Abstract

In recent times, the significance of advancing road transportation technologies has notably increased. This is mainly driven by the escalating need for road transportation systems that are not only safe but also environmentally sustainable. Moreover, enhancing fuel efficiency in road vehicles (i.e., automobiles) holds the potential to contribute significantly to the reduction of a country’s economic vulnerability (i.e., improved energy security), by reducing the reliance on energy imports. While research reports and scientific journals provide valuable information on automobile fuel consumption, it is essential to continually update our understanding of the factors that influence it. This document aims to review and describe the various factors, both direct and indirect, that play a role in an automotive’s overall energy efficiency and fuel consumption.

1. Introduction

Motorized road transportation (i.e., automobiles) is fundamental to a country’s economy. It facilitates the distribution of food, raw materials, equipment, and finished products. Notably, the transportation sector is responsible for about one-third of global energy consumption [1,2]. Within the transportation sector, road transportation (in particular) remains an essential link between production, market, and service operations, even though it is not directly related to material or energy production. As a result, transportation expenses (including fuel and energy costs) have a direct impact on the sustainability and efficiency of businesses, cities, and countries. Therefore, it is necessary to perform an ongoing analysis of the structures of private and public road vehicle fleets, driving behaviors, and other associated factors in order to understand their influence on fuel consumption. It is important to examine engineering approaches and public policies to propose and reinforce fuel-saving political measures. Furthermore, elements such as traffic dynamics, congestion, traffic signal coordination, roadway design, overall road conditions, and externalities arising from automobile configuration directly affect fuel consumption. These factors affect key operational variables such as resistance, service load, and vehicular speed, which in turn determine overall fuel efficiency.

It is important to consider that an automobile’s fuel consumption constitutes only a segment of the large energy continuum involved in road transportation. The energy expended in an automobile is the culmination of intricate processes including fuel production (and transportation) and automobile manufacturing (among others). For a holistic understanding of overall efficiency, it is important to adopt a full fuel life cycle approach, enfolding both well-to-tank and tank-to-wheel efficiencies. The energy required to transform a primary energy source (i.e., petroleum) into its utilizable form (i.e., fuel), be it transforming crude oil to gasoline or diesel or processing biomass into ethanol or bio-diesel, profoundly influences the net efficiency of diverse automobile–fuel combinations.

Moreover, due to the current global environmental circumstances, it is imperative that countries implement policies aimed at improving energy efficiency, both in passenger cars and transportation fleets (public and private). Such policies can help in the following ways: (a) promoting fuel efficiency improvements and helping to transition to sustainable energy sources; (b) reducing the reliance on imported fuels to minimize economic vulnerability by shielding against the volatility of international fuel prices; (c) reducing trade deficits linked to energy imports; and (d) reducing the environmental footprint associated with road transportation. Governments must build collaborative ties with the automotive industry, research communities, and general society to enact robust policies promoting efficient and sustainable road transportation. Such policies align with and contribute to global initiatives addressing energy security and climate change challenges.

This article aims to provide a comprehensive literature review of factors affecting fuel consumption in road transportation modalities (i.e., automobile), particularly on the tank-to-wheel segment of the fuel cycle. Information from a wide range of academic, industrial, and governmental sources was methodically extracted and synthesized. By systematically analyzing recent strategies and technological approaches aimed at optimizing fuel efficiency, this text provides a holistic view of the current and potential innovations in automotive technology. Key challenges and opportunities inherent in implementing fuel-saving technologies were identified, indicating possible courses for future research and aiming to support policy formulation and industry practice. The text is divided into six chapters, as follows: Section 1 is an introduction to road transportation, dealing with aspects such as fuel consumption, energy balance, and operational factors. Section 2 gives a general view of the factors affecting fuel consumption in road vehicles. Section 3 presents relevant developments in road vehicle design and technology, alongside advancements in internal combustion engines (ICEs) and alternative fuels. Section 4 specifies operational factors and driving modes affecting fuel consumption. Section 5 discusses other indirect effects, such as governmental policies, and some alternatives to reduce fuel consumption, such as electric mobility. The authors’ final remarks are registered in Section 6. This review specifically included data and strategies applied in Colombia (South America) as an indication of the country’s institutional commitments and initiatives toward sustainable road transportation. Through a detailed review and analysis of both global and context-specific factors, this study presents minute insights into the everchanging field of automotive fuel efficiency, offering valuable information to stakeholders committed to advancing sustainable and efficient transportation solutions.

1.1. Fuel Economy vs. Fuel Consumption

Fuel economy and fuel consumption are the most important metrics for assessing fuel efficiency in road vehicles. The former quantifies the distance a vehicle covers per unit of fuel, typically denoted as miles per gallon (mpg)—a standard adopted predominantly in North America by stakeholders ranging from consumers to regulatory entities. Conversely, fuel consumption offers an inverse perspective, indicating the volume of fuel expended over a specified distance, with customary units such as gallons per 100 miles or liters per kilometer [3]. In this review, both terminologies will be employed interchangeably to discuss vehicle fuel efficiency.

1.2. Energy Balance of a Vehicle

The fuel consumption of a motor vehicle over a distance (including the fuel consumed during unproductive stops) is controlled by the vehicle’s efficiencies, both in converting the chemical energy of the fuel into mechanical energy and in transmitting it to the axles to drive the wheels (all this while overcoming resistance to motion). Excluding factors like road curvature and losses due to parasitic dynamic effects in various vehicle components and mechanisms, the instantaneous power demand (Pload) of a vehicle can be determined as follows [4,5]:

where Proll ≈ CR M g v represents the power required to overcome rolling resistance, CR being the dimensionless coefficient of rolling resistance, M the mass of the loaded vehicle, g the acceleration due to gravity, and v the vehicle’s speed.

Pload = Proll + Paero + Pinertia + Pslope + Paux

Paero = 0.5 ρ CD A v3/1000 represents the power required to overcome aerodynamic resistance. In this equation, ρ is the air density, CD is the coefficient of aerodynamic resistance, A is the frontal area, and v is the vehicle’s speed.

Pinertia = 0.5 M* [Δv2/Δt] represents the power required to overcome inertial resistance. In this equation, M* is the effective inertial mass, which is approximately 1.03 times the mass of the vehicle M. This factor accounts for the inertia of rotating and reciprocating components. The fraction [Δv2/Δt] quantifies the change in vehicle speed (i.e., acceleration).

Pslope = M g v sinθ represents the power necessary to overcome the inclination of the road (θ). This component of power is needed to counteract the gravitational forces when the vehicle navigates uphill.

Paux denotes the power consumed by the vehicle’s auxiliary systems, encompassing lighting, audio systems, windshield wipers, power steering, air conditioning, and additional electronic components. Such systems contribute significantly to the total power demand and fuel consumption of the vehicle.

In the instantaneous power demand equation, both the inertia and slope components can assume negative values, indicating that inertia and slope can contribute to facilitating the motion of the vehicle, complementing the power generated by the engine. The instantaneous power demand (Pload) represents the power required by the propelling source, be it an internal combustion engine, an electric motor, or a hybrid of the two. The requisite power (Pb) is calculated as Pload divided by the overall efficiency (ε) of the powertrain: Pb = Pload/ε.

Friction and parasitic dynamic effects acting in different vehicle components and systems act as energy sinks. Such effects (which include oscillations on the suspension, the chassis, and the body) are not explicitly integrated into the instantaneous power demand equation and tend to amplify energy losses. Consequently, mitigating these losses reduces the power requisite, elevating the overall vehicle efficiency. Achieving significant fuel savings directly depends on reducing the overall vehicular required power.

Notably, one of the most important factors influencing fuel efficiency is the reduction of the vehicle’s mass. In the automotive industry, the strategy of reducing vehicle mass, known as lightweighting, is evolving from traditional steel and iron toward a diverse mix of materials to enhance fuel efficiency and lower emissions. Historically dominated by heavier metals, modern vehicles increasingly incorporate aluminum, high-strength steel (HSS), and advanced high-strength steel (AHSS) for favorable strength-to-weight ratios. Emerging materials like carbon fiber- and glass fiber-reinforced polymers (CFRP and GFRP), alongside magnesium alloys, are gaining traction for their exceptional lightness and strength, particularly in body panels, frames, and engine components. This shift reflects a transition over time from single-material dominance to a multi-material approach, balancing considerations like cost, manufacturing processes, and environmental impact. However, challenges remain in terms of the higher costs and complex manufacturing and repair techniques associated with composite materials, as well as the recycling and environmental considerations of this multi-material trend. This ongoing evolution in material use aims to achieve an optimal balance between vehicle performance, safety, and sustainability. Additionally, optimizing the constituent factors in the instantaneous power demand equation can contribute to this objective. These factors include rotational inertia, frontal area (related to aerodynamical drag), center of gravity, and coefficients related to tire rolling resistance, aerodynamic resistance, and friction. Strategies to reduce vehicular power requirements include advanced design methodologies for all systems, the incorporation of materials with superior properties, and the utilization of advanced manufacturing and assembly techniques. Moreover, it is important to minimize frictional losses in the contact pairs across all systems and mechanisms.

During transient operations, the inertia of the vehicle’s moving components significantly contributes to inertial resistance. This is further increased by factors such as rolling and aerodynamic resistance and by inclined roads (slopes) [6,7]. In vehicles of different configurations, such as four-wheel drive (FWD), rear-wheel drive (RWD), or all-wheel drive (AWD), there is potential to increase energy efficiency by utilizing the vehicle’s energy to complement the power generated by the engine. Commonly, all means of transport make use of hydraulic- or pneumatic-assisted braking systems for which some energy must be provided, usually by the powertrain. For instance, in electrical powertrains, three important energy storage mechanisms can be used: first, the potential energy a battery stores from elevation changes; second, the kinetic energy a battery stores from the vehicle’s speed and mass; and third, the chemical battery that stores the electrical energy. Such vehicles employ flywheels, which can be combined with electrical or hydraulic energy storage systems. When vehicles operate in a coast-down mode, also named free-wheeling, they can seize accumulated inertia disengaging from the powertrain. This not only conserves fuel but also minimizes brake usage (another energy-consuming factor).

In vehicular dynamics, braking systems are indirectly related to fuel consumption. Traditional braking systems do not directly consume fuel, they dissipate the kinetic energy produced by the engines by means of the combustion of fuel. This energy dissipation occurs through frictional heat loss while decelerating and imposes an additional fuel requirement to regain momentum while accelerating.

Although a vehicle might exhibit optimal design and technology, the driver’s behavior (and consequently fuel consumption) is greatly affected by numerous factors related to climatic conditions and several aspects of road infrastructure, such as road gradient, intersection frequency, traffic signaling, road surface integrity, and lane dimensions. Additionally, the vehicle’s payload (i.e., its carrying capacity, excluding the mass of the vehicle) and its intrinsic acceleration/deceleration characteristics further shape driving behavior. Moreover, traffic dynamics such as traffic volume, vehicular spacing, visibility, environmental factors, pedestrian activity, traffic light sequencing, and road signage further mold the driver’s decision-making [8,9].

In order to model vehicular motion, dynamic programming offers a robust framework that facilitates the optimization of multi-faceted dynamics to reduce fuel consumption. Notable models, such as the fuel consumption paradigm formulated by the Swiss Federal Institute of Technology Zurich (ETH) [10], serve as tools for improving fuel efficiency and fine-tuning performance metrics. By utilizing these models, researchers and engineers can make data-driven decisions that enhance vehicular performance and reduce fuel usage.

1.3. Generalities about Fuel Consumption and Road Vehicle Operation

Automobile fuel consumption profiles can exhibit considerable variation based on the vehicle type and its intended function. As a road vehicle moves, a portion of the fuel’s chemical energy is transformed into mechanical energy by an internal combustion engine (ICE). This portion of energy serves various roles, such as propelling the vehicle’s mass, helping to overcome rolling and aerodynamic resistances, ascending inclines, offsetting energy losses derived from friction in mechanical elements and viscosity in oil, and supplying power to auxiliary devices and accessories. Urban buses and delivery trucks, which predominantly navigate at reduced speeds within city traffic, frequently experience transient operations. Delivery trucks, engaged primarily in goods distribution in urban areas, exhibit operational trends similar to urban buses, albeit with less frequent halts and possibly an increased number of idle stops. The necessary energy for the vehicle’s acceleration and deceleration is of utmost importance in such contexts. The energy consumed for the acceleration of the vehicle and for counteracting rolling resistance is greater than that consumed due to aerodynamic resistance, due to the restricted speeds inherent in urban scenarios. During deceleration, kinetic energy is largely dissipated as thermal energy due to the utilization of friction brakes (friction bands and discs).

Conversely, light-duty vehicles (i.e., passenger cars and commercial vehicles) often operate at higher speeds, typically characterized by more consistent driving patterns. Under these conditions, the energy expended to counteract aerodynamic resistance becomes significant, while the roles of acceleration and rolling resistance are reduced. Discerning these operational patterns (i.e., driving cycles) is crucial for conceiving precise measures to reduce fuel consumption and fine-tune vehicle performance across diverse vehicular types and environments.

Regarding governmental action, a comprehensive vehicular energy policy requires consideration of important factors determining fuel consumption. Such factors encompass (a) advanced vehicle and powertrain design: Powertrain efficiency improvements and integration of automobiles with modern, energy-efficient technologies (e.g., hybrid or electric systems) can lead to substantial reductions in fuel use and emissions; (b) Strategic acquisition and deployment of transport: A sustainable strategy for transportation procurement should emphasize vehicle size, load capacity, and energy efficiency; (c) Upholding vehicle technical integrity: Routine maintenance and inspections can help vehicles to better function. Peak efficiency can be achieved with more sophisticated approaches to maintenance, thereby reducing fuel consumption from technical sources; (d) Enhancing road and urban infrastructure: Improved road design and urban planning can facilitate smoother traffic flow, reduce congestion, and reduce fuel consumption during transit; (e) Training programs for drivers and mechanics: Educating drivers and mechanics about efficient driving practices, vehicle upkeep, and energy conservation can lead to more judicious fuel use; and (f) Promoting societal engagement: Raising societal awareness about the synergy between pedestrians, vehicular traffic, and air quality can spur sustainable transport choices. A holistic vehicular energy legislation that addresses these elements can pave the way for reduced fuel consumption, enhanced air quality, and a sustainable transportation ecosystem.

2. Factors Affecting Fuel Consumption

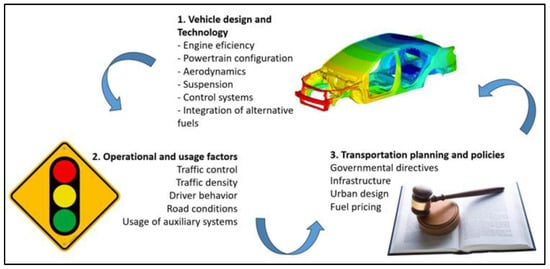

In Figure 1, a general diagram is presented, illustrating factors related to the energy consumption of vehicles in the transportation sector.

Figure 1.

Factors influencing vehicle energy consumption.

Three categories are presented: 1. vehicle design and technology, 2. operational and usage factors, and 3. transportation planning and policies. This classification offers an integrated perspective of the interdependent factors influencing vehicular energy consumption and reinforces the need for synergizing vehicle technological advancements, prudent driving behaviors, and effective policy frameworks to reduce fuel consumption and promote sustainability within the road transportation sector of the economy.

Regarding vehicle design and technology, continuous development is being applied to all engine mechanisms and systems. Central to this evolution is the dual objective of enhancing functionality and optimizing factors to reduce fuel consumption. Such holistic progression ensures that innovations in vehicle architecture and technology foster superior fuel efficiency and performance. Such endeavors include (a) increasing engine efficiency, (b) reducing the inertial resistance of components, and (c) reducing friction energy losses across power transmission, steering, suspension, and stability systems. Furthermore, necessary improvements include refining suspension and braking dynamics, enhancing vehicle aerodynamics, and implementing effective thermal management across all subsystems (from cooling to energy recovery). The energy demands of auxiliary systems are being continuously decreased, and tire designs are evolving to reduce rolling resistance. The integration of sophisticated control and communication systems further increases fuel efficiency and vehicle performance.

The effective utilization of the constructive and technological advantages of vehicles is contingent upon their operational and usage factors. Such factors, which encompass the type of fuel, monitoring, servicing, maintenance, and prevailing environmental conditions, play a significant role in determining overall performance and fuel consumption. In urban environments, driving patterns are significantly shaped by the driver’s education and prevailing traffic dynamics. These patterns are frequently constrained by elements like traffic signals, intersections, and safety provisions. Congestion in such locales extends its impact beyond motor vehicles, affecting the mobility of pedestrians, domestic animals, street vendors, and manually propelled conveyances such as tricycles, carts, and wheelbarrows. This complexity of urban dynamics distinctly modulates vehicle velocities and driving cycles, with consequential effects on fuel consumption.

Furthermore, vehicular transportation systems are directly influenced by transportation planning and policies and road and traffic planning systems, in both urban and extra-urban areas. These policies and planning decisions affect traffic flow and driving cycles, which, in turn, greatly impact the operation of road transportation systems. By optimizing the speed and load regimes, in alignment with fuel consumption objectives, transportation systems can achieve maximum efficiency and reduced fuel consumption.

Consequently, the fuel consumption of road vehicles is influenced by different factors, ranging from the mechanical and design aspects of the vehicle itself to the behavior of the driver and the driving environment. Mechanical factors include engine efficiency, vehicle weight, and aerodynamic design, while environmental factors encompass road conditions, weather, and traffic patterns. Driver behavior, such as acceleration patterns, speed, and gear-shifting practices, also significantly affects fuel consumption. For example, in the study of Alemdar et al. [11] an additional behavioral factor is examined—driver distraction, particularly through mobile phone use at traffic lights. This study demonstrated that distractions lead to delayed responses when lights turn green, causing unnecessary idling, increased fuel consumption, and higher emissions. This delay, albeit brief, when multiplied across countless traffic lights and vehicles, significantly contributes to increased urban fuel consumption and environmental pollution. Such studies underscore the importance of formulating policies that consider this kind of driver behavior, in order to mitigate fuel consumption and its environmental impact.

3. Vehicle Design and Technology

In vehicular design, the mass is a major factor influencing fuel efficiency. The reduction of the vehicle’s mass brings about tangible benefits, such as the reduction of both traction power requirements and wheel rolling resistance during acceleration (therefore leading to fuel savings). The Vehicle-Specific Power (VSP) is an important metric in vehicle design and parameter optimization. It quantifies the power output relative to the vehicle’s mass; that is, a higher VSP indicates a more powerful engine relative to the vehicle’s weight. The VSP is commonly expressed in kilowatts per ton (kW/ton) for passenger cars, or in kilowatts per amount of passengers (kW/passenger) for public transportation systems.

Mathematically, the VSP is expressed as

where:

- v: Vehicle speed.

- a: Vehicle acceleration.

- ε: Mass factor that considers the conversion of the inertia of rotating masses to translational mass

- g: Gravity.

- grade: Road grade (road inclination).

- CR: Coefficient of rolling resistance.

- ρ: Air density.

- CD: Coefficient of aerodynamic resistance.

- A: Frontal area.

- m: Vehicle mass.

With progressive design efforts aimed at reducing the vehicle’s mass and enhancing its VSP, there have been noticeable improvements in fuel efficiency and (correspondingly) some reductions in environmental impact.

Some previous works provide comprehensive insights into vehicle fuel consumption, highlighting various aspects, from predictive models to real-world emissions conditions. A study by Du et al. [12] focuses on analyzing and predicting fuel consumption in China, using floating vehicle data and a Back Propagation Neural Network model. This study identifies key factors affecting fuel consumption, such as (a) human-related, such as gender and age, (b) technology-related, such as transmission type and fuel type, and (c) road-related: road hierarchy (express way, arterial road, collector road, and branch road). Zhou et al. [13] offer a detailed review of models assessing vehicle fuel consumption. This review emphasizes the impact of driving behaviors, road conditions, and vehicle characteristics on fuel consumption. Zhao et al. [14] present a review of data-driven methods for the forecasting of vehicle fuel consumption, in which they compare traditional machine learning methods with neural network methods. This study highlights the advantages of using hybrid predictive models and multivariate data fusion technology for enhanced prediction accuracy, underlining that it can be further increased by using big data and advanced computational methods. Pathak et al. [15] aimed to quantify the disparity between standard test procedures and real-world driving conditions in India. Their findings indicate that significantly higher emissions are present in real-world conditions compared to those present in standardized tests, underscoring the need for more accurate emission testing procedures that correlate better with actual driving conditions. Each of these studies contributes to a broader understanding of vehicle fuel consumption, emphasizing the importance of model selection, accurate data analysis, and the consideration of real-world conditions, both for research and policy-making purposes.

In vehicle design, engineers undertake predictive analyses to estimate operational metrics and fuel consumption, emphasizing VSP as an important design criterion. Advanced mathematical tools, such as the Powertrain System Analysis Toolkit (PSAT), developed by Argonne in the MATLAB/Simulink environment, allow the simulation of vehicular performance and fuel economy dynamics [16,17]. Leveraging these tools, engineers can survey diverse design configurations, powertrain alternatives, and operational scenarios, improving vehicle efficiency and fuel consumption even before the creation of a physical prototype. The utilization of such predictive platforms enhances the design process’s efficiency by preempting extensive physical testing and by ensuring that the resultant vehicle design is strategically tailored for optimal fuel efficiency, performance, and environmental sustainability.

3.1. Advances in Internal Combustion Engines (ICEs)

Over the decades, technological innovations have substantially increased ICE efficiency. Contemporary high-power, low-speed diesel engines present efficiency values of up to 50% [18]. Notwithstanding these advances, many opportunities remain to refine ICE systems. Prospective advancements for diesel and gasoline engines, projected to decrease passenger cars’ fuel consumption by approximately 20% within the next decade, incorporate strategies such as friction reduction, enhanced compression ratios, comprehensive variable valve control, two-stage turbochargers, cylinder deactivation, direct fuel injection, accessory electrification, start/stop system integration, refined transmission systems, and reductions in vehicle weight, tire resistance, friction, and aerodynamic drag [19]. Such evolution in ICE technologies and vehicular architecture holds significant promise for augmented fuel efficiency and a diminished ecological footprint.

Recent advancements in gasoline engine combustion paradigms comprise [20] Compression Ignition (GCI), Homogeneous Charge Compression Ignition (HCCI), Partially Premixed Combustion (PPC), Low-Temperature Combustion (LTC), Octane-on-Demand (OOD), and Reactivity-Controlled Compression Ignition (RCCI). Such combustion paradigms have effectively and positively transformed contemporary engine efficiencies. Their distinctiveness lies in their unique fuel–air mixture preparation and their reliance on varying degrees of flameless combustion. Additionally, combustion strategies often combine technologies such as High-Pressure Direct Injection (HPDI), Cyclical Multi-Injection (CMI), Extensive Exhaust Gas Recirculation (EEGR), and Adaptive Valve Timing (AVT). Contemporary gasoline engines have been optimized to operate at elevated compression ratios, consequently increasing engine efficiency and reducing emission levels. Moreover, high compression ratios in compression ignition engines fueled with gasoline also help increase efficiency. Nevertheless, the attainment of such efficiencies typically requires the concurrent evolution of fuel formulations and engine designs, which underscores the importance of developing fuels and engines simultaneously.

Some modern innovations in engine technology include turbocharged gasoline direct injection compression ignition (GDCI) engines, which have notably delivered a 22% reduction in fuel consumption [16,21]. The use of gasoline direct injection (GDI) engines, supported by lean combustion techniques, might contribute to enhancements in fuel economy up to 15%. Furthermore, other super-lean combustion technologies are projected to reach thermal efficiency values of up to 45%.

When subjected to increased injection pressures, diesel engines exhibit enhanced fuel atomization, promoting improved air–fuel mixing, which subsequently increases the engine’s efficiency [22]. Thermal efficiency values up to 52.9% are being obtained in heavy-duty diesel engines, with improvements such as (approximately) 2% reductions in gas exchange losses, a 0.9% reduction in frictional losses, and a 0.6% reduction in accessory consumption. Concurrently, additional efforts are directed toward energy recovery: up to 2.5% from exhaust gases, and up to 1.3% from the thermal energy of the coolant. These endeavors support energy recovery systems that are based on the organic Rankine cycle (ORC) and incorporate advanced methodologies like turbocompounding [23], which produces work (or generates electricity) by utilizing the exhaust gas energy by means of a gas turbine, mirroring a cogeneration approach [24,25].

Energy recovery via complementary thermodynamic bottoming cycles presents an important resource for increasing the fuel efficiency of ICEs. Such cycles encompass the following: (a) Organic Rankine Cycle, (b) Kalina Cycle, (c) Trilateral Flash Cycles, (d) Supercritical CO2 Rankine Cycle, and (e) Gas-based Stirling and Brayton Cycles. Furthermore, the vaporization of LNG has been identified as a potential heat sink for the Rankine Cycle, as pointed out by Paanu [26]. Moreover, the Miller Cycle offers another way to enhance fuel efficiency. At an ICE technology level, innovative solutions such as increasing the mean effective pressure (MEP), supported by multistage turbochargers, and integrating turbocompounding are being explored.

Engine downsizing (ED), which consists of reducing engine displacement while sustaining (or even increasing) power and torque densities, has become a focal strategy among many ICE manufacturers [27]. The primary objective behind ED lies in the drive to operate engines within specific speed/mean-effective-pressure regimes, yielding diminished frictional and heat transfer losses, thereby optimizing efficiency [27]. In effect, ED can replace larger, multi-cylinder engines with smaller, fewer-cylinder engines, thereby minimizing friction. Such downsized engines can complement hybrid electric vehicles, whether in parallel or series configurations. In the former, the engine benefits from supplementary battery power; in the latter, it predominantly serves as a generator, providing electricity either for direct propulsion or battery replenishment. In this case, an electric machine propels the vehicle.

In the current market, a significant number of gasoline engines are categorized as downsized engines, which typically exhibit a reduction factor, also called downsizing factor (DF), of approximately 35–40%. The DF is a metric that quantifies the decrease in engine displacement (when compared to traditional engines) and can be defined by the following expression:

where DF is the downsizing factor, is the swept volume of a naturally aspirated traditional engine with a given output power, and is the swept volume of a downsized alternative engine with a similar power output.

According to Turner [27], a reduction factor of 40% can result in an improvement in fuel economy of approximately 12%. This improvement is attributed to the reduction in the engine’s swept volume and the corresponding decrease in friction within the cylinders.

The optimization of modern engines across a wide range of operating regimes (i.e., speed–torque ranges) is now achievable through a comprehensive understanding of the factors influencing fuel consumption. Such factors include intake air flows, fuel atomization, combustion, and exhaust gas formation, as well as their interaction with other factors, such as chamber/piston geometry and fuel injection strategies. Currently, these interactions can be modeled with robust computational tools. Moreover, advanced ignition systems, such as High-Energy Inductive Systems (HEISs), Plasma, Corona, and Laser, have significantly reduced combustion variability. Furthermore, the development of Variable Valve Timing (VVT) and Variable Compression Ratio (VCR) strategies for gasoline engines, along with multiple-pulse injection (MPI) techniques, have enabled higher thermodynamic efficiency within a wide range of operating regimes. Engineers are also exploring the use of multiple pulses and multiple fuels in the same combustion cycle to further enhance engine performance.

Another approach considered for improving fuel efficiency in ICEs is the implementation of the start–stop system. This system automatically shuts off the engine when the vehicle comes to a stop (e.g., at traffic lights) [28,29]. During this idle period, all systems operate using battery power. In second-generation start–stop systems, the engine shuts off at a specific speed during deceleration, with the speed being a determining factor for the system’s efficiency. The engine remains off throughout the periods of zero speed in each cycle, contributing to energy savings and enhanced overall efficiency [30]. However, when the engine restarts (i.e., transient state), fuel consumption briefly increases above the reference at a specific operating temperature. This increase occurs because the generator is activated to compensate for the battery charge lost during engine startup. The overall benefit of the start–stop system is determined by balancing the energy saved during zero-speed operation and the energy required for engine restart. The final outcome depends on factors such as the duration of idleness in each cycle, the engine’s consumption rate during idleness, the additional energy needed to start the engine, and the specific strategy employed by the generator during operation. These factors account for variations in fuel consumption between different vehicles and driving cycles [31].

The landscape of vehicle powertrain technologies is undergoing a transformative shift in response to the stringent CO2 and fuel economy regulations set beyond 2020. Conventional powertrains and fuels alone are no longer sufficient to meet these everchanging standards. This fact has catalyzed an increasing diversification of powertrain technologies and energy carriers, highlighting engine rightsizing as a pivotal strategy for both conventional vehicles (i.e., powered by ICEs) and electric vehicles (EVs). Integral to this change is the integration of Connected Powertrains and Advanced Driver Assistance Systems (ADASa). These technologies are becoming increasingly prevalent in vehicle designs, offering significant improvements in fuel consumption, safety, and comfort. The development of these systems requires a comprehensive full life-cycle methodology, fostering the advancement of new engine technologies, sensors, and on-board computing. These innovations are central in enabling real-world implementations of high-efficiency engine technologies, like low-temperature combustion and high-speed controls. A prominent example of such advancements is the SuperTruck II program (by Cummins), recognized by the U.S. Department of Energy (DoE) for its pioneering research in heavy-duty diesel engine technology. It achieves a milestone of 55% brake thermal efficiency (BTE), which is the power taken by the engine crankshaft out of the total power generated by the ICE, through the integration of waste heat recovery systems. This initiative underscores the synergy between hardware optimization and sophisticated engine calibration. The SuperTruck II program (an extension of the SuperTruck I initiative) aims to further double efficiency and halve CO2 emissions, contributing significantly to global energy savings.

A study by Brooker et al. [32] investigated the effects of reducing vehicle weight (i.e., lightweighting) on fuel efficiency and cost for different powertrains: conventional gasoline vehicles, hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and battery electric vehicles (EVs). Using the FASTSim tool, the study found that lightweighting has the most significant impact on conventional vehicles, reducing fuel consumption by about 0.58 L/100 km for a 150 kg mass reduction. While the impact on HEVs, PHEVs, and EVs is less pronounced in terms of fuel efficiency, lightweighting considerably reduces battery costs, particularly for PHEVs and EVs. The study concluded that the lightweighting practice is cost-effective only when it costs less than USD 6 for each kg of mass reduced and emphasizes its importance in lowering both component and fuel costs. The work of Dahham et al. [18] focused on improving thermal efficiency and reducing carbon emissions in ICEs. It reviewed advanced strategies for higher efficiency and cleaner combustion, considering thermodynamic cycles, gas exchange systems, advanced combustion strategies, and thermal and energy management. This study discusses the challenges in these modules and suggests integrating different technologies, like hybrid thermal cycles and variable intake systems, into powertrains with advanced electrification and artificial intelligence. The potential to achieve over 55% (effective) thermal efficiency for ICEs was highlighted. Meresht et al. [33] reviewed recent advancements in ICEs regarding fuel efficiency. They focused on thermodynamic cycles, gas exchange systems, advanced combustion strategies, and thermal and energy management. They highlight that by applying advanced technologies to ICEs, an effective thermal efficiency of over 60% can be achieved. The results emphasize the need for integrating various technologies like hybrid thermal cycles, variable intake systems, and extreme condition combustion, alongside thermal and energy management and electrified, intelligent powertrains. The study also discusses the challenges and potential solutions in each area, underscoring the importance of ongoing research and development in these fields.

3.2. Advances in Alternatives to Petroleum-Based Fuels

In the field of ICEs, traditionally powered by fuels such as gasoil (i.e., diesel) and gasoline (i.e., petrol), recent studies have highlighted the potential of the use of diverse alternative fuels. Hydrogen stands out for its high energy efficiency and clean combustion, emitting only water vapor, but faces challenges in efficient storage and sustainable production methods. Other fuels like biofuels (biodiesel and bioethanol) offer sustainability and lower emissions, despite the fact that their production can impact food resources and land use. Natural gas, with its cleaner burn compared to traditional fuels, struggles with storage and refueling infrastructure. Synthetic fuels (e-fuels), compatible with existing ICEs and infrastructure, are hindered by high production costs and energy-intensive manufacturing. Each fuel presents a unique set of advantages and challenges, indicating that a multi-faceted approach is required for sustainable transportation solutions.

Bedar et al. [34] showed the effectiveness of the use of simarouba glauca biodiesel in a diesel engine for improving brake thermal efficiency and reducing emissions of carbon monoxide (CO), hydrocarbon (HC), and smoke opacity, especially when combined with exhaust gas recirculation (EGR). A study by Vadivelu et al. [35] investigated the performance of a diesel engine using biodiesel derived from cashew nut shell liquid, augmented with hydrogen and ethanol. This combination was found to significantly boost brake thermal efficiency and reduce CO and HC emissions, suggesting a promising pathway for reducing diesel engine pollution [35].

Hydrogen’s unique combustion characteristics are being harnessed to develop reduced-emissions spark-ignition engines, with dynamic performances comparable to that of conventional gasoline engines but achieving efficiencies comparable to that of diesel engines. Hydrogen’s particular properties, such as low flammability limit and high flame speed, promote stable combustion in spark-ignition engines, resulting in reduced NOx formation. This characteristic enables efficient engine operation, particularly at low- and medium-torque regimes. Innovative engine design improvements (e.g., increased combustion pressure and engine downsizing) further enhance the efficiency and power densities of hydrogen-fueled engines, surpassing those of conventional hydrocarbon-fueled engines [36].

Shivaprasad et al. [37,38] investigated the impact of hydrogen blending with gasoline in spark-ignition engines, indicating that a 20% hydrogen blend can improve engine efficiency and reduce emissions. While such blending has been shown to reduce HC and CO emissions, contributing to improved combustion efficiency, it is also associated with an increase in nitrogen oxide (NOx) emissions. Collectively, these studies illuminate the potential of biofuels and hydrogen blends in transitioning toward more sustainable and efficient internal combustion engine technologies. While alternative fuels like hydrogen present promising benefits in terms of efficiency and reduced certain emissions, they necessitate careful management and further technological innovation to mitigate trade-offs, particularly concerning increased nitrogen oxide emissions.

In investigating the performance of hydrogen/diesel reactivity-controlled compression ignition (H2/diesel RCCI) engines, a study by Duan et al. [39] reveals that the indicated thermal efficiency (ITE) is significantly enhanced by employing a double direct injection (DDI) strategy over a single direct injection (DI) strategy, primarily due to improved fuel distribution and combustion conditions. The ITE increases notably when intake pressure is raised from approximately 100 to 120 kPa but decreases with further pressure enlargements due to reduced combustion efficiency and higher combustion temperatures. This research underscores the importance of optimizing injection strategies and managing intake pressures to balance efficiency gains and emission reductions, marking these as critical factors in advancing the performance of H2/diesel RCCI engines. Oztürk and Can [40] evaluated techniques like exhaust gas recirculation and ethanol addition in biodiesel blends, noting improvements in combustion and emissions, though with some trade-offs in engine performance.

3.3. Other Technologies Related to Fuel Economy

The entire planet is linked by a massive transportation infrastructure, which is largely based on the use of the internal combustion engine (ICE). It would take decades and tremendous financial expense to replace ICEs, so it is probable that they continue to be the central powertrain technology used for road transportation all over the world in the coming years. Reitz [41] indicated the obstacles still faced by current alternatives to ICEs, such as electric vehicles (EVs) powered by batteries. Currently, electric batteries have high cost, weight, and other limitations. Furthermore, they are expected to be charged using energy obtained from renewable sources, such as wind and solar. Nevertheless, these sources still represent a small fraction of the world’s energy supply. The reduction of fuel consumption in road transportation needs to be addressed by a mix of solutions, involving battery and hybrid electric vehicles (BEVs and HEVs), fuel cell electric vehicles (FCEVs), and conventional vehicles (ICEs), depending on the consumer, the country, and the specific application considered.

Energy consumption during fuel production and transportation is closely related to fuel economy. In this sense, the life cycle assessment (tank-to-wheels) is an adequate measure of fuel performance. The selection of the feedstock and the fuel production pathways have a great impact on the overall energy efficiency of road vehicles. BEVs have a higher in-use energy efficiency as compared to HEVs; BEVs can convert 70–90% of the energy stored in the battery into movement, whereas the theoretical peak efficiency of HEVs is only 40%. Some of the in-use efficiency advantages of BEVs over HEVs are offset by the conversion losses occurring during electricity generation from fossil fuels and by losses during transmission and charging. Collectively, this can add up to around 60% of the total energy use.

Another factor affecting the energy efficiency of BEVs is the electricity consumption of auxiliary systems, like heating and air conditioning. To provide energy for A/C systems, BEVs must use energy from the battery, while HEVs can make use of waste heat from the engine. Energy consumption varies across different electric vehicle sizes, and the average BEV is heavier than the average HEV. The extra weight of BEVs, imputable to the weight of the battery and the associated secondary weight required to strengthen the vehicle body, reduces the energy advantage of EVs over HEVs in terms of energy consumption. The reduced mass of vehicle components, obtained by replacing existing materials with lighter ones, must be balanced with the energy expenses during vehicle production. On the other side, it seems that road transportation will always have some energy externalities, even if all ICEs were replaced by EVs. Although the energy efficiency of electric motors is far larger than ICEs, the energy required to produce electrical energy for EVs is far higher than that required to produce fossil fuels. Moreover, the production of batteries is an energy-demanding activity. The reduction of the mass of EVs would contribute to lower energy required per km. Additionally, the recycling of batteries is also an energetic and environmental task to be solved.

Modern control systems, characterized by their adaptability, are important in increasing a vehicle’s efficiency, especially in managing the engagement of engine cylinders. Some manufacturers have pioneered the Cylinder on Demand technology, aiming to improve fuel efficiency through selective cylinder deactivation. Concurrently, Dynamic Skip Fire systems have been introduced. This innovative approach intelligently deactivates distinct cylinders based on immediate operational demands, thus ensuring proficient torque delivery while maintaining optimal noise, vibration, and harshness levels (i.e., NVH levels). Such cylinder deactivation strategies introduce unprecedented versatility and precision, promoting holistic enhancements in vehicular performance.

3.4. Control Signals Transmission

In contemporary vehicular power architectures, the integration of modern communication interfaces, which compute the measured operational variables to control powertrain modules, can contribute significantly to fuel efficiency. A synergistic interplay between the engine and the transmission allows for the crankshaft rotational velocity optimization. Specifically, by transferring data points to a computer for the calculation of torque and power requirements in a real-time context, vehicle dynamics, ride quality, and fuel efficiency can be improved. The central role of the Controller Area Network (CAN) protocol is to promote better communication between engine subsystems and the Electronic Engine Control Module (EECM). Modern controllers and algorithms are continuously improved, enhancing communication between powertrain modules and other vehicular systems. These improvements allow for adjustments in engine configuration and calibration and are reinforced by automated shift strategies and agile software, which can recalibrate in response to fluctuations in load demands, terrains, velocities, and engine torque outputs. Moreover, the integration of communication interfaces with navigation infrastructures and satellite-derived data further enhances fuel economy. Such integrations empower vehicles to judiciously modulate speeds during curvilinear trajectories or to preemptively accelerate before uphill gradients, tailoring operations to improve fuel efficiency.

Thermocoasting is an innovative energy-conservation mechanism, which is electronically activated during regenerative processes in ICEs and employs engine braking without reducing (significantly) the vehicle’s momentum. This mechanism is initiated when the accelerator is released, allowing the vehicle to roll. This strategy not only facilitates energy preservation during downhill trajectories but also mitigates drastic temperature variations, often observed in engines without energy recovery systems.

While the necessary transition to electric powertrains progresses, a strategic approach to mitigate the negative impacts of the ICE (an obsolescent technology that has been the basis of our mobility paradigm for over a century) is paramount. Hence, there persists a necessity for the research and development of the ICE, aimed at improving both its spark-ignition and compression-ignition variations.

3.5. Improved Fuel Economy of Vehicles by Reducing Friction Losses

Friction is an inherent and, in many instances, requisite phenomenon. It plays fundamental roles in the operation of the components in a vehicle. An automobile comprises numerous tribological components, including bearings, pistons, transmissions, clutches, gears, windshield wipers, tires, and electrical contacts. Understanding and applying tribological principles to vehicle design is crucial for promoting the reliability of road vehicles. The mass production and utilization of automobiles have propelled significant advancements in the field of tribology. Specifically, the rising demands for automotives with better tribological performance have driven notable progress in lubrication technology, and the development of advanced tribological surfaces. These advancements have played an important role in enhancing the overall performance and durability of vehicles.

Friction reduction in the tribological pairs of engine systems has a significant impact on fuel consumption across all operating regimes. An optimized tribological design of engine systems (e.g., the powertrain, the valvetrain) can be achieved through improved clearances, low-friction surfaces, and decreased contact areas. Increasing the specific output of the engine without altering its geometric dimensions further reduces specific friction losses. The ongoing development of the piston ring/cylinder assembly plays a central role in achieving friction reduction. For instance, a topographical optimization analysis during the piston’s design phase can help identify areas where less material can be utilized without compromising the piston’s strength. Additionally, optimizing tribological pairs in the engine allows for the use of low-viscosity oils, which in turn reduces the thermal load in the oil circuit, as less cooling oil is required to lubricate the pistons. Controlling the oil pump based on specific power demand at each operating regime can lead to further fuel savings, particularly in real-world driving conditions [42].

Numerous research efforts that are aimed at mitigating friction’s deleterious impact on energy consumption in specific engine systems or components (e.g., piston groups, bearings). Potential reductions in friction losses could reach up to 40%, consequentially reducing the global primary energy consumption by as much as 8.6% [43]. Therefore, while the complete eradication of friction remains unattainable, the pursuit of substantial reductions in frictional losses is important for reducing fuel consumption. Holmberg et al. [44] have conducted calculations of friction dissipation in different systems (and sub-systems) in passenger cars, comprising the engine, transmission, tires, and brakes. They estimated that one-third of the global fuel consumption is utilized to overcome friction (excluding brake friction) in these components in passenger cars. Efforts to reduce friction losses hold the potential to triple fuel economy, as it would additionally decrease exhaust and cooling energy losses. Several measures are being explored to reduce friction in passenger vehicles. These measures include (a) the implementation of advanced coatings and surface-finishing technology in engine and transmission components to reduce friction losses and control wear processes, (b) the utilization of new low-viscosity lubricants and additives to perform better in extreme operating conditions, and (c) the development of tire designs that minimize rolling friction [43].

In an urban driving cycle, a relatively small fraction of the energy of the fuel is applied to propelling the wheels (in a medium-sized passenger car). This highlights the significant potential for efficiency improvements in vehicle design and operation. By examining mechanical losses (predominantly from friction) and their relation to fuel consumption, opportunities for substantial enhancements in energy utilization can be identified. A particular focus is given to the predominant contributors to these losses, including the piston-ring/cylinder assembly and various drivetrain components. The distribution of energy consumption, including frictional losses, of a medium-sized passenger car is detailed in Table 1 [44].

Table 1.

Energy distribution and frictional losses in a medium-sized passenger car.

Moreover, understanding the intricacies of bearing tribology and valvetrain dynamics is crucial in addressing these losses. These components can significantly affect overall vehicle efficiency under different operational conditions. The multifaceted nature of mechanical losses is related to various factors such as lubricant quality, thermal conditions, and material properties. Furthermore, it is crucial not to overlook the auxiliary components, as they can account for 20% (or more) of the mechanical friction losses [45].

Initiatives have been undertaken to reduce boundary-type lubricated friction in bearings and other tribological systems in ICEs. A notable example includes the incorporation of friction-reducing additives into engine lubricants, such as molybdenum dithiocarbamate (MoDTC) [46]. On the other hand, the valvetrain presents a diverse array of tribological challenges. Its complexity includes several tribological interfaces: cam/follower, valve-guide/stem-seals, valve-heads/valve-seat, and other tribological systems, such as hydraulic lash adjusters, lifter guides, pivots, camshaft bearings, and both belt and chain drives. Refinement of these components can help ensure the valvetrain’s efficient functionality.

The dual objectives of obtaining more sustainable designs of vehicles and (specifically) the development of stringent regulatory standards advocating for efficient engines with augmented power-to-weight ratios require tribological components to operate at the minimum oil film thickness. A prevailing trend leans toward the adoption of engine oils with lower viscosities, such as SAE 5 W-20 and 0 W-20, targeting enhanced fuel economy. While this strategy reduces frictional losses, it also raises concerns regarding engine longevity, accentuating the importance of the surface technology in engine components in relative motion. These lubrication intricacies underscore the necessity of consistent oil replacements and the utilization of premium engine oils, which are formulated as a response to the requirements imposed by diverse driving scenarios. In this regard, appropriate maintenance protocols serve to anticipate problems stemming from degraded oil, safeguarding the engine from potential wear and corrosion. The tribological community that specializes in engine systems is faced with a substantial challenge when trying to reconcile the complex tribological effects affecting engine components with the (also) complex chemical interactions and degradation processes exhibited by engine lubricants, both in their fluidic state and on component surfaces. The general objective is to engineer lubricants that extend the components’ longevity, while concurrently optimizing engine performance.

During cold starts and brief journeys of an ICE, engine oil may not achieve sufficient operating temperatures, hindering the lubrication of systems and subsystems. Persistent low oil temperatures can generate problems such as the accumulation of fuel, combustion residuals, and water. Concurrently, the sedimentation of engine oil additives at the sump base, due to moisture contamination, can potentially neutralize the oil’s corrosion inhibitors, thereby risking the engine’s integrity against corrosive elements. Specifically in gasoline-fueled vehicles, fuel filtration into the oil can substantially reduce its viscosity, diverging from anticipated values at given temperatures. In such driving conditions, the oil’s natural thickening at decreased temperatures is somewhat counterbalanced by reduced viscosity from fuel incorporation during a cold start of the engine [47]. During this period, it is crucial to focus on increasing the rate of heating of the cylinder liner. This helps to improve combustion, resulting in reduced emissions. Moreover, a faster warming of the cylinder liner reduces friction levels against the piston ring, leading to improved fuel efficiency. In addition to this, it is advisable to enhance the rate of lubricant heating to minimize losses.

In nanotribological research, several pressing requirements have been delineated. These include (a) the design of nanostructured materials with higher strength and hardness and with self-repairing capabilities and safety features; (b) the incorporation of carbon and ceramic structural materials, with strength values superior to that of steel (by as much as ten times); (c) the evolution of polymer components that not only possess three times the strength of currently used materials but also have melting temperatures surpassing 100 °C; (d) the quest for multifunctional materials for mitigating friction, wear, and corrosion; (e) the exploration of nanoparticles’ incorporation to reinforce aluminum alloys against wear; (f) the application of nanocoatings on metallic substrates to achieve higher hardness values and reduce friction; (g) the innovative utilization of nanoparticle-reinforced materials, as potential replacements for metallic elements in vehicular contexts; and (h) the development of predictive models and simulations leveraging multi-scale computations to produce materials (bulk and surface) with superior tribological attributes. Such advancements are aligned with a future where materials exhibit enhanced performance and longevity, especially in industries such as automotive engineering, harmonizing with sustainability objectives.

While tribology plays a significant role in increasing the efficiency of road vehicles (and other industries), it has, until recently, remained somewhat sidelined in climate change discourses [43]. According to the BP Energy Outlook 2019 [1], the total primary energy supply (TPES) required was quantified at 584 exajoules (EJ). Leveraging proficient tribological strategies could have caused a medium- to long-term CO2 emission reduction of 6% to 11% in 2019, translating to global savings of 35–64 EJ. Importantly, forecasts predict an increase in TPES to 961 EJ by 2050 [48,49,50]. Given such increasing energy demands, refining tribological technologies and strategies becomes crucial.

3.6. Improved Fuel Economy by Reducing Rolling Resistance (Tire Technology)

In a vehicle, tire dynamics play a critical role in energy efficiency. The rolling resistance (RR), a result of the tire’s interaction with the road, significantly impacts the vehicle’s fuel consumption. Understanding the mechanisms behind rolling resistance helps in developing tires that contribute to fuel economy and environmental sustainability. This involves exploring various factors from hysteresis in the tire materials to aerodynamic effects and the role of tire pressure. Contemporary advancements in tire technology, including material composition and tire labeling systems, offer promising avenues for reducing rolling resistance and, consequently, fuel consumption. A detailed breakdown of the contributions of different rolling resistance aspects is presented in Table 2.

Table 2.

Rolling resistance in tires and fuel economy.

Furthermore, if the tire pressure is 40% lower than the recommended level, fuel consumption can rise up to 8%. It is important to mention that tire pressure can naturally be reduced monthly by one to two psi during normal operating conditions. Additionally, ambient temperature fluctuations have a direct effect on tire pressure: a 5 °C temperature variation corresponds to a 2% change in pressure. A series of studies [51,54,55,56,57] have focused on the intricate relationship between tire pressure (P) and rolling resistance (RR), considering different proportionality relations, such as (1/P), (1/P)0.5, and linear and quadratic relations involving the vehicles’ service load (Z), speed (V), and pressure (P). The proposed correlation is expressed as RR ∝ Pα, where the value of the α index typically ranges between −0.3 and −0.5 for contemporary radial tires.

The use of nitrogen (instead of regular air) in tires offers the advantage of reducing tire pressure loss [55]. Laboratory tests have shown that new tires inflated with nitrogen experience approximately two-thirds less pressure loss compared to those inflated with air, both under static and dynamic loads. This difference can be attributed to the higher diffusivity ratio of oxygen through the rubber, making nitrogen a more effective option for maintaining tire pressure over time.

3.7. Improved Fuel Economy by Improving Thermal Management in Automobiles

Recent innovations in thermal management technology offer ways to mitigate parasitic thermal losses across diverse vehicular systems, thereby increasing efficiency in engines, transmissions, and equipment for heating, ventilation, and air conditioning (HVAC). Regarding thermal management systems, several innovative solutions are emerging. Notably, among these are intelligent coolant pumps, electronic coolant control mechanisms, proactive engine heating strategies, transmission oil bypass valves, and exhaust heat recovery systems. Moreover, new concepts like thermoelectric generators, the Organic Rankine Cycle (ORC) for optimized heat recovery, and innovative thermal energy storage methodologies are being explored [58]. Other thermal management constructive alternatives include residual heat recovery, insulated glazing, solar reflective paint, active seat and cabin ventilation, active transmission heating, solar panels for battery charging and cabin ventilation, active aerodynamics, and engine start–stop systems (with or without heater circulation).

It is important to mitigate heat absorption in vehicles, also known as heat soak or thermal soak, when exposed to prolonged sun exposure [59]. For instance, enhancing the treatment of glass and windshields’ surface and composition (e.g., providing higher transmissivity during cold weather and lower transmissivity during hot weather) plays an important role in reducing thermal soak and cabin temperatures, leading to reduced fuel consumption by air conditioning systems. By incorporating infrared reflective coatings and advanced glass technologies, vehicles can effectively reduce thermal loads and contribute to overall fuel efficiency improvements. Osborne’s research [58] covers thermal management technologies designed to optimize vehicle performance and reduce fuel consumption, in consideration of cost factors. These technologies comprise active engine heating (AEH), active seat ventilation (ASV), and cooled exhaust gas recirculation (EGR). Efficient thermal management can lead to a fuel consumption reduction of approximately 2% to 7.5%, depending on the vehicle’s underlying thermal management characteristics.

Other thermal management methods are being investigated, including independent cooling for different cabin zones, automatic climate control (ACC), and air quality management. Implementing techniques to decrease thermal loads and improve heating, ventilation, and air conditioning (HVAC) systems plays a significant role in achieving sustainable objectives [60,61]

4. Utilization-Related Factors

The fuel consumption in both private passenger cars and commercial transportation systems is significantly influenced by various utilization factors (i.e., operational) [8]. These factors can be grouped as follows: (a) Driving Mode of Vehicles: This aspect depends on the vehicle’s performance and characteristics, such as dynamics and acceleration/deceleration capabilities. Additionally, driver training, including the physical and psychological condition of the driver during driving, plays an important role in fuel efficiency. (b) Traffic Flow: Traffic conditions (e.g., speed limits, traffic signs, road type and surface condition, intersection density, and resistance to motion) also influence driving modes, and significantly impact fuel consumption. (c) Consumable Materials: The choice and quality of consumable materials like fuels, lubricants, filters, spark plugs, injectors, etc., also influence fuel economy; (d) Environmental Conditions: External factors like weather and climate can determine fuel consumption, particularly in extreme conditions. (e) Monitoring, Service, and Maintenance Practices: Regular monitoring, proper servicing, and maintenance of vehicles are crucial in ensuring optimal fuel efficiency and performance. Improving awareness and management of these operational factors can lead to more efficient transportation systems and reduced fuel consumption.

4.1. Considerations on the Influence of Driving Modes on Energy Consumption

Driving modes (commonly identified by the more standard concept of driving cycles) encompass various driving characteristics and significantly impact a vehicle’s fuel consumption, regardless of its technological level and maintenance practices [62]. These driving modes include factors such as the frequency and duration of stops, average speed, acceleration patterns, time spent in motion or idle, and driver behavior regarding speed and acceleration. Driving modes are influenced by variables such as road type, lanes, driver style, and time of day. Notably, different driving modes can lead to substantial variations in fuel consumption, with differences of up to 30–40% [63]. Variations in the vehicle’s operation intensity lead to changes in fuel consumption due to varying instantaneous acceleration values. ICEs also exhibit operating regimes of higher energy efficiency, known as green zones. By predominantly driving in these efficient regimes, fuel savings can be achieved.

For conventional vehicles (i.e., ICE-propelled), both wheel work and efficiency are significantly low at low speeds. As the vehicle’s speed increases, the wheel work experiences a slight increase, while the efficiency increases at a higher rate, resulting in reduced total fuel consumption. At moderate speeds, the wheel work and efficiency increase roughly in proportion. Within this speed range, changes in fuel consumption occur at an approximately constant speed. However, at higher speeds, the efficiency either remains constant or decreases, while the wheel work increases substantially, leading to a notable increase in fuel consumption. Additionally, a challenging task is to isolate the individual effects of weight, power-to-weight ratio, and aerodynamic resistance in different types of vehicles. Generally, a vehicle with more gear changes within a specific speed range spends a higher percentage of driving time operating with high efficiency. Therefore, it is essential to recommend, during driver education, the practice of early gear shifting to a higher gear as one of the primary methods of saving fuel. When considering driving aggressiveness (with respect to a reference value of 1.0 m/s2), reducing accelerations and decelerations by 10% saves more fuel than reducing road speeds by 10% [64].

Taking these considerations into account, the best driving practices for economical driving include [62] (a) driving at lower speeds allowed on roads (but staying above the posted minimum driving speed), while avoiding very low speeds in urban areas; (b) reducing the intensity of accelerations during driving; (c) minimizing short and low-speed trips whenever possible; (d) driving in the highest gear possible (for vehicles with manual transmission); (e) utilizing cruise control in vehicles equipped with this feature; (f) maintaining properly calibrated tire pressure values; (g) avoiding add-ons and parts that increase aerodynamic resistance; (h) eliminating excess weight from the vehicle; and (i) using air conditioning and other accessories only when necessary. In urban driving cycles, particularly at relatively low speeds, the primary cause of fuel usage is the generalized friction of the engine, which is directly related to the number of engine revolutions during the trip. By increasing the travel speed while keeping the engine speeds relatively constant, the travel time decreases, resulting in a reduction in the total number of engine revolutions.

Access to high-quality driver education indirectly contributes to improved fuel economy by fostering sensible and conscious decision-making during driving. It empowers drivers to understand how vehicle handling impacts fuel consumption. Furthermore, such education enhances citizens’ environmental and energy awareness, encouraging the adoption of energy-sustainable driving practices. The values of the operating parameters of an ICE can be monitored and stored through the OBD-II diagnostic protocol, allowing us to correlate them with vehicle performance and fuel consumption. For instance, this enables the analysis of the relationship between user driving behavior and the fuel consumption of a specific vehicle model [65,66].

4.2. Promotion of Traffic Flow Improvement

In general, streets with frequent interruptions of vehicular flow, usually caused by intersections or pedestrian facilities, tend to exhibit higher fuel consumption and increased emissions from brake and tire wear [64]. Improving driving speed through smoother traffic flow positively affects the mileage index (e.g., miles per gallon), resulting in reduced fuel consumption. To achieve this, several measures can be implemented. For instance, developing bypass roads and other arterial networks can effectively reduce through-traffic in city centers. Additionally, ensuring smooth and safe transportation services requires intelligent road usage, improved road maintenance practices, and updating of existing road infrastructure.

Moreover, eliminating vehicle congestion is crucial for economic and environmental reasons. In heavily congested urban areas, fuel consumption can be twice as much as that occurring in free-flow conditions. This fact underscores the importance of conducting studies on traffic-light optimization, considering factors such as road design, intersections, gradients, and topography of commonly used routes within the city. In managing passenger and commercial vehicle operations, substantial fuel economy improvements can be achieved through strategic and operational decisions. These decisions include route selection and vehicle load optimization, all aimed at maximizing fuel efficiency [67,68].

The implementation of Intelligent Transportation Systems (ITSs) involves the integration of people, roads, and vehicles using state-of-the-art Information and Communication Technologies (ICTs). These systems have the potential to significantly enhance the utilization of roads, improve transportation efficiency, and tackle various traffic, congestion, and energy-related challenges. As a result, they contribute to creating a more cost-effective society concerning road traffic management. ITSs achieve this by providing real-time traffic information through onboard electronic control units that are compatible with the Vehicle Information and Communication System (VICS). This information includes details such as travel time, congestion conditions, and traffic restrictions. By utilizing these data, drivers can make informed decisions, leading to improved mileage per liter of fuel [69].

5. Transportation Policies, Alternatives, and Externalities

Technological applications aimed at enhancing vehicle efficiency have a broad spectrum of indirect economic implications, spanning initial capital investments, recurring operational expenses, maintenance outlays, and dividends from fuel conservation. For entities overseeing public service or commercial transportation fleets, different considerations emerge. These include the implications of fleet renewal, fuel expenditure per distance covered (mileage index), potential shifts in vehicle class preferences among consumers, environmental fiscal impacts, repercussions on traffic congestion, safety ramifications, the influence of incremental weight, and facets of manufacturing and product evolution [70,71,72].

5.1. Transportation Planning and Policy-Related Factors

Addressing vehicular fuel consumption through effective policies requires a holistic approach, encapsulating three primary strategic ways: (a) regulatory frameworks, (b) economic incentives, and (c) awareness campaigns. Regulatory frameworks, defined by legislative actions, set energy conservation benchmarks, endorsing stringent fuel efficiency standards while advocating for the adoption of green technologies. Economic incentives, by manipulating operational expenses and consumer profitability metrics, often manifest as fuel efficiency-based tax structures or fiscal incentives, stimulating the uptake of fuel-efficient road transportation solutions. Awareness campaigns, including educational outreach, guidance, corporate reputation, and societal responsibility, act as catalysts in promoting knowledge and collaboration amongst stakeholders. Integrating these tripartite strategies, urban planners are better positioned to lead fuel conservation efforts, paving the way for a more sustainable and efficient transport paradigm.

For example, in Colombia (South America), the enactment of Law 1083 in 2006 established a framework for sustainable urban development, compelling municipalities and districts to adopt Territorial Ordering Plans (TOPs). Commencing in 2008, these jurisdictions have been mandated to formulate Mobility Plans within TOPs, with alternative transportation modalities. Central to these plans is the promotion of pedestrian pathways, cycling routes, and other eco-friendly ways of transportation. Moreover, mobility plans advocate for the integration of public transportation systems fueled by cleaner energy sources to reduce urban pollution.

Urban planning policies must prioritize comprehensive mobility strategies to enhance vehicle efficiency and reduce fuel consumption. Such strategies should include (a) incentivizing the adoption of vehicles utilizing cleaner fuel sources and advanced fuel-efficient technologies, including electric and hydrogen propulsion; (b) implementing tax policies, such as certification or energy efficiency labeling, to promote the utilization of energy-efficient vehicles; (c) adopting tax measures like road usage-based taxation, heightened parking charges, and escalated fuel taxes to stimulate energy-efficient decisions and deter superfluous vehicle utilization; (d) intensifying technical–mechanical inspections, especially for high-mileage vehicles, to ensure adherence to emission and efficiency standards; (e) promoting alternative transportation modalities like public transit, bicycling, and walking, thereby reducing the dependency on private vehicles; and (f) executing traffic management strategies (e.g., alternate-day driving-type restrictions) to mitigate congestion and optimize fuel utilization during peak periods or in dense zones. Other institutional approaches also play a critical role in advancing energy optimization within transportation systems. Some of these strategies include (a) significant investments in road surfacing to enhance driving conditions and subsequently decrease fuel consumption; (b) consistent maintenance and upgrade of roads and highways to facilitate uninterrupted and efficient vehicular transit; (c) intelligent urban planning to regulate density and zoning, promoting the proliferation of public transportation networks and spaces conducive to pedestrian activity; and (d) a decided commitment to refining traffic engineering methodologies to bolster traffic fluidity, reduce congestion, and reduce fuel consumption.