Benefits of Using Pomace from Sea Buckthorn Fruit (Hippophaë rhamnoides L.) in the Production of Rye Bread for a Strategy of Sustainable Production and Consumption

Abstract

Featured Application

Abstract

1. Introduction

- ✔

- Determining, using statistical tools, the optimal level of pomace addition to allow one to obtain the maximum nutritional and health-promoting value of bread, thus increasing its attractiveness on the market.

- ✔

- Estimating, by making a balance of the maceration process of sea buckthorn fruit pulp (both without and with the use of enzymes), the practical possibilities of sustainable management of this by-product toward the goal of minimizing potential environmental burdens and optimizing the production technology of a new bakery product.

2. Materials and Methods

- ✔

- Nutritional energy components (total lipids, fatty acids, starch, total ash, total carbohydrates, energy value).

- ✔

- Nutritional building components (total protein and its fractions).

- ✔

- Bioactive compounds (phenolic compounds, carotenoids, lutein, zeaxanthin, cryptoxanthin, α- and β-carotene).

2.1. Determination of Total Lipid Content and Fatty Acid Composition

2.2. Determination of Starch Content

2.3. Total Ash Content Determination

2.4. Determination of Total Protein Content and Its Fractions

2.5. Determination of Total Carbohydrate Content in Bread and Calculation of Its Energy Value

- W—water content (moisture) [%];

- TA—total ash content [% d.m];

- TP—total protein content [% d.m.];

- TL—total lipid content [% d.m.].

- TP—total protein content [% d.m.];

- TL—total lipid content [% d.m.];

- TC—total carbohydrate content [%].

2.6. Determination of Total Phenolic Compounds Using the Folin–Ciocalteau Method

2.7. Analysis of Carotenoid Content

2.8. Statistical Analysis

3. Results and Discussion

3.1. Characteristics of the Main Raw Materials Used for Baking Bread

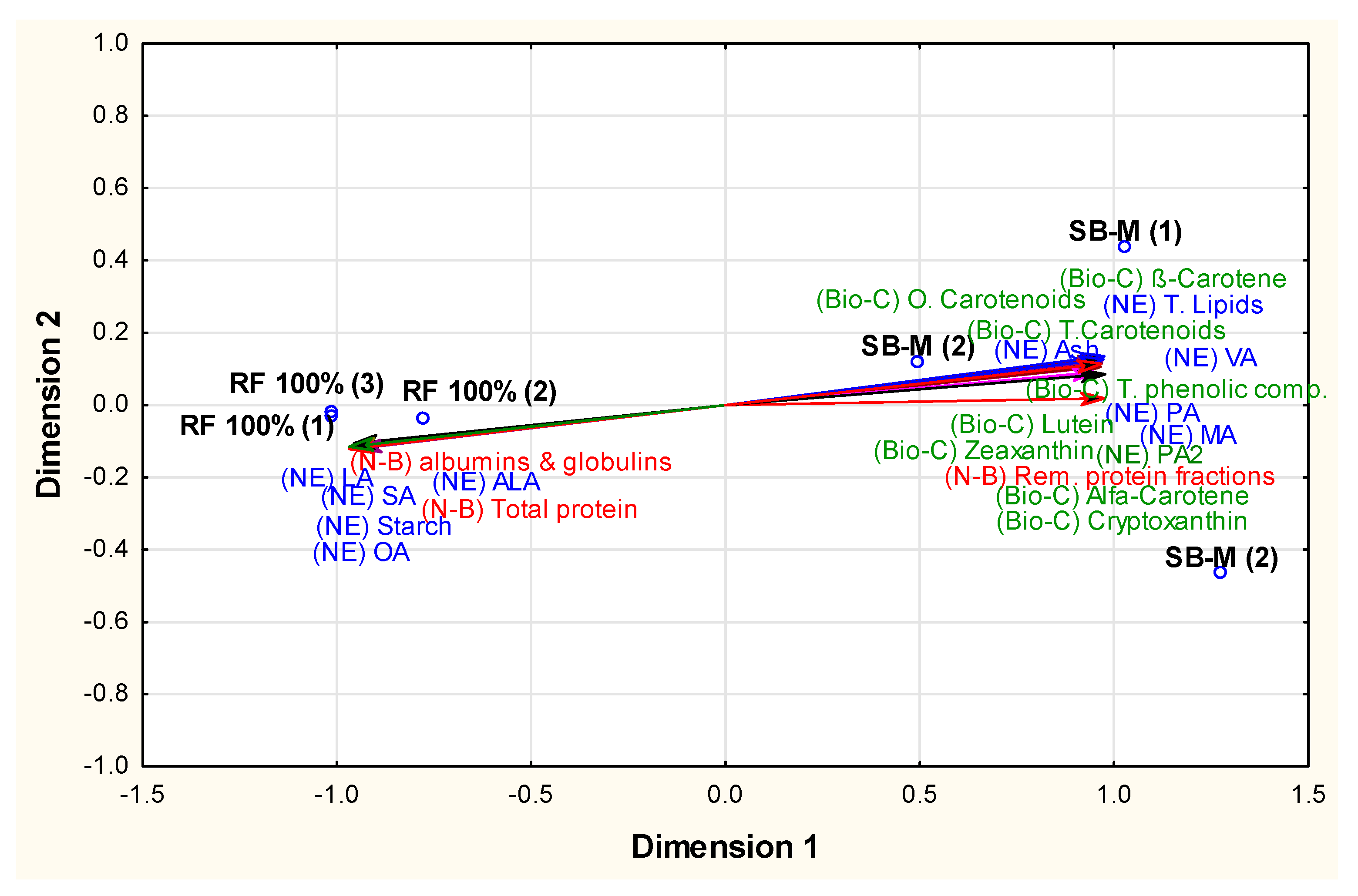

3.2. Characteristics of the Main Raw Materials (Rye Flour, Sea Buckthorn Pomace Meal) for Baking—Selected Ingredients: NE, N-B, Bio-C

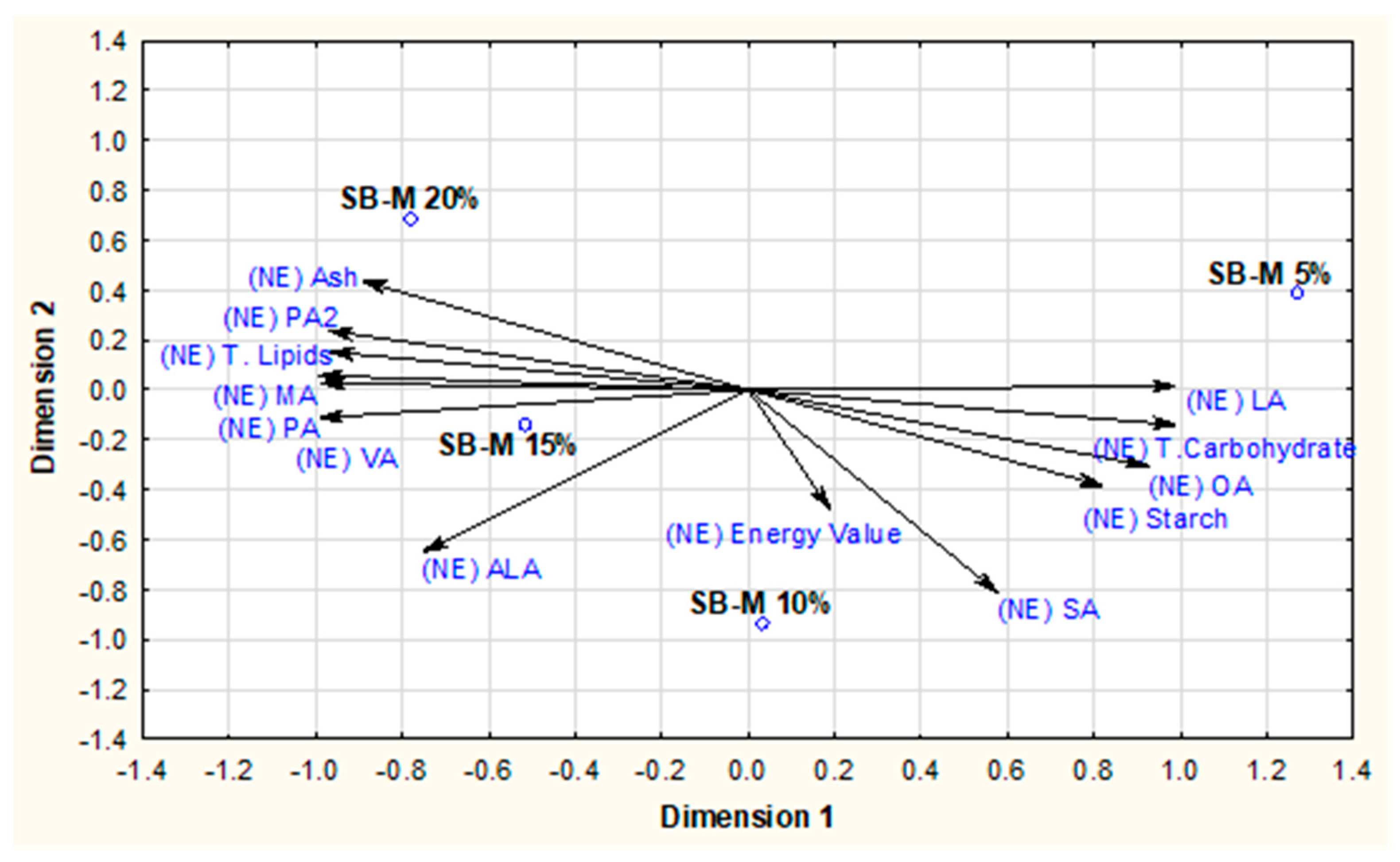

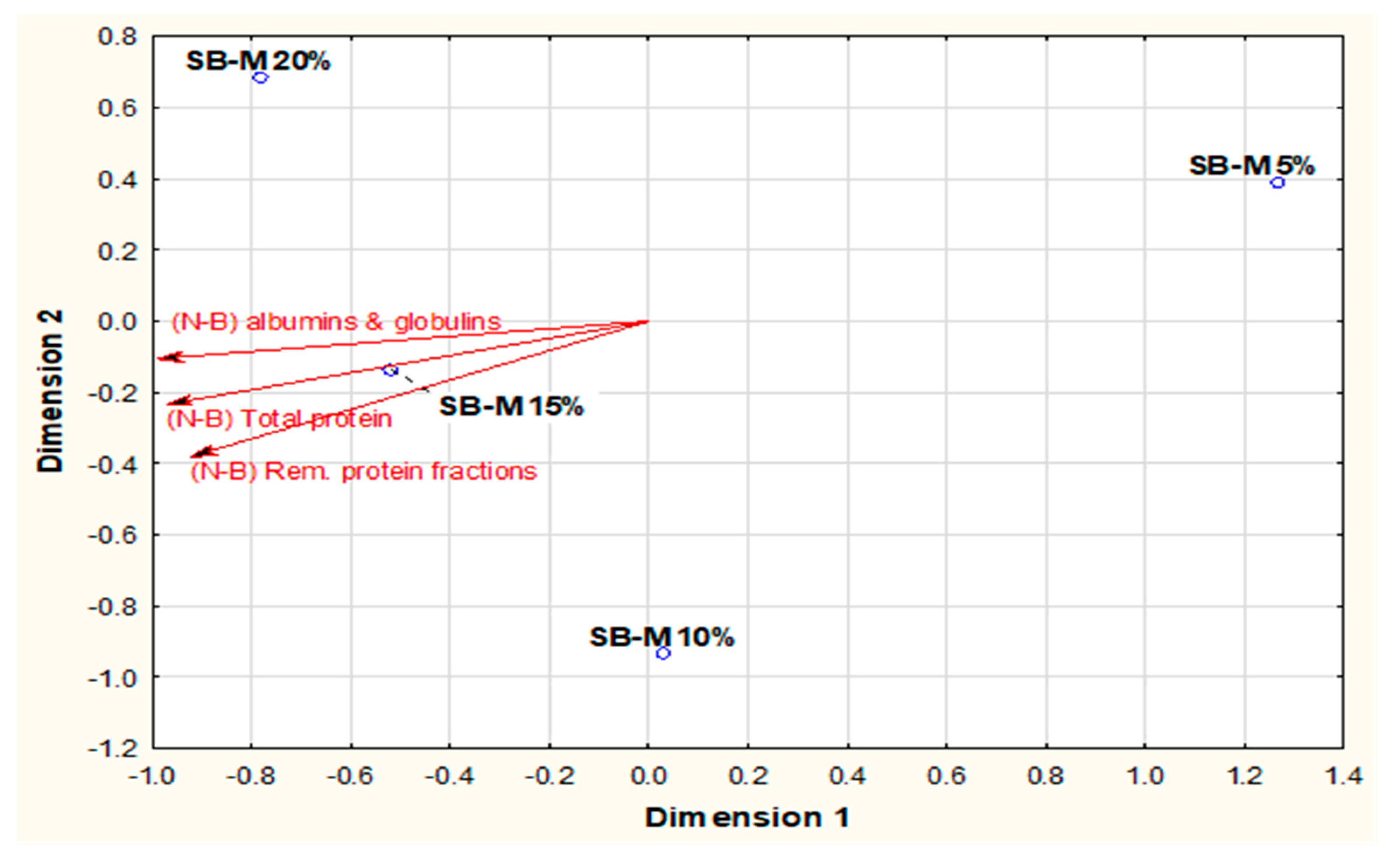

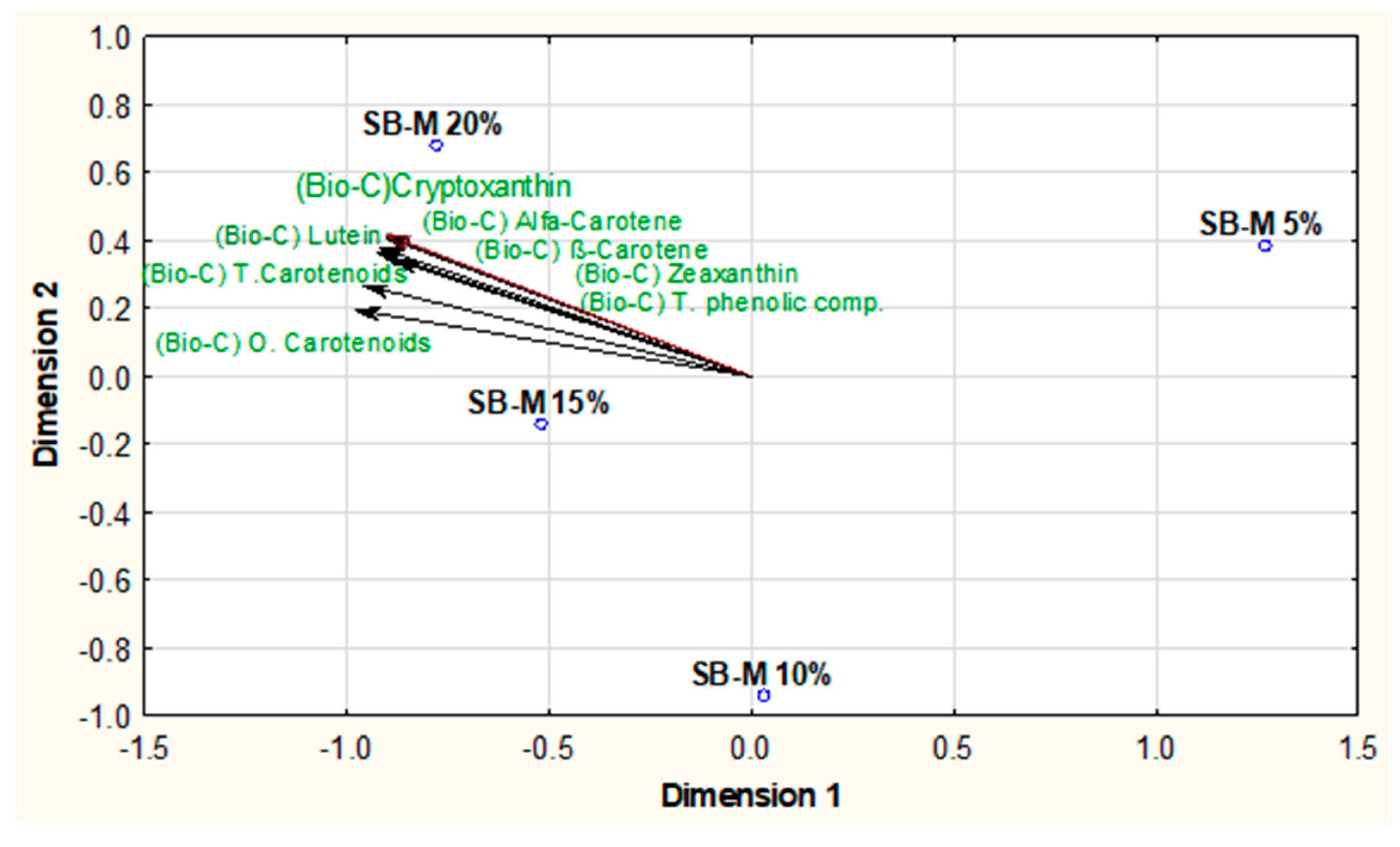

3.3. The Effect of Adding Sea Buckthorn Pomace on the Nutritional and Health-Promoting Value of Rye Bread

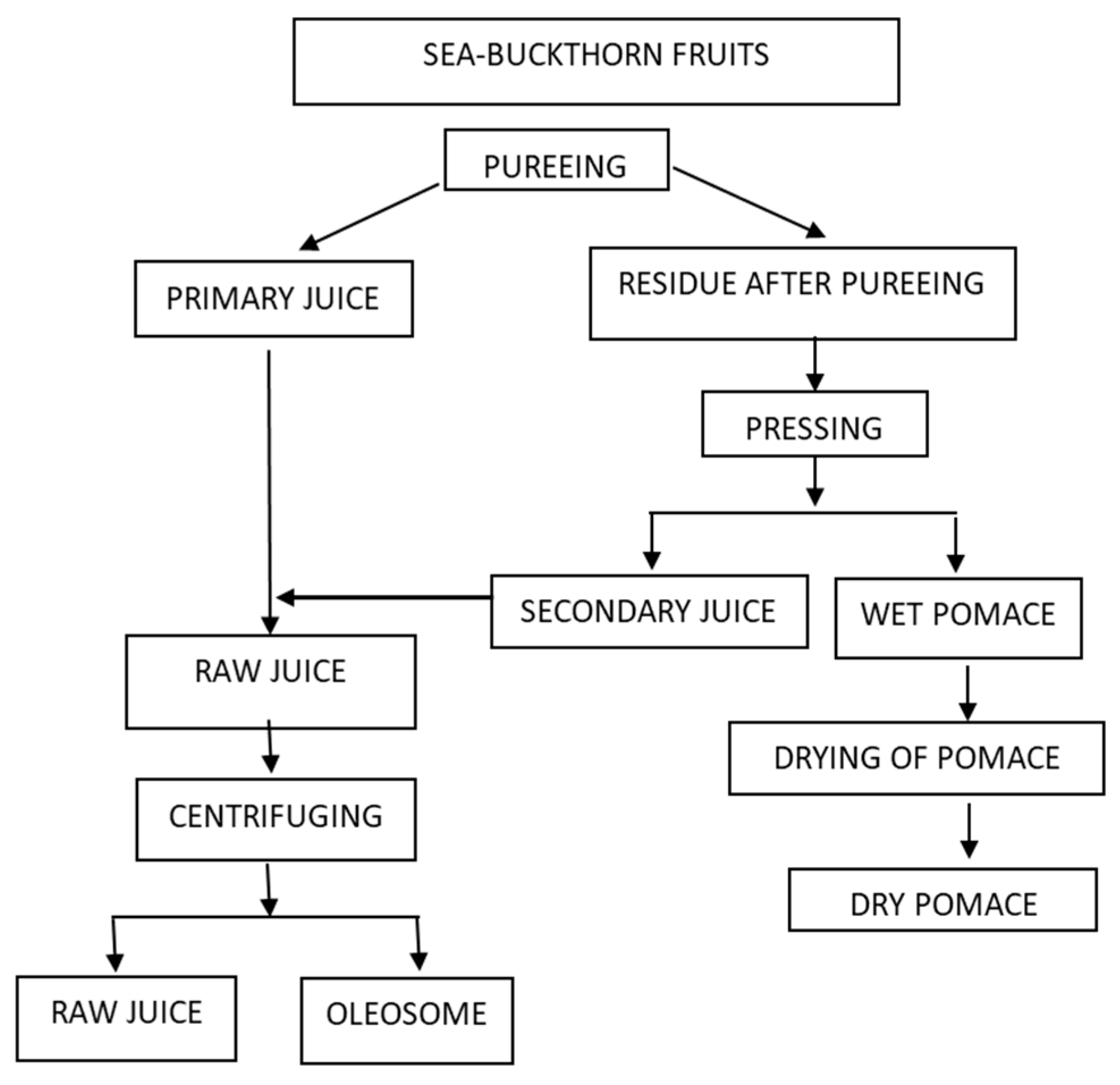

3.4. Sustainable Production of Sea Buckthorn Fruit Pomace

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Esteban, J.; Ladero, M. Food waste as a source of value-added chemicals and materials: A biorefinery perspective. Int. J. Food Sci. Technol. 2018, 53, 1095–1108. [Google Scholar] [CrossRef]

- Verni, M.; Rizello, C.G.; Coda, R. Fermentation biotechnology applied to cereal industry by-products: Nutritional and functional insights. Front. Nutr. 2019, 6, 42. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’Amico, M. Circular economy models in agro-food systems: A review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- Górecka, D.; Pospiech, E. (Eds.) Zagospodarowanie Ubocznych Produktów Przemysłu Spożywczego. (Management of By-Products of the Food Industry), 1st ed.; Wydział Nauk o Żywności i Żywieniu, Uniwersytet Przyrodniczy w Poznaniu: Poznań, Poland, 2016; ISBN 978-83-7160-836-0. (In Polish) [Google Scholar]

- De la Peña-Armada, R.; Mateos-Aparicio, I. Sustainable approaches using green technologies for apple by-product valorisation as a new perspective into the history of the apple. Molecules 2022, 27, 6937. [Google Scholar] [CrossRef]

- Michota-Katulska, E.; Zegan, M. Efektywne Zarządzanie Żywnością. Zapobieganie Marnowaniu i Techniki Utrwalania dla Zrównoważonego Spożycia. (Effective Food Management. Waste Prevention and Preservation Techniques for Sustainable Consumption), 1st ed.; Wydawnictwo Naukowe PWN S.A., PZWL Wydawnictwo Lekarskie: Warszawa, Poland, 2024; ISBN 978-83-01-23390-7. (In Polish) [Google Scholar] [CrossRef]

- Caponio, F.; Piga, A.; Poiana, M. Valorization of food processing by-products. Foods 2022, 11, 3246. [Google Scholar] [CrossRef] [PubMed]

- Stanciu, I.; Ungureanu, E.L.; Popa, E.E.; Geicu-Cristea, M.; Draghici, M.; Mitelut, A.C.; Mustatea, G.; Popa, M.E. The experi mental development of bread with enriched nutritional properties using organic sea buckthorn pomace. Appl. Sci. 2023, 13, 6513. [Google Scholar] [CrossRef]

- Tarko, T.; Duda-Chodak, A.; Bebak, A. Aktywność biologiczna wybranych wytłoków owocowych oraz warzywnych (Biological activity of selected fruit and vegetable pomaces). Żywność. Nauka. Technol. Jakość. 2012, 4, 55–65. (In Polish) [Google Scholar]

- Dziki, D.; Różyło, R.; Gawlik-Dziki, U.; Świeca, M. Current trends in the enhancement of antioxidant activity of wheat bread by the addition of plant materials rich in phenolic compounds. Trends Food Sci. Technol. 2014, 40, 48–61. [Google Scholar] [CrossRef]

- Zdybel, B.; Różyło, R.; Sagan, A. Use of a waste product from the pressing of chia seed oil in wheat and gluten-free bread processing. J. Food Process. Preserv. 2019, 43, e14002. [Google Scholar] [CrossRef]

- Djeghim, F.; Bourekoua, H.; Różyło, R.; Bieńczak, A.; Tanaś, W.; Zidoune, M.N. Effect of by-products from selected fruits and vegetables on gluten-free dough rheology and bread properties. Appl. Sci. 2021, 11, 4605. [Google Scholar] [CrossRef]

- Łopaciuk, W. (Ed.) Rynek Zbóż. Stan i Perspektywy. Analizy Rynkowe (Cereal Market. Status and Prospects. Market Analyses); Nr. 65; Instytut Ekonomiki Rolnictwa i Gospodarki Żywnościowej. Państwowy Instytut Badawczy: Warszawa, Poland, 2023; ISSN 1231-3149. (In Polish) [Google Scholar]

- Dziki, D. Rye flour and rye bran: New perspectives for use. Processes 2022, 10, 293. [Google Scholar] [CrossRef]

- Piłat, B.; Zadernowski, R. Owoce rokitnika (Hippophae rhamnoides L.)—Bogate źródło związków biologicznie aktywnych. (Fruits of sea buckthorn Hippophae rhamnoides L.—Rich source of biologically active compounds). Postępy Fitoter. 2016, 17, 298–306. (In Polish) [Google Scholar]

- Piłat, B.; Zadernowski, R. Rokitnik zwyczajny (Hippophaë rhamnoides L.) w profilaktyce nowotworowej. (The sea buckthorn Hippophaë rhamnoides L. fruit in cancer prevention). Postępy Fitoter. 2019, 20, 111–117. (In Polish) [Google Scholar] [CrossRef]

- Majewska, K.M.; Banach, J.K.; Piłat, B.; Złotkowska, K.; Sobiechowska, D. Shaping the quality features of rye bread using a diversified share of sea-buckthorn fruit pomace. P-60. In Proceedings of the 11th Central European Congress on Food and Nutrition (CEFood 2022)—“Food, technology and nutrition for healthy people in healthy environment”, Čatež ob Savi, Slovenia, 27–30 September 2022; p. 206. [Google Scholar]

- Rafalska, A.; Abramowicz, K.; Krauze, M. Sea buckthorn (Hippophae rhamnoides L.) as a plant for universal application. World Sci. News 2017, 72, 123–140. [Google Scholar]

- Galanakis, C.M. Food Waste Recovery: Processing Technologies, Industrial Techniques, and Applications; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Lubczyńska, H.; Lipińska, H.; Jarosz, K.; Woźniakowski, A.; Kosakowska, J.; Walewska, M. Vademecum Piekarza do Nauki Zawodu (Baker’s Vademecum for Learning the Profession); Wydawca Handlowo-Usługowa Spółdzielnia “Samopomoc Chłopska”: Warszawa, Poland, 2006; ISBN 83-919549-5-1. (In Polish) [Google Scholar]

- PN–EN ISO 712:2012; Cereals and Cereal Products—Determination of Moisture Content—Reference Method. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Krełowska-Kułas, M. Badanie Jakości Produktów Spożywczych. (Quality Testing of Food Products); Polskie Wydawnictwo Ekonomiczne (PWN): Warszawa, Poland, 1993; ISBN 83-208-0902-9. (In Polish) [Google Scholar]

- Czaplicki, S.; Tańska, M.; Konopka, I. Sea-buckthorn oil in vegetable oils stabilisation. Ital. J. Food Sci. 2016, 28, 412–425. [Google Scholar]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemistry, 15th ed.; Association of Official Analytical Chemists, Inc.: Arlington, VA, USA, 1990. [Google Scholar]

- PN-ISO 2171:2010; Ziarno Zbóż, Nasiona Roślin Strączkowych i Ich Przetwory. Oznaczanie Zawartości Popiołu Metodą Spalania (Cereal Grains, Legume Seeds and Their Products. Determination of Ash Content by Combustion). Wydawnictwo SGGW: Warszawa, Poland, 2010. (In Polish)

- Wieser, H.; Antes, S.; Seilmeier, W. Quantitative determination of gluten protein types in wheat flour by Reversed-Phase High-Performance Liquid Chromatography. Cereal Chem. 1998, 75, 644–650. [Google Scholar] [CrossRef]

- Gronowska-Senger, A. Podstawy Biooceny Żywności (Basics of Food Bioassessment); SGGW: Warszawa, Poland, 2004; ISBN 83-7244-553-2. (In Polish) [Google Scholar]

- Zaborski, A.; Pełka, M. Geometrical presentation of preferences by using profit analysis and R program. Acta Univ. Lodz. Folia Oecon. 2013, 285, 191–197. [Google Scholar]

- PN-A-74032:2002; Cereal Products. Rye Flour. Polish Committee for Standardization: Warsaw, Poland, 2010. (In Polish)

- Hussain, A.; Larsson, H.; Johansson, E. Carotenoid extraction from locally and organically produced cereals using saponification method. Processes 2021, 9, 783. [Google Scholar] [CrossRef]

- Fernández-Peláez, J.; Paesani, C.; Gómez, M. Sourdough Technology as a Tool for the Development of Healthier Grain-Based Products: An Update. Agronomy 2020, 10, 1962. [Google Scholar] [CrossRef]

- Guo, X.; Shi, L.; Yang, S.; Yang, R.; Dai, X.; Zhang, T.; Liu, R.; Chang, M.; Jin, Q.; Wang, X. Effect of sea-buckthorn pulp and flaxseed residues on quality and shelf life of bread. Food Funct. 2019, 10, 4220–4230. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, M.; Zhu, L.; Geng, Z.; Liu, X.; Cheng, Z.; Zhao, M.; Zhang, Q.; Yang, X. Sea Buckthorn Pretreatment, Drying, and Processing of High-Quality Products: Current Status and Trends. Foods 2023, 12, 4255. [Google Scholar] [CrossRef]

- Pecyna, A.; Krzywicka, M.; Blicharz-Kania, A.; Buczaj, A.; Kobus, Z.; Zdybel, B.; Domin, M.; Siłuch, D. Impact of incorporating two types of dried raspberry pomace into gluten-free bread on its nutritional and antioxidant characteristics. Appl. Sci. 2024, 14, 1561. [Google Scholar] [CrossRef]

- Popa, E.E.; Anghel, A.A.; Stanciu, I.; Miteluţ, A.C.; Popescu, P.A.; Drăghici, M.C.; Geicu-Cristea, M.; Popa, M.E. Preliminary research on using organic sea buckthorn powder in bread making. AgroLife Sci. J. 2022, 11, 136–141. [Google Scholar] [CrossRef]

- Ciesarová, Z.; Kukurová, K.; Jelemenská, V.; Horváthová, J.; Kubincová, J.; Belovi´c, M.; Torbica, A. Asparaginase treatment of sea buckthorn berries as an effective tool for acrylamide reduction in nutritionally enriched wholegrain wheat, rye and triticale biscuits. Foods 2023, 12, 3170. [Google Scholar] [CrossRef]

- Samilyk, M.; Demidova, E.; Bolgova, N.; Savenko, O.; Cherniavska, T. Development of bread technology with high biological value and increased shelf life. East.-Eur. J. Enterp. Technol. 2022, 2, 116. [Google Scholar] [CrossRef]

- Janotková, L.; Potočňáková, M.; Kreps, F.; Krepsová, Z.; Ácsová, A.; Ház, A.; Jablonsky, M. Effect of sea buckthorn biomass on oxidation stability and sensory attractiveness of cereal biscuits. BioResources 2021, 16, 5097. [Google Scholar] [CrossRef]

- Radziejewska-Kubzdela, E. Effect of ultrasonic, thermal and enzymatic treatment of mash on yield and content of bioactive compounds in strawberry juice. Appl. Sci. 2023, 13, 4268. [Google Scholar] [CrossRef]

- Hussain, S.; Sharma, M.; Bhat, R. Valorisation of sea buckthorn pomace by optimization of ultrasonic-assisted extraction of soluble dietary fibre using response surface methodology. Foods 2021, 10, 1330. [Google Scholar] [CrossRef] [PubMed]

- Hamed, I.; Jakobsen, A.N.; Lerfall, J. Sustainable edible packaging systems based on active compounds from food processing byproducts: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 198–226. [Google Scholar] [CrossRef] [PubMed]

- Gómez-García, R.; Campos, D.A.; Aguilar, C.N.; Madureira, A.R.; Pintado, M. Valorisation of food agro-industrial by-products: From the past to the present and perspectives. J. Environ. Manag. 2021, 299, 113571. [Google Scholar] [CrossRef] [PubMed]

| Components/Raw Material | RF | SB-M |

|---|---|---|

| Nutritional Energy Ingredients (NE) | ||

| Total lipids [% d.m.] | 1.48 ± 0.00 a | 34.15 ± 0.25 b |

| Palmitic acid | 22.04 ± 1.35 a | 37.80 ± 1.31 b |

| Palmitoleic acid | 1.65 ± 0.16 a | 40.63 ± 0.27 b |

| Margaric acid | 0.00 a | 1.59 ± 0.04 b |

| Stearic acid | 1.14 ± 0.13 b | 0.58 ± 0.01 a |

| Oleic acid | 17.44 ± 0.17 b | 2.41 ± 0.02 a |

| Vaccenic acid | 2.97 ± 0.40 a | 6.09 ± 0.04 b |

| Linoleic acid | 50.57 ± 2.06 b | 10.49 ± 0.06 a |

| Linolenic acid | 4.54 ± 0.51 b | 0.69 ± 0.03 a |

| Starch [% d.m.] | 79.49 ± 0.23 b | 0.00 a |

| Ash [% s.m.] | 0.78 ± 0.00 a | 2.53 ± 0.09 b |

| Nutritional Building Ingredients (N-B) | ||

| Total protein [% d.m.] | 4.74 ± 0.03 b | 2.58 ± 0.02 a |

| Albumins and globulins [% d.m.] | 2.53 ± 0.01 b | 0.04 ± 0.00 a |

| Rem. protein fractions [% d.m.] | 2.20 ± 0.01 a | 2.53 ± 0.02 b |

| Bioactive Compounds (Bio-C) | ||

| T. phenolic comp. [mg/100 g d.m.] | 65.43 ± 2.63 a | 903.38 ± 30.70 b |

| T. carotenoids [mg/100 g d.m.] | 0.21 ± 0.00 a | 19.09 ± 0.04 b |

| Lutein | 0.10 ± 0.01 a | 1.26 ± 0.02 b |

| Zeaxanthin | 0.09 ± 0.00 a | 1.25 ± 0.02 b |

| Cryptoxanthin | 0.00 a | 0.81 ± 0.01 b |

| α-Carotene | 0.00 a | 0.67 ± 0.00 b |

| β-Carotene | 0.00 a | 1.05 ± 0.03 b |

| Rem. carotenoids | 0.00 a | 14.03 ± 0.04 b |

| Components/Bread Variants | RB, Control | 5% SB-M | 10% SB-M | 15% SB-M | 20% SB-M |

|---|---|---|---|---|---|

| Total lipids [% d.m.] | 0.65 ± 0.01 a | 1.05 ± 0.03 b | 1.82 ± 0.01 c | 2.04 ± 0.03 d | 2.60 ± 0.03 e |

| Palmitic acid | 22.93 ± 0.62 a | 23.65 ± 0.41 a | 27.73 ± 0.60 b | 30.89 ± 0.36 cC | 31.31 ± 0.40 D |

| Palmitoleic acid | 1.96 ± 0.03 a | 19.42 ± 0.05 b | 24.38 ± 0.56 c | 29.96 ± 0.07 d | 32.66 ± 0.02 e |

| Margaric acid | 0.00 a | 0.49 ± 0.02 b | 0.74 ± 0.09 c | 0.79 ± 0.00 d | 0.90 ± 0.01 e |

| Stearic acid | 1.63 ± 0.13 e | 0.96 ± 0.02 d | 0.99 ± 0.04 c | 0.93 ± 0.02 b | 0.86 ± 0.01 a |

| Oleic acid | 17.67 ± 0.50 e | 18.86 ± 0.21 d | 16.13 ± 0.57 c | 8.64 ± 0.29 b | 7.90 ± 0.04 a |

| Vaccenic acid | 1.96 ± 0.15 a | 4.33 ± 0.09 b | 5.45 ± 0.10 c | 5.91 ± 0.09 d | 5.91 ± 0.02 d |

| Linoleic acid | 50.47 ± 1.92 e | 27.93 ± 0.25 d | 21.74 ± 0.07 c | 20.74 ± 0.12 b | 18.24 ± 0.17 a |

| Linolenic acid | 4.99 ± 0.07 e | 3.49 ± 0.02 d | 2.98 ± 0.16 c | 2.43 ± 0.05 b | 2.12 ± 0.04 a |

| Starch [% d.m.] | 79.82 ± 0.63 c | 79.70 ± 0.52 c | 77.76 ± 0.61 b | 77.66 ± 0.00 b | 73.55 ± 0.45 a |

| Ash [% d.m.] | 1.15 ± 0.00 a | 1.17 ± 0.06 a | 1.18 ± 0.06 b | 1.22 + 0.06 c | 1.24 ± 0.02 c |

| Energy value [kcal] | 220.30 ± 0.10 ec | 218.30 ± 0.00 db | 220.00 ± 0.00 c | 216.90 ± 0.00 a | 218.46 ± 0.0 b |

| Total carbohydrate [%] | 49.31 ± 0.00 e | 47.87 ± 0.01 d | 45.79 ± 0.00 c | 44.41 ± 0.01 b | 43.50 ± 0.01 a |

| Components/Bread Variants | RB, Control | 5% SB-M | 10% SB-M | 15% SB-M | 20% SB-M |

|---|---|---|---|---|---|

| Total protein [% d.m.] | 4.28 ± 0.02 a | 4.31 ± 0.01 b | 5.11 ± 0.01 c | 5.22 ± 0.01 d | 5.26 ± 0.02 e |

| Albumins and globulins [% d.m.] | 0.62 ± 0.00 b | 0.55 ± 0.00 a | 0.95 ± 0.01 c | 1.02 ± 0.00 d | 1.11 ± 0.00 e |

| Rem. protein fractions [% d.m.] | 3.66 ± 0.01 a | 3.76 ± 0.01 b | 4.17 ± 0.02 c | 4.22 ± 0.00 d | 4.16 ± 0.02 ec |

| Components/Bread Variants | RB, Control | 5% SB-M | 10% SB-M | 15% SB-M | 20% SB-M |

|---|---|---|---|---|---|

| T. phenolic comp. [mg/100 g d.m.] | 109.14 ± 2.40 a | 228.55 ± 9.43 b | 266.05 ± 13.29 c | 278.88 ± 12.50 d | 338.98 ± 10.92 e |

| T. carotenoids [mg/100 g d.m.] | 2.99 ± 0.00 a | 16.61 ± 0.09 b | 25.42 ± 1.65 c | 32.60 ± 1.08 d | 40.30 ± 3.48 e |

| Lutein | 1.00 ± 0.00 a | 1.60 ± 0.00 b | 2.68 ± 0.01 c | 4.16 ± 0.32 d | 5.71 ± 0.76 e |

| Zeaxanthin | 1.00 ± 0.0 a | 1.48 ± 0.00 b | 2.38 ± 0.01 c | 3.55 ± 0.26 d | 4.75 ± 0.64 e |

| Cryptoxanthin | 0.00 a | 1.09 ± 0.00 b | 1.28 ± 0.01 c | 1.54 ± 0.07 d | 1.87 ± 0.16 e |

| α-Carotene | 0.00 a | 1.02 ± 0.00 b | 1.06 ± 0.00 c | 1.12 ± 0.01 d | 1.19 ± 0.04 e |

| β-Carotene | 0.99 ± 0.00 a | 1.17 ± 0.00 b | 1.55 ± 0.01 c | 2.13 ± 0.14 d | 2.81 ± 0.28 e |

| Rem. carotenoids | 0.00 a | 11.00 ± 0.78 b | 16.51 ± 1.65 c | 20.38 ± 0.23 d | 23.74 ± 1.36 e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banach, J.K.; Majewska, K.; Piłat, B.; Grzywińska-Rąpca, M. Benefits of Using Pomace from Sea Buckthorn Fruit (Hippophaë rhamnoides L.) in the Production of Rye Bread for a Strategy of Sustainable Production and Consumption. Appl. Sci. 2024, 14, 11067. https://doi.org/10.3390/app142311067

Banach JK, Majewska K, Piłat B, Grzywińska-Rąpca M. Benefits of Using Pomace from Sea Buckthorn Fruit (Hippophaë rhamnoides L.) in the Production of Rye Bread for a Strategy of Sustainable Production and Consumption. Applied Sciences. 2024; 14(23):11067. https://doi.org/10.3390/app142311067

Chicago/Turabian StyleBanach, Joanna Katarzyna, Katarzyna Majewska, Beata Piłat, and Małgorzata Grzywińska-Rąpca. 2024. "Benefits of Using Pomace from Sea Buckthorn Fruit (Hippophaë rhamnoides L.) in the Production of Rye Bread for a Strategy of Sustainable Production and Consumption" Applied Sciences 14, no. 23: 11067. https://doi.org/10.3390/app142311067

APA StyleBanach, J. K., Majewska, K., Piłat, B., & Grzywińska-Rąpca, M. (2024). Benefits of Using Pomace from Sea Buckthorn Fruit (Hippophaë rhamnoides L.) in the Production of Rye Bread for a Strategy of Sustainable Production and Consumption. Applied Sciences, 14(23), 11067. https://doi.org/10.3390/app142311067