Abstract

Wire and cable are important industrial products involving the national economy and people’s livelihood, which are hailed as the “blood vessel” and “nerve” of the national economy, providing the basic guarantee for the normal operation of modern economy and society. The data traceability of their production and circulation process is a key factor in ensuring their quality and safety management. We aim to solve the problems of unsafe data transmission, weak quality control, and information islands in the process of wire and cable quality traceability in order to improve the production management efficiency of wire and cable manufacturing enterprises and to reduce the cost of consumer quality traceability of wire and cable products. We analyzed the technical characteristics and advantages of Industrial Internet of Things (IIoT) identity resolution and the blockchain. Key technologies are introduced, a traceability method that integrates the two is proposed, and a quality traceability framework based on the IIoT identity resolution system and blockchain technology is constructed. By analyzing the quality information composition of the wire and cable supply chain, a new quality traceability model based on the wire and cable supply chain is established. Finally, through the verification of the developed quality traceability system, the quality traceability function and quality information of each production link of wire and cable are successfully realized. This paper fills a gap in the field of cable product quality traceability using the combination of IIoT and blockchain technology. According to this model, it also has some potential for the traceability of other industrial products.

1. Introduction

The wire and cable industry is regarded as a basic industry of the national economy and plays a vital role in the power system. Wire and cable, as important industrial products, are directly involved in developing the country’s economy and people’s livelihoods. The wire and cable industry, due to product homogenization, low barriers to entry, low-level duplication of construction, and other reasons, is faced with a chaotic market order, lack of corporate integrity, tampering, product counterfeiting, and other issues; as such, wire and cable companies are often caught up in the issues of shoddy quality, poor sales, and capital constraints, so that counterfeiting and shoddy production seriously restrict the quality improvement of wire and cable products. From the vertical point of view, due to its wide range of brands and varieties, the quality of wire and cable products is difficult to unify [1,2,3]. The production and manufacturing process is complex and involves many factors, such as production personnel, equipment, the use of raw materials, etc., which impact the quality of wire and cable.

In recent years, the concept of the IIoT has provided favorable ground for the quality traceability of industrial products, and research on traceability has gradually shifted from food and agricultural products to industrial products. With the applications of traceability continuing to deepen, wire and cable quality traceability still faces many problems, such as the traceability process of data transmission security issues and product production, circulation of quality management, enterprise between “information island”, and other issues. The IIoT is a network system formed through connection and communication between a large number of items, which realizes intelligent management and decision making for the physical world. In the traditional Internet of Things application solution, the items in each application scenario are closed and autonomously managed due to the technical implementation route, forming an information island. In all closed networks, each item is expressed with an identifier, and the identity resolution service can be used to establish a correlation between each independent item in the Internet of Things to realize the interconnection between things. The blockchain is a distributed ledger technology with the technical characteristics of decentralization, openness, and transparency, distributed storage, immutability, and safety and reliability, among others. It is considered to be a kind of inherent trust machine that can be used to solve the traditional traceability system problems of centralization, trust crises, and others, improving the reliability and security of traceability. Therefore, IIoT identity resolution technology is the key to solving the IIoT information island problem; its advantage lies in data collection and its ability to solve the problem of multi-source heterogeneous data in the cable supply chain through identification and coding specifications and improving the degree of information interaction between enterprises. The advantage of blockchain technology lies in the storage and utilization of data, and its characteristics of information traceability and immutability based on the blockchain can ensure the authenticity, security, and effectiveness of data.

Numerous scholars have produced a large amount of research on applying these two technologies in quality traceability. Shujaat A. et al. [4] reviewed the application scenarios of the blockchain in the field of intelligent manufacturing. They proposed constructing an open quality system to expand the transparency of industrial product quality. Wang et al. [5] proposed a spinning production data traceability method based on Elasticsearch in order to realize the digital management and data traceability of the whole process of spinning production. Chen et al. [6] built an electronic product traceability system based on blockchain and ORS technology to solve problems such as easy tampering and insecurity of electronic product production and supply chain process information. Wang et al. [7] proposed a method of managing IIoT identification data through blockchain technology, which solved the problems of heterogeneity, different owners, and remote identification data in IIoT identification management. Wang et al. [8] constructed a full traceability management system for seafood quality and safety based on the application of information technology in quality traceability to realize the traceability and control of seafood quality information. In the United States, in terms of the quality and safety of aquatic products, enterprises importing aquatic products are required to provide quality and safety data before entering the market, and a series of quality traceability systems have been established [9]. Yi [10] improved the dual-storage design of “database + blockchain” to solve the problem of low query efficiency of applying blockchain technology in a fruit and vegetable quality traceability system. Figorilli et al. [11] combined blockchain and RFID technology to build a wood supply chain traceability system within the blockchain architecture to realize the online traceability of wood from standing trees to users. Su [12] investigated identity resolution and blockchain technology and proposed a new supply chain management solution. Zhu et al. [13] analyzed an Internet digital identity management solution combined with the blockchain in the context of the Internet of Things. Kumar et al. [14] proposed a framework for traceability in the textile supply chain. They designed a sequence diagram to demonstrate the interaction and information exchange between the participants in the supply chain when tracking information is required. Concerning interaction and information exchange between the participants in the supply chain, Shahid, A. et al. [15] proposed an Interplanetary File Storage System (IPFS) to address the issues of credibility and transaction process accountability arising from blockchain-based agricultural product quality traceability. Dai et al. [16] studied and designed a benefit-sharing mechanism, through which manufacturers can share with suppliers reduced recall liability due to traceability improvement to promote the improvement of traceability.

Although many scholars have made a lot of studies on quality, safety, and traceability in the production and supply chain of different industrial, agricultural, fishery, and forestry products, taking IIoT identity resolution and the blockchain as the technical entry point, the specific technology of the integration of identity resolution and blockchain has not been in-depth [17,18]. No particular application method for the integration of the two has been given. To promote the mutual circulation of product information and data, make the query more convenient, and ensure the safety of information and data, the contributions of this paper are as follows: (i) The complementary advantages of IIoT identity resolution and blockchain technology for product quality traceability are analyzed. (ii) According to the actual product quality traceability needs of the cable manufacturing industry, a set of wire and cable product traceability system methods based on the integration of an IIoT identity resolution system and blockchain technology is proposed to solve the problems of insecure data transmission, weak quality control, and information islands in the process of cable quality traceability. (iii) We developed and tested a cable quality traceability system based on identity resolution and blockchain technology to provide theoretical and technical support for realizing data sharing among all parties in the cable industry chain. Ensuring data security in the production process and enhancing the efficiency of manufacturing enterprises provides theoretical and technical support for collaborative efforts so as to make cable quality tracing more reliable.

The rest of this paper is organized as follows: Section 2 describes the principles and characteristics of the key technologies of identity resolution and the blockchain, and Section 3 proposes a scheme for their integration and data interaction. Section 4 constructs a cable quality traceability model and technical framework based on IIoT identity resolution and the blockchain, and Section 5 develops and tests a cable quality traceability system. Finally, in Section 6, the work of this paper is summarized, and the conclusion and future work are introduced.

2. Key Technologies

2.1. Industrial Internet of Things Identity Resolution System

The IIoT identity resolution system is a key component of the Industrial Internet network system and a neural hub to realize industrial interconnection. It establishes a corresponding mapping relationship between industrial equipment, data, address information, and identification in the IIoT through identity coding and identity resolution technology. The identification is used to monitor industrial equipment and acquire and process industrial data to realize intelligent industrial manufacturing. At present, the global existence of the identity resolution system is a traditional domain name system (DNS) architecture to expand and improve the path, such as the Internet of Things unified identity (entity code for IoT, Ecode) technology and object identifier (OID) technology, and so on. The other category is a new identity resolution system proposed for the application scenarios of the IIoT without using DNS architecture, such as Handle identity resolution technology, ubiquitous ID (UID) technology, etc. [19]. Currently, the Handle identity resolution system is the most commonly used system in the world, so the description begins with the identification encoding and parsing of the Handle system. The existing IIoT identity resolution architecture mainly includes international root nodes, national top-level nodes, secondary nodes, enterprise nodes, and public recursive nodes. In addition to the public recursive nodes, other nodes constitute a top-down hierarchical structure. Because of the convenience of data flow and information acquisition, identity resolution technology is not only used in the industrial field but also in many fields, such as science, education, health, and finance.

2.1.1. Establishing Identification Rules

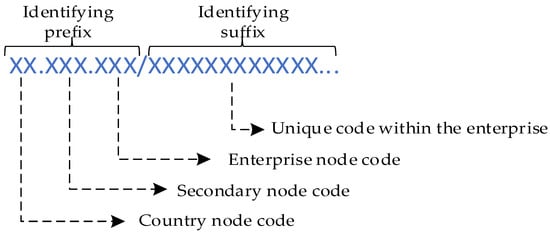

Identity coding is a technology that gives an object a digital identity, similar to the ID number in the “ID card”, which can identify physical resources such as materials, equipment, and products, and virtual resources such as production processes, data, algorithms, and models. The application basis of identification traceability is identification coding, and it is also the basis for quality traceability at the end user’s entrance. Therefore, when the product is connected with the production and the application systems, the identification coding rules should be unified first. According to the coding specification of the Alliance of Industrial Internet (AII) [20] and the “Handle” system, the unique code in the original production system of an enterprise and the enterprise prefix are used as the industrial code to establish the IIoT identification coding rules. Figure 1 shows the Handle identification code composition.

Figure 1.

Handle identification code coding rules.

Handle encoding is divided into two parts by the “/” separator into prefix and suffix, and the enterprise prefix is divided into several parts by the separator “.”. The number is divided into several parts, corresponding to the node information one by one, and the suffix is the internal unique encoding under the naming mechanism, which is composed of any UTF-8 characters.

2.1.2. Identification of Data Resolution

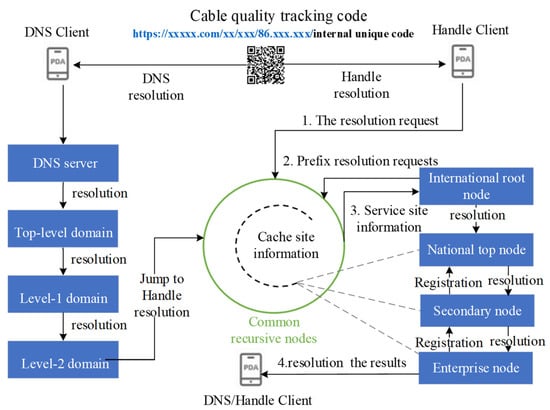

Identity resolution is a process of defining data resource retrieval. The Handle identifier is assigned to a web address and carried by the two-dimensional code. Users can scan the code to jump to the web page and facilitate product traceability. The Handle system accesses different domain servers in iterative resolution until the address of the required information is obtained, and the client communicates directly with the target server. The Handle is resolved by accessing the enterprise node based on the prefix information. The enterprise node parses and queries the suffix of the Handle identifier and sends the resolution result to the Handle client. The identity of the same product can also be queried using DNS, and eventually, the local associated data can be accessed. Figure 2 shows the analytic architecture diagram of Handle. The national root node and secondary node correspond to the global Handle registry and local Handle service, respectively, and the public recursive node can cache node information.

Figure 2.

Handle system resolution architecture.

The internal unique code in the string of two-dimensional code stands for cable quality traceability, internal sales, or supplier code scanning, and consumers can view different information through different terminals or entrances: Users scan the codes on the DNS and Handle clients to trace the product quality information on the cables. Enterprises or suppliers scan the codes on internal PDAs to trace raw material, manufacturing, and quality inspection information.

2.2. Blockchain Technology

Blockchain technology is a distributed and decentralized database technology with the main features of data decentralization, transparency, security, and immutability [21]. It realizes secure storage, transparent verification, and immutability through encryption algorithms and consensus mechanisms. The blockchain consists of date blocks, each containing a certain number of transaction records, linked together by hash pointers to form a chain. The core concepts are decentralization and consensus mechanisms. Decentralization means that no central authority or third party controls the entire system, but rather it is maintained and managed by multiple nodes in the network. The consensus mechanism is used to ensure that agreement is reached among the nodes in the network to guarantee the accuracy and consistency of the data.

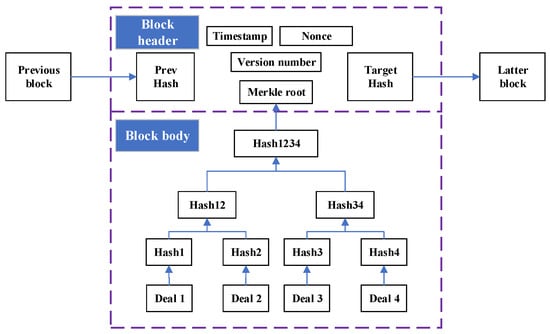

2.2.1. Blockchain Structure

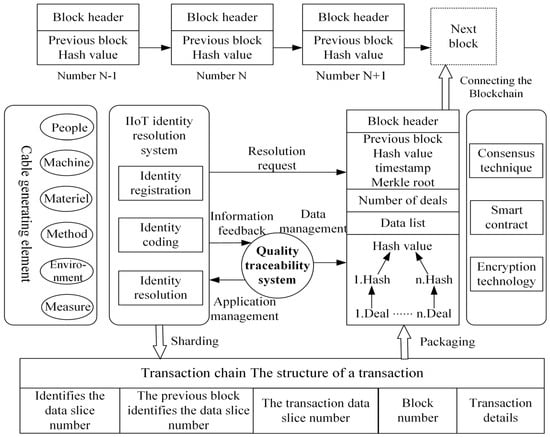

The reason why the blockchain is tamper-proof is due to the strong correlation of the chain data structure. This structure determines the binding relationships between data that will be broken when a piece of data is tampered with. Because the cost of forging such a relationship is extremely high, and the effort required to test it is minimal, the probability of tampering is extremely low. The basic data unit of the chain structure is a “block”, and the basic block structure is shown in Figure 3.

Figure 3.

Basic block structure.

The block consists of two parts: the block header and the block body. The block body contains a certain number of transaction sets. The block header maintains its association with the previous block through ‘’PrevHash” to form a chain structure, and the integrity of the block’s transaction set is quickly verified by the “Root Hash” generated by “MerkleTree”.

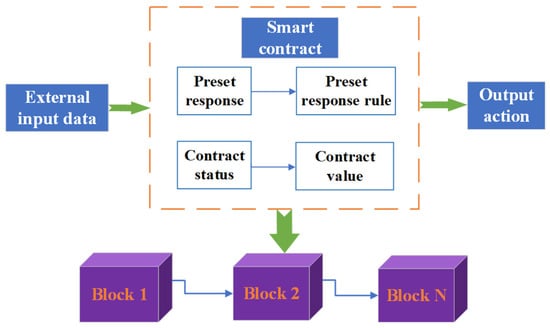

2.2.2. Smart Contract

The smart contract is a kind of contract that can be automatically executed on the blockchain and written in the form of code. Smart contracts can realize various functions such as transferring money, verifying identity, and creating digital identity [22]. Smart contracts do not have a centralized control body, and their execution results are jointly verified by all nodes on the blockchain, which ensures fair and transparent transactions. Smart contracts play a role on the blockchain as shown in Figure 4.

Figure 4.

Smart contract.

Once a smart contract is deployed on the blockchain, its code and execution results cannot be tampered with, ensuring the security of the transaction.

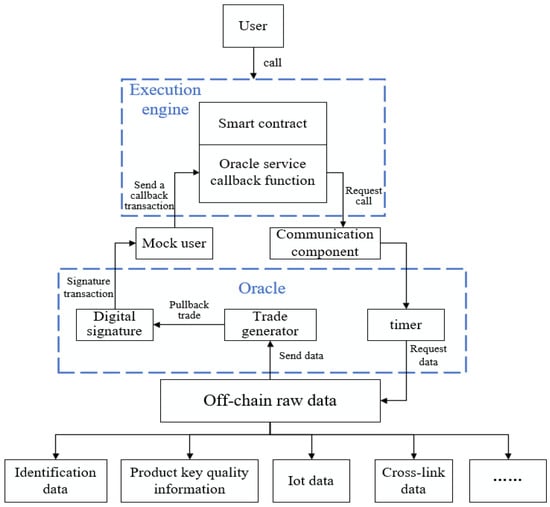

2.3. Middleware for Blockchain and IIoT Technology

Middleware for Blockchain and IIoT is a key link in the information exchange between IIoT identity resolution technology and blockchain technology. Because the blockchain is a closed system, smart contracts alone cannot upload data from the chain to the blockchain. Therefore, the middleware is needed to act as a bridge connecting Internet cloud services and blockchain smart contracts. The oracle is used for data services in the blockchain network, which realizes the link between the chain and the chain, and can ensure the authenticity of the original data uploaded by users. Figure 5 shows the architecture model diagram of the oracle link middleware.

Figure 5.

Middleware for blockchain and IIoT architecture model diagram.

The oracle interacts with the execution engine of the blockchain as an independent service module, which is not directly involved in the execution of transactions but only responsible for the trusted acquisition of data [23]. The user invokes the smart contract or API interface service to initiate a service request to the oracle, and the blockchain execution engine passes this message to the oracle through the internal components. In order to make the source of the external data reliable, this request also contains information such as the address of the data source. After the oracle sends a request to the data provider and obtains the corresponding data, it is input to a node in the oracle module, sent to the transaction generator for callback, and then returned to the execution engine through the signature algorithm. The execution engine stores the obtained data on the chain. The oracle node corresponds to one or more data providers, and the data submitted by each data provider are shared in the oracle network to ensure the relative credibility of the data.

3. Identity Resolution System and Blockchain Technology Integration Method

The IIoT identity resolution is combined with the blockchain to identify the information of each link in the whole industrial chain of the product. The identification information and the key quality data of the corresponding link are linked up. The cryptographic technology is used to encrypt it to ensure the credibility of the information on the chain. The user nodes of all parties jointly maintain the data on the chain, and the information is open and transparent so that the information of the whole product manufacturing process can be traced.

3.1. Blockchain-Based Identity Data Storage

In terms of data processing, the IIoT supports the interconnection and sharing of data elements, but it is difficult to ensure data security and confirm data rights. Especially for discrete enterprises, the use of blockchain technology to solve data storage, sharing, security, and other problems in the manufacturing process of industrial products has become a consensus in the industry.

The enterprise node uniquely identifies and encodes the information of the entire production elements such as personnel, machines, goods, raw materials, methods, environment, and testing in the cable production process through the IIoT identity resolution system, and the identification code runs through the cable supply chain. With the help of the blockchain to store the identification data, a system with the characteristics of decentralization, de-trust, and open traceability is formed [24]. Blockchain system user nodes utilize the consensus mechanism for common maintenance. Each transaction makes the blockchain generate new data records, and the endorsers peer is responsible for simulating the execution of the transaction. When a transaction request is received, it simulates the execution of this transaction request; no matter whether it is agreed to or rejected, it encrypts the result of the execution and return the signature to the client. Based on the pow (proof of workload) mechanism, the committing peers are selected to carry out bookkeeping and broadcast to synchronize with the whole network. When other user nodes receive the broadcast, they generate the corresponding hash value from the local identification coding data in piecewise records and then send them to the blockchain for encrypting and storing the data after being packaged into a block. The generated block structure consists of a block header, transaction number, and data list. The identity resolution data storage scheme based on blockchain technology is shown in Figure 6.

Figure 6.

Identity data storage scheme based on blockchain technology.

The management of transaction data is carried out through the quality traceability system. When the user applies for access resolution, the blockchain smart contract is executed to verify the user’s access rights, the data corresponding to the resolved identification are analyzed, and the data are finally shared and traced.

3.2. Smart Contract Design Based on Identity Resolution

Identity resolution ensures that the quality information of each roll of cable can be verified and that any participant can view and trace the history. The decentralized trust mechanism of the blockchain reduces the dependence on a single centralized institution. This fusion method enables the smart contract to be applied to the business logic of Handle identification management, the authentication management of user identity, the verification of identification data resolution process, and the verification of data integrity in data synchronization through the interaction of the smart contract with the distributed ledger.

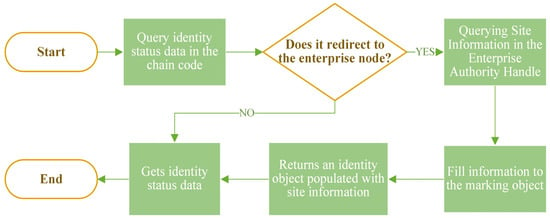

For user identity management, the key issues that need to be solved include architecture, trust model, authentication, and privacy protection. The decentralized identity management module aims to use distributed ledger technology to realize the verification and management of user identity. The module generates the user’s private key binary file and follows the Handle protocol, using the public key of the authoritative Handle as the basis for verifying the user’s identity. The user’s registration, update, and audit operations are directly read and written to the distributed ledger. At the same time, the smart contract is responsible for verifying the validity of the content in the ledger. Endorser peers act as both executors and witnesses in this management module, ensuring the credibility and security of decentralized management. The data resolution module is a general function module that includes enterprise nodes, identification service nodes, network management nodes, and public recursive nodes. The resolution process starts with recursive resolution from the top-level nodes of the country and then relies on the identification service nodes for internal resolution, and each node can establish direct communication with the blockchain nodes. Figure 7 shows the smart contract process of identity data resolution.

Figure 7.

Identify data resolution smart contract process.

For the resolution process of the identification data, Chaincode first uses the getState method of the “ChaincodeStub” interface to obtain the identification state data and then determines whether its state needs to be redirected to the enterprise nodes, and if it does, it calls “getState” again to query the information in the enterprise authority Handle. Finally, the data are populated into the “uhdsite” field of the business identity object entity and returned.

3.3. Data Interaction Synchronization for the Integration of Identity Resolution and Blockchain

The interactive synchronization problem of cable quality data is divided into the data synchronization of the identity resolution system and the data synchronization between the identity resolution system and the blockchain system.

Identity resolution system data synchronization consists of product data synchronization and identity data synchronization. Product data synchronization through the product add interface or directly in the background exists to enter product information; if product information entry is complete, it occurs in secondary node synchronization to generate data templates. Product data to be synchronized include product name, model specification, length, rated voltage, standard number, production date, inspection number, etc. The identity data synchronization first generates the identity on the application platform through the identity creation interface, returns the IIoT identity and QR code link (consistent with the agreed format content), and then uploads the identity data through the identity update interface.

Data synchronization between the two systems is then achieved by using the identification service node to listen to the state ledger of the blockchain node through the “SYN” method. The smart contract code is shown in Algorithm 1.

| Algorithm 1: Synchronization Algorithm |

Input:

|

“CouchDB” notification of changes to the document is used to monitor the modifications and updates to the database in order to synchronize and process the subsequent data. A CouchDB client is first created through “Ektorp” and used to interact with the blockchain node’s state database. Then, a long connection is created using the “changesFeed” method to continuously get notifications of changes to the database. Whenever a new notification is received, “CouchDbLooker” is used to obtain the corresponding status data through CouchDB’s “http” interface. It then extracts the site identity and untrusted data summary. If the site registered by the untrusted data is not the current node itself, a Handle resolution request is sent to the corresponding node. Then the resolution result is verified, and if the verification passes, the Handle is written to the local Handle database.

4. Wire and Cable Quality Traceability Method Based on the Integration of Identity Resolution and Blockchain

Due to the different rules of wire and cable product identification, poor information sharing, and low level of digitization of production enterprises, it is difficult to understand the process information of wire and cable production and key technical parameter information through the digital transparent supply chain. Thus, realizing the reliable traceability of quality and safety is not easy. Therefore, using wire and cable products as the object of research, based on the IIoT identity resolution and blockchain technology, we created a wire and cable quality traceability system to support the enterprise’s rapid and low-cost use of related technical services.

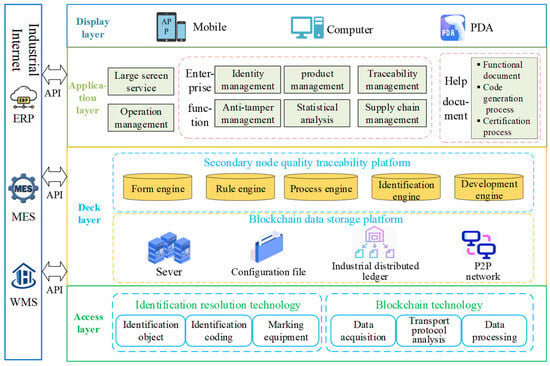

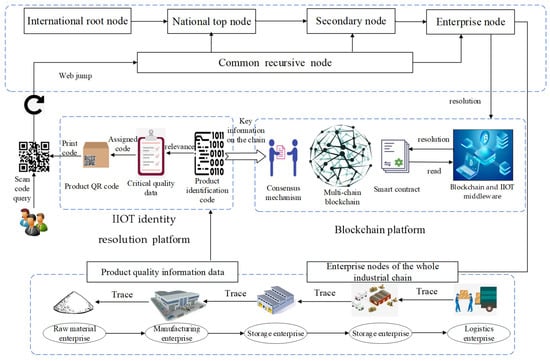

4.1. Overall Framework

Coding is the premise and basis of product quality traceability. The coding information of cable products is printed on the cable product body and product certificate in the form of a QR code. According to the direction of cable product flow, the key quality data information generated by its production, testing, circulation, sales, and other links is assigned code associations. With a wide range of cable models and types, when tracing the quality of cables, not only does it require a large amount of data, but it also needs to ensure the authenticity of the data content. Therefore, a cable quality traceability system that integrates identity resolution and blockchain technology can provide a more transparent and trustworthy quality management process, ensuring the data’s trustworthiness and integrity and preventing it from being tampered with and falsified. Participants can track cable production and supply chain quality information through identifiers to ensure that cables comply with standards and specifications. Its structural framework is shown in Figure 8.

Figure 8.

Technical framework for the integration of identity resolution and blockchain.

The display layer is the topmost layer of the quality traceability system. Users can access the basic information of the cable by scanning the QR code. The system allows companies to access the quality information data of each part in the cable design and manufacturing process.

The application layer is mainly responsible for data operation and collaborative business logic processing on the platform layer, and feedback data processing results in the display layer through the six core functions for internal personnel to query the quality information of the cable.

The platform layer connects the identity systems by introducing key technologies such as blockchain’s distributed storage technology, P2P (peer-to-peer network), and middleware for blockchain and the IIoT to solve the problem of logo heterogeneity of different identity resolution systems [25]. The user invokes the smart contract and API interface service to initiate a service request to the oracle, and the blockchain’s execution engine delivers this message to the oracle via an internal component, which also contains information such as the address of the data source in order to make the external data source reliable. When the oracle sends a request to the data provider and obtains the corresponding cable product data, they are handed over to the transaction generator for a callback, and then through the signature algorithm, it returns the callback transaction to the execution engine for uploading and storing the data by the execution engine.

The main function of the access layer is to collect data through active marking and passive marking. The active marking mainly contains the ICC (integrated circuit card), chip, communication module, and various induction devices, and the passive marking has barcode, QR code, and so on. The traceability system introduces the enterprise’s IIoT system, Manufacturing Execution System (MES), Warehouse Management System (WMS), and Enterprise Resource Planning (ERP) system through the interface, and utilizes the blockchain database information sharing to realize the collection of quality information data and the formation of transaction records to be deposited in the blockchain ledger, which ensures the safe access, transmission, and reading of data in case of the terminal equipment being maliciously attacked.

4.2. Analysis of Quality Elements

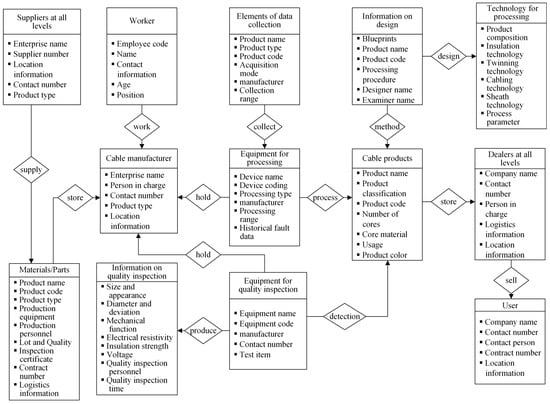

Constructing the model from the demand of analyzing and decision making and determining the corresponding core quality data of wire and cable products according to the type of identified objects can well guide the development of the IIoT and the establishment of data resources for cataloging, archiving, library building, sharing, exchange and querying [26,27]. Figure 9 is the corresponding core quality data model for cables proposed according to relevant standards.

Figure 9.

Wire and cable core quality traceability data model.

This model from the supplier, the cable manufacturing plant, through all levels of distributors ultimately reaches the user of the entire supply chain, as do the wire and cable quality metadata model, extracted personnel, enterprises, production and processing technology, environmental data, product quality inspection, geographic location, and other relevant information, that is, a comprehensive and systematic description of the information composition of the wire and cable, to facilitate the subsequent systematic coding of the cable and the study of quality traceability methods.

4.3. Construction of Quality Traceability Model

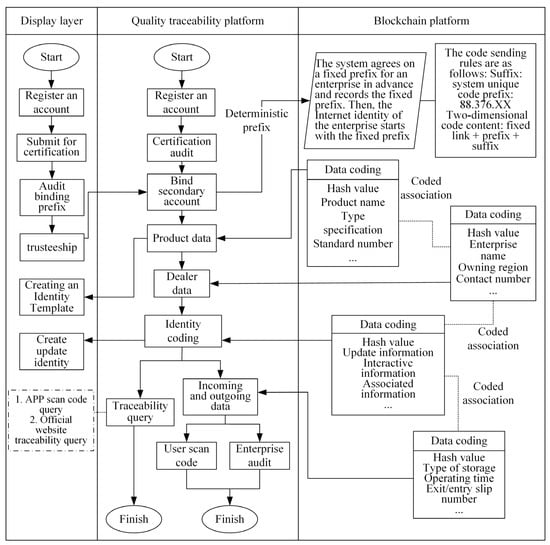

The enterprise user applies to the secondary node to register the Handle’s prefix, and at the same time, according to the realization of the agreement in the system, saves the fixed prefix and fixed link part of the enterprise, according to the set rules for code generation. Identity data need to synchronize basic data (product information and dealer data) and dynamic data (identity registration, identity update, in/out flow data). By docking the logistics identification data, distributor data, warehouse in/out data, and distributor in/out data with the production system, we can view the flow information of each logistics identification and its current state in the application system [28,29]. The cable quality traceability process with the integration of identity resolution and the blockchain is shown in Figure 10.

Figure 10.

Flowchart of cable quality traceability for the integration of identity resolution and blockchain.

After analyzing the quality characteristics of the whole industrial chain of cable products and building a complete cable quality and safety credible traceability block data structure, a cable quality and safety credible traceability model is designed, including IIoT identity resolution system nodes and enterprise blockchain nodes. In this model, identity resolution technology and blockchain technology are organically integrated. In data collection, all the basic data of the enterprise stored on the blockchain have the problems of high cost and low efficiency, so through the middleware for the blockchain and IIoT, the internal MES, WMS, ERP, and other systems of the enterprise are set up with blockchain nodes, so as to achieve the purpose of rapid transaction of data information and cost reduction. After the enterprise user successfully applies for identification in the identity resolution application platform, the key data of the cable product will be uploaded to the chain for certification and the complete transaction hash value will be generated [30,31].

It is aiming at the quality traceability of each enterprise in different links of the whole industrial chain of cable products. It connects the nodes of each enterprise in the whole industrial chain and establishes a cable quality traceability system with the fusion of identity resolution and blockchain [32]. Its model functions include identity registration, identity coding, data uploading and storage, and data query. It can effectively solve the problems of difficult traceability, data inaccessibility, and data inaccuracy that exist in the current traceability system, as well as the information interaction between the blockchain system and the IIoT identity resolution system, and provide a feasible solution for truly realizing the traceability of the whole industrial chain of industrial product quality, and the overall architecture of the product quality traceability model combining the blockchain and identity resolution is shown in Figure 11 below.

Figure 11.

Cable quality traceability model for the integration of identity resolution and blockchain.

In the production completion link, synchronize the basic product information and cable logistics identification data, including the roll label and bag label, the correspondence between them into the anti-tampering sub-system, as the subsequent logistics anti-tampering query as well as the identification of the resolution of the basic data. In order to facilitate dealer management in the application system, the dealer information is synchronized before the delivery of the dealer, to facilitate the subsequent binding of the goods information on the delivery order with the dealer.

In the testing link, samples are collected and mailed to the National Wire and Cable Quality Supervision and Inspection Center for testing, and test reports are generated, and the test reports are coded the same as the samples sent for testing to ensure the uniqueness of the reports of the samples sent for testing.

In the production process of warehousing, links need to synchronize warehousing information to the application system, to ensure that all synchronized product identification information are warehousing operations, according to the delivery order to the corresponding dealers for delivery, but also need to make the corresponding inventory data processing, and ultimately, through the identification of the goods sent to the supplier to determine the binding relationship of the goods sold in the region.

5. Implementation of Wire and Cable Quality Traceability System by Integration of Identity Resolution and Blockchain

5.1. System Environment Deployment

The development technical architecture of the quality traceability system based on IIoT identity resolution and blockchain technology follows the principles of security, advancement, reliability, practicability, and scalability. Under the Linux operating system environment, the core framework is developed by “Spring Boot 3.0” framework, the view is developed by “Layui 2.5” framework, the “Tomcat 8.5” server is used, the “Mysql 5.0” database is used, and it is compatible with mainstream browsers; the mobile client adopts “Vant 3.0” framework + “HBuilder 3.7” mode to realize multi-terminal adaptation. Blockchain data storage adopts Hyperledger Fabric distributed ledger, based on which it realizes the basic configuration, the application of container, the creation of channels, and the deployment of chain code.

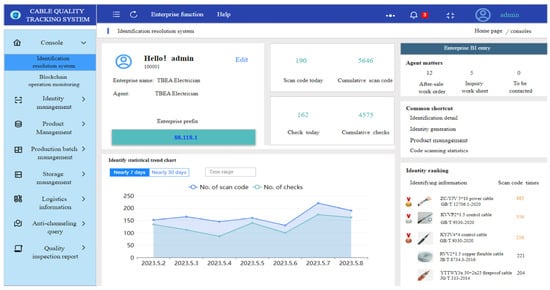

5.2. System Application Realization

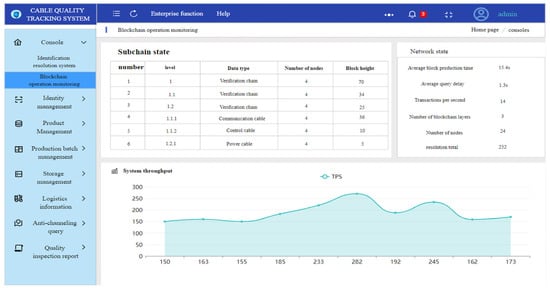

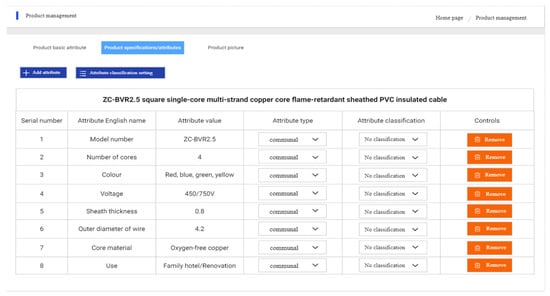

The system’s main functions are console, identity management, product management, production batch management, warehousing management, anti-tampering query, and so on. Figure 12 is the identity resolution system monitoring diagram, Figure 13 is the blockchain operation monitoring diagram, and Figure 14 is the product management information diagram, showing the specific information of the cable-related product models.

Figure 12.

Identity Resolution System Monitoring Diagram.

Figure 13.

Blockchain operation monitoring diagram.

Figure 14.

Product management information diagram.

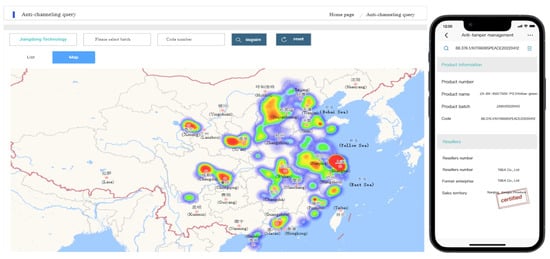

Figure 15 is the warning diagram of the tampering prevention system, according to the product, batch, and code number for the combination of queries to determine whether the tampering, query the system from the blockchain to obtain the internal Hash value of the traceability and automatically calculate the Hash value of the original data, through comparison can be judged whether the original data is true. The regional coverage map shows that the product should be in the region, otherwise it represents tampering.

Figure 15.

Warning diagram of the tampering prevention system.

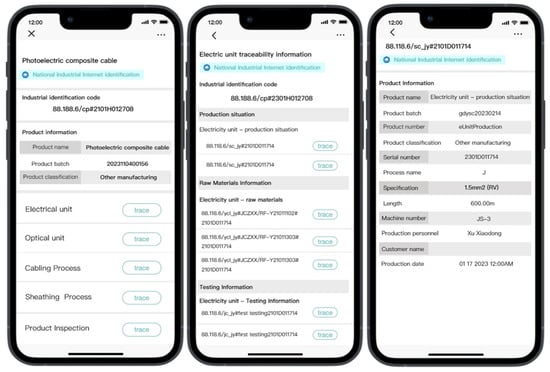

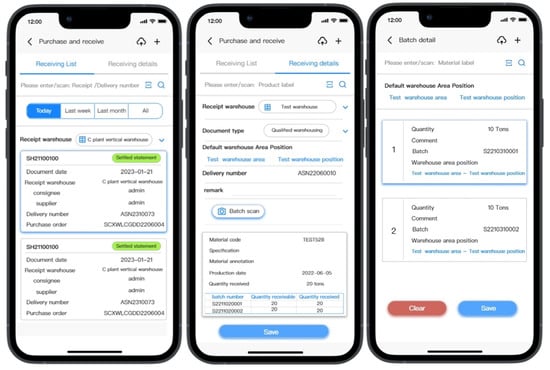

Mobile users enter the traceability management page by scanning the QR code of the products. Figure 16 shows the process traceability diagram of the photoelectric composite cable and the production information traceability of its electric unit. Figure 17 shows the batch and detail diagram of the photoelectric composite cable’s procurement receipt and storage stage. Identity authentication through different port access enables enterprises to trace the identity data for controllable open, and different users can scan the code to obtain cable products in the storage of relevant information in the block. The key fusion of identity resolution and blockchain enables enterprises to record the whole process data information of a batch of products in data management, which can be displayed in the product template.

Figure 16.

Traceability of quality information in the manufacturing stage of photoelectric composite cable.

Figure 17.

Information tracing in the stage of photoelectric composite cable acquisition and storage.

5.3. Quality Standards and Safeguards

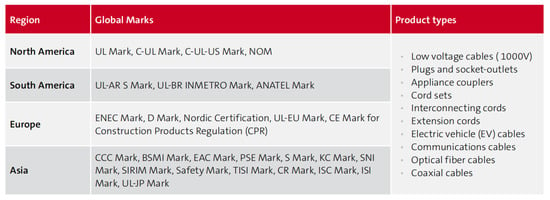

Product quality and safety is an important business basis for enterprises. There are many types of wires and cables, and according to the different uses, there are some differences in the manufacturing process and quality standards. Each industrialized country has also introduced the corresponding quality testing standards [33,34]. For example, ANSI/UL 9990, the Information and Communications Technology (ICT) power cable standard released in July 2023, was identified as the U.S. national standard for ICT power cable assemblies. ANSI/UL 9990 certified ICT cable assemblies can be affixed with the UL mark on product packaging, which increases consumer confidence and allows them to identify UL-certified ICT power cable assemblies. As shown in Figure 18, these are the entry-mark requirements for major global markets for major cable products.

Figure 18.

Main cable product market access requirements.

In order to protect the sustainable development of enterprises and the rights and interests of consumers, according to the quality standards and market access requirements of cable products, it is very necessary to establish a non-conforming product disposal management system and consumer rights protection program in the quality traceability system [35,36]. Reasonable disposal of non-conforming products and active protection of consumer rights and interests can ensure that enterprises respond to quality incidents promptly and effectively, and improve product quality and safety management.

5.3.1. Management of Non-Conforming Products

In the production stage, the operation and maintenance personnel through the quality traceability system accurately locate all links of cable production and distribute the corresponding rectification measures. There are three ways to deal with non-conforming products: rework, downgrade, and scrap. Rework: the quality inspection personnel or quality department will approve the rework of the “non-conforming product notice” through the quality traceability system to the corresponding production department for rework so that it can reach the normal standard; Degrade: Change of the quality grade of a non-conforming product to make it conform to the original requirements; Scrap: For products that do not meet quality standards after rework and degrade, scrap them after review. In the market circulation stage, defective products circulated on the market shall be recalled and destroyed promptly before causing losses to consumers. If there has been a loss to the consumer, according to the harm to the consumer, actively give the corresponding compensation processing.

5.3.2. Consumer Rights Protection

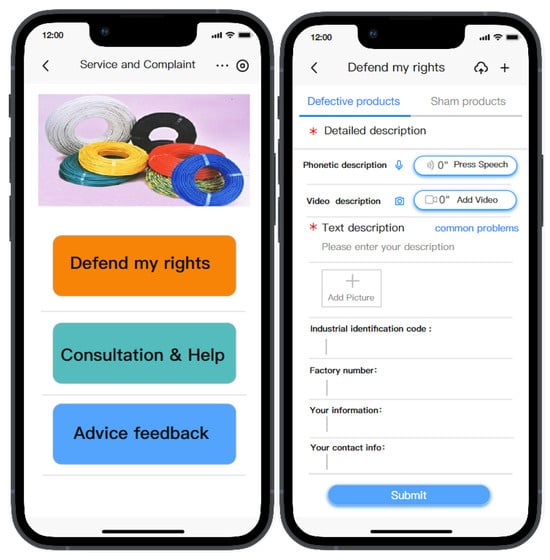

Wire and cable manufacturers take the interests of consumers as the primary consideration, and the quality traceability system establishes a consumer complaint and claim window, as shown in Figure 19, which is one of the important measures to ensure the rights and interests of consumers.

Figure 19.

Consumer Complaints and Claims window.

For counterfeit products, assist consumers and hold counterfeit enterprises accountable through relevant market supervision departments.

5.4. System Performance Testing

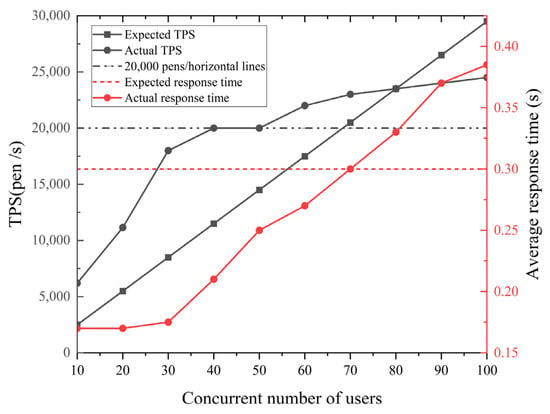

This paper uses the “Jmeter2.9” framework for the identity resolution module to conduct performance tests, setting 100 sets of identification user codes ranging from 0 to 99. Each set has 50 identification codes, using the concurrent gradient method to gradually increase the number of concurrent users, and running each group for 20 to 25 min to collect various data after the test group completes the query and resolution. The gradient curve is obtained.

As shown in Figure 20, the actual average response time and Transactions Per Second (TPSs) of the system reach the expected value before the number of concurrent users reaches 70, and part of the TPS reaches more than 20,000 strokes/s. After the number of concurrent users exceeds 70, the actual response time and TPS of the system cannot reach the expected value, but the TPS of the system reaches more than 20,000 pens/s, and the actual response time is within the preset range. The experimental data show that the system has a sensitive response time and high throughput, and meets the expected standards in terms of performance, which in turn realizes such functions as timely response to decision-making commands and powerful data processing, and improves the robust performance of the system to a greater extent.

Figure 20.

System query and resolution processing capacity gradient change curve.

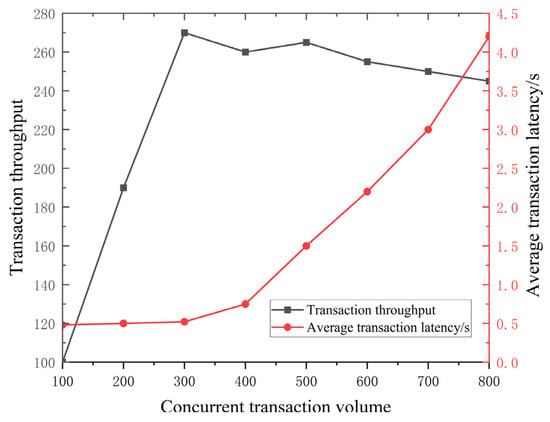

For the blockchain module, the “Hyperledger Fabric 2.5” has a field for setting block parameters, setting the number of transactions that can be accommodated as 100, the block size as 16 MB, and the time interval between blocks as 2.5 s. Caliper, a blockchain performance testing tool, is used to track the performance of the blockchain in real-time, and TPS and latency are chosen as the system’s performance testing indexes here. Design 8 performance test experiments, using Caliper custom script to initiate transactions to the system, each round of transactions concurrently 1000 times, a total of 8000 times, the number of transactions, and latency of the experiments to record and calculate the success rate of transactions. The transaction throughput results and average transaction latency are shown in Figure 21.

Figure 21.

System transaction performance test curve.

When the test script is set to 100–300 TPS, the transaction throughput will increase with the increase in transaction volume. After that, it will remain stable at around 260 transactions/s, and then the transaction time of the system will increase because the number of transactions is too large, and the average delay of the transactions within this number is about 0.5 s. In the 8 experiments, some of the transactions cannot be completed due to network reasons, and the average success rate of the system is calculated to be about 99.95%. The chain code under blockchain network deployment did not crash in many experiments. The performance can meet the traceability system application.

6. Conclusions and Future Studies

In this paper, from the perspective of wire and cable product manufacturing enterprises, we analyzed the key quality information and the complexity of business logic in the cable traceability process. Fully integrating the IIoT identity resolution system and blockchain technology, a complete set of cable quality traceability system construction methods is proposed.

First, the identity data storage scheme based on blockchain technology and the smart contract design scheme based on identity resolution are analyzed and elaborated. Secondly, the data interaction and synchronization problems of identity resolution and blockchain are solved, and the quality traceability system framework integrating identity resolution and blockchain technology is built. The core quality data model of the cable supply chain is constructed, the detailed process of cable quality traceability empowered by identity resolution is elaborated, and a quality traceability model with the fusion of identity resolution and blockchain technology as the basic support and the whole industrial chain of cables as the orientation is proposed. Finally, the applicability of the quality traceability method proposed in the paper is verified through the development of a wire and cable quality traceability system, which improves the quality management efficiency of the wire and cable manufacturing enterprises and reduces the cost of information acquisition and recall of goods among the supply chain. This method will have a better reference value for discrete enterprises. The establishment of wire and cable product quality supervision and consumer rights protection mechanisms will have a certain positive impact on market regulators and consumers.

With the arrival of 5G technology, industrial data with more modes and more complex structures will be mass-accessed and have high-speed transmission. The access frequency of public services will also reach an unprecedented height. These new challenges will put higher requirements on the information processing capacity of wire and cable quality traceability systems. In the subsequent research, not only we will consider the compatible collection and accurate analysis of a large number of effective industrial data, develop a consensus mechanism more suitable for the wire and cable quality and safety traceability model and the chain network connector of the smart contract to improve the stability of the system and the ability to process information and in the conditions of the enterprise carry out rapid demonstration and popularization, but we will also pay attention to the mining of data with added value and derivative services to promote the deep integration of the Big Data industry with the manufacturing industry and improve the level of industrial information management of enterprises.

Author Contributions

Conceptualization, J.Z. and C.L.; methodology, J.Z.; formal analysis, J.Z.; funding acquisition, W.S.; investigation, J.Z.; software, J.Z. and X.Z.; resources, J.Z.; data curation, J.Z.; validation, L.W.; writing—original draft preparation, J.Z.; writing—review and editing, J.Z.; visualization, J.Z.; supervision, W.S.; project administration, D.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Industrial Internet of Things Identity Resolution All Elements Integrated Platform project (a major project of the Ministry of Industry and Information Technology, Grant No. TC210A02E) and the Research and Development of Key Technology for Integration of All Elements of Industrial Internet of Things Identity Resolution (Natural Science Foundation of Xinjiang Province, Grant No. 2022B01049).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data covered in this paper is the property of the author’s institution and may not be used publicly.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhu, Z.; Shen, J. Wire and Cable Testing and Quality Control Analysis. Pract. Electron. 2018, 8, 18–26. [Google Scholar]

- Zhang, J.; Gao, J.; Zhang, C.-Y. Analysis of Wire and Cable Quality Based on Supervision and Spot Check Results. Pract. Electron. 2023, 8, 18–26. [Google Scholar] [CrossRef]

- Yu, Y. Analysis of Wire and Cable Testing and Quality Control Points. China Plant Eng. 2022, 6, 24–26. [Google Scholar]

- Ali, S.; Shin, W.S.; Song, H. Blockchain-Enabled Open Quality System for Smart Manufacturing: Applications and Challenges. Sustainability 2022, 14, 11677. [Google Scholar] [CrossRef]

- Wang, B.; Zheng, X.; Shen, X. Method for Data Tracing Based on Elasticsearch during Spinning Production. J. Text. Res. 2021, 42, 55–62. [Google Scholar]

- Chen, J.; Zhang, X.; Shangguan, P. Electronic Product Traceability System Based on Blockchain and ORS. Comput. Eng. Des. 2021, 42, 349–355. [Google Scholar]

- Wang, Y.; Li, H.; Wang, H. Research on Identifier Data Management Strategy of Industrial Internet Based on Blockchain. Comput. Eng. Appl. 2020, 56, 1–7. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Shi, J.; Wang, S.; Zhou, M.; Wang, D. Quality Information Traceability System Based on Seafood’s Production Process. Trans. Chin. Soc. Agric. Eng. 2015, 31, 264–271. [Google Scholar] [CrossRef]

- Willette, D.A.; Cheng, S.H. Delivering on Seafood Traceability under the New U.S. Import Monitoring Program. Ambio 2018, 47, 25–30. [Google Scholar] [CrossRef]

- Yi, W.; He, J.; Liu, G. Development and Implementation of Blockchain to Enhance Traceability and Reliability of Fruit and Vegetable Quality. Trans. Chin. Soc. Agric. Mach. 2022, 53, 309–315. [Google Scholar]

- Figorilli, S.; Antonucci, F.; Costa, C.; Pallottino, F.; Raso, L.; Castiglione, M.; Pinci, E.; Del Vecchio, D.; Colle, G.; Proto, A.R.; et al. A Blockchain Implementation Prototype for the Electronic Open Source Traceability of Wood along the Whole Supply Chain. Sensors 2018, 18, 3133. [Google Scholar] [CrossRef] [PubMed]

- Su, X.; Xu, X.; Guo, W. Integrated Application of Identity Resolution and Blockchain Technology for Supply Chain Management. Mod. Supply Chain. Res. Appl. 2021, 3, 78–97. [Google Scholar]

- Zhu, X.; Badr, Y. Identity Management Systems for the Internet of Things: A Survey towards Blockchain Solutions. Sensors 2018, 18, 4215. [Google Scholar] [CrossRef]

- Kumar, V.; Hallqvist, C.; Ekwall, D. Developing a Framework for Traceability Implementation in the Textile Supply Chain. Systems 2017, 5, 33. [Google Scholar] [CrossRef]

- Shahid, A.; Almogren, A.; Javaid, N.; Al-Zahrani, F.A.; Zuair, M.; Alam, M. Blockchain-Based Agri-Food Supply Chain: A Complete Solution. IEEE Access 2020, 8, 69230–69243. [Google Scholar] [CrossRef]

- Dai, H.; Tseng, M.M.; Zipkin, P.H. Design of Traceability Systems for Product Recall. Int. J. Prod. Res. 2015, 53, 511–531. [Google Scholar] [CrossRef]

- Li, J.; Qiu, J.J.; Zhou, Y.; Wen, S.; Dou, K.Q.; Li, Q. Study on the Reference Architecture and Assessment Framework of Industrial Internet Platform. IEEE Access 2020, 8, 164950–164971. [Google Scholar] [CrossRef]

- Li, T.; Xiang, Y.; Zhang, Z.; Yang, T.; Xin, W.U.; Li, C. Application Research of Blockchain + Internet of Things in Agricultural Product Traceability. Comput. Eng. Appl. 2021, 53, 50–60. [Google Scholar] [CrossRef]

- Yuzheng, R.; Renchao, X.; Shiqin, Z.; Haoran, Z.; Jiayi, Y.U.; Ru, H.; Huang, T.; Yunjie, L. Survey of Identity Resolution System in Industrial Internet of Things. J. Commun. 2019, 40, 138–155. [Google Scholar]

- Zang, J.; Liu, Y.; Wang, B.; Miao, Z.; Xue, Y.; Li, P. Industrial Internet Identification Analysis Product Traceability White Paper. Alliance Ind. Internet 2022, 58, 285–308. [Google Scholar] [CrossRef]

- Bao, Z.; He, D.; Khan, M.K.; Luo, M.; Xie, Q. PBidm: Privacy-Preserving Blockchain-Based Identity Management System for Industrial Internet of Things. IEEE Trans Ind. Inf. 2023, 19, 1524–1534. [Google Scholar] [CrossRef]

- Xie, R.; Wang, Z.; Yu, F.R.; Huang, T.; Liu, Y. A Novel Identity Resolution System Design Based on Dual-Chord Algorithm for Industrial Internet of Things. Sci. China Inf. Sci. 2021, 64, 182301. [Google Scholar] [CrossRef]

- Ali, M.S.; Vecchio, M.; Antonelli, F. A Blockchain-Based Framework for IoT Data Monetization Services. Comput. J. 2021, 64, 195–210. [Google Scholar] [CrossRef]

- Yang, H.; Xiong, S.; Frimpong, S.A.; Zhang, M. A Consortium Blockchain-Based Agricultural Machinery Scheduling System. Sensors 2020, 20, 2643. [Google Scholar] [CrossRef] [PubMed]

- Lin, R.; Wang, S. Identity Resolution and Blockchain Technology in the “Supply Chain” Financial Field Application Exploration. Netw. Secur. Technol. Appl. 2020, 08, 120–123. [Google Scholar]

- Xu, J.; Han, J.; Qi, Z.; Jiang, Z.; Xu, K.; Zheng, M.; Zhang, X. A Reliable Traceability Model for Grain and Oil Quality Safety Based on Blockchain and Industrial Internet. Sustainability 2022, 14, 15144. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, K.; Lin, Y.; Xu, W. Lightchain: A Lightweight Blockchain System for Industrial Internet of Things. IEEE Trans Ind. Inf. 2019, 15, 3571–3581. [Google Scholar] [CrossRef]

- Li, J.; Qiao, Z.; Peng, J. Asymmetric Group Key Agreement Protocol Based on Blockchain and Attribute for Industrial Internet of Things. IEEE Trans Ind. Inf. 2022, 18, 8326–8335. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, T. Distributed Watchdogs Based on Blockchain for Securing Industrial Internet of Things. Sensors 2021, 21, 4393. [Google Scholar] [CrossRef]

- Kumar, R.L.; Khan, F.; Kadry, S.; Rho, S. A Survey on Blockchain for Industrial Internet of Things: Blockchain for Internet of Things. Alex. Eng. J. 2022, 61, 6001–6022. [Google Scholar] [CrossRef]

- Wang, J.; Chen, J.; Ren, Y.; Sharma, P.K.; Alfarraj, O.; Tolba, A. Data Security Storage Mechanism Based on Blockchain Industrial Internet of Things. Comput. Ind. Eng. 2022, 164, 107903. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, H.; Pei, X.; Wang, J. Food Safety Traceability System Based on Blockchain and EPCIS. IEEE Access 2019, 7, 20698–20707. [Google Scholar] [CrossRef]

- Pong, I.; Cooley, L.D.; Lin, A.; Higley, H.C.; Sanabria, C. Diameter Quality Control of Nb3Sn Wires for MQXF Cables in the USA. IEEE Trans. Appl. Supercond. 2019, 29, 6001505. [Google Scholar] [CrossRef]

- Pong, I. Materials Naming Scheme. US-HL-LHC AUP Document 41. 2018. Available online: https://us-hilumi-docdb.fnal.gov/cgi-bin//ShowDocument?docid=41 (accessed on 20 December 2023).

- Conklin, J. The Road to Quality Control: The Industrial Application of Statistical Quality Control. J. Qual. Technol. 2021, 53, 438–439. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; Xu, X.; Li, W.; Dong, G. Intelligent Cable Joint Quality Management System Based on RFID Technology. J. Phys. Conf. Ser. 2021, 1852, 022070. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).