Analysis and Optimization of the Effectiveness of Production Safety Standardization Construction Based on Set-Pair Analysis

Abstract

1. Introduction

2. Research Subjects and Methods

2.1. Selection of Research Subjects

2.2. Set-Pair Analysis (SPA) Theory

- μ is the degree of association;

- N is the total number of features in the two sets;

- S is the number of common features in the two sets;

- P is the number of similar features in the two sets;

- F is the number of opposing features in the two sets;

- i is the coefficient of the degree of dissimilarity, ranging from −1 to 1;

- j is the coefficient of opposition, with a constant value of −1.

2.3. Potential

2.3.1. Set-Pair Potential

2.3.2. Pessimistic Potential

2.3.3. Optimistic Potential

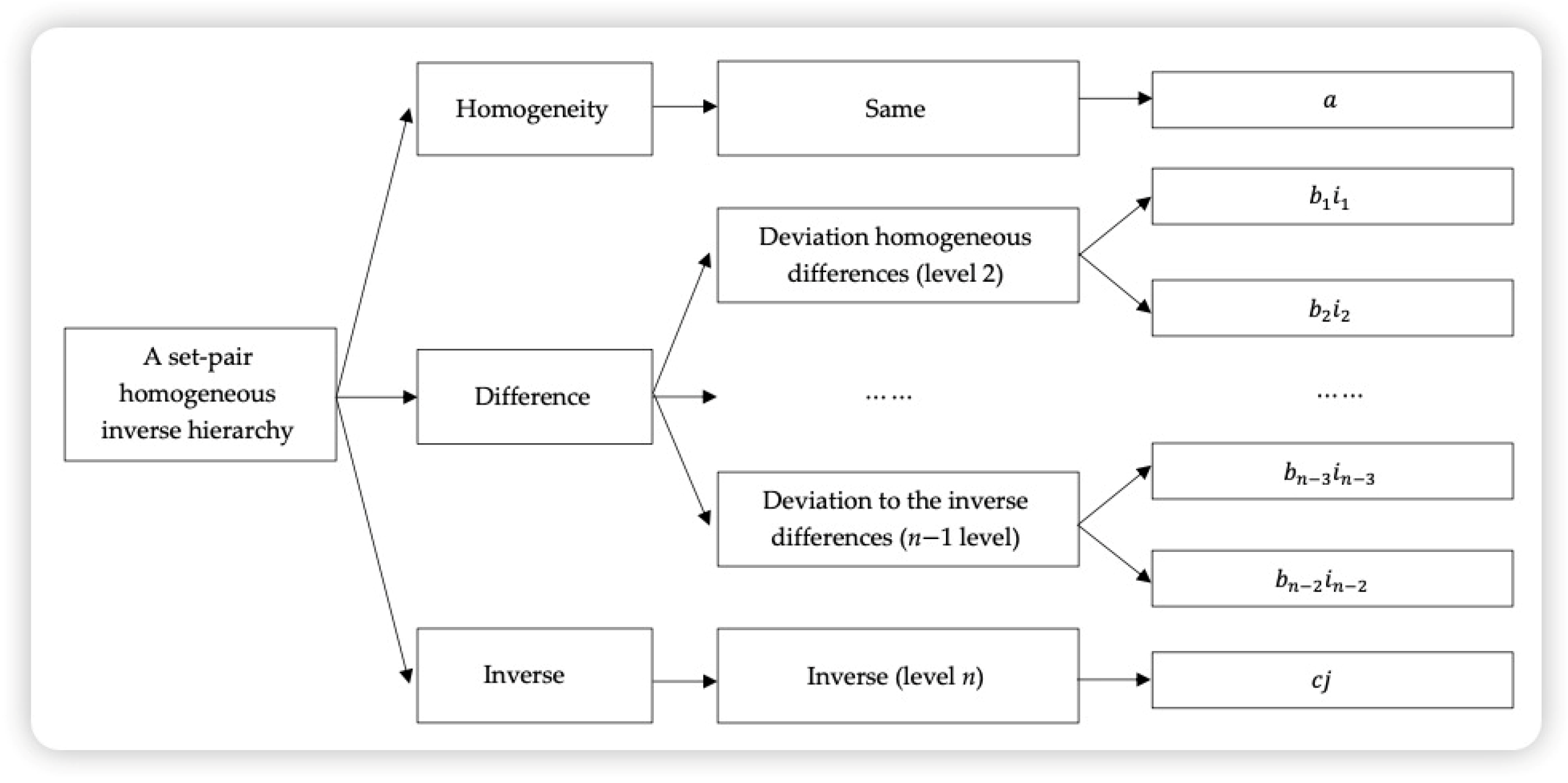

2.4. Construction of the Linkage Degree Equation of the Set-Pair Homogeneous Inverse Hierarchy Method

- μm is the linkage degree of the mth enterprise;

- Wk is the weight of the kth security standard evaluation element;

- μmk is the linkage degree of the security standard evaluation element k of the mth enterprise.

3. SPA-Based Analysis of Safety Standard Assessments in Industrial and Trade Enterprises

3.1. Comprehensive Analysis of Standardized Production Safety Assessment Scores

3.2. SPA Analysis of Safety Standard Assessment Results of Enterprises in the Same Industry

3.3. SPA Analysis of Safety Standard Assessment Results in Different Industries

4. Results

4.1. The Model Based on Quintic Linking Number Calculus Is Constructed Rationally and Efficiently

4.2. Breaking the Standard of Assessing Results Based on Scores

4.3. The Weighting of Evaluation Elements Determines the Development Trend of Enterprise Security

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISO 9001; QMS Manual. Eric Sutherland T/A Trog Associates: London, UK, 2007.

- Tong, R.P.; Fan, B.Q.; Li, Z.Q.; Wang, L.H.; Zhang, J.B. Progress of work safety standardization in China: A case study of hundred local standards in Beijing. Process Saf. Prog. 2020, 40, e12187. [Google Scholar] [CrossRef]

- Wang, Z.Y. China’s industrial and trade industry enterprise safety production standardization construction work thinking. China Occup. Saf. Health 2016, 11, 38–39. [Google Scholar]

- Li, Y.H.; Xue, Y.G. Reflections on the Standardized Construction Work of Safety Production in China's Industry and Trade Enterprises. Manag. Technol. SME 2021, 2, 134–135. [Google Scholar]

- Zhang, E.B.; Zhang, Z.; Xia, Y.; Hu, B.; Li, J.; Geng, T.; Wang, B. Construction of Safety Production Standardization Information System of Ninggang. Highlights Sci. Eng. Technol. 2022, 23, 285–290. [Google Scholar] [CrossRef]

- Bensonch, C.; Argyropoulos, C.D.; Dimopoulos, C.; Varianou Mikellidou, C.; Boustras, C. Analysis of safety climate elements and safety compliance relationships in the oil and gas industry. Saf. Sci. 2022, 151, 105744. [Google Scholar] [CrossRef]

- Circular of the Office of the Safety Commission of the State Council on the Issuance of the Implementation Guidelines for the Construction of Work Safety Standardization and the Construction of the System for the Investigation and Management of Hidden Trouble in Work Safety Accidents for Enterprises in the Industry and Trade Sectors. Bull. State Adm. Work Saf. State Coal Mine Saf. Superv. Bur. 2012, 8, 42–43.

- Zhu, B.; Chen, L.P.; Yan, Q.Z.; Zheng, H.T.; Ke, Z.Z.; Chen, H.L. Application and Problem Analysis of Safety Production Standardization in Management of Small and Medium-sized Enterprises. China Stand. 2024, 13, 166–170. [Google Scholar]

- Yan, F.; Xu, K. A set pair analysis based layer of protection analysis and its application in quantitative risk assessment. J. Loss Prev. Process Ind. 2018, 55, 313–319. [Google Scholar] [CrossRef]

- Zhao, K.Q. Set-pair analysis and its preliminary application. Nat. Explor. 1994, 1, 67–72. [Google Scholar]

- Wang, R.D.; Pan, W.J.; Chen, X.G.; Bian, X.F. Risk Assessment of Apron Control Operation in Entropy Weight Extension Model. Sci. Technol. Eng. 2020, 20, 12636–12643. [Google Scholar]

- Wang, Y.; Jing, H.; Yu, L.; Su, H.; Luo, N. Set Pair Analysis for Risk Assessment of Water Inrush in Karst Tunnels. Bull. Eng. Geol. Environ. 2016, 76, 1199–1207. [Google Scholar] [CrossRef]

- He, S.Y.; Fan, S.Y.; Ye, S.L.; Zhao, L.; Zhang, Y.Q. Influence Analysis of Soft Soil Foundation Pit Construction on Surrounding Environment Based on Set Pair Analysis-Variable Fuzzy Set Coupling Model. Sci. Technol. Eng. 2021, 21, 12655–12664. [Google Scholar]

- Yang, D.M.; Lian, J.J.; Zhao, X. Evaluation of safe winter operation of water transmission projects in cold regions based on set-pair analysis. J. Saf. Environ. 2023, 23, 3018–3028. [Google Scholar]

- Liu, S.Y.; Wang, J.; He, F.L. Optimization research of coal mine safety quality standardization based on four-element connection number model. J. Saf. Sci. Technol. 2012, 8, 32–37. [Google Scholar]

- He, F.L.; Hu, H.H.; Wang, J.; Wei, Y.X. Evaluating the Depth of Metallurgical Enterprises Safety Quality Standardization Based on SPA. China Saf. Sci. J. 2012, 22, 110–117. [Google Scholar]

- Li, S.D.; Xu, K.L.; Zhang, J.H. Research and Application of Set Pair Situation in the Set Pair Analysis. Ind. Saf. Environ. 2009, 35, 8–9. [Google Scholar]

- Zhang, Y.; Wang, M.W.; Chen, G.Y. Coupled model of SPA and PTFN for pre-evaluation of coal mine safety. J. Hefei Univ. Technol. 2011, 34, 98–101. [Google Scholar]

- Pan, Q.W.; Wu, K.Y.; Jin, J.L.; Wang, M.W. A set-pair analysis method for water resource renewability assessment. Hydropower Energy Sci. 2009, 27, 24–26. [Google Scholar]

- Wang, X.; Peng, X.H. The Methods to Fetch I in Difference Degree Coefficient of Set Pair Analysis and its Applications. J. Tianjin Univ. Light Ind. 2002, 4, 56–58. [Google Scholar]

- Zhou, J.H.; Xu, K.L.; Chen, Z.Y. On the Dynamic Assessment of System Safety. J. Northeast. Univ. (Nat. Sci.) 2008, 3, 416–419. [Google Scholar]

| No. | Rating | Name of the Set of Potentials | a, b1, b2, b3, c Interrelationships | Meaning |

|---|---|---|---|---|

| I | homogeneous potential | quasi-homogeneous potential | Homogeneous potential is completely determined. | |

| II | strong homogeneous potential | Homogeneous potential is predominant. | ||

| III | weak homogeneous potential | Homogeneous potential exists but is relatively weak. | ||

| IV | slight homogeneous potential | Homogeneous potential exists but is weaker. | ||

| I | equilibrium potential | slight equilibrium potential | Equilibrium potential not dominant, uncertainty trend dominant. | |

| II | weak equilibrium potential | Uncertainty evident, equilibrium potential weaker. | ||

| III | strong equilibrium potential | Equilibrium potential dominates. | ||

| IV | quasi-equilibrium potential | Homogeneous potential and opposite potential are enemies. | ||

| I | Opposite potential | quasi-opposite potential | Opposite potential completely determined. | |

| II | strong opposite potential | Opposite potential dominates. | ||

| III | weak opposite potential | Opposite potential exists but is weaker. | ||

| IV | slight opposite potential | Opposite potential exists but is weaker. | ||

| uncertain homogeneous potential | Uncertainty is evident, homogeneous potential exists. | |||

| Uncertainty of uncertainty | Uncertainty dominates. | |||

| Rating | Secure | General Security | Hazard |

|---|---|---|---|

| degree of linkage μ | [0.33,1] | [−0.33,0.33] | [−0.33,−1] |

| Linkage Degree μmk | |

|---|---|

| Thirteen Elements of Work Safety Standardization | Average Score | Thirteen Elements of Work Safety Standardization | Average Score |

|---|---|---|---|

| 1. Objectives | 87.67% | 8. Identification and management of hidden dangers | 76.55% |

| 2. Organizational structure and responsibilities | 53.33% | 9. Monitoring of major sources of danger | 60.48% |

| 3. Inputs to production safety | 69.19% | 10. Occupational health | 76.61% |

| 4. Laws, regulations, and safety management | 54.33% | 11. Emergency relief | 68.97% |

| 5. Education and training | 58.53% | 12. Accident reporting, investigation, and handling | 80.00% |

| 6. Production equipment and facilities | 59.15% | 13. Continuous improvement | 75.41% |

| 7. Operational safety | 62.26% | Composite score rate for each element | 67.88% |

| Enterprise | Element 1 | Element 2 | Element 3 | Element 4 | Element 5 | Element 6 | Element 7 | Element 8 | Element 9 | Element 10 | Element 11 | Element 12 | Element 13 | Overall Score |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 90.00 | 53.33 | 70.00 | 53.00 | 58.00 | 57.89 | 69.32 | 82.86 | 65.38 | 75.00 | 73.08 | 80.00 | 77.78 | 66.01 |

| II | 90.00 | 53.33 | 70.00 | 53.00 | 58.00 | 57.89 | 68.92 | 77.14 | 65.38 | 75.00 | 73.08 | 80.00 | 77.78 | 65.25 |

| III | 90.00 | 53.33 | 70.00 | 53.00 | 58.00 | 57.89 | 71.74 | 62.86 | 65.38 | 75.00 | 73.08 | 80.00 | 77.78 | 64.79 |

| IV | 55.00 | 36.67 | 52.78 | 65.00 | 54.00 | 64.42 | 65.38 | 71.25 | 28.57 | 73.17 | 42.31 | 80.00 | 60.00 | 61.93 |

| V | 90.00 | 53.33 | 70.00 | 53.00 | 58.00 | 57.89 | 46.53 | 82.86 | 65.38 | 75.00 | 73.08 | 80.00 | 77.78 | 61.33 |

| Element | Element | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| μI11 | 1 | 0 | 0 | 0 | 0 | μI18 | 0 | 131/500 | 1/2 | 119/500 | 0 |

| μI12 | 0 | 0 | 0 | 0 | 1 | μI19 | 0 | 0 | 59/329 | 1/2 | 135/421 |

| μI13 | 0 | 0 | 1/3 | 1/2 | 1/6 | μI10 | 0 | 0 | 1/2 | 1/2 | 0 |

| μI14 | 0 | 0 | 0 | 0 | 1 | μI11 | 0 | 0 | 109/250 | 1/2 | 8/125 |

| μI15 | 0 | 0 | 0 | 0 | 1 | μI12 | 0 | 1/6 | 1/2 | 1/3 | 0 |

| μI16 | 0 | 0 | 0 | 0 | 1 | μI13 | 0 | 24/259 | 1/2 | 200/491 | 0 |

| μI17 | 0 | 0 | 233/750 | 1/2 | 71/375 | — | — | — | — | — | — |

| Enterprise | Linkage Degree | Set-Pair Potential | Level of Set-Pairing Potential | Pessimistic Potential | Optimistic Potential |

|---|---|---|---|---|---|

| I | −0.637 | 0.039 | weak opposition potential | 0.029 | 0.393 |

| II | −0.670 | 0.039 | weak opposition potential | 0.028 | 0.391 |

| III | −0.692 | 0.038 | weak opposition potential | 0.028 | 0.399 |

| IV | −0.621 | 0.000 | weak opposition potential | 0.000 | 0.373 |

| V | −0.759 | 0.029 | weak opposition potential | 0.025 | 0.192 |

| Secondary Elements | Achievement of Standards | Company I and Company II | Company III |

|---|---|---|---|

| 7.1 Production site management and production process control | Identify, assess, and grade the risks and hidden dangers that exist at the production site and in the production process and environment, and formulate appropriate control measures. | Failure to carry out risk identification of plant layout and earth moving operations; inaccurate risk assessment of storage and use of flammable and explosive chemicals. | Failure to identify the risks of spray booth equipment and facilities, confined space operations, and spray-painting operations. |

| Provide emergency lighting; emergency lighting should be able to start automatically when the normal lighting is interrupted. | —— | The office building is not equipped with emergency evacuation lighting signs; emergency lights cannot be fully illuminated. | |

| Establish a management system for “three violations”, and clarify the responsibilities, methods, records, assessment, and other matters of monitoring. | Lack of records of inspection and assessment of “three violations” behaviors. | Lack of records of inspection and assessment of “three violations” behaviors. | |

| Establish a safety management system for hazardous operations, specifying the responsible departments, personnel, scope of authorization, approval procedures, and authorization issuers. | Failure to formulate the Safety Management System for Cross-over Operations; the Approval System for Dangerous Operations does not cover the approval of operations in confined spaces. | The Management System for Pyrotechnic Operations and the Management System for Restricted Spaces have not been adjusted to the latest norms. | |

| The safety management of hazardous operations is carried out by means of an operating license, which should contain an analysis of hazardous elements and safety measures. | Temporary electricity operation ticket is not filled in the analysis of hazardous elements, no signature of the guardian; temporary electricity, fire operation, work tickets do not contain hazardous elements identification, not set up the information column of the guardian | Inadequate identification of hazards in the restricted space operation ticket, no time filled in the signatures of all levels of personnel, no gas analysis and detection values, no completion acceptance | |

| 7.2 Operational behaviors management | Identify human unsafe behaviors during production operations and develop appropriate control measures. | Failure to carry out risk identification for welding operations and refrigeration operations. | Failure to carry out risk identification for welding operations. |

| A permit and work ticket system is in place for hazardous operations. | Fire operation ticket without construction acceptance; results of combustible gas testing not reported. | —— | |

| Employees shall be equipped with labor protective equipment that meets national or industry standards appropriate to their jobs and supervised and educated to wear and use them in accordance with their rules of use. | Labor protective equipment was not classified and managed and the quantities received did not correspond to actual needs. | —— | |

| 7.3 Warning signs | Safety warning signs and safety colors are installed in workplaces with greater risk elements or on related equipment. | No height restriction on crossing shelves, evacuation sign on the first floor of the workshop is not light type. | Paint booths, sewage treatment tanks, and pool treatment are without warning signs. |

| Special warehouses for hazardous chemicals, special equipment, and jobs that produce serious occupational hazards should be marked and warned in accordance with the relevant regulations. | Some of the “ovens” were not labelled with a “beware of high temperatures” warning sign; the office premises failed to provide a visually continuous lighted evacuation indicator sign. | —— | |

| Setting up warning areas and warning signs at the operation sites of equipment and facilities inspection and maintenance, construction, lifting, etc. | Failure to provide warning signs for earth moving operations. | —— | |

| Places where gas is likely to leak and accumulate should be marked with conspicuous warning signs. | Empty acetylene cylinders were stored in an abandoned facility with a large amount of flammable material piled up around them, and no warning signs were set up. | —— | |

| 7.4 Related party management | Manage the pre-qualification and selection of contractors, suppliers, and other related parties; pre-service preparation; supervision of the operational processes, products and technical services provided; and performance evaluation and renewal of employment; and establish a directory and file of related parties. | Failure to include the construction engineering team in the list of related parties. | Some of the parties involved have no established management files. |

| Regularly identify service behavior risks based on the nature and behavior of the service operations provided by the relevant parties, adopt effective risk control measures, and monitor their safety performance. | Lack of targeting of service risk controls for related parties in the product and service categories. | —— | |

| Engineering projects should not be contracted out to units that do not possess the appropriate qualifications. The contracting agreement for the project should clearly stipulate the production safety responsibilities and obligations of both parties. | Failure to provide the relevant party’s special operator certificate. | —— |

| Enterprise | Element 1 | Element 2 | Element 3 | Element 4 | Element 5 | Element 6 | Element 7 | Element 8 | Element 9 | Element 10 | Element 11 | Element 12 | Element 13 | Overall Score |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 90.00 | 53.33 | 70.00 | 53.00 | 58.00 | 83.85 | 46.53 | 82.86 | 65.38 | 75.00 | 73.08 | 80.00 | 77.78 | 66.76 |

| II | 90.00 | 53.33 | 70.00 | 53.00 | 58.00 | 57.89 | 69.32 | 82.86 | 65.38 | 75.00 | 73.08 | 80.00 | 77.78 | 66.01 |

| III | 90.00 | 53.33 | 70.00 | 53.00 | 58.00 | 57.89 | 71.74 | 62.86 | 65.38 | 75.00 | 73.08 | 80.00 | 77.78 | 64.79 |

| IV | 90.00 | 53.33 | 70.00 | 53.00 | 58.00 | 57.89 | 60.49 | 82.86 | 65.38 | 75.00 | 73.08 | 80.00 | 77.78 | 64.02 |

| V | 90.00 | 53.33 | 70.00 | 53.00 | 58.00 | 51.80 | 46.53 | 82.86 | 65.38 | 75.00 | 73.08 | 80.00 | 77.78 | 60.14 |

| Enterprise | Linkage Degree | Set-Pair Potential | Level of Set-Pairing Potential | Pessimistic Potential | Optimistic Potential |

|---|---|---|---|---|---|

| I | −0.47 | 0.046 | weak opposition potential | 0.032 | 0.471 |

| II | −0.64 | 0.039 | weak opposition potential | 0.029 | 0.393 |

| III | −0.69 | 0.038 | weak opposition potential | 0.028 | 0.399 |

| IV | −0.70 | 0.035 | weak opposition potential | 0.027 | 0.308 |

| V | −0.76 | 0.029 | weak opposition potential | 0.025 | 0.192 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Zhu, P. Analysis and Optimization of the Effectiveness of Production Safety Standardization Construction Based on Set-Pair Analysis. Appl. Sci. 2024, 14, 9460. https://doi.org/10.3390/app14209460

Zhang S, Zhu P. Analysis and Optimization of the Effectiveness of Production Safety Standardization Construction Based on Set-Pair Analysis. Applied Sciences. 2024; 14(20):9460. https://doi.org/10.3390/app14209460

Chicago/Turabian StyleZhang, Shaojie, and Peng Zhu. 2024. "Analysis and Optimization of the Effectiveness of Production Safety Standardization Construction Based on Set-Pair Analysis" Applied Sciences 14, no. 20: 9460. https://doi.org/10.3390/app14209460

APA StyleZhang, S., & Zhu, P. (2024). Analysis and Optimization of the Effectiveness of Production Safety Standardization Construction Based on Set-Pair Analysis. Applied Sciences, 14(20), 9460. https://doi.org/10.3390/app14209460