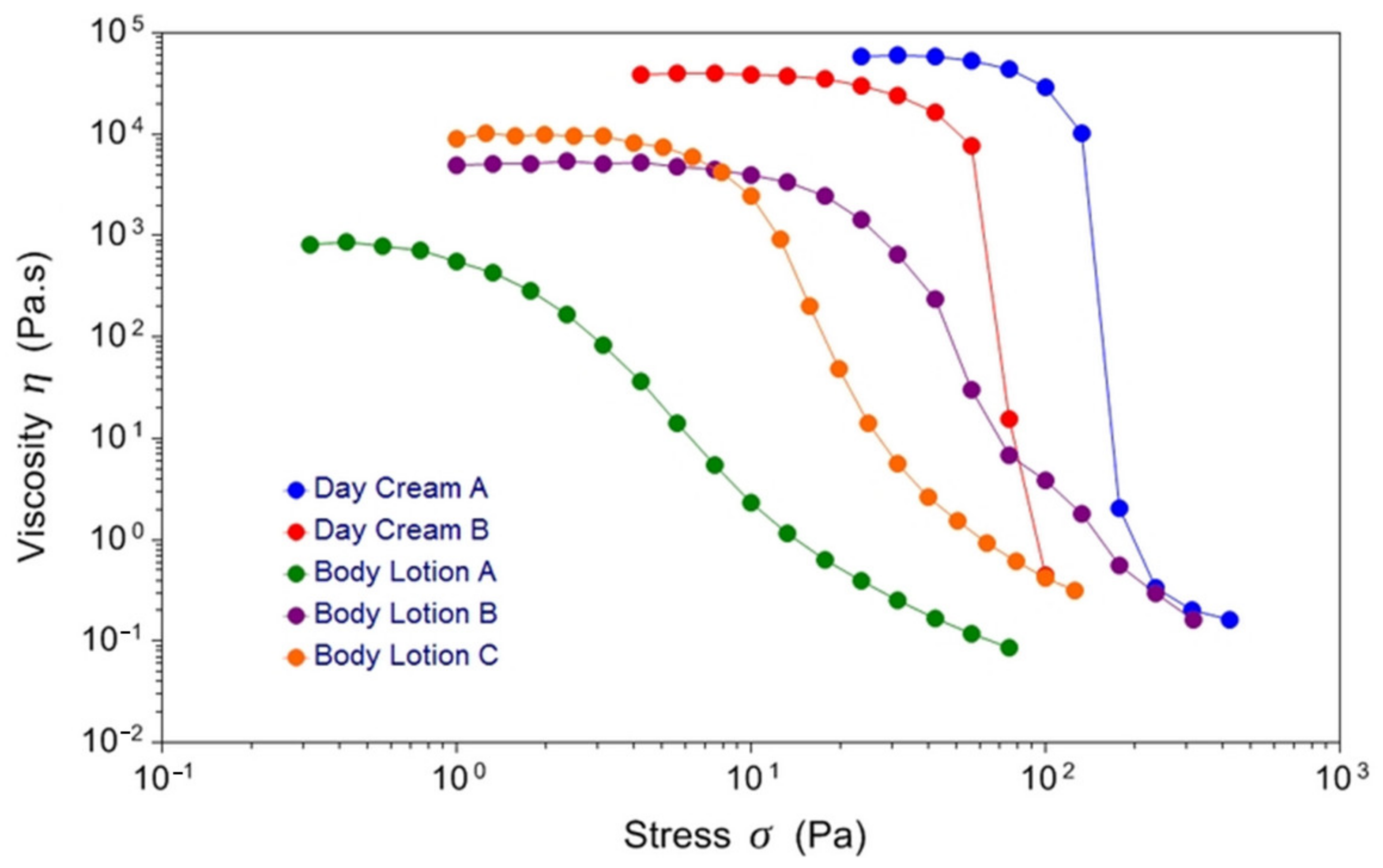

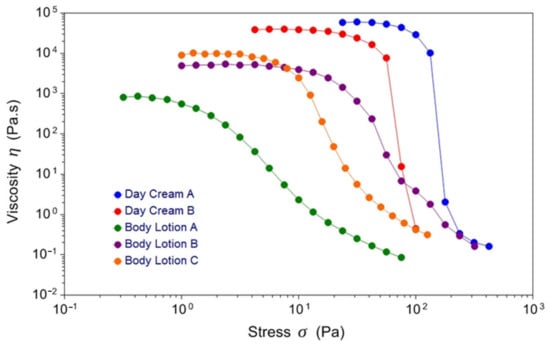

The more accurate method to establish emulsion zero-shear viscosity is based on the experimental determination of changes in emulsion viscosity under different levels of shear stress. In this approach, the range of zero-shear stress viscosity is identified based on the curve depicting the correlation between viscosity and shear stress obtained by fitting a set of experimental data. For instance, Figure 11 shows the effect of shear stress on the viscosity of five cosmetic emulsions. Body Lotion A demonstrates a zero-shear viscosity plateau of around 103 Pa·s (1 million centiPoise), whereas Day Cream A exhibits zero-shear viscosity at approximately 7 × 104 Pa·s (70 million centiPoise). This implies that lotion A has around 70 times higher droplet mobility than cream A, which may contribute to its substantially shorter shelf-life.

Figure 11.

Rheological behavior of five cosmetic emulsions. Reprinted with permission from [137]. Copyright © 1999–2023 John Wiley and Sons, Inc.

The rheological properties of emulsions are strongly related to their stability. Depending on the nature and mechanism of destabilization processes occurring in the system, emulsion rheology can be affected in numerous ways. Separation of the emulsion through flocculation tends to increase its relative viscosity due to the entrapment of liquid within droplet flocs, and an increase in floc volume fraction compared to single droplets. On the other hand, coalescence and Ostwald ripening may reduce the relative viscosity, especially in high-volume fraction emulsions. Phase inversion leads to a substantial decrease in emulsion viscosity due to the drastically reduced volume of the dispersed phase after inversion. The reduction results from the fact that the volume of the continuous phase (which becomes the dispersed phase after the inversion) is typically lower than the volume of the dispersed phase. However, correlating rheological parameters to emulsion breakdown phenomena has been challenging due to the complexity and overlapping timing of multiple separation processes. Therefore, changes in the rheological behavior of emulsions may not directly relate to stability. As a result, rheological analysis alone cannot provide a reliable prediction of long-term emulsion stability.