Design of a Lower Limb Prosthesis for Ballet Practice

Abstract

1. Introduction

- The prosthesis should be lightweight, to avoid interfering with the required movements in ballet and maintaining the characteristic sensation of lightness in the discipline.

- The selected materials should provide sufficient strength and durability to withstand the intensity and physical demands of ballet, ensuring long-term functionality. Additionally, the material should guarantee user safety, avoiding potential failures.

- Materials will be preferably selected with a lower cost, if they meet the necessary characteristics, in order to obtain an affordable prosthetic device for all types of users.

- The device should ensure continued gait during activity, through dynamic response and active tibial progression.

- The design of the prosthesis should be proportional to the type of user. Dimensions, amount of material, and shape will depend on the user under study. Additionally, it should allow for personalized adaptation and adjustment to the individual’s body structure and the dancer’s preferences.

2. Materials and Methods

2.1. Analysis of the Foot in Ballet

2.1.1. Biomechanical Analysis

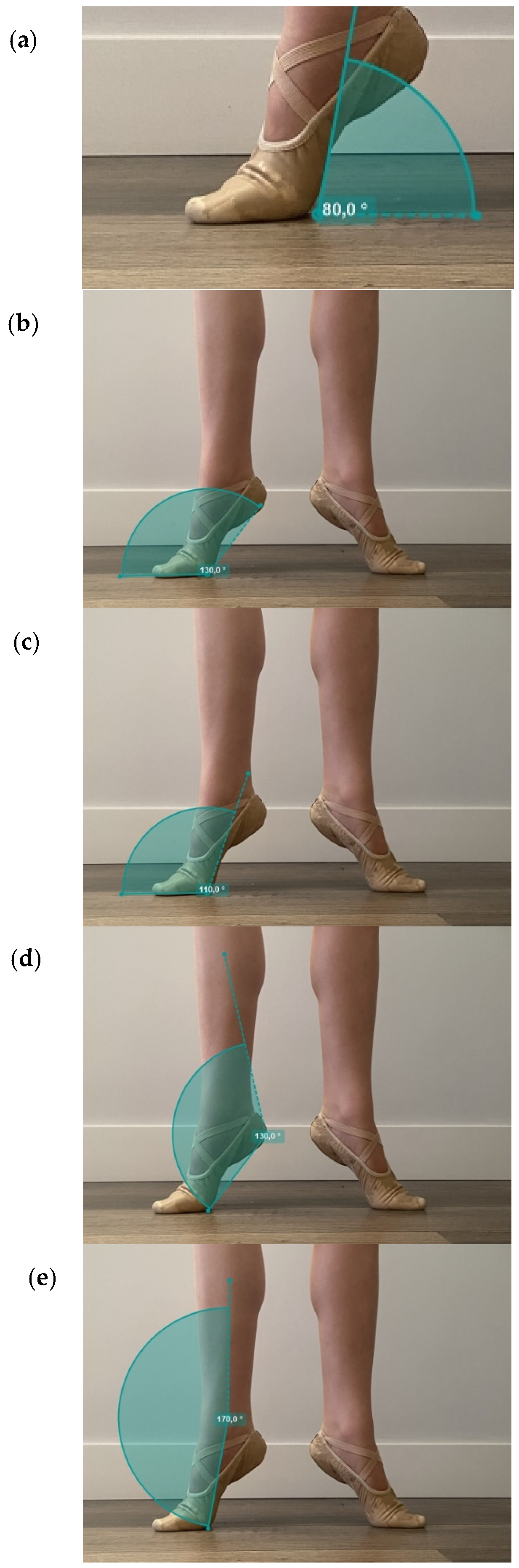

Biomechanical Study of the Foot in Relevé

Biomechanical Study of the Foot in Plié

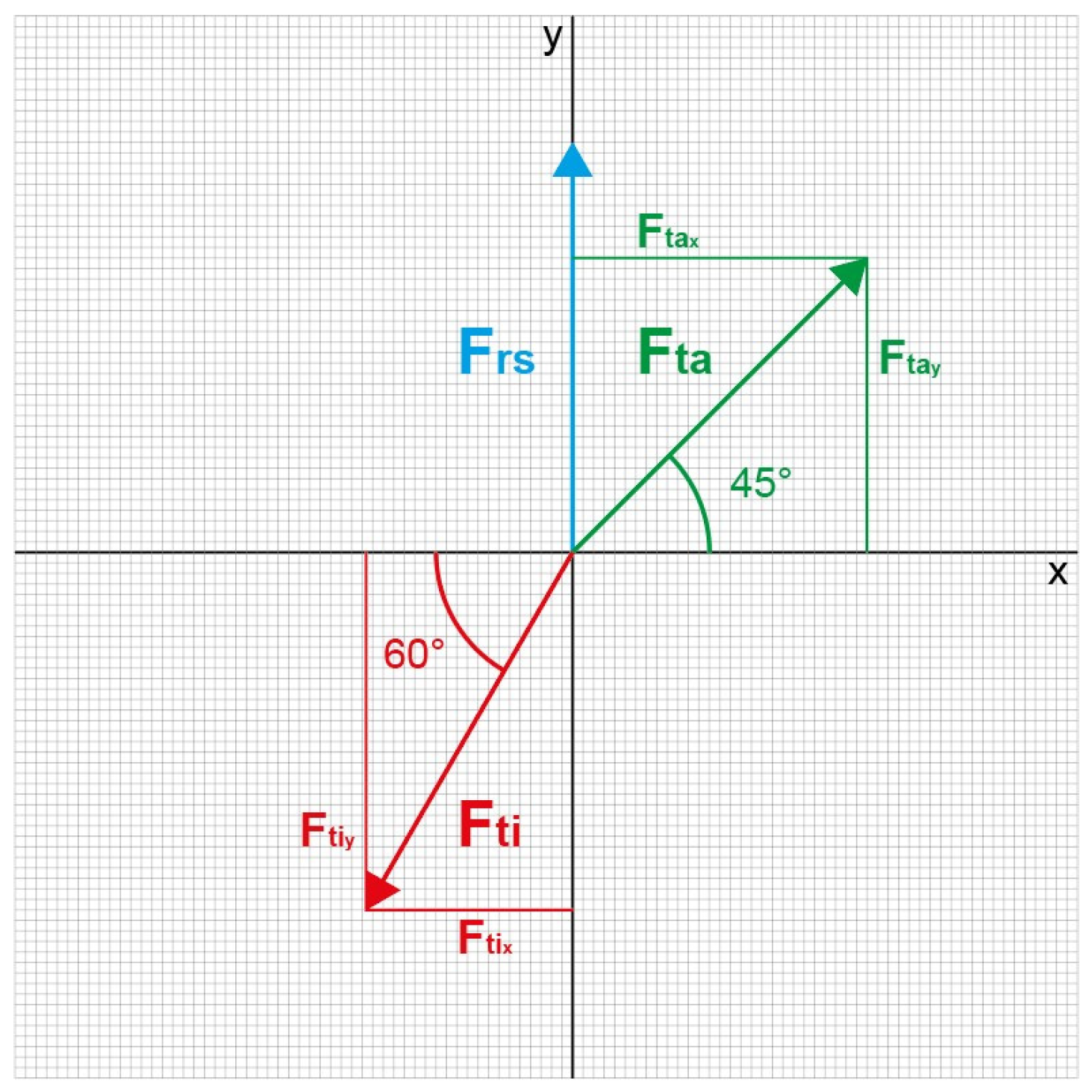

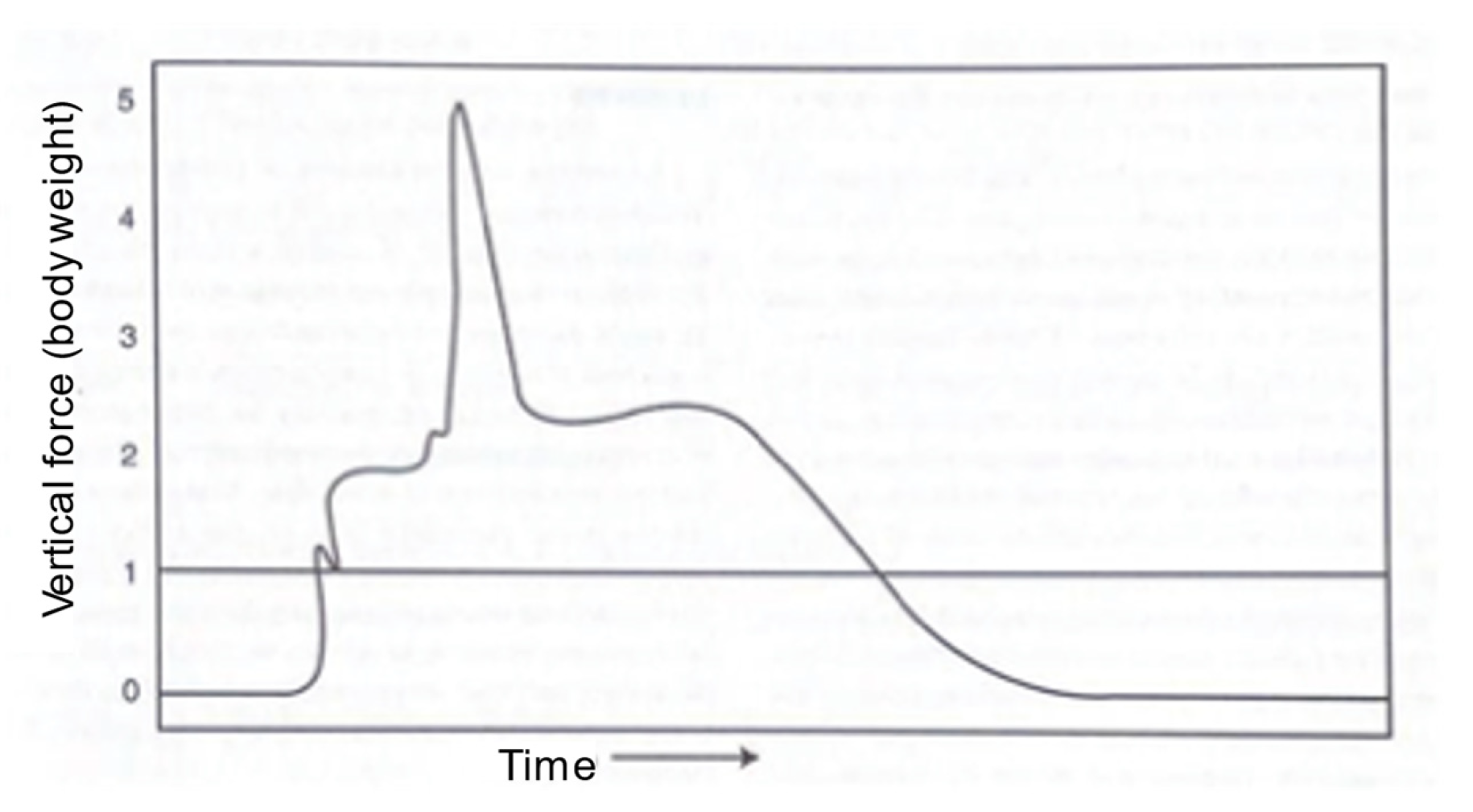

2.1.2. Kinetic Analysis of the Foot in Ballet

2.2. Prosthetic Design

2.3. Population of the Study

2.4. Phases and Methodology

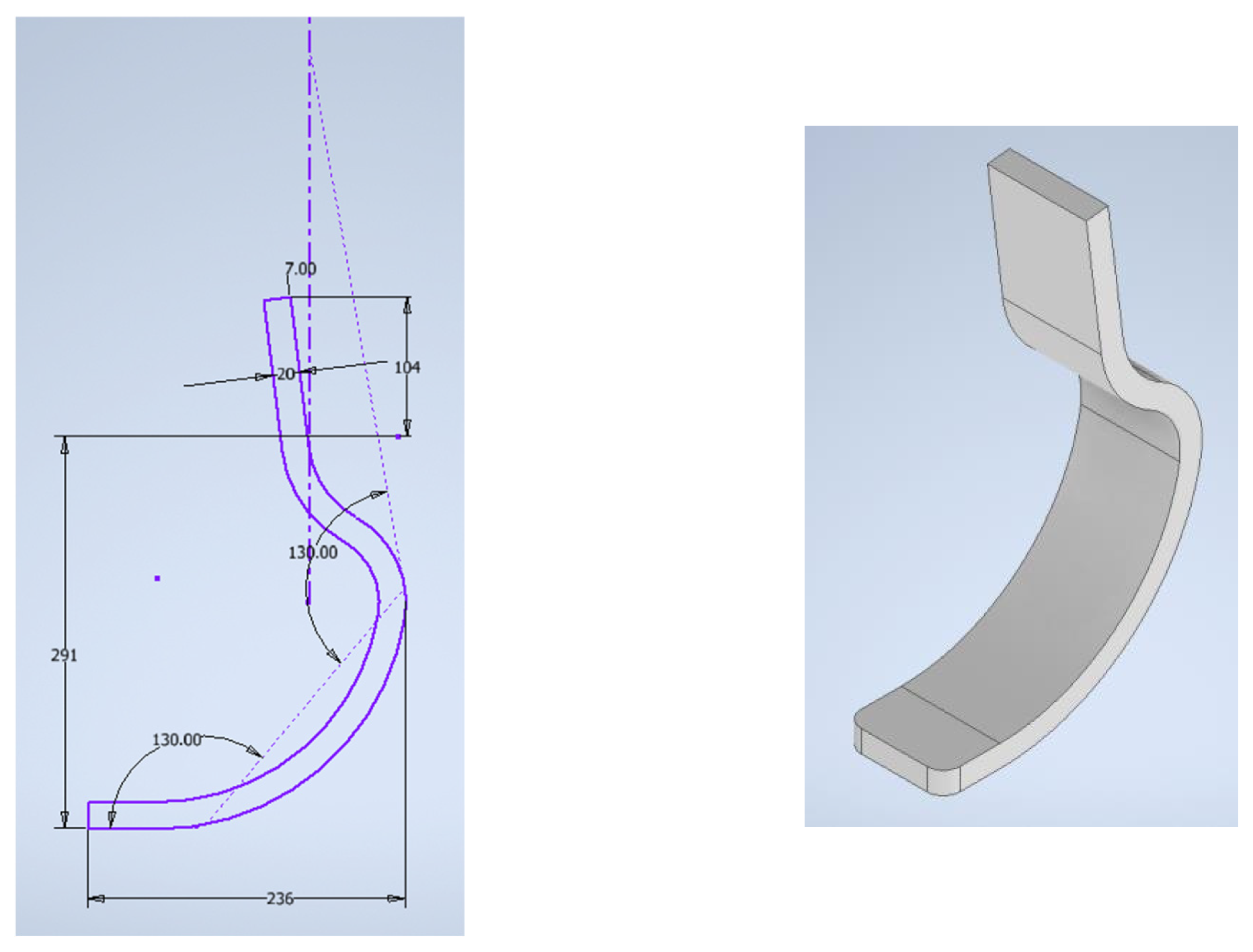

- Phase 1. Defining geometry constraints. The main dimensions for both genders are defined in Table 2. Obtaining detailed dimensions for the studied case: transtibial amputation considering the difference between the percentile extremes in the studied population: 5% and 95%.

- Phase 2. Idea generation. Based on the previous phase, in this phase, preliminary sketches are generated. Best sketches should be defined in more detail.

- Phase 3. Stress analysis. Static stress analysis is performed for defined solutions. The simulation is carried out with Fusion 360 software [16]. Stress and deformation will be calculated and checked. Previous to the simulations, materials should be selected and also constraints and load force should be included in the finite element model.

- Phase 4. Results and review. Results from phase 3 should accomplish the displacement established range and safety factor considered for stress maximum values.

- Phase 5. Optimization. This phase tries to minimize prosthesis weight, by adjusting geometry (contours, thickness, and holes).

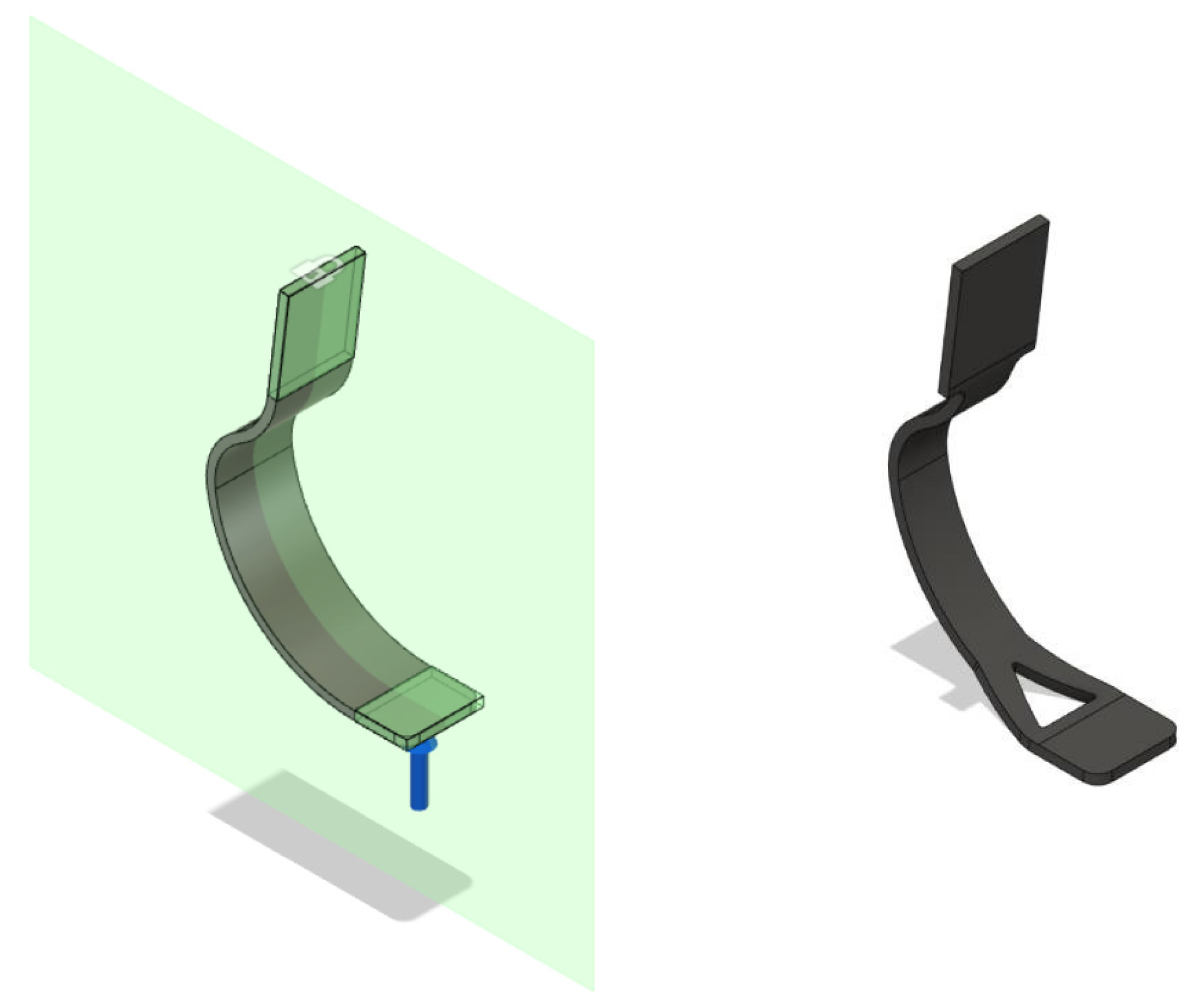

- Phase 6. Prototyping. Developing a prototype for checking and even improving the selected solution. In this case, to create a tangible representation of the model, a 9/20 scale prototype was fabricated using 3D printing with the 3D printer Onyx One by Markforged, which produces nylon parts reinforced with carbon or glass microfibers through fused filament fabrication (FFF). The printer’s proprietary software, Eiger, was used to convert and prepare the 3D model for printing, ensuring the necessary adjustments for the desired outcome.

3. Results and Discussion

3.1. Requirements of Prosthesis

3.2. Prosthesis Definition and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ROMP—Todo Sobre Amputación y Cuidados Protésicos. 2022. Available online: https://romptemueve.org/ (accessed on 16 September 2024).

- México, M. Beneficios de Adquirir una Prótesis con un Licenciado en Prótesis. mediprax. 2024. Available online: http://mediprax.mx/adquirir-una-protesis-con-un-licenciado-en-protesis/ (accessed on 16 September 2024).

- Leimkuehler Orthotic-Prosthetic Centers|Northeast Ohio. Available online: https://leimkuehleroandp.com/ (accessed on 24 September 2024).

- Prótesis de Miembro Inferior y Superior|Össur. Available online: https://www.ossur.com/es-es (accessed on 16 September 2024).

- Tecnología Punta y Deporte. Available online: https://tecnologiapuntaydeporte.wordpress.com/201%201/11/15/ossu-cheeta-flex-foot-%C2%BFalgo-mas-%20que-una-protesis-deportiva/ (accessed on 16 September 2024).

- Ahonen, J. Biomechanics of the Foot in Dance: A Literature Review. J. Dance Med. Sci. 2008, 12, 99–108. [Google Scholar] [CrossRef] [PubMed]

- Kinovea. Available online: https://www.kinovea.org/ (accessed on 16 September 2024).

- Nihat, Ö.; Dawn, L.; David, G.; Margareta, N. Fundamentals of Biomechanics; Springer International Publishing Switzerland: Cham, Switzerland, 2017; corrected publication 2018; ISBN 978-3-319-44738-4. [Google Scholar]

- Definición de Carga Dinámica|Diccionario de Arquitectura y Construcción. Available online: https://www.parro.com.ar/definicion-de-%20carga+din%C3%A1mica (accessed on 16 September 2024).

- Pohjola, H.; Sayers, M.; Mellifont, R.; Mellifont, D.; Venojärvi, M. Three-Dimensional Analysis of a Ballet Dancer with Ischial Tuberosity Apophysitis. A Case Study. J. Sports Sci. Med. 2014, 13, 874–880. [Google Scholar] [PubMed]

- Beedigital, C.M. ¿Qué es la ductilidad? Bezabala. 2021. Available online: https://www.bezabala.es/que-es-la-ductilidad/ (accessed on 17 September 2024).

- Budynas, R.; Nisbett, K. Diseño en Ingenieria Mecánica de Shigley; McGraw-Hill Interamericana de España S.L: Madrid, Spain, 2012; ISBN 978-607-15-0771-6. [Google Scholar]

- Resistencia Mecánica a Fatiga. Available online: https://ingemecanica.com/tutorialsemanal/tutorialn217.html (accessed on 17 September 2024).

- Benjumea, A.C. Datos Antropométricos de la Población Laboral Española. Available online: https://documentacion.fundacionmapfre.org/documentacion/publico/es/media/group/1055028.do (accessed on 16 September 2024).

- Davinia, R.B. Intervención de Enfermería en el Proceso de Protetización de los Pacientes Sometidos a una Amputación. 2014. Available online: https://uvadoc.uva.es/handle/10324/4438 (accessed on 16 September 2024).

- Autodesk Fusion|3D CAD, CAM, CAE, & PCB Cloud-Based Software|Autodesk. Available online: https://www.autodesk.com/products/fusion-360/overview (accessed on 17 September 2024).

- Autodesk Inventor Software|Get Prices & Buy Official Inventor 2025. Available online: https://www.autodesk.com/products/inventor/overview (accessed on 17 September 2024).

- Ramos Leguel, L.G. Diseño Conceptual de una Prótesis Deportiva de Miembro Inferior. 2017. Available online: http://www.ptolomeo.unam.mx:8080/jspui/handle/132.248.52.100/12631 (accessed on 17 September 2024).

- Autodesk Inventor Nastran Software|Get Prices & Buy Inventor Nastran 2025. Available online: https://www.autodesk.com/products/inventor-nastran/overview (accessed on 14 October 2024).

- Ansys Mechanical: Structural FEA Analysis Software. Available online: https://www.ansys.com/products/structures/ansys-mechanical (accessed on 17 April 2023).

| Prosthetic Category | Description | Example Use |

|---|---|---|

| Dynamic response foot | Absorbs impact and uses stored energy for propulsion | Running, fast walking |

| Articulated foot | Has joints for increased flexibility | Casual walking |

| Multi-axial response foot | Allows movement in multiple planes | Uneven terrain, outdoor activities |

| High-performance foot | Designed for specific high-performance activities | Athletics, competitive sports |

| Female Population | |||

| Measure | P5 | P95 | Average |

| Body mass (kg) | 48.1 | 77 | 62.55 |

| Tibia height (mm) | 384 | 488 | 436 |

| Foot length (mm) | 215 | 257 | 236 |

| Foot width (mm) | 79 | 100 | 89.5 |

| Male Population | |||

| Measure | P5 | P95 | Average |

| Body mass (kg) | 58.6 | 95.8 | 77.2 |

| Tibia height (mm) | 409 | 520 | 464.5 |

| Foot length (mm) | 234 | 282 | 258 |

| Foot width (mm) | 87 | 112 | 99.5 |

| Model with 20 mm Thickness | ||

|---|---|---|

| Study Type | Results | |

| Max | Min | |

| von Mises stress | 116.4 MPa | 0.416 MPa |

| Safety factor | 15 | 15 |

| Displacement | 6.227 mm | 0 mm |

| Model with 10 mm Thickness | ||

|---|---|---|

| Study Type | Results | |

| Max | Min | |

| von Mises stress | 465.2 MPa | 1.029 MPa |

| Safety factor | 15 | 4.202 |

| Displacement | 46.06 mm | 0 mm |

| Optimized Model with 10 mm Thickness | ||

| Study Type | Results | |

| Max | Min | |

| von Mises stress | 824.8 MPa | 0.900 MPa |

| Safety factor | 15 | 2.37 |

| Displacement | 79.48 mm | 0 mm |

| Optimized Model with 12 mm Thickness | ||

| Study Type | Results | |

| Max | Min | |

| von Mises stress | 535.9 MPa | 0.6475 MPa |

| Safety factor | 15 | 3.648 |

| Displacement | 45.84 mm | 0 mm |

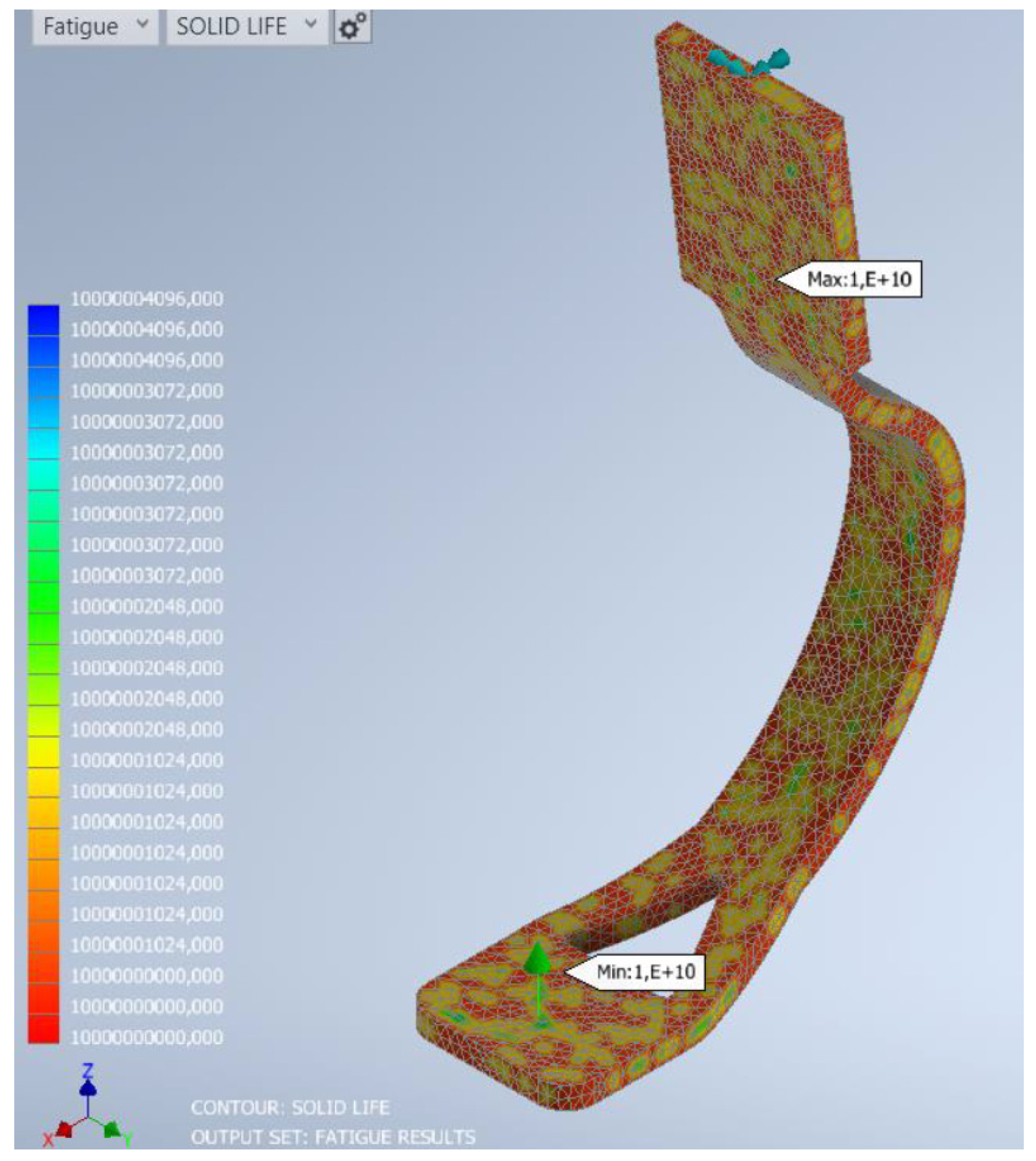

| Study Type | Results | |

|---|---|---|

| Max | Min | |

| Fatigue resistance | 109 cycles | 109 cycles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez, B.M.; Alía García, C.; Cano-Moreno, J.D. Design of a Lower Limb Prosthesis for Ballet Practice. Appl. Sci. 2024, 14, 9591. https://doi.org/10.3390/app14209591

Pérez BM, Alía García C, Cano-Moreno JD. Design of a Lower Limb Prosthesis for Ballet Practice. Applied Sciences. 2024; 14(20):9591. https://doi.org/10.3390/app14209591

Chicago/Turabian StylePérez, Blanca Monge, Cristina Alía García, and Juan David Cano-Moreno. 2024. "Design of a Lower Limb Prosthesis for Ballet Practice" Applied Sciences 14, no. 20: 9591. https://doi.org/10.3390/app14209591

APA StylePérez, B. M., Alía García, C., & Cano-Moreno, J. D. (2024). Design of a Lower Limb Prosthesis for Ballet Practice. Applied Sciences, 14(20), 9591. https://doi.org/10.3390/app14209591