Study on the Development Rule of Mudstone Cracks in Open-Pit Mine Dumps Improved with Xanthan Gum

Abstract

1. Introduction

2. Materials and Methods

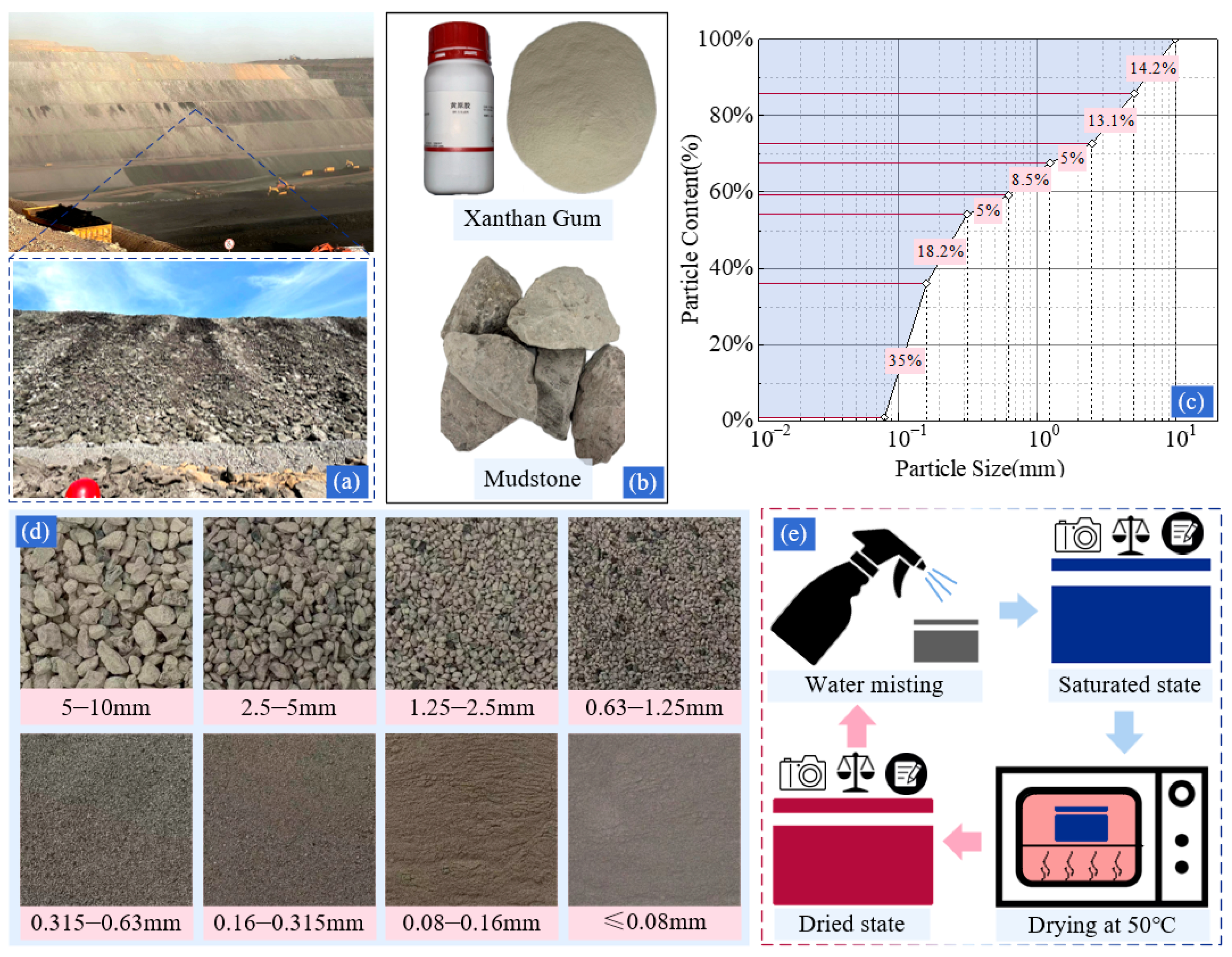

2.1. Specimen Preparation

2.1.1. Open-Pit Mine Mudstone

2.1.2. Xanthan Gum

2.1.3. Preparation Standards

2.2. Experimental Conditions

2.2.1. Specimen Air-Drying Conditions

2.2.2. Wet–Dry Cycle Test

2.2.3. Surface Hardness Measurement

2.2.4. Microscopic Tests

2.3. Experimental Equipment

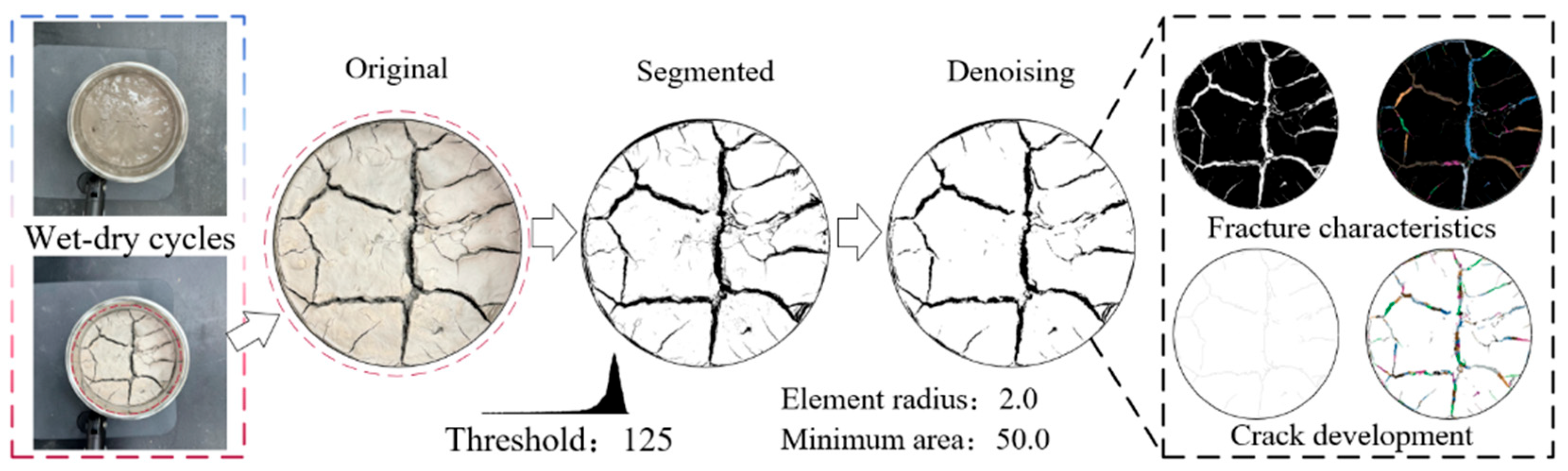

2.4. Image Capture and Analysis

3. Results

3.1. Image Analysis

3.1.1. Crack Ratio

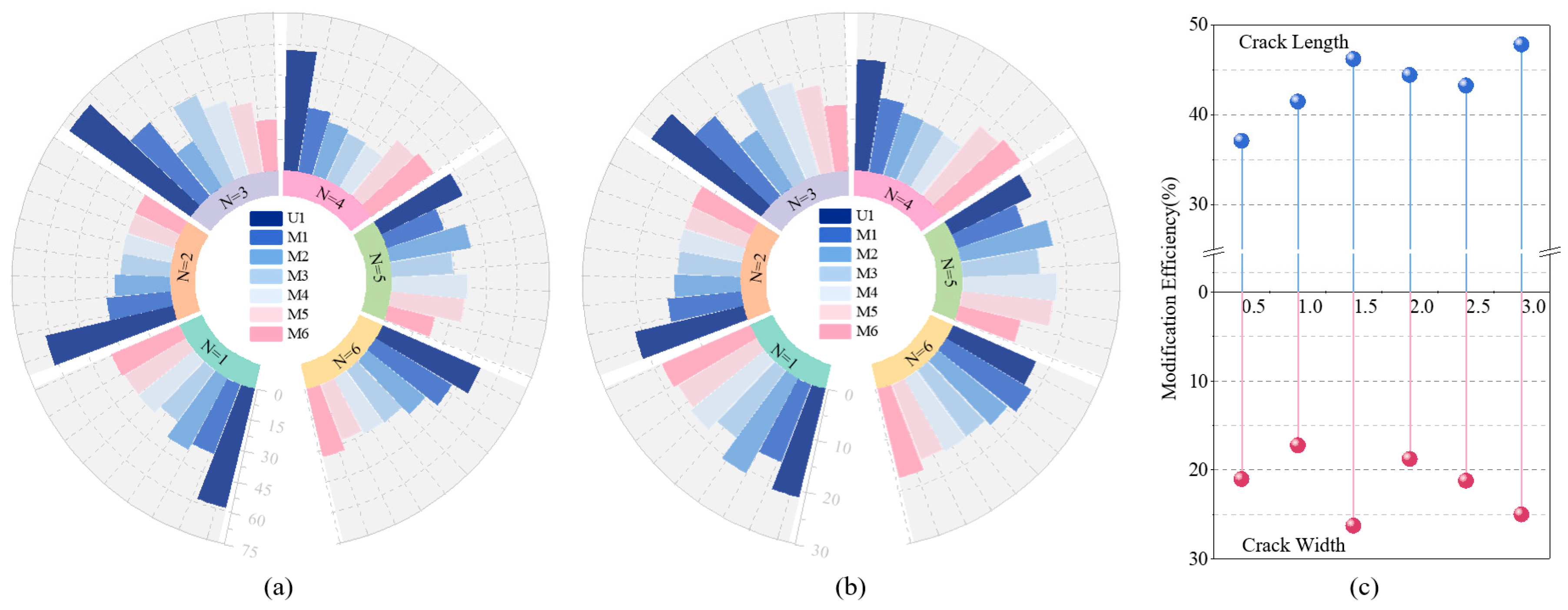

3.1.2. Crack Length and Width

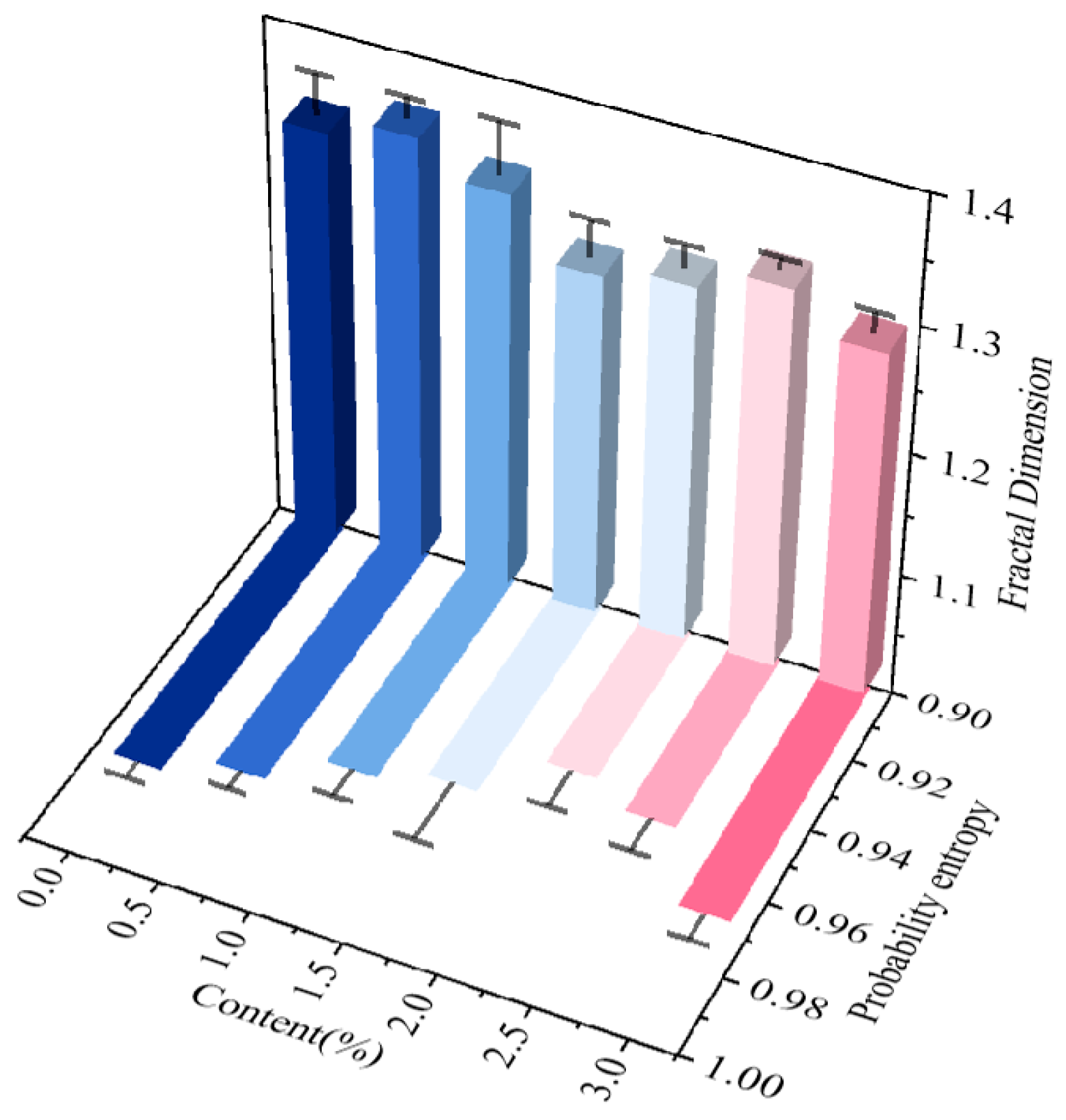

3.1.3. Fractal Dimension and Probability Entropy

3.2. Physicochemical Characteristics

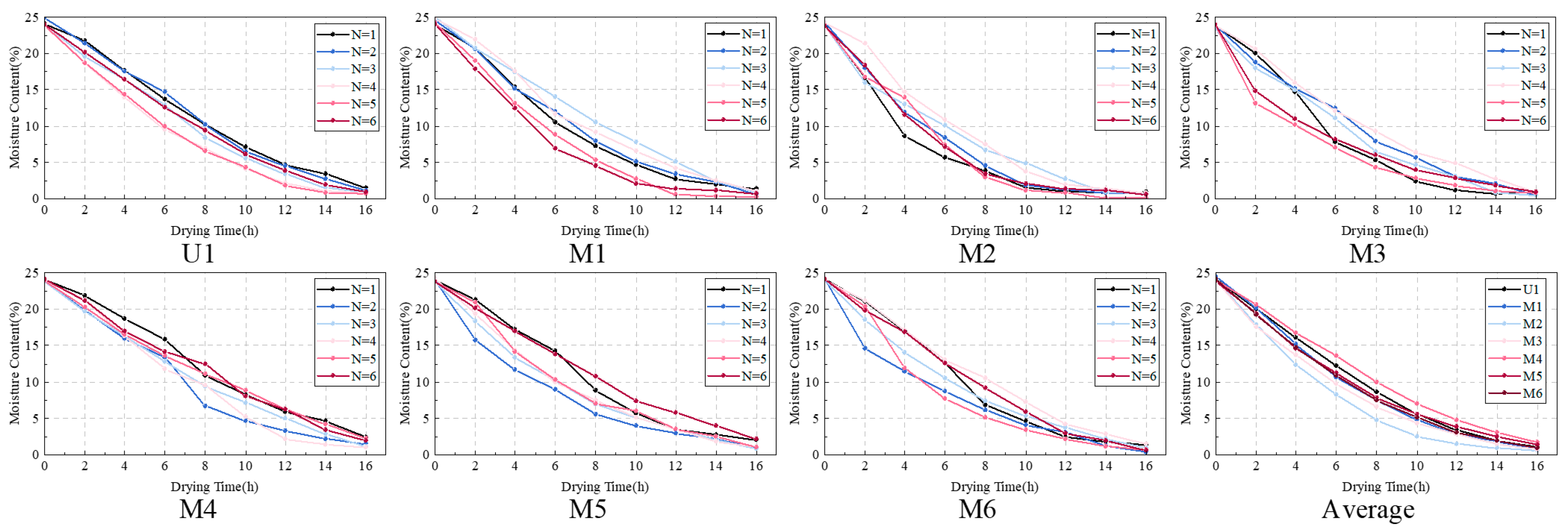

3.2.1. Water Content

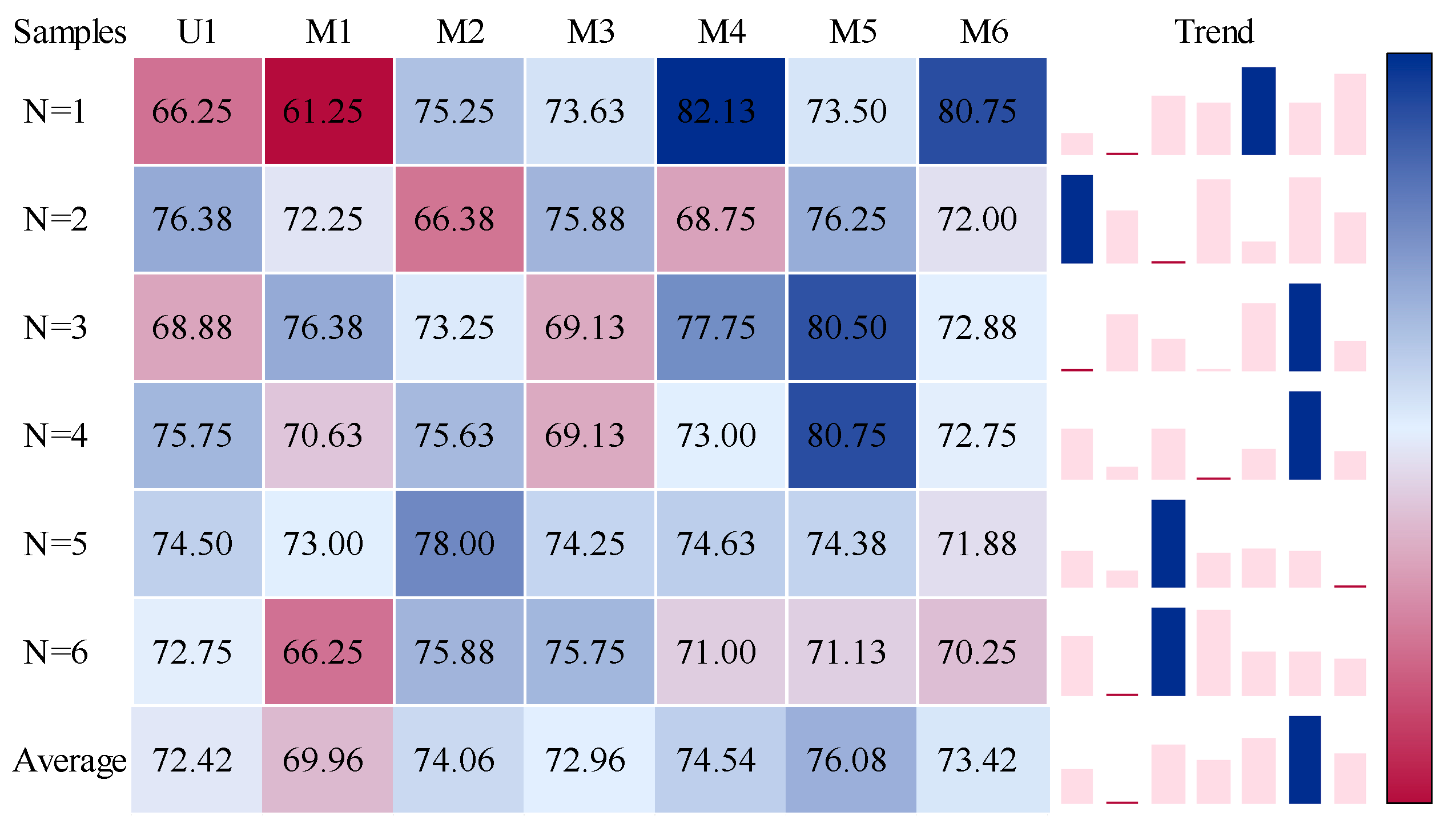

3.2.2. Surface Hardness

4. Discussion

4.1. Microscopic Changes

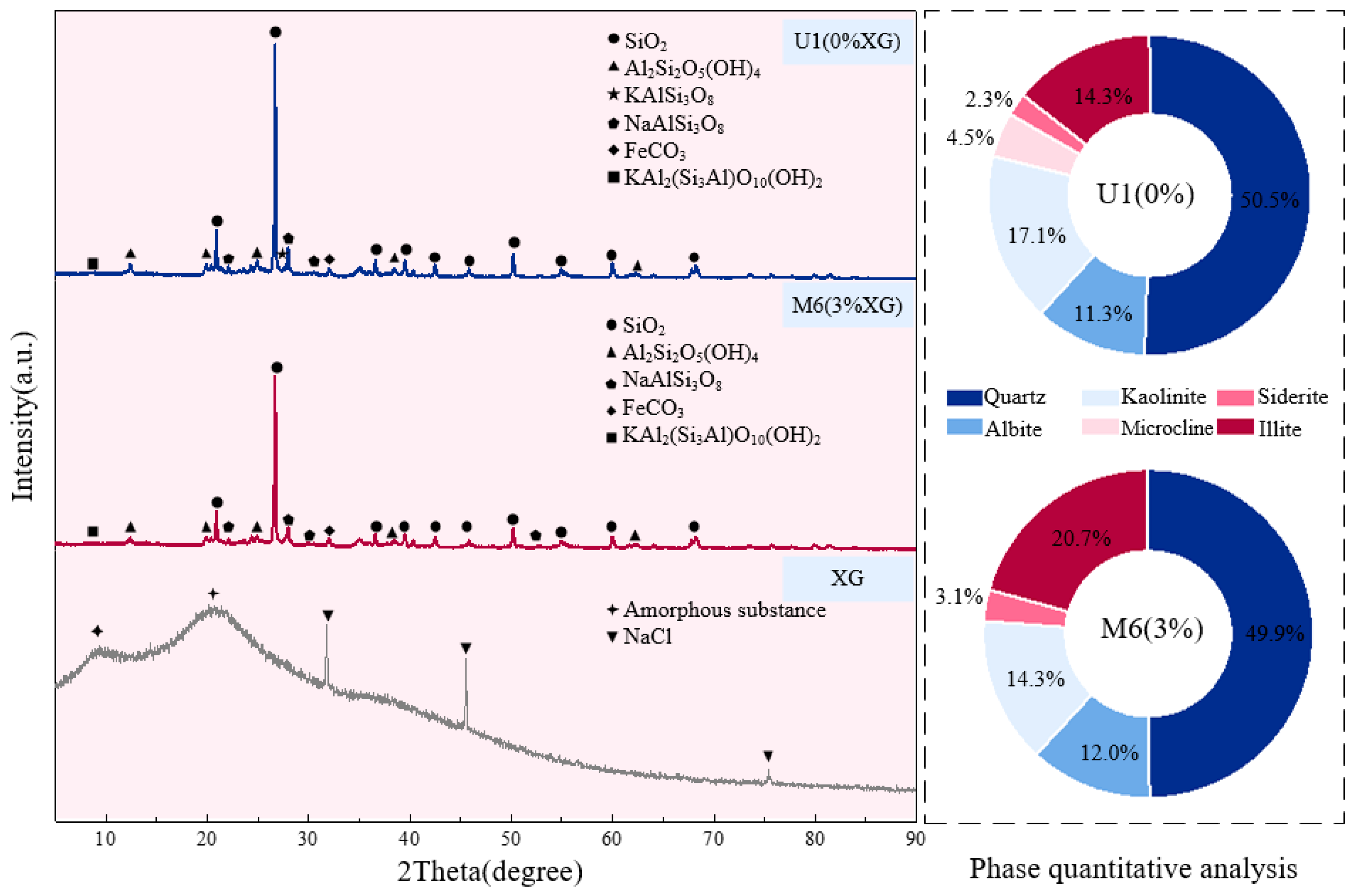

4.1.1. X-Ray Diffraction

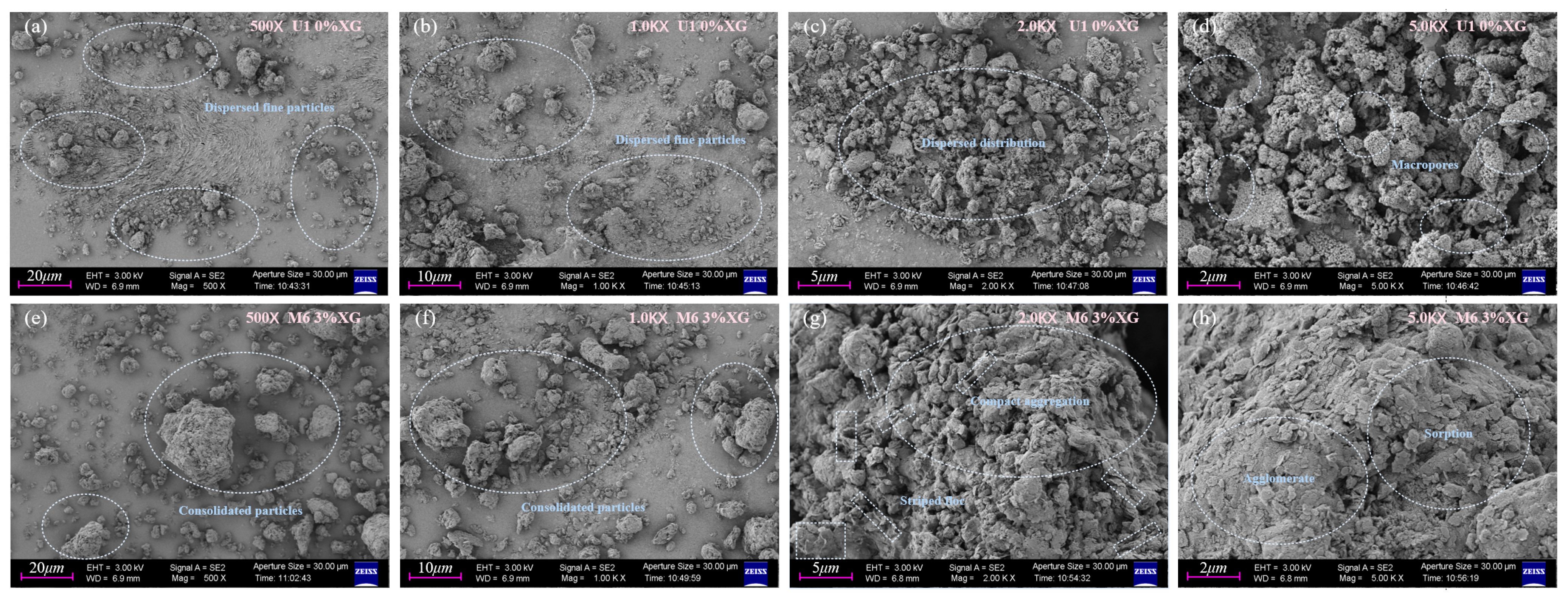

4.1.2. Scanning Electron Microscopy

4.2. Modification Mechanism

5. Conclusions

- (1)

- The analysis of the specimen images shows that adding XG to mudstone can significantly reduce the area of cracks after drying shrinkage, manifested explicitly in the changes in crack ratio, crack length, and crack width. The modification efficiency index is introduced to evaluate the effect of modification. A quadratic function relationship exists between the specimen’s crack ratio and XG’s content. When the content of XG is between 0.5% and 2%, the average modification efficiency is positively correlated with the content. After 2%, it shows a negative correlation, with the maximum average modification efficiency reaching 45%. Similarly, although there is no apparent functional relationship between the length and width of the cracks and the content, adding XG can reduce the height and width of the crack development to a certain extent. Among them, the average modification efficiency of the crack length and width with 1.5% content of XG is 46.2% and 26.3%, respectively.

- (2)

- Taking the fractal dimension and probability entropy as indicators, the shape of the cracks and the direction of crack development are comprehensively analyzed. A small amount of XG does not affect the complexity of the mudstone crack boundary. As the content of XG increases, the fractal dimension gradually decreases, indicating that a specific content helps improve mudstone permeability. Since the calculation of probability entropy is greatly affected by the image quality and the number of cracks, combined with the actual performance of the specimen cracks, it is found that the addition of XG does not reduce the disorder of crack development.

- (3)

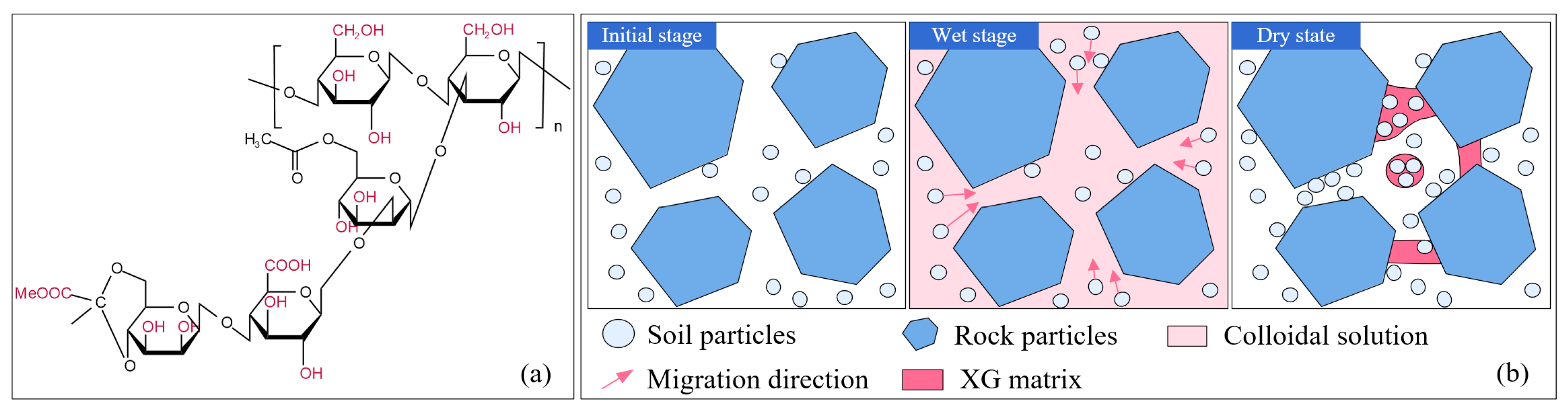

- Based on the results of micro-experiments and the properties of XG itself, the modification mechanism of XG affecting the crack development pattern of mudstone is revealed. During the wet–dry cycle, no new substances were produced in the specimen. In the wet state, XG powder dissolves in water to form a viscous XG colloidal solution, which carries fine soil particles to fill the pores between the mudstone particles and adheres to the surface of the soil body through electrostatic bonding and hydrogen bonding. During the drying process, due to the loss of water, the XG colloidal solution gradually transforms into an XG matrix, forming connections and fillings between the mudstone bodies to resist the tension of mudstone water loss and cracking. The transformation between the XG colloidal solution and the filamentous matrix in the wet–dry cycle is stable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peter, K.; Omotayo, O.G.; Omar, S.K.; Ismail, L.A.; Moshood, O.; Prosper, M. An Overview of Slope Failure in Mining Operations. Mining 2022, 2, 350–384. [Google Scholar] [CrossRef]

- Ahmad, S.S. Slope Stability Analysis of Opencast Mine Dump using the Limit Equilibrium Method—A Case Study. Min. Metall. Explor. 2024, 41, 2555–2566. [Google Scholar] [CrossRef]

- Zhao, H.; Wei, Z.; Luo, K.; Su, B.; Ren, C.; Wu, G. Stability and control measures of open-pit mine dump slope under rainfall conditions. Coal Sci. Technol. 2019, 47, 67–74. [Google Scholar] [CrossRef]

- Wei, X.; Gao, C.; Yan, D.; Liu, K. Experimental Study on Cracking Behavior and Mechanism in Desiccating Soils in in Xi’an, Shaanxi Province, China. Adv. Civ. Eng. 2020, 2020, 8874986. [Google Scholar] [CrossRef]

- Lv, G.; He, C.; Du, X.; Li, Y. Simulation Study on Hydrological Process of Soil Cracks in Open-Pit Coal Mine Dump. Water 2022, 14, 2302. [Google Scholar] [CrossRef]

- Choi, S.-G.; Chang, I.; Lee, M.; Lee, J.-H.; Han, J.-T.; Kwon, T.-H. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Zhao, Y.; Li, N.; Luo, J.; Belete, A.M.; Ping, J. Modification Effect of Nano-Clay on Mechanical Behavior of Composite Geomaterials: Cement, Nano-Silica and Coastal Soft Soil. Materials 2022, 15, 8735. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Ye, Y.; Li, K.; Wang, Y.-Q. Stress Path Efforts on Palm Fiber Reinforcement of Clay in Geotechnical Engineering. Water 2023, 15, 4053. [Google Scholar] [CrossRef]

- Gao, Q.-F.; Zeng, L.; Yu, G.-T.; Huang, X.-J. Desiccation cracking behavior and its suppression methods in lateritic soil under drying and wetting cycles. IOP Conf. Ser. Earth Environ. Sci. 2024, 1330, 012014. [Google Scholar] [CrossRef]

- Qi, X.; Zhou, W.; Wang, Z.; Li, R.; Tian, Y.; Tu, L.; Zhang, Z.; Dong, Z.; Yang, H. Study on the anti-cracking properties of biopolymer-improved clay on open pit mine slopes. Coal Sci. Technol. 2024, 1–10. [Google Scholar]

- Wang, T.; Wang, L.; Liu, S.; Zhang, S.; Wang, O. Experimental Study on Mechanical Properties of Expansive Soil Improved by Xanthan Gum and Guar Gum. China Railw. Sci. 2023, 44, 1–10. [Google Scholar]

- Yue, J.; Li, J.; Liu, D.; Wang, S.; Xing, X.; Chen, Y. Study on Crack Prevention of Earthen Sites Using MICP Technology. J. Disaster Prev. Mitig. 2021, 41, 455–462. [Google Scholar] [CrossRef]

- Wang, Z.; Tian, Y.; Zhou, W.; Wang, Y.; Li, R.; Guo, Y.; Tian, Y.; Lu, A. Study on the mechanism of the effect of chitosan combined with EICP on the erosion resistance of slopes in open-pit mine dump. J. China Coal Soc. 2024, 1–16. [Google Scholar] [CrossRef]

- An, Y.; Lu, J.; Niu, R.; Li, M.; Zhao, X.; Huang, X.; Huang, H.; Garg, A.; Zhussupbekov, A. Exploring effects of novel chemical modification of biochar on soil water retention and crack suppression: Towards commercialization of production of biochar for soil remediation. Biomass Convers. Biorefinery 2021, 13, 13897–13910. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Li, S.; Zhu, Y.; Wang, C.; Zhang, H. Anti-erosion ability and water retention of spreading PAM powder granules and spraying PAM gum liquid on inner dump. Environ. Dev. Sustain. 2024, 1–20. [Google Scholar] [CrossRef]

- Liu, B.; Tang, C.S.; Pan, X.H.; Xu, J.J.; Zhang, X.Y. Suppressing Drought-Induced Soil Desiccation Cracking Using MICP: Field Demonstration and Insights. J. Geotech. Geoenviron. Eng. 2024, 150, 04024006. [Google Scholar] [CrossRef]

- Dai, C.; Liu, J.; Mei, H.; Hao, S.; Song, Z.; Wang, Y.; Che, W.; Chen, Z.; Bu, F.; Wang, Z. Investigation into Xanthan Gum Biopolymer on Mitigating Cracking and Erosion Behavior of Soil. J. Mater. Civ. Eng. 2023, 35, 04023460. [Google Scholar] [CrossRef]

- Cai, Y.; Wan, Y.; He, X.; Chen, Z.; Liu, L.; Li, J. Dry shrinkage cracking and permeability of biopolymer-modified clay under drywet cycles. Environ. Geotech. 2023, 40, 1–13. [Google Scholar] [CrossRef]

- SL 126-2011; Inspection Methods of Testing Sieves for Aggregates. China Institute of Water Resources and Hydropower Research: Beijing, China; Sinohydro Third Engineering Bureau Co., Ltd.: Xi’an, China, 2011.

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Water Resources Water Resources and Hydropower Planning and Design Institute: Beijing, China; Nanjing Hydraulic Research Institute: Nanjing, China, 2019.

- Zheng, Z.; Sun, Z.; Li, M.; Yang, J.; Yang, Y.; Liang, H.; Xiang, H.; Meng, J.; Zhou, X.; Liu, L.; et al. An update review on biopolymer Xanthan gum: Properties, modifications, nanoagrochemicals, and its versatile applications in sustainable agriculture. Int. J. Biol. Macromol. 2024, 281, 136562. [Google Scholar] [CrossRef]

- Feng, M.; Wang, J.; Liu, S.; Wanatowski, D.; Ren, Y. Coupling effect of curing temperature and relative humidity on the unconfined compressive strength of xanthan gum-treated sand. Constr. Build. Mater. 2024, 448, 138224. [Google Scholar] [CrossRef]

- Ni, J.; Zhao, R.J.; Chen, J.Q.; Geng, X.Y. Mechanical and hydraulic characteristics of unvegetated or vegetated loess soils amended with xanthan gum. Transp. Geotech. J. 2024, 48, 101350. [Google Scholar] [CrossRef]

- Khadse, S.; Sekhar, K.; Begum, G.; Rao, B.H. Effectiveness of Xanthan Gum and Guar Gum in Mitigating Dust Emission from Bauxite Residue Tailings Facility. Indian Geotech. J. 2024, 1–10. [Google Scholar] [CrossRef]

- An, R.; Deng, C.; Zhang, X.; Ge, X.; Yin, S.; Wang, Y. Study on mechanical properties and microscopic mechanism of Xanthan gum enhanced microbial solidification of coral sand. Adv. Eng. Sci. 2024, 1–12. [Google Scholar]

- Wan, J.; Ouyang, F.; Xiao, H.; Wang, L.; Tao, G. Experimental Study on the Physical and Mechanical Properties of Modified Clay Using Xanthan Gum and Guar Gum Composite Materials. Sustainability 2024, 16, 5432. [Google Scholar] [CrossRef]

- ISO 48-4:2018; Rubber, Vulcanized or Thermoplastic—Determination of Hardness. Part 4: Indentation Hardness by Durometer Method (Shore Hardness). ISO: Geneva, Switzerland, 2018.

- Ali, A.; Zhang, N.; Santos, R.M. Mineral Characterization Using Scanning Electron Microscopy (SEM): A Review of the Fundamentals, Advancements, and Research Directions. Appl. Sci. 2023, 13, 12600. [Google Scholar] [CrossRef]

- Bastida, J.; Ibañez, P.P. Applications of X-ray Powder Diffraction Microstructural Analysis in Applied Clay Mineralogy. Minerals 2024, 14, 584. [Google Scholar] [CrossRef]

- Liu, C.; Shi, B.; Zhou, J.; Tang, C. Quantification and characterization of microporosity by image processing, geometric measurement and statistical methods: Application on SEM images of clay materials. Appl. Clay Sci. 2011, 54, 97–106. [Google Scholar] [CrossRef]

- Liu, C.; Xu, Q.; Shi, B.; Gu, Y. Digital image recognition method of rock particle and pore system and its application. Chin. J. Geotech. Eng. 2018, 40, 925–931. [Google Scholar]

- Pang, M.; Pan, H.; Zhu, S.; Zhang, Y.; Zhang, T. Influence of fractal dimensions of fissures on the characteristic parameters of non-Darcy seepage of coal gas in peripore coal bodie. J. China Coal Soc. 2024, 7, 574. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, A.; Zhao, C.; Wang, W.; Jiang, Y.; Vandeginste, V.; Xue, Z.; Guo, Y.; Miao, H. A new parameter for characterizing pore-fracture structure heterogeneity: Fractal dimension based on the mercury extrusion curve. Front. Earth Sci. 2024, 1–15. [Google Scholar] [CrossRef]

- Fortuna, B.; Logar, J.; Sorze, A.; Valentini, F.; Smolar, J. Influence of Xanthan Gum-Based Soil Conditioners on the Geotechnical Properties of Soils. Appl. Sci. 2024, 14, 4044. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, J.; Wang, Y.; Qi, C.; Ma, X.; Che, W.; Ma, K. Wetting–drying effects on the mechanical performance of xanthan gum biopolymer-stabilized soil. Environ. Earth Sci. 2024, 83, 197. [Google Scholar] [CrossRef]

- Das, B.M. Advanced Soil Mechanics, 4th ed.; CRC Press: Boca Raton, FL, USA, 2019; p. 734. [Google Scholar]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.-C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Ouyang, M.; Zhang, H.; Deng, R.; Wang, G.; Xiao, J.; Zhao, Y. Study on Development of Cracks in Expansive Soil Improved by Xanthan Gum Biopolymer. Chin. J. Geotech. Eng. 2024, 1–10. [Google Scholar]

- Jiang, T.; Zhao, J.D.; Zhang, J.R. Splitting tensile strength and microstructure of xanthan gum-treated loess. Sci. Rep. 2022, 12, 9921. [Google Scholar] [CrossRef] [PubMed]

| Specimen | U1 | M1 | M2 | M3 | M4 | M5 | M6 |

|---|---|---|---|---|---|---|---|

| Mass fraction | 0% | 0.5% | 1% | 1.5% | 2% | 2.5% | 3% |

| NO. | Equipment Name | Model | Manufacturer |

|---|---|---|---|

| 1 | Drying oven | 101-1B | Shanghai Jingmai Instrument Equipment Co., Ltd., Shanghai, China |

| 2 | Electronic scale | LQC-50002 | Shanghai Yaoxin Electronic Technology Co., Ltd., Shanghai, China |

| 3 | Shore durometer | 0-100HA-A | Xingweiqiang Hardware Tools Co., Ltd., Dongguan, China |

| 4 | Scanning electron microscope | Zeiss Gemini 300 | Carl Zeiss AG, Oberkochen, Germany |

| 5 | X-ray diffraction instrument | Rigaku SmartLab SE | Rigaku Holdings Corporation, Tokyo, Japan |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, X.; Zhou, W.; Li, R.; Tian, Y.; Lu, X. Study on the Development Rule of Mudstone Cracks in Open-Pit Mine Dumps Improved with Xanthan Gum. Appl. Sci. 2024, 14, 10194. https://doi.org/10.3390/app142210194

Qi X, Zhou W, Li R, Tian Y, Lu X. Study on the Development Rule of Mudstone Cracks in Open-Pit Mine Dumps Improved with Xanthan Gum. Applied Sciences. 2024; 14(22):10194. https://doi.org/10.3390/app142210194

Chicago/Turabian StyleQi, Xiang, Wei Zhou, Rui Li, Ya Tian, and Xiang Lu. 2024. "Study on the Development Rule of Mudstone Cracks in Open-Pit Mine Dumps Improved with Xanthan Gum" Applied Sciences 14, no. 22: 10194. https://doi.org/10.3390/app142210194

APA StyleQi, X., Zhou, W., Li, R., Tian, Y., & Lu, X. (2024). Study on the Development Rule of Mudstone Cracks in Open-Pit Mine Dumps Improved with Xanthan Gum. Applied Sciences, 14(22), 10194. https://doi.org/10.3390/app142210194