Development and Application of Digital Twin Technique in Steel Structures

Abstract

1. Introduction

2. Literature Bibliometric Analysis

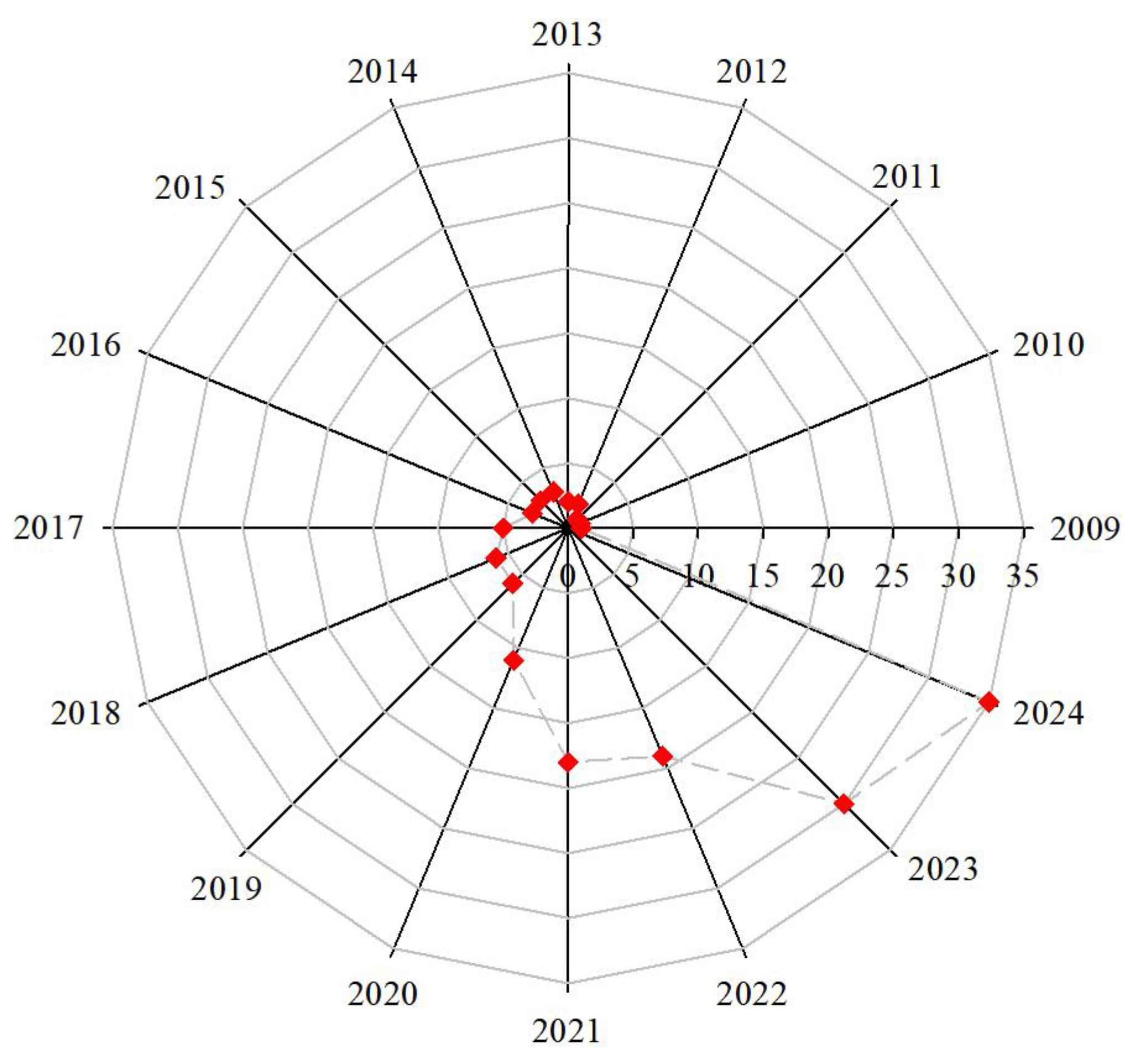

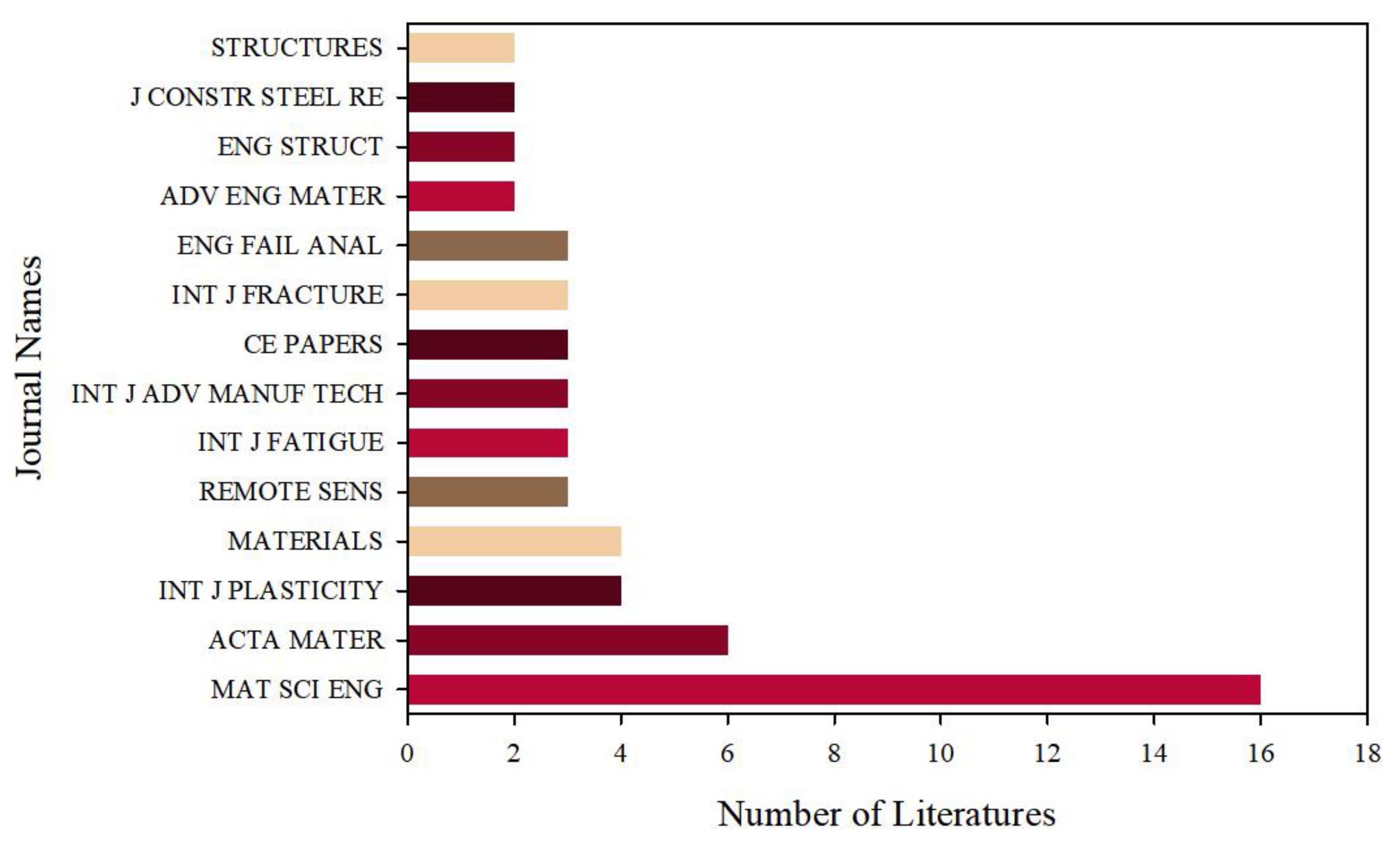

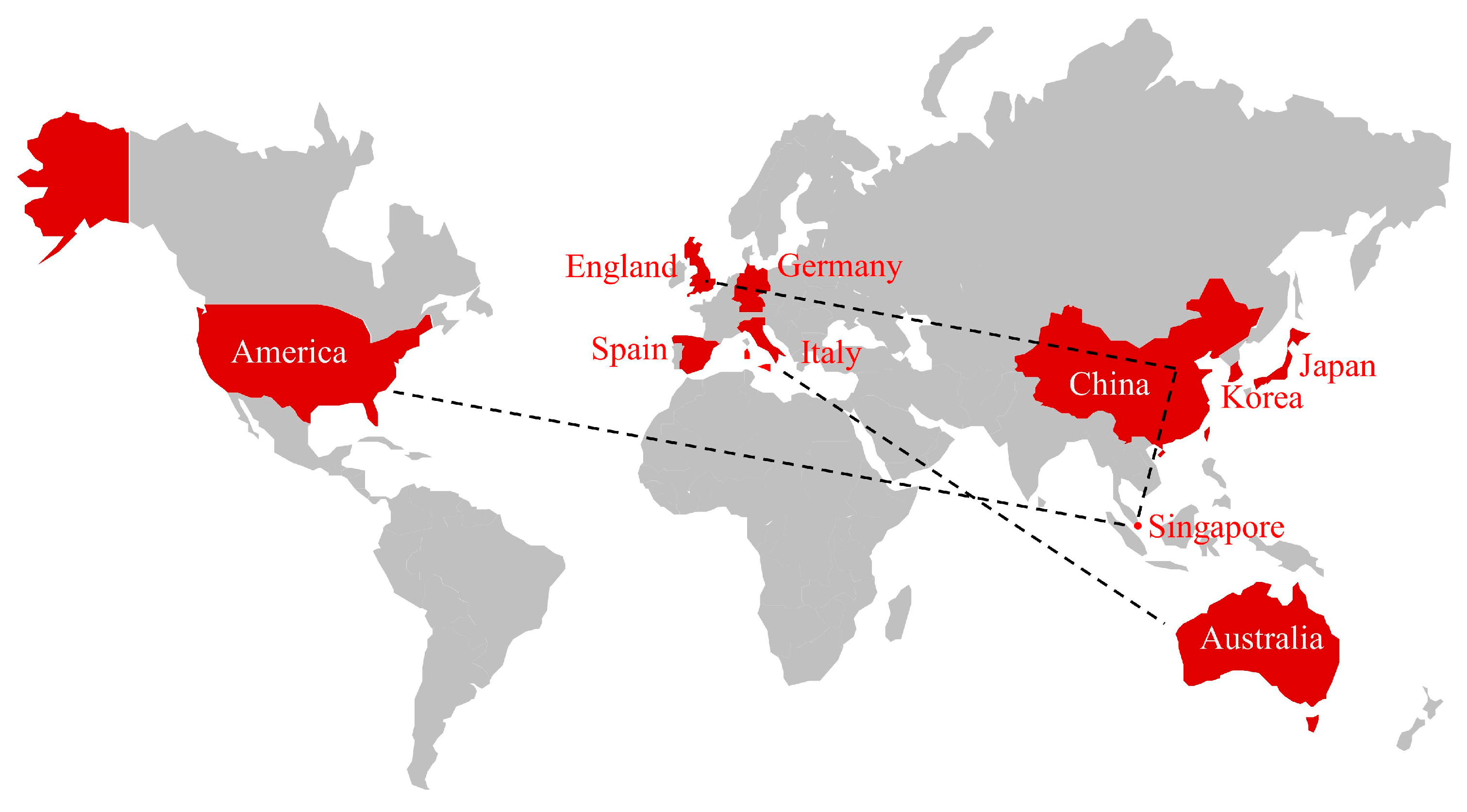

2.1. Publication Analysis

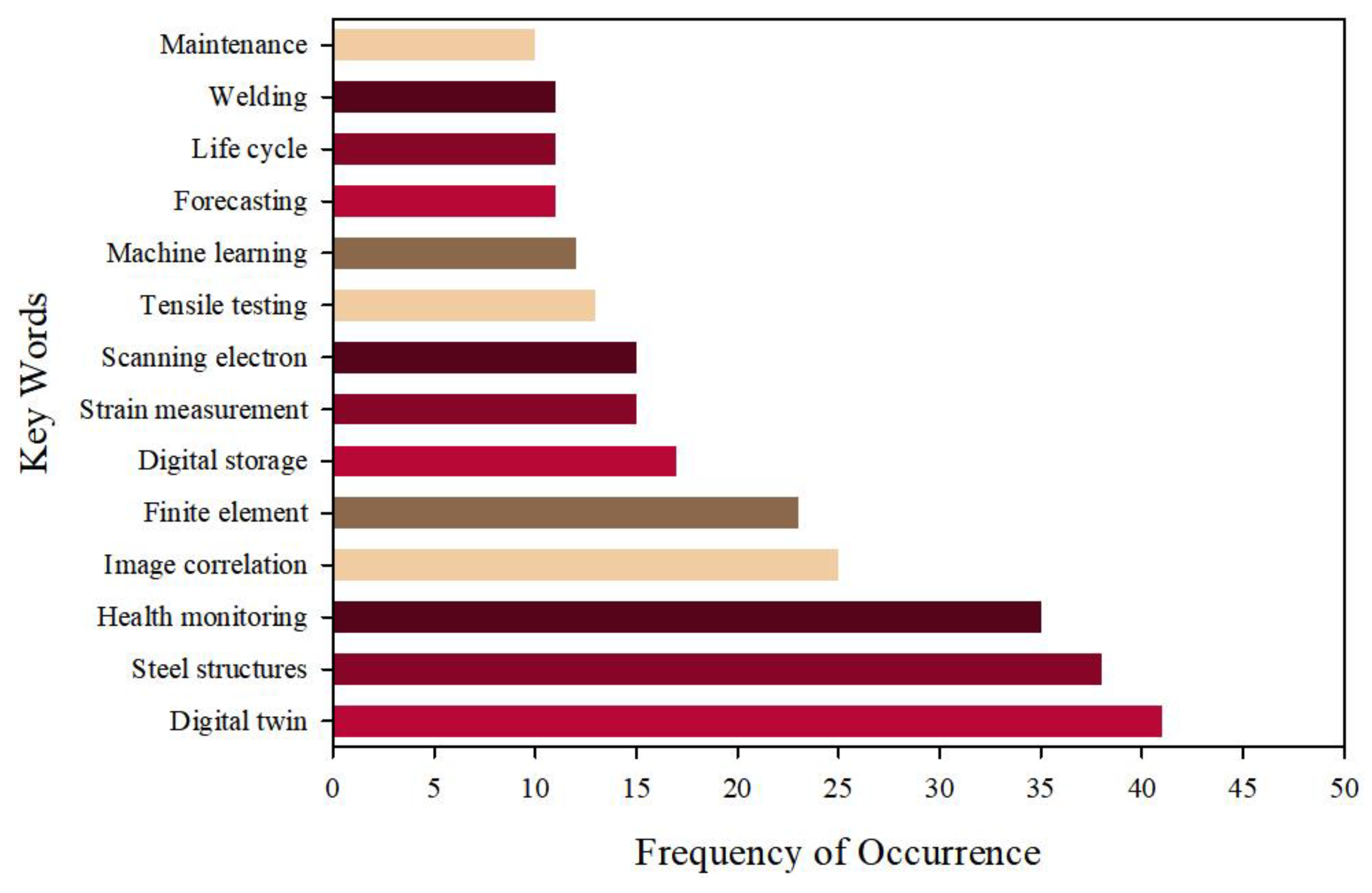

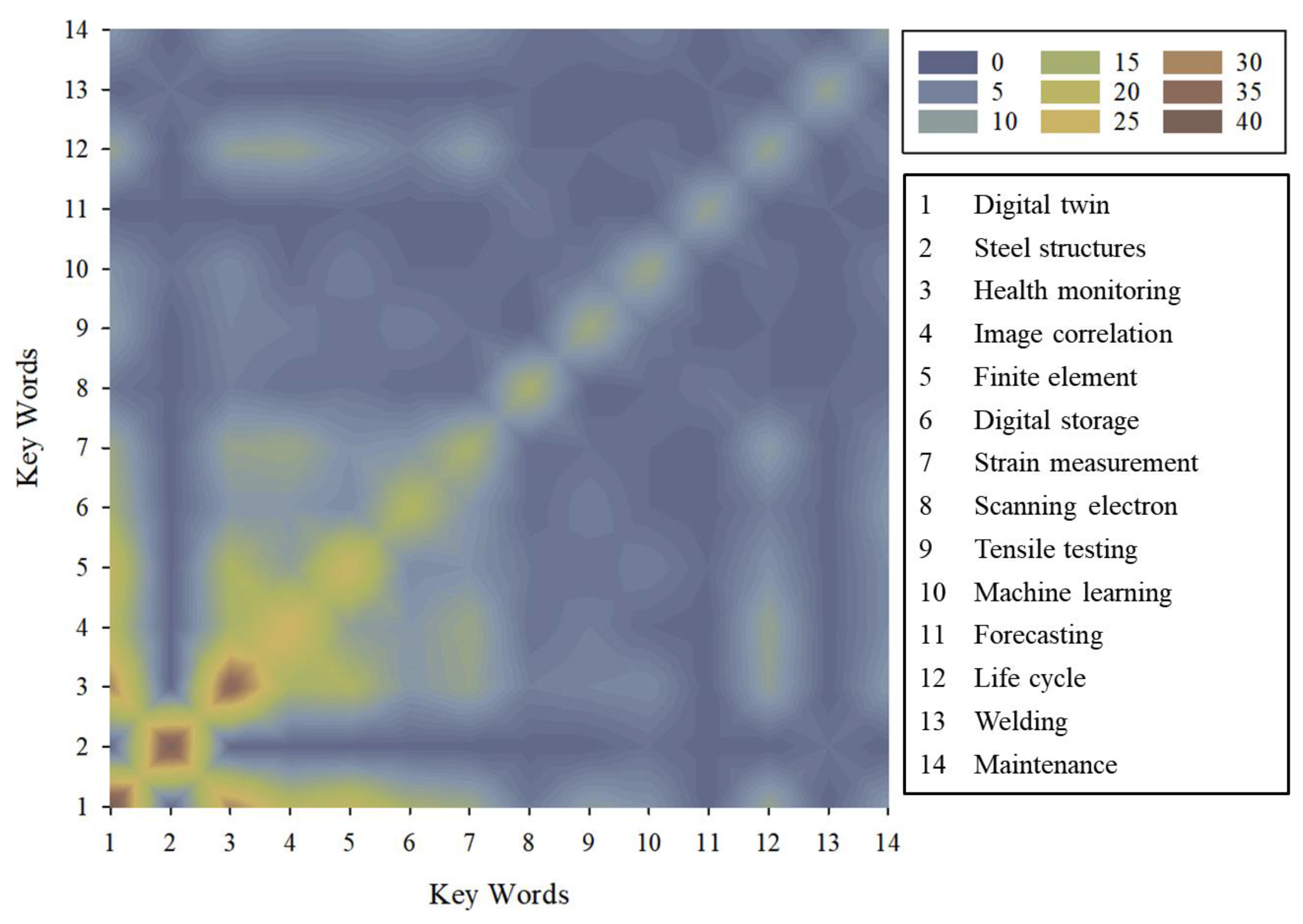

2.2. Keyword Investigation

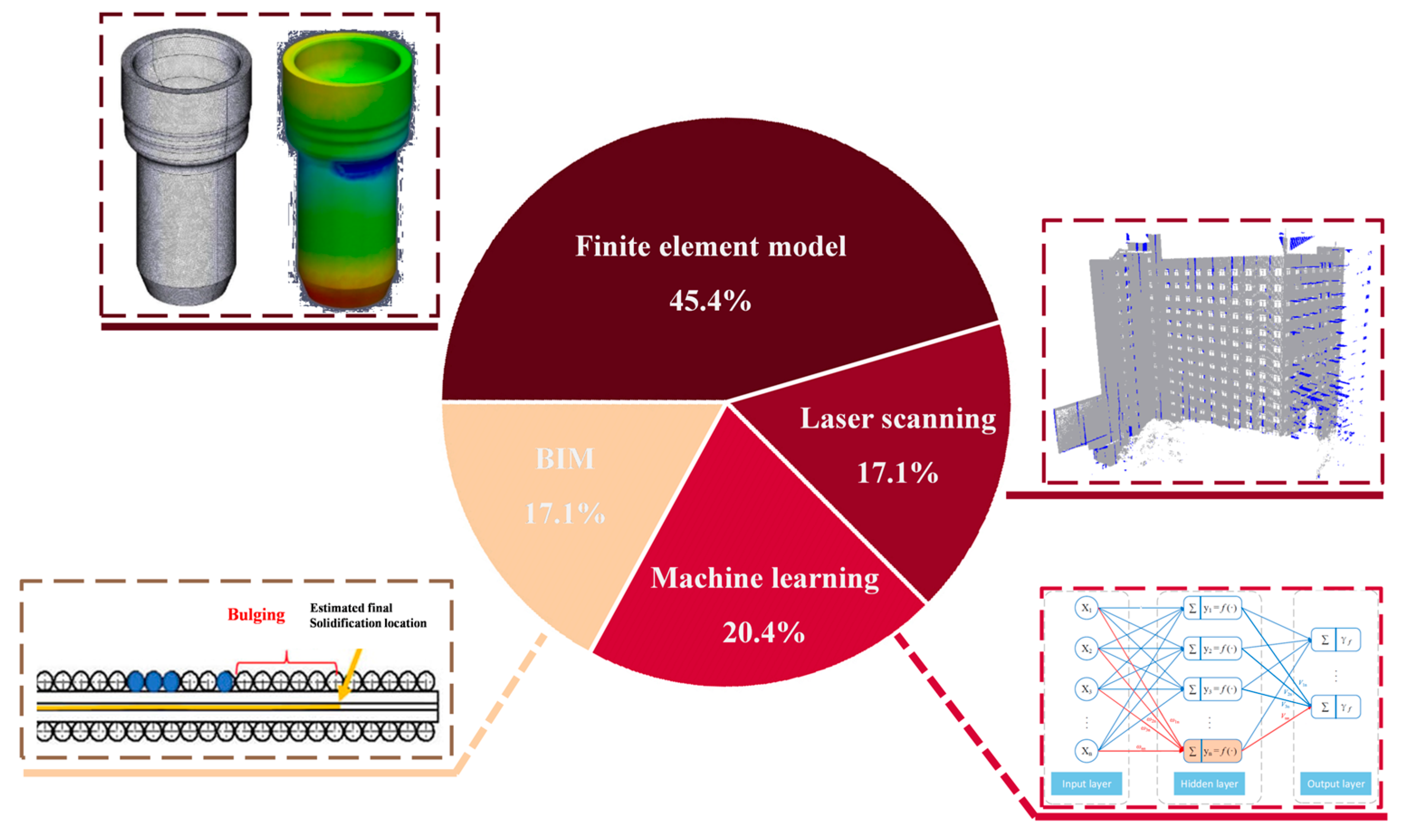

2.3. Usage Exploration

3. Literature Innovation Discussion

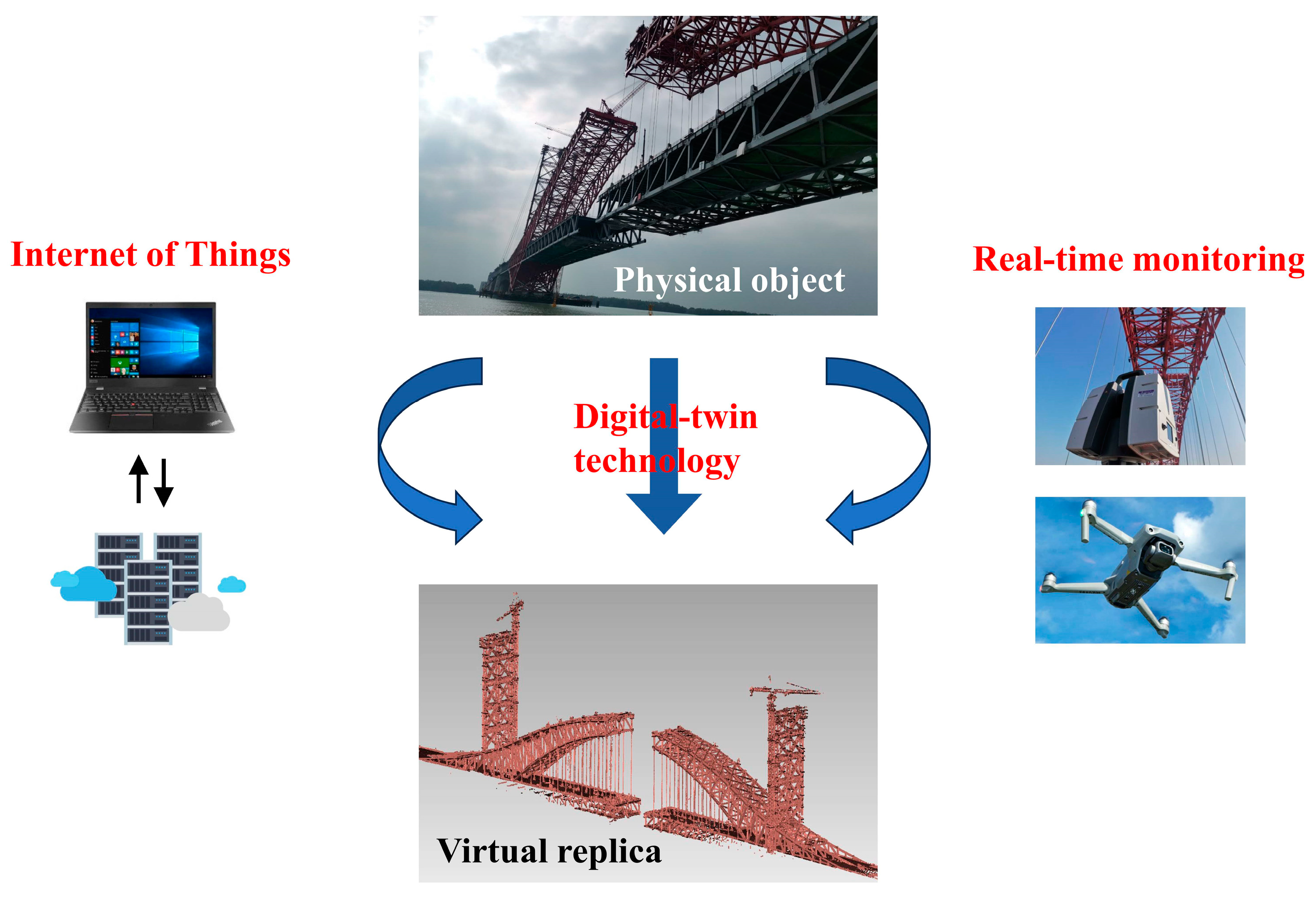

3.1. Definition Evolution

3.2. Methodology Development

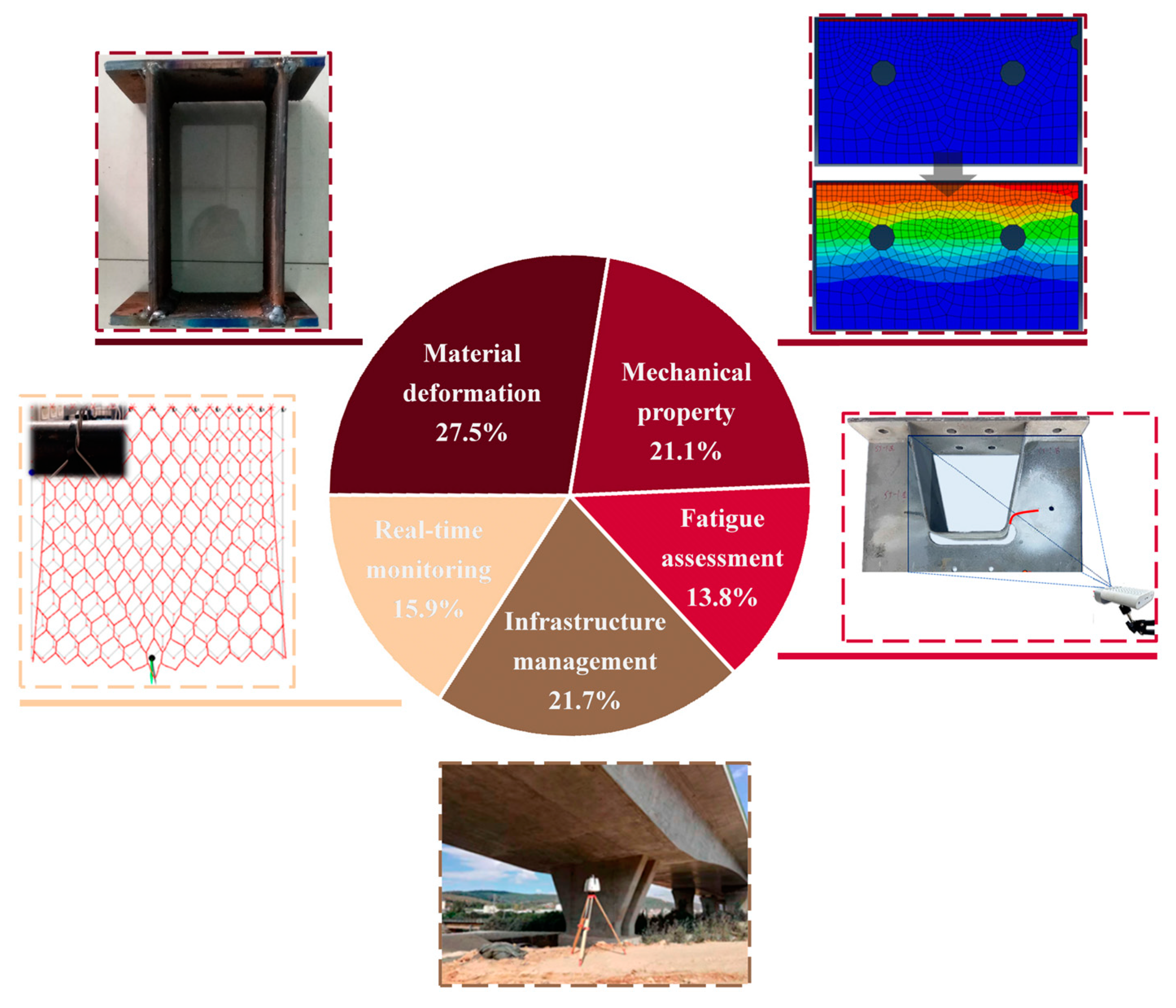

3.3. Application Field

4. Conclusions and Recommendations

- The bibliometric analysis of the literature focused on the publication details, keyword information, and application specifics, indicating that the digital twin technique in steel structures had developed rapidly, with most publications hailing from the Asia–Pacific and European regions. The keywords emphasized that the function of the digital twin technique can be the monitoring, maintenance, and assessment of steel structures. Meanwhile, usage exploration around bridges, buildings, and materials indicated that the digital twin technique was first applied in the research on material aspects and then used in bridges and buildings.

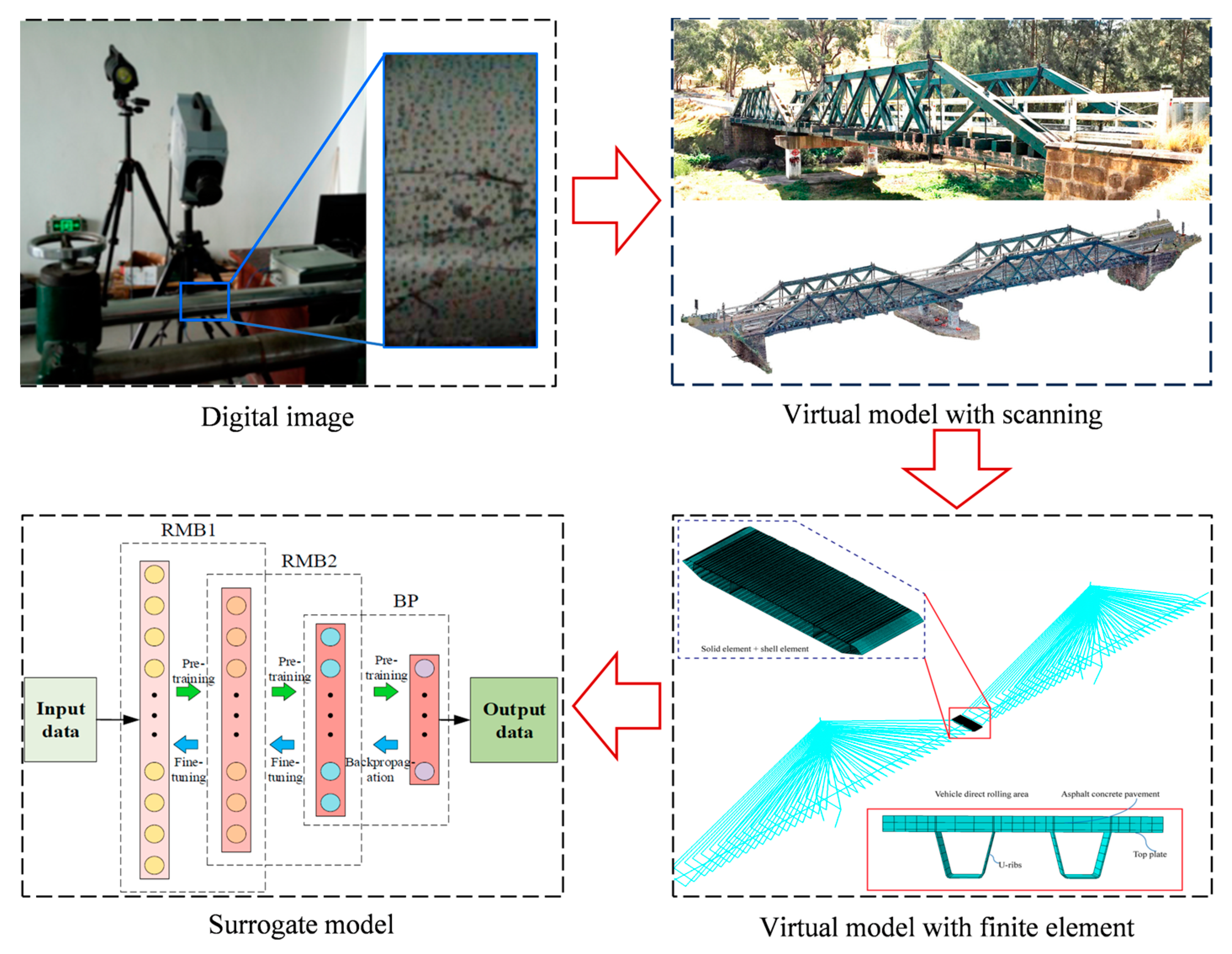

- The discussion of the literature innovations primarily addressed the evolution of digital twin definitions, the development of modeling methodologies, and the corresponding application fields. These definitions evolve from a digital image to a virtual model and then to a surrogate model, and these models can gradually deal with more complex features of a structure. Meanwhile, these methodologies demonstrate their respective advantages in monitoring data usage, model visualization, and updating. Moreover, the digital twin technique is suitable to apply in various fields of steel structure, especially in healthy monitoring and condition maintenance, while different application fields may be appropriate for different digital twin methodologies.

- Model innovation should focus on the multiple-dimension model and high-precision modeling, where the established model not only has the ability of data utilization with large amounts and heterogeneous properties but also can reflect the multi-property of a steel structure, such as the surrogate model combined with machine learning.

- Application expansion means that the digital twin technique should obtain potential to be applied in the broader field of steel structures, although it already has many usages. Meanwhile, digital twin methodology and its application should get multidisciplinary fusion and boundary crossing; for example, the material damage prediction can also use digital twin models combined with verification tests in real conditions.

- Performance optimization should concentrate on the improvement of the functions of the digital twin model to extract structural properties. As the key problem of structural maintenance, structural life cycle forecasting is achieved by BIM, while the issue can be explored more broadly to achieve better performance using other digital twin methods like the finite element model or machine learning.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheok, E.W.W.; Qian, X.; Chen, C.; Quek, S.T.; Si, M.B.I. A local digital twin approach for identifying, locating and sizing cracks in CHS X-joints subjected to brace axial loading. Eng. Struct. 2024, 299, 117085. [Google Scholar] [CrossRef]

- Bayron, P.; Kelso, R.; Chin, R. Experimental investigation of tip-speed-ratio influence on horizontal-axis wind turbine wake dynamics. Renew. Energy 2024, 225, 120201. [Google Scholar] [CrossRef]

- Velazquez De La Hoz, J.L.; Cheng, K. Investigation on the modeling and simulation of hydrodynamics in asymmetric conduction laser micro-welding of austenitic stainless steel and its process optimization. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 1–14. [Google Scholar] [CrossRef]

- Tervo, J.; Junttila, J.; Lamsa, V.; Savolainen, M.; Ronkainen, H. Hybrid methodology development for lubrication regimes identification based on measurements, simulation, and data clustering. Tribol. Int. 2024, 195, 109631. [Google Scholar] [CrossRef]

- Zhu, B.; Tang, Y.; Ran, J.; Wang, Z.; Wang, L.; Zhang, Y. Research on digital twin monitoring system for hot stamping. Int. J. Adv. Manuf. Technol. 2024, 133, 81–98. [Google Scholar] [CrossRef]

- Liu, Z.; Lin, S. Digital twin model and its establishment method for steel structure construction processes. Buildings 2024, 14, 1043. [Google Scholar] [CrossRef]

- Lao, W.; Xu, Y.; Ye, Y.; Cui, C.; Zhang, Q. Digital twin-based probabilistic prediction of microcrack initiation and propagation in the weld zone of orthotropic steel deck. Int. J. Fatigue 2024, 186, 108407. [Google Scholar] [CrossRef]

- Peng, A.; Ma, Y.; Huang, K.; Wang, L. Digital twin-driven framework for fatigue life prediction of welded structures considering residual stress. Int. J. Fatigue 2024, 181, 108144. [Google Scholar] [CrossRef]

- Li, H.; Zhang, R.; Zheng, S.; Shen, Y.; Fu, C.; Zhao, H. Digital twin-driven intelligent operation and maintenance platform for large-scale hydro-steel structures. Adv. Eng. Inform. 2024, 62, 102661. [Google Scholar] [CrossRef]

- Liu, G.; Bai, Z.; Liu, W.; He, Y. Research on compression failure characteristics and damage constitutive model of steel fiber-reinforced concrete with 2% copper-coated fibers under impact load. Materials 2024, 17, 5724. [Google Scholar] [CrossRef]

- Qu, H.; Chen, J.; Cai, Y. A digital twin approach for weld penetration prediction of tig welding with dual ellipsoid heat source. J. Intell. Manuf. 2024, 1–21. [Google Scholar] [CrossRef]

- Fu, T.; Liu, S.; Li, P. Digital twin-driven smelting process management method for converter steelmaking. J. Intell. Manuf. 2024, 1–17. [Google Scholar] [CrossRef]

- Fu, T.; Li, P.; Shi, C.; Liu, Y. Digital-twin-based monitoring system for slab production process. Future Internet 2024, 16, 59. [Google Scholar] [CrossRef]

- Li, J.; Wang, X.; Yang, Q.; Sun, Y.; Zhao, J.; Mao, X.; Qie, H. IoT-based framework for digital twins in steel production: A case study of key parameter prediction and optimization for CSR. Expert Syst. Appl. 2024, 250, 123909. [Google Scholar] [CrossRef]

- Venturini, S.; Bonisoli, E.; Rosso, C.; Velardocchia, M. A tyre-rim interaction digital twin for biaxial loading conditions. Mech. Mach. Theory 2024, 191, 105491. [Google Scholar] [CrossRef]

- Lee, Y.; Jin, C.; Kim, M.; Xu, W. Digital twin approach with minimal sensors for Riser’s fatigue-damage estimation. Int. J. Nav. Archit. Ocean Eng. 2024, 16, 100603. [Google Scholar] [CrossRef]

- Zhang, A.; Ma, H.; Zhao, X.; Zhang, Y.; Wang, J.; Su, M. 3D laser scanning for automated structural modeling and deviation monitoring of multi-section prefabricated cable domes. Autom. Constr. 2024, 165, 105573. [Google Scholar] [CrossRef]

- Ponzo, F.C.; Auletta, G.; Ielpo, P.; Ditommaso, R. DInSAR–SBAS satellite monitoring of infrastructures: How temperature affects the “Ponte della Musica” case study. J. Civ. Struct. Health Monit. 2024, 14, 745–761. [Google Scholar] [CrossRef]

- Pawlowicz, J.A.; Knyziak, P.; Krentowski, J.R.; Mackiewicz, M.; Skotnicka-Siepsiak, A.; Serrat, C. Reverse engineering as a non-invasive examining method of the water tower brick structure condition. Eng. Fail. Anal. 2024, 161, 108280. [Google Scholar] [CrossRef]

- Go, J.; Park, M.; Gao, S.; Tsuji, N. Strain localization behavior in a polycrystalline magnesium alloy with de-twinning. Scr. Mater. 2024, 250, 116207. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, J.; Song, X.; Wu, D.; Su, L.; Tang, L. Data-driven quasi-convex method for hit rate optimization of process product quality in digital twin. J. Ind. Inf. Integr. 2024, 41, 100610. [Google Scholar] [CrossRef]

- Venturini, S.; Rosso, C.; Velardocchia, M. An automotive steel wheel digital twin for failure identification under accelerated fatigue tests. Eng. Fail. Anal. 2024, 158, 107979. [Google Scholar] [CrossRef]

- Vuokila, N.; Cunning, C.; Zhang, J.; Akel, N.; Khan, A.; Lowther, D.A. The application of neural networks to the modeling of magnetic hysteresis. IEEE Trans. Magn. 2024, 60, 3326708. [Google Scholar] [CrossRef]

- Gao, T.; Yuanzhou, Z.; Ji, B.; Xie, Z. Vision-based fatigue crack automatic perception and geometric updating of finite element model for welded joint in steel structures. Comput. Aided Civil Infrastruct. Eng. 2024, 39, 1659–1675. [Google Scholar] [CrossRef]

- Cheok, E.W.W.; Qian, X.; Quek, S.T.; Si, M.B.I. A digital twin approach toward unlocking elasto-plastic fatigue crack growth rates under negative load ratios. Eng. Fract. Mech. 2024, 301, 110034. [Google Scholar] [CrossRef]

- Shang, G.; Xu, L.; Li, Z.; Zhou, Z.; Xu, Z. Digital-twin-based predictive compensation control strategy for seam tracking in steel sheets welding of large cruise ships. Robot. Comput. Integr. Manuf. 2024, 88, 102725. [Google Scholar] [CrossRef]

- Kasper, L.; Schwarzmayr, P.; Birkelbach, F.; Javernik, F.; Schwaiger, M.; Hofmann, R. A digital twin-based adaptive optimization approach applied to waste heat recovery in green steel production: Development and experimental investigation. Appl. Energy 2024, 353, 122192. [Google Scholar] [CrossRef]

- Nistala, S.H.; Kumar, R.; Parihar, M.S.; Runkana, V. metafur: Digital twin system of a blast furnace. Trans. Indian Inst. Met. 2024, 1–11. [Google Scholar] [CrossRef]

- Popov, I.; Griffiths, C.A. Digital twin model of a large scale hot molten metal ladle pouring system. Int. J. Adv. Manuf. Technol. 2024, 133, 491–506. [Google Scholar] [CrossRef]

- D’Urso, D.; Chiacchio, F.; Cavalieri, S.; Gambadoro, S.; Khodayee, S.M. Predictive maintenance of standalone steel industrial components powered by a dynamic reliability digital twin model with artificial intelligence. Reliab. Eng. Syst. Safe. 2024, 243, 109859. [Google Scholar] [CrossRef]

- Masanes Didyk, M.; Ebrahimzadeh Hassanabadi, M.; Eftekhar Azam, S. An output-only unbiased minimum variance state estimator for linear systems. Mech. Syst. Signal Proc. 2024, 211, 111204. [Google Scholar] [CrossRef]

- Bjork, T.; Ahola, A.; Skriko, T.; Lipiainen, K. On the backward design—An advanced concept for the design of welded structures for demanding applications. Weld. World 2023, 67, 1247–1257. [Google Scholar] [CrossRef]

- Rahman, M.; Liu, H.; Masri, M.; Durazo-Cardenas, I.; Starr, A. A railway track reconstruction method using robotic vision on a mobile manipulator: A proposed strategy. Comput. Ind. 2023, 148, 103900. [Google Scholar] [CrossRef]

- Heng, J.; Zhang, J.; Kaewunruen, S.; Dong, Y.; Baniotopoulos, C. Digital twin-based deterioration prognosis of steel wind turbine towers in modular energy islands. Ce/papers 2023, 6, 1111–1118. [Google Scholar] [CrossRef]

- Briffod, F.; Shiraiwa, T.; Yamazaki, K.; Enoki, M. Integrated experimental–numerical investigation of strain partitioning and damage initiation in a low-carbon lath martensitic steel. Mat. Sci. Eng. A 2023, 876, 145148. [Google Scholar] [CrossRef]

- Hu, G.; Zhou, Y.; Xiang, Z.; Zhao, L.; Chen, G.; Li, T.; Zhu, J.; Hu, K. Fast and accurate generation method of geometric digital twin model of RC bridge with box chambers based on terrestrial laser scanning. Remote Sens. 2023, 15, 4440. [Google Scholar] [CrossRef]

- Kazantseva, N.; Koemets, Y.; Davydov, D.; Vinogradova, N.; Ezhov, I. Analysis of unstable plastic flow in the porous 316L samples manufactured with a laser 3D printer. Materials 2023, 16, 14. [Google Scholar] [CrossRef]

- Yin, W.; Briffod, F.; Hu, H.; Shiraiwa, T.; Enoki, M. Three-dimensional configuration of crystal plasticity in stainless steel assessed by high resolution digital image correlation and confocal microscopy. Int. J. Plast. 2023, 170, 103762. [Google Scholar] [CrossRef]

- Fan, L.; Wang, X.; Chen, Y.; Wang, L.; Liu, S.; Wang, Y.; Li, X.; Du, K.; Zhang, J.; Gao, X.; et al. Smart design and manufacturing the welded Q350 steel frames via lifecycle management strategy of digital twin. J. Beijing Inst. Tech. (Engl. Ed.) 2023, 32, 385–395. [Google Scholar]

- Jiang, F.; Ding, Y.; Song, Y.; Geng, F.; Wang, Z. Digital Twin-driven framework for fatigue lifecycle management of steel bridges. Struct. Infrastruct. Eng. 2023, 19, 1826–1846. [Google Scholar] [CrossRef]

- Wang, W.; Dan, D.; Jian, F. Study on strain characteristic function for performance evaluation of high-speed railway steel truss bridge. Structures 2023, 55, 441–452. [Google Scholar] [CrossRef]

- Wilby, A.; Corteen, J.; Lewis, S.; Lewis, R.; Fletcher, D.I. Nano and micro-indentation driven characterisation of asperity and bulk plasticity at the surface of modern premium rail steels. Wear 2023, 530–531, 205004. [Google Scholar] [CrossRef]

- Mokhtari, F.; Imanpour, A. A digital twin-based framework for multi-element seismic hybrid simulation of structures. Mech. Syst. Signal Proc. 2023, 186, 109909. [Google Scholar] [CrossRef]

- Suarez, L.; Jonsen, P.; Kajberg, J. Valorization of air-cooled EAF manganese slag in comminution processes: An investigation into the breakage characterization. Mining Metall. Explor. 2023, 40, 2449–2462. [Google Scholar] [CrossRef]

- Momber, A.W.; Nattkemper, T.W.; Langenkamper, D.; Moller, T.; Brun, D.; Schaumann, P.; Shojai, S. A data-based model for condition monitoring and maintenance planning for protective coating systems for wind tower structures. Renew. Energy 2022, 186, 957–973. [Google Scholar] [CrossRef]

- Song, C.; Shen, X.; Xia, J. A digital twin model for automatic width control of hot rolling mill. IEEE Access 2023, 11, 90613–90621. [Google Scholar] [CrossRef]

- Jin, J.; Hu, J.; Li, C.; Shi, Z.; Lei, P.; Tian, W. A digital twin system of reconfigurable tooling for monitoring and evaluating in aerospace assembly. J. Manuf. Syst. 2023, 68, 56–71. [Google Scholar] [CrossRef]

- Coroas, C.; Vieitez, I.; Martin, E.; Roman, M. Numerical modeling for the prediction of microstructure and mechanical properties of quenched automotive steel pieces. Materials 2023, 16, 4111. [Google Scholar] [CrossRef]

- Atatreh, S.; Alyammahi, M.S.; Vasilyan, H.; Alkindi, T.; Susantyoko, R.A. Evaluation of the infill design on the tensile properties of metal parts produced by fused filament fabrication. Results Eng. 2023, 17, 100954. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rashidi, M.; Azandariani, M.G.; Mousavi, V.; Yu, Y.; Samali, B. Modern damage measurement of structural elements: Experiment, terrestrial laser scanning, and numerical studies. Structures 2023, 58, 105574. [Google Scholar] [CrossRef]

- Sun, Y.; Lu, Y.; Bao, J.; Tao, F. Prognostics and health management via long short-term digital twins. J. Manuf. Syst. 2023, 68, 560–575. [Google Scholar] [CrossRef]

- Fu, X.; Han, J.; Castle, M.; Cao, K. Digital twin-driven vibration amplitude simulation for condition monitoring of axial blowers in blast furnace ironmaking. Syst. Sci. Control Eng. 2023, 11, 2152400. [Google Scholar] [CrossRef]

- Xu, J.; Lou, J.; Lu, W.; Wu, L.; Chen, C. Ensuring construction material provenance using Internet of Things and blockchain: Learning from the food industry. J. Ind. Inf. Integr. 2023, 33, 100455. [Google Scholar] [CrossRef]

- Gonzalez, O.B.; Ronnow, D. Time series modelling of a radial-axial ring rolling system. Int. J. Model Identif. 2023, 43, 13–25. [Google Scholar] [CrossRef]

- Kaya, A.C.; Salamci, M.U.; Fleck, C. Influence of anisotropy on the deformation behaviour in microtensile 316L steel specimens fabricated by laser powder bed fusion (PBF-LB/M). Mat. Sci. Eng. A 2023, 863, 144521. [Google Scholar] [CrossRef]

- Sommer, N.; Lee, S.; Stredak, F.; Wolf, C.; Suckau, A.; Vollmer, M.; Shao, S.; Niendorf, T.; Shamsaei, N.; Bohm, S. Dynamic tensile deformation behavior of AISI 316L stainless steel fabricated by laser-beam directed energy deposition. J. Mater. Res. Technol. 2023, 27, 5896–5909. [Google Scholar] [CrossRef]

- Gussev, M.N.; Mcclintock, D.A.; Lach, T.G. Origin, parameters, and underlying deformation mechanisms of propagating deformation bands in irradiated 316L stainless steel. Acta Mater. 2023, 242, 118434. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, Y.; Xiong, R.; Zhang, T.; Chen, H.; Kim, H.S. Quantitative characterization of mechanical twins based on new digital image processing method. Mater. Charact. 2023, 195, 112492. [Google Scholar] [CrossRef]

- Hussain, F.; Mohammadian, M.; Goecke, R. Topology and material optimization of an underactuated robot for gait rehabilitation. Mech. Based Des. Struct. Mech. 2023, 52, 5308–5325. [Google Scholar] [CrossRef]

- Abio, A.; Bonada, F.; Pujante, J.; Grane, M.; Nievas, N.; Lange, D.; Pujol, O. Machine learning-based surrogate model for press hardening process of 22MnB5 sheet steel simulation in Industry 4.0. Materials 2022, 15, 3647. [Google Scholar] [CrossRef] [PubMed]

- Mucci, V.; Cardellicchio, A.; Ruggieri, S.; Nettis, A. Artificial intelligence in structural health management of existing bridges. Automat. Constr. 2024, 167, 105719. [Google Scholar] [CrossRef]

- Cimino, A.; Longo, F.; Mirabelli, G.; Solina, V.; Verteramo, S. An ontology-based, general-purpose and Industry 4.0-ready architecture for supporting the smart operator (Part II—Virtual Reality case). J. Manuf. Syst. 2024, 73, 52–64. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, T.; Chen, H.; Li, Z.; Li, S.; Wang, D.; Wang, Y.; Kosiba, K. Impact behaviors of additively manufactured metals and structures: A review. Int. J. Impact Eng. 2024, 191, 104992. [Google Scholar] [CrossRef]

- Bautista Gonzalez, O.; Ronnow, D. Physical modeling of a water hydraulic proportional cartridge valve for a digital twin in a hydraulic press machine. Processes 2024, 12, 693. [Google Scholar] [CrossRef]

- Khalil, M.; Ruggieri, S.; Tateo, V.; Nascimbene, R.; Uva, G. A numerical procedure to estimate seismic fragility of cylindrical ground-supported steel silos containing granular-like material. Bull Earthq. Eng. 2023, 21, 5915–5947. [Google Scholar] [CrossRef]

- Udugama, I.A.; Bayer, C.; Baroutian, S.; Gernaey, K.V.; Yu, W.; Young, B.R. Digitalisation in chemical engineering: Industrial needs, academic best practice, and curriculum limitations. Educ. Chem. Eng. 2022, 39, 94–107. [Google Scholar] [CrossRef]

- Ramonell, C.; Chacon, R.; Krenn, B.; Puig-Polo, C. Automated pipeline for the analysis of a scale-reduced steel cable net. Ce/papers 2022, 5, 1060–1066. [Google Scholar] [CrossRef]

- Parareda, S.; Casellas, D.; Lara, A.; Mateo, A. Fatigue resistance evaluation of high Mn-TWIP steel through damage mechanics: A new method based on stiffness evolution. Int. J. Fatigue 2022, 156, 106643. [Google Scholar] [CrossRef]

- Wang, W.; Qiu, W. Energy-dissipation support technology for large deformation tunnels based on the post-peak behavior of steel plate buckling: A case study. Appl. Sci. 2023, 13, 11972. [Google Scholar] [CrossRef]

- Wei, Z.; Zhang, X.; Sun, F.; Wang, W.Y. Digital twin assistant active design and optimization of steel mega-sub controlled structural system under severe earthquake waves. Materials 2022, 15, 6382. [Google Scholar] [CrossRef]

- Febrianto, E.; Butler, L.; Girolami, M.; Cirak, F. Digital twinning of self-sensing structures using the statistical finite element method. Data Centric Eng. 2022, 3, e31. [Google Scholar] [CrossRef]

- Momber, A.W.; Moller, T.; Langenkamper, D.; Nattkemper, T.W.; Brun, D. A digital twin concept for the prescriptive maintenance of protective coating systems on wind turbine structures. Wind Eng. 2022, 46, 949–971. [Google Scholar] [CrossRef]

- Fillmore, T.B.; Wu, Z.; Vega, M.A.; Hu, Z.; Todd, M.D. A surrogate model to accelerate non-intrusive global–local simulations of cracked steel structures. Struct. Multidiscip. Optim. 2022, 65, 1–20. [Google Scholar]

- Neelakandan, D.P.; Alla, D.R.; Huang, J.; Omalley, R.J. Liquid core detection and strand condition monitoring in a continuous caster using optical fiber. Sensors 2022, 22, 9816. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Fan, Q.; Yao, J.; Yang, L.; Xu, S.; Lei, W.; Wang, D.; Yuan, J.; Gong, H.; Cheng, X. Composition design of a novel Ti-6Mo-3.5Cr-1Zr alloy with high-strength and ultrahigh-ductility. J. Mater. Sci. Technol. 2022, 131, 276–286. [Google Scholar] [CrossRef]

- Kumar, D.; Jhavar, S.; Arya, A.; Prashanth, K.G.; Suwas, S. Mechanisms controlling fracture toughness of additively manufactured stainless steel 316L. Int. J. Fract. 2022, 235, 61–78. [Google Scholar] [CrossRef]

- Lange, J.; Waldschmitt, B.; Borg Costanzi, C. 3D-gedruckte Stützen mit außergewöhnlicher Geometrie. Stahlbau 2022, 91, 365–374. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, C.; Sun, Z.; Cao, C. Digital twins-based impact response prediction of prestressed steel structure. Sensors 2022, 22, 1647. [Google Scholar] [CrossRef]

- Peng, X.X.; Wang, L.Y.; Xu, W.; Liang, Z.Y. Correlations between the plastic instabilities occurring in indentation and the Portevin Le-Chatelier effect in uniaxial tension. Mat. Sci. Eng. A 2022, 854, 143799. [Google Scholar] [CrossRef]

- Chacon, R. Geometrical digital twinning of a tapered, horizontally curved composite box girder bridge. Ce/papers 2022, 5, 52–58. [Google Scholar] [CrossRef]

- Yu, S.; Li, D.; Ou, J. Digital twin-based structure health hybrid monitoring and fatigue evaluation of orthotropic steel deck in cable-stayed bridge. Struct. Control Health 2022, 29, e2976. [Google Scholar] [CrossRef]

- Momber, A.; Nattkemper, T.; Langenkamper, D.; Moller, T.; Brun, D.; Schaumann, P.; Shojai, S. Digitalisierung und verarbeitung von sensordaten für die zustandsbewertung von oberflächenschutzsystemen stählerner türme von onshore-windenergieanlagen. Stahlbau 2021, 90, 528–541. [Google Scholar] [CrossRef]

- Weidner, A.; Biermann, H. Review on strain localization phenomena studied by high-resolution digital image correlation. Adv. Eng. Mater. 2021, 23, 2001409. [Google Scholar] [CrossRef]

- Klingaa, C.G.; Mohanty, S.; Funch, C.V.; Hjermitslev, A.B.; Haahr-Lillevang, L.; Hattel, J.H. Towards a digital twin of laser powder bed fusion with a focus on gas flow variables. J. Manuf. Process. 2021, 65, 312–327. [Google Scholar] [CrossRef]

- Dutta, A.; Park, T.M.; Nam, J.; Lee, S.; Hwang, B.; Choi, W.S.; Sandlobes, S.; Ponge, D.; Han, J. Enhancement of the tensile properties and impact toughness of a medium-Mn steel through the homogeneous microstrain distribution. Mater. Charact. 2021, 174, 110992. [Google Scholar] [CrossRef]

- Yang, H.; Ramirez Lopez, P.E.; Vasallo, D.M. New concepts for prediction of friction, taper, and evaluation of powder performance with an advanced 3D numerical model for continuous casting of steel billets. Metall. Mater. Trans. B 2021, 52, 2760–2785. [Google Scholar] [CrossRef]

- Li, X.Z.; Li, C.; Lu, L.; Huang, J.Y.; Luo, S.N. Interactions between slip bands and interfaces in a compressed duplex stainless steel. Mat. Sci. Eng. A 2021, 818, 141325. [Google Scholar] [CrossRef]

- Jacoby, M.; Jovicic, B.; Stojanovic, L.; Stojanovi, N. An approach for realizing hybrid digital twins using asset administration shells and apache streampipes. Information 2021, 12, 217. [Google Scholar] [CrossRef]

- Baisthakur, S.; Chakraborty, A. Experimental verification for load rating of steel truss bridge using an improved Hamiltonian Monte Carlo-based Bayesian model updating. J. Civ. Struct. Health Monit. 2021, 11, 1093–1112. [Google Scholar] [CrossRef]

- Chen, M.; Liu, X.; Zhang, X.; Wang, M.; Zhao, L. Building extraction from terrestrial laser scanning data with density of projected points on polar grid and adaptive threshold. Remote Sens. 2021, 13, 4392. [Google Scholar] [CrossRef]

- Liu, H.; Liu, S.; Wei, C.; Qian, L.; Feng, Y.; Zhang, F. Effect of grain size on dynamic strain aging behavior of C-bearing high Mn twinning-induced plasticity steel. J. Mater. Res. Technol. 2021, 15, 6387–6394. [Google Scholar] [CrossRef]

- Jiang, F.; Ding, Y.; Song, Y.; Geng, F.; Wang, Z. Digital Twin-driven framework for fatigue life prediction of steel bridges using a probabilistic multiscale model: Application to segmental orthotropic steel deck specimen. Eng. Struct. 2021, 241, 112461. [Google Scholar] [CrossRef]

- Yavari, R.; Riensche, A.; Tekerek, E.; Jacquemetton, L.; Halliday, H.; Vandever, M.; Tenequer, A.; Perumal, V.; Kontsos, A.; Smoqi, Z.; et al. Digitally twinned additive manufacturing: Detecting flaws in laser powder bed fusion by combining thermal simulations with in-situ meltpool sensor data. Mater. Design 2021, 211, 110167. [Google Scholar] [CrossRef]

- Zhao, C.; Li, X. Quantitative study of residual strain and geometrically necessary dislocation density using HR-EBSD method. Exp. Mech. 2021, 61, 1281–1290. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rashidi, M.; Mousavi, V.; Karami, A.; Yu, Y.; Samali, B. Quality evaluation of digital twins generated based on uav photogrammetry and tls: Bridge case study. Remote Sens. 2021, 13, 3499. [Google Scholar] [CrossRef]

- D’Hondt, C.; Doquet, V.; Couzinie, J.P. Direct monitoring of twinning/detwinning in a TWIP steel under reversed cyclic loading. Mat. Sci. Eng. A 2021, 814, 141250. [Google Scholar] [CrossRef]

- Wanni, J.; Michopoulos, J.G.; Bagchi, A.; Banerjee, S.; Banerjee, N.; Achuthan, A. High-resolution optical microscopy for characterising microstructural deformation in microtensile testing. J. Microsc. 2021, 281, 202–213. [Google Scholar] [CrossRef] [PubMed]

- Ragheb, H.; Sobey, A. Effects of extensible modelling on composite riser mechanical responses. Ocean Eng. 2021, 220, 108426. [Google Scholar] [CrossRef]

- Schwarz, M.; Anbalagan, S.N.; Jagers, S.; Loendersloot, R. Implementing industry 4.0 in steel manufacturing’s evolving IIoT systems. Iron Steel Tech. 2021, 18, 154–163. [Google Scholar] [CrossRef]

- Kang, S.; Jeong, S.; Ahn, Y. Effect of discontinuous yielding on the strain hardening behavior of fine-grained twinning-induced plasticity steel. Front. Mater. 2021, 8, 599534. [Google Scholar] [CrossRef]

- Urtsev, V.N.; Shmakov, A.V.; Urtsev, N.V.; Mokshin, E.D.; Khabibulin, D.M.; Degtyarev, V.N.; Stekanov, P.A.; Gornostyrev, Y.N.; Lobanov, M.L.; Platov, S.I.; et al. Phenomenological model of austenite decomposition kinetics in low-carbon low-alloy high-strength Steels. Steel Transl. 2020, 50, 496–500. [Google Scholar] [CrossRef]

- Kraus, M.A.; Taras, A. Physik-informierte Künstliche Intelligenz zur Berechnung und Bemessung im Stahlbau. Stahlbau 2020, 89, 824–832. [Google Scholar] [CrossRef]

- Dobrowolska, M.; Velthuis, J.; Kopp, A.; Perry, M.; Pearson, P. Towards an application of muon scattering tomography as a technique for detecting rebars in concrete. Smart Mater. Struct. 2020, 29, 055015. [Google Scholar] [CrossRef]

- Botz, M.; Emiroglu, A.; Osterminski, K.; Raith, M.; Wuchner, R.; Groce, C. überwachung und modellierung der tragstruktur von windenergieanlagen: Beitrag zu einem digitalen zwilling. Beton Stahlbetonbau 2020, 115, 342–354. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, G.; Zhang, A.; Huang, C. Intelligent tensioning method for prestressed cables based on digital twins and artificial intelligence. Sensors 2020, 20, 7006. [Google Scholar] [CrossRef]

- Sinha, S.; Komarasamy, M.; Wang, T.; Haridas, R.S.; Agrawal, P.; Shukla, S.; Thapliyal, S.; Frank, M.; Mishra, R.S. Notch-tensile behavior of Al0.1 CrFeCoNi high entropy alloy. Mat. Sci. Eng. A 2020, 774, 138918. [Google Scholar] [CrossRef]

- Bertulessi, M.; Bignami, D.F.; Boschini, I.; Chiarini, A.; Ferrario, M.; Mazzon, N.; Menduni, G.; Morosi, J.; Zambrini, F. Conceptualization and prototype of an anti-erosion sensing revetment for levee monitoring: Experimental tests and numerical modeling. Water 2020, 12, 3025. [Google Scholar] [CrossRef]

- He, J.; Yuan, F.; Yang, M.; Zhou, L.; Jiao, S.; Wu, X. Exceptional tensile properties under cryogenic temperature in heterogeneous laminates induced by non-uniform martensite transformation and strain delocalization. Mat. Sci. Eng. A 2020, 791, 139780. [Google Scholar] [CrossRef]

- Rudskoy, A.I.; Kolbasnikov, N.G. Digital twins of processes of thermomechanical treatment of steel. Met. Sci. Heat Treat. 2020, 62, 3–10. [Google Scholar] [CrossRef]

- Souza Filho, I.R.; Dutta, A.; Almeida Junior, D.R.; Lu, W.; Sandim, M.J.R.; Ponge, D.; Sandim, H.R.Z.; Raabe, D. The impact of grain-scale strain localization on strain hardening of a high-Mn steel: Real-time tracking of the transition from the γ → Ε → α’ transformation to twinning. Acta Mater. 2020, 197, 123–136. [Google Scholar] [CrossRef]

- Sedighiani, K.; Diehl, M.; Traka, K.; Roters, F.; Sietsma, J.; Raabe, D. An efficient and robust approach to determine material parameters of crystal plasticity constitutive laws from macro-scale stress-strain curves. Int. J. Plast. 2020, 134, 102779. [Google Scholar] [CrossRef]

- Lehnert, R.; Weidner, A.; Schimpf, C.; Wendler, M.; Biermann, H. Martensite formation during tensile deformation of high-alloy TRIP steel after quenching and partitioning route investigated by digital image correlation. Materialia 2019, 8, 100498. [Google Scholar] [CrossRef]

- Salas-Reyes, A.E.; Mejia, I.; Ruiz-Baltazar, A.; Cabrera, J.M. Transmission electron microscopy characterization and high-resolution modeling of second-phase particles of V- and Ti-containing twinning-induced plasticity steel under uniaxial hot-tensile condition. Steel Res. Int. 2019, 90, 1900098. [Google Scholar] [CrossRef]

- Russo Spena, P.; Cortese, L.; Nalli, F.; Majlinger, K. Local formability and strength of TWIP-TRIP weldments for stamping tailor welded blanks (TWBs). Int. J. Adv. Manuf. Technol. 2019, 101, 757–771. [Google Scholar] [CrossRef]

- Liu, L.; Wan, X.; Gao, Z.; Li, X.; Feng, B. Research on modelling and optimization of hot rolling scheduling. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1201–1216. [Google Scholar] [CrossRef]

- Madivala, M.; Schwedt, A.; Prahl, U.; Bleck, W. Anisotropy and strain rate effects on the failure behavior of TWIP steel: A multiscale experimental study. Int. J. Plast. 2019, 115, 178–199. [Google Scholar] [CrossRef]

- Benzing, J.T.; Liu, Y.; Zhang, X.; Luecke, W.E.; Ponge, D.; Dutta, A.; Oskay, C.; Raabe, D.; Wittig, J.E. Experimental and numerical study of mechanical properties of multi-phase medium-Mn TWIP-TRIP steel: Influences of strain rate and phase constituents. Acta Mater. 2019, 177, 250–265. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, S.; Gazder, A.A.; Saleh, A.A.; Santos, D.B.; Pereloma, E.V. Effect of uniaxial tension on the microstructure and texture of high Mn steel. Adv. Eng. Mater. 2018, 20, 1800258. [Google Scholar] [CrossRef]

- Shcherba, D.; Tarasov, A.; Borovkov, A.I. Developing of phenomenological damage model for automotive low-carbon structural steel for using in validation of Euroncap frontal impact. Mater. Phys. Mech. 2018, 40, 246–253. [Google Scholar]

- Koyama, M.; Kaneko, T.; Sawaguchi, T.; Tsuzaki, K. Microstructural damage evolution and arrest in binary Fe–high-Mn alloys with different deformation temperatures. Int. J. Fract. 2018, 213, 193–206. [Google Scholar] [CrossRef]

- Michler, T.; Bruder, E. Local strains in 1.4301 austenitic stainless steel with internal hydrogen. Mat. Sci. Eng. A 2018, 725, 447–455. [Google Scholar]

- Sun, Z.; Tan, X.; Tor, S.B.; Chua, C.K. Simultaneously enhanced strength and ductility for 3D-printed stainless steel 316L by selective laser melting. NPG Asia Mater. 2018, 10, 127–136. [Google Scholar] [CrossRef]

- Luo, Z.C.; Liu, R.D.; Wang, X.; Huang, M.X. The effect of deformation twins on the quasi-cleavage crack propagation in twinning-induced plasticity steels. Acta Mater. 2018, 150, 59–68. [Google Scholar] [CrossRef]

- Kang, M.; Park, J.; Sohn, S.S.; Kim, H.S.; Kim, N.J.; Lee, S. Interpretation of quasi-static and dynamic tensile behavior by digital image correlation technique in TWinning Induced Plasticity (TWIP) and low-carbon steel sheets. Mat. Sci. Eng. A 2017, 693, 170–177. [Google Scholar] [CrossRef]

- Bian, X.; Yuan, F.; Wu, X. Correlation between strain rate sensitivity and characteristics of Portevin-LeChátelier bands in a twinning-induced plasticity steel. Mat. Sci. Eng. A 2017, 696, 220–227. [Google Scholar] [CrossRef]

- Knapp, G.L.; Mukherjee, T.; Zuback, J.S.; Wei, H.L.; Palmer, T.A.; De, A.; Debroy, T. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017, 135, 390–399. [Google Scholar] [CrossRef]

- Efthymiadis, P.; Dashwood, R.; Shollock, B.; Curry, L.; Ghadbeigi, H.; Barrow, A.; Robertson, D. Multiscale characterisation of the mechanical properties of austenitic stainless steel joints. Mat. Sci. Eng. A 2016, 676, 324–335. [Google Scholar] [CrossRef]

- Wang, H.; Song, G.; Tang, G. Effect of electropulsing on surface mechanical properties and microstructure of AISI 304 stainless steel during ultrasonic surface rolling process. Mat. Sci. Eng. A 2016, 662, 456–467. [Google Scholar] [CrossRef]

- Yang, H.K.; Doquet, V.; Zhang, Z.F. Micro-scale measurements of plastic strain field, and local contributions of slip and twinning in TWIP steels during in situ tensile tests. Mat. Sci. Eng. A 2016, 672, 7–14. [Google Scholar] [CrossRef]

- Unal, O.; Varol, R. Surface severe plastic deformation of AISI 304 via conventional shot peening, severe shot peening and repeening. Appl. Surf. Sci. 2015, 351, 289–295. [Google Scholar] [CrossRef]

- Weidner, A.; Biermann, H. Combination of different in situ characterization techniques and scanning electron microscopy investigations for a comprehensive description of the tensile deformation behavior of a CrMnNi TRIP/TWIP steel. JOM 2015, 67, 1729–1747. [Google Scholar] [CrossRef]

- Rossini, M.; Spena, P.R.; Cortese, L.; Matteis, P.; Firrao, D. Investigation on dissimilar laser welding of advanced high strength steel sheets for the automotive industry. Mat. Sci. Eng. A 2015, 628, 288–296. [Google Scholar] [CrossRef]

- Eskandari, M.; Yadegari-Dehnavi, M.R.; Zarei-Hanzaki, A.; Mohtadi-Bonab, M.A.; Basu, R.; Szpunar, J.A. In-situ strain localization analysis in low density transformation-twinning induced plasticity steel using digital image correlation. Opt. Lasers Eng. 2015, 67, 1–16. [Google Scholar] [CrossRef]

- Min, J.; Lin, J.; Sun, B. Effect of strain rate on spatio-temporal behavior of Portevin-Le Châtelier bands in a twinning induced plasticity steel. Mech. Mater. 2014, 68, 164–175. [Google Scholar] [CrossRef]

- Niendorf, T.; Brenne, F.; Liu, C.; Ozcan, O. In-situ characterization of the damage evolution in thin polyelectrolyte films on TWIP steel substrates. Mat. Sci. Eng. A 2013, 566, 82–89. [Google Scholar] [CrossRef]

- Rusinga, C.J.; Niendorfa, T.; Lackmanna, J.; Frehnb, A.; Maiera, H.J. Microstructure—Deformation relationships in fine grained high manganese TWIP steel the role of local texture. Int. J. Mater. Res. 2012, 103, 12–16. [Google Scholar] [CrossRef]

- Rehrl, C.; Kleber, S.; Antretter, T.; Pippan, R. A methodology to study crystal plasticity inside a compression test sample based on image correlation and EBSD. Mater. Charact. 2011, 62, 793–800. [Google Scholar] [CrossRef]

- Weidner, A.; Yanina, A.; Guk, S.; Kawalla, R.; Biermann, H. Microstructure and local strain fields in a high-alloyed austenitic cast steel and a steel-matrix composite material after in situ tensile and cyclic deformation. Steel Res. Int. 2011, 82, 990–997. [Google Scholar] [CrossRef]

- Xu, X.; Quan, L.; Li, B.; Guo, J. Modeling, simulation and experiment of electro-hydraulic screw down servo system of seamless tube rolling mill. Chin. J. Mech. Eng. (Engl. Ed.) 2011, 24, 113–120. [Google Scholar] [CrossRef]

- Rahimi, S.; Engelberg, D.L.; Duff, J.A.; Marrow, T.J. In situ observation of intergranular crack nucleation in a grain boundary controlled austenitic stainless steel. J. Microsc. 2009, 233, 423–431. [Google Scholar] [CrossRef]

| Definition | Aspect | References Number |

|---|---|---|

| First step: Digital form | Surface damage in tensile process | [10,82,108,118,131] |

| Deformation behavior of steel | [35,55,56,94,97,125] | |

| Strain mechanism of steel | [57,83,85,91,96,127,138] | |

| Plasticity behavior of steel | [38,58,100,110] | |

| Fracture mechanism of metallic materials | [44,68,76,123,140] | |

| Quality evaluation of alloys | [75,87,113,129,130,132] | |

| Instrumented indentation of steel | [79,128] | |

| Dynamic behavior of metal tests | [124,134] | |

| Second step: Virtual model | Monitoring for steel structures | [6,16,17,62,104,107] |

| Maintenance for large-span structures | [5,34,45,65,72,104] | |

| Research on strip rolling technique | [14,27,46,115,139] | |

| Additive manufacturing | [51,63,76,126] | |

| Prediction for steel manufacturing | [26,28,29,48,73] | |

| Fatigue evaluation of infrastructure | [7,16,24,34,40,81,92] | |

| Construction of steel materials | [53,70,99] | |

| Digitalization in chemical engineering | [66,101] | |

| Third step: Surrogate model | Crack identification and location | [1,8] |

| Improvement of steel production | [11,13,21,88] | |

| Mechanical mechanism modeling | [23,64,102] | |

| Condition monitoring for steel equipment | [52,104] | |

| Prediction and maintenance of structure | [30,54,78] |

| Method | Subject | References Number |

|---|---|---|

| Finite element | Algorithm fusion | [3,7,9,24,31,43,48,70,81,89,109] |

| Monitoring technique | [4,16,39,49,59,77,93,104,107,117] | |

| Application effect | [18,22,25,32,40,41,55,69,80,92,119] | |

| BIM model | Date exchange | [6,14,28,34,115] |

| Framework establishment | [5,27,53,62,66,99,101] | |

| Management effectiveness | [29,63,72,74,103] | |

| Laser scanning | Point-cloud analysis | [37,45,84,90] |

| Model establishment | [12,17,19,33,36,67] | |

| Model function | [26,50,95,122] | |

| Machine learning | Algorithm innovation | [1,8,105] |

| Data-driven effect | [11,23,54,88] | |

| Model fusion | [30,52,60,64,78,102] |

| Application Field | Subject | References Number |

|---|---|---|

| Material deformation | High-performance material deformation | [20,35,37,87,94,106,108,109,112,118,121] |

| Deformation observation | [50,69,83] | |

| Complex deformation condition | [47,55,56,91] | |

| Deformation mechanism | [57,85,97,100,113,124,125,127,128,129,130,131,132,133,134,136,137,138] | |

| Infrastructure management | Large-scale facility maintenance | [5,19,33,65,70,82] |

| Bridge management | [36,40,41,80,95] | |

| Advanced steel manufacturing | [14,21,26,59,77,99] | |

| Steel mechanic assessment | [39,54,78,84,89,102,122] | |

| Fatigue assessment | Fatigue crack detection | [1,8,10,22,34] |

| Crack growth monitoring | [25,76] | |

| Fatigue crack prediction | [7,16,24,73,92] | |

| Fatigue resistance evolution | [68,81] | |

| Real-time monitoring | Structural condition identification | [4,6,45,52,62,74,107] |

| Steelmaking monitoring | [12,13,51,63,88,115,126] | |

| Large-scale facility manufacturing | [17,39,71,104] | |

| Structural measurement | [31,88,96,103] | |

| Other applications | Special material property | [11,15,23,38,42,44,49,60,64,75,98,101,111,117] |

| Advanced measurement | [18,27,28,30,58,79] | |

| Typical manufacturing process | [29,46,72,109] | |

| Special industry | [53,66,119] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, L.; Ding, Y.; Cheng, B. Development and Application of Digital Twin Technique in Steel Structures. Appl. Sci. 2024, 14, 11685. https://doi.org/10.3390/app142411685

Shi L, Ding Y, Cheng B. Development and Application of Digital Twin Technique in Steel Structures. Applied Sciences. 2024; 14(24):11685. https://doi.org/10.3390/app142411685

Chicago/Turabian StyleShi, Linze, Yong Ding, and Bin Cheng. 2024. "Development and Application of Digital Twin Technique in Steel Structures" Applied Sciences 14, no. 24: 11685. https://doi.org/10.3390/app142411685

APA StyleShi, L., Ding, Y., & Cheng, B. (2024). Development and Application of Digital Twin Technique in Steel Structures. Applied Sciences, 14(24), 11685. https://doi.org/10.3390/app142411685