Artificial Intelligence-Enhanced Colorimetric Assessment of Self-Cleaning Road Marking Paints

Abstract

1. Introduction

2. Methodology

2.1. Materials

2.2. Methods

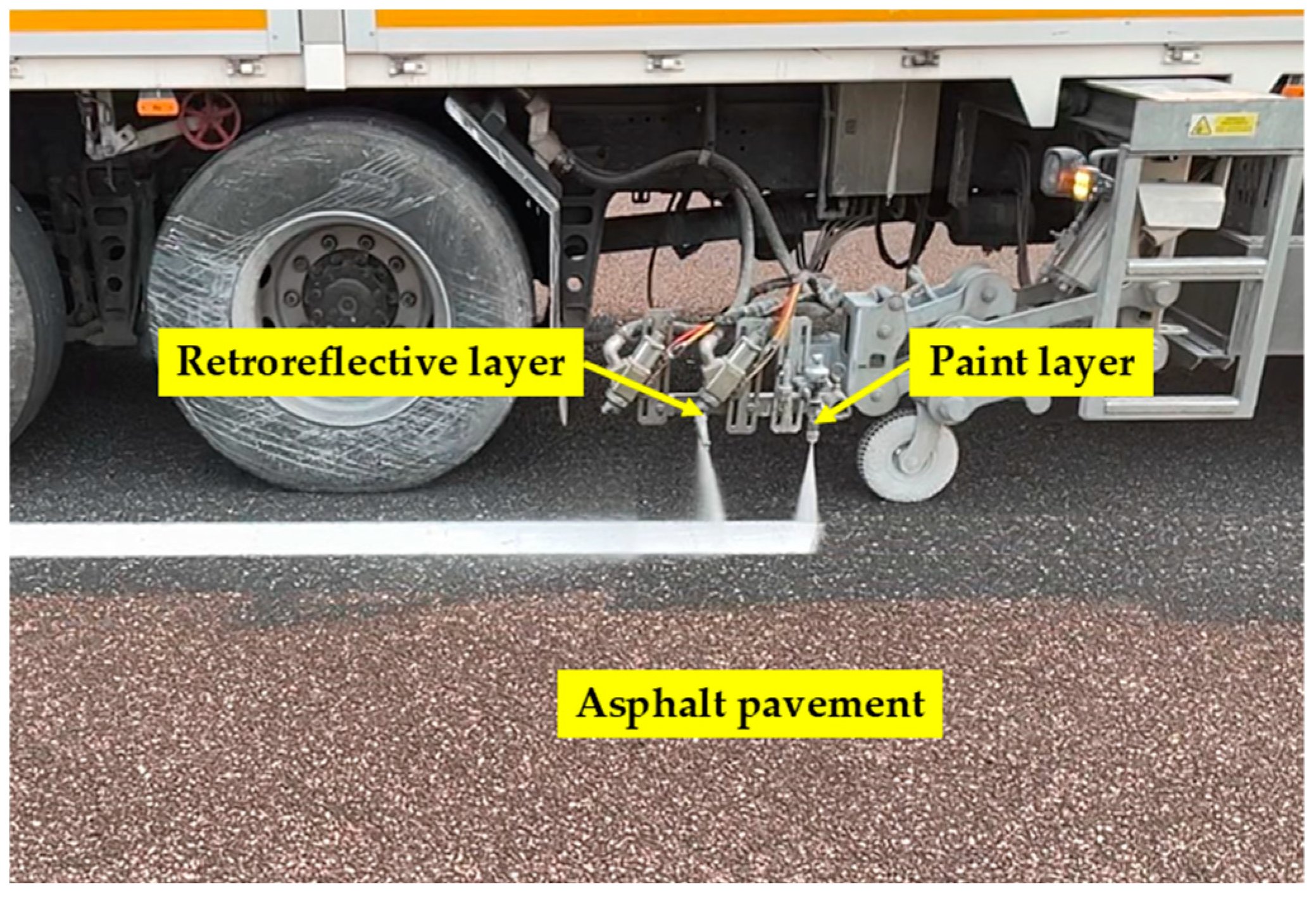

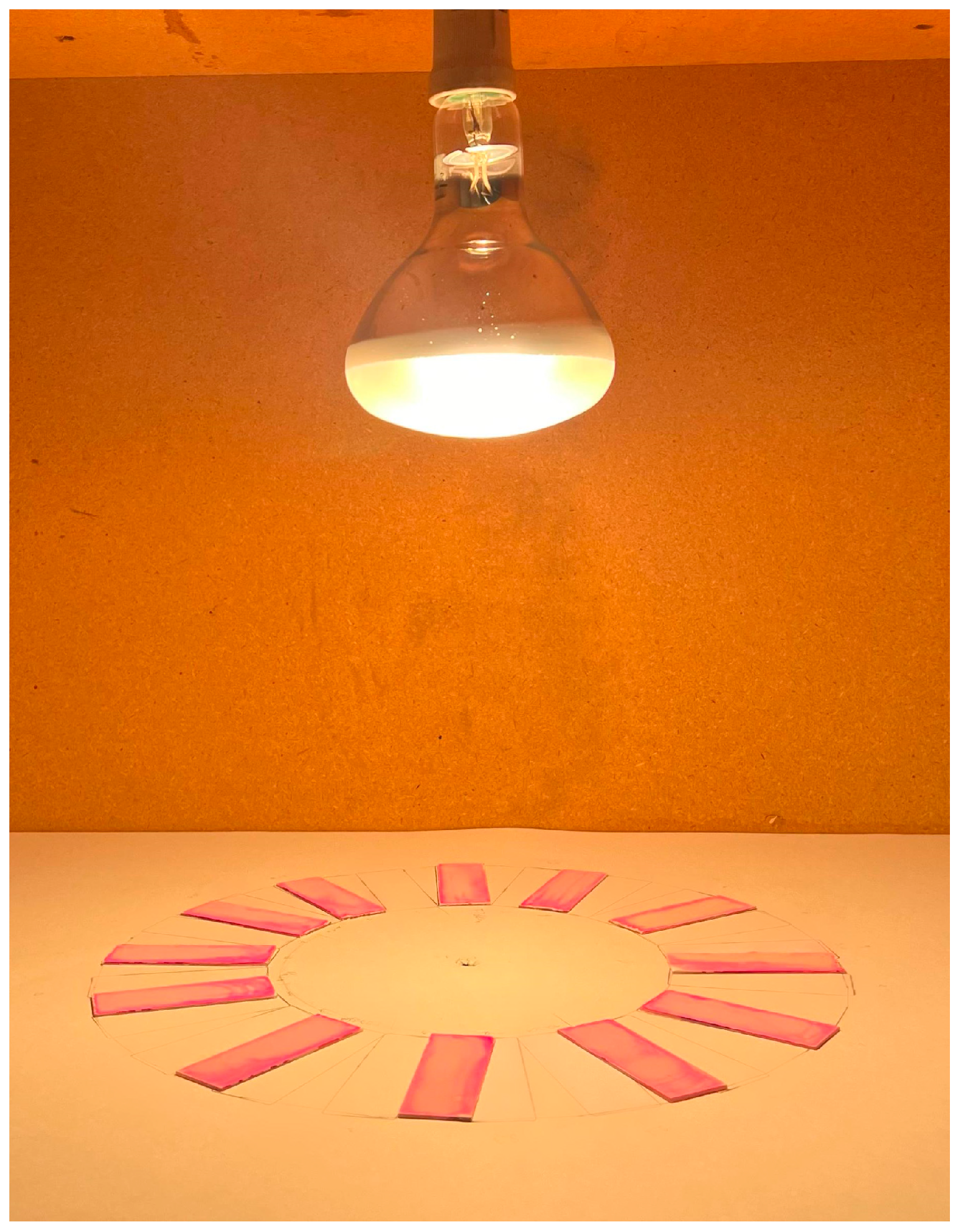

2.2.1. RM Paint Functionalization and Evaluation of the Self-Cleaning Ability

2.2.2. Visual Analysis

2.2.3. Spectrophotometric CIELAB Color Space

2.2.4. Artificial Intelligence-Enhanced CIELAB Color Space

2.2.5. Photocatalytic Efficiency and Color Variation Assessment

3. Results and Discussion

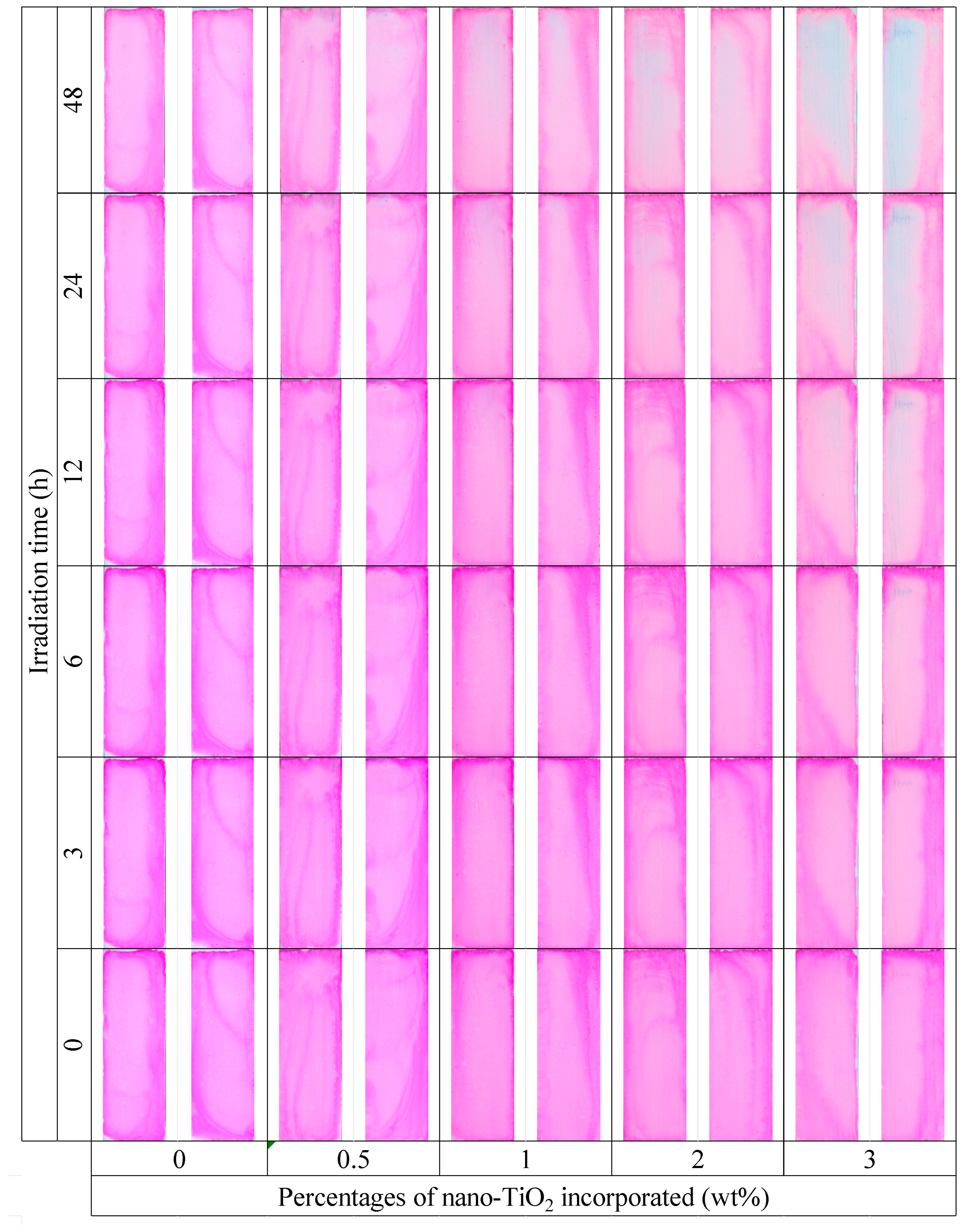

3.1. Self-Cleaning Assessment by Visual Analysis

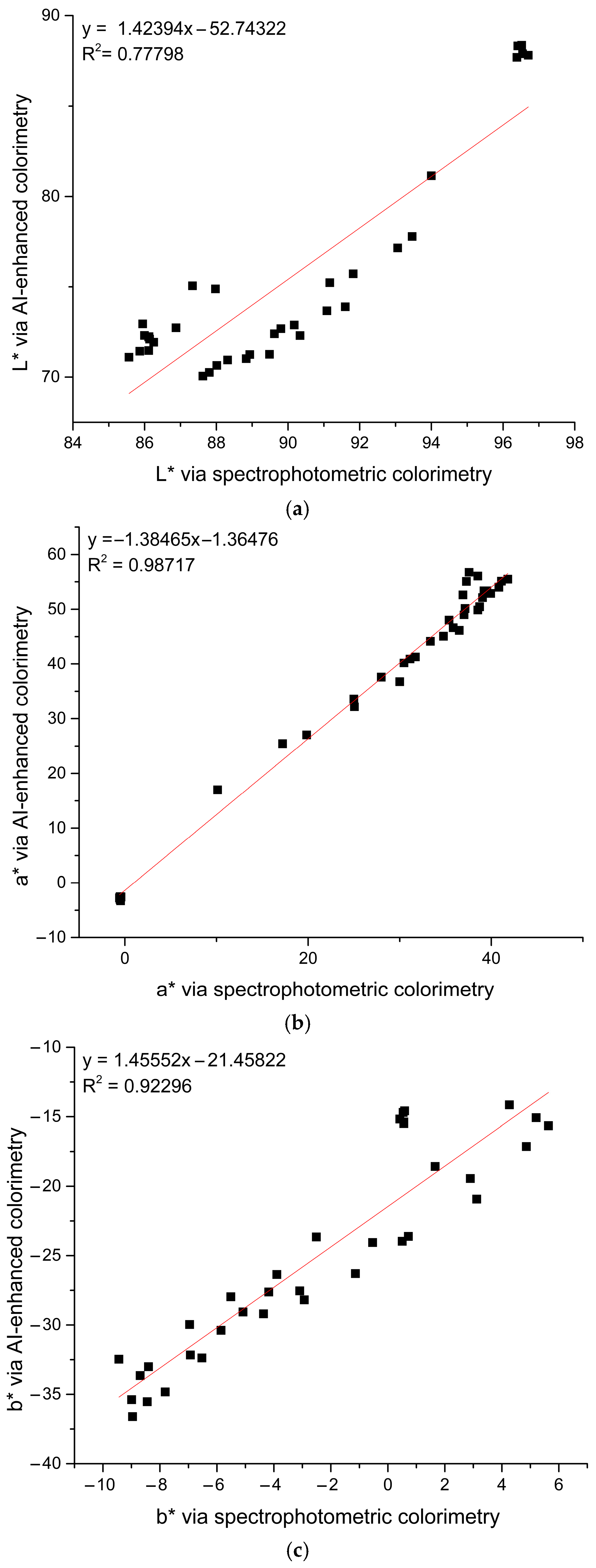

3.2. CIELAB Color Coordinates Comparative Analysis

3.3. Self-Cleaning Assessment by CIELAB Color Space

4. Conclusions

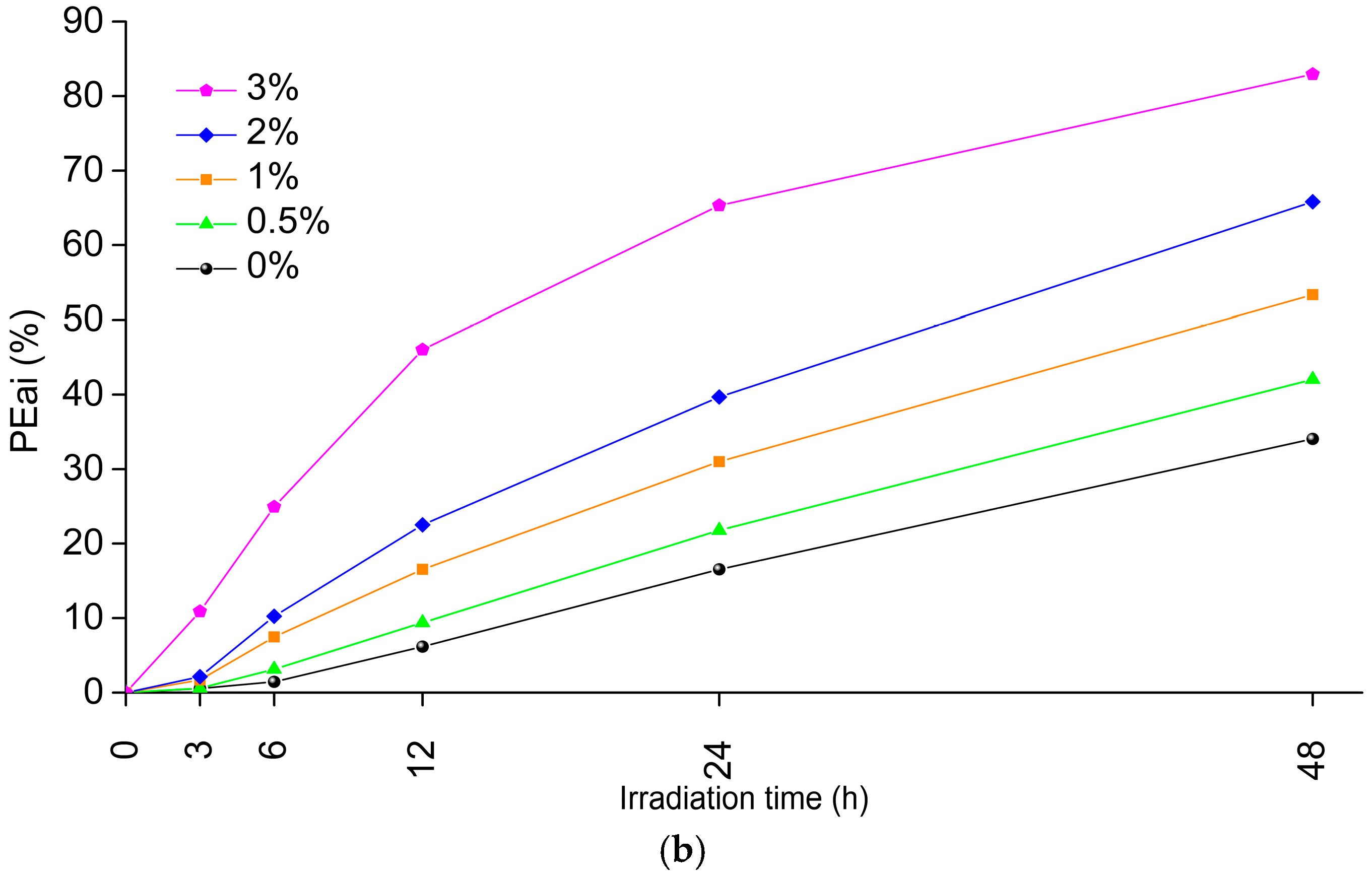

- Visual analysis showed that, after 48 h of light irradiation, samples with 2% and 3% of nano-TiO2 exhibited greater discoloration (self-cleaning) than the reference samples or those with lower rates.

- The CIELAB color coordinates exhibited a strong linear correlation between the spectrophotometric and AI-assisted colorimetric methods, particularly for a* and b*, with R2 values of 0.98717 and 0.92296, respectively. The L* coordinate also demonstrated a positive correlation between the methods, with an R2 value of 0.77798, although this correlation was lower compared to a* and b*.

- Colorimetric analysis revealed higher values of photocatalytic efficiency (up to 82%) and color variation (up to 35.76) for the samples with 3% of nano-TiO2 after 48 h of light irradiation.

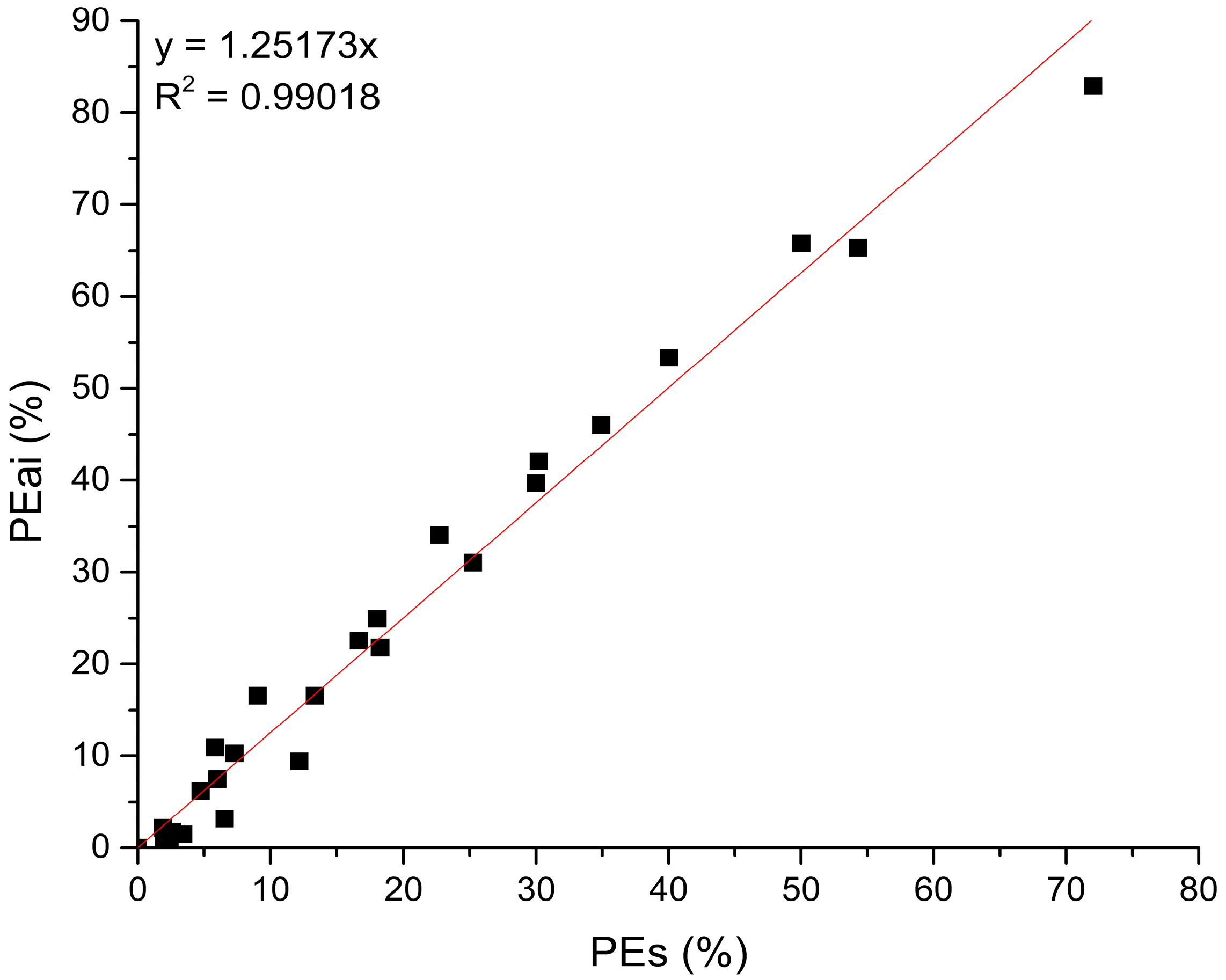

- The R2 for PEs versus PEai was 0.99018, and the R2 for ∆Es versus ∆Eai was 0.97825. For both parameters, the values obtained by AI-enhanced colorimetry were slightly higher.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pocock, B.W.; Rhodes, C.C. Principles of Glass-Bead Reflectorization. Highw. Res. Board Bull. 1952, 57, 32–48. [Google Scholar]

- Burghardt, T.E.; Pashkevich, A. Materials Selection for Structured Horizontal Road Markings: Financial and Environmental Case Studies. Eur. Transp. Res. Rev. 2020, 12, 11. [Google Scholar] [CrossRef]

- Burghardt, T.E.; Pashkevich, A. Green Public Procurement Criteria for Road Marking Materials from Insiders’ Perspective. J. Clean. Prod. 2021, 298, 126521. [Google Scholar] [CrossRef]

- Migletz, J.; Graham, J.L.; Harwood, D.W.; Bauer, K. Service Life of Durable Pavement Markings. Transp. Res. Rec. J. Transp. Res. Board 2001, 1749, 13–21. [Google Scholar] [CrossRef]

- Theeuwes, J.; Snell, J.; Koning, T.; Bucker, B. Self-Explaining Roads: Effects of Road Design on Speed Choice. Transp. Res. Part F Traffic Psychol. Behav. 2023, 102, 335–361. [Google Scholar] [CrossRef]

- Oktopianto, Y.; Rukman, R. Analysis of the Road Markings Reflectivity Service Life on Highways to Improve Safety. RSF Conf. Ser. Eng. Technol. 2022, 2, 316–323. [Google Scholar] [CrossRef]

- Burghardt, T.E.; Maki, E.; Pashkevich, A. Yellow Thermoplastic Road Markings with High Retroreflectivity: Demonstration Study in Texas. Case Stud. Constr. Mater. 2021, 14, e00539. [Google Scholar] [CrossRef]

- Babić, D.; Ščukanec, A.; Fiolić, M. Model for Predicting Road Markings Service Life. Balt. J. Road Bridge Eng. 2019, 14, 341–359. [Google Scholar] [CrossRef]

- Babić, D.E.; Burghardt, T.; Babić, D. Application and Characteristics of Waterborn Road Marking Paint. Int. J. Traffic Transp. Eng. 2015, 5, 150–169. [Google Scholar] [CrossRef]

- Boucher, J.; Friot, D. Primary Microplastics in the Oceans: A Global Evaluation of Sources; IUCN International Union for Conservation of Nature: Gland, Switzerland, 2017; ISBN 9782831718279. [Google Scholar]

- Kole, P.J.; Löhr, A.J.; van Belleghem, F.; Ragas, A. Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment. Int. J. Environ. Res. Public Health 2017, 14, 1265. [Google Scholar] [CrossRef] [PubMed]

- Segundo, I.R.; Freitas, E.; Branco, V.T.F.C.; Landi, S.; Costa, M.F.; Carneiro, J.O. Review and Analysis of Advances in Functionalized, Smart, and Multifunctional Asphalt Mixtures. Renew. Sustain. Energy Rev. 2021, 151, 111552. [Google Scholar] [CrossRef]

- Lima, O.; Cardoso, P.; Segundo, I.R.; Freitas, E.; Costa, M.F.M.; Nascimento, H.; Afonso, C.; Landi, S.; Teixeira, V.; Carneiro, J. Thermochromism Applied to Transportation Engineering: Asphalt Roads and Paints. J. Phys. Conf. Ser. 2022, 2407, 012042. [Google Scholar] [CrossRef]

- Carneiro, J.O.; Azevedo, S.; Teixeira, V.; Fernandes, F.; Freitas, E.; Silva, H.; Oliveira, J. Development of Photocatalytic Asphalt Mixtures by the Deposition and Volumetric Incorporation of TiO2 Nanoparticles. Constr. Build. Mater. 2013, 38, 594–601. [Google Scholar] [CrossRef]

- Rocha Segundo, I.; Ferreira, C.; Freitas, E.F.; Carneiro, J.O.; Fernandes, F.; Júnior, S.L.; Costa, M.F. Assessment of Photocatalytic, Superhydrophobic and Self-Cleaning Properties on Hot Mix Asphalts Coated with TiO2 and/or ZnO Aqueous Solutions. Constr. Build. Mater. 2018, 166, 500–509. [Google Scholar] [CrossRef]

- Reza Omranian, S.; Geluykens, M.; Van Hal, M.; Hasheminejad, N.; Rocha Segundo, I.; Pipintakos, G.; Denys, S.; Tytgat, T.; Fraga Freitas, E.; Carneiro, J.; et al. Assessing the Potential of Application of Titanium Dioxide for Photocatalytic Degradation of Deposited Soot on Asphalt Pavement Surfaces. Constr. Build. Mater. 2022, 350, 128859. [Google Scholar] [CrossRef]

- Liu, K.; Cao, M.; Fujishima, A.; Jiang, L. Bio-Inspired Titanium Dioxide Materials With Special Wettability and Their Applications. Chem. Rev. 2014, 114, 10044–10094. [Google Scholar] [CrossRef]

- Paramés, J.; Brito, J. de Materiais de Construção Nanotecnológicos de Auto-Limpeza-Self-Cleaning Nanotechnologic Construction Materials. Teor. Prática Eng. Civ. 2010, 15, 55–62. [Google Scholar]

- Van Hal, M.; Verbruggen, S.W.; Yang, X.-Y.; Lenaerts, S.; Tytgat, T. Image Analysis and in Situ FTIR as Complementary Detection Tools for Photocatalytic Soot Oxidation. Chem. Eng. J. 2019, 367, 269–277. [Google Scholar] [CrossRef]

- Silva, A.S.; Borsoi, G.; Parracha, J.L.; Flores-Colen, I.; Veiga, R.; Faria, P.; Dionísio, A. Evaluating the Effectiveness of Self-Cleaning Products Applied on External Thermal Insulation Composite Systems (ETICS). J. Coat. Technol. Res. 2022, 19, 1437–1448. [Google Scholar] [CrossRef]

- Pal, S.; Contaldi, V.; Licciulli, A.; Marzo, F. Self-Cleaning Mineral Paint for Application in Architectural Heritage. Coatings 2016, 6, 48. [Google Scholar] [CrossRef]

- Quan, X.; Yang, L.; Li, H.; Chen, Y.; Shi, S. Performance Evaluation of a Multifunctional Road Marking Coating for Tunnels Based on Nano SiO2 and TiO2 Modifications. Buildings 2024, 14, 459. [Google Scholar] [CrossRef]

- Fang, M.; Peng, L.; Li, Y.; Cheng, Y.; Zhan, L. Evaluation Test of NO Degradation by Nano-TiO2 Coatings on Road Pavements under Natural Light. Coatings 2022, 12, 1200. [Google Scholar] [CrossRef]

- Smits, M.; Chan, C.K.; Tytgat, T.; Craeye, B.; Costarramone, N.; Lacombe, S.; Lenaerts, S. Photocatalytic Degradation of Soot Deposition: Self-Cleaning Effect on Titanium Dioxide Coated Cementitious Materials. Chem. Eng. J. 2013, 222, 411–418. [Google Scholar] [CrossRef]

- Folli, A.; Jakobsen, U.H.; Guerrini, G.L.; Macphee, D.E. Rhodamine B Discolouration on TiO2 in the Cement Environment: A Look at Fundamental Aspects of the Self-Cleaning Effect in Concretes. J. Adv. Oxid. Technol. 2009, 12, 126–133. [Google Scholar] [CrossRef]

- Sikora, P.; Horszczaruk, E.; Rucinska, T. The Effect of Nanosilica and Titanium Dioxide on the Mechanical and Self-Cleaning Properties of Waste-Glass Cement Mortar. Procedia Eng. 2015, 108, 146–153. [Google Scholar] [CrossRef]

- Wirunchit, S.; Wonganan, N.; Koetniyom, W. Multi Self-Cleaning Properties of Zinc Oxide Nanoparticles/ Polydimethylsiloxane (ZnO/PDMS) Composite on Polyester Textile. Curr. Appl. Sci. Technol. 2023, 23. [Google Scholar] [CrossRef]

- Hirashima, T.; Adachi, T. Procedures for the Quantification of Whole-Tissue Immunofluorescence Images Obtained at Single-Cell Resolution During Murine Tubular Organ Development. PLoS ONE 2015, 10, e0135343. [Google Scholar] [CrossRef]

- Zanuncio, A.J.V.; Costa, E.A.; Carvalho, A.G.; De Castro, V.R.; Carneiro, A.D.C.O.; Araújo, S.D.O.; Florestais, P.C.d.E. Artificial Intelligence and Colorimetry as a Combined Non-Destructive Method to Predict Properties of Heat-Treated Wood. Cellul. Chem. Technol. 2022, 56, 941–948. [Google Scholar] [CrossRef]

- Feng, F.; Ou, Z.; Zhang, F.; Chen, J.; Huang, J.; Wang, J.; Zuo, H.; Zeng, J. Artificial Intelligence-Assisted Colorimetry for Urine Glucose Detection towards Enhanced Sensitivity, Accuracy, Resolution, and Anti-Illuminating Capability. Nano Res. 2023, 16, 12084–12091. [Google Scholar] [CrossRef]

- Lin, C.-S.; Pan, Y.-C.; Kuo, Y.-X.; Chen, C.-K.; Tien, C.-L. A Study of Automatic Judgment of Food Color and Cooking Conditions with Artificial Intelligence Technology. Processes 2021, 9, 1128. [Google Scholar] [CrossRef]

- Hoque Tania, M.; Lwin, K.T.; Shabut, A.M.; Najlah, M.; Chin, J.; Hossain, M.A. Intelligent Image-Based Colourimetric Tests Using Machine Learning Framework for Lateral Flow Assays. Expert. Syst. Appl. 2020, 139, 112843. [Google Scholar] [CrossRef]

- Pereira, A.P.; Ribeiro, J.L.; Oliveira, A.C.F.; Vasconcelos, C.K.B.; Viana, M.M.; Lins, V.d.F.C. Lignin-Modified Road Marking Paint: Weathering Aging Studies. REM-Int. Eng. J. 2021, 74, 225–233. [Google Scholar] [CrossRef]

- EN 1436:2009; Road Marking Materials—Road Marking Performance for Road Users. German Institute for Standardization: Berlin, Germany, 2009.

- Munafò, P.; Quagliarini, E.; Goffredo, G.B.; Bondioli, F.; Licciulli, A. Durability of Nano-Engineered TiO2 Self-Cleaning Treatments on Limestone. Constr. Build. Mater. 2014, 65, 218–231. [Google Scholar] [CrossRef]

- Lima, O.; Freitas, E.; Cardoso, P.; Segundo, I.R.; Margalho, É.; Moreira, L.; José, J.H.; Landi, S.; Carneiro, J. Mitigation of Urban Heat Island Effects by Thermochromic Asphalt Pavement. Coatings 2023, 13, 35. [Google Scholar] [CrossRef]

- Robertson, A.R. The CIE 1976 Color-difference Formulae. Color Res. Appl. 1977, 2, 7–11. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lima, O., Jr.; Segundo, I.R.; Mazzoni, L.; Costa, M.F.M.; Freitas, E.; Carneiro, J. Artificial Intelligence-Enhanced Colorimetric Assessment of Self-Cleaning Road Marking Paints. Appl. Sci. 2024, 14, 9718. https://doi.org/10.3390/app14219718

Lima O Jr., Segundo IR, Mazzoni L, Costa MFM, Freitas E, Carneiro J. Artificial Intelligence-Enhanced Colorimetric Assessment of Self-Cleaning Road Marking Paints. Applied Sciences. 2024; 14(21):9718. https://doi.org/10.3390/app14219718

Chicago/Turabian StyleLima, Orlando, Jr., Iran Rocha Segundo, Laura Mazzoni, Manuel F. M. Costa, Elisabete Freitas, and Joaquim Carneiro. 2024. "Artificial Intelligence-Enhanced Colorimetric Assessment of Self-Cleaning Road Marking Paints" Applied Sciences 14, no. 21: 9718. https://doi.org/10.3390/app14219718

APA StyleLima, O., Jr., Segundo, I. R., Mazzoni, L., Costa, M. F. M., Freitas, E., & Carneiro, J. (2024). Artificial Intelligence-Enhanced Colorimetric Assessment of Self-Cleaning Road Marking Paints. Applied Sciences, 14(21), 9718. https://doi.org/10.3390/app14219718