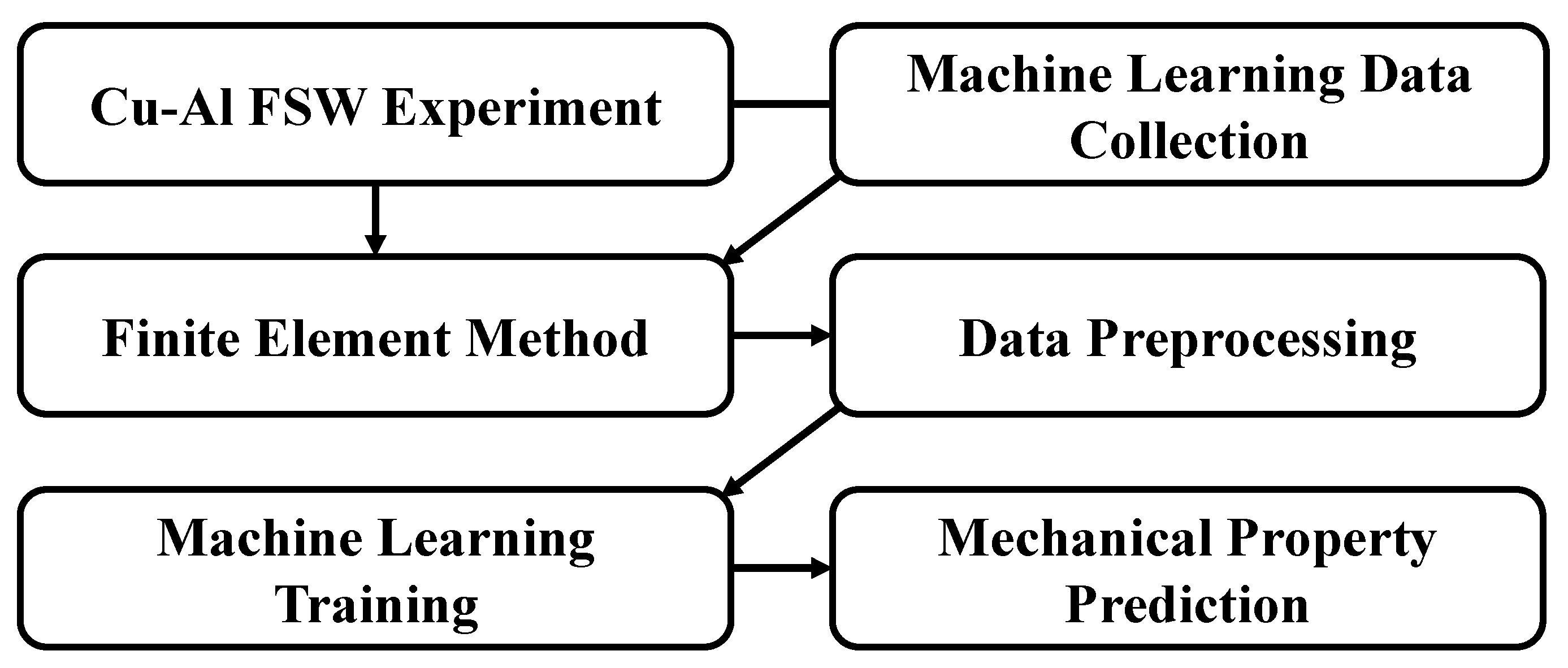

Development of an Artificial Neural Network Model to Predict the Tensile Strength of Friction Stir Welding of Dissimilar Materials Using Cryogenic Processes

Abstract

1. Introduction

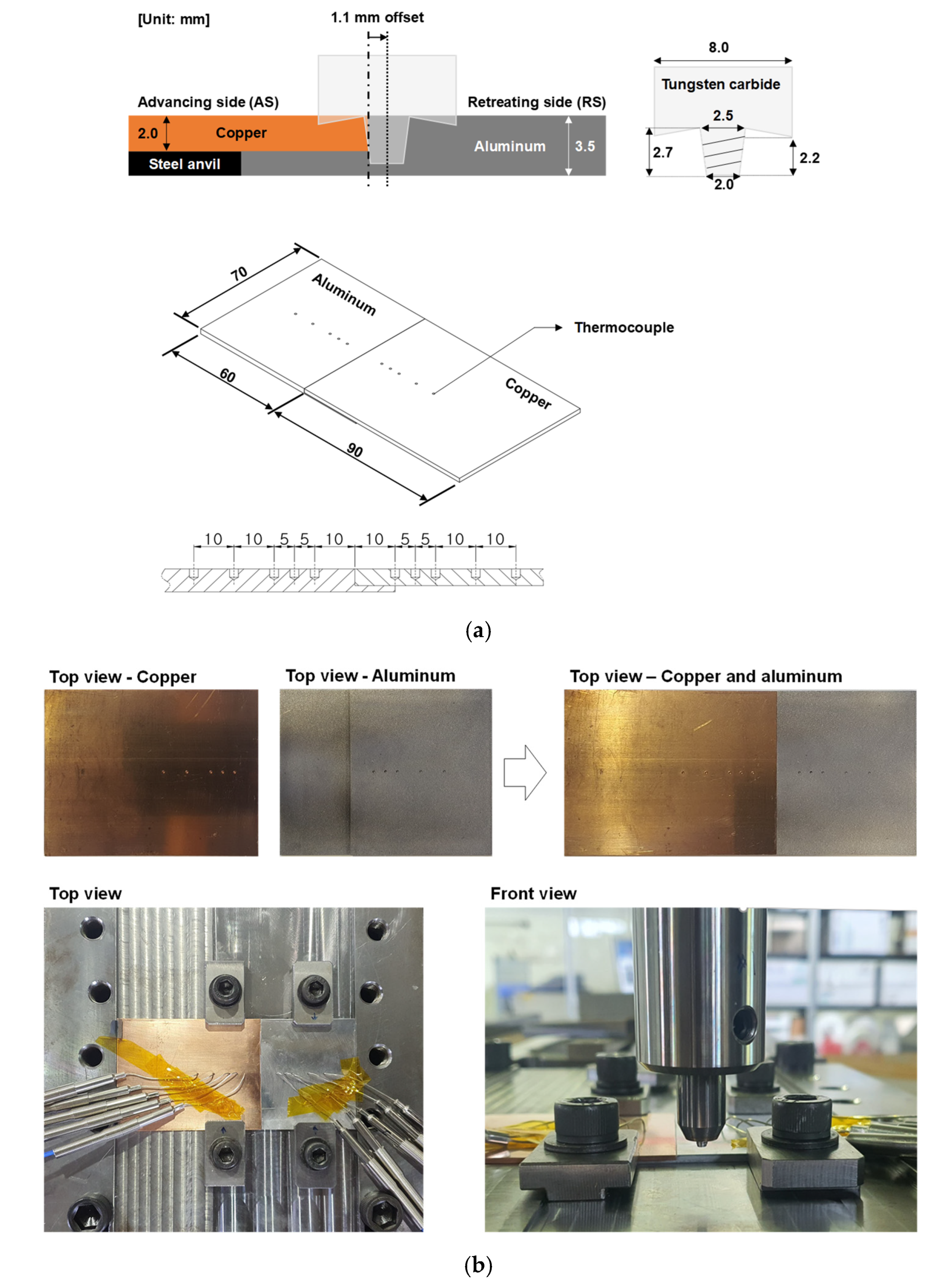

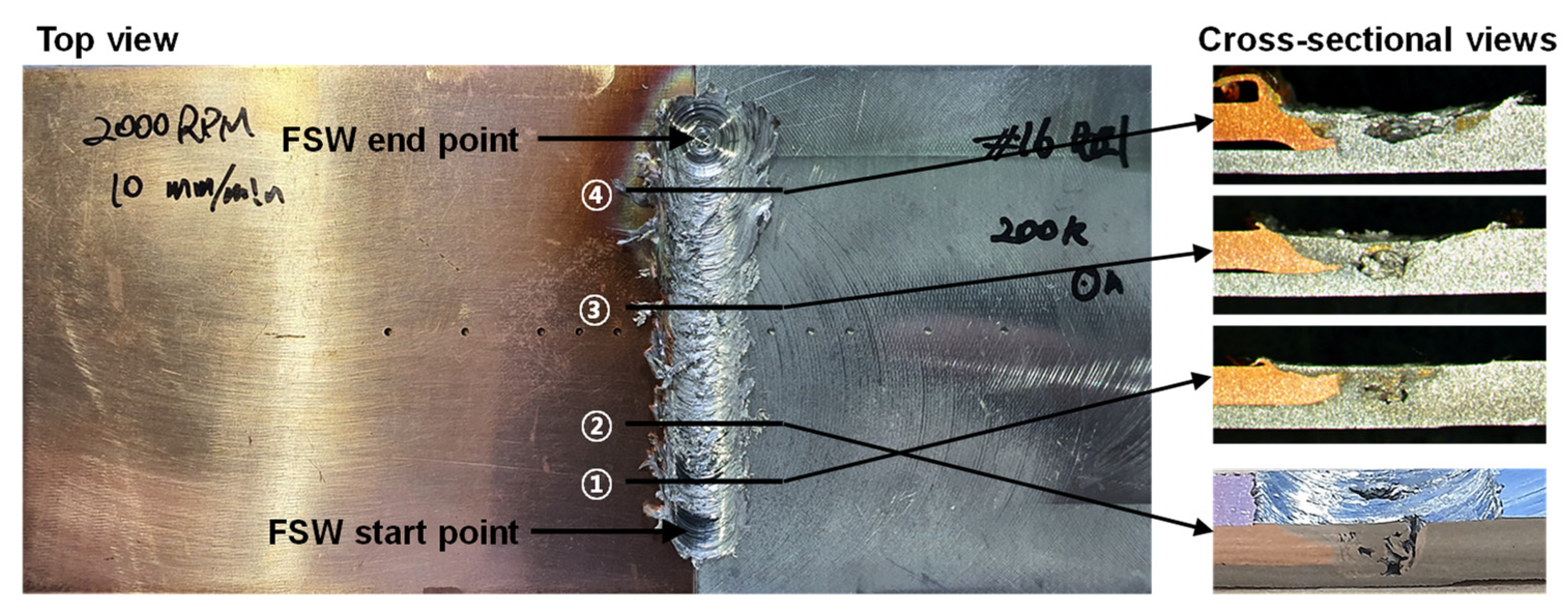

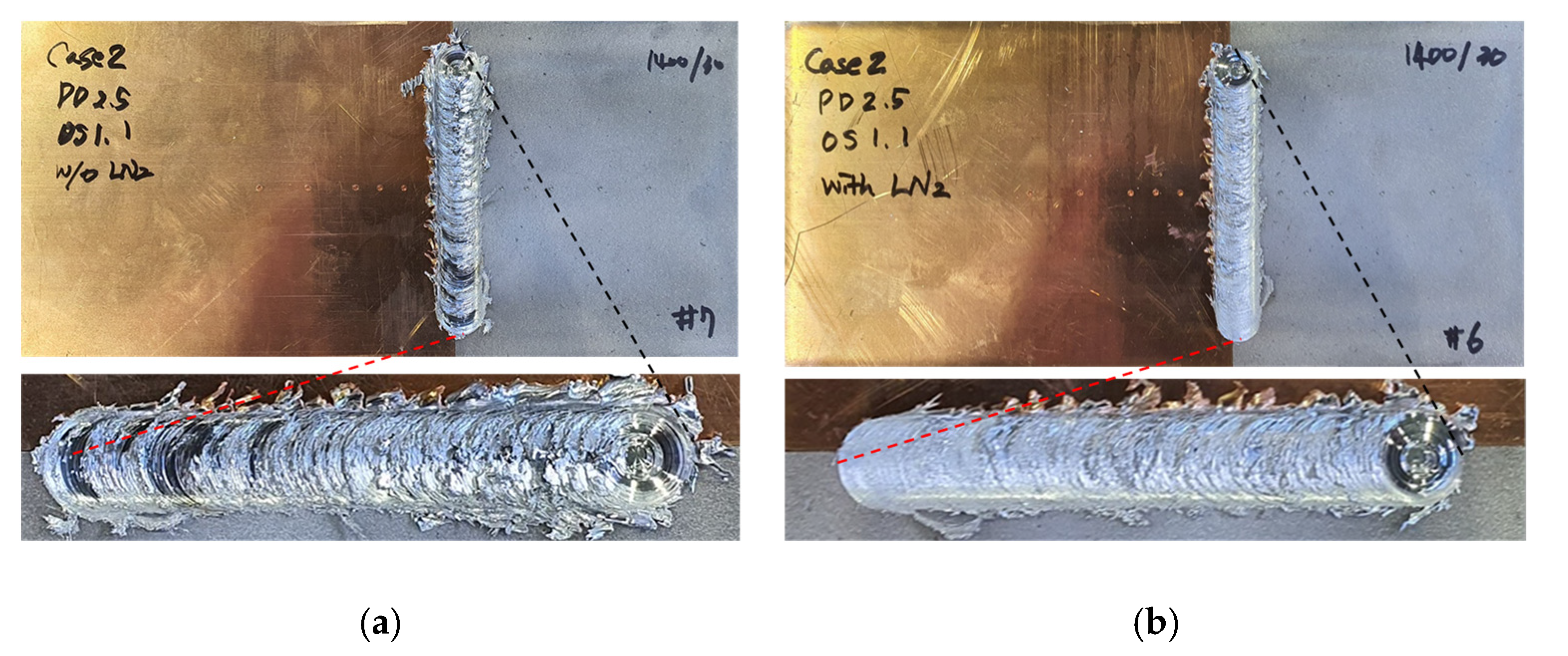

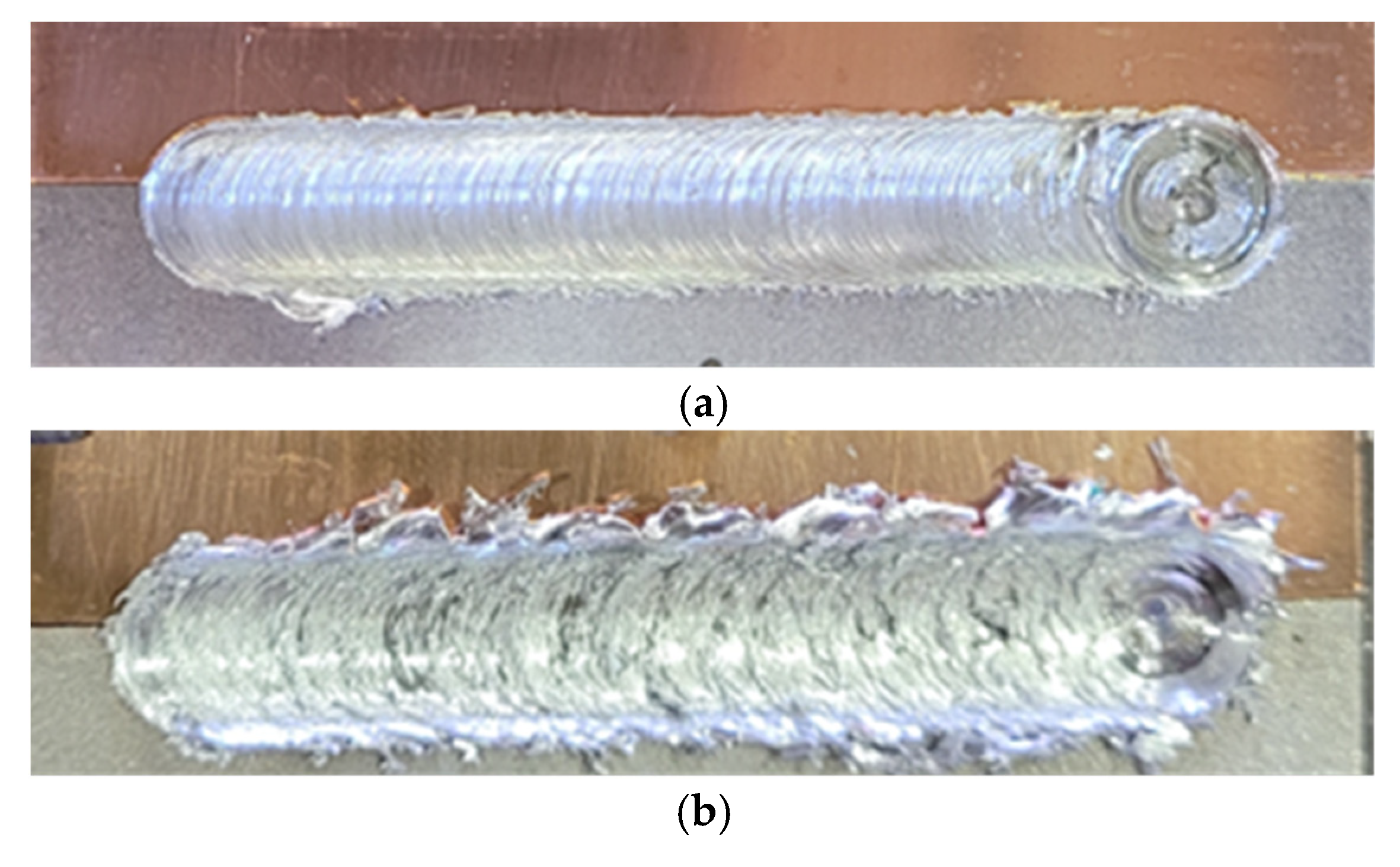

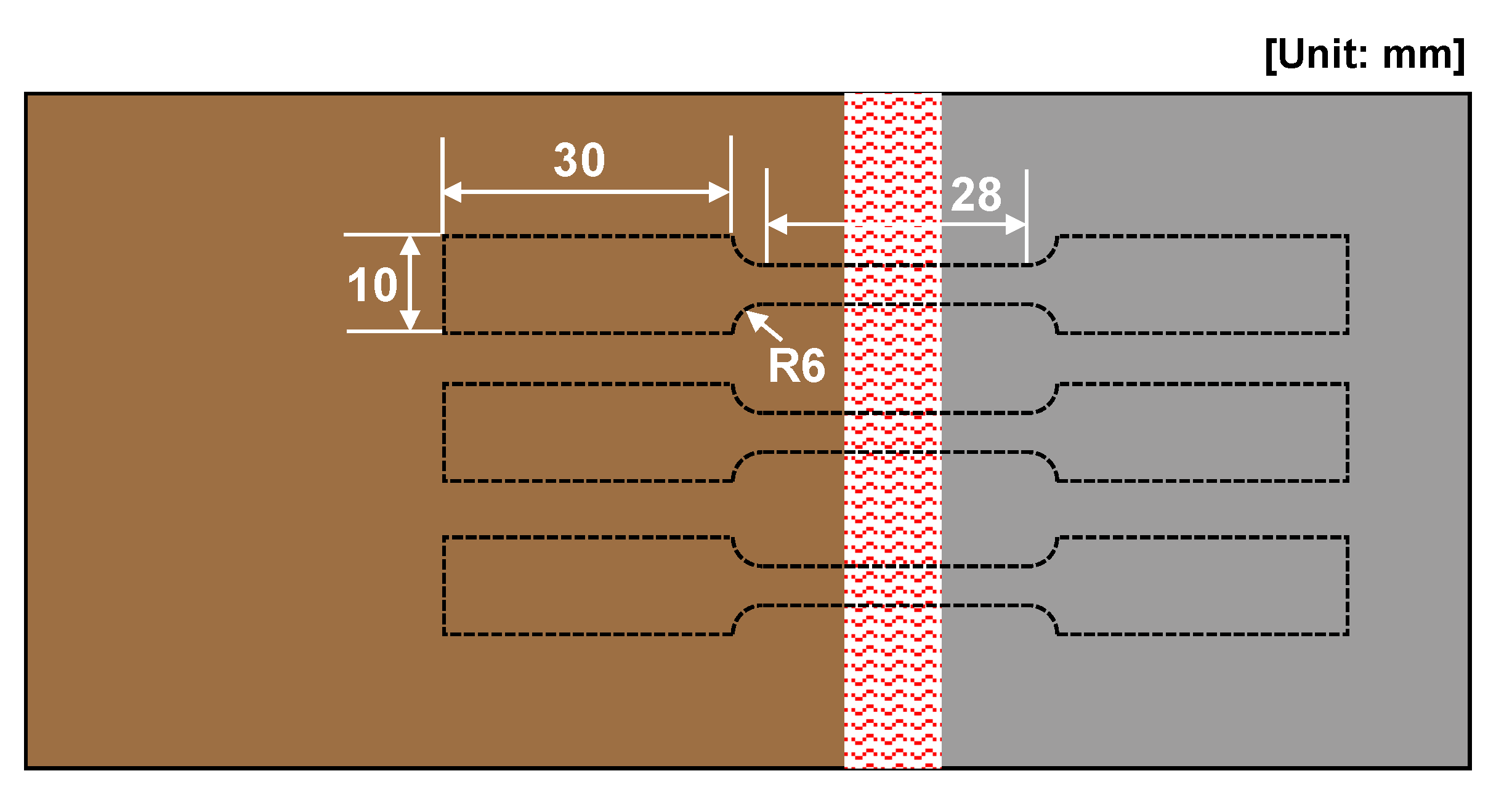

2. Dissimilar FSW Experiments

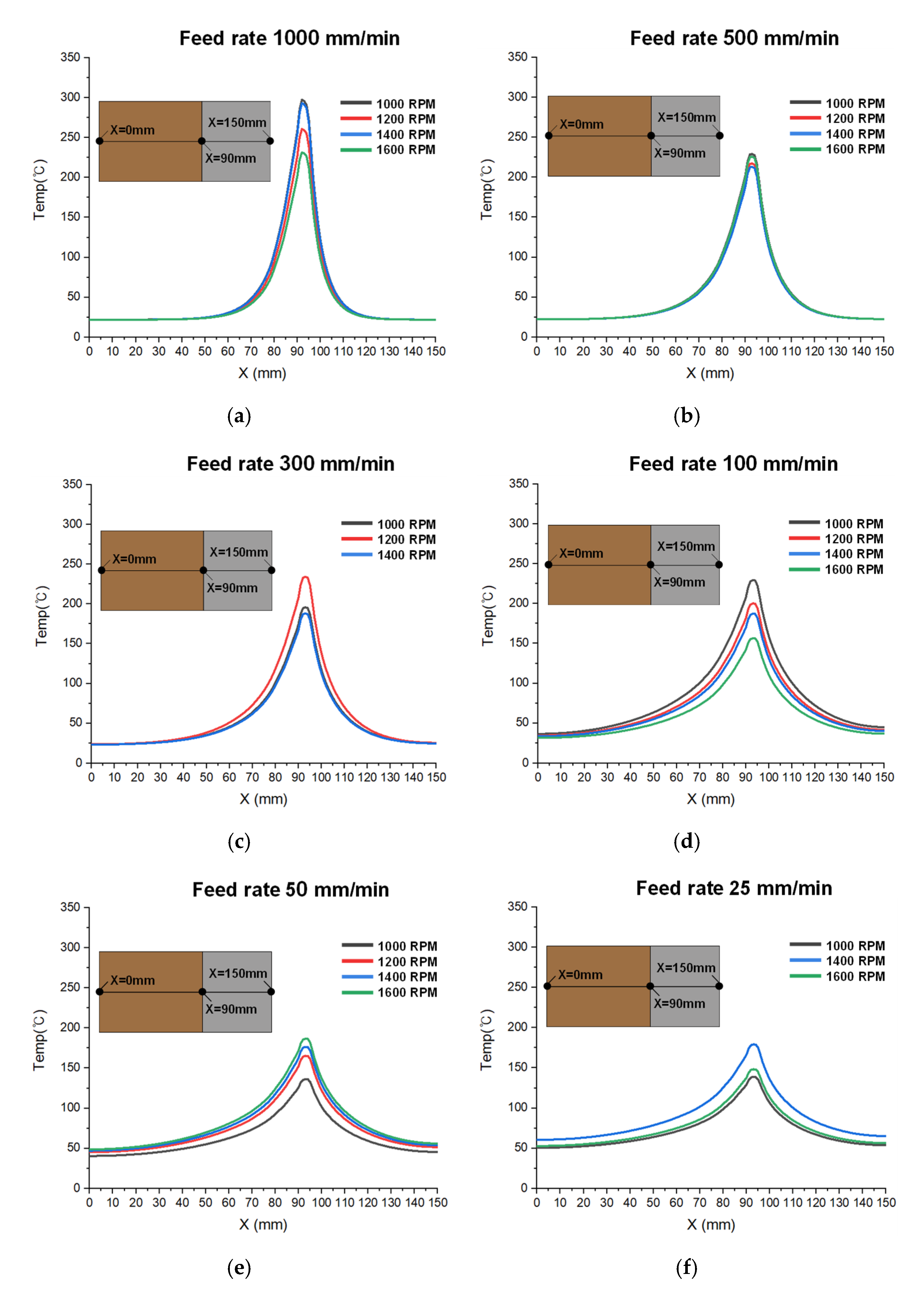

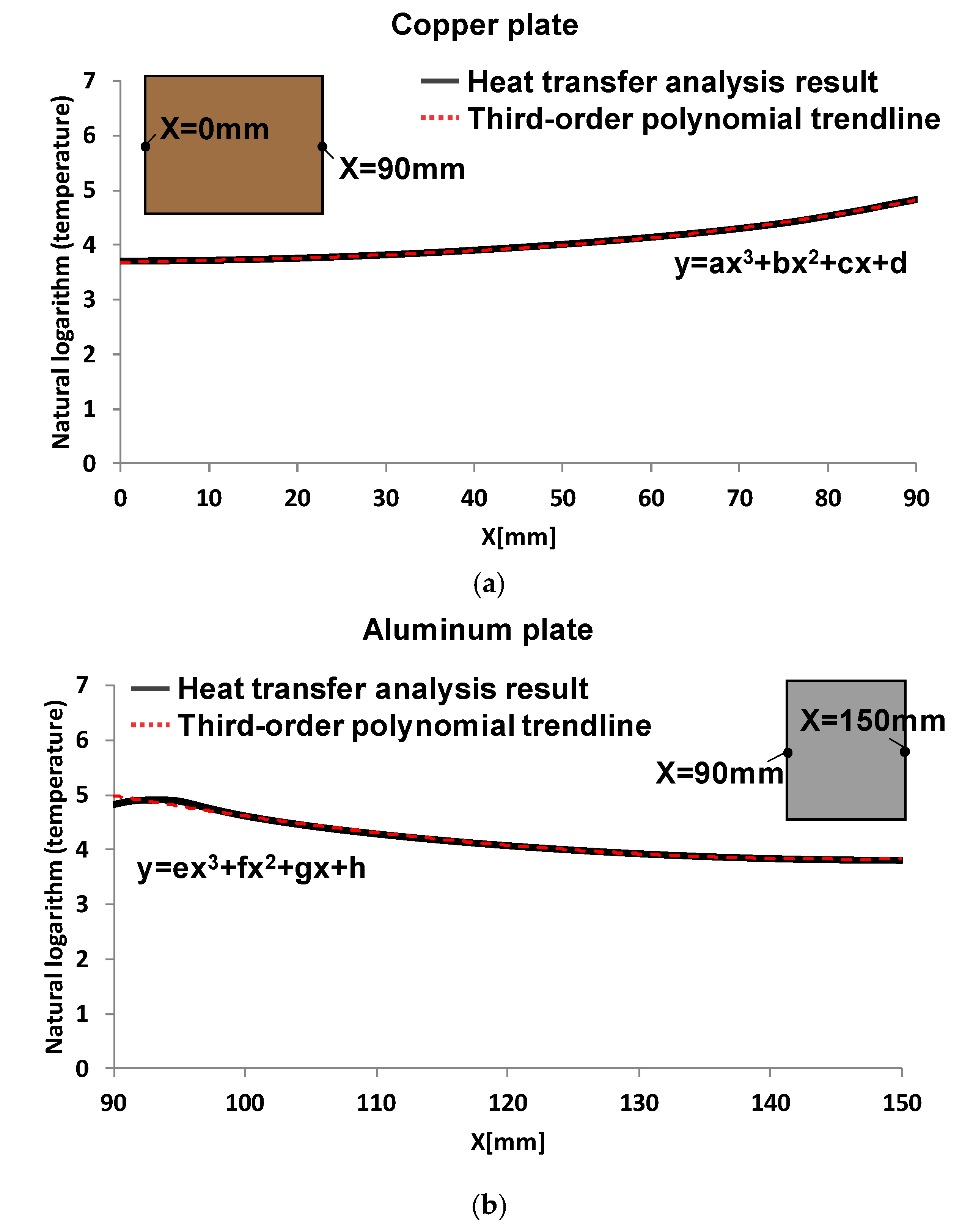

3. Heat Transfer Analysis Using Finite Element Method

3.1. Finite Element Model and Mesh

3.2. Material Properties and Boundary Conditions

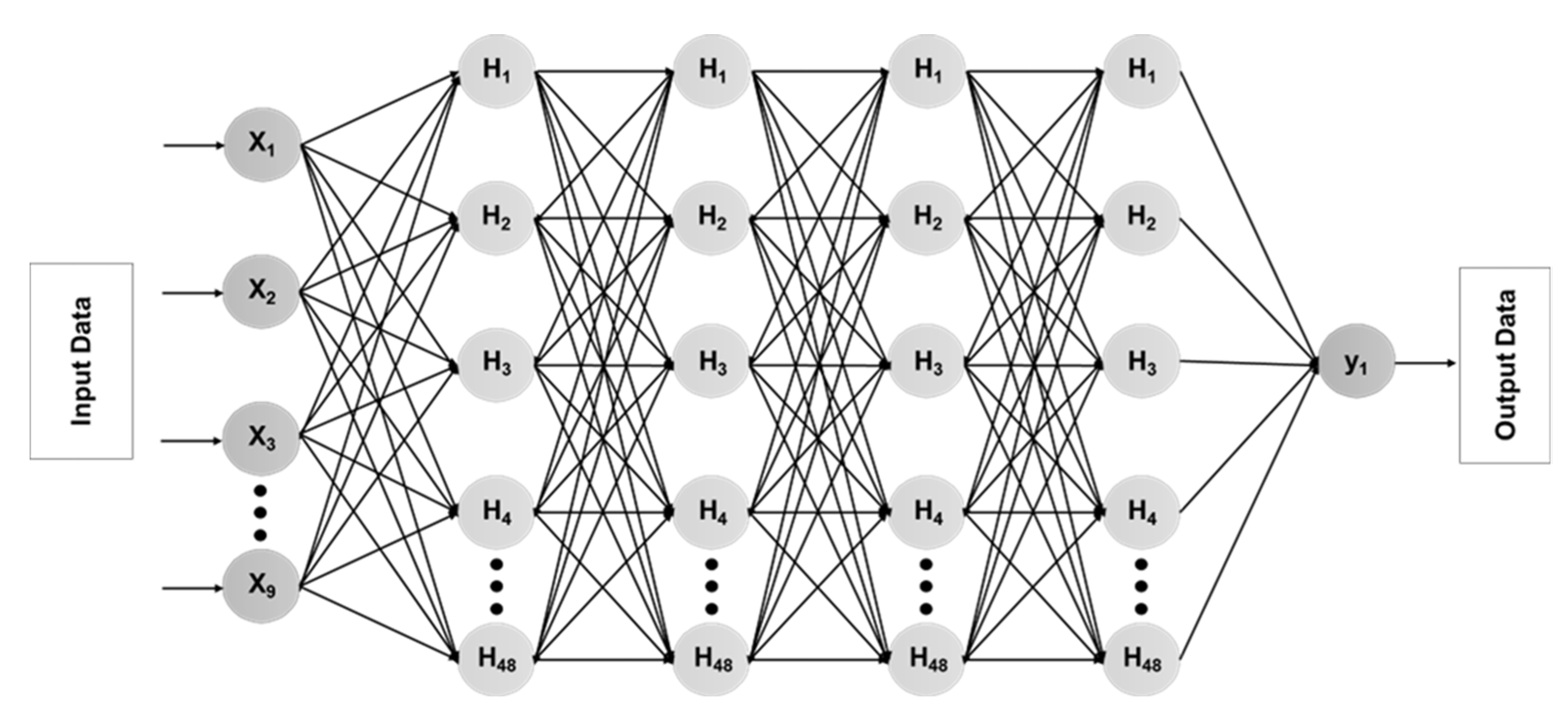

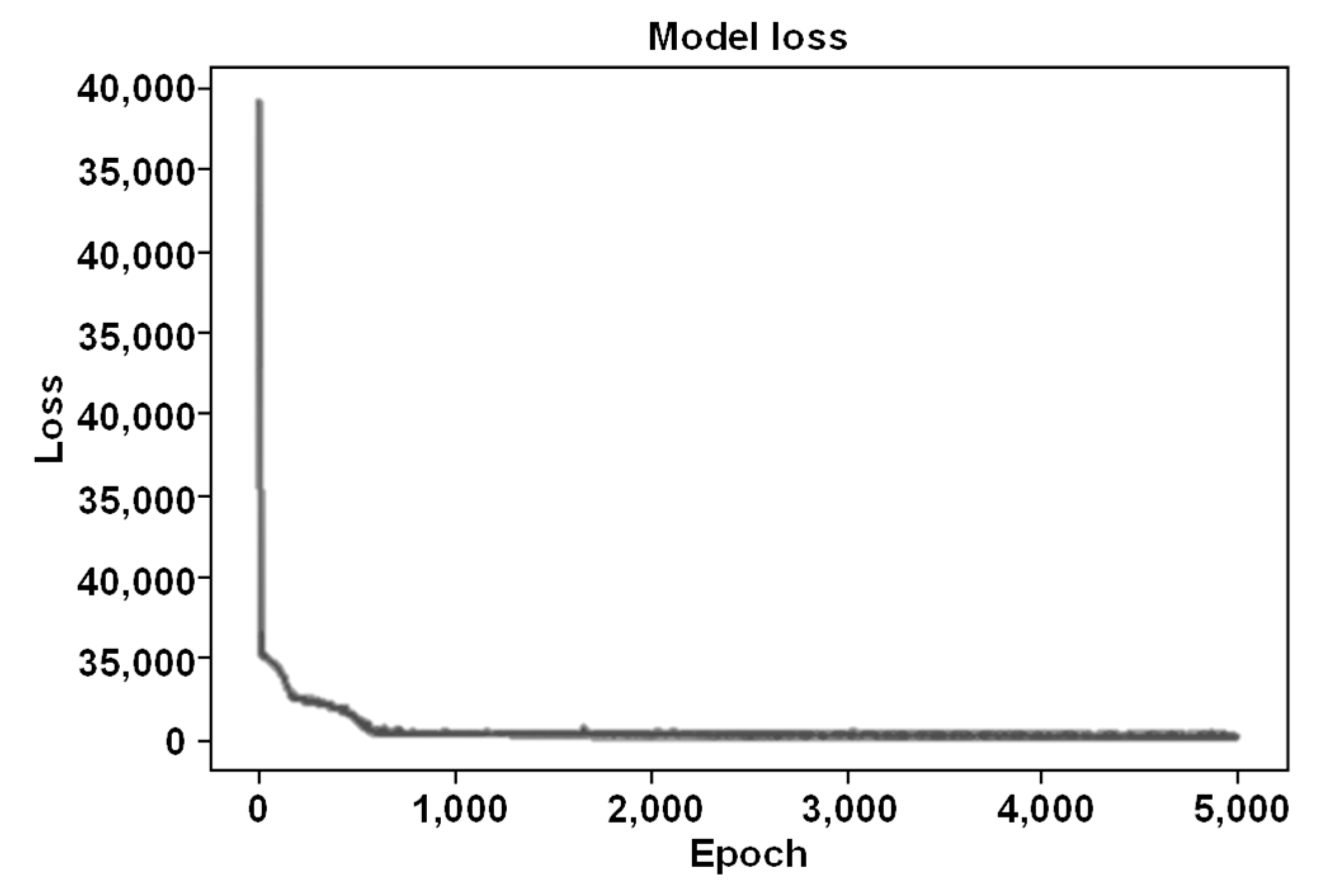

4. Artificial Neural Network

4.1. Artificial Neural Network for Friction Stir Welding

4.2. Artificial Neural Network Verification for Friction Stir Welding

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thaiping, C. Process parameters study on FSW joint of dissimilar metals for aluminum-steel. J. Mater. Sci. 2009, 44, 2573–2580. [Google Scholar]

- Morishige, T.; Kawaguchi, A.; Tsujikawa, M.; Higashi, K. Dissimilar Welding of Al and Mg Alloys by FSW. Mater. Trans. 2008, 49, 1129–1131. [Google Scholar] [CrossRef]

- Pietras, A.; Zadroga, L.; Lomozik, M. Characteristics of welds formed by pressure welding incorporating stirring of the weld material (FSW). Weld. Int. 2010, 18, 5–10. [Google Scholar] [CrossRef]

- Bruce, H.; John, F.H. Friction Stir Welding (FSW) of Littoral Combat Ship Deckhouse Structure. J. Ship Prod. Des. 2007, 23, 161–163. [Google Scholar]

- Tanaka, T.; Morishige, T.; Hirata, T. Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminum alloy. Scr. Mater. 2009, 61, 756–759. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, Y.; Hao, Y. Friction stir welding of high-strength aerospace aluminum alloy and application in rocket tank manufacturing. J. Mater. Sci. Technol. 2018, 34, 73–91. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Hu, W. The study on defects in aluminum 2219-T6 thick butt friction stir welds with the application of multiple non-destructive testing methods. Mater. Des. 2011, 32, 2073–2084. [Google Scholar] [CrossRef]

- Prakash, K.S.; Sukhomay, P.; Surjya, K.P.; Rahul, J. Influence of plate position, tool offset and tool rotational speed on mechanical properties and microstructures of dissimilar Al/Cu friction stir welding joints. J. Mater. Process. Technol. 2016, 235, 55–67. [Google Scholar]

- Tan, C.W.; Jiang, Z.G.; Chen, Y.B.; Chen, X.Y. Microstructure evolution mechanical properties of dissimilar Al-Cu joints produced by friction stir welding. Mater. Des. 2013, 51, 466–473. [Google Scholar] [CrossRef]

- Mononen, J.; Siren, M.; Hanninen, H. Cost Comparison of FSW and MIG Welded Aluminium Panels. Weld. World 2003, 47, 32–35. [Google Scholar] [CrossRef]

- Kallee, S.W. 5-Industrial applications of Friction stir welding. In Friction Stir Welding; Woodhead Publishing Series in Welding and other Joining Technologies; Woodhead Publishing: Sawston, UK, 2010; pp. 118–163. [Google Scholar]

- Pedemonte, M.; Gambaro, C.; Lertora, E.; Mandolfino, C. Fatigue assessment of AA 8090 friction stir butt welds after surface finishing treatment. Aerosp. Sci. Technol. 2013, 27, 188–192. [Google Scholar] [CrossRef]

- Isa, M.S.M.; Moghadasi, K.; Ariffin, M.A.; Raja, S.; bin Muhamad, M.R.; Yusof, F.; Jamaludin, M.F.; bin Yusoff, N.; bin Ab Karim, M.S. Recent research progress in friction stir welding of aluminum and copper dissimilar joint: A review. J. Mater. Res. Technol. 2021, 15, 2735–2780. [Google Scholar]

- Vivek, P.; Jeroen, D.B.; Henrik, H.; Mattias, I.; Saeed, A.; Joel, A.; Jorgen, S. High-speed friction stir welding in light weight battery trays for the EV industry. Sci. Technol. Weld. Join. 2022, 27, 250–255. [Google Scholar]

- Omkar, M.; Tarig, A.; Desham, M.; Surjya, K.P.; Prakash, S. Characterization and modelling of Al and Cu busbar during charging and discharging of Li-ion battery for electric vehicles. Appl. Therm. Eng. 2023, 218, 119239. [Google Scholar]

- Beygi, R.; Kazeminezhad, M.; Kokabi, A.H. Butt joining Al-Cu bilayer sheet through friction stir welding. Trans. Nonferrous Met. Soc. China 2012, 22, 2925–2929. [Google Scholar] [CrossRef]

- Al-Roubaiy, A.O.; Nabat, S.M.; Batako, A.D.L. Experimental and theoretical analysis of friction stir welding of Al-Cu joints. Int. J. Adv. Manuf. Technol. 2014, 71, 1631–1642. [Google Scholar] [CrossRef]

- Liu, P.; Shi, Q.; Wang, W.; Wang, X.; Zhang, Z. Microstructure and XRD analysis of FSW joints for copper T2/aluminum 5A06 dissimilar materials. Mater. Lett. 2008, 62, 4106–4108. [Google Scholar] [CrossRef]

- Arun, K.K.; Pankaj, B. The study of material flow behaviour in dissimilar material FSW of AA6061 and Cu-B370 alloys plates. J. Manuf. Process. 2018, 34, 96–105. [Google Scholar]

- Khodaverdizadeh, H.; Mahmoudi, A.; Heidarzadeh, A.; Nazari, E. Effect of friction stir welding(FSW) Parameters on strain hardening nehavior of pure copper joints. Mater. Des. 2012, 35, 330–334. [Google Scholar] [CrossRef]

- Yang, J.; Wang, D.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Effects of Rotation Rates on Microstructure, Mechanical Properties, and Fracture Behavior of Friction stir-Welded (FSW) AZ31 Magnesium Alloy. Metall. Mater. Trans. A 2013, 44, 517–530. [Google Scholar] [CrossRef]

- Elmetwally, H.T.; SaadAllah, H.N.; AbdElhady, M.S.; AbdelMagied, R.K. Optimum combination of rotational and wlding speeds for welding of Al/Cu-butt joint by friction stir welding. Int. J. Adv. Manuf. Technol. 2020, 110, 163–175. [Google Scholar] [CrossRef]

- Tauqir, N.; Mohammed, A.; Qasim, Z.; Davut, S. Applications of Machine Learning to Friction Stir Welding Process Optimization. J. Kejuruter. 2020, 32, 171–186. [Google Scholar]

- Abdelhakim, D.; Fouzi, H.; Ying, S. Exploring Deep Learning Methods to Forecast Mechanical Behavior of FSW Aluminum Sheets. J. Mater. Eng. Perform. 2023, 32, 4047–4063. [Google Scholar]

- Jayaraman, M.; Sivasubramanian, R.; Balasubramanian, V.; Lakshminarayanan, A.K. Application of RSM and ANN to predict the tensile strength of Friction Stir Welded A319 cast aluminium alloy. Int. J. Manuf. Res. 2009, 4, 306–323. [Google Scholar] [CrossRef]

- Vignesh, R.V.; Padmanaban, R. Comparison of ANN Training Algorithms for Predicting the Tensile Strength of Friction Stir Welded Aluminium Alloy AA1100. Int. J. Veh. Struct. Syst. 2018, 10, 98–102. [Google Scholar] [CrossRef]

- Okuyucu, H.; Kurt, A.; Arcaklioglu, E. Artificial neural network application to the friction stir welding of aluminum plate. Mater. Des. 2007, 28, 78–84. [Google Scholar] [CrossRef]

- Maleki, E. Artificial neural network application for modeling of friction stir welding effects on mechanical properties of 7075-T6 aluminum alloy. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015; Volume 103. [Google Scholar]

- Watanabe, T.; Takayama, T.; Yanagisawa, A. Joining of aluminum alloy to steel by friction stir welding. J. Mater. Process. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- DebRoy, T.; Bhadeshia, H.K.D.H. Friction stir welding of dissimilar alloys—A perspective. Sci. Technol. Weld. Join. 2010, 15, 266–270. [Google Scholar] [CrossRef]

- Choi, D.H.; Lee, C.Y.; Ahn, B.W.; Yeng, Y.M.; Park, S.H.C.; Sato, Y.S.; Kokawa, H.; Jung, S.B. Effect of fixed location variation in friction stir welding of steel with different carbon contents. Sci. Technol. Weld. Join. 2010, 15, 266–336. [Google Scholar] [CrossRef]

- Xue, P.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al-Cu joints. Mater. Sci. Eng. A 2011, 528, 4683–4689. [Google Scholar] [CrossRef]

- Bakkiyaraj, M.; Stephen Bernard, S.; Saikrishnan, G.; Guruyogesh, S.; Guruprasanna, T.G.; Dineshkumar, K. Effect of tool offset condition on mechanical and metallurgical properties of FSW dissimilar Al-Cu joint. Mater. Today Proc. 2021, 43, 824–827. [Google Scholar] [CrossRef]

- Chetkin, E.; Kilickap, E.; Celik, Y.H. Investigation of the Effects of Welding Force, Vibration and Temperature on Mechanical Properties and Microstructure in FSW Welding. J. Polytech. 2023, 26, 445–455. [Google Scholar]

- Sakthivel, T.; Sengar, G.S.; Mukhopadhyay, J. Effect of welding speed on microstructure and mechanical properties of friction-stir-welding aluminum. Int. J. Adv. Manuf. Technol. 2009, 43, 468–473. [Google Scholar] [CrossRef]

- El-Rayes, M.M.; Soliman, M.S.; Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Abdel-mawla, M.M. Effect of Feed Rate in FSW on the Mechanical and Microstructural Properties of AA5754 Joint. Adv. Mater. Sci. Eng. 2019, 12, 4156176. [Google Scholar] [CrossRef]

- Kang, S.W.; Kim, J.W.; Jang, Y.J.; Lee, K.J. Welding Deformation Analysis, Using an Inherent Strain Method for Friction Stir Welded Electric Vehicle Aluminum Battery Housing, Considering Productivity. Appl. Sci. 2019, 9, 3848. [Google Scholar] [CrossRef]

- Mughal, M.P.; Fawad, H.; Mufti, R. Parametric thermal analysis of a single molten metal droplet as applied to layered manufacturing. Heat Mass Transf. 2006, 42, 226–237. [Google Scholar] [CrossRef]

- Kang, S.W.; Jang, B.S. Comparisons with friction stir welding heat transfer analysis methods and parametric study on unspecified input variables. J. Mech. Sci. Technol. 2014, 28, 4233–4246. [Google Scholar] [CrossRef]

| Rotation Speed (RPM) | Feed Rate (mm/min) | |||||

|---|---|---|---|---|---|---|

| 1000 | 500 | 300 | 100 | 50 | 25 | |

| 1000 | #1 | #5 | #9 | #13 | #17 | #21 |

| 1200 | #2 | #6 | #10 | #14 | #18 | #22 |

| 1400 | #3 | #7 | #11 | #15 | #19 | #23 |

| 1600 | #4 | #8 | #12 | #16 | #20 | #24 |

| Rotation Speed (RPM) | Feed Rate (mm/min) | |||||

|---|---|---|---|---|---|---|

| 1000 | 500 | 300 | 100 | 50 | 25 | |

| 1000 | 367.77 | 264.9 | 219.45 | 248.04 | 145.43 | 147.3 |

| 1200 | 321.66 | 251.07 | 262.96 | 216.37 | 176.81 | X |

| 1400 | 362.51 | 245.92 | 210.7 | 202.24 | 188.74 | 190.52 |

| 1600 | 284.9 | 261.07 | X | 168.72 | 199.82 | 157.44 |

| Temperature [°C] | Density [kg/m3] | Specific Heat [J/kg°C] | Thermal Conductivity [W/m°C] |

|---|---|---|---|

| 25 | 2700 | 900 | 198.33 |

| 100 | 2690 | 940 | 203.54 |

| 150 | 2680 | 960 | 205.17 |

| 200 | 2670 | 990 | 205.82 |

| 260 | 2650 | 1010 | 205.66 |

| 320 | 2640 | 1040 | 204.72 |

| 370 | 2630 | 1060 | 194.91 |

| 420 | 2620 | 1080 | 194.14 |

| 570 | 2580 | 1170 | 191.81 |

| Temperature [°C] | Density [kg/m3] | Thermal Conductivity [W/m°C] | Temperature [°C] | Specific Heat [J/kg°C] |

|---|---|---|---|---|

| 26.85 | 8910 | 398 | 24.85 | 385 |

| 126.85 | 392 | 599.85 | 442 | |

| 526.85 | 371 | 799.85 | 462 | |

| 726.85 | 357 | 999.85 | 482 |

| Input Data | Output Data | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. | a | b | c | d | e | f | g | h | Max. Temp. | Tensile Strength |

| #1 | 1.0 × 10−5 | −7.0 × 10−4 | 0.0136 | 3.0419 | −1.0 × 10−5 | 0.0062 | −0.9558 | 51.55 | 367.77 | 185.5 |

| #2 | 1.0 × 10−5 | −7.0 × 10−4 | 0.0148 | 3.0337 | −1.0 × 10−5 | 0.0067 | −1.0026 | 52.845 | 321.66 | 176.1 |

| #3 | 1.0 × 10−5 | −7.0 × 10−4 | 0.0137 | 3.041 | −1.0 × 10−5 | 0.0062 | −0.9613 | 51.71 | 362.51 | 199 |

| #4 | 1.0 × 10−5 | −7.0 × 10−4 | 0.0158 | 3.0273 | −1.0 × 10−5 | 0.007 | −1.0364 | 53.674 | 284.9 | 233.4 |

| #5 | 4.0 × 10−6 | −1.0 × 10−4 | 0.0019 | 3.0996 | −2.0 × 10−5 | 0.0008 | −0.2581 | 22.02 | 264.9 | 194.9 |

| #6 | 4.0 × 10−6 | −2.0 × 10−4 | 0.0024 | 3.0963 | 6.0 × 10−7 | 0.001 | −0.2815 | 22.777 | 251.07 | 189.4 |

| #7 | 4.0 × 10−6 | −2.0 × 10−4 | 0.0026 | 3.0951 | −3.0 × 10−8 | 0.0011 | −0.2903 | 23.058 | 245.92 | 182.1 |

| #8 | 4.0 × 10−6 | −1.0 × 10−4 | 0.002 | 3.0987 | −3.0 × 10−7 | 0.0009 | −0.2646 | 22.229 | 261.07 | 194.1 |

| #9 | 2.0 × 10−6 | 2.0 × 10−5 | 0.0013 | 3.1378 | 4.0 × 10−7 | −0.0004 | −0.0776 | 13.425 | 219.45 | 143.1 |

| #10 | 2.0 × 10−6 | 9.0 × 10−5 | 0.0005 | 3.1527 | 3.0 × 10−6 | −0.001 | −0.0162 | 11.427 | 262.96 | 226.2 |

| #11 | 2.0 × 10−6 | 1.0 × 10−5 | 0.0015 | 3.1347 | 5.0 × 10−6 | −0.0003 | −0.0911 | 13.859 | 210.7 | 161.6 |

| #13 | 8.0 × 10−7 | 9.0 × 10−5 | 0.0047 | 3.5734 | 3.0 × 10−6 | −0.0007 | 0.002 | 8.8281 | 248.04 | 200.6 |

| #14 | 9.0 × 10−7 | 7.0 × 10−5 | 0.0045 | 3.5167 | 3.0 × 10−6 | −0.0006 | −0.0137 | 9.2287 | 216.37 | 224.6 |

| #15 | 1.0 × 10−6 | 7.0 × 10−5 | 0.0044 | 3.4903 | 3.0 × 10−6 | −0.0005 | −0.0218 | 9.3438 | 202.24 | 210.7 |

| #16 | 1.0 × 10−6 | 4.0 × 10−5 | 0.0041 | 3.4247 | 3.0 × 10−6 | −0.0003 | −0.0444 | 10.012 | 168.72 | 241.5 |

| #17 | 1.0 × 10−6 | −1.0 × 10−5 | 0.0039 | 3.682 | 2.0 × 10−6 | 0.0003 | −0.1019 | 11.468 | 145.43 | 254.8 |

| #18 | 1.0 × 10−6 | −1.0 × 10−6 | 0.004 | 3.7925 | 1.0 × 10−7 | 0.0002 | −0.0911 | 11.362 | 176.81 | 210.6 |

| #19 | 1.0 × 10−6 | 3.0 × 10−6 | 0.0041 | 3.8315 | 5.0 × 10−7 | 0.0002 | −0.0875 | 11.322 | 188.74 | 234.4 |

| #20 | 1.0 × 10−6 | 6.0 × 10−6 | 0.0041 | 3.8665 | 6.0 × 10−7 | 0.0001 | −0.0844 | 11.286 | 199.82 | 246.6 |

| #21 | 1.0 × 10−6 | −4.0 × 10−5 | 0.0036 | 3.9051 | 7.0 × 10−7 | 0.0005 | −0.1178 | 11.804 | 147.3 | 198.8 |

| #23 | 1.0 × 10−6 | −3.0 × 10−5 | 0.0038 | 4.0842 | −5.0 × 10−7 | 0.0004 | −0.1107 | 11.909 | 190.52 | 218.8 |

| #24 | 1.0 × 10−6 | −4.0 × 10−5 | 0.0037 | 3.95 | −2.0 × 10−7 | 0.0005 | −0.1162 | 11.841 | 157.44 | 239 |

| Rotation Speed (RPM) | Feed Rate (mm/min) | ||

|---|---|---|---|

| 200 | 40 | 20 | |

| 800 | #3 | ||

| 1000 | #4 | ||

| 1400 | #2 | #1 | |

| 1600 | #5 | ||

| Input Data | Output Data | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. | a | b | c | d | e | f | g | h | Max. Temp. | Tensile Strength |

| #1 | 1.0 × 10−6 | −4.0 × 10−5 | 0.0037 | 4.0346 | −5.0 × 10−7 | 0.0005 | −0.1165 | 11.89 | 167.42 | 234.7 |

| #2 | 1.0 × 10−6 | −2.0 × 10−5 | 0.0038 | 3.7764 | −1.0 × 10−7 | 0.0004 | −0.1091 | 11.653 | 148.04 | 259.9 |

| #3 | 1.0 × 10−6 | −1.0 × 10−5 | 0.0039 | 3.8878 | 1.0 × 10−7 | 0.0003 | −0.1014 | 11.636 | 177.24 | 233.6 |

| #4 | 2.0 × 10−6 | 6.0 × 10−5 | 0.0022 | 3.1735 | 4.0 × 10−6 | −0.0008 | −0.0089 | 9.5664 | 176.57 | 199.4 |

| #5 | 2.0 × 10−6 | −3.0 × 10−5 | 0.003 | 3.1377 | 1.0 × 10−6 | 8.0 × 10−5 | −0.0999 | 12.261 | 120.99 | 200.1 |

| No. | Feed Rate (mm/min) | Rotation Speed (RPM) | Tensile Strength (MPa) | Predict Tensile Strength (MPa) | Error (%) |

|---|---|---|---|---|---|

| #1 | 20 | 1300 | 234.7 | 252.1 | 7.4 |

| #2 | 40 | 800 | 259.9 | 246.8 | 5.0 |

| #3 | 40 | 1300 | 233. | 239.9 | 2.7 |

| #4 | 200 | 1000 | 199.4 | 211.9 | 6.3 |

| #5 | 200 | 1400 | 200.1 | 211.7 | 5.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, M.; Gim, J.; Kim, J.H.; Kang, S. Development of an Artificial Neural Network Model to Predict the Tensile Strength of Friction Stir Welding of Dissimilar Materials Using Cryogenic Processes. Appl. Sci. 2024, 14, 9309. https://doi.org/10.3390/app14209309

Cho M, Gim J, Kim JH, Kang S. Development of an Artificial Neural Network Model to Predict the Tensile Strength of Friction Stir Welding of Dissimilar Materials Using Cryogenic Processes. Applied Sciences. 2024; 14(20):9309. https://doi.org/10.3390/app14209309

Chicago/Turabian StyleCho, Mingoo, Jinsu Gim, Ji Hoon Kim, and Sungwook Kang. 2024. "Development of an Artificial Neural Network Model to Predict the Tensile Strength of Friction Stir Welding of Dissimilar Materials Using Cryogenic Processes" Applied Sciences 14, no. 20: 9309. https://doi.org/10.3390/app14209309

APA StyleCho, M., Gim, J., Kim, J. H., & Kang, S. (2024). Development of an Artificial Neural Network Model to Predict the Tensile Strength of Friction Stir Welding of Dissimilar Materials Using Cryogenic Processes. Applied Sciences, 14(20), 9309. https://doi.org/10.3390/app14209309