Seismic Resilience of CRC- vs. RC-Reinforced Buildings: A Long-Term Evaluation

Abstract

1. Introduction

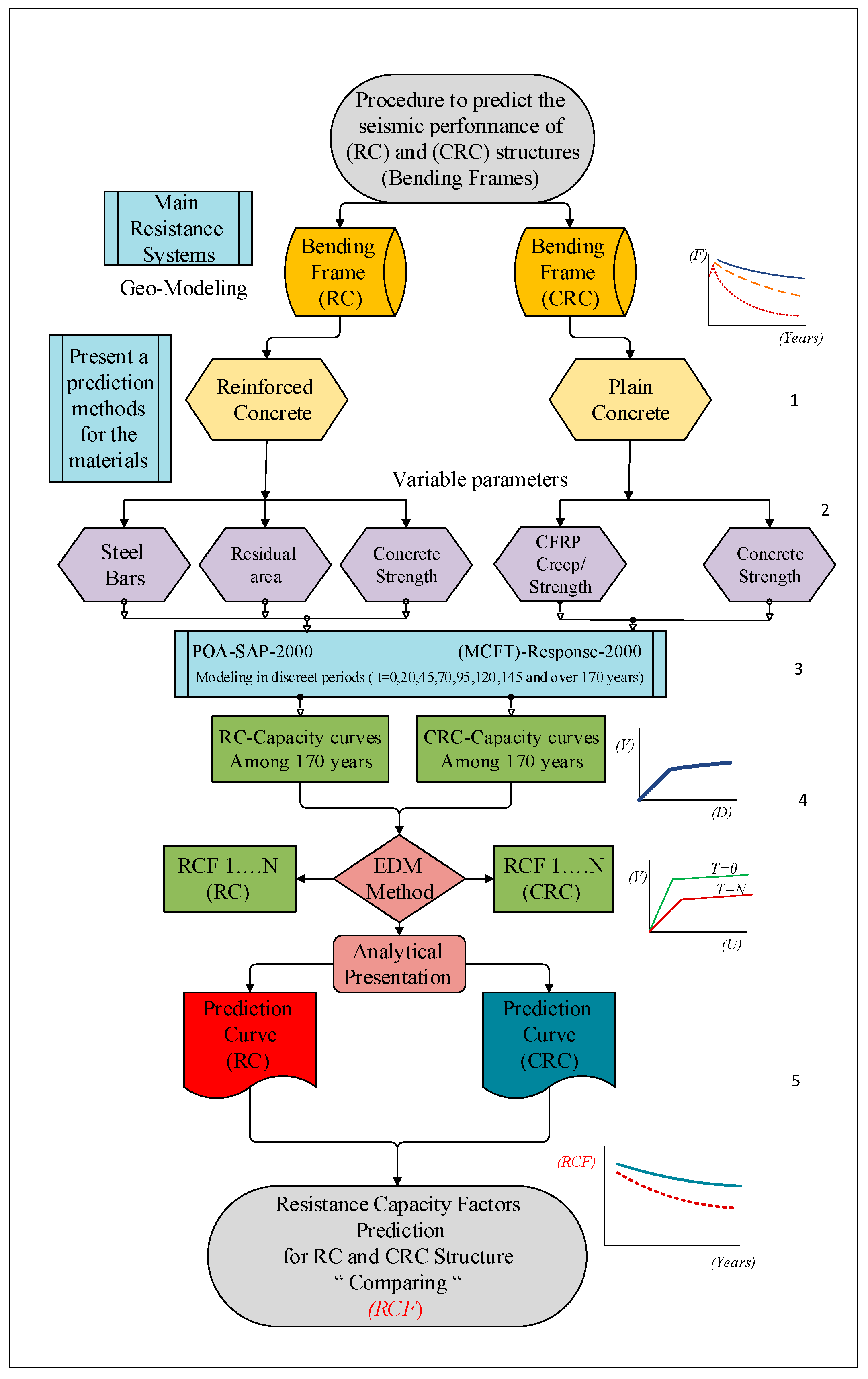

2. Methodology

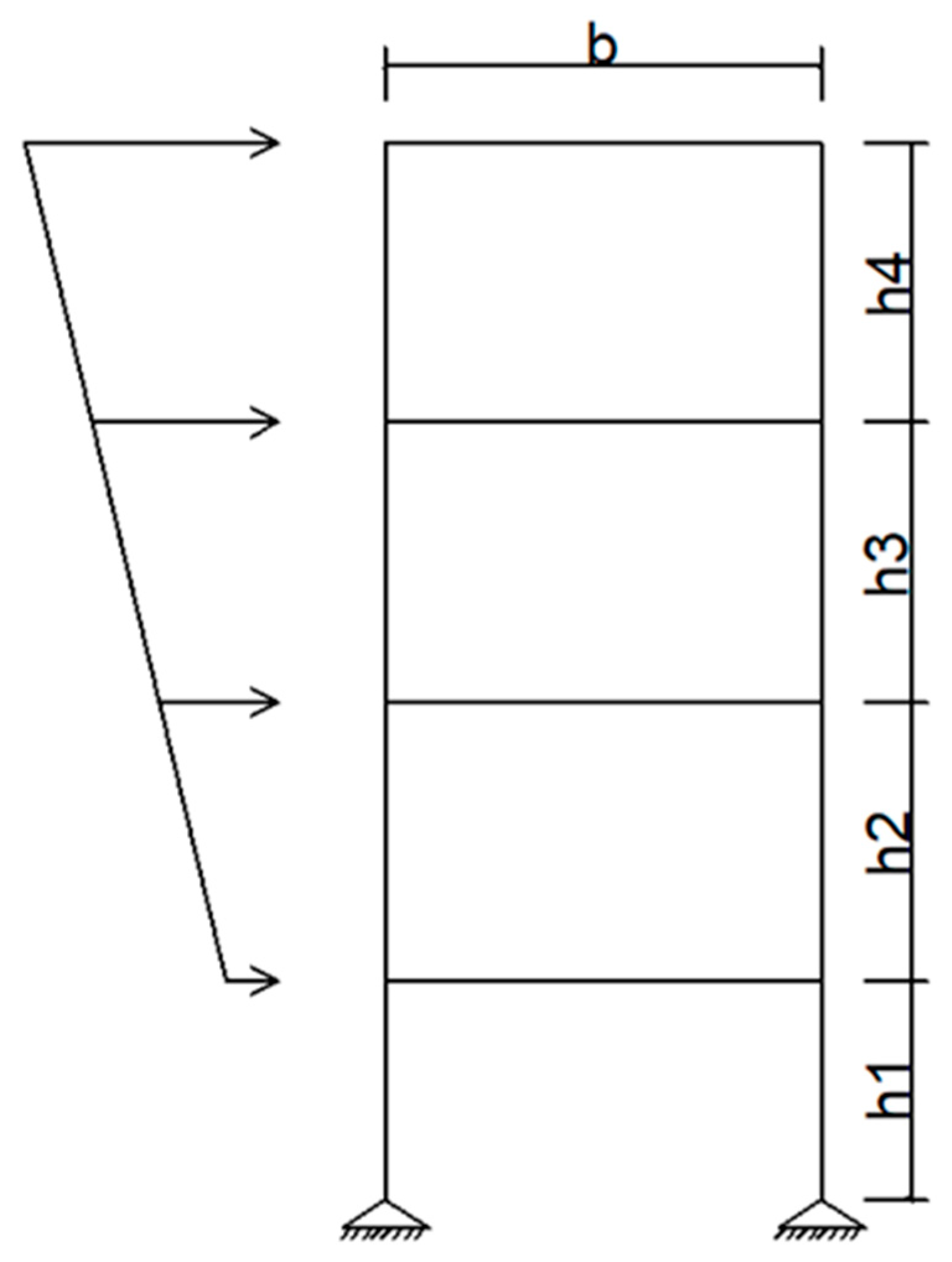

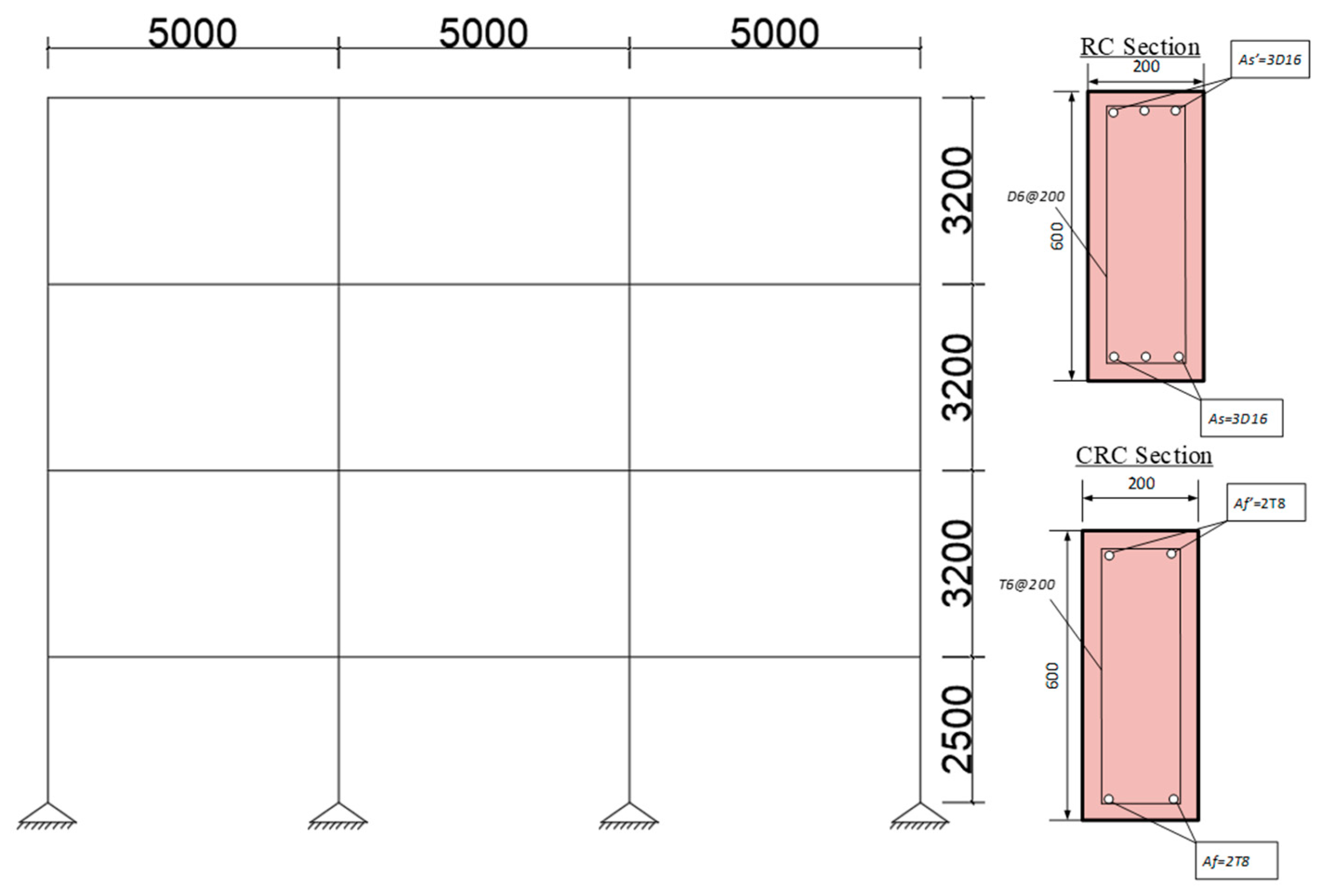

- We begin by generating detailed geometric models of the structural frames.

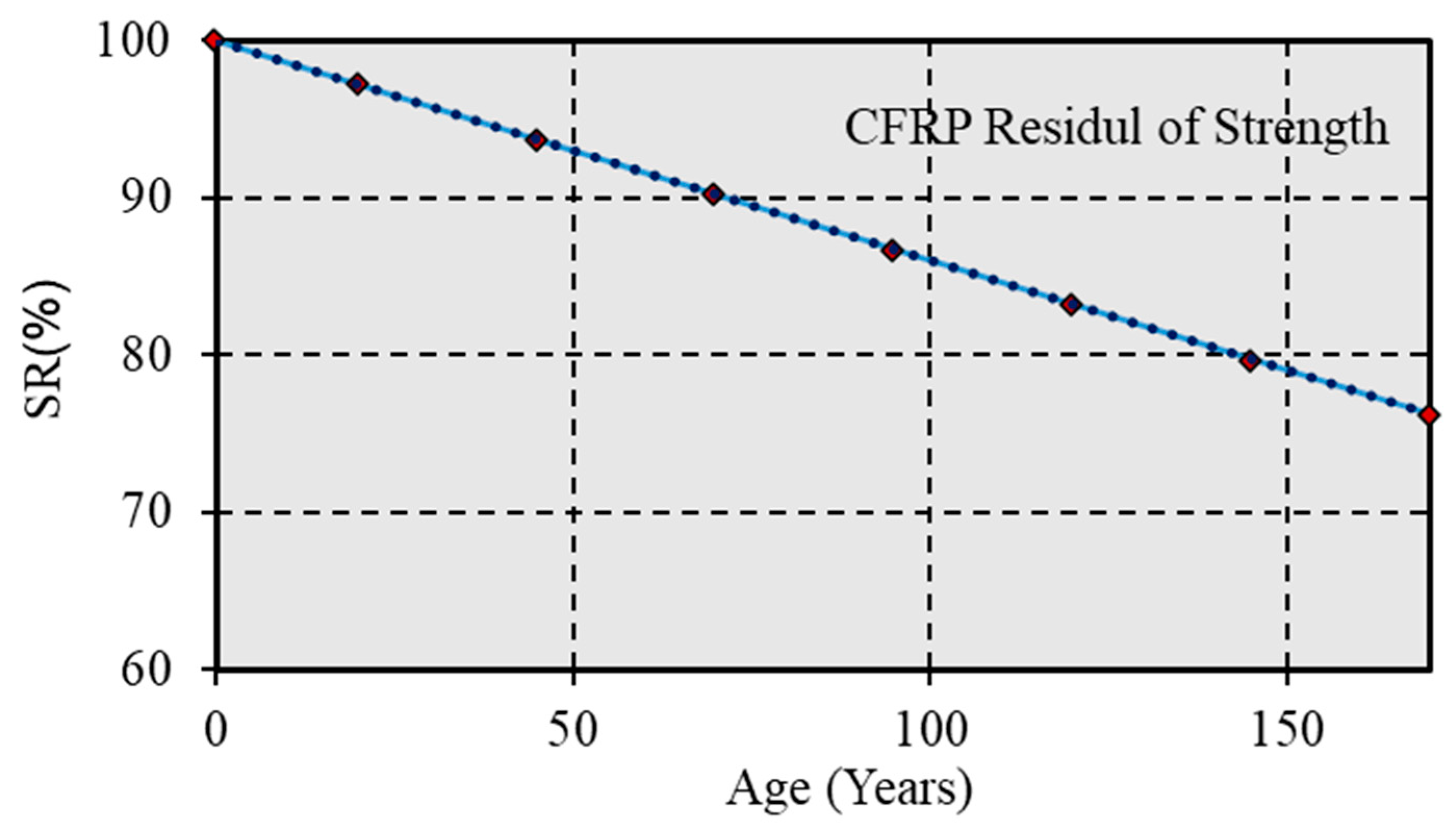

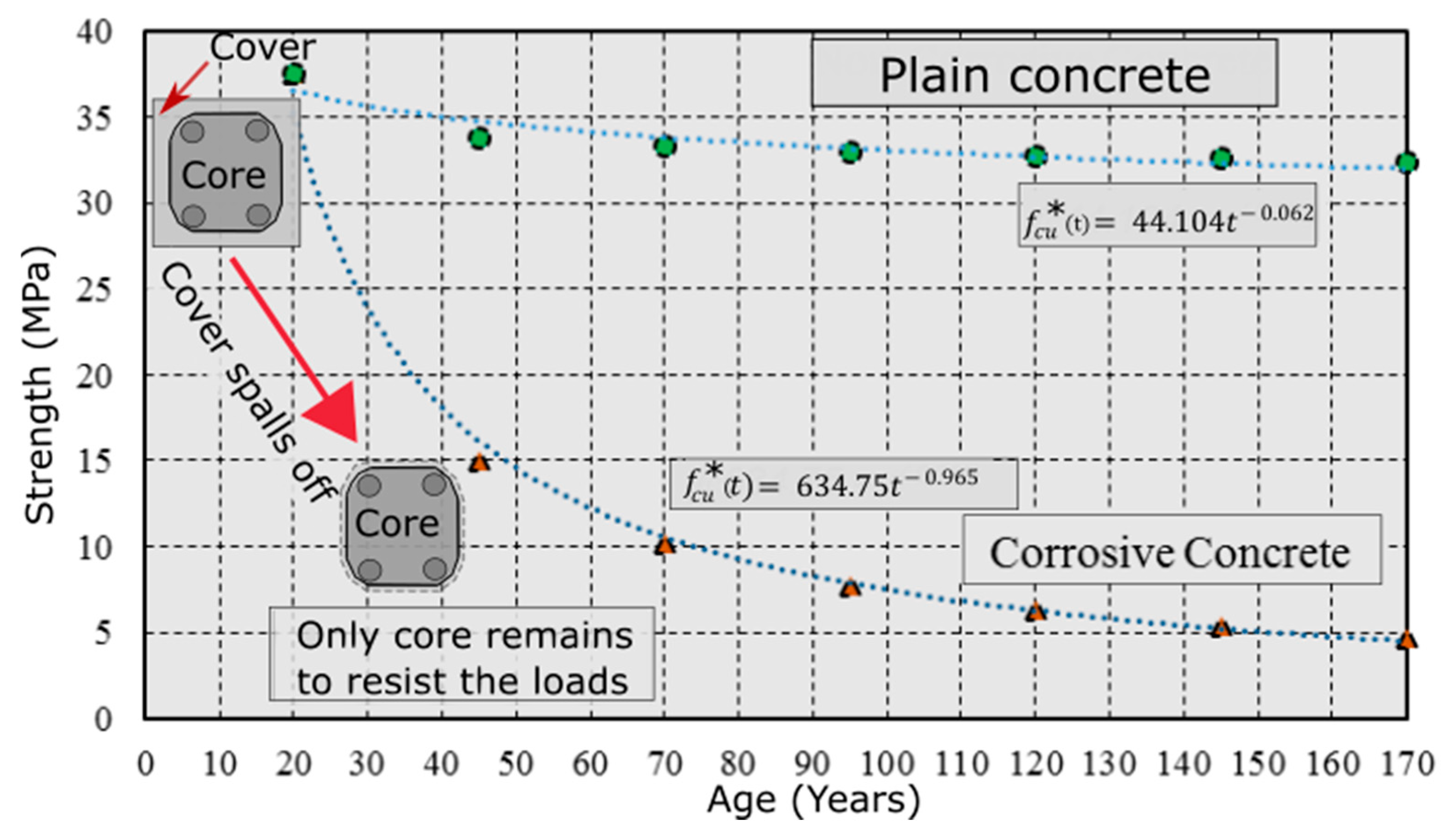

- Identification of the parameters likely to deteriorate due to corrosion, including the steel reinforcement area, the residual cross-section area, the strength and elastic modulus of both reinforced and plain concretes, as well as the residual strength of the CFRP. These parameters are critical as they directly impact the structural integrity and load-bearing capacity of RC and CRC structures. The identified parameters are then used as input for the models so that the simulations are performed in discreet periods throughout the structure’s expected lifetime.

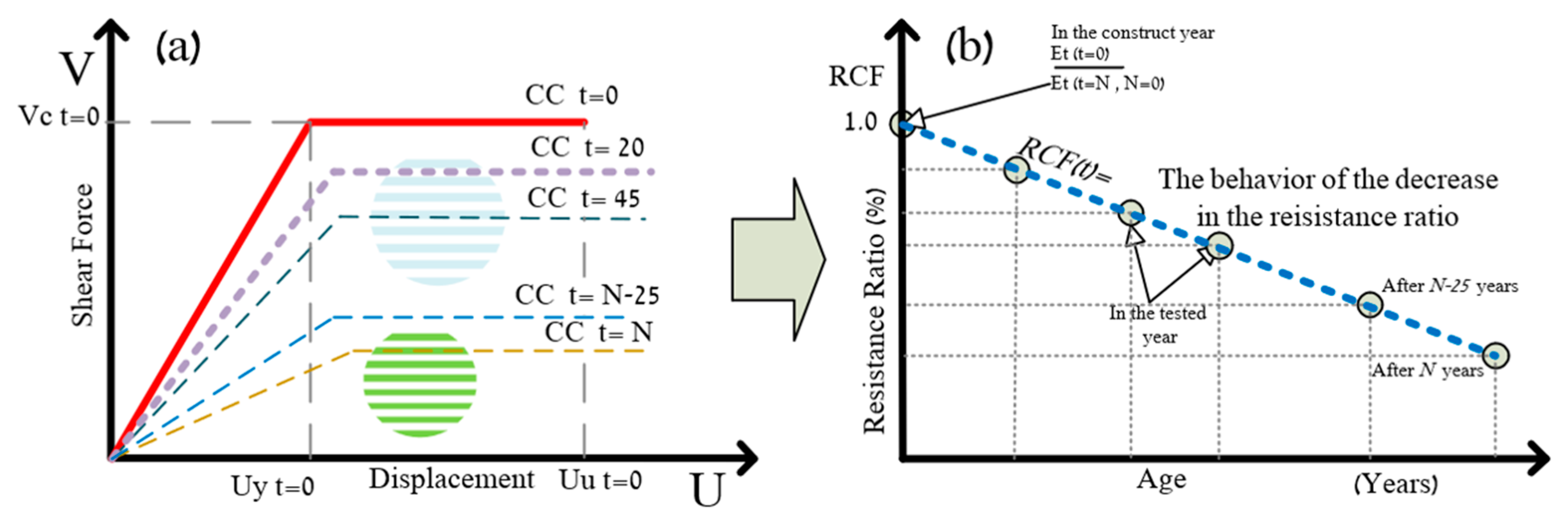

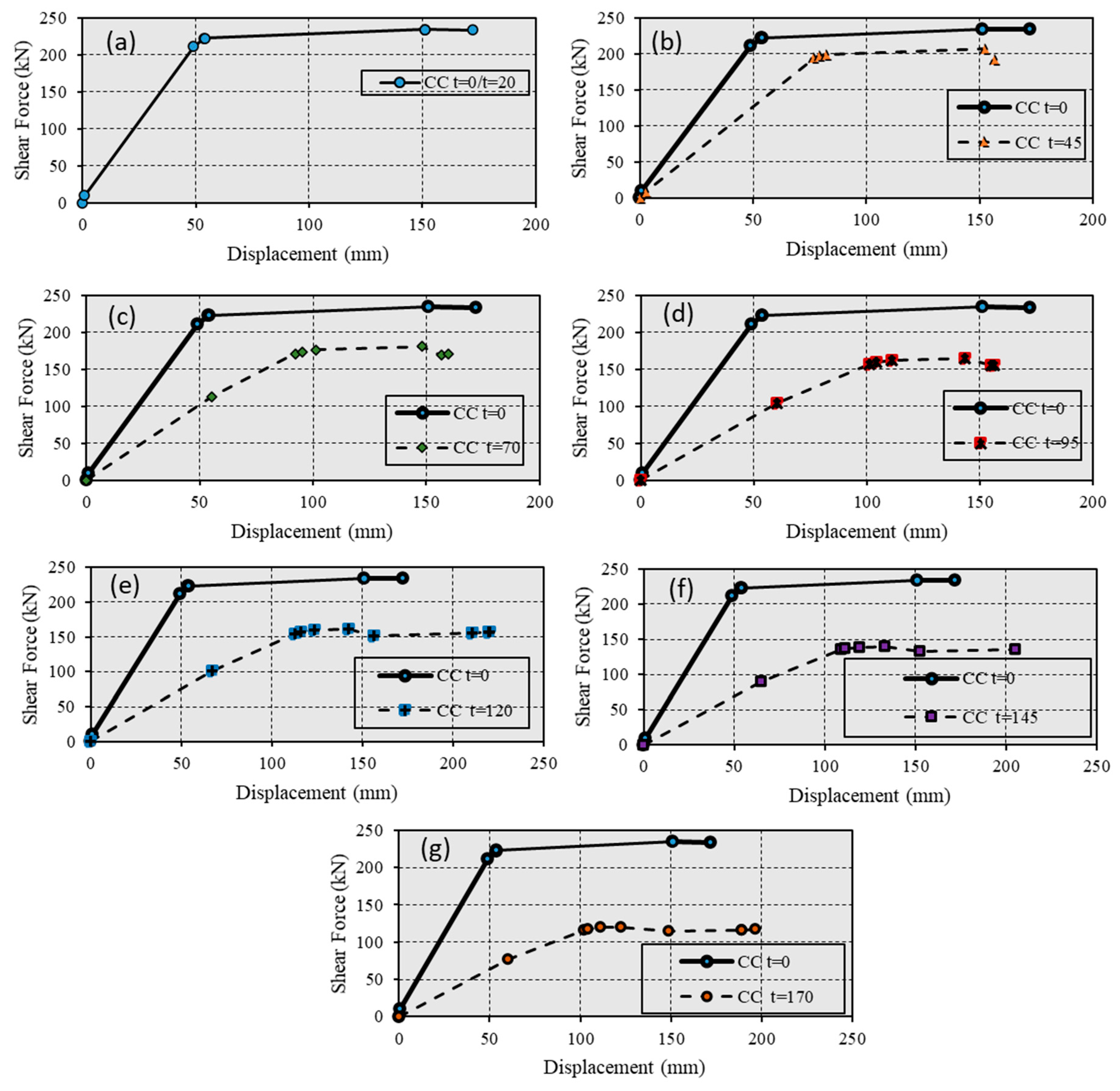

- Simulation of both structures utilizing the POA technique with SAP2000 ver. 17 [28] and Response2000 ver. 1.9.6. beta [29] models to evaluate the response to lateral seismic loads. These simulations utilize the parameters defined in the first step. The analysis yields load–displacement curves for the following step.

- The simulations generate load–displacement curves, which are then used to calculate dissipation energy ratios. This step is pivotal as it allows us to determine the energy dissipation at any selected time, providing insights into the resilience of the structure and its effectiveness in dissipating seismic energy.

- The energy values obtained from integrating the load–displacement curves for each specified age interval (e.g., t = 20, …, t = N) are compared with the structure’s non-corrosive state at t = 0. The resulting ratio, the RCF, quantitatively measures the structure’s ability to dissipate energy relative to its original condition. This factor is crucial for understanding how corrosion impacts structural resilience and durability, highlighting the long-term effects of environmental and material degradation on structural integrity.

- The main innovation of this methodology lies in its potential to enhance the motivation for using CFRP as a reinforcement material in concrete structures. This is due to CFRP’s superior performance in terms of seismic resistance, particularly over long periods, compared to conventional steel-reinforced concrete.

3. Prediction of Material Properties

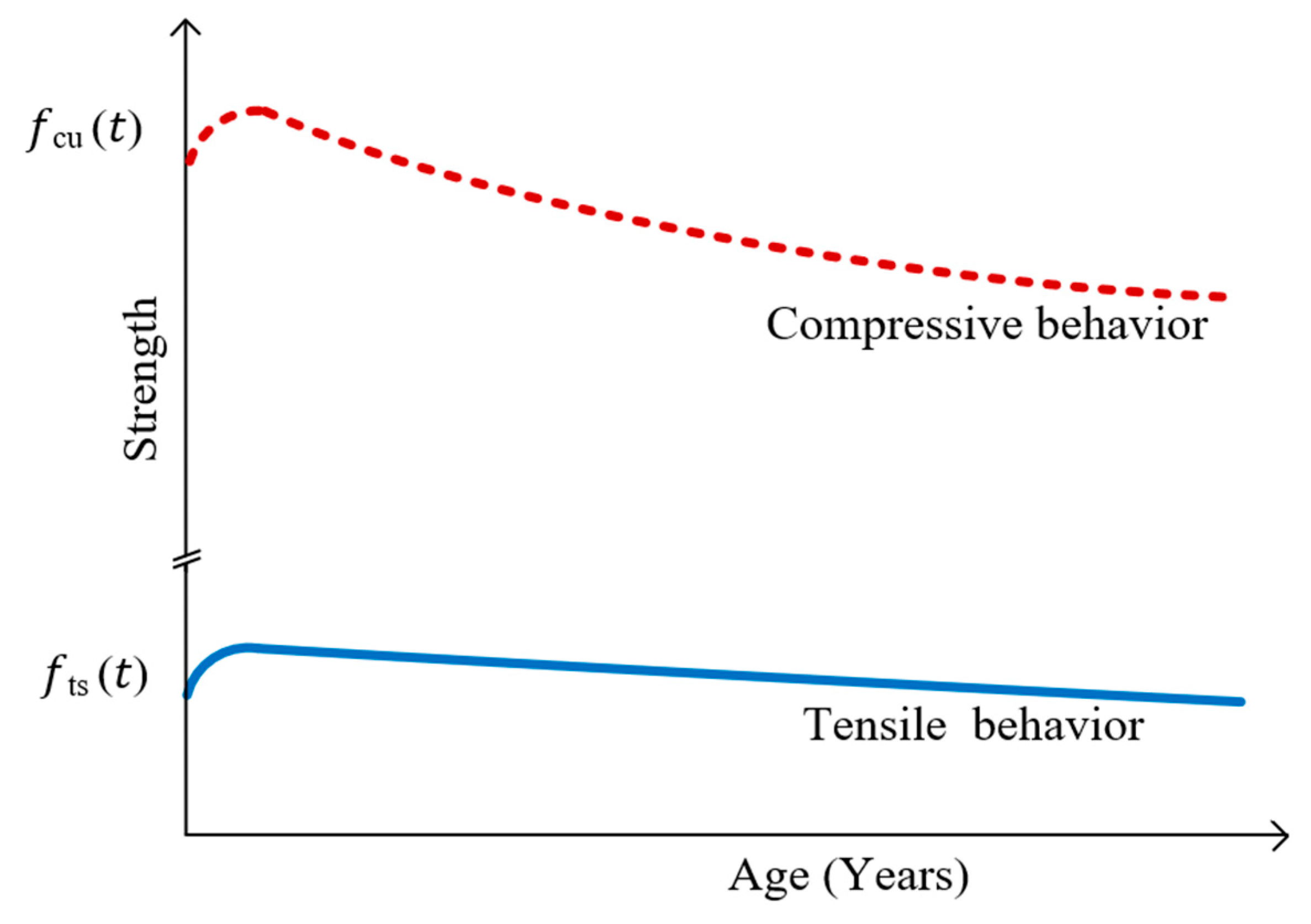

3.1. Normal-Strength Plain Concrete

3.2. Steel Reinforcement Bars

3.3. Bonding Strength

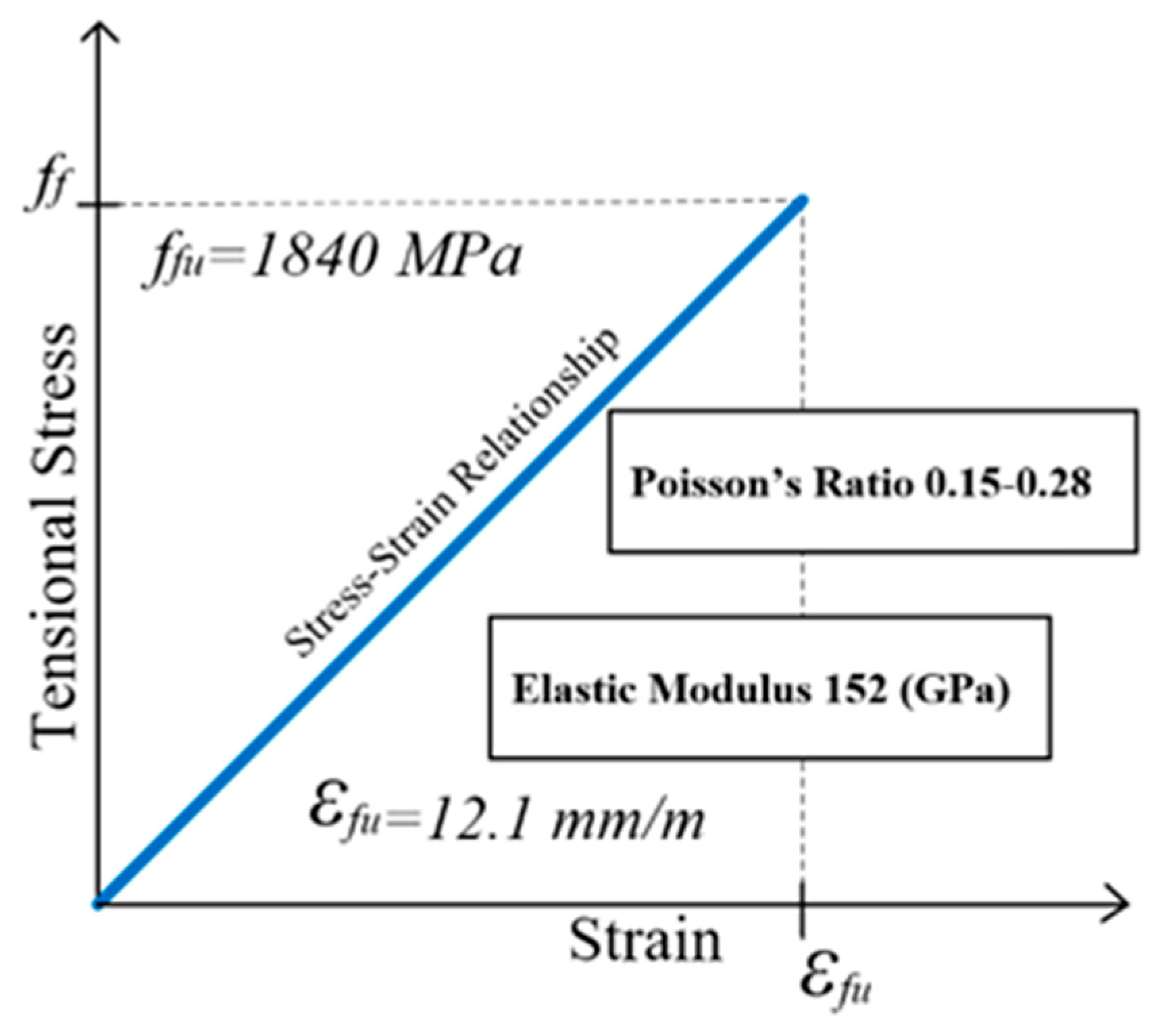

3.4. CFRP Reinforcement Bars

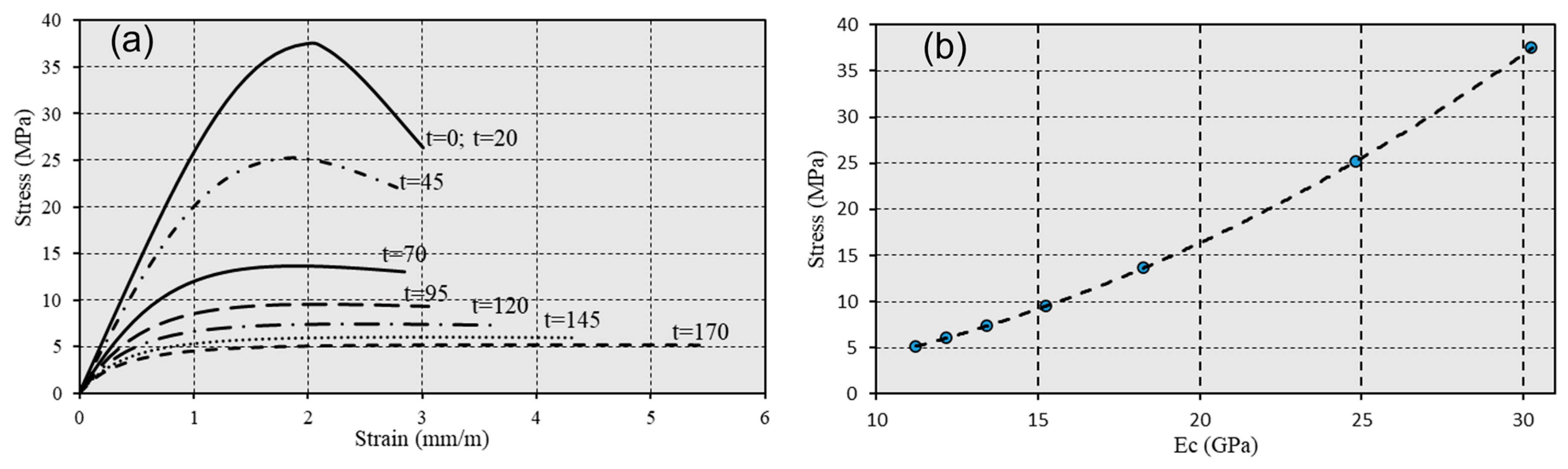

3.5. Reinforced Concrete

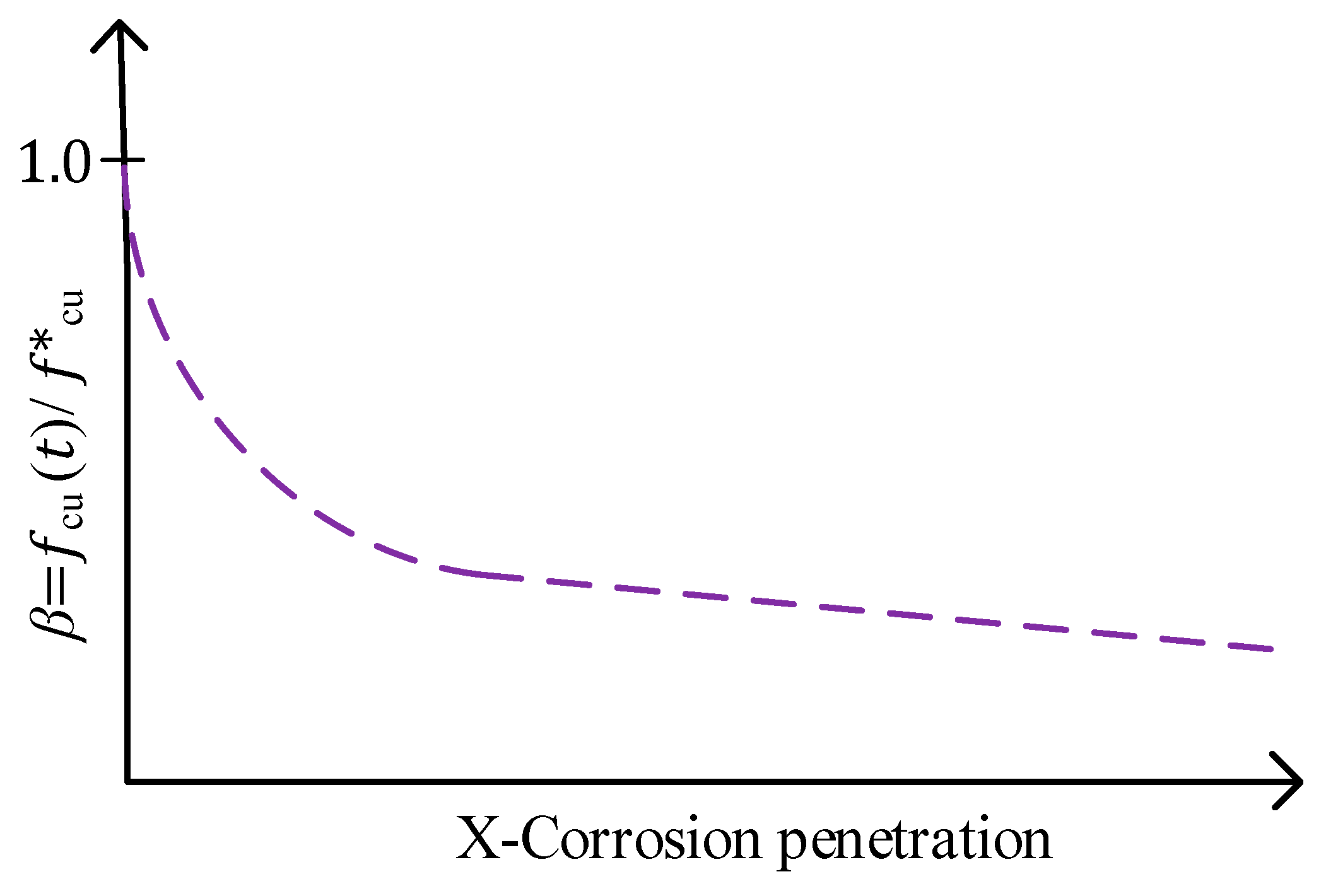

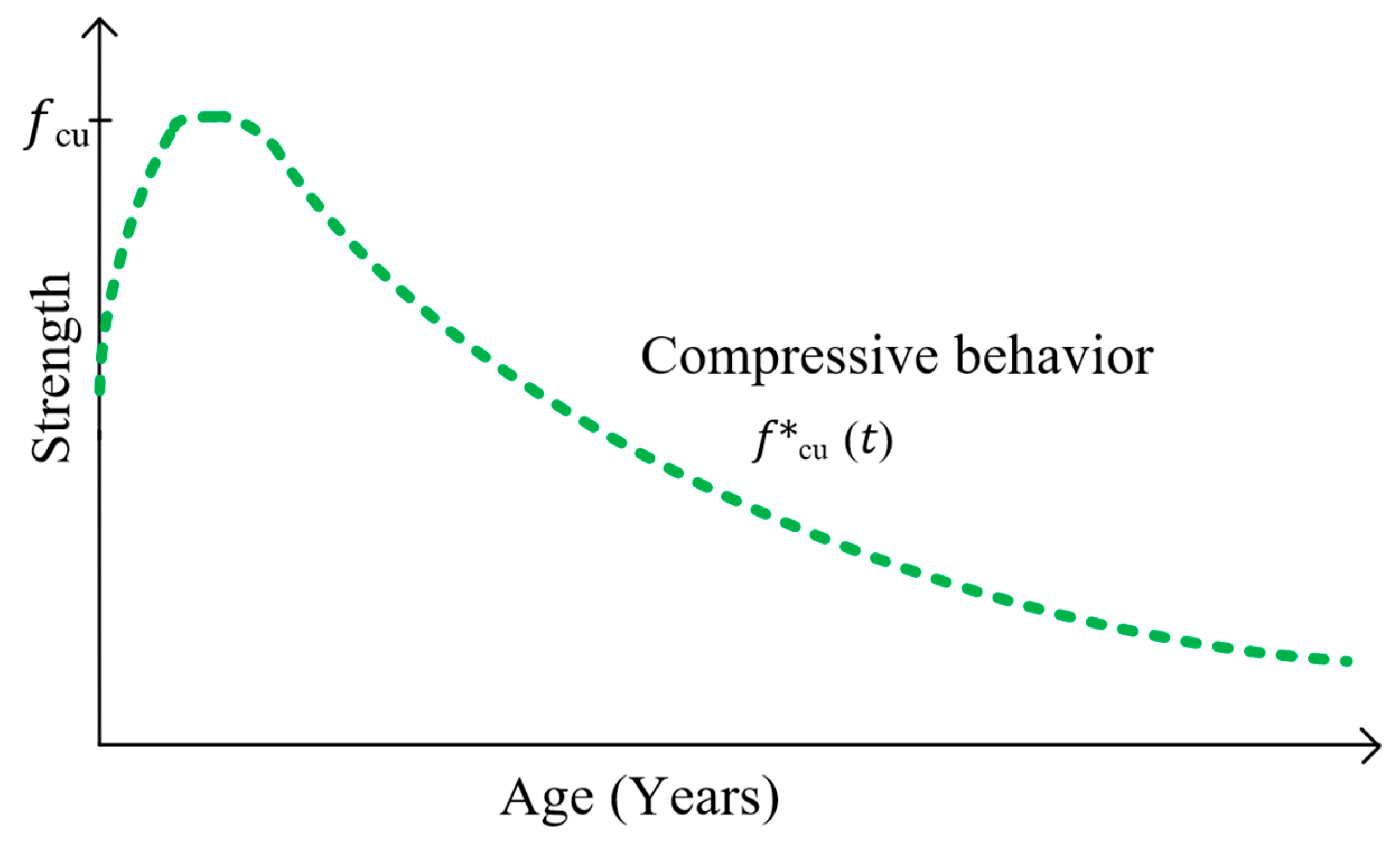

3.5.1. Concrete Compressive Strength

3.5.2. Concrete Elastic Modulus

3.5.3. Reduction in Cross-Sectional Area Due to Corrosion-Induced Cover Cracking

4. Predictive Analysis of Seismic Capacity Resistance

4.1. Pushover Analysis

4.2. DEM Analysis

4.3. Seismic Resistance Prediction Method (SRPM) Overview

5. Case Study

5.1. Overview of the Case Study

5.2. Modeling the Case Study

5.2.1. CFRP REBARS

5.2.2. STEEL BARS

5.3. Long-Term Evolution of Section Properties

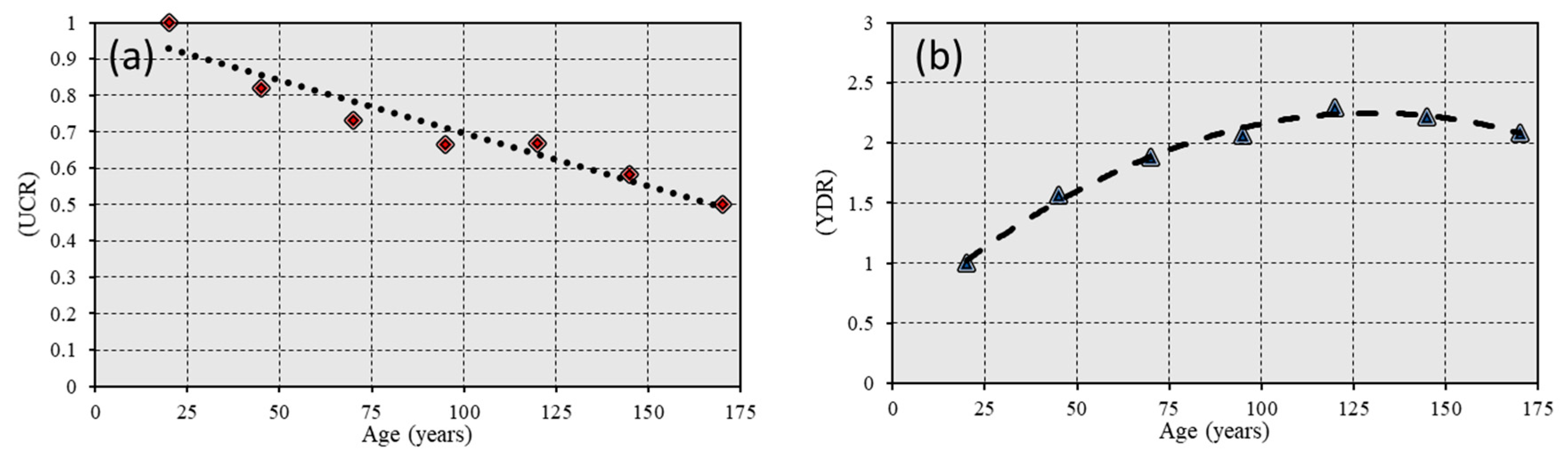

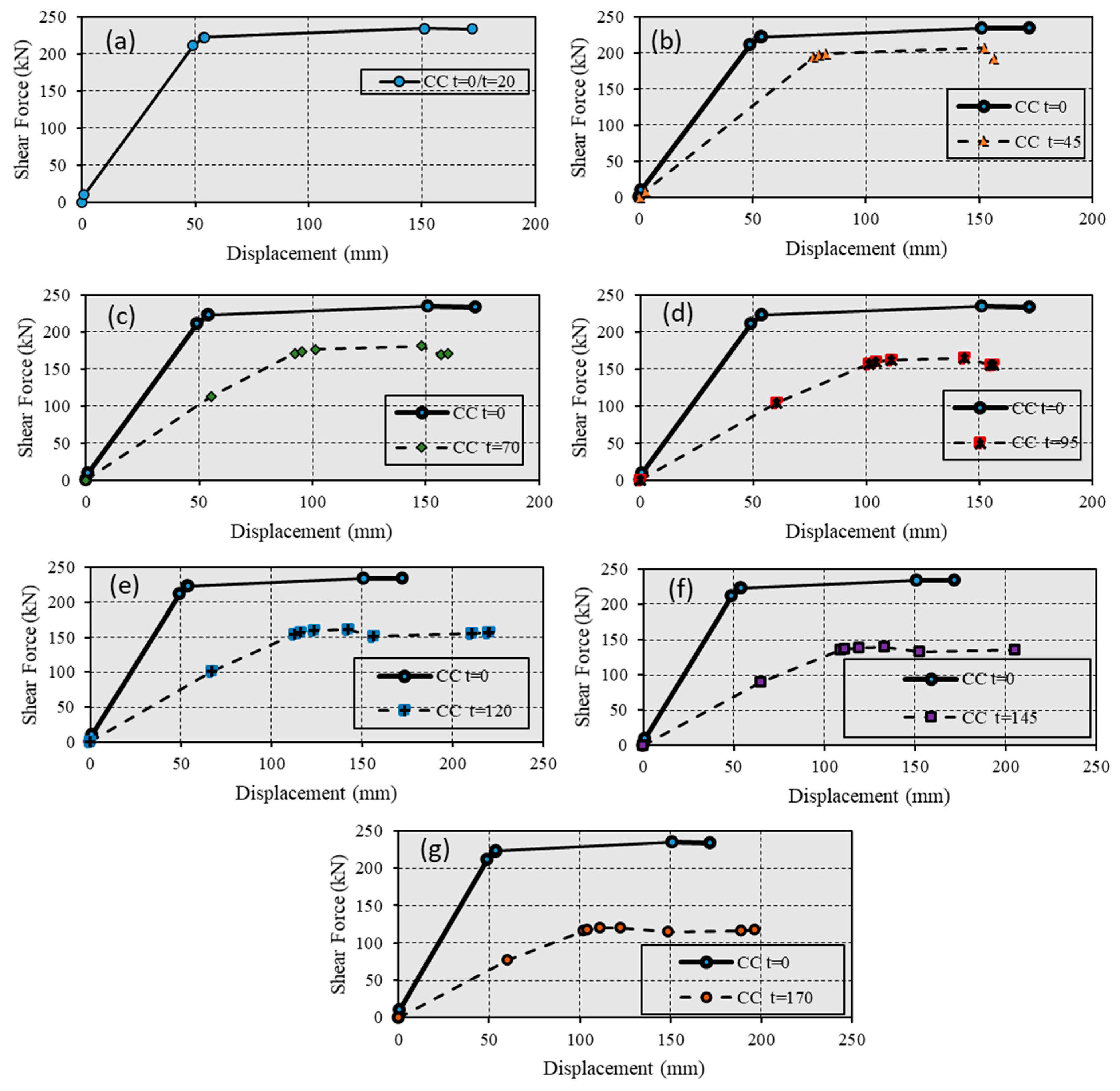

5.4. RC Structure Analysis and Results

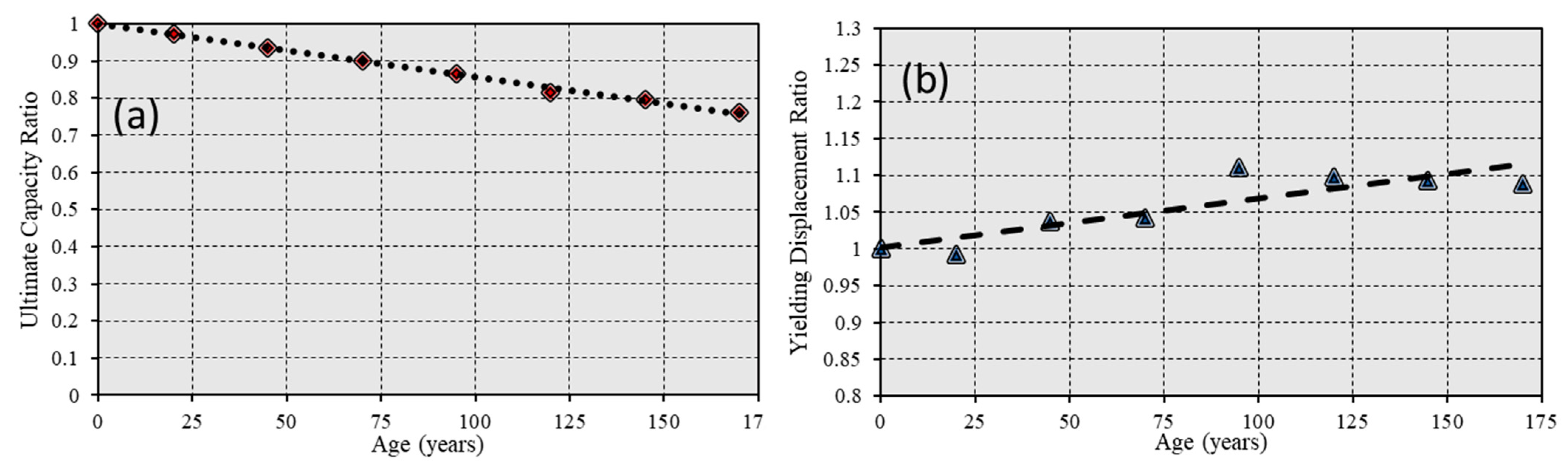

5.5. Analysis of CRC Structures

5.6. Case Study Summary

6. Conclusions

- Our findings indicate that CRC-reinforced structures exhibit higher shear capacity than those reinforced with traditional steel. This conclusion is supported by the comparative analysis of shear tests performed across various sample structures, as detailed in Section 4.

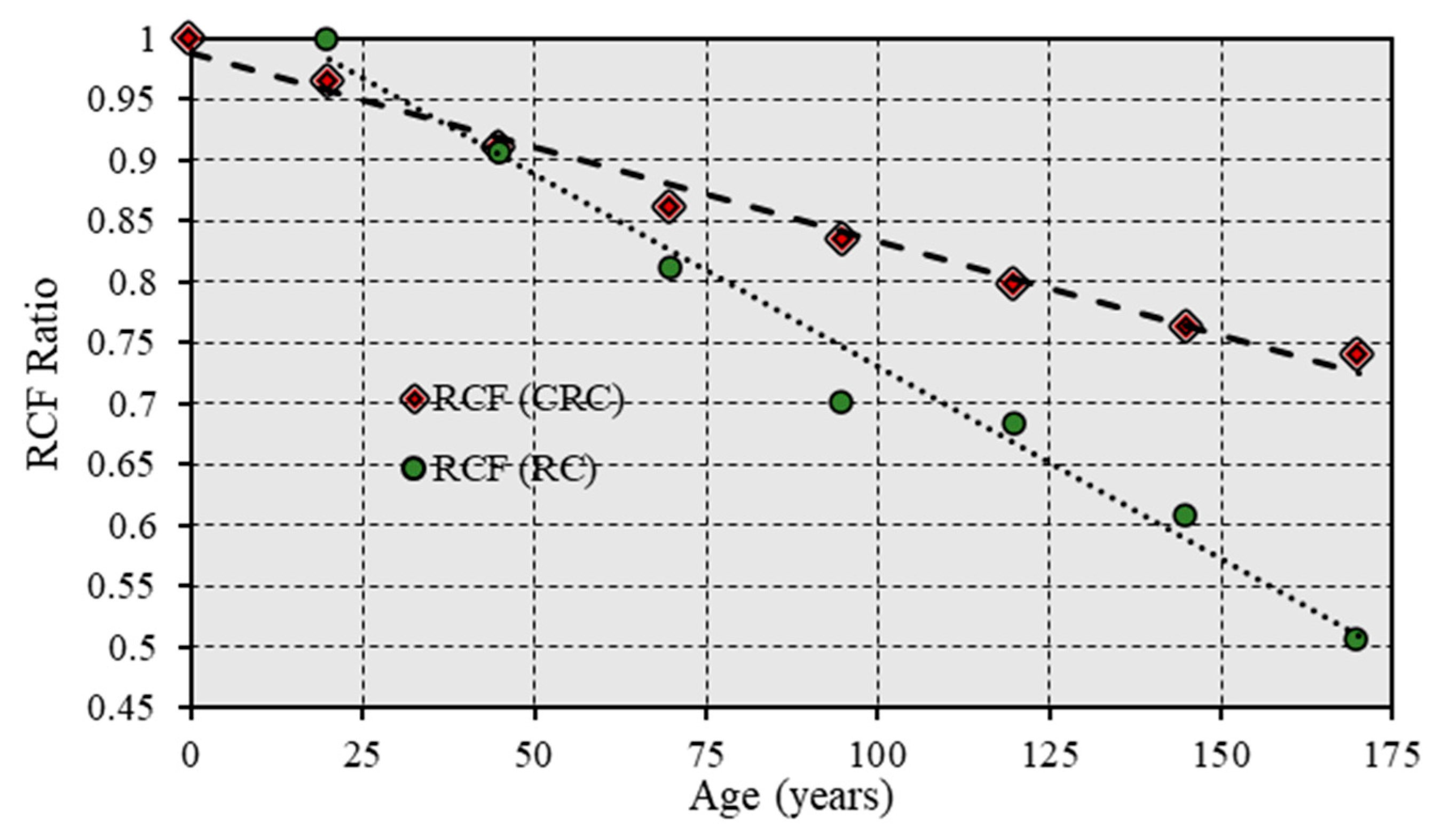

- Steel and RC show a steep decrease in their ability to dissipate seismic energy over time, losing 54.4% of their capacity after 170 years, compared to a 25.5% loss in CRC structures. This observation is based on the long-term degradation analysis presented in Section 5, highlighting CRC’s resilience against environmental wear and tear.

- The significant reduction in the RCF for RC structures is attributed to a 10% reduction in the concrete cross-sectional area, a 38% decrease in the steel reinforcement area, and an 84% reduction in concrete strength. These factors, thoroughly analyzed in Section 5.4, reflect the critical impact of material degradation on overall structural integrity.

- In contrast to RC, CRC structures maintain a consistent ultimate capacity and minimal variation in yield displacements over time, as elaborated in Section 5.4. This consistency in performance enhances their suitability for long-term applications in environments prone to corrosion.

- The decrease in the RCF for the RC structures is primarily attributed to three significant factors:

- ○

- 10% due to the reduction in the concrete cross-sectional area;

- ○

- 38% due to the decrease in the cross-sectional area of the steel reinforcement;

- ○

- 84% due to the reduction in concrete strength. This large percentage reflects the critical impact of material degradation on the overall structural integrity.

- The level of residual seismic resistance in existing buildings can be quantitatively measured, providing a more precise understanding of a structure’s longevity and safety, as demonstrated through the application of the developed predictive model in Section 5.4.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abosrra, L.; Ashour, A.F.; Youseffi, M. Corrosion of Steel Reinforcement in Concrete of Different Compressive Strengths. Constr. Build. Mater. 2011, 25, 3915–3925. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M.; Hosseini, S.A.S.; Pacheco, J.; Schlangen, E. Corrosion Induced Cover Cracking Studied by X-Ray Computed Tomography, Nanoindentation, and Energy Dispersive X-Ray Spectrometry (EDS). Mater. Struct. 2015, 48, 2043–2062. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M.; Pacheco, J.; Schlangen, E. Cracking of the Concrete Cover Due to Reinforcement Corrosion: A Two-Dimensional Lattice Model Study. Constr. Build. Mater. 2013, 44, 626–638. [Google Scholar] [CrossRef]

- Di Sarno, L.; Pugliese, F. Numerical Evaluation of the Seismic Performance of Existing Reinforced Concrete Buildings with Corroded Smooth Rebars. Bull. Earthq. Eng. 2020, 18, 4227–4273. [Google Scholar] [CrossRef]

- Sherzer, G.L.; Ye, G.; Schlangen, E.; Kovler, K. The Role of Porosity on Degradation of Concrete under Severe Internal and External Brine Attack in Confined Conditions. Constr. Build. Mater. 2022, 341, 127721. [Google Scholar] [CrossRef]

- El Maaddawy, T.; Soudki, K. A Model for Prediction of Time from Corrosion Initiation to Corrosion Cracking. Cem. Concr. Compos. 2007, 29, 168–175. [Google Scholar] [CrossRef]

- Chung, L.; Jay Kim, J.H.; Yi, S.T. Bond Strength Prediction for Reinforced Concrete Members with Highly Corroded Reinforcing Bars. Cem. Concr. Compos. 2008, 30, 603–611. [Google Scholar] [CrossRef]

- Kabashi, N.; Këpuska, A.; Krasniqi, E.; Avdyli, B. Bond Coefficient Kb of Concrete Beams Reinforced with GFRP, CFRP, and Steel Bars. Civ. Eng. J. 2021, 7, 1235–1243. [Google Scholar] [CrossRef]

- Berto, L.; Vitaliani, R.; Saetta, A.; Simioni, P. Seismic Assessment of Existing RC Structures Affected by Degradation Phenomena. Struct. Saf. 2009, 31, 284–297. [Google Scholar] [CrossRef]

- Berto, L.; Caprili, S.; Saetta, A.; Salvatore, W.; Talledo, D. Corrosion Effects on the Seismic Response of Existing Rc Frames Designed According to Different Building Codes. Eng. Struct. 2020, 216, 110397. [Google Scholar] [CrossRef]

- Otieno, M.B.; Alexander, M.G.; Beushausen, H.D. Corrosion in Cracked and Uncracked Concrete—Influence of Crack Width, Concrete Quality and Crack Reopening. Mag. Concr. Res. 2010, 62, 393–404. [Google Scholar] [CrossRef]

- Stewart, M.G.; Mullard, J.A. Spatial Time-Dependent Reliability Analysis of Corrosion Damage and the Timing of First Repair for RC Structures. Eng. Struct. 2007, 29, 1457–1464. [Google Scholar] [CrossRef]

- Bohni, H. Corrosion in Reinforced Concrete Structures; Related Titles from Woodhead s Materials Engineering List; Woodhead Publishing: Cambridge, UK, 2005; ISBN 185573768X. [Google Scholar]

- Zhou, Y.; Zheng, Y.; Sui, L.; Hu, B.; Huang, X. Study on the Flexural Performance of Hybrid-Reinforced Concrete Beams with a New Cathodic Protection System Subjected to Corrosion. Materials 2020, 13, 234. [Google Scholar] [CrossRef]

- Musavi, S.A. Reinforcement of Weakened Concrete Beams Using Cfrp Composites. Int. J. 2023, 6, 732–737. [Google Scholar]

- Guo, Y. Assessing the Seismic Performance of Corroding RC Bridge Columns. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 2011. [Google Scholar]

- Garcia, R.; Hajirasouliha, I.; Pilakoutas, K. Seismic Behaviour of Deficient RC Frames Strengthened with CFRP Composites. Eng. Struct. 2010, 32, 3075–3085. [Google Scholar] [CrossRef]

- Capozucca, R.; Cerri, M.N. Influence of Reinforcement Corrosion-in the Compressive Zone-on the Behaviour of RC Beams. Eng. Struct. 2003, 25, 1575–1583. [Google Scholar] [CrossRef]

- Toumpanaki, E.; Lees, J.M.; Terrasi, G.P. Analytical Predictive Model for the Long-Term Bond Performance of CFRP Tendons in Concrete. Compos. Struct. 2020, 250, 112614. [Google Scholar] [CrossRef]

- Wu, W.; He, X.; Yang, W.; Dai, L.; Wang, Y.; He, J. Long-Time Durability of GFRP Bars in the Alkaline Concrete Environment for Eight Years. Constr. Build. Mater. 2022, 314, 125573. [Google Scholar] [CrossRef]

- Sadowski, L.; Nikoo, M. Corrosion Current Density Prediction in Reinforced Concrete by Imperialist Competitive Algorithm. Neural Comput. Appl. 2014, 25, 1627–1638. [Google Scholar] [CrossRef]

- Maidi, M.; Sherzer, G.L.; Gal, E. Enhancing Ductility in Carbon Fiber Reinforced Polymer Concrete Sections: A Multi-Scale Investigation. Comput. Concr. 2024, 33, 385–398. [Google Scholar] [CrossRef]

- Valente, M. Seismic Upgrading Strategies for Non-Ductile Plan-Wise Irregular R/C Structures. Procedia Eng. 2013, 54, 539–553. [Google Scholar] [CrossRef]

- Valente, M.; Milani, G. Alternative Retrofitting Strategies to Prevent the Failure of an Under-Designed Reinforced Concrete Frame. Eng. Fail. Anal. 2018, 89, 271–285. [Google Scholar] [CrossRef]

- Sokołowski, P.; Bąk-Patyna, P.; Bysiec, D.; Maleska, T. Experimental Test of Reinforced Timber of FRCM-PBO with Pull-Off Adhesion Method. Materials 2022, 15, 7702. [Google Scholar] [CrossRef] [PubMed]

- Carlos, D.A.; Henrique, N.J.; Maria, C.H.; Maria, B.A. Bending Strength of Timber Beams Rehabilitated with Reinforced Epoxy Mortar Plates. J. Struct. Eng. 2008, 134, 792–800. [Google Scholar] [CrossRef]

- Seręga, S.; Kotynia, R.; Lasek, K. Numerical Modelling of Preloaded RC Beams Strengthened with Prestressed CFRP Laminates. Eng. Struct. 2018, 176, 917–934. [Google Scholar] [CrossRef]

- SAP-2000 SAP2000; Three Dimensional Static and Dynamic Finite Element Analysis and Design of Structures, Analysis Reference, Version 17. Computer and Structures, Inc.: Berkeley, CA, USA, 2017. Available online: https://www.csiamerica.com/products/sap2000 (accessed on 21 November 2024).

- Response-2000 Reinforced Concrete Sectional Analysis Using the Modifed Compression Field Theorty 2000. Available online: http://www.hadrianworks.com (accessed on 21 November 2024).

- Yao, W.; Jiang, S.; Fei, W.; Cai, T. Correlation between the Compressive, Tensile Strength of Old Concrete under Marine Environment and Prediction of Long-Term Strength. Adv. Mater. Sci. Eng. 2017, 2017, 251842. [Google Scholar] [CrossRef]

- Diab, A.M.; Elyamany, H.E.; Abd Elmoaty, A.E.M.; Shalan, A.H. Prediction of Concrete Compressive Strength Due to Long Term Sulfate Attack Using Neural Network. Alex. Eng. J. 2014, 53, 627–642. [Google Scholar] [CrossRef]

- ACI 440.1R-15 CNR-DT 200 R1/2012; Guide for the Design and Construction of Externally Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures Materials, RC and PC Structures, Masonry Structures. Consiglio Nazionale delle Ricerche: Rome, Italy, 2015.

- Saje, D.; Bandelj, B.; Šušteršič, J.; Lopatic, J.; Saje, F. Shrinkage and Creep of Steel Fiber Reinforced Normal Strength Concrete. J. Test. Eval. 2013, 41, 959–969. [Google Scholar] [CrossRef]

- Monteiro, I.; Branco, F.A.; De Brito, J.; Neves, R. Statistical Analysis of the Carbonation Coefficient in Open Air Concrete Structures. Constr. Build. Mater. 2012, 29, 263–269. [Google Scholar] [CrossRef]

- Bertolini, L. Steel Corrosion and Service Life of Reinforced Concrete Structures. Struct. Infrastruct. Eng. 2008, 4, 123–137. [Google Scholar] [CrossRef]

- Ismail, M.; Muhammad, B.; Ismail, M.E.G. Compressive Strength Loss and Reinforcement Degradations of Reinforced Concrete Structure Due to Long-Term Exposure. Constr. Build. Mater. 2010, 24, 898–902. [Google Scholar] [CrossRef]

- Eurocode 2 Design of Concrete Structures; European Committee for Standardization: Lausanne, Switzerland, 1992; 250p.

- Tuutti, K. Corrosion of Steel in Concrete. Ph.D. Thesis, Swedish Cement and Concrete Research Institute, Lund University, Stockholm, Sweden, 1982. [Google Scholar]

- Broomfield, J.P. Corrosion of Steel in Concrete, 3rd ed.; Broomfield, J.P., Ed.; CRC Press: London, UK, 2023; ISBN 9781003223016. [Google Scholar]

- Song, S.; Wang, G.; Min, X.; Duan, N.; Tu, Y. Experimental Study on Cyclic Response of Concrete Frames Reinforced by Steel-CFRP Hybrid Reinforcement. J. Build. Eng. 2021, 34, 101937. [Google Scholar] [CrossRef]

- Lu, C.; Yang, J.; Liu, R. Probability Model of Corrosion-Induced Cracking Time in Chloride-Contaminated Reinforced Concrete. In Proceedings of the International Conference on Durability of Concrete Structures, ICDCS 2016, Shenzhen, China, 30 June–1 July 2016; pp. 309–314. [Google Scholar] [CrossRef]

- AL-Ameeri, A.; Rafiq, M.I.; Tsioulou, O. Influence of Cracks on the Carbonation Resistance of Recycled Aggregate Concrete. In Proceedings of the fib Symposium, Lisbon, Portugal, 14–16 June 2021; pp. 422–431. [Google Scholar]

- FEMA-356; Prestandard and Commentary for the Seismic Rehabilitation of Buildings. FEMA: Washington, DC, USA, 2000; 518p.

- Shapiro, D.; Rojahn, C.; Reaveley, L.D.; Smith, J.R.; Morelli, U. NEHRP Guidelines and Commentary for the Seismic Rehabilitation of Buildings. Earthq. Spectra 1997, 435, 1–435. [Google Scholar] [CrossRef]

- Hakim, R.A.; Alama, M.S.; Ashour, S.A. Seismic Assessment of RC Building According to ATC 40, FEMA 356 and FEMA 440. Arab. J. Sci. Eng. 2014, 39, 7691–7699. [Google Scholar] [CrossRef]

- Maidi, M.; Shufrin, I. Evaluation of Existing Reinforced Concrete Buildings for Seismic Retrofit through External Stiffening: Limit Displacement Method. Buildings 2024, 14, 2781. [Google Scholar] [CrossRef]

- Beneldjouzi, M.; Remki, M.; Kehila, F. Displacement-Based Methodology for Seismic Analysis of a Retrofitted Substandard Low-Rise RC Building Using Conditional Mean Spectra. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 48, 2847–2873. [Google Scholar] [CrossRef]

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering, 4th ed.; Pearson: London, UK, 2012; ISBN 1292249188. [Google Scholar]

- Chopra, A.K.; Goel, R.K. Chopra-Goel-Capacity Demand Driagram Methods Based on Inelastic Design Spectrum-1999.Pdf. Earthq. Spectra 1999, 15, 637–656. [Google Scholar] [CrossRef]

- CSA S806-12; Design and Construction of Building Structures with Fibre-Reinforced Polymer. Canadian Standards Association: Toronto, ON, Canada, 2012; 198p.

| Properties | Ultimate Strain (mm/m) | Yield Strength (MPa) | Ultimate Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| Steel bars | 7 | 276 | 414 | 200 |

| Age (Years) | As (mm2) | As’ (mm2) | f*cu (MPa) | Ec (GPa) | Residual Cover—Top/Bottom (mm) |

|---|---|---|---|---|---|

| 0 | 602.88 | 602.88 | 37.50 | 30.28 | 30 |

| 20 | 602.88 | 602.88 | 37.50 | 30.28 | 30 |

| 45 | 559.96342 | 559.96342 | 25.24 | 24.85 | 0 |

| 70 | 518.63129 | 518.63129 | 13.67 | 18.28 | 0 |

| 95 | 478.8836 | 478.8836 | 9.55 | 15.28 | 0 |

| 12 | 440.72035 | 440.72035 | 7.40 | 13.45 | 0 |

| 145 | 404.14155 | 404.14155 | 6.07 | 12.19 | 0 |

| 170 | 369.14719 | 369.14719 | 5.17 | 11.24 | 0 |

| Age (Years) | As (mm2) | As’ (mm2) | f*cu (MPa) | Ec (GPa) | Residual Cover—Top/Bottom (mm) |

|---|---|---|---|---|---|

| 0 | 100.48 | 100.48 | 37.50 | 30.28 | 30 |

| 20 | 97.66656 | 97.66656 | 37.50 | 30.28 | 30 |

| 45 | 94.14976 | 94.14976 | 33.75 | 28.73 | 30 |

| 70 | 90.63296 | 90.63296 | 33.12 | 28.46 | 30 |

| 95 | 87.11616 | 87.11616 | 33.00 | 28.40 | 30 |

| 120 | 83.59936 | 83.59936 | 32.78 | 28.31 | 30 |

| 145 | 80.08256 | 80.08256 | 32.63 | 28.25 | 30 |

| 170 | 76.56576 | 76.56576 | 32.48 | 28.18 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maidi, M.; Lifshitz Sherzer, G.; Shufrin, I.; Gal, E. Seismic Resilience of CRC- vs. RC-Reinforced Buildings: A Long-Term Evaluation. Appl. Sci. 2024, 14, 11079. https://doi.org/10.3390/app142311079

Maidi M, Lifshitz Sherzer G, Shufrin I, Gal E. Seismic Resilience of CRC- vs. RC-Reinforced Buildings: A Long-Term Evaluation. Applied Sciences. 2024; 14(23):11079. https://doi.org/10.3390/app142311079

Chicago/Turabian StyleMaidi, Moab, Gili Lifshitz Sherzer, Igor Shufrin, and Erez Gal. 2024. "Seismic Resilience of CRC- vs. RC-Reinforced Buildings: A Long-Term Evaluation" Applied Sciences 14, no. 23: 11079. https://doi.org/10.3390/app142311079

APA StyleMaidi, M., Lifshitz Sherzer, G., Shufrin, I., & Gal, E. (2024). Seismic Resilience of CRC- vs. RC-Reinforced Buildings: A Long-Term Evaluation. Applied Sciences, 14(23), 11079. https://doi.org/10.3390/app142311079