Abstract

The advancement of wearable technology has entered a new phase, leading to the creation of various wearable sensors due to the rise of technologies like IoT and AI. Wearable chemical sensors are essential components of wearable electronics and hold significant promise in monitoring health. This review reports on the recent achievements and advantages of portable smart chemical sensing for health monitoring and discusses portable chemical sensing using frictional/piezoelectric electrochemical generators, photovoltaics and thermal power accumulators. This paper also evaluates the potential of wearable chemical sensors for health monitoring.

1. Introduction

Wearable technologies and devices are evolving from faddish consumer electronics to become deeply integrated into human lives [1,2], with smart wearable sensors becoming increasingly popular due to their flexible, simple [3] and portable nature. From smart watches and eyewear to health monitoring devices [4], the scope of wearable devices is widening [5,6], bringing convenience and comfort to our lives. Health and fitness are not the only areas where wearable technology and devices are used [7,8,9]. As technology continues to evolve, wearable devices have begun to infiltrate healthcare, entertainment, industry, education and security [10,11,12,13,14]. Wearable chemical sensors, a technology on the rise, have garnered significant interest in recent years. A wearable chemical sensor is a portable, wearable electronic device that detects chemicals in the human body and converts the results into electrical or digital signals for monitoring human health and providing early warnings [15,16,17]. Such sensors offer advantages such as small size, lightweight, easy operation and reusability and usually consist of sensing elements, signal-processing circuits, display devices, etc. [18,19,20]. Current research is focusing on wearable chemical sensors, which have a variety of potential uses in medical care, monitoring health [21], sports [22,23] and so on.

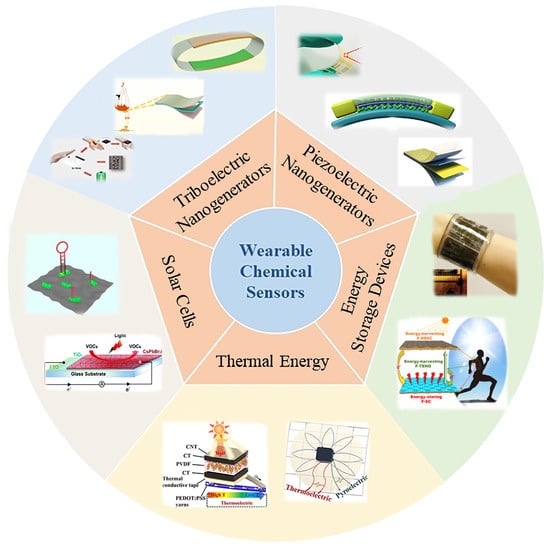

Various uses of chemical sensors in wearable technology have been documented, including those utilizing triboelectric nanogenerators (TENGs), piezoelectric nanogenerators (PENGs), solar cells, thermal energy and energy storage devices [24,25], as illustrated in Figure 1. The integration of chemical sensors into wearable devices has a variety of advantages, which are mainly reflected in their small size, lightweight [26], easy operation, strong adaptability [27,28] and ability to meet a variety of application scenarios [29,30]. While these sensors play an important role in wearable devices, some challenges need to be further addressed in terms of improving the sensitivity and selectivity of the sensors, as well as reducing power consumption and improving stability [31,32,33].

However, there has been considerable progress in the practical applications of wearable smart chemical sensors, including the real-time monitoring and analysis of human motion [34], improving the efficiency and accuracy of healthcare systems, assisting smart wearable devices [35] and recycling energy [36,37]. This article examines the latest advancements in and benefits of wearable intelligent chemical detectors for monitoring health, exploring wearable chemical detectors utilizing TENGs, PENGs, solar cell-based sensors, thermal energy-based sensors and energy storage device-based sensors in terms of their energy consumption [38,39]. In the conclusion, the potential and challenges of wearable chemical sensors are discussed, offering potential insights for the advancement of self-powered chemical sensors based on TENGs technology for future use in wearable devices.

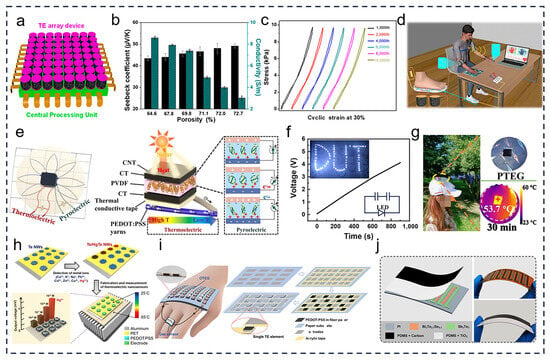

Figure 1.

Applications of wearable chemical sensors [40,41,42,43,44,45,46,47,48,49].

2. Wearable Chemical Sensors Based on Different Working Principles

Wearable intelligent chemical sensors are widely used in the field of health monitoring. This article focuses on the applications of piezoelectric nanogenerators, triboelectric nanogenerators, solar cell sensors, thermal energy sensors and energy storage device sensors in this field. Each of these sensors has its own advantages and disadvantages, as shown in Table 1.

Table 1.

The advantages and disadvantages of different wearable smart chemical sensors [50,51,52,53,54,55,56].

2.1. Wearable Chemical Sensors Based on Triboelectric Nanogenerators

Mechanical energy is a green and ubiquitous natural resource [57]. TENGs, a novel innovation for transforming scattered, unpredictable, low-frequency mechanical power into electricity, are gaining attention from the general public because of their cost-effectiveness, variety of material options, uncomplicated design and high efficiency in energy conversion. Consequently, they are now extensively employed in wearable electronic gadgets [58]. Nowadays, triboelectric nanogenerators based on four working modes, namely, sliding friction, contact separation, single electrode and independent layers, have been applied in the fields of e-skin, health management and the environment as well as sports training. The rapid development of triboelectric nanogenerator technology is closely related to the chemical modification of friction layer materials [59,60].

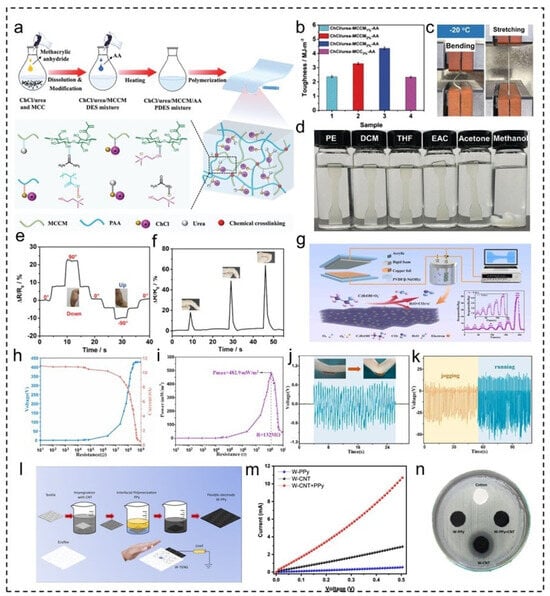

Cellulose, currently one of the most abundant renewable natural polymers on Earth, is characterized by a wide applicability, excellent cost-effectiveness and superior flexibility. As a result, it has emerged as one of the most promising friction materials for TENGs in recent years. Owing to its high proneness to electron loss, it is frequently utilized as a positive friction material. Nevertheless, numerous materials within the cellulose family, including cellulose, cellulose nanocrystals and cellulose nanofibers, suffer from drawbacks such as poor flexibility, complex manufacturing processes and performance limitations. These shortcomings restrict their application as negative friction materials in TENGs. Consequently, to address these issues, Lu et al. [61] have conducted relevant research and prepared ionic conductive elastomers with dual crosslinked networks through the in situ polymerization of deep eutectic solvents that are polymerizable. In Figure 2a, the creation process and a diagram of the interconnected structure of ionic conducting elastomers derived from cellulose-based polymerizable deep eutectic solvents (PDESs) are shown. Figure 2b demonstrates that the mechanical strength and toughness were more than doubled by the formation of the dual crosslinked network. Cellulose plays a role in creating a strong interconnected network held together by hydrogen bonds, enhancing the elastomer’s ability to recycle, protect against frost and resist solvents. Figure 2c illustrates the elastomer’s ability to stretch and flex effortlessly at −20 °C without any signs of damage, showcasing its excellent resistance to frost. The conductive elastomers’ resistance to solvents was assessed by immersing the elastomer samples in various solvents at room temperature for 12 h, including petroleum ether, dichloromethane, tetrahydrofuran, ethyl acetate, acetone and methanol. After the immersion period, the elastomer samples maintained their original structure, except for those in the methanol. This change was due to methanol molecules forming new hydrogen bonds with acrylic acid (AA) and choline chloride (ChCl), disrupting the ion-conducting elastomers’ hydrogen-bonded cross-linking network, as depicted in Figure 2d. As shown in Figure 2e,f, the wearable sensing capabilities of conductive elastomers based on PDES were investigated. It can be used to determine the wrist bending angle and different finger movements. This study paves the way for the development of promising strategies for the fabrication of sustainable and multifunctional flexible electronics for use in harsh environments [62].

Figure 2.

Wearable chemical sensors based on triboelectric nanogenerators. (a) Schematic of the fabrication process and crosslinking structure of cellulose-derived PDES-based ion-conductive elastomers. (b) Toughness of the elastomer. (c) Digital photograph of the elastomer undergoing stretching at −20 °C. (d) Digital photographs of elastomers immersed in different solvents. (e) Strain transducer for monitoring wrist movement. (f) Strain sensor for monitoring finger movement. (g) Schematic of a self-powered ethanol system driven by NP-TENGs. (h) Relationship between output voltage and current and load resistance of NP−TENGs. (i) Relationship between output power density and load resistance of NP−TENGs. (j) Motion monitoring application of flexible NP−TENG in the human elbow. (k) Motion monitoring application of flexible NP-TENG in the human foot. (l) Fabrication of S−TENG devices impregnated with CNTs followed by chemical polymerization and assembly of wearable modified textiles into wearable TENG devices. (m) I-V curves of textile-modified samples with polypyrrole (W−PPy), CNTs (W−CNT) and CNT−polypyrrole (W−CNT+PPy). (n) Inhibition of S. aureus by pure and modified textiles (cotton/W-CNT/W−CNT+PPy/W−PPy) in Petri dishes in the absence of an external field.

The spread of autonomous ethanol detectors is essential in sectors like farming and chemical manufacturing. He et al. [63] introduced a TENG (NP−TENG) that utilized β-Ni(OH)2/MXene gas-responsive composites and β-Ni(OH)2@PVDF. The preparation process and working schematic are shown in Figure 2g. NP-TENG employs β−Ni(OH)2 as a superior additive to boost the efficiency of TENGs. As the external resistor value increases, the peak-to-peak value of the open-circuit voltage rises from 0 to 427.95 V, as shown in Figure 2h, i, while the short-circuit current drops from 11 μA to 0 μA. The power density reaches its peak (482.9 mW/m)2) at a load resistance of 132 MΩ. Doping with MXene enhances the charge transfer in the gas-sensitive response of β−Ni(OH)2, allowing for the wide-ranging and highly sensitive detection of ethanol gas under room temperature and high humidity conditions. Moreover, linking the NP-TENG to the elbow joint of the body can transmit the usual voltage signals produced by the elbow motion, while attaching the NP-TENG to the bottom of a shoe can detect two distinct body motion conditions, jogging and running, instantly, as shown in Figure 2j, k. Expanding the scope of TENG usage for autonomous gas sensors is the focus of this project.

Candido et al. [40] introduced friction nanogenerators that were created using altered cotton along with conductive and antimicrobial substances in a separate project, aiming to power a self-sufficient device for electric antimicrobial treatment. Figure 2l shows the process of fabricating W−TENG. After impregnation with carbon nanotubes, wearable modified textiles were chemically polymerized and assembled in wearable TENG devices. The enhanced cotton exhibits outstanding electrical properties as a result of the interaction between polypyrrole and carbon nanotubes within a sophisticated network, leading to improved electrical conductivity in the final material, as shown in Figure 2m. Figure 2n exhibits the inhibition halo of the modified cotton fiber (W−PPy+CNT). It can be seen that the inhibition halo is negligible and shows good antimicrobial properties. Research on the antimicrobial characteristics of polypyrrole and its excellent conductivity was conducted to develop a single electrode friction generator induction layer, providing further benefits compared to skin contact, making it crucial for treating various infections.

Recent advancements in wearable chemical sensors utilizing triboelectric nanogenerators have significantly improved their capabilities through chemical enhancements primarily focused on tracking human activity and improving efficiency and safety in daily tasks. With the continuous progression of technology and the expansion of application fields, wearable sensors based on triboelectric nanogenerators will play a more important role in future development.

2.2. Wearable Chemical Sensors Based on PENG

PENGs are tools that harness piezoelectric effects to detect the electrical charge generated when pressure is applied to a piezoelectric substance. Utilizing electromechanical energy conversion principles, these devices offer benefits such as rapid response rates, a strong parametric response, compact design, durable construction and efficient output, making them popular in wearable sensor technology.

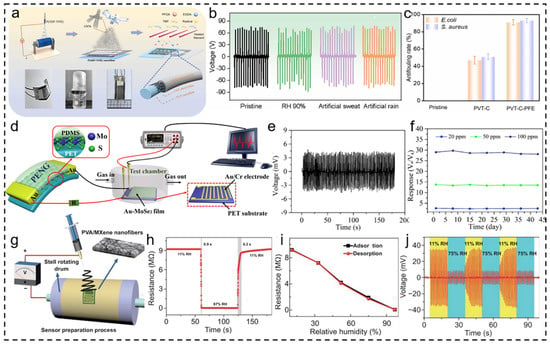

PENGs are one of the most popular power sources for wearable chemical sensors. Su et al. [64] reported a robust superhydrophobic antimicrobial self-powered PENG sensor. As shown in Figure 3a, this figure demonstrates the preparation process of the PENG sensor, which consists of a flexible electrostatically spun poly (vinylidene fluoride-co-tetrafluoroethylene) piezoelectric nanofiber membrane and sprayed fork-finger carbon nanotube electrodes, which are subsequently encapsulated by cross-linked conformal hydrophobic nano-coatings wrapped around each fiber by initiated chemical vapor deposition (iCVD). The acquired sensors are capable of precisely tracking a range of human activities, including respiration and various motions. iCVD nano-coatings offer superior sensor protection, including self-cleaning properties, super hydrophobicity and over 90% resistance to bacterial fouling, as shown in Figure 3b,c. These durable ultra water-repellent self-sustaining PENG sensors are anticipated to have broader real-world uses in monitoring human behavior, advanced medical systems and interactions between humans and computers.

Figure 3.

Wearable chemical sensors based on PENGs. (a) The preparation process for self-powered PENG sensor. (b) Output voltage signals of the original sensor and the sensor after exposure to RH90% for 168 h, artificial sweat immersion for 72 h and artificial rain immersion for 72 h. (c) Antifouling rates of pristine PVT−C and PVT−C−PFE against E. coli and Staphylococcus aureus determined by the plate counting method. (d) Schematic of the self-powered NH3 sensor based on MoS2 sheet piezoelectric nanogenerator drive. (e) Mechanical reliability test of PEAS based on Au-MoSe2 composite exposed to 20 ppm NH3. (f) Long-term stability test of Au−MoSe2-based PEAS exposed to 20, 50 and 100 ppm of NH3 for 7 weeks. (g) Schematic of the fabrication of the PVA/MXene humidity sensor. (h) Resistance response and recovery curves of the PVA/MXene sensor over time between 11% RH and 97% RH. (i) Humidity hysteresis curve of the PVA/MXene nanofiber thin film sensor. (j) Repeatability of the self-powered PVA/MXene sensor.

Zhang et al. [46] proposed a flexible PENG powered room-temperature ammonia gas detector utilizing a gold–molybdenum selenide (Au-MoSe2) compound and a two-dimensional (2D) semiconductor MoS2 layer (Figure 3d). The synthesis of Au NPs was achieved by heating 0.12 mmol of HAuCl4·3H2O under continuous stirring, during which sodium citrate solution was added. Subsequently, 10 mL of the prepared gold solution and 100 mg of MoSe2 were mixed by stirring and then centrifuged in deionized water for the synthesis process. Eventually, the resulting Au-MoSe2 sample manifested as a metallic state within the composite material. The ammonia gas sensor also exhibited excellent mechanical reliability (Figure 3e) and outstanding long-term stability (Figure 3f). Moreover, the PENGs utilizing MoS2 can capture kinetic energy from body movements and show promising prospects for integration into autonomous wearable gadgets. Wang et al. [65] proposed a self-sustaining flexible humidity sensor utilizing a PVA/MXene nanofiber film and MoSe2 piezoelectric nanogenerator, as shown in Figure 3g. Utilizing a single-layer MoSe2 PENG, the humidity sensor on a flexible PET substrate, which is constructed using electrospun PVA/MXene nanofibres, demonstrates a significant response of 40%. The PVA/MXene sensor’s time-varying resistance response and recovery rates between 11% and 97% relative humidity (RH) are 0.9 s and 6.3 s, respectively, thus demonstrating a relatively low delay time (Figure 3h). The hysteresis characteristics of the PVA/MXene sensor related to RH have been investigated. The results reveal that the PVA/MXene humidity sensor has a delay of 1.8%. This sensor presents excellent humidity-sensing performance, which can be ascribed to the humidity sensitivity of the composite material (Figure 3i). Additionally, through a comparison of the test results, it can be observed that the output voltage of the PVA/MXene sensor shows no significant variation at 11% and 97% RH, indicating its outstanding repeatability (Figure 3j). The advancements in PENGs for wearable chemical sensors are remarkable, showcasing excellent water resistance and flexibility. This innovative technology has diverse applications and can offer valuable technical assistance to human health, environmental monitoring and safety detection. It is believed that, with the continuous progress and development of this technology, the application prospects of piezoelectric nanogenerator-based wearable chemical sensors will be even broader.

2.3. Wearable Chemical Sensors Based on Solar Cells

Solar energy is an important renewable and clean energy source, which can be converted into electricity to meet the energy needs of human beings. Solar cells are one of the most important ways to collect solar energy. Thanks to its unique performance features, it is commonly used in photovoltaic power generation devices. It uses silicon-containing semiconductors to generate a photovoltaic effect, directly converting light energy into electricity. This provides a sustainable energy solution for wearable chemical sensors, enabling them to operate for long periods outdoors or in well-lit environments. The integration of solar cells and wearable chemical sensors promotes device miniaturization and multifunctionality. By integrating solar cells, chemical sensors and signal-processing units into a small wearable device, energy collection and chemical substance detection can be achieved simultaneously without increasing the device’s size [66]. Based on this, solar cell-based photovoltaic systems are typically applied for monitoring human motion and health information, with a focus on flexible and wearable sensor technologies. Extensive research has been conducted on chemical sensors that can be worn and are powered by solar cells.

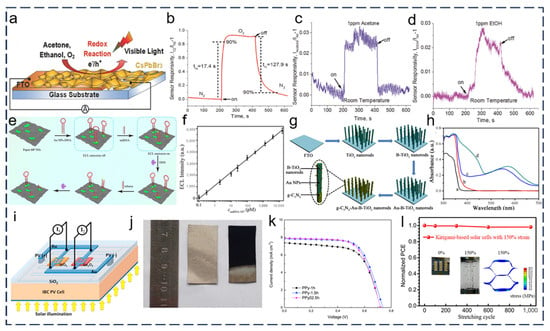

Hybrid halide chalcogenides are promising light absorbers that have been intensively studied in many photovoltaic applications. They have recently been utilized for self-powered chemical sensors. Chen et al. [67] demonstrated a prototype of self-sustaining inorganic halide-thalate for detecting chemical gasses under visible light at room temperature, as shown in Figure 4a. Comprising a permeable lattice of CsPbBr3 (CPB), these gadgets generate a 0.87 V open-circuit voltage when exposed to visible light, enabling the detection of different levels of O2 and medically significant volatile organic compounds like acetone and ethanol in parts per million, all while maintaining rapid response and recovery times (Figure 4b–d). Such a device has positive implications for the upcoming era of wearable technology. Similarly, Gao et al. [43] synthesized two-dimensional black phosphorus nanosheets (NSs) through a simple yet highly efficient n—methylpyrrolidone (NMP) solvent exfoliation approach. Subsequently, these synthesized nanosheets were employed as an electrochemiluminescence (ECL) luminophore within the context of peroxydisulfate (S2O82−). They developed a chalcogenide solar cell (PSC) device on paper to substitute the costly and large electrochemical workstations typically utilized, as shown in Figure 4e. Utilizing the PSC-based paper platform, the constant-potential ECL−RET system demonstrated an exceptional sensitivity in detecting miRNA-107 across a wide concentration range of 0.1 pM to 15 nM, as shown in Figure 4f. Crucially, this research not only established a model for creating a very responsive PSC-induced ECL detection system but also investigated the potential uses of BP nanomaterials in biological analysis. Additionally, a sensing platform that is self-powered and has dual-response capabilities was created using photoelectrochemical cells. g−C3N4−Au-B−TiO2 nanorod probes were constructed as photoanodes and PB-modified FTOs served as cathodes. Wang et al. [68] illustrated the development of g-C3N4-Au-B-TiO2 nanorods, as shown in Figure 4g. The solar-to-chemical energy conversion efficiency in the device was enhanced by the gold nanoparticles placed between the B-TiO2 nanorods and g-C3N4, as illustrated in Figure 4h. Juan et al. [57] developed a self-sustaining versatile detector by combining crystalline silicon IBC photovoltaic cells with a vertically stacked structure on a single chip. The IBC PV cells were arranged vertically in parallel with a humidity sensor and a photodetector (PD) as illustrated in Figure 4i. Researchers’ efforts have been focused on creating flexible photovoltaic power sources for wearable electronics, which benefit from the advantages of both electronics and textiles. Xu et al. [69] deposited polypyrrole as a catalytic material on nickel-plated cotton fabrics through the electrochemical polymerization of pyrrole, as shown in Figure 4j. Polypyrrole-coated counter electrodes were used to create dye-sensitized solar cells, achieving a power conversion efficiency of approximately 3.83% under AM1.5 lighting conditions, as illustrated in Figure 4k. Creating flexible solar panels that can withstand significant stretching and maintain durability through repeated cycles presents a challenge for electronic devices designed to be worn on the body or integrated into the skin. Li et al. [59] designed a chalcogenide solar cell using a paper-cut structure. The chalcogenide solar cell made from paper-cut material, featuring ideal geometric dimensions, demonstrated an exceptional flexibility and superior strength; for more details, refer to Figure 4i.

Figure 4.

Wearable chemical sensors based on solar cells. (a) Schematic of CPB-based chemical sensor. (b) Response time of the CPB sensor to pure O2 gas under visible light irradiation. (c) Responsiveness of the dynamic CPB sensor to the injection of 1 ppm of acetone and ethanol (d) in air under visible light irradiation at room temperature. (e) Preparation process and mechanism of paper-based electrochemiluminescence-resonance energy transfer (ECL−RET) sensing platform. (f) Calibration plot of ECL intensity relative to miRNA-107 concentration. (g) Schematic diagram of the formation process of g−C3N4−Au−B−TiO2 nanorods. (h) UV−Vis absorption spectra. (i) Schematic diagram of the self-powered humidity sensor and UV photodetector integrated with a fork-finger back-contact photovoltaic cell. (j) Photographs of nickel-coated (left) and polypyrrole/nickel-coated (right) fabrics. (k) Current–voltage (J-V) characteristics of dye-sensitized solar cells employing polypyrrole-coated fabric counter electrodes measured under AM 1.5 illumination. (l) Mechanical deformability and durability of the paper-cut structure of chalcogenide solar cells.

Wearable chemical sensors powered by solar cells provide us with a new way to monitor and sense the world and the highly efficient transfer rate of solar energy conversion to chemical energy allows us to achieve comprehensive, real-time monitoring of ourselves and our surroundings without violating our privacy. The further development and application of this technology will bring more convenience and safety to our lives.

2.4. Wearable Chemical Sensors Based on Thermal Energy

Thermal energy sensors are eco-friendly technologies that utilize thermoelectric and pyroelectric effects to transform heat into electricity by harnessing energy from human movements. The pyroelectric effect pertains to the alteration of spontaneous polarization within certain polar materials due to temperature fluctuations. By leveraging the temperature variations over time, this effect enables the conversion of heat into electrical energy. The underlying mechanism is that time-dependent temperature fluctuations modify the spontaneous polarization of polar crystals, which subsequently leads to the redistribution of surface charges and the generation of a temporary electric current. During human movement, muscles undergo continuous contraction and relaxation. After exercise, the body’s metabolism is enhanced, accompanied by an increased energy consumption, thereby resulting in the production of a substantial amount of heat. The abundance of thermal energy in the environment has sparked significant interest in creating wearable energy harvesters that utilize the process of thermal energy conversion. In recent years, scholars at home and abroad have proposed wearable thermal energy harvesting devices based on the thermoelectric effect and applied them to wearable sensors.

Utilizing human body heat to produce electricity is an excellent approach for creating self-sustaining wearable technology. Zhang et al. [70] aim to improve upon the limitations of current thermoelectric fibers, films and blocks, which include limited power generation capabilities and a lack of flexibility. A versatile superelastic sponge made of graphene was created for use in wearable electronics and thermal regulation, as depicted in Figure 5a. The sponge exhibits a substantial Seebeck coefficient of 49.2 μV/K and an extensive compressive strain of 98% as shown in Figure 5b. Following 10,000 rounds of compression, the sponge displayed outstanding mechanical and thermal expansion stability, as shown in Figure 5c. In Figure 5d, the impressive thermoelectric performance and promising applications of thermoelectric sponges in everyday life are demonstrated through the utilization of human body heat. The human body serves as a reliable source of heat, supplying a constant stream of thermal energy. The efficient extraction of heat from the human body shows promise for use in creating wearable technology. Zhang et al. [49] introduced a new wearable hydrothermal electric generator (PTEG) powered by solar energy, which was created by combining a solar absorber with high efficiency, a pyroelectric film and a thermoelectric yarn, as shown in Figure 5e. The PTEG is more effective at capturing energy from changing temperatures and temperature differences compared to other wearable pyroelectric and thermoelectric generators mentioned in previous studies, as illustrated in Figure 5f. The PTEG was attached to the top of a hat in real-world scenarios. Following 30 min of exposure to solar radiation, the top layer of the PTEG material reached a temperature of 53.7 degrees Celsius, as illustrated in Figure 5g. The PTEG can efficiently capture solar energy when worn, showing potential as a wearable energy generator for everyday use. Tsao et al. [71] presented a novel thermoelectric nano-sensor utilizing the thermoelectric effect to detect mercury ions for the first time, as shown in Figure 5h. The thermoelectric nano-sensor’s structure consists of aluminum foil serving as the bottom electrode and a substrate of tellurium nanowires (Te NWs). The thermoelectric nano-sensor utilizes Te NWs as a highly specific substance in the reaction with mercury ions, enabling it to achieve a detection limit of 1.7 nM and a wide linear range (from 10 nm to 1 µm) for detecting mercury ions with high sensitivity. Upon contact between Te NWs and Hg2+ ions, a HgTe core/shell structure is formed. With an increase in the Hg concentration, the proportion of HgTe on Te NWs rises, thereby leading to a stronger electrical output. Consequently, the variation in electrical output can be exploited for the detection of the Hg2+ concentration. Through this mechanism, the thermoelectric nano-sensor can accomplish highly sensitive detection of mercury ions. The thermoelectric nano-sensor utilizes Te NWs as a highly specific substance in the reaction with mercury ions, enabling it to achieve a detection limit of 1.7 nM and a wide linear range (from 10 nm to 1 µm) for detecting mercury ions with a high sensitivity. The thermoelectric nano-sensor exhibited a strong selectivity towards mercury ions, with its voltage increasing ninefold in their presence compared to other ions. The analysis of these studies clearly shows that thermoelectric-based chemical sensors show clear potential for future wearable and flexible miniaturized sensing systems, as proposed by Zheng et al. [72] and demonstrated in Figure 5i. A flexible self-powered sensing component was created through the combination of an organic transistor chemical sensor with a flexible power-organic thermoelectric (OTE) generator. The OTE array constructed on a paper substrate has a maximum open-circuit voltage of 0.52 V and a maximum power output of 0.32 μW. According to reports, the device can power gas sensors utilizing organic field-effect transistors at a very low voltage and accurately detect the existence of ammonia. The traditional lithium battery, currently the primary energy source for wearable electronic gadgets, faces significant challenges like environmental harm and the need for frequent recharging. To address these issues, Wen et al. [73] described a versatile hybrid photo-thermal electric generator (PTEG) that utilizes a basic design comprising a thermoelectric generator (TEG) and a photo-thermal conversion layer to capture both thermal and radiant energy using a unified operating mechanism, as shown in Figure 5j. Proven screen-printing techniques are used to fabricate large-scale n-type (Bi2Te2.7Se0.3) and p-type (Sb2Te3) thermoelectric inks on polyimide substrates, creating TEGs with serpentine-shaped thermocouple chains. These TEGs are then coated with a photo-thermal conversion layer to form PTEGs. It has been reported that PTFGs can be used to harvest both biothermal and infrared radiant energies to power electronic devices, providing new solutions to the current problem of powering wearable electronic devices.

Figure 5.

Wearable chemical sensors based on thermal energy. (a) CPU surface covered with an array of graphene-based thermoelectric (TE) sponge devices for power generation and CPU cooling. (b) Seebeck coefficient and conductivity of TE sponges with different porosities. (c) Stress–strain curves of TE sponges under cyclic strain from 0% to 30%. (d) Potential application scenarios of TE sponges as wearable electronic devices in daily life. (e) Schematic of the structural design and working mechanism of a solar-driven pyroelectric hybrid generator. (f) The voltage obtained on two series-connected commercial capacitors as a function of charging time. (g) Scheme of the solar-driven pyroelectric hybrid generator integrated on the top of the hat. The inset shows the temperature rise under natural solar illumination conditions. (h) Structure of a self-powered thermoelectric nanosensor and its sensing process for mercury ion detection. (i) Schematic of an organic field effect transistor-based sensor and its fabrication process. (j) Structural design of hybrid photothermal electric generator (PTEG).

Advancements in wearable chemical sensors utilizing thermal energy offer new potential for enhancing our daily lives. By utilizing thermal energy from the environment or the human body, electronic devices enable us to continuously monitor ourselves and our surroundings in real-time, regardless of location. The further development and application of this technology will bring more convenience and safety to our lives.

2.5. Wearable Chemical Sensors Based on Energy Storage Devices

The emergence of the ‘flexible’ era has made the integration of wearable flexible electronic devices and energy storage devices a popular research topic that is greatly appreciated by society. To address the energy issue, people can continuously collect energy from the environment by harnessing thermal energy, mechanical energy or solar energy to achieve self-powered sensing. To ensure better long-term operation without being affected by the surrounding environment, the development of sensors for energy storage devices is of great importance. Although a series of studies such as the development of planar supercapacitors with interdigitated electrodes constructed on a single substrate have been carried out before to achieve self-powered sensing, the addition of internal energy storage elements may lead to reduced stability and reliability, and even cause problems such as slower response speeds. Through the design of sensor structures and the selection of materials, this impact can be mitigated to enable the continuous operation of the sensors. Generally, numerous self-sustaining sensing gadgets equipped with built-in energy storage components have been effectively developed in this area, yet there remains ample opportunity for further investigation. The incorporation of energy storage units with sensors provides significant advantages for chemical sensor uses [74].

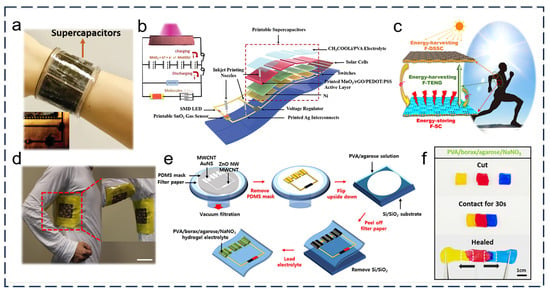

Lin et al. [47] designed a gas sensor using inkjet printing technology, printed super capacitors and solar cells as an energy source to be used as a wearable wristband, as shown in Figure 6a, b. The wearable wristband directly drives the sensor by collecting solar energy and is also able to store it in standby mode in the super capacitor for easy use. The super capacitor with a printed design has a face capacitance of 12.9 mF·cm−2, while the gas sensor shows a high sensitivity to ethanol and acetone under normal room conditions. Printing technology for product fabrication and integration demonstrates great potential for the scalable and simple fabrication of various wearable devices. Wen et al. [48] designed a portable hybrid self-powered power textile system that generates energy by harvesting outdoor sunlight with random motions to store it in an energy storage unit like that shown in Figure 6c. Both gathered energies can be effortlessly transformed into electricity through the use of fiber-shaped dye-sensitized solar cells (for solar power) and fiber-shaped triboelectric nanogenerators (for kinetic energy from body movements), which are subsequently stored as chemical energy in fiber-shaped supercapacitors, as shown in Figure 5d. All fiber-like structures have a broad range of uses in the wearable electronics industry. Kim et al. [75] developed a comprehensive system equipped with versatile sensors for detecting No2. The system consists of a planar super capacitor fabricated by interconnecting gold nanosheets (AuNS) and a multifunctional sensor, as shown in Figure 6e. The super capacitor was prepared from a polyvinyl alcohol/borax/agarose/NaNO3 electrolyte and multiwalled carbon nanotubes (MWCNTs) electrodes coated on the AuNS collector, which provided a sensor with high performance and self-repairing properties, as shown in Figure 6f. Moreover, the chemo-sensor consisted of a composite of ZnO nanowires and multi-walled carbon nanotubes. At room temperature, the sensor offered a consistent detection of NO2. This work provides a reference for the preparation of high-performance wearable devices with high durability and an increased lifetime.

Figure 6.

Wearable chemical sensors based on energy storage devices. (a) Schematic of a supercapacitor-based gas detection system. (b) Schematic of a printable fabrication procedure and system operation mechanism for a self-powered smart sensor system. (c) Hybrid self-powered power textile system. (d)Self-powered textile fabric using weaving under motion conditions. (e) The preparation process of self-healable hydrogel electrolyte with high-performance supercapacitors. (f) Self-healing process of self-healable hydrogel electrolyte.

Energy storage device-based wearable chemical sensors offer a fresh approach to the advancement of wearable technology [54]. Energy storage device-driven wearable chemical sensors mainly use energy storage devices to store electrical energy, thus providing the sensors with the power required for efficient and reliable energy storage and release. Considering the monitoring purposes and requirements of various sensors and the charging efficiency of power supply devices, capacitors of different sizes have been established to ensure that the energy consumption during the sensor’s operation matches the energy supply. In the future, we expect to see more innovative designs and a wider range of application areas as this technology continues to advance and the research deepens.

3. Conclusions and Outlook

This review provides a concise overview of the latest advancements in five types of wearable smart chemical sensors for health monitoring. While a variety of commercial health monitoring sensors are available on the market, they often face significant limitations, such as complex structures, high costs and cumbersome operation, which hinder their widespread adoption in practical scenarios. In contrast, wearable chemical sensors offer advantages including convenience, real-time monitoring and continuous detection, making them highly promising for applications in healthcare, environmental monitoring and safety assessment. Notwithstanding their inherent potential, the extensive dissemination and application of wearable smart chemical sensors in the domain of health monitoring are confronted with a multiplicity of critical issues that warrant further in-depth consideration. In order to surmount these challenges, the following aspects are deserving of particular and meticulous attention: (1) Interference resistance and signal stability: Variations in external environmental factors, such as humidity and temperature, can severely impact signal output stability, thereby reducing the reliability and consistency of detection results. This issue can be mitigated by enhancing device encapsulation or employing materials and components that are less sensitive to environmental changes. (2) Comfort and breathability: Non-stretchable, rigid and non-breathable materials can significantly compromise wearing comfort, limiting prolonged usage and negatively affecting user experience. To address this, lightweight, breathable, and skin-friendly materials should be prioritized to enhance user comfort. (3) Equipment Durability: Prolonged health monitoring requires that equipment has the ability to operate for long periods of time, which places stringent demands on the durability of equipment materials. Solutions include the use of wear-resistant and self-repairing materials, the incorporation of protective coatings, and the optimization of structural design. In summary, while wearable chemical sensors demonstrate immense potential for health monitoring applications, their development is hindered by significant technical and practical challenges. Future research should focus on developing skin-friendly, flexible materials and structural optimization to minimize wear and increase durability. In addition, relying on advanced packaging technology also solves the problem of environmental interference, thus ensuring the reliability and stability of sensor performance. Addressing these challenges is essential to realize the potential of wearable smart chemical sensors for health monitoring applications.

Author Contributions

Conceptualization, methodology, investigation, analysis, writing—original draft and visualization, N.B. and W.Y.; writing—review and editing, W.W.; conceptualization, methodology and writing—review, C.C. and P.C.; All authors have read and agreed to the published version of the manuscript.

Funding

Not applicable.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

The authors would like to thank all participants of this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Seshadri, D.R.; VanBibber, H.D.; Sethi, M.P.; Harlow, E.R.; Voos, J.E. Wearable Devices and Digital Biomarkers for Optimizing Training Tolerances and Athlete Performance: A Case Study of a National Collegiate Athletic Association Division III Soccer Team over a One-Year Period. Sensors 2024, 24, 1463. [Google Scholar] [CrossRef] [PubMed]

- Bayo-Monton, J.-L.; Martinez-Millana, A.; Han, W.; Fernandez-Llatas, C.; Sun, Y.; Traver, V. Wearable Sensors Integrated with Internet of Things for Advancing eHealth Care. Sensors 2018, 18, 1851. [Google Scholar] [CrossRef] [PubMed]

- Agir, I.; Yildirim, R.; Nigde, M.; Isildak, I. Internet of Things Implementation of Nitrate and Ammonium Sensors for Online Water Monitoring. Anal. Sci. 2021, 37, 971–976. [Google Scholar] [CrossRef]

- Zhao, T.; Fu, Y.; Sun, C.; Zhao, X.; Jiao, C.; Du, A.; Wang, Q.; Mao, Y.; Liu, B. Wearable biosensors for real-time sweat analysis and body motion capture based on stretchable fiber-based triboelectric nanogenerators. Biosens. Bioelectron. 2022, 205, 114115. [Google Scholar] [CrossRef] [PubMed]

- Nagabooshanam, S.; Roy, S.; Mathur, A.; Mukherjee, I.; Krishnamurthy, S.; Bharadwaj, L.M. Electrochemical micro analytical device interfaced with portable potentiostat for rapid detection of chlorpyrifos using acetylcholinesterase conjugated metal organic framework using Internet of things. Sci. Rep. 2019, 9, 19862. [Google Scholar] [CrossRef] [PubMed]

- Kaiwartya, O.; Abdullah, A.H.; Cao, Y.; Lloret, J.; Kumar, S.; Shah, R.R.; Prasad, M.; Prakash, S. Virtualization in Wireless Sensor Networks: Fault Tolerant Embedding for Internet of Things. IEEE Internet Things J. 2018, 5, 571–580. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Jayathilaka, W.A.D.M.; Qi, K.; Qin, Y.; Chinnappan, A.; Serrano-García, W.; Baskar, C.; Wang, H.; He, J.; Cui, S.; Thomas, S.W.; et al. Significance of Nanomaterials in Wearables: A Review on Wearable Actuators and Sensors. Adv. Mater. 2018, 31, e1805921. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Lou, Z.; Chen, D.; Jiang, K.; Han, W.; Shen, G. Recent Advances in Flexible/Stretchable Supercapacitors for Wearable Electronics. Small 2018, 14, e1702829. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Xia, K.; Wang, H.; Liang, X.; Yin, Z.; Zhang, Y. Advanced Carbon for Flexible and Wearable Electronics. Adv. Mater. 2019, 31, e1801072. [Google Scholar] [CrossRef]

- Ai, Y.; Lou, Z.; Chen, S.; Chen, D.; Wang, Z.M.; Jiang, K.; Shen, G. All rGO-on-PVDF-nanofibers based self-powered electronic skins. Nano Energy 2017, 35, 121–127. [Google Scholar] [CrossRef]

- Merelli, I.; Morganti, L.; Corni, E.; Pellegrino, C.; Cesini, D.; Roverelli, L.; Zereik, G.; D’agostino, D. Low-power portable devices for metagenomics analysis: Fog computing makes bioinformatics ready for the Internet of Things. Future Gener. Comput. Syst. 2018, 88, 467–478. [Google Scholar] [CrossRef]

- Islam, S.M.R.; Kwak, D.; Kabir, M.H.; Hossain, M.; Kwak, K.-S. The Internet of Things for Health Care: A Comprehensive Survey. IEEE Access 2015, 3, 678–708. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, T.; Zhu, M.; Lu, J.; Liu, X.; Sun, W.; So, M.Y.; Xu, B. Scalable, Fast Light-Responsive, and Excellent Color-Retention Fiber-Based Photochromic Wearables for Sustainable Photo-Patterning and Information Security Encryption. Adv. Funct. Mater. 2024. [CrossRef]

- Bandodkar, A.J.; Hung, V.W.S.; Jia, W.; Valdés-Ramírez, G.; Windmiller, J.R.; Martinez, A.G.; Ramírez, J.; Chan, G.; Kerman, K.; Wang, J. Tattoo-based potentiometric ion-selective sensors for epidermal pH monitoring. Analyst 2013, 138, 123–128. [Google Scholar] [CrossRef] [PubMed]

- Matzeu, G.; Florea, L.; Diamond, D. Advances in wearable chemical sensor design for monitoring biological fluids. Sens. Actuators B Chem. 2015, 211, 403–418. [Google Scholar] [CrossRef]

- Yu, Y.; Nyein, H.Y.Y.; Gao, W.; Javey, A. Flexible Electrochemical Bioelectronics: The Rise of In Situ Bioanalysis. Adv. Mater. 2020, 32, e1902083. [Google Scholar] [CrossRef]

- Yang, Y.; Gao, W. Wearable and flexible electronics for continuous molecular monitoring. Chem. Soc. Rev. 2019, 48, 1465–1491. [Google Scholar] [CrossRef] [PubMed]

- Heikenfeld, J.; Jajack, A.; Rogers, J.; Gutruf, P.; Tian, L.; Pan, T.; Li, R.; Khine, M.; Kim, J.; Wang, J.; et al. Wearable sensors: Modalities, challenges, and prospects. Lab Chip 2018, 18, 217–248. [Google Scholar] [CrossRef] [PubMed]

- An, B.W.; Shin, J.H.; Kim, S.-Y.; Kim, J.; Ji, S.; Park, J.; Lee, Y.; Jang, J.; Park, Y.-G.; Cho, E.; et al. Smart Sensor Systems for Wearable Electronic Devices. Polymers 2017, 9, 303. [Google Scholar] [CrossRef]

- Zheng, Q.; Jia, C.; Sun, F.; Zhang, M.; Wen, Y.; Xie, Z.; Wang, J.; Liu, B.; Mao, Y.; Zhao, C. Ecoflex Flexible Array of Triboelectric Nanogenerators for Gait Monitoring Alarm Warning Applications. Electronics 2023, 12, 3226. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, F.; Wen, Y.; Zheng, Q.; Xie, Z.; Liu, B.; Mao, Y. A self-powered intelligent integrated sensing system for sports skill monitoring. Nanotechnology 2024, 35, 035501. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Wen, Y.; Sun, F.; Zhang, M.; Zheng, Q.; Liu, B.; Yang, T.; Mao, Y. A Biodegradable and Flexible Triboelectric Nanogenerator Based on Human Motion Monitoring. Energy Technol. 2024, 12, 2300767. [Google Scholar] [CrossRef]

- Zhao, J.; Fu, Y.; Xiao, Y.; Dong, Y.; Wang, X.; Lin, L. A Naturally Integrated Smart Textile for Wearable Electronics Applications. Adv. Mater. Technol. 2020, 5, 1900781. [Google Scholar] [CrossRef]

- Kim, J.; Campbell, A.S.; de Ávila, B.E.-F.; Wang, J. Wearable biosensors for healthcare monitoring. Nat. Biotechnol. 2019, 37, 389–406. [Google Scholar] [CrossRef] [PubMed]

- Takei, K.; Gao, W.; Wang, C.; Javey, A. Physical and Chemical Sensing With Electronic Skin. Proc. IEEE 2019, 107, 2155–2167. [Google Scholar] [CrossRef]

- Wu, H.; Huang, Y.; Xu, F.; Duan, Y.; Yin, Z. Energy Harvesters for Wearable and Stretchable Electronics: From Flexibility to Stretchability. Adv. Mater. 2016, 28, 9881–9919. [Google Scholar] [CrossRef]

- Pu, X.; Hu, W.; Wang, Z.L. Toward Wearable Self-Charging Power Systems: The Integration of Energy-Harvesting and Storage Devices. Small 2018, 14, 1702817. [Google Scholar] [CrossRef]

- Xu, W.; Huang, L.-B.; Wong, M.-C.; Chen, L.; Bai, G.; Hao, J. Environmentally Friendly Hydrogel-Based Triboelectric Nanogenerators for Versatile Energy Harvesting and Self-Powered Sensors. Adv. Energy Mater. 2017, 7, 1601529. [Google Scholar] [CrossRef]

- Sun, F.; Zhu, Y.; Jia, C.; Zhao, T.; Chu, L.; Mao, Y. Advances in self-powered sports monitoring sensors based on triboelectric nanogenerators. J. Energy Chem. 2023, 79, 477–488. [Google Scholar] [CrossRef]

- Wang, Z.L. Self-Powered Nanosensors and Nanosystems. Adv. Mater. 2012, 24, 280–285. [Google Scholar] [CrossRef] [PubMed]

- Glynne-Jones, P.; White, N. Self-powered systems: A review of energy sources. Sens. Rev. 2001, 21, 91–98. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, Y.; Cho, J.; Lee, J.; Huang, X.; Jia, L.; Fan, J.A.; Su, Y.; Su, J.; Zhang, H.; et al. Stretchable batteries with self-similar serpentine interconnects and integrated wireless recharging systems. Nat. Commun. 2013, 4, 1543. [Google Scholar] [CrossRef] [PubMed]

- Wen, Y.; Sun, F.; Xie, Z.; Zhang, M.; An, Z.; Liu, B.; Sun, Y.; Wang, F.; Mao, Y. Machine learning-assisted novel recyclable flexible triboelectric nanogenerators for intelligent motion. iScience 2024, 27, 109615. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Zhu, Y.; Zhao, T.; Jia, C.; Wang, X.; Wang, Q. Portable Mobile Gait Monitor System Based on Triboelectric Nanogenerator for Monitoring Gait and Powering Electronics. Energies 2021, 14, 4996. [Google Scholar] [CrossRef]

- Berchmans, S.; Bandodkar, A.J.; Jia, W.; Ramírez, J.; Meng, Y.S.; Wang, J. An epidermal alkaline rechargeable Ag–Zn printable tattoo battery for wearable electronics. J. Mater. Chem. A 2014, 2, 15788–15795. [Google Scholar] [CrossRef]

- Li, H.; Han, C.; Huang, Y.; Zhu, M.; Pei, Z.; Xue, Q.; Wang, Z.; Liu, Z.; Tang, Z.; Wang, Y.; et al. An extremely safe and wearable solid-state zinc ion battery based on a hierarchical structured polymer electrolyte. Energy Environ. Sci. 2018, 11, 941–951. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Ren, J.; Weng, W.; Peng, H. Advances in Wearable Fiber-Shaped Lithium-Ion Batteries. Adv. Mater. 2016, 28, 4524–4531. [Google Scholar] [CrossRef]

- Dong, L.; Xu, C.; Li, Y.; Wu, C.; Jiang, B.; Yang, Q.; Zhou, E.; Kang, F.; Yang, Q. Simultaneous Production of High-Performance Flexible Textile Electrodes and Fiber Electrodes for Wearable Energy Storage. Adv. Mater. 2015, 28, 1675–1681. [Google Scholar] [CrossRef] [PubMed]

- Candido, I.C.M.; Oliveira, G.d.S.; Viana, G.G.; G. da Silva, F.A., Jr.; da Costa, M.M.; de Oliveira, H.P. Wearable Triboelectric Nanogenerators Based on Chemical Modification of Conventional Textiles for Application in Electrically Driven Antibacterial Devices. ACS Appl. Electron. Mater. 2022, 4, 334–344. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Y.; Feng, Q.; Zhang, M.; Mao, Y.; Hu, P. A portable self-powered biosensor for monitoring artistic gymnastics techniques. AIP Adv. 2024, 14. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, M.; Fu, X.; Fusco, Z.; Bo, R.; Xing, B.; Nguyen, H.T.; Barugkin, C.; Zheng, J.; Lau, C.F.J.; et al. Light-activated inorganic CsPbBr2I perovskite for room-temperature self-powered chemical sensing. Phys. Chem. Chem. Phys. 2019, 21, 24187–24193. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Yu, H.; Wang, Y.; Liu, D.; Wen, T.; Zhang, L.; Ge, S.; Yu, J. Paper-Based Constant Potential Electrochemiluminescence Sensing Platform with Black Phosphorus as a Luminophore Enabled by a Perovskite Solar Cell. Anal. Chem. 2020, 92, 6822–6826. [Google Scholar] [CrossRef]

- Sun, F.; Zhu, Y.; Jia, C.; Wen, Y.; Zhang, Y.; Chu, L.; Zhao, T.; Liu, B.; Mao, Y. Deep-Learning-Assisted Neck Motion Monitoring System Self-Powered Through Biodegradable Triboelectric Sensors. Adv. Funct. Mater. 2024, 34, 2310742. [Google Scholar] [CrossRef]

- Xue, Y.; Yang, T.; Zheng, Y.; Wang, K.; Wang, E.; Wang, H.; Zhu, L.; Du, Z.; Wang, H.; Chou, K.C.; et al. Heterojunction Engineering Enhanced Self-Polarization of PVDF/CsPbBr3/Ti3C2Tx Composite Fiber for Ultra-High Voltage Piezoelectric Nanogenerator. Adv. Sci. 2023, 10, 2300650. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Yang, Z.; Li, P.; Pang, M.; Xue, Q. Flexible self-powered high-performance ammonia sensor based on Au-decorated MoSe2 nanoflowers driven by single layer MoS2-flake piezoelectric nanogenerator. Nano Energy 2019, 65, 103974. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, J.; Tavakoli, M.M.; Gao, Y.; Zhu, Y.; Zhang, D.; Kam, M.; He, Z.; Fan, Z. Printable Fabrication of a Fully Integrated and Self-Powered Sensor System on Plastic Substrates. Adv. Mater. 2019, 31, e1804285. [Google Scholar] [CrossRef] [PubMed]

- Wen, Z.; Yeh, M.-H.; Guo, H.; Wang, J.; Zi, Y.; Xu, W.; Deng, J.; Zhu, L.; Wang, X.; Hu, C.; et al. Self-powered textile for wearable electronics by hybridizing fiber-shaped nanogenerators, solar cells, and supercapacitors. Sci. Adv. 2016, 2, e1600097. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Fan, Z.; Wen, N.; Yang, S.; Li, C.; Huang, H.; Cong, T.; Zhang, H.; Pan, L. Novel Wearable Pyrothermoelectric Hybrid Generator for Solar Energy Harvesting. ACS Appl. Mater. Interfaces 2022, 14, 17330–17339. [Google Scholar] [CrossRef] [PubMed]

- Shao, Z.; Chen, J.; Xie, Q.; Mi, L. Functional metal/covalent organic framework materials for triboelectric nanogenerator. Coord. Chem. Rev. 2023, 486, 215118. [Google Scholar] [CrossRef]

- Wang, Z.L.; Jiang, T.; Xu, L. Toward the blue energy dream by triboelectric nanogenerator networks. Nano Energy 2017, 39, 9–23. [Google Scholar] [CrossRef]

- Xia, J.; Lu, H.; Chen, G.; Lin, D.; Yang, W.; Liu, C.; Hu, B.; Zhao, Y. High performance piezoelectric nanogenerator by fiber microstructure engineering toward self-powered wireless sensing system. Nano Energy 2024, 128, 109901. [Google Scholar] [CrossRef]

- Pei, H.; Jing, J.; Chen, Y.; Guo, J.; Chen, N. 3D printing of PVDF-based piezoelectric nanogenerator from programmable metamaterial design: Promising strategy for flexible electronic skin. Nano Energy 2023, 109, 108303. [Google Scholar] [CrossRef]

- Aaryashree; Sahoo, S.; Walke, P.; Nayak, S.K.; Rout, C.S.; Late, D.J. Recent developments in self-powered smart chemical sensors for wearable electronics. Nano Res. 2021, 14, 3669–3689. [Google Scholar] [CrossRef]

- Min, J.; Demchyshyn, S.; Sempionatto, J.R.; Song, Y.; Hailegnaw, B.; Xu, C.; Yang, Y.; Solomon, S.; Putz, C.; Lehner, L.E.; et al. An autonomous wearable biosensor powered by a perovskite solar cell. Nat. Electron. 2023, 6, 630–641. [Google Scholar] [CrossRef]

- Tawiah, B.; Seidu, R.K.; Asinyo, B.K.; Fei, B. A review of fiber-based supercapacitors and sensors for energy-autonomous systems. J. Power Sources 2024, 595, 234069. [Google Scholar] [CrossRef]

- Juan, Y.; Chang, S.; Hsueh, H.; Chen, T.; Huang, S.; Lee, Y.; Hsueh, T.; Wu, C. Self-powered hybrid humidity sensor and dual-band UV photodetector fabricated on back-contact photovoltaic cell. Sens. Actuators B Chem. 2015, 219, 43–49. [Google Scholar] [CrossRef]

- Gleissner, C.; Mayer, P.; Bechtold, T.; Pham, T. Multifunctional Polypyrrole-Based Textile Sensors for Integration into Personal Protection Equipment. Sensors 2024, 24, 1387. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.; Yang, Y.; Wang, Y.; Li, P.; Huang, J.; Li, J.; Lu, Y.; Li, Z.; Wang, Z.; et al. Kirigami-Based Highly Stretchable Thin Film Solar Cells That Are Mechanically Stable for More than 1000 Cycles. ACS Nano 2020, 14, 1560–1568. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Caccese, J.B.; Kiourti, A. Wearable Loop Sensor for Bilateral Knee Flexion Monitoring. Sensors 2024, 24, 1549. [Google Scholar] [CrossRef]

- Lu, C.; Wang, X.; Shen, Y.; Wang, C.; Wang, J.; Yong, Q.; Chu, F. Liquid-Free, Anti-Freezing, Solvent-Resistant, Cellulose-Derived Ionic Conductive Elastomer for Stretchable Wearable Electronics and Triboelectric Nanogenerators. Adv. Funct. Mater. 2022, 32, 2207714. [Google Scholar] [CrossRef]

- Shooshtari, M. Ammonia gas sensors based on multi-wall carbon nanofiber field effect transistors by using gate modulation. Colloids Surf. A Physicochem. Eng. Asp. 2025, 704, 135563. [Google Scholar] [CrossRef]

- He, S.; Gui, Y.; Wang, Y.; Yang, J. A self-powered β-Ni(OH)2/MXene basedethanol sensor driven by an enhanced triboelectric nanogenerator based on β-Ni(OH)2@PVDF at room temperature. Nano Energy 2023, 107. [Google Scholar]

- Su, C.; Huang, X.; Zhang, L.; Zhang, Y.; Yu, Z.; Chen, C.; Ye, Y.; Guo, S. Robust superhydrophobic wearable PENG for self-powered body motion sensors. Nano Energy 2023, 107, 108095. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Li, P.; Yang, Z.; Mi, Q.; Yu, L. Electrospinning of Flexible Poly(vinyl alcohol)/MXene Nanofiber-Based Humidity Sensor Self-Powered by Monolayer Molybdenum Diselenide Piezoelectric Nanogenerator. Nano-Micro Letters 2021, 13, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Beinert, A.J.; Imm, M.; Benick, J.; Becker, F.; Seitz, S.; Heinrich, M.; Paul, O.; Glunz, S.W.; Aktaa, J.; Eitner, U.; et al. Silicon solar cell–integrated stress and temperature sensors for photovoltaic modules. Prog. Photovolt. Res. Appl. 2020, 28, 717–724. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, M.; Bo, R.; Barugkin, C.; Zheng, J.; Ma, Q.; Huang, S.; Ho-Baillie, A.W.; Catchpole, K.R.; Tricoli, A. Superior Self-Powered Room-Temperature Chemical Sensing with Light-Activated Inorganic Halides Perovskites. Small 2018, 14, 1702571. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Gao, C.; Ge, S.; Zhang, L.; Yu, J.; Yan, M. Self-powered sensing platform equipped with Prussian blue electrochromic display driven by photoelectrochemical cell. Biosens. Bioelectron. 2017, 89, 728–734. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Li, M.; Yan, P.; Wei, C.; Fang, L.; Wei, W.; Bao, H.; Xu, J.; Xu, W. Polypyrrole-coated cotton fabrics prepared by electrochemical polymerization as textile counter electrode for dye-sensitized solar cells. Org. Electron. 2016, 29, 107–113. [Google Scholar] [CrossRef]

- Zhang, D.; Mao, Y.; Bai, P.; Li, Q.; He, W.; Cui, H.; Ye, F.; Li, C.; Ma, R.; Chen, Y. Multifunctional Superelastic Graphene-Based Thermoelectric Sponges for Wearable and Thermal Management Devices. Nano Lett. 2022, 22, 3417–3424. [Google Scholar] [CrossRef]

- Tsao, Y.-H.; Husain, R.A.; Lin, Y.-J.; Khan, I.; Chen, S.-W.; Lin, Z.-H. A self-powered mercury ion nanosensor based on the thermoelectric effect and chemical transformation mechanism. Nano Energy 2019, 62, 268–274. [Google Scholar] [CrossRef]

- Zheng, C.; Xiang, L.; Jin, W.; Shen, H.; Zhao, W.; Zhang, F.; Di, C.; Zhu, D. A Flexible Self-Powered Sensing Element with Integrated Organic Thermoelectric Generator. Adv. Mater. Technol. 2019, 4, 1900247. [Google Scholar] [CrossRef]

- Wen, D.-L.; Liu, X.; Bao, J.-F.; Li, G.-K.; Feng, T.; Zhang, F.; Liu, D.; Zhang, X.-S. Flexible Hybrid Photo-Thermoelectric Generator Based on Single Thermoelectric Effect for Simultaneously Harvesting Thermal and Radiation Energies. ACS Appl. Mater. Interfaces 2021, 13, 21401–21410. [Google Scholar] [CrossRef]

- Kim, S.; Ko, T.Y.; Jena, A.K.; Nissimagoudar, A.S.; Lee, J.; Lee, S.; Oh, T.; Kang, Y.C.; In, I.; Bhattacharjee, S.; et al. Instant Self-Assembly of Functionalized MXenes in Organic Solvents: General Fabrication to High-Performance Chemical Gas Sensors. Adv. Funct. Mater. 2024, 34, 2310641. [Google Scholar] [CrossRef]

- Kim, M.S.; Kim, J.W.; Yun, J.; Jeong, Y.R.; Jin, S.W.; Lee, G.; Lee, H.; Kim, D.S.; Keum, K.; Ha, J.S. A rationally designed flexible self-healing system with a high performance supercapacitor for powering an integrated multifunctional sensor. Appl. Surf. Sci. 2020, 515, 146018. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).