Computer-Aided Analysis of the Formation of the Deformation Zone in the Burnishing Process

Abstract

1. Introduction

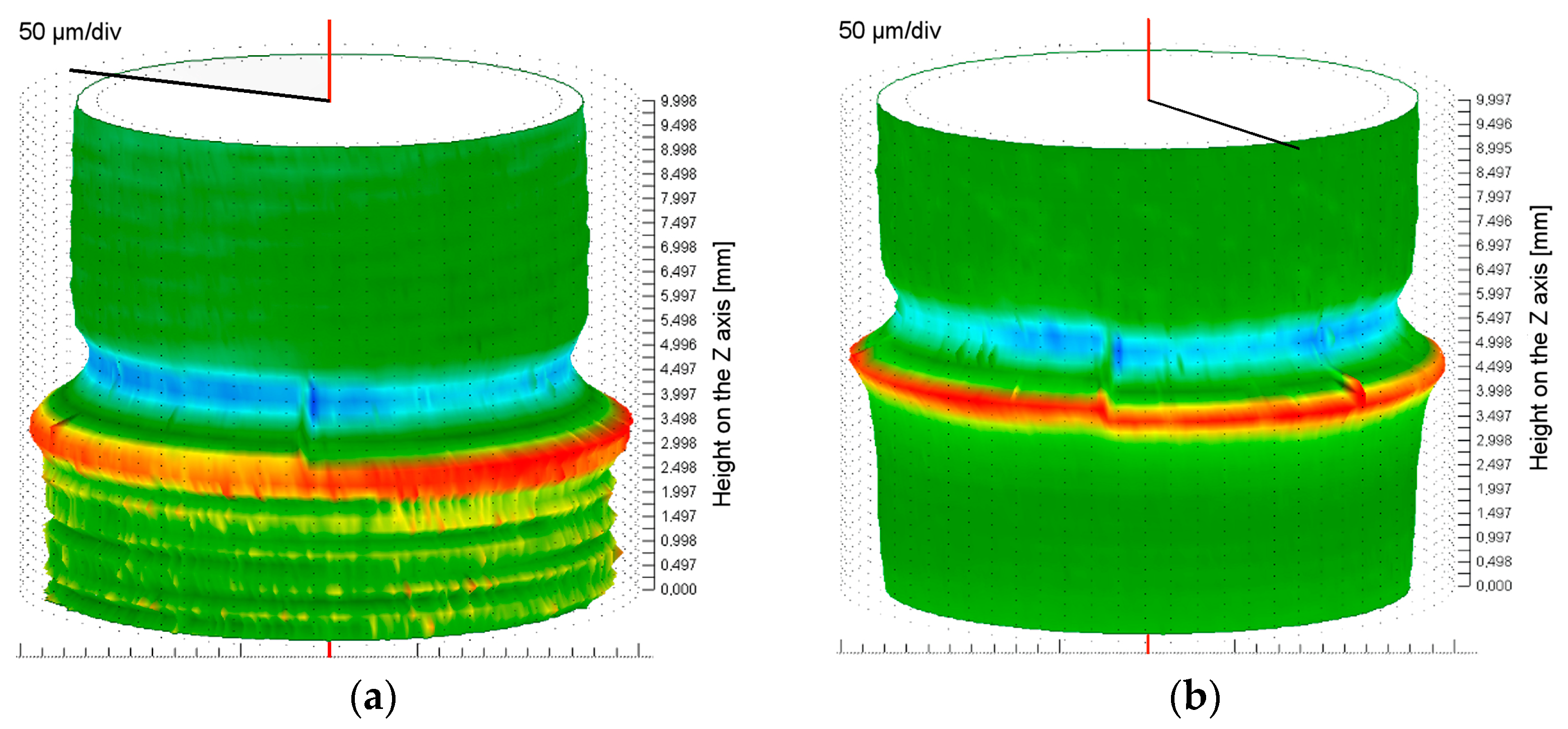

2. Analysis of the Stereometry of the Deformation Zone

- hf/hv: deformation wave height,

- hfo/hvo: tool cavity height relative to the surface of the raw material,

- L1/L2: initial deformation wavelength,

- a = a1 + a2/b = b1 + b2: length and width of the deformation centre,

- Lf/Lv: length and width of the deformation wave.Additionally, the parameters describing forces, geometry and roughness were used:

- F—burnishing force [kN],

- R—radius of the ball-shaped tools [mm],

- Rk—radius of the disc-shaped tools [mm],

- fturn—feed used in turning [mm/rev],

- fburn—feed used in burnishing process [mm/rev],

- Sa—parameter, similar to Ra, characterizing the stereometric profile [µm]. The arithmetic averages of roughness from the average plane within the sampling area—the elementary square,

- Sz—parameter, similar to Rz, characterizing the stereometric profile [µm]. The ten-point height of the surface irregularities—the average value of the absolute heights of the five highest peaks and the five lowest depressions within the sampling area—the elementary square.

3. Three-Dimensional Deformation Zone Imaging

4. The Use of a Digital Microscope to Examine the Deformation Area

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Przybylski, W. Low Plasticity Burnishing Processes: Fundamentals, Tools and Machine Tools; Institute for Sustainable Technologies, National Research Institute in Radom: Radom, Poland, 2019. [Google Scholar]

- Korzyński, M. Sliding Burnishing; WNT: Warsaw, Poland, 2007. [Google Scholar]

- Tubielewicz, K. Analysis of Stresses Arising in the Surface Layer during the Burnishing Process; Wydawnictwo Politechniki Częstochowskiej: Częstochowa, Poland, 1993. [Google Scholar]

- Tubielewicz, K. Analysis of Phenomena Accompanying the Deformation of the Surface Layer in the Burnishing Proces; Seria Monografie nr 13; Wydawnictwo Politechniki Częstochowskiej: Częstochowa, Poland, 1990. [Google Scholar]

- Balland, P.; Tabourot, L.; Degre, F.; Moreau, V. Mechanics of the burnishing process. Precis. Eng. 2013, 37, 129–134. [Google Scholar] [CrossRef]

- Hassan, A.M.; Al-Bsharat, A.S. Influence of burnishing process on surface roughness, hardness, and microstructure of some non-ferrous metals. Wear 1996, 199, 1–8. [Google Scholar] [CrossRef]

- Malleswara Rao, J.N.; Chenna Kesava Reddy, A.; Rama Rao, P.V. The effect of roller burnishing on surface hardness and surface roughness on mild steel specimens. Int. J. Appl. Eng. Res. 2011, 1, 777–785. [Google Scholar]

- Raza, A.; Kumar, S. A critical review of tool design in burnishing process. Tribol. Int. 2022, 174, 107717. [Google Scholar] [CrossRef]

- Kułakowska, A.; Kukiełka, L. Numerical analysis of the influence of deviations of the surface roughness outline after turning on selected properties of the surface layer of a burnished product. In Współczesne Problemy w Technologii Obróbki przez Nagniatanie; Praca Zbiorowa pod Redakcją Włodzimierza Przybylskiego; Wydawnictwo Politechniki Gdańskiej: Gdańsk Poland, 2008; Volume 2, pp. 127–134. [Google Scholar]

- Zaleski, K.; Skoczylas, A. Effect of slide burnishing on the surface layer and fatigue life of titanium alloy parts. Adv. Mater. Sci. 2019, 19, 35–45. [Google Scholar] [CrossRef]

- Grzesik, W.; Żak, K. Modification of surface finish produced by hard turning using superfinishing and burnishing operations. J. Mater. Process. Technol. 2012, 212, 315–322. [Google Scholar] [CrossRef]

- Korzyński, M. Modeling and experimental validation of the force-surface roughness relation for smoothing burnishing with a spherical tool. Int. J. Mach. Tools Manuf. 2007, 47, 1956–1964. [Google Scholar] [CrossRef]

- Korzyński, M.; Lubas, J.; Świrad, S.; Dudek, K. Surface layer characteristics due to slide diamond burnishing with a cylindrical-ended tool. J. Mater. Process. Technol. 2011, 211, 84–94. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wang, S.W.; Lai, H.Y. The relationship between surface roughness and burnishing factor in the burnishing process. Int. J. Adv. Manuf. Technol. 2004, 23, 666–671. [Google Scholar] [CrossRef]

- Sagbas, A. Analysis and optimization of surface roughness in the ball burnishing process using response surface methodology and desirabilty function. Adv. Eng. Softw. 2011, 42, 992–998. [Google Scholar] [CrossRef]

- Oliveira, D.A.; Martins, A.M.; Magalhaes, F.C.; Abrao, A.M. Characterization of the topography generated by low plasticity burnishing using advanced techniques. Surf. Coat. Technol. 2022, 448, 128891. [Google Scholar] [CrossRef]

- Swirad, S.; Wdowik, R. Determining the effect of ball burnishing parameters on surface roughness using the Taguchi method. Procedia Manuf. 2019, 34, 287–292. [Google Scholar] [CrossRef]

- Cagan, S.C.; Pruncu, C.I.; Buldum, B.B. An investigation into ball burnishing process of magnesium alloy on CNC lathe using different environments. J. Magnes. Alloys 2020, 8, 1061–1070. [Google Scholar] [CrossRef]

- Saldana-Robles, A.; Plascencia-Mora, H.; Aguilera-Gómez, E.; Saldana-Robles, A.; Marquez-Herrera, A.; Angel Diosdado-De la Pena, J.A. Influence of ball-burnishing on roughness, hardness and corrosion resistance of AISI 1045 steel. Surf. Coat. Technol. 2018, 339, 191–198. [Google Scholar] [CrossRef]

- El-Tayeb, N.S.M.; Low, K.O.; Brevern, P.V. Enhancement of surface quality and tribological properties using ball burnishing process. Mach. Sci. Technol. 2008, 12, 234–248. [Google Scholar] [CrossRef]

- El-Tayeb, N.S.M.; Low, K.O.; Brevern, P.V. Influence of roller burnishing contact width and burnishing orientation on surface quality and tribological behaviour of Aluminium 6061. J. Mater. Process. Technol. 2007, 186, 272–278. [Google Scholar] [CrossRef]

- El-Tayeb, N.S.M.; Low, K.O.; Brevern, P.V. On the surface and tribological characteristics of burnished cylindrical Al-6061. Tribol. Int. 2008, 42, 320–326. [Google Scholar] [CrossRef]

- Tubielewicz, K.; Zaborski, A. The course of the burnishing surface layer wear proces. Tribologia 2008, 4, 165–174. [Google Scholar]

- Zaborski, A.; Tubielewicz, K. Analysis of the wear course of the surface layer after burnishing. In Współczesne Problemy w Technologii Obróbki przez Nagniatanie; Praca Zbiorowa pod Redakcją Włodzimierza Przybylskiego; Wydawnictwo Politechniki Gdańskiej: Gdańsk, Poland, 2005; pp. 255–264. [Google Scholar]

- Zaborski, A. Analysis of the Wear Process of Surface Layers after Burnishing. Tribologia 2022, 1, 97–109. [Google Scholar] [CrossRef]

- Kovács, Z.F.; Viharos, Z.J.; Kodácsy, J. Determination of the working gap and optimal machining parameters for magnetic assisted ball burnishing. Measurement 2018, 118, 172–180. [Google Scholar] [CrossRef]

- Kovacs, Z.F.; Viharos, Z.J.; Kodacsy, J. Improvements of surface tribological properties by magnetic assisted ball burnishing. Surf. Coat. Technol. 2022, 437, 128317. [Google Scholar] [CrossRef]

- Kovacs, Z.F.; Viharos, Z.J.; Kodacsy, J. Surface flatness and roughness evolution after magnetic assisted ball burnishing of magnetizable and non-magnetizable materials. Measurement 2020, 158, 107750. [Google Scholar] [CrossRef]

- Frihat, M.H.; Al Quran, F.M.F.; Al-Odat, M.Q. Experimental Investigation of the Influence of Burnishing Parameters on Surface Roughness and Hardness of Brass Alloy. J. Mater. Sci. Eng. 2015, 5, 216. [Google Scholar]

- Saini, D.; Kapoor, M.; Jawalkar, C.S. Parametric Analysis of Mild steel specimens using roller burnishing process. Int. Ref. J. Eng. Sci. 2017, 6, 45–51. [Google Scholar]

- Dix, M.; Posdzich, M. Force-controlled burnishing process for high surface integrity on additive manufactured parts. Procedia CIRP 2022, 108, 642–647. [Google Scholar] [CrossRef]

- Zaborski, A. Analysis of Deformation Zone Formation in the Burnishing Proces; Seria Monografie nr 260; Wydawnictwo Politechniki Częstochowskiej: Częstochowa, Poland, 2013. [Google Scholar]

- Zaborski, A. Computer-aided measurement of geometrical parameters of the deformation zone in the burnishing proces. Mechanik 2019, 8–9, 548–550. [Google Scholar] [CrossRef]

- EN ISO 683-17:2015; Heat-Treated Steels, Alloy Steels and Free-Cutting Steels—Part 17: Ball and Roller Bearing Steels. ISO: Geneva, Switzerland, 2015. Available online: https://sklep.pkn.pl/pn-en-iso-683-17-2015-01e.html (accessed on 20 January 2024).

- Zaborski, A.; Winczek, J. Imaging and computer analysis in the shape error measurements and in the cylindrical object’s stereometry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 776, 012077. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| 0.52–0.60 | 0.60–0.90 | Max 0.40 | Max 0.045 | Max 0.045 | Max 0.40 | Max 0.40 | Max 0.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piotrowski, A.; Zaborski, A.; Tyliszczak, A. Computer-Aided Analysis of the Formation of the Deformation Zone in the Burnishing Process. Appl. Sci. 2024, 14, 1062. https://doi.org/10.3390/app14031062

Piotrowski A, Zaborski A, Tyliszczak A. Computer-Aided Analysis of the Formation of the Deformation Zone in the Burnishing Process. Applied Sciences. 2024; 14(3):1062. https://doi.org/10.3390/app14031062

Chicago/Turabian StylePiotrowski, Andrzej, Andrzej Zaborski, and Artur Tyliszczak. 2024. "Computer-Aided Analysis of the Formation of the Deformation Zone in the Burnishing Process" Applied Sciences 14, no. 3: 1062. https://doi.org/10.3390/app14031062

APA StylePiotrowski, A., Zaborski, A., & Tyliszczak, A. (2024). Computer-Aided Analysis of the Formation of the Deformation Zone in the Burnishing Process. Applied Sciences, 14(3), 1062. https://doi.org/10.3390/app14031062