The Identification of Microstructural Changes in High-Temperature Superconducting Tapes for Superconducting Fault Current Limiters

Abstract

:1. Introduction

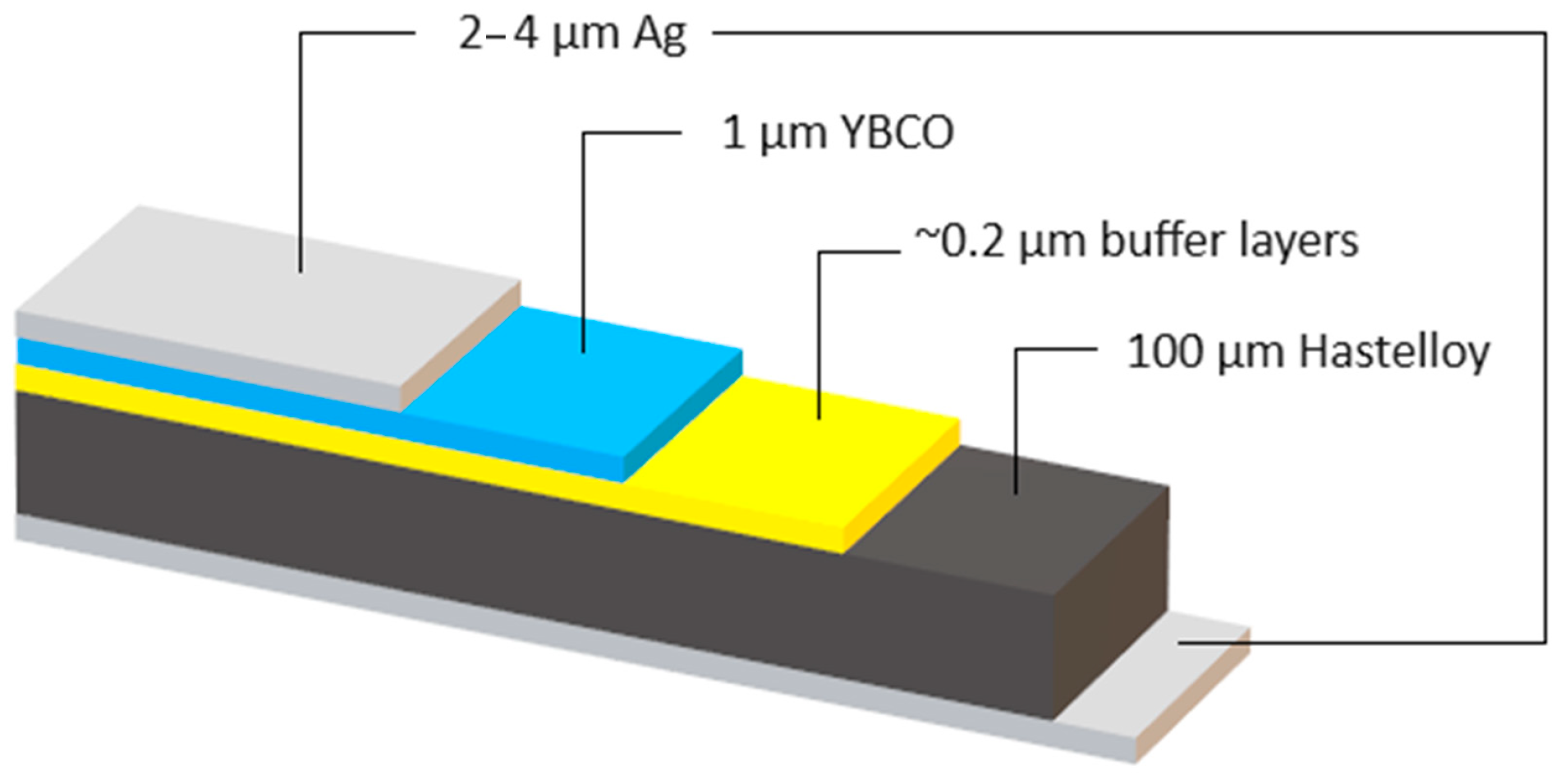

2. Tested Materials

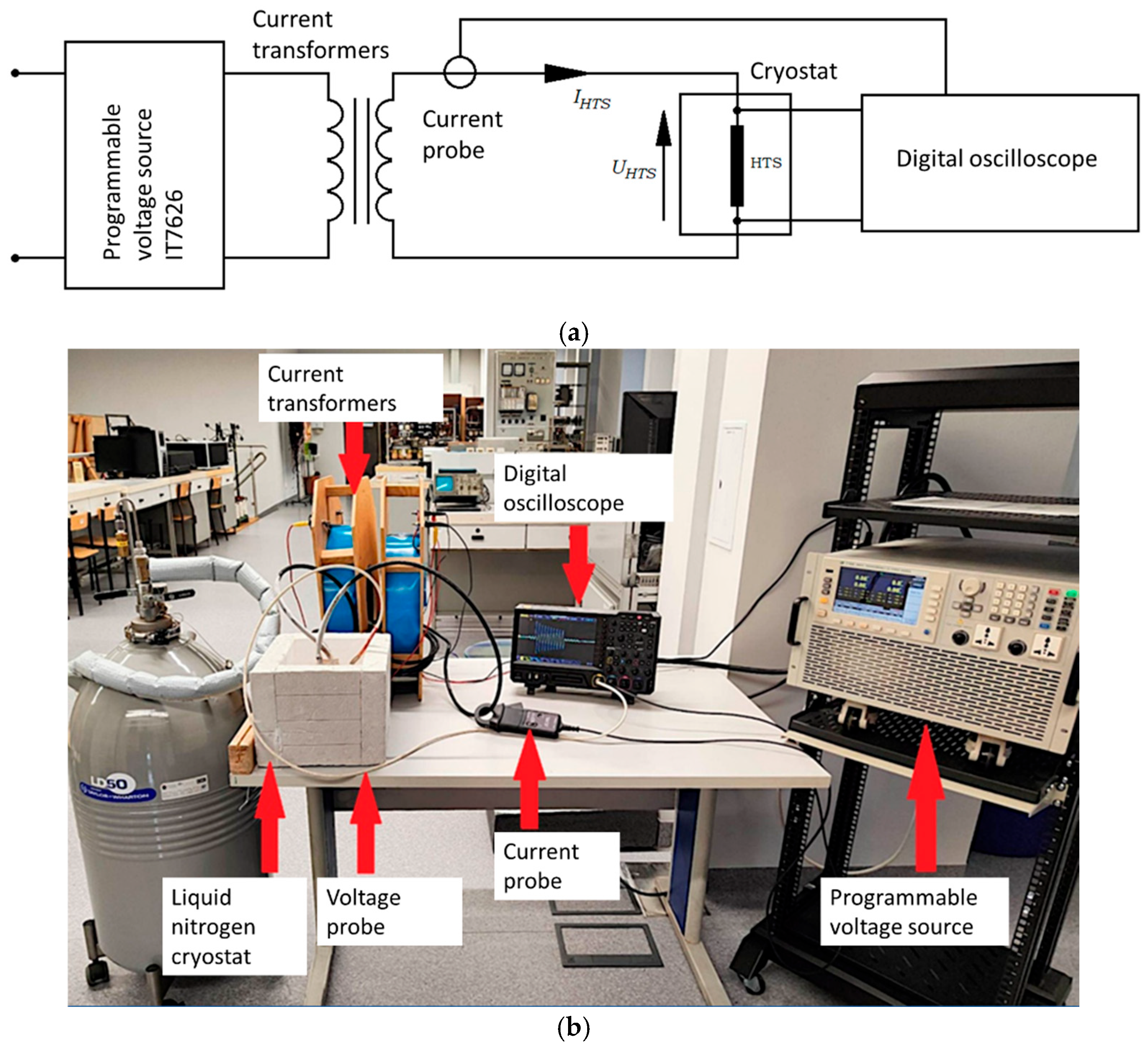

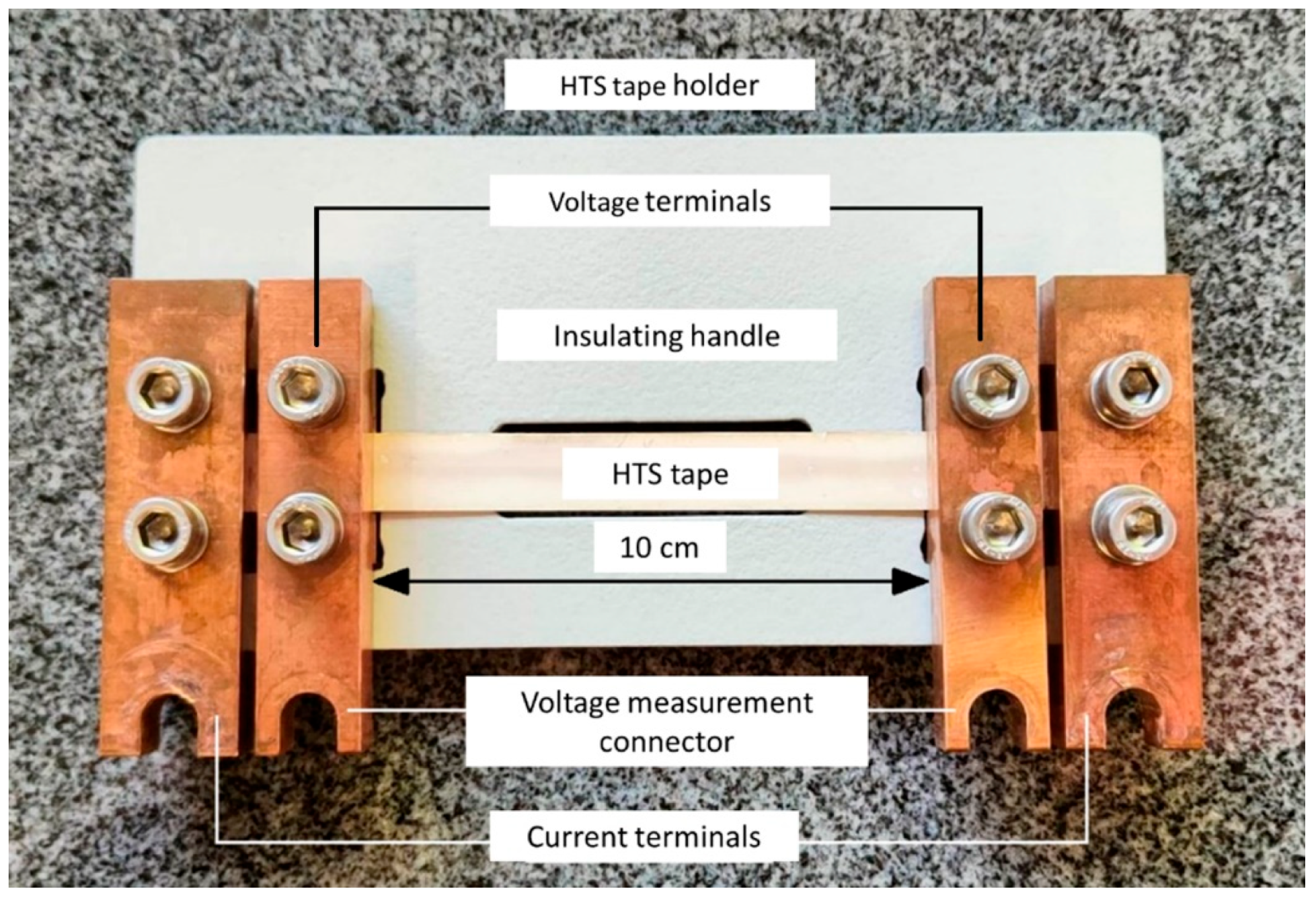

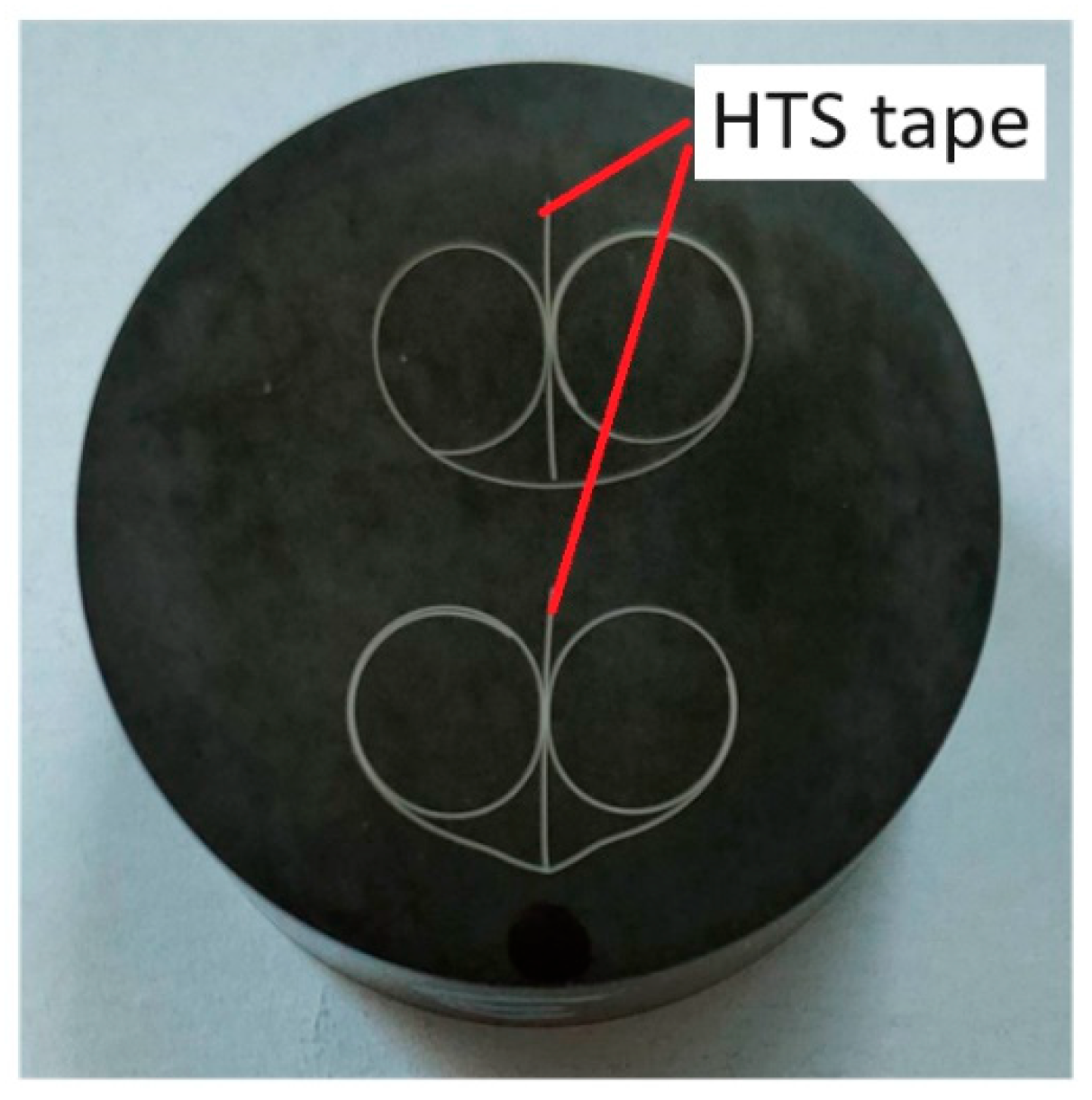

3. 2G HTS Tape Sample Preparation Station

4. Preparation of HTS Tape Samples

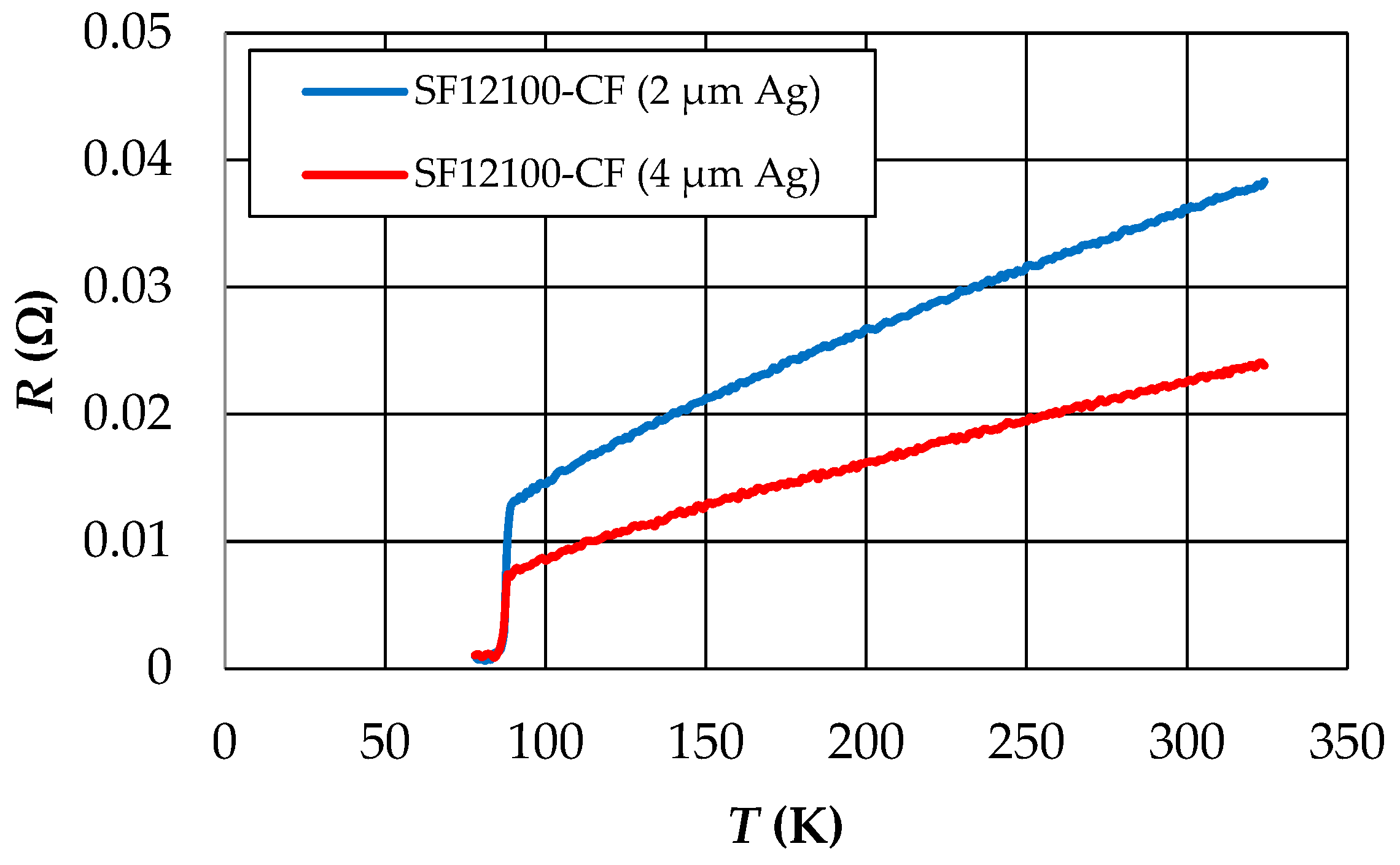

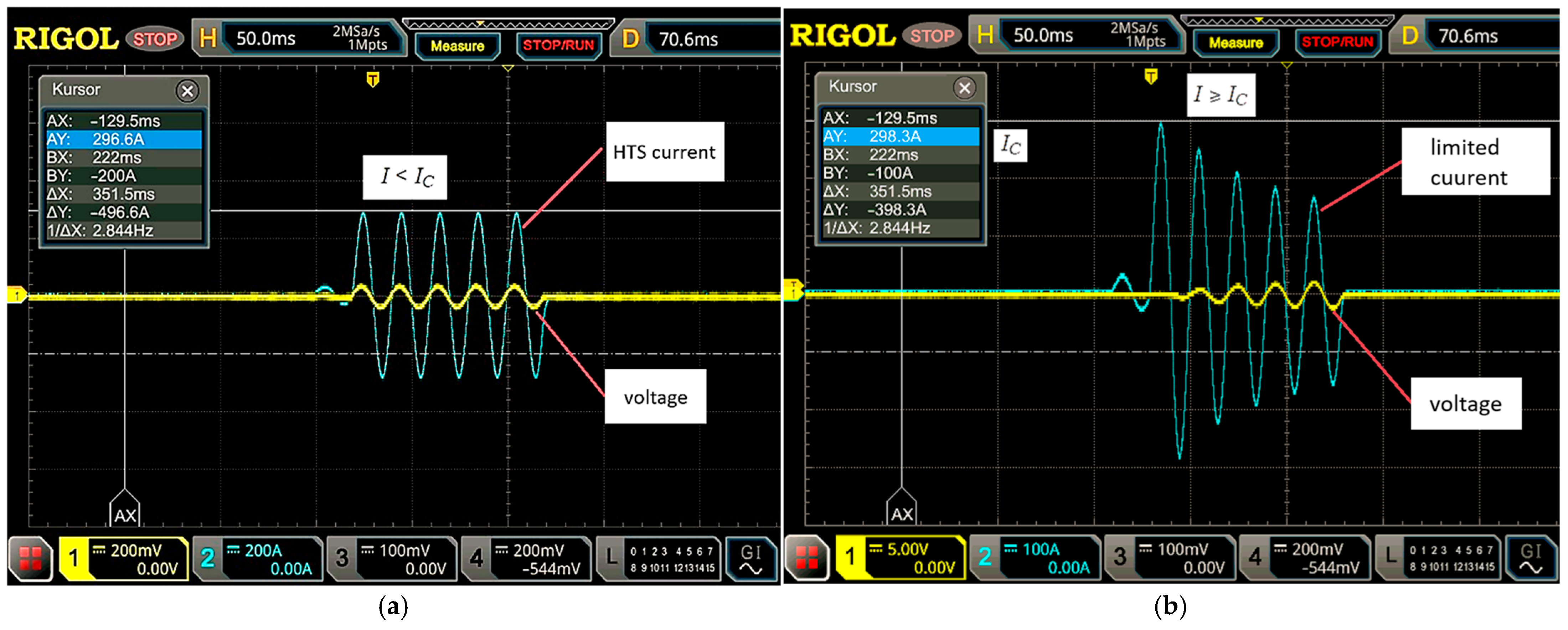

4.1. Method of Measuring the Critical Current Value

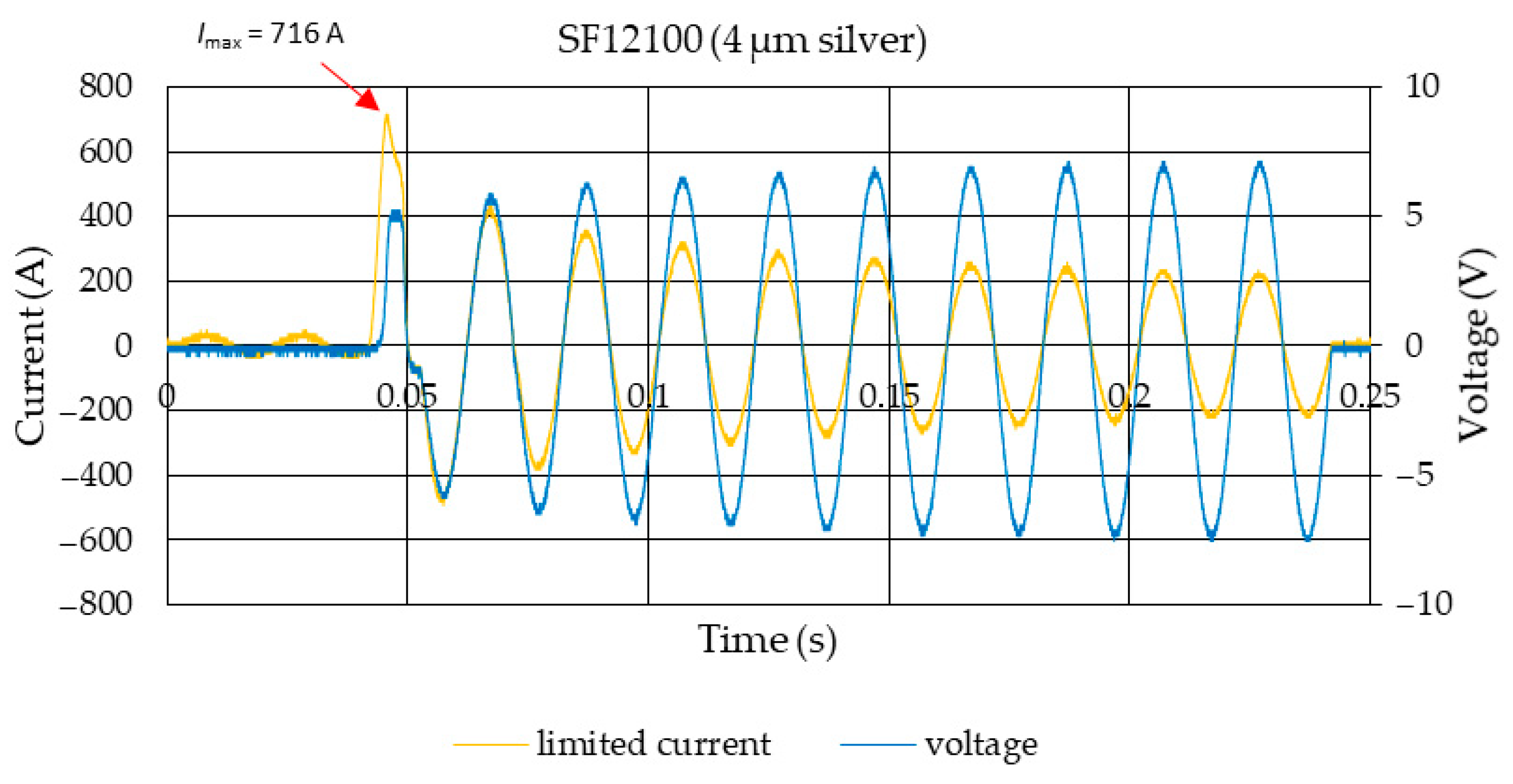

4.2. Test Current Impulse

4.3. Determination of the Energy Generated on the HTS Tape

4.4. HTS Tape Sample Parameters

5. HTS Tapes Studies Using Scanning Electron Microscope

5.1. Research Methodology

- A scanning probe current intensity of 8 mA;

- An electron beam acceleration voltage of 7–8 kV.

5.2. Scope of Research

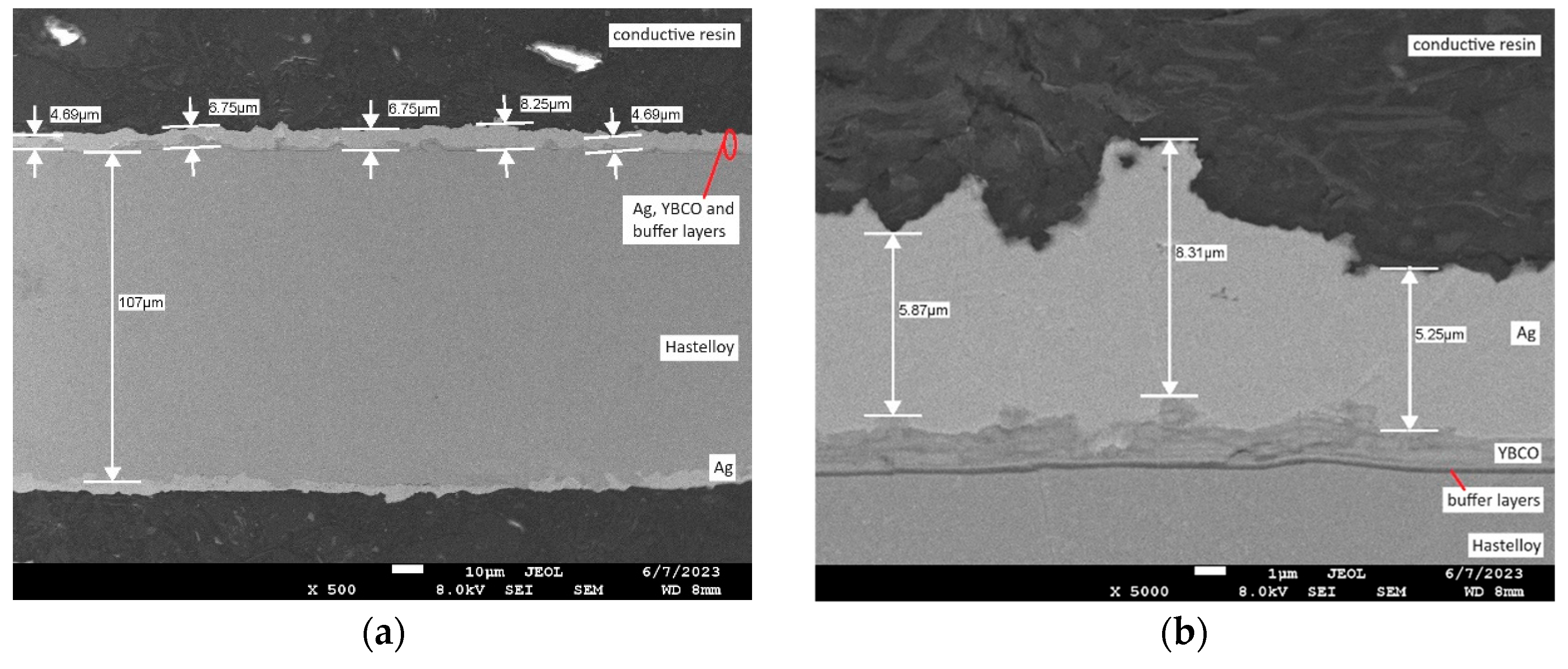

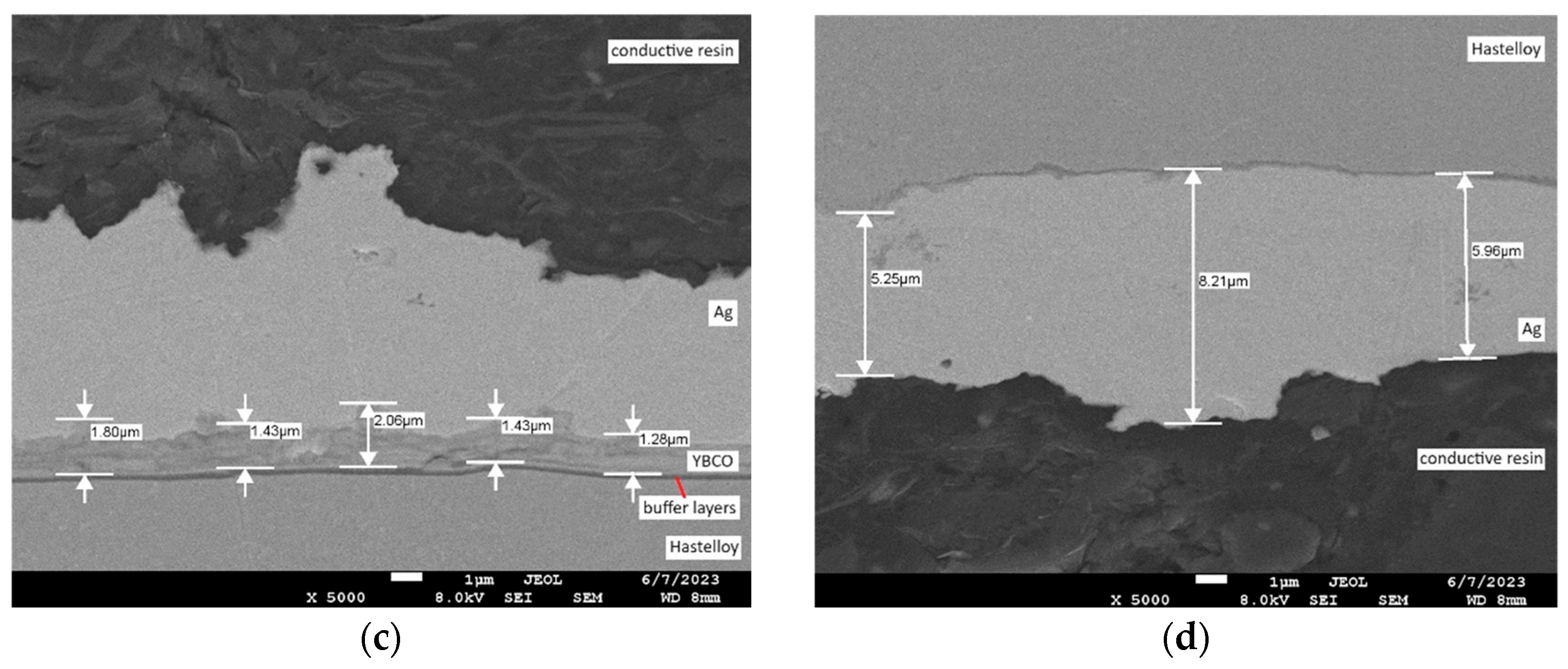

5.3. Measuring the Thickness of HTS Tape Layers

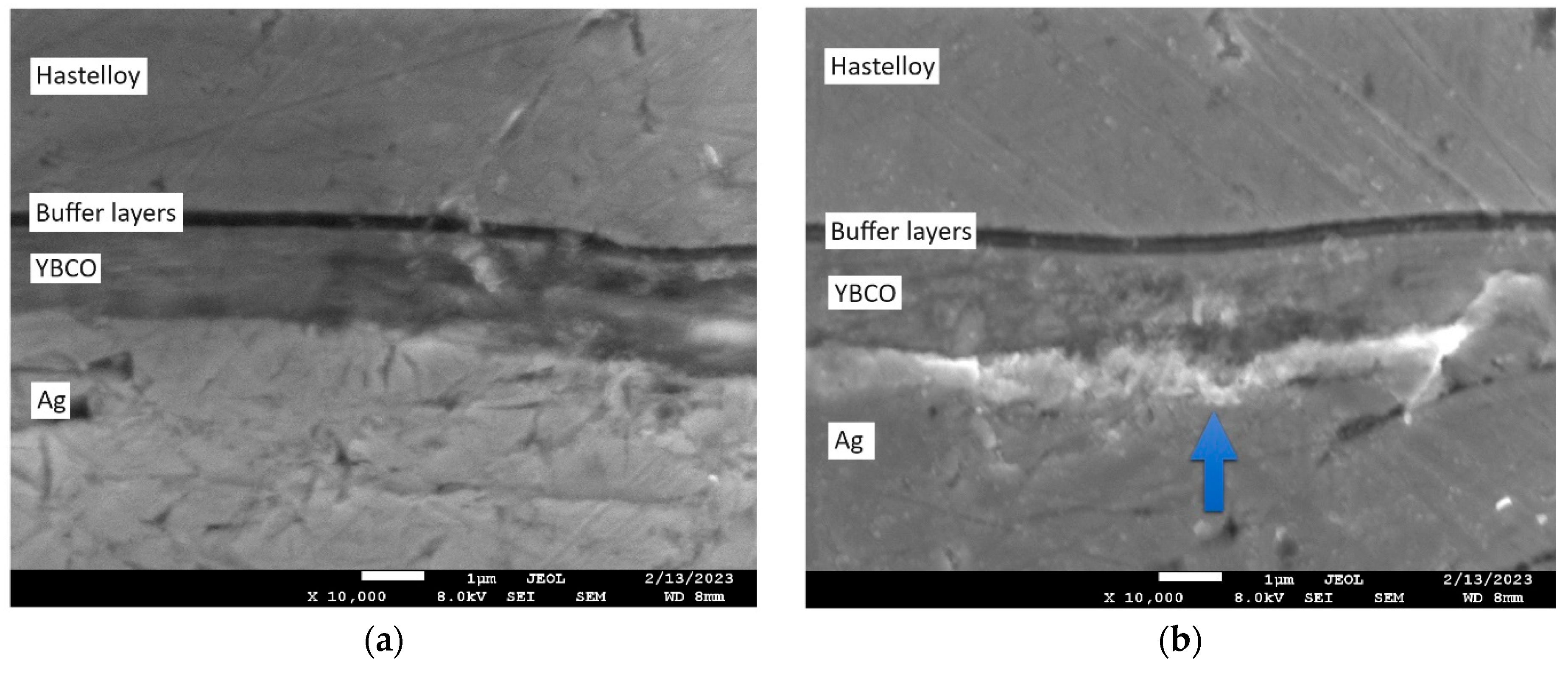

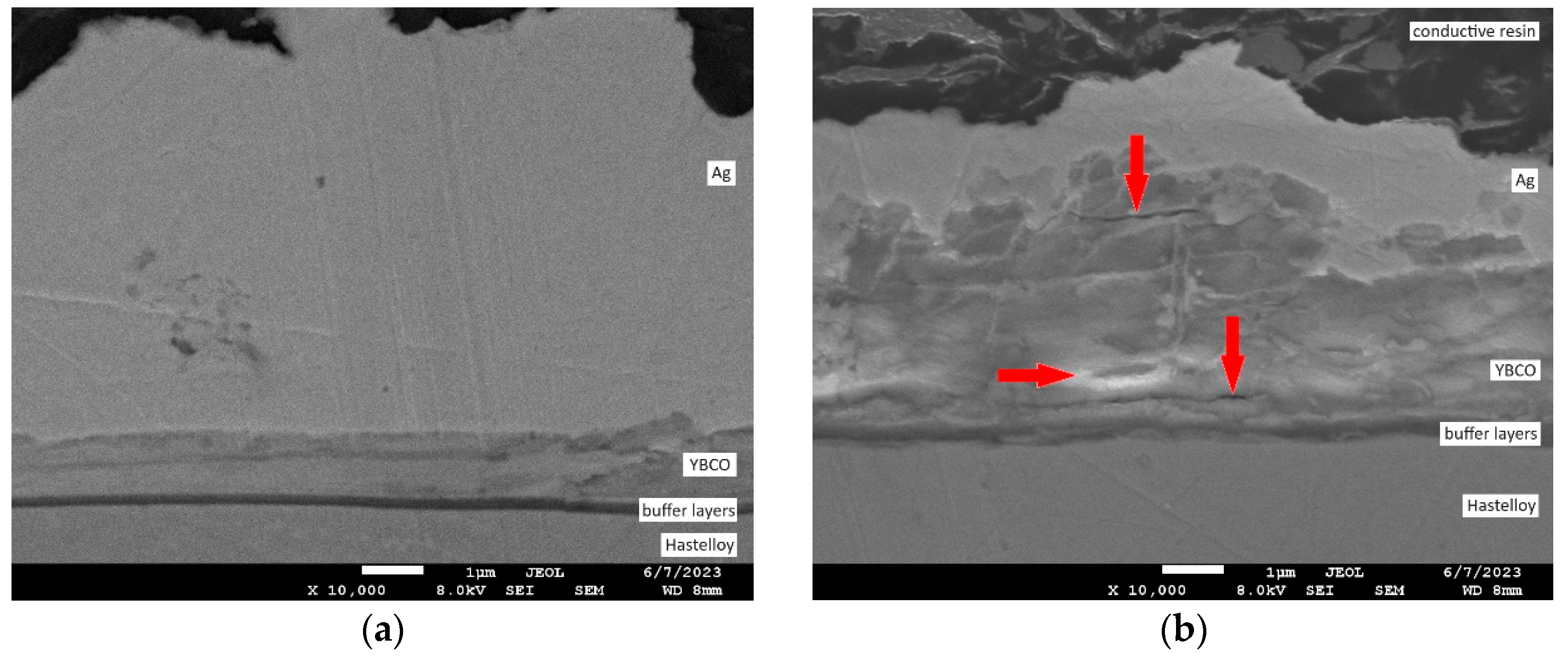

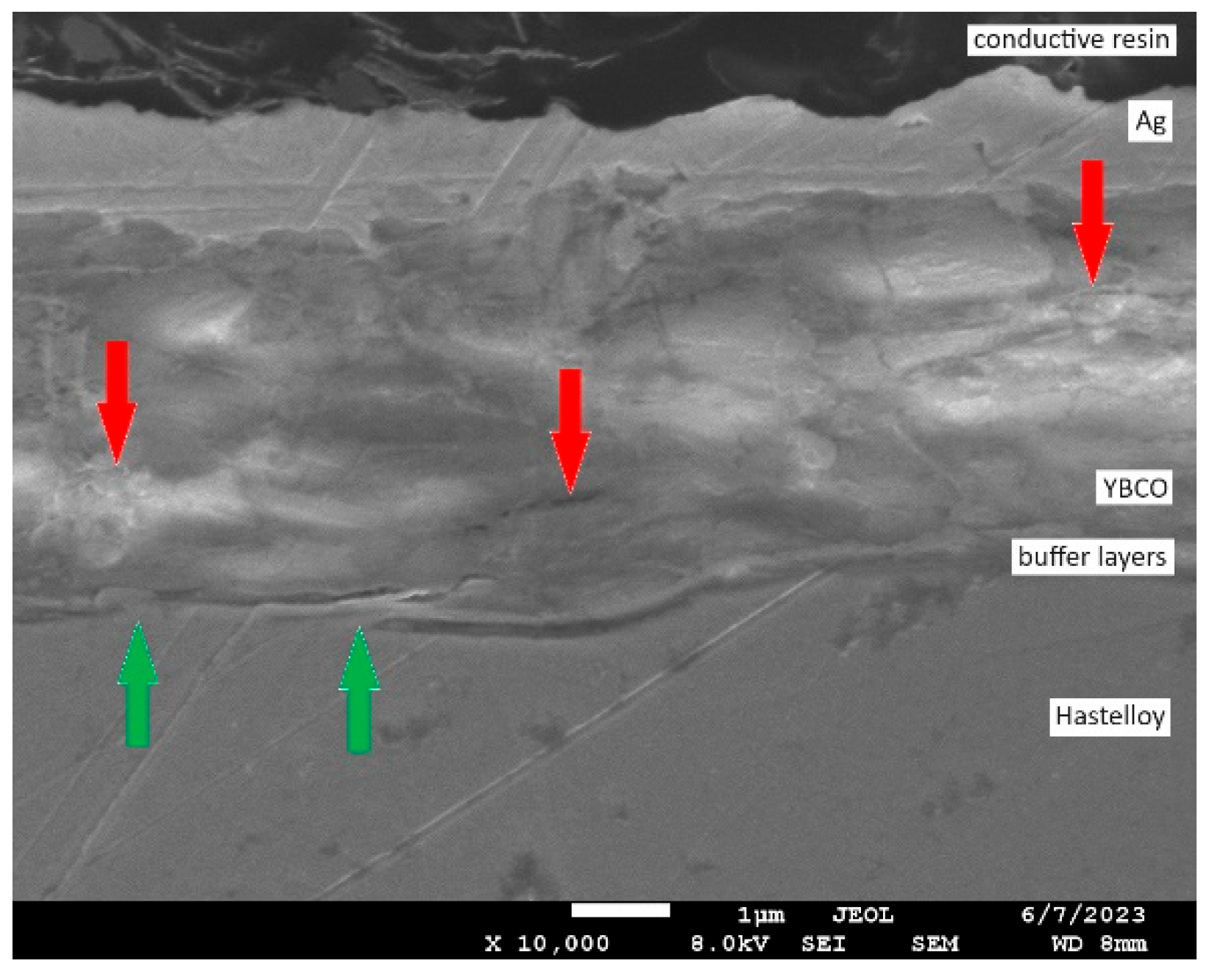

5.4. Changes to HTS Tape Images

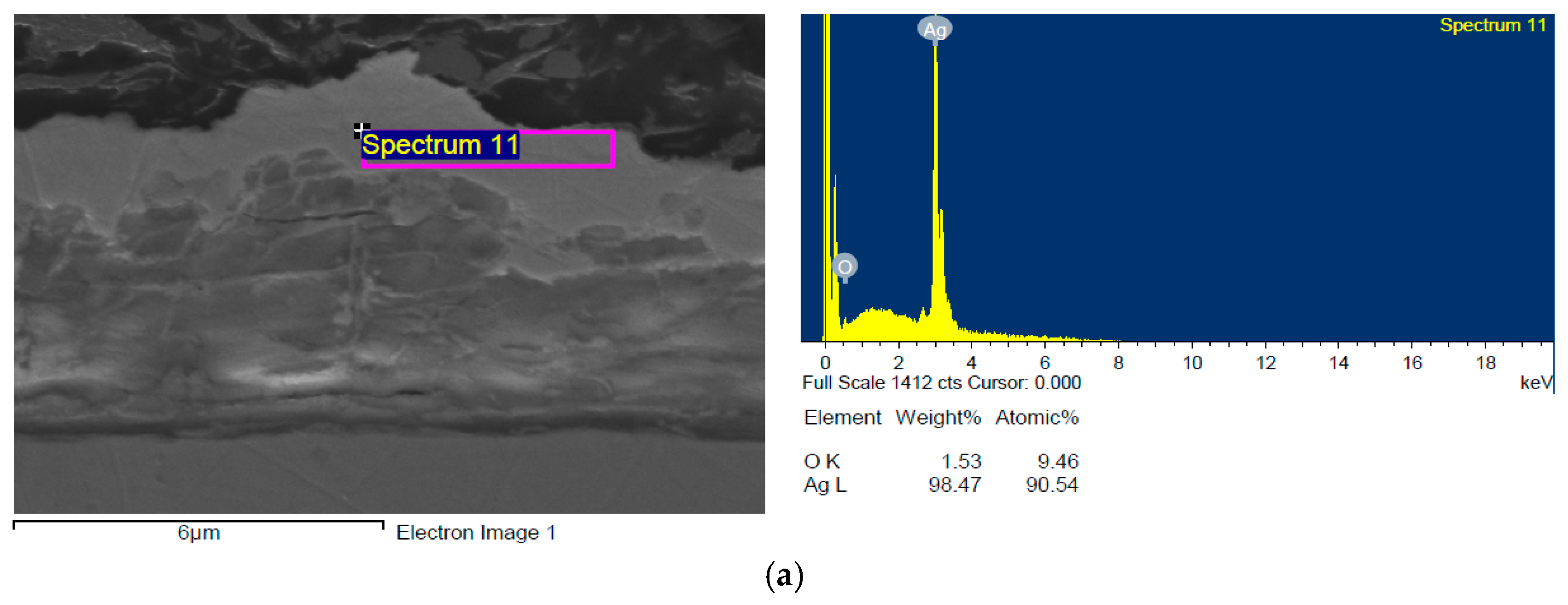

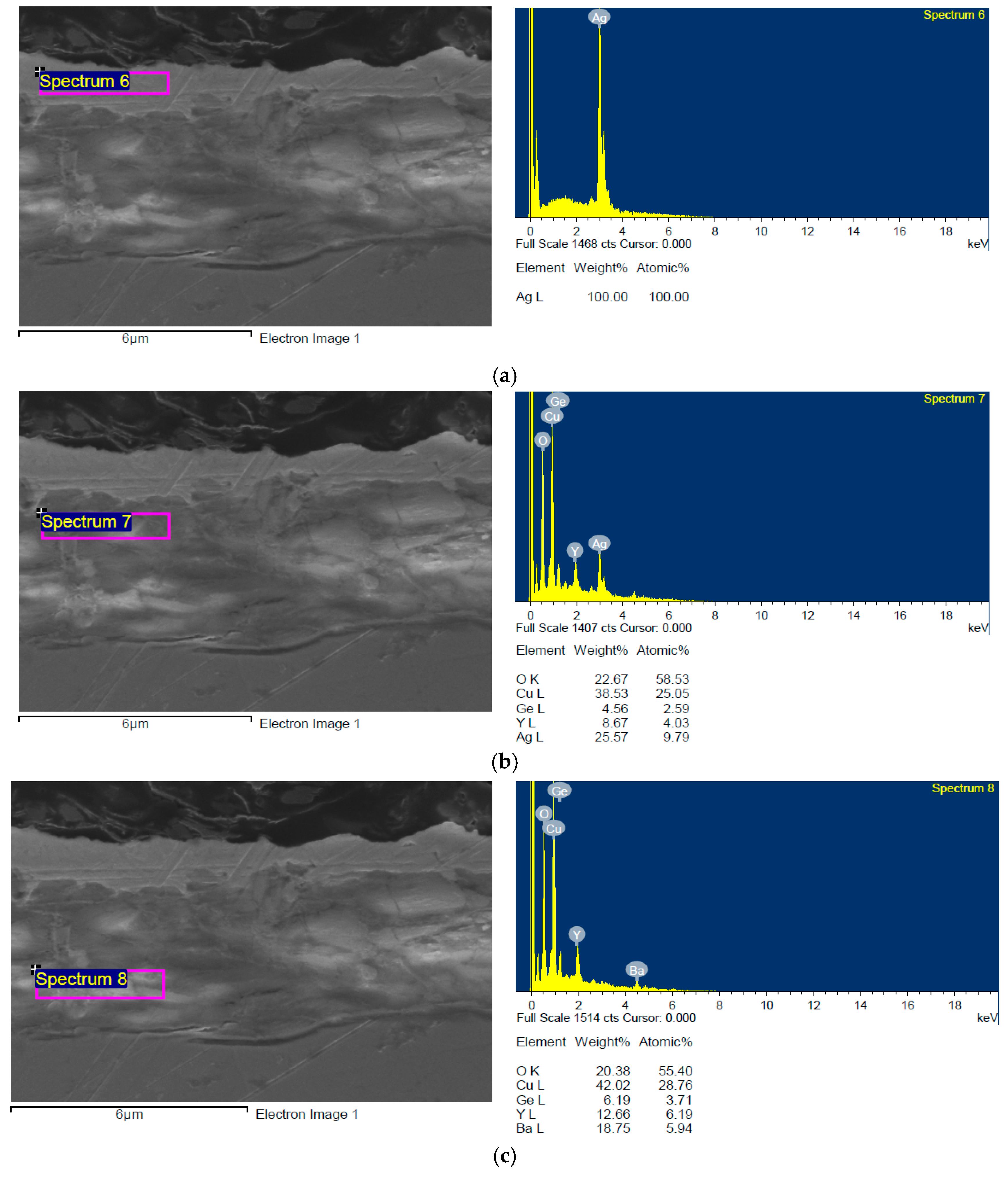

5.5. Chemical Composition Analysis of the SF12100-CF Tape (4 μm Ag)—the Control Sample

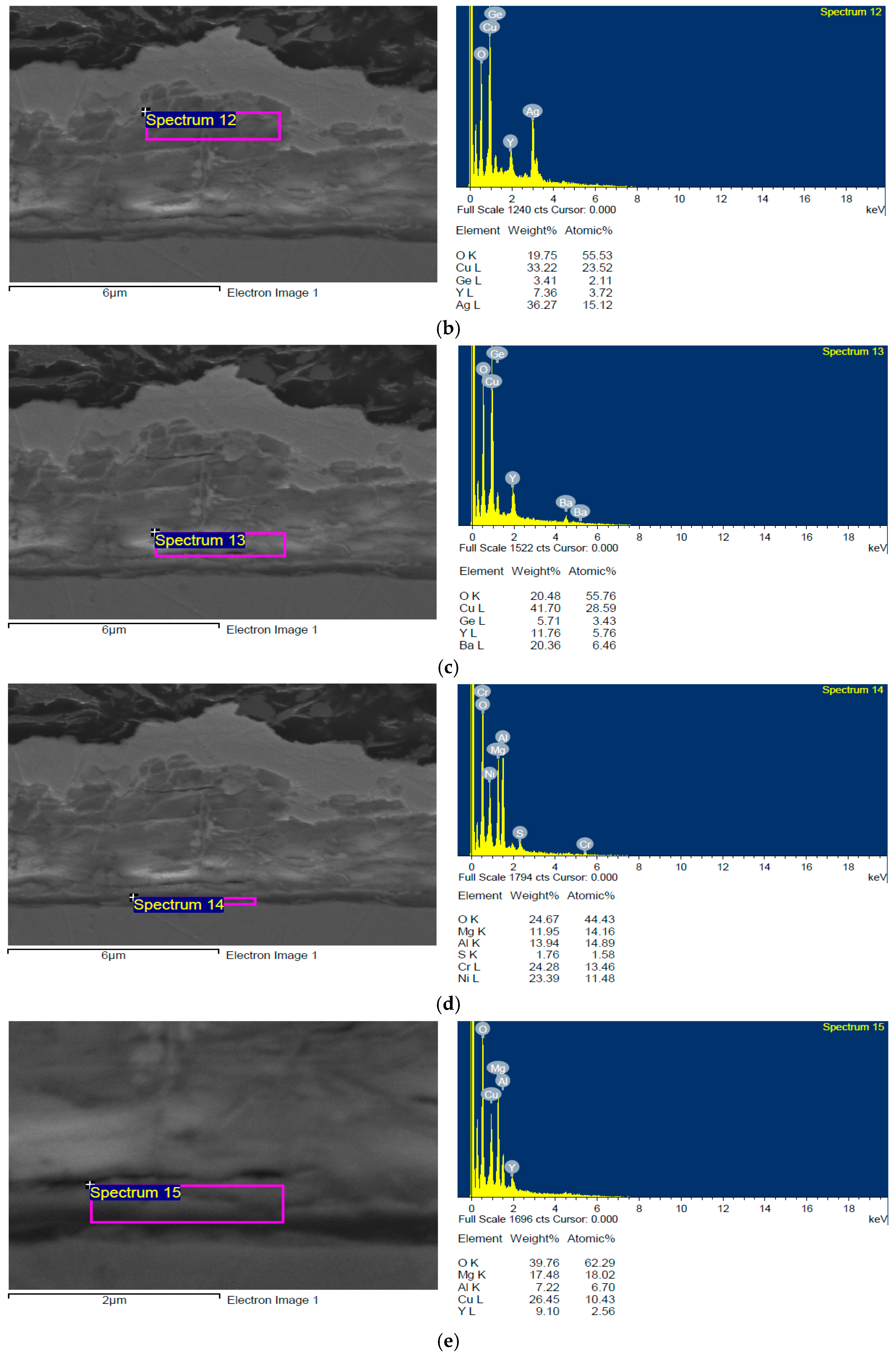

5.6. Analysis of the Chemical Composition of the SF12100-CF Tape (4 μm Ag)—the Sample with Reduced Critical Current Value

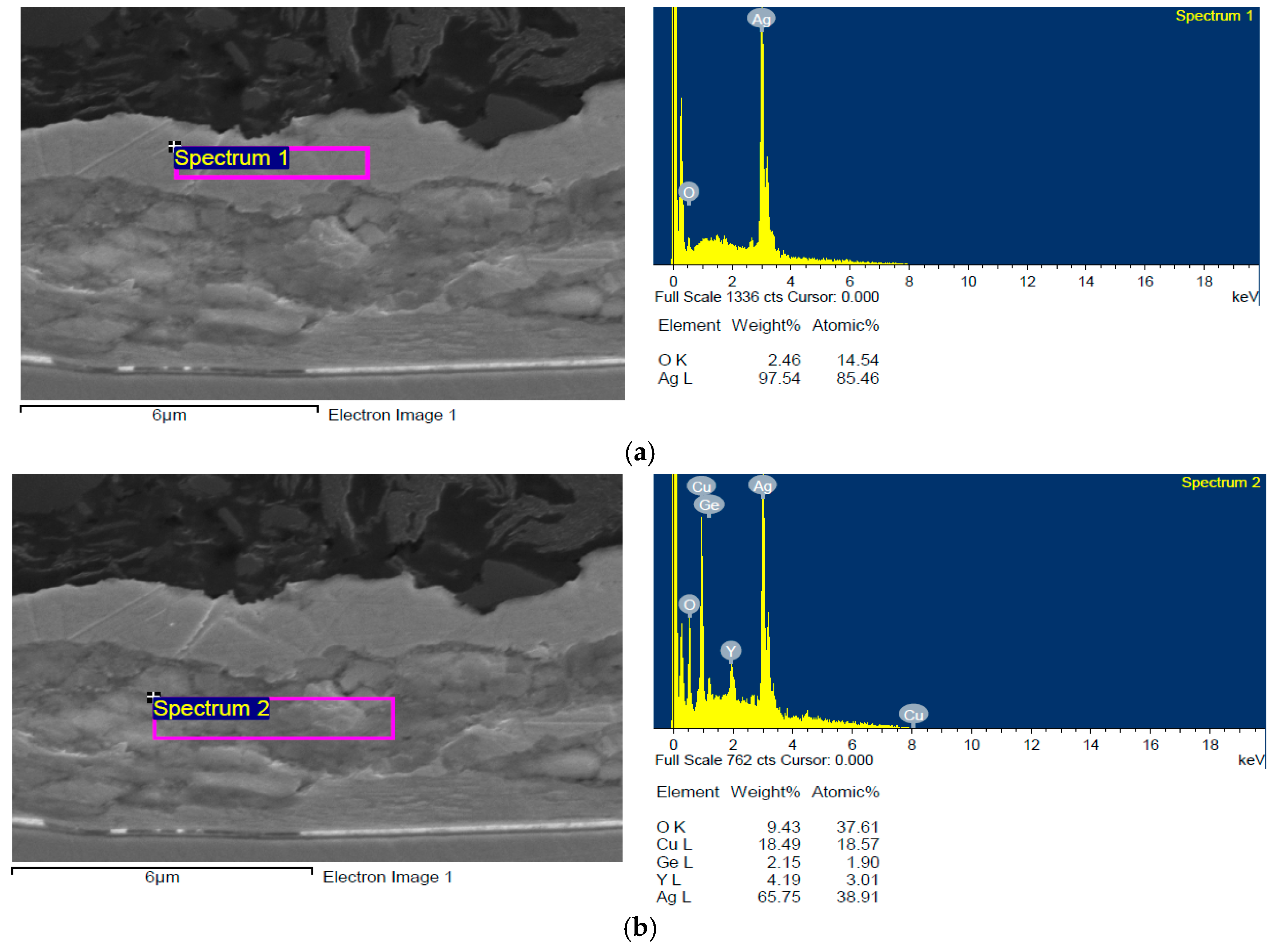

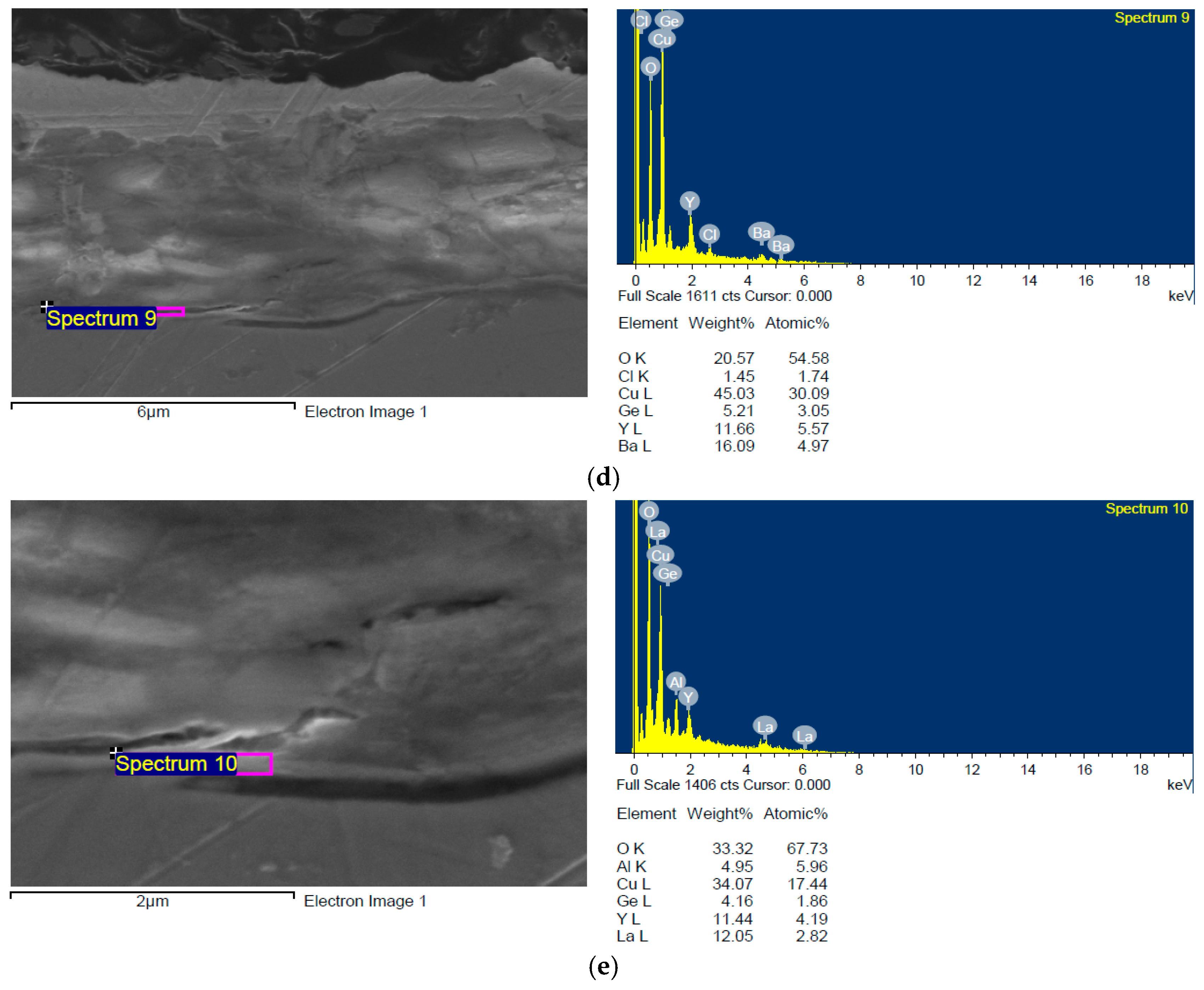

5.7. Analysis of the Chemical Composition of the SF12100-CF Tape (2 μm Ag)—the Control Sample

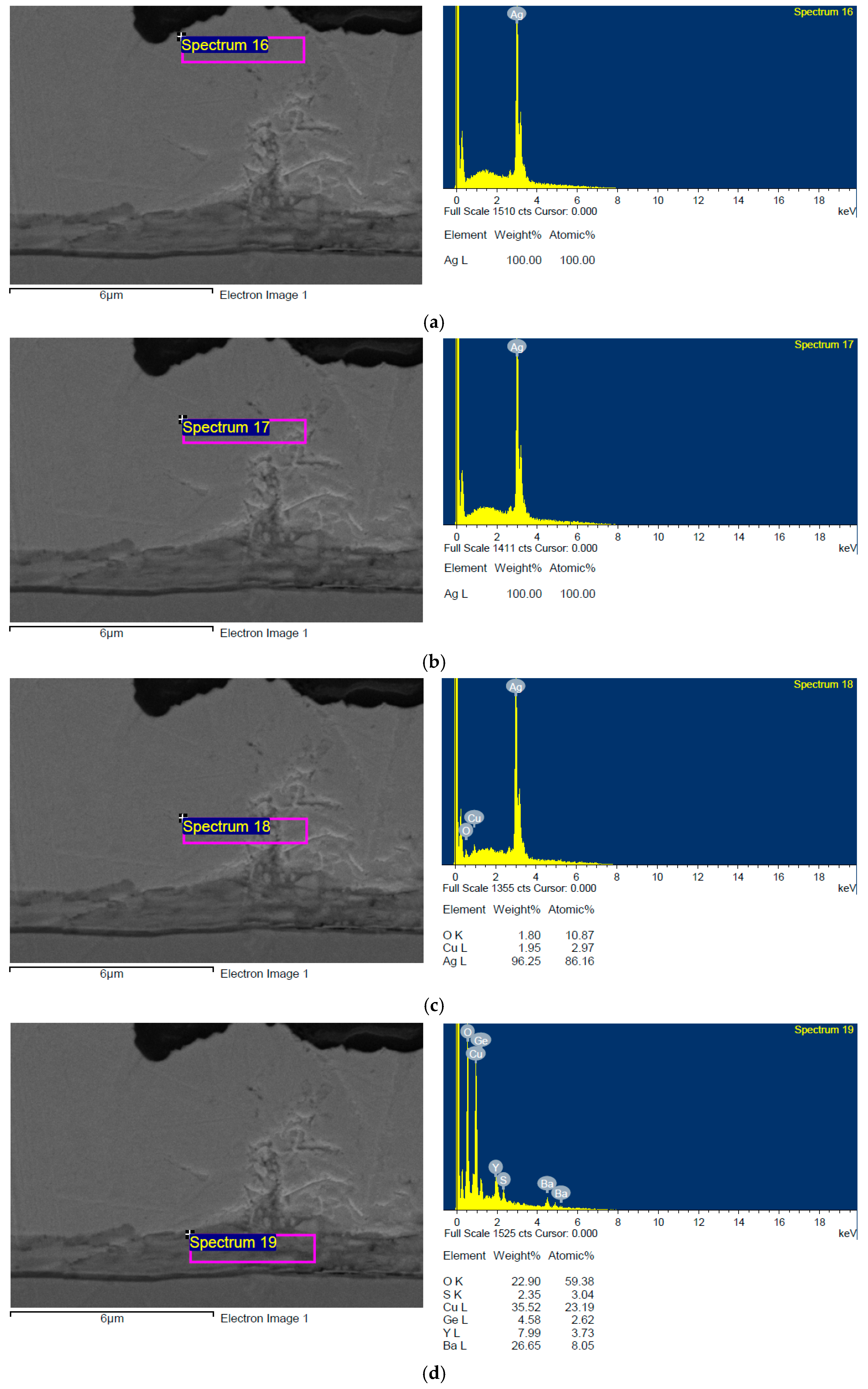

5.8. Chemical Composition Analysis of the SF12100-CF Tape (2 μm Ag)—the Sample with Reduced Critical Current Value

6. Discussion

7. Conclusions

- HTS tapes subjected to surge currents show defects in the form of deformations and cavities in the buffer layers, and cracks at the silver–YBCO interface and in the superconductor.

- As a result of the exposure of the HTS tapes to surge currents, diffusion processes may occur between the silver and YBCO layers, and the silver layer may oxidize.

- Changes in the superconducting layer may result in a reduction in the critical current value of the HTS tapes.

- In order to determine the quantitative diffusion changes in the individual layers of superconducting tapes subjected to the expected surge current Ic, it is necessary to perform tests on a large number of samples and to perform statistical analyses of the obtained results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yadav, S.; Bharati, K.; Tewari, V. Superconducting Fault Current Limiter—A Review. Int. J. Appl. Eng. Res. 2019, 14, 1–6. [Google Scholar]

- Rao, V.V.; Kar, S. Superconducting Fault Current Limiters—A Review. Indian J. Cryog. 2011, 36, 14. [Google Scholar]

- Nagarathna, M.C.; Murthy, H.V.; Shashikumar, R. A Review on Super Conducting Fault Curremt Limiter (SFCL) in Power System. Int. J. Eng. Res. Gen. Sci. 2015, 3, 485–489. [Google Scholar]

- Kar, S.; Rao, V. Step-by-step design of a single phase 3.3 kV/200 A resistive type superconducting fault current limiter (R-SFCL) and cryostat. Phys. C Supercond. Its Appl. 2018, 550, 107–116. [Google Scholar] [CrossRef]

- Zhang, Y.; Dougal, R.A. State of the Art of Fault Current Limiters and their Applications in Smart Grid. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Ko, S.-C.; Han, T.-H.; Lim, S.-H. Power consumption and cumulative energy of bridge type SFCL with simultaneous quench. Phys. C Supercond. Its Appl. 2022, 592, 1354001. [Google Scholar] [CrossRef]

- Lee, H.-Y.; Asif, M.; Park, K.-H.; Lee, B.-W. Assessment of appropriate SFCL type considering DC fault interruption in full bridge modular multilevel converter HVDC system. Phys. C Supercond. Its Appl. 2019, 563, 1–6. [Google Scholar] [CrossRef]

- Alam, M.S.; Abido, M.A.Y.; El-Amin, I. Fault Current Limiters in Power Systems: A Comprehensive Review. Energies 2018, 11, 1025. [Google Scholar] [CrossRef]

- Ganev, G.; Hinov, K.; Karadzhov, N.; Kostov, D. Solid-state switches for fault current limiter control. In Proceedings of the 2014 18th International Symposium on Electrical Apparatus and Technologies (SIELA), Bourgas, Bulgaria, 29–31 May 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Jo, H.-C.; Joo, S.-K.; Lee, K. Optimal Placement of Superconducting Fault Current Limiters (SFCLs) for Protection of an Electric Power System with Distributed Generations (DGs). IEEE Trans. Appl. Supercond. 2012, 23, 5600304. [Google Scholar] [CrossRef]

- SuperPower. SuperPower 2G HTS Wire Specification. Available online: https://studylib.net/doc/18207918/2g-hts-wire---superpower (accessed on 15 December 2023).

- Kozak, J.; Majka, M.; Kwoka, R. Studies of Superconducting Tapes (2G HTS) Without Stabilizer. Electrotech. Rev. 2017, 93, 185–188. [Google Scholar] [CrossRef]

- Xiong, X.; Lenseth, K.P.; Reeves, J.L.; Rar, A.; Qiao, Y.; Schmidt, R.M.; Chen, Y.; Li, Y.; Xie, Y.; Selvamanckam, V. High Throughput Processing of Long-Length IBA MgO and Epi-Buffer Templates at SuperPower. IEEE Trans. Appl. Supercond. 2007, 17, 3375–3378. [Google Scholar] [CrossRef]

- Hazelton, D.W. SuperPower 2G HTS Conductors. In Proceedings of the WAMHTS-1, Hamburg, Germany, 21 May 2014. [Google Scholar]

- Kim, J.H.; Park, M.; Ali, M.H.; Kim, A.R.; Lee, S.R.; Yoon, J.Y.; Cho, J.; Sim, K.D.; Kim, S.H.; Yu, I.K. A SFCL modelin and application with real HTS material connecting to real time simulator. Phys. C Supercond. 2008, 468, 2067–2071. [Google Scholar] [CrossRef]

- Suarez, P.; Alvarez, A.; Ceballos, J.M.; Perez, B. Loss and Transition Studies of Shunted Free-Stabilized YBCO Tape for SFCL Applications. IEEE Trans. Appl. Supercond. 2011, 21, 1267–1270. [Google Scholar] [CrossRef]

- Kwon, N.Y.; Kim, H.S.; Kim, K.L.; Yim, S.W.; Kim, H.-R.; Hyun, O.-B.; Kim, H.M.; Lee, H.G. Influence of stabilizer thickness on over-current test of YBCO-coated conductors. Supercond. Sci. Technol. 2009, 22, 045033. [Google Scholar] [CrossRef]

- Ishiyama, A.; Nishio, Y.; Ueda, H.; Kashima, N.; Mori, M.; Watanabe, T.; Nagaya, S.; Yagi, M.; Mukoyama, S.; Machi, T.; et al. Degradation Characteristics of YBCO-Coated Conductors Subjected to Overcurrent Pulse. IEEE Trans. Appl. Supercond. 2009, 19, 3483–3486. [Google Scholar] [CrossRef]

- Kozak, J.; Majka, M. Soldering Technology of HTS 2G Tapes in Windings of Superconducting Device. Electrotech. Rev. 2014, R. 90. nr 3/2014. [Google Scholar] [CrossRef]

- Amaro, N.; Souc, J.; Vojenciak, M.; Pina, J.M.; Martins, J.; Ceballos, J.M.; Gomory, F. AC Losses and Material Degradation Effects in a Superconducting Tape for SMES Applications. In Proceedings of the 5th IFIP WG 5.5/SOCOLNET Doctoral Conference on Computing, Electrical and Industrial Systems, DoCEIS 2014, Costa de Caparica, Portugal, 7–9 April 2014. [Google Scholar] [CrossRef]

- Yazaki, S.; Karasawa, A.; Kotoyori, T.; Ishiyama, A.; Miyahara, N. Critical Current Degradation in High-Temperature Superconducting Tapes Caused by Temperature Rise. IEEE Trans. Appl. Supercond. 2013, 23, 4602304. [Google Scholar] [CrossRef]

- Chen, G.; Ren, L.; Xu, Y.; Feng, T.; Liang, S.; Li, X.; Li, J.; Shi, J.; Tang, Y. Critical Current Degradation Behavior of Coated Conductor Subjected to Repeat Overcurrent. IEEE Trans. Appl. Supercond. 2020, 30, 6600406. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, G.; Feng, T.; Cai, Z.; Yue, Y.; Ren, L.; Liang, S.; Li, J.; Shi, J.; Tang, Y. Experimental Study on the Performance Change of YBCO Tapes Under Repeated Overcurrent. IEEE Trans. Appl. Supercond. 2020, 30, 8000310. [Google Scholar] [CrossRef]

- Hajdasz, S.; Kempski, A.; Solak, K.; Marc, M.; Rusinski, J.; Szczesniak, P. Critical Current Degradation in HTS Tapes for Superconducting Fault Current Degradation under Repeated Overcurrent. Appl. Sci. 2023, 13, 4323. [Google Scholar] [CrossRef]

- Surdacki, P. The Quench Parameter Analysis of YBCO and MgB2 Superconducting Wires. Electrotech. Rev. 2014, R. 90, nr 2/2014. [Google Scholar] [CrossRef]

- Available online: https://www.superpower-inc.com/specification.aspx (accessed on 15 December 2023).

- Hajdasz, S.; Kempski, A.; Rusinski, J. Study of HTS 2G Superconductor Tapes Properties for Applications in SFCL. In Proceedings of the 2018 Innovative Materials and Technologies in Electrical Engineering—i-MITEL, Sulecin, Poland, 18–20 April 2018. [Google Scholar]

- Hajdasz, S.; Rusinski, J.; Kempski, A.; Brusilowicz, B. Operational Degradation of HTS Tape Parameters Used in SFCL and Its Impact on the Coordination of Power System Protection. In Proceedings of the 2019 Modern Electric Power System—MEPS’19, Wroclaw, Poland, 9–12 September 2019. [Google Scholar]

- Kim, A.-R.; Lim, Z.-S.; Kim, T.; Yun, K.; Yoon, S.; Park, M.; Yu, I.-K. Development of Critical Current Measurement System of HTS Tape Using Pulsed Current. IEEE Trans. Appl. Supercond. 2016, 26, 9001504. [Google Scholar] [CrossRef]

| Buffer Layers | Layer Thickness |

|---|---|

| alumina | ~80 nm |

| yttria YSZ | ~7 nm |

| IBAD MgO | ~10 nm |

| homo epi MgO | ~20 nm |

| LMO (LaMnO3) | ~30 nm |

| HTS Tape | SF12100-CF | SF12100-CF |

|---|---|---|

| silver layer thickness | 2 μm | 4 μm |

| width | 12 mm | 12 mm |

| thickness | 0.105 mm | 0.105 mm |

| substrate thickness (Hastelloy) | 0.1 mm | 0.1 mm |

| minimum critical current IC (77K) | 281 A | 312 A |

| SF12100-CF | Estimated Short-Circuit Current ISC (A) | Surge Current Imax (A) | Energy Released on the HTS Tape During the Surge E (J) | Voltage Drop Across the Sample Udrop (V) | Initial Critical Current IC(0) (A) | Critical Current After 25 Transitions IC(25) (A) | Percentage Change in the Ic Value After 25 Transitions (%) |

|---|---|---|---|---|---|---|---|

| 4 µm Ag | 950 | 617 | 146 | 0.61 | 318 | 276 | 13.21 |

| 2 µm Ag | 950 | 535 | 119 | 0.65 | 294 | 274 | 6.80 |

| Layer: | Average Thickness of the HTS SF12100-CF Tape Layers | |||

|---|---|---|---|---|

| 4 μm Ag (Control Sample) | 4 μm Ag | 2 μm Ag (Control Sample) | 2 μm Ag | |

| silver (top of the tape) | 6.48 μm | 2.02 μm | 2.33 μm | 1.00 μm |

| YBCO | 1.60 μm | 3.36 μm | 2.67 μm | 4.83 μm |

| Hastelloy | 107 μm | 112 μm | 107 μm | 109 μm |

| silver (bottom of the tape) | 6.74 μm | 2.21 μm | 1.38 μm | 0.98 μm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hajdasz, S.; Kempski, A.; Arkusz, K.; Michalski, M.; Szczesniak, P. The Identification of Microstructural Changes in High-Temperature Superconducting Tapes for Superconducting Fault Current Limiters. Appl. Sci. 2024, 14, 9520. https://doi.org/10.3390/app14209520

Hajdasz S, Kempski A, Arkusz K, Michalski M, Szczesniak P. The Identification of Microstructural Changes in High-Temperature Superconducting Tapes for Superconducting Fault Current Limiters. Applied Sciences. 2024; 14(20):9520. https://doi.org/10.3390/app14209520

Chicago/Turabian StyleHajdasz, Sylwia, Adam Kempski, Katarzyna Arkusz, Mariusz Michalski, and Paweł Szczesniak. 2024. "The Identification of Microstructural Changes in High-Temperature Superconducting Tapes for Superconducting Fault Current Limiters" Applied Sciences 14, no. 20: 9520. https://doi.org/10.3390/app14209520

APA StyleHajdasz, S., Kempski, A., Arkusz, K., Michalski, M., & Szczesniak, P. (2024). The Identification of Microstructural Changes in High-Temperature Superconducting Tapes for Superconducting Fault Current Limiters. Applied Sciences, 14(20), 9520. https://doi.org/10.3390/app14209520