Featured Application

Pomace from sea buckthorn fruit constitutes the largest part of the waste that is generated during the production process of sea buckthorn juice and oil. It is an inexpensive but very valuable, functional, and ecological addition to the design of new food products. The management of this type of pomace is justified in order to obtain benefits for potential producers in the bakery and confectionery industries and for consumers looking for another food with pro-health properties. Studies on the use of sea buckthorn pomace in the production of rye bread have shown that the addition of 15–20% of pomace optimally enriches the bread with valuable bioactive and nutritional components, supporting healthy and sustainable consumption. In addition, the use of this pomace as a functional additive to bread reduces the burden on the environment thanks to effective waste management and allows for the maceration of sea buckthorn pulp without the need for enzymes, which supports more ecological production practices.

Abstract

The aim of the research was to optimize the addition of sea buckthorn pomace to rye bread for sustainable production and consumption. Profit analysis was used to evaluate the optimal impact of added pomace on bread quality. The effects of the management of the by-product (pomace) during the maceration of sea buckthorn fruit pulp were determined on the basis of process efficiency balance. The research materials included five baking variants of bread containing type 720 rye flour, differing in the level of pomace added (0, 5, 10, 15, and 20%). The bread was produced in laboratory conditions on rye sourdough using the three-phase method. The impact of pomace addition on the quality of baked goods was determined by assessing the content of nutritional and energy components, nutritional and building materials, and bioactive compounds. The results show that greater qualitative benefits, including health benefits, were obtained when rye bread was enriched with 15 and 20% pomace. These results have been confirmed by PROFIT analysis. The analysis of the efficiency balance of the sea buckthorn fruit pulp maceration process showed that it is more beneficial to subject these substrates to the processes of drying at 50 °C, separation (removal of seeds), and grinding than it is to use enzymatic maceration.

1. Introduction

Sustainable food production and consumption are becoming a priority for the food industry, which is faced with the challenge of reducing the negative impact of its activities on the environment. In this context, the use of the by-products generated during food processing is becoming increasingly important. By-products, such as pomace, can be valuable secondary resources that, after appropriate treatment, can be reused, thus contributing to waste reduction and supporting a more sustainable economy. Such an approach not only minimizes waste but also promotes the creation of a circular economy model, in which waste is transformed into valuable raw materials, while supporting the development of a sustainable food industry [1,2,3].

The development of the food industry is related not only to the implementation of new techniques and technologies and the development and production of innovative products, but also to the emergence of increasingly new and more effective ways of managing various types of post-production residues. The largest amounts of by-products are generated in the sugar, brewing, and distilling industries, but also during the processing of fruits and vegetables, cereals, meat, and fish [2,4,5].

The management of by-products from the food industry is very diverse and closely related to the progress in science and technology [2]. Sustainable food production is becoming a contemporary priority, one where the effective and recent use of food processing by-products has begun to play a key role [6]. The actions taken are consistent with the implementation of sustainable development goal (SDG) 12, which focuses on ensuring sustainable consumption and production patterns. Sustainable resource management and the reduction of food waste are key elements of this goal. The use of sea buckthorn pomace in bread production not only contributes to waste reduction but also promotes a circular economy, responding to the needs of a sustainable food industry and conscious consumers [7,8]. Some of these products, particularly those originating from plants, serve as valuable sources of biologically active compounds and have the potential to enhance traditional food products like bread, endowing them with health-promoting properties [4,9,10,11,12]. Bread can be enriched by adding synthetic nutrients or by adding natural raw materials. However, the latter is a much more rational way of meeting the criteria of sustainable production and consumption, especially when adding nutritionally valuable by-products.

Bread and other bakery products currently constitute approximately 70% of all cereal processing products in the Polish diet [13]. Wheat and rye flour are mainly used to produce bread. Rye flour (white and whole meal) is commonly used as the main ingredient for the preparation of sourdough bread [14].

Due to the fact that bread (despite the decline in consumption) is still widely consumed, its quality should be as high as possible. Its quality should also always correspond with the important role it plays in human nutrition—as an important source of energy and in building and regulating nutritious components. Obtaining high-quality bread, with a high nutritional value, largely depends on the raw materials used for its production—both basic materials and enriching additives (especially those with a high content of biologically active substances). One such raw material, which has great potential as a valuable functional additive in bread production, may be sea buckthorn fruit pomace, a by-product created during the production process of sea buckthorn juice and oil [15,16,17].

Sea buckthorn is a plant whose biologically active components are concentrated in fruits, bark, roots, leaves, and flowers [18]. All of the above-mentioned morphological parts are used by the pharmaceutical, cosmetic, and food industries; however, the fruits are most widely used [16]. In the chemical composition of sea buckthorn fruit, primary metabolites, i.e., proteins, carbohydrates, minerals, and fiber, have limited bioactive properties. These are essential nutrients or building blocks. The exception here are lipids, to which both nutritional and bioactive properties are attributed. On the other hand, the high value of sea buckthorn fruit is mainly determined by secondary metabolites (including polyphenolic compounds, carotenoids, tocopherols, and phytosterols), whose content and bioavailability are significantly higher than in other plant raw materials (fruits, vegetables, and seeds) [16,18].

So far, sea buckthorn pomace has been used mainly in animal feeding and for the production of fiber preparations, phospholipid–carotenoid concentrates, and dietary supplements. Research on the use of sea buckthorn pomace in the production of rye bread is of significant importance for the development of a sustainable food industry. The inclusion of this by-product may not only enrich bread with valuable bioactive ingredients (sustainable consumption) but also contribute to waste reduction (sustainable production) [1]. Therefore, this research responds to the assumptions of SDG 12, supporting the creation of a sustainable food industry and promoting activities consistent with the idea of a circular economy. The implementation of such a research direction will allow for the assessment of the potential of sea buckthorn pomace as a secondary raw material in bread, supporting the goals of the circular economy and responding to the needs of consumers looking for health-promoting and ecological food [19].

Taking the above in mind, the aim of the undertaken research was to determine the effect of adding sea buckthorn fruit pomace on the sustainable production and quality of rye bread, taking into account the potential benefits for consumers.

The partial objectives of the research were established as follows:

- ✔

- Determining, using statistical tools, the optimal level of pomace addition to allow one to obtain the maximum nutritional and health-promoting value of bread, thus increasing its attractiveness on the market.

- ✔

- Estimating, by making a balance of the maceration process of sea buckthorn fruit pulp (both without and with the use of enzymes), the practical possibilities of sustainable management of this by-product toward the goal of minimizing potential environmental burdens and optimizing the production technology of a new bakery product.

2. Materials and Methods

The research materials were commercial light rye flour type 720 (producer: Młyn Szczepanki, Szczepanki, Poland), dried sea buckthorn fruit pomace (Hippophaë rhamnoides L.) (producer: Szarłat, Cibory Gałeckie, Poland), and five variants of special rye bread, produced on rye sourdough in laboratory conditions.

Sea buckthorn fruit pomace was ground into meal (average particle size of 1 mm) using a laboratory mill type WŻ-1 (Sadkiewicz Instruments, Bydgoszcz, Poland). A total of 5 variants of mixtures for bread production were prepared, as follows: 100% rye flour (control variant) and then substituting sea buckthorn meal for this flour in the proportions of of 5, 10, 15, and 20%. The proportions of sea buckthorn flour were primarily arrived at due to technological reasons and the acceptability of the sour taste and the intensity of the crumb color of the resulting bread. The baked goods were baked in two separate series using a laboratory baking test set consisting of a GM-2 dough mixer, fermentation chamber (Sadkiewicz Instruments, Bydgoszcz, Poland) and a laboratory baking oven type XVC105 (UNOX, Milan, Italy).

The bread was produced using a three-phase method [20]. Fermentation of the sourdoughs was carried out in a Benchmark Incu-Shaker mini incubator (Benchmark Scientific, Sayreville, NJ, USA) (time: 72 h, temp. 30 °C). Approximate efficiency of the fermentation phases preceding the dough were as follows: 200%, dough efficiency: 165%. sourdough share: approximately 30%, salt addition to the dough: 1.5%, weight of individual dough pieces for baking: 250 g. The bread was baked in standardized molds made of acid-resistant stainless steel (Sadkiewicz Instruments, Bydgoszcz, Poland). The baking temperature was 230 °C and the baking time was 30 min.

For the rye flour, the sea buckthorn meal, the baking mixtures with the addition of sea buckthorn meal and in the obtained bread, the moisture was determined according to [21].

The assessment of the effect of the addition of meal from sea buckthorn fruit pomace on selected quality features of the experimental baked goods was carried out based on the determination or calculation of the contents of the following:

- ✔

- Nutritional energy components (total lipids, fatty acids, starch, total ash, total carbohydrates, energy value).

- ✔

- Nutritional building components (total protein and its fractions).

- ✔

- Bioactive compounds (phenolic compounds, carotenoids, lutein, zeaxanthin, cryptoxanthin, α- and β-carotene).

2.1. Determination of Total Lipid Content and Fatty Acid Composition

The total lipid content in the tested samples was determined using the Folch method [22] and the fatty acid composition was determined using gas chromatography.

Fatty acid determination was undertaken according to the method described by Czaplicki et al. [23]. Methylated fatty acids were analyzed by gas chromatography with a GC–MS QP2010 PLUS (Shimadzu, Kyoto, Japan) system. Separation was performed on a BPX70 (25 m × 0.22 mm × 0.25 μm) capillary column (SGE Analytical Science, Ringwood, VIC, Australia) with helium as the carrier gas at a flow rate of 0.9 mL/min. The column temperature was programmed as follows: a subsequent increase from 150 to 180 °C at the rate of 10 °C/min, to 185 °C at the rate of 1.5 °C/min, to 250 °C at the rate of 30 °C/min, and then held for 10 min. The interface temperature of the GC–MS was set at 240 °C. The temperature of the ion source was 240 °C and the electron energy was 70 eV.

2.2. Determination of Starch Content

The starch content in the tested samples was determined using the polarimetric method [24] with modification according to Krełowska-Kułas [22]. An amount of 2.5 g of the crushed sample was ground in a 100–150 cm3 beaker with 10 cm3 of distilled water and 20 cm3 of concentrated (density 1.19) hydrochloric acid was added and left for 30 min. After this time, the entire sample was quantitatively transferred to a 100 cm3 volumetric flask, rinsing the beaker with hydrochloric acid with a density of 1.125. Deproteinization was carried out using Carrez I and Carrez II reagents. The obtained solution was filtered (hard quantitative filter, type 06-0014, AHLSTROM, Espoo, Finland) and determined polarimetrically in a 2 dm tube. In order to quantify the starch content, the read rotation angle of the polarization plane was multiplied by the factor 9.90.

2.3. Total Ash Content Determination

The total ash determination method consists of incinerating the analytical sample until the organic substances are completely burned and then determining the residue by weight. Total ash content was determined according to PN-ISO 2171:2010 [25].

2.4. Determination of Total Protein Content and Its Fractions

The content of total protein and its fractions (albumin, globulin, gliadin and glutenin/or remaining protein fractions) was determined spectrophotometrically using Bradford reagent [26]. For this purpose, 100 mg of the sample were weighed into an Eppendorf tube. Albumins and globulins were extracted using a salt solution (0.4 mol/dm3 NaCl + 0.067 mol/dm3 HKNaPO4 at pH 7.6). Three extractions were performed in an Eppendorf ThermoMixer (Sigma-Aldrich, St. Louis, MO, USA) for 10 min at 20 °C and at 1200 rpm. The homogenate was centrifuged (EPPENDORF AG, Hamburg, Germany) for 5 min at 16,000 rpm. Gliadin extraction was carried out in a test tube with a sediment remaining after extraction of albumin and globulin fractions using 60% ethyl alcohol. Glutenins were eluted using a solution of 50% propanol −1 + 2 mol/dm3 urea + 0.05 mol/dm3 Tris-HCl at pH 7.5 + 1% DTE, at a temperature of 60 °C. The extraction was carried out in the presence of an inert gas (nitrogen). A color reaction was carried out with Bradford’s reagent and the absorbance of the obtained colored solutions was measured using a spectrophotometer (SP6-500UV PYE UNICAM, Cambridge, UK) at a wavelength of λ = 595 nm against a blank sample.

2.5. Determination of Total Carbohydrate Content in Bread and Calculation of Its Energy Value

The total carbohydrate content TC was calculated per the following (Equation (1)):

where

TC [%] = 100 − (W + TA + TP + TL)

- W—water content (moisture) [%];

- TA—total ash content [% d.m];

- TP—total protein content [% d.m.];

- TL—total lipid content [% d.m.].

The energetic value (E) was calculated per the following (Equation (2)) [27]:

where

E [kcal] = TP × 4 kcal + TL × 9 kcal + TC × 4 kcal

- TP—total protein content [% d.m.];

- TL—total lipid content [% d.m.];

- TC—total carbohydrate content [%].

2.6. Determination of Total Phenolic Compounds Using the Folin–Ciocalteau Method

The content of phenolic compounds extracted with 80% methanol was determined with the Folin–Ciocalteau reagent (FC), using gallic acid to prepare a standard curve. The extracts obtained were concentrated on a rotary vacuum evaporator type R210 (Büchi Labortechnik AG, Flawil, Switzerland), transferred quantitatively to a 10 cm3 measuring flask. An amount of 0.25 cm3 of the methanol extract of phenolic compounds was placed in a reaction tube, added to the Folin–Ciocalteau reagent solution (diluted with distilled water in a ratio of 1:2) in the amounts of 0.25 cm3 and 0.5 cm3 of 20% sodium carbonate solution and supplemented with distilled water to a volume of 5 cm3. After 25 min, the solution was centrifuged for 5 min (EPPENDORF AG, Hamburg, Germany) at 12,000 rpm and the absorbance of the solution was measured at a wavelength of 760 nm using a spectrophotometer (SP6-500UV PYE UNICAM, UK). The measurements were taken in the presence of a reagent sample. A standard curve was prepared, where 100 mg of gallic acid was dissolved in methanol and topped up to 100 mL. From the stock solution, dilutions from 1 to 10 were prepared, containing corresponding amounts of 0.01–1.0 mg of gallic acid. An amount of 0.25 cm3 was taken from each dilution, with 0.25 cm3 of Folin–Ciocalteau reagent solution and 0.5 cm3 of sodium carbonate solution added successively before the entirety was topped up to 5 cm3 with distilled water. The measurements were taken in the presence of a reagent sample.

2.7. Analysis of Carotenoid Content

Carotenoid content was analyzed with a reversed phase high performance liquid chromatography (RP–HPLC) technique according to the method previously described by Czaplicki et al. [23]. Carotenoid separation was performed at 30 °C on a YMC-C30 150 mm × 4.6 mm, 5 μm column (YMC-Europe GmbH, Dinslaken, Germany) with the use a 1200 series liquid chromatograph manufactured by Agilent Technologies (Palo Alto, CA, USA) and equipped with a diode array detector (DAD). A gradient of methanol—methyl tert-butyl ether (MTBE)—was used as a mobile phase. Carotenoids were identified based on retention times and by comparing the UV–visible absorption spectra of available standards (Sigma-Aldrich, St. Louis, MO, USA).

2.8. Statistical Analysis

The obtained results of physicochemical parameter determinations were subjected to statistical calculations using the Statistica v.13.1 program. The characteristics of the studied parameters were determined (arithmetic mean, standard deviation, variance), and the strength and direction of the relationship between the level of the addition of sea buckthorn fruit pomace (5–20%) and the nutritional and health-promoting components were identified at the level of significance of differences (p < 0.05; p < 0.01). Then, PROFIT analysis was performed (a two-stage procedure), which allows for vector scaling (non-linear reduction of the dimensionality of the number of variables) and regression analysis [28]. This method was used to indicate the optimal addition of sea buckthorn fruit pomace to bread, which would most favorably affect the parameters characterizing the balanced nutritional and health-promoting value of the new type of bread.

3. Results and Discussion

3.1. Characteristics of the Main Raw Materials Used for Baking Bread

The moisture content of the tested rye bread flour type 720 was 12.8%, while the sea buckthorn pomace meal (SB-M) was characterized by a lower level (10.6%). Baking mixes with the addition of sea buckthorn meal were characterized by moisture content in the range of 11.08–12.12%, which decreased with the increase of the proportion of this meal (5–20%) to the rye flour. The above moisture values were within the permissible standards (<15%) [29]. In the case of the tested bread, the moisture content, depending on the baking variant, ranged from 44.6 to 47.4%. The above-mentioned data are not included in the table, they are presented only in the text of this publication.

Water, next to flour or flour substitutes, is the basic ingredient of bread dough and its content changes both quantitatively and qualitatively during baking. It is bound, primarily by starch granules and proteins and—especially in the case of rye flour—by pentosans (rye hemicelluloses). This is visible in the relatively dry state of the bread, compared with the dough, despite the fact that the amount of water decreases relatively little in the finished fresh bread. Depending on the type of fresh bread, this can range from 30 to 50% (or, in the case of rye bread, from 42 to 50%) [20]. The increasing addition of sea buckthorn pomace (SB-M) increased the moisture content of the bread crumb by 1–2.7%, compared with the 100% rye bread (RB) control. The obtained bread had a crumb that was dry to the touch, the addition of sea buckthorn pomace (rich in fiber) influenced the binding of a slightly larger amount of water in the crumb, but with a benefit for its structure. Fruit/vegetable pomace is particularly valuable for its high dietary fiber content (and consequently its high capacity to absorb water), which is why it can be used as a functional additive to improve food texture [9].

3.2. Characteristics of the Main Raw Materials (Rye Flour, Sea Buckthorn Pomace Meal) for Baking—Selected Ingredients: NE, N-B, Bio-C

Table 1 presents a comparative presentation of the content of selected chemical components: nutritional energetic (NE), nutritional building (N-B), and bioactive components (Bio-C) in rye flour (RF) used in baking and in sea buckthorn pomace meal (SB-M).

Table 1.

Characteristics of the main raw materials for baking—rye flour (RF) and sea buckthorn pomace meal (SB-M).

Sea buckthorn pomace meal contained 23 times more total lipids than rye flour. Considering the composition of the eight fatty acids analyzed, SB-M was characterized by a significantly higher content of primarily palmitoleic, palmitic, vaccenic, and margarine acids. On the other hand, RF contained significantly more acids, primarily linoleic, oleic, linolenic, and stearic. Of note is the high concentration of palmitoleic acid in SB-M, which belongs to the group of unsaturated omega-7 fatty acids, and the significantly higher content of vaccenic acid in SB-M (also an omega-7 acid) compared with the tested rye flour. The above-mentioned omega-7 acids are monounsaturated fatty acids, with high health-promoting potential, and both sea buckthorn fruit and their pomace are a very good source of these. In the lipids of sea buckthorn fruit, palmitoleic acid constitutes 36–41% of its total contents [15], while in the tested SB-M, its content was approximately 40.6%. RF contained approximately 79% starch on a dry matter basis; SB-M did not contain starch but was characterized by a significantly higher total ash content. The ash content in rye flour resulted from its type, in a similar manner to the starch content [29]. The total protein content in RF was 1.8 times higher than in SB-M, which in turn had a higher content of this component than that of sea buckthorn fruit (0.92–2.15%) [15]. In the case of RF, 53% of the total protein content comprised albumin and globulin fractions; in the case of SB-M, protein fractions with similar extractability/solubility, such as gliadins and glutenins, dominated. SB-M contained almost 14 times more total phenolic compounds (903.4 mg/100 g d.m.) than the tested rye flour (65.4 mg/100 g d.m.). In the case of sea buckthorn fruit from varieties grown in Poland, the average total content of phenolic compounds has been found to range from 129 to 283 mg/100 g [15,16], while in the tested pomace from the fruit of this plant species, the concentration of phenolic compounds was several times higher. SB-M in the form of meal is a very good source of carotenoids, in contrast with rye flour, which was found to contain little of them (Table 1). Carotenoids are very important phytochemicals, contributing nutritional health benefits to the human diet [30]. Of the approximately 600 carotenoid pigments described in the literature, 39 have been identified in sea buckthorn fruit. In the tested SB-M, the highest contents of lutein, zeaxanthin, and β-carotene were found among the analyzed carotenoid pigments, which is consistent with other literature data on sea buckthorn fruit [15]. In Polish literature, the content of carotenoids in fruits, depending on the sea buckthorn variety, is reported at a level of approximately 7.94–28.16 mg/100 g d.m.

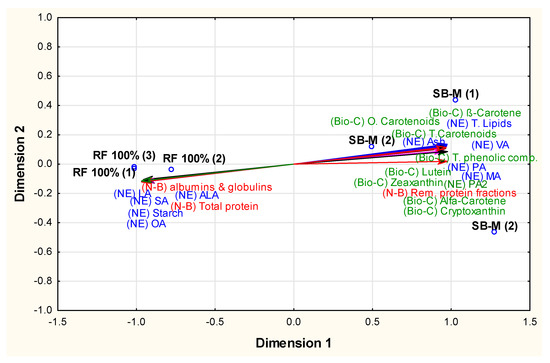

The distribution of points and vectors in Figure 1 pertains to the shaping of the quality characteristics of the raw materials used for bread baking, rye flour and sea buckthorn pomace related to the concentration of the selected substances: NE, N-B, and Bio-C. The presented PROFIT analysis indicates regression dependencies. To the greatest extent, RF 100% (1,2,3) is influenced by N-B, in the form of albumins and globulins and total protein, and by NE, in the form of LA, ALA, SA, OA, and starch. Meanwhile, SB-M (1,2,3) is influenced by all components of Bio-C, as well as by components of NE (T. lipids, ash, VA, PA, MA) and N-B. (rem. protein fractions). The strong positive regression relationship between RF 100% and the components of NE and N-B, as well as SB-M and the components of Bio-C, NE, and N-B, indicates the direction and length of the vectors. At the same time, there is also a negative regression relationship between the RF 100% components and the SB-M components. In Figure 1, points located near the ends of the vectors are more associated with the given variable, e.g., the sample “SB-M (2)” is associated with a high level of “T. phenolic” and “PA.”

Figure 1.

Correlations between nutritional energy (NE), nutritional building (N-B) and bioactive components (Bio-C) and raw materials used for baking bread (RF 100% rye flour, SB-M—Sea buckthorn pomace meal). (NE components: PA—palmitic acid; PA2—palmitoleic acid; MA—margaric acid; SA—stearic acid; OA—oleic acid ; VA—vaccenic acid; LA—linoleic acid; ALA—linolenic acid.).

The distribution of points and vectors indicates that the scores are determined by two dimensions, and two groups of points can be observed (e.g., RF 100% or SB-M), suggesting differences between them in terms of the analyzed variables.

The preference map (Figure 1) shows that the most expected from the point of view of the content of health-promoting and nutritional components (Bio-C: all tested components; NE: T. lipids, ash, VA, PA, MA; and N-B: rem. protein fractions) is the use of sea buckthorn pomace additives (SB-M).

Taking into account the obtained statistical differences between the components present in the raw materials used for baking bread—rye flour and sea buckthorn pomace meal—further analyses were carried out to show the effect of the pomace additive level (5–20%) on the differentiation of nutritional energy, nutritional building, and bioactive components.

3.3. The Effect of Adding Sea Buckthorn Pomace on the Nutritional and Health-Promoting Value of Rye Bread

With the increase in the addition of SB-M to RF, the total lipid content in the tested special bread increased significantly, as much as four-fold, compared with the control bread (RB), in the case of the 20% SB-M variant, (Table 2). The 100% rye bread had the same composition and a similar content of fatty acids as RF. The addition of pomace significantly increased the content of palmitoleic and vaccenic acids (from the omega-7 group) and palmitic acid in the tested variants of enriched bread in relation to RB. However, it caused a decrease mainly in the content of linoleic and oleic acids. It also reduced the starch content in relation to the control RB, and as a consequence, the calorific value of the bread decreased (although slightly) as did, more significantly, its content of total carbohydrate. The bread from the 15% SB-M variant was characterized by the lowest calorific value. Ash content in the tested bread variants remained at a similar level.

Table 2.

Nutritional and energy components of rye bread (RB) and with the addition of 5, 10, 15, 20% of sea buckthorn pomace meal (SB-M).

Enrichment of rye bread in SB-M had an effect on the content of total protein and its fractions, increasing them with the increasing level of enrichment, though this was not particularly significant (Table 3).

Table 3.

Nutritional and structural components of rye bread (RB) and with the addition of 5, 10, 15, 20% of sea buckthorn pomace flour (SB-M).

As for the content of selected bioactive components (Bio-C) in rye bread enriched with SB-M, the addition of SB-M, as expected, very significantly increased (by a maximum of three-fold) the content of total phenolic compounds in all variants of enriched bread (5–20% SB-M) compared with RB (Table 4). Moreover, it increased the concentration of T. carotenoids in these variants, in the case of 20% SB-M, as much as 13-fold. The obtained bread was especially enriched in lutein, zeaxanthin, and α- and β-carotene.

Table 4.

Bioactive components of rye bread (RB) and with the addition of 5, 10, 15, 20% of sea buckthorn pomace meal (SB-M).

It should be emphasized that the enriched light RB was produced by fermentation on natural sourdough, and therefore already had a high nutritional value due to its production method [31]. Its nutritional and health-promoting value was additionally increased by using a very valuable source of bioactive substances, which are SB-M, in production.

In order to indicate the optimal level of addition of sea buckthorn pomace needed to obtain the most beneficial effect on the parameters characterizing the balanced nutritional and health-promoting value of the new type of bread, a statistical tool was used.

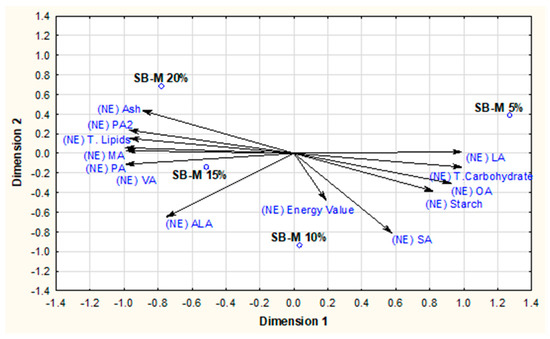

Profit analysis of the effect of adding sea buckthorn pomace on the nutritional and energy value of the produced bread (Figure 2) showed that the use of 15 and 20% SB-M additions to rye bread correlates with the following components: PA2, T. lipids, MA, PA, VA, and ALA. In turn, the addition of 5% SB-M is most strongly correlated with the content of such ingredients as LA, T. carbohydrate, OA, and the content of starch. A slightly weaker relationship was observed between the content of 10% SB-M in bread and energy value (this may result from the information load of variables, i.e., the length of vectors).

Figure 2.

Correlations between nutritional energy (NE) components and the level of SB-M addition (PA—palmitic acid; PA2—palmitoleic acid; MA—margaric acid; SA—stearic acid; OA—oleic acid; VA—vaccenic acid; LA—linoleic acid; ALA—linolenic acid).

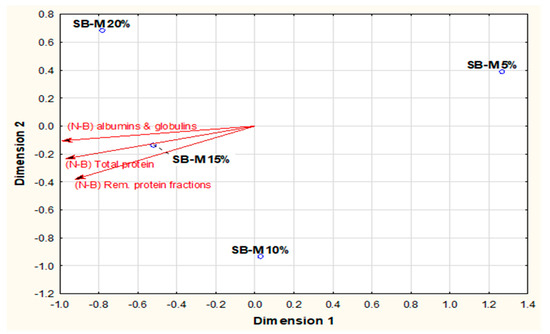

In the case of nutritional and building components (N-B), the strongest correlations were obtained between all tested components (total protein, albumins and globulins, and rem. protein fractions) and bread characterized by the addition of 15% SB-M (Figure 3).

Figure 3.

Correlations between nutritional building ingredients (N-B) and the level of SB-M addition.

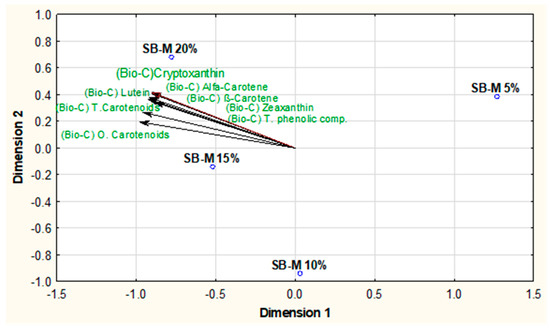

The highest levels of SB-M additives, i.e., 15 and 20%, correlated most strongly with all bioactive ingredients (Figure 4). This clearly indicates the beneficial effect of these additives on the health-promoting value of the produced special rye bread.

Figure 4.

Correlations between bioactive compounds (Bio-C) and the level of SB-M addition.

Based on the obtained research results and their statistical analysis, it is evident that adding sea buckthorn fruit pomace at a level of 15 to 20% optimally shapes the balanced nutritional and health-promoting value of rye bread.

In addition to the above benefits, adding sea buckthorn pomace to bread may extend its shelf life thanks to several important bioactive properties of these ingredients. The natural antioxidant compounds contained in them, such as polyphenols, vitamin C, and carotenoids, can slow down the oxidation of lipids in bread, thus delaying the rancidity of fats and the bread’s structural degradation. Thanks to this, the product retains its freshness, taste, and aroma for longer [8,32,33]. The fiber contained in pomace increases the water-binding capacity of bread, which limits its drying and moisture loss and also, therefore, its staling [33,34].

The presence of natural ingredients with antibacterial and antifungal properties, such as organic acids and flavonoids, may also limit the development of the microorganisms responsible for bread spoilage [35,36].

Bread with the addition of sea buckthorn pomace may be characterized not only by increased nutritional and health-promoting value but also by better durability [37,38], which is a significant advantage for both producers and consumers looking for fresh products for a longer period of time without the need to use artificial preservatives.

3.4. Sustainable Production of Sea Buckthorn Fruit Pomace

Sustainable production of sea buckthorn pomace is a key element in minimizing industrial waste and promoting a circular economy. The use of sea buckthorn pomace as a secondary raw material not only allows one to reduce waste but also promotes the production of functional food with high nutritional value [19]. Thanks to modern pressing/squeezing and processing technologies, sea buckthorn pomace can be successfully incorporated into various food products, contributing to effective resource management and environmental protection [1].

The use of enzyme preparations for the maceration of fruit and vegetable pulp is used to facilitate the pressing process, which in turn contributes to increased juice yield. Preparations used for pulp maceration are composed of pectinolytic enzymes, hemicellulases, and cellulases. The action of hemicellulolytic enzymes, in addition to supporting the pressing process, prevents the occurrence of secondary turbidity in the juice that is caused by an excessive amount of soluble hemicellulose. An appropriately selected (for specific raw materials) enzyme preparation also facilitates further juice processing, i.e., depectinization, clarification, and filtration of the juice [39].

Sea buckthorn fruit fiber is obtained as a by-product during oleosome production [40]. In technology, for economic reasons and due to the fact that preparations significantly affect the structure of the fiber and the bioavailability of the proteins, such as oleosome, that are the main components of the final product, enzymatic maceration is not used. The pomace constituting the by-product was dried at 50 °C, separated to remove seeds, and then crushed.

Processing sea buckthorn fruit pomace without the use of enzymes, although more technologically demanding, can be equally valuable due to the preservation of the fiber structure and the bioavailability of nutrients. Such a process also allows one to obtain a raw material in line with consumer trends toward a preference for natural and less processed products [41]. Therefore, the sustainable production of sea buckthorn pomace can be particularly valuable, supporting the development of an environmentally friendly industry [1,3] that is in line with consumer expectations.

The balance of the efficiency of sea buckthorn pomace production is a key element of sustainable processing, allowing one to assess the efficiency of raw material use and minimize waste. In the process of the enzymatic maceration of fruit pulp, juice yield is increased, and the volume of remaining pomace is reduced, which contributes to better resource management [19,42]. In addition, the optimization of the drying and separation of seeds allows one to obtain a stable raw material for the production of functional food products without harming the environment [1]. Such a balance is also necessary to achieve economic and ecological efficiency in production, thus supporting the circular economy [3,41].

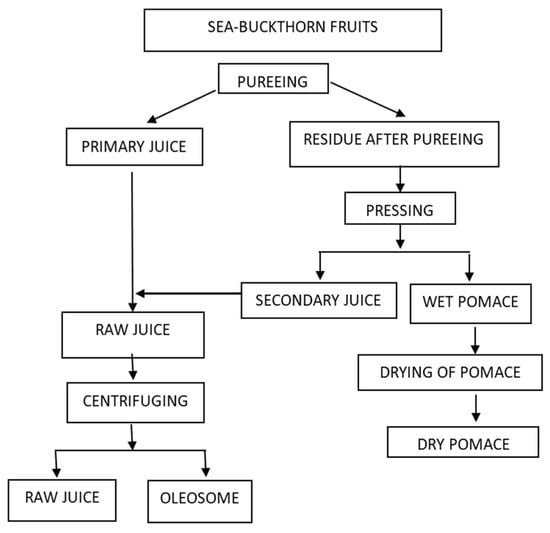

Experimental research, which may be the basis for creating the technology for processing sea buckthorn fruit on an industrial scale, has shown that, as a result of pureeing 1000 kg of fruit, approximately 200 kg (with the use of an enzymatic preparation) and approximately 300 kg (without the enzymatic preparation) of wet pomace are obtained. The pomace, for further extraction, was subjected to pressing using a hydraulic press (Figure 5).

Figure 5.

Simplified scheme of the processing stages of sea buckthorn fruit into juice, pomace and oleosome.

As a result of such a procedure, the following mass division was obtained: secondary juice constituting about 60% and pomace about 40% in the case of enzymatic processing and 51% secondary juice and 49% pomace in the variant without the enzyme preparation. In the subsequent procedure, the secondary juice was combined with the primary juice and the pomace, dried at 50 °C, could potentially be an intermediate product for the production of a bioactive carotene–fiber concentrate (fiber) or a carotenoid–phospholipid extract.

4. Conclusions

The results of the analyses showed that greater quality benefits, including health benefits, were obtained when rye bread was enriched with the addition of 15 and 20% pomace. These benefits were also confirmed by statistical analysis, which proves that this range of pomace addition is optimal from the point of view of the nutritional value and quality of the new food products.

Nutrients, energy, and bioactive components showed the most significant correlations with the bread to which 15 and 20% pomace had been added, while the content of nutrients and building blocks (protein and its fractions) showed significant correlations only with the bread to which 15% pomace had been added.

In connection with the above, the management of pomace from sea buckthorn fruit is justified in order to obtain benefits for potential producers in the bakery and confectionery industry and consumers looking for new food with pro-health properties.

From the perspective of sustainable waste management, the analysis of the balance of efficiency of the maceration process of sea buckthorn pulp showed that the best results are obtained using methods such as drying at 50 °C, separating the seeds, and grinding. This approach minimizes the negative impact on the environment and allows one to avoid additional costs related to enzymatic maceration. In addition, the reduction of the use of enzymes favors the preservation of the natural properties of fiber and bioactive components, which translates into the stability and high quality of the secondary raw material. Such actions allow one to optimize production technologies, increase the value of the final product, and make it more attractive from an ecological and economic point of view.

Author Contributions

Conceptualization, J.K.B. and K.M.; methodology, K.M. and B.P.; validation, J.K.B., K.M. and M.G.-R.; formal analysis, J.K.B., K.M. and M.G.-R.; investigation, K.M. and J.K.B.; data curation, K.M. and J.K.B.; writing—original draft preparation, K.M., J.K.B., B.P. and M.G.-R.; writing—review and editing, K.M., J.K.B., B.P. and M.G.-R.; funding acquisition, K.M. and J.K.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Ministry of Science and Higher Education of Poland as part of: 1. Statutory activities from the Faculty of Economics, University of Warmia and Mazury in Olsztyn, project No. 22.610.100-110, and 2. Research project registration number N N312 170939 entitled “Development of a waste-free technology for processing sea buckthorn fruit (Hippophaë rhamnoides L.) and assessment of the bioactive properties of the obtained products”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Esteban, J.; Ladero, M. Food waste as a source of value-added chemicals and materials: A biorefinery perspective. Int. J. Food Sci. Technol. 2018, 53, 1095–1108. [Google Scholar] [CrossRef]

- Verni, M.; Rizello, C.G.; Coda, R. Fermentation biotechnology applied to cereal industry by-products: Nutritional and functional insights. Front. Nutr. 2019, 6, 42. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’Amico, M. Circular economy models in agro-food systems: A review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- Górecka, D.; Pospiech, E. (Eds.) Zagospodarowanie Ubocznych Produktów Przemysłu Spożywczego. (Management of By-Products of the Food Industry), 1st ed.; Wydział Nauk o Żywności i Żywieniu, Uniwersytet Przyrodniczy w Poznaniu: Poznań, Poland, 2016; ISBN 978-83-7160-836-0. (In Polish) [Google Scholar]

- De la Peña-Armada, R.; Mateos-Aparicio, I. Sustainable approaches using green technologies for apple by-product valorisation as a new perspective into the history of the apple. Molecules 2022, 27, 6937. [Google Scholar] [CrossRef]

- Michota-Katulska, E.; Zegan, M. Efektywne Zarządzanie Żywnością. Zapobieganie Marnowaniu i Techniki Utrwalania dla Zrównoważonego Spożycia. (Effective Food Management. Waste Prevention and Preservation Techniques for Sustainable Consumption), 1st ed.; Wydawnictwo Naukowe PWN S.A., PZWL Wydawnictwo Lekarskie: Warszawa, Poland, 2024; ISBN 978-83-01-23390-7. (In Polish) [Google Scholar] [CrossRef]

- Caponio, F.; Piga, A.; Poiana, M. Valorization of food processing by-products. Foods 2022, 11, 3246. [Google Scholar] [CrossRef] [PubMed]

- Stanciu, I.; Ungureanu, E.L.; Popa, E.E.; Geicu-Cristea, M.; Draghici, M.; Mitelut, A.C.; Mustatea, G.; Popa, M.E. The experi mental development of bread with enriched nutritional properties using organic sea buckthorn pomace. Appl. Sci. 2023, 13, 6513. [Google Scholar] [CrossRef]

- Tarko, T.; Duda-Chodak, A.; Bebak, A. Aktywność biologiczna wybranych wytłoków owocowych oraz warzywnych (Biological activity of selected fruit and vegetable pomaces). Żywność. Nauka. Technol. Jakość. 2012, 4, 55–65. (In Polish) [Google Scholar]

- Dziki, D.; Różyło, R.; Gawlik-Dziki, U.; Świeca, M. Current trends in the enhancement of antioxidant activity of wheat bread by the addition of plant materials rich in phenolic compounds. Trends Food Sci. Technol. 2014, 40, 48–61. [Google Scholar] [CrossRef]

- Zdybel, B.; Różyło, R.; Sagan, A. Use of a waste product from the pressing of chia seed oil in wheat and gluten-free bread processing. J. Food Process. Preserv. 2019, 43, e14002. [Google Scholar] [CrossRef]

- Djeghim, F.; Bourekoua, H.; Różyło, R.; Bieńczak, A.; Tanaś, W.; Zidoune, M.N. Effect of by-products from selected fruits and vegetables on gluten-free dough rheology and bread properties. Appl. Sci. 2021, 11, 4605. [Google Scholar] [CrossRef]

- Łopaciuk, W. (Ed.) Rynek Zbóż. Stan i Perspektywy. Analizy Rynkowe (Cereal Market. Status and Prospects. Market Analyses); Nr. 65; Instytut Ekonomiki Rolnictwa i Gospodarki Żywnościowej. Państwowy Instytut Badawczy: Warszawa, Poland, 2023; ISSN 1231-3149. (In Polish) [Google Scholar]

- Dziki, D. Rye flour and rye bran: New perspectives for use. Processes 2022, 10, 293. [Google Scholar] [CrossRef]

- Piłat, B.; Zadernowski, R. Owoce rokitnika (Hippophae rhamnoides L.)—Bogate źródło związków biologicznie aktywnych. (Fruits of sea buckthorn Hippophae rhamnoides L.—Rich source of biologically active compounds). Postępy Fitoter. 2016, 17, 298–306. (In Polish) [Google Scholar]

- Piłat, B.; Zadernowski, R. Rokitnik zwyczajny (Hippophaë rhamnoides L.) w profilaktyce nowotworowej. (The sea buckthorn Hippophaë rhamnoides L. fruit in cancer prevention). Postępy Fitoter. 2019, 20, 111–117. (In Polish) [Google Scholar] [CrossRef]

- Majewska, K.M.; Banach, J.K.; Piłat, B.; Złotkowska, K.; Sobiechowska, D. Shaping the quality features of rye bread using a diversified share of sea-buckthorn fruit pomace. P-60. In Proceedings of the 11th Central European Congress on Food and Nutrition (CEFood 2022)—“Food, technology and nutrition for healthy people in healthy environment”, Čatež ob Savi, Slovenia, 27–30 September 2022; p. 206. [Google Scholar]

- Rafalska, A.; Abramowicz, K.; Krauze, M. Sea buckthorn (Hippophae rhamnoides L.) as a plant for universal application. World Sci. News 2017, 72, 123–140. [Google Scholar]

- Galanakis, C.M. Food Waste Recovery: Processing Technologies, Industrial Techniques, and Applications; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Lubczyńska, H.; Lipińska, H.; Jarosz, K.; Woźniakowski, A.; Kosakowska, J.; Walewska, M. Vademecum Piekarza do Nauki Zawodu (Baker’s Vademecum for Learning the Profession); Wydawca Handlowo-Usługowa Spółdzielnia “Samopomoc Chłopska”: Warszawa, Poland, 2006; ISBN 83-919549-5-1. (In Polish) [Google Scholar]

- PN–EN ISO 712:2012; Cereals and Cereal Products—Determination of Moisture Content—Reference Method. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Krełowska-Kułas, M. Badanie Jakości Produktów Spożywczych. (Quality Testing of Food Products); Polskie Wydawnictwo Ekonomiczne (PWN): Warszawa, Poland, 1993; ISBN 83-208-0902-9. (In Polish) [Google Scholar]

- Czaplicki, S.; Tańska, M.; Konopka, I. Sea-buckthorn oil in vegetable oils stabilisation. Ital. J. Food Sci. 2016, 28, 412–425. [Google Scholar]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemistry, 15th ed.; Association of Official Analytical Chemists, Inc.: Arlington, VA, USA, 1990. [Google Scholar]

- PN-ISO 2171:2010; Ziarno Zbóż, Nasiona Roślin Strączkowych i Ich Przetwory. Oznaczanie Zawartości Popiołu Metodą Spalania (Cereal Grains, Legume Seeds and Their Products. Determination of Ash Content by Combustion). Wydawnictwo SGGW: Warszawa, Poland, 2010. (In Polish)

- Wieser, H.; Antes, S.; Seilmeier, W. Quantitative determination of gluten protein types in wheat flour by Reversed-Phase High-Performance Liquid Chromatography. Cereal Chem. 1998, 75, 644–650. [Google Scholar] [CrossRef]

- Gronowska-Senger, A. Podstawy Biooceny Żywności (Basics of Food Bioassessment); SGGW: Warszawa, Poland, 2004; ISBN 83-7244-553-2. (In Polish) [Google Scholar]

- Zaborski, A.; Pełka, M. Geometrical presentation of preferences by using profit analysis and R program. Acta Univ. Lodz. Folia Oecon. 2013, 285, 191–197. [Google Scholar]

- PN-A-74032:2002; Cereal Products. Rye Flour. Polish Committee for Standardization: Warsaw, Poland, 2010. (In Polish)

- Hussain, A.; Larsson, H.; Johansson, E. Carotenoid extraction from locally and organically produced cereals using saponification method. Processes 2021, 9, 783. [Google Scholar] [CrossRef]

- Fernández-Peláez, J.; Paesani, C.; Gómez, M. Sourdough Technology as a Tool for the Development of Healthier Grain-Based Products: An Update. Agronomy 2020, 10, 1962. [Google Scholar] [CrossRef]

- Guo, X.; Shi, L.; Yang, S.; Yang, R.; Dai, X.; Zhang, T.; Liu, R.; Chang, M.; Jin, Q.; Wang, X. Effect of sea-buckthorn pulp and flaxseed residues on quality and shelf life of bread. Food Funct. 2019, 10, 4220–4230. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, M.; Zhu, L.; Geng, Z.; Liu, X.; Cheng, Z.; Zhao, M.; Zhang, Q.; Yang, X. Sea Buckthorn Pretreatment, Drying, and Processing of High-Quality Products: Current Status and Trends. Foods 2023, 12, 4255. [Google Scholar] [CrossRef]

- Pecyna, A.; Krzywicka, M.; Blicharz-Kania, A.; Buczaj, A.; Kobus, Z.; Zdybel, B.; Domin, M.; Siłuch, D. Impact of incorporating two types of dried raspberry pomace into gluten-free bread on its nutritional and antioxidant characteristics. Appl. Sci. 2024, 14, 1561. [Google Scholar] [CrossRef]

- Popa, E.E.; Anghel, A.A.; Stanciu, I.; Miteluţ, A.C.; Popescu, P.A.; Drăghici, M.C.; Geicu-Cristea, M.; Popa, M.E. Preliminary research on using organic sea buckthorn powder in bread making. AgroLife Sci. J. 2022, 11, 136–141. [Google Scholar] [CrossRef]

- Ciesarová, Z.; Kukurová, K.; Jelemenská, V.; Horváthová, J.; Kubincová, J.; Belovi´c, M.; Torbica, A. Asparaginase treatment of sea buckthorn berries as an effective tool for acrylamide reduction in nutritionally enriched wholegrain wheat, rye and triticale biscuits. Foods 2023, 12, 3170. [Google Scholar] [CrossRef]

- Samilyk, M.; Demidova, E.; Bolgova, N.; Savenko, O.; Cherniavska, T. Development of bread technology with high biological value and increased shelf life. East.-Eur. J. Enterp. Technol. 2022, 2, 116. [Google Scholar] [CrossRef]

- Janotková, L.; Potočňáková, M.; Kreps, F.; Krepsová, Z.; Ácsová, A.; Ház, A.; Jablonsky, M. Effect of sea buckthorn biomass on oxidation stability and sensory attractiveness of cereal biscuits. BioResources 2021, 16, 5097. [Google Scholar] [CrossRef]

- Radziejewska-Kubzdela, E. Effect of ultrasonic, thermal and enzymatic treatment of mash on yield and content of bioactive compounds in strawberry juice. Appl. Sci. 2023, 13, 4268. [Google Scholar] [CrossRef]

- Hussain, S.; Sharma, M.; Bhat, R. Valorisation of sea buckthorn pomace by optimization of ultrasonic-assisted extraction of soluble dietary fibre using response surface methodology. Foods 2021, 10, 1330. [Google Scholar] [CrossRef] [PubMed]

- Hamed, I.; Jakobsen, A.N.; Lerfall, J. Sustainable edible packaging systems based on active compounds from food processing byproducts: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 198–226. [Google Scholar] [CrossRef] [PubMed]

- Gómez-García, R.; Campos, D.A.; Aguilar, C.N.; Madureira, A.R.; Pintado, M. Valorisation of food agro-industrial by-products: From the past to the present and perspectives. J. Environ. Manag. 2021, 299, 113571. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).