An Ergonomic Study on the Operation Method and In-Vehicle Location of an Automotive Electronic Gearshift

Abstract

1. Introduction

2. Materials and Methods

2.1. Respondents

2.2. Design Alternatives

2.2.1. Operation Method

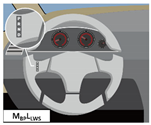

2.2.2. In-Vehicle Location

2.2.3. Design Alternatives

2.3. Questionnaires

2.4. Freehand Design Session

2.5. Survey Procedure

- Before the survey, an introduction was provided, explaining the research background and objectives, along with the survey questionnaire structure.

- After obtaining informed consent from all respondents, detailed explanations were provided for each of the 15 design alternatives, the nine ergonomic evaluation measures, and the associated rating scale.

- Respondents evaluated the 15 design alternatives across the nine measures, with the presentation order of the alternatives randomized for each respondent to minimize potential order effects.

- Following the evaluation of all design alternatives, a freehand design session was conducted.

2.6. Data Analyses

3. Results

3.1. Overall Scores for the 15 Design Alternatives

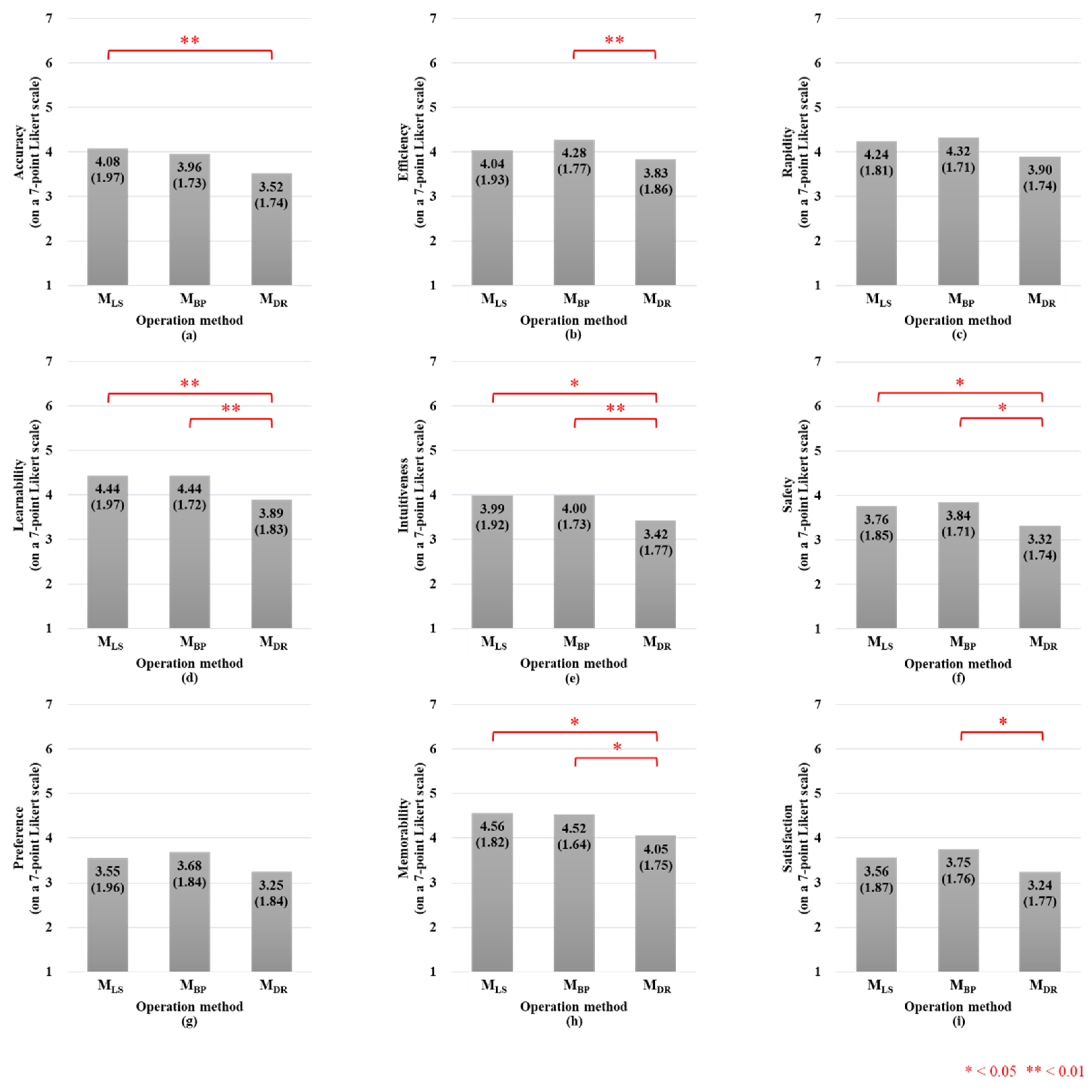

3.2. Main Effects of Operation Method

- MLS showed significantly higher mean scores than MDR in accuracy, learnability, intuitiveness, safety, and memorability.

- MBP exhibited significantly higher mean scores than MDR in efficiency, learnability, intuitiveness, safety, memorability, and satisfaction.

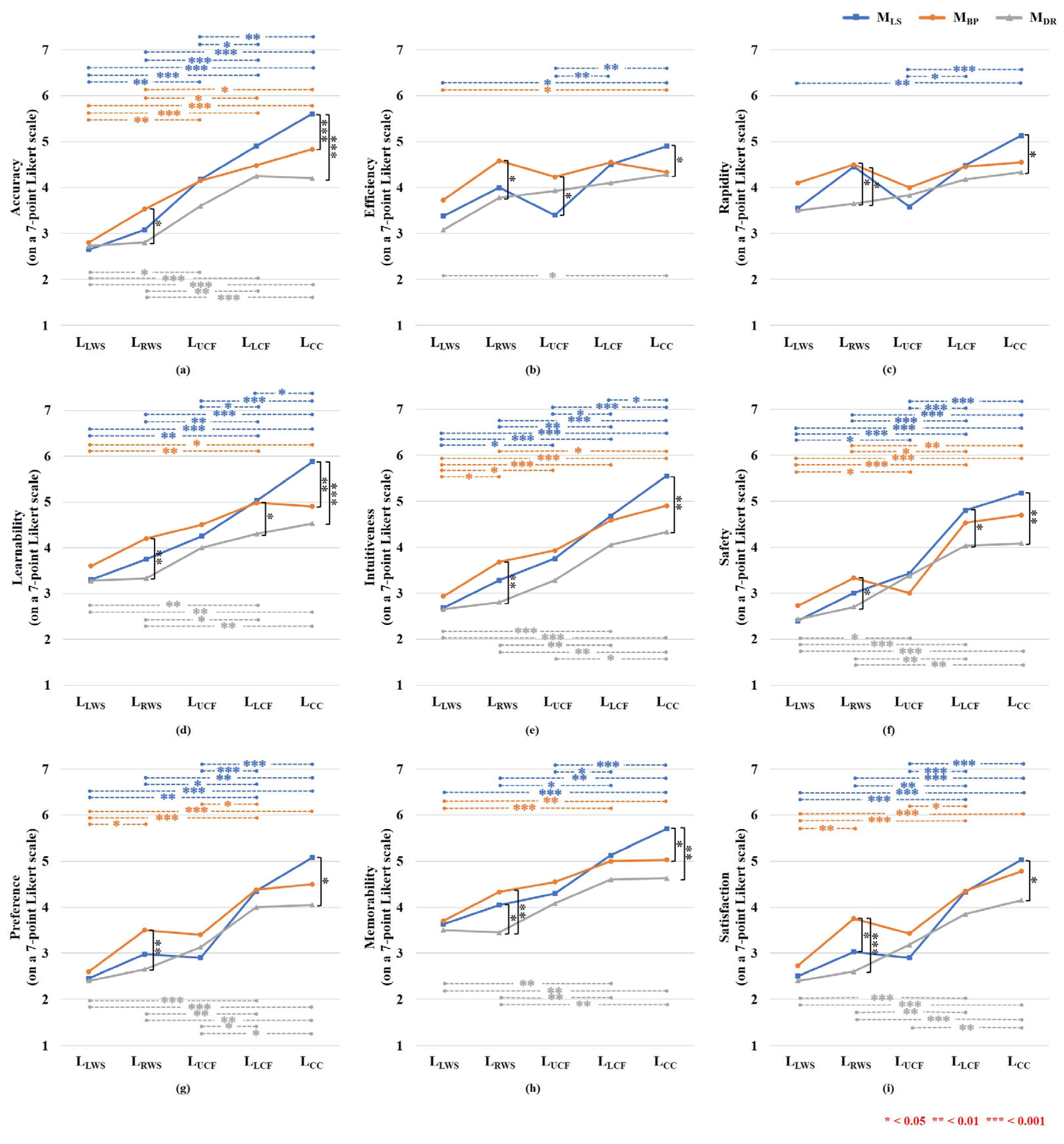

3.3. Main Effects of In-Vehicle Location

- LRWS showed significantly higher mean scores than LLWS in efficiency and satisfaction.

- LUCF exhibited significantly higher mean scores than (1) LLWS in accuracy, learnability, intuitiveness, safety, and memorability; and (2) LRWS in accuracy.

- LLCF had significantly higher mean scores than (1) LLWS across all measures except rapidity; (2) LRWS across all measures except efficiency and rapidity; and (3) LUCF in accuracy, intuitiveness, safety, preference, memorability, and satisfaction.

- LCC obtained significantly higher mean scores than (1) LLWS across all nine measures; (2) LRWS across all measures except efficiency and rapidity; and (3) LUCF across all measures except efficiency.

3.4. Interaction Effects between the Operation Method and In-Vehicle Location

- When the in-vehicle location was LRWS,

- ▪

- MLS showed significantly higher mean scores than MDR in rapidity and memorability.

- ▪

- MBP exhibited significantly higher mean scores than (1) MLS in satisfaction and (2) MDR across all nine measures.

- When the in-vehicle location was LUCF,

- ▪

- MBP showed significantly higher mean scores than MLS in efficiency.

- When the in-vehicle location was LLCF,

- ▪

- MLS showed significantly higher mean scores than MDR in safety.

- ▪

- MBP exhibited significantly higher mean scores than MDR in learnability.

- When the in-vehicle location was LCC,

- ▪

- MLS showed significantly higher mean scores than (1) MBP in accuracy, learnability, and memorability and (2) MDR across all nine measures.

- When the operation method was MLS,

- ▪

- ▪ LUCF showed significantly higher mean scores than LLWS in accuracy, intuitiveness, and safety.

- ▪

- LLCF exhibited significantly higher mean scores than (1) LLWS and LRWS across all measures except efficiency and rapidity and (2) LUCF across all nine measures.

- ▪

- LCC had significantly higher mean scores than (1) LLWS and LUCF across all nine measures; (2) LRWS across all measures except efficiency and rapidity; and (3) LLCF in learnability and intuitiveness.

- When the operation method was MBP,

- ▪

- LRWS showed significantly higher mean scores than LLWS in intuitiveness, preference, and satisfaction.

- ▪

- LUCF exhibited significantly higher mean scores than LLWS in accuracy, intuitiveness, and safety.

- ▪

- LLCF had significantly higher mean scores than (1) LLWS across all measures except efficiency and rapidity; (2) LRWS in accuracy and safety; and (3) LUCF in preference and satisfaction.

- ▪

- LCC obtained significantly higher mean scores than (1) LLWS across all measures except rapidity and (2) LRWS in accuracy, intuitiveness, and safety.

- When the operation method was MDR,

- ▪

- LUCF showed significantly higher mean scores than LLWS in accuracy and safety.

- ▪

- LLCF exhibited significantly higher mean scores than (1) LLWS and LRWS across all measures except efficiency and rapidity and (2) LUCF in preference.

- ▪

- LCC had significantly higher mean scores than (1) LLWS across all measures except rapidity; (2) LRWS across all measures except efficiency and rapidity; and (3) LUCF in intuitiveness, preference, and satisfaction.

3.5. Freehand Design Session

4. Discussion

- Major finding C-1. When the operation method was MLS, LCC was evaluated as significantly superior compared to LLCF. When the in-vehicle location was LCC, MLS was evaluated as significantly superior compared to MBP (Figure 4).

- Major finding C-2. When the in-vehicle location was LRWS or LUCF, MLS was evaluated as significantly inferior compared to MBP (Figure 4).

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lindner, M.; Tille, T. Design of highly integrated mechatronic gear selector levers for automotive shift-by-wire systems. IEEE/ASME Trans. Mechatron. 2009, 15, 961–968. [Google Scholar] [CrossRef]

- Kwon, K.; Kang, J.; Kang, S. Electronic Gearshift Pattern Application using Three Axis Hall Sensor. In Proceedings of the Transactions of the Korean Society of Automotive Engineers 2015 Spring Conference, Gwangju, Korea, 28–30 May 2015. [Google Scholar]

- Nakade, Y.; Kamada, A.; Ueno, K.; Kume, M.; Sakaguchi, K. Shift-by-wire system for Lexus RWD vehicles. SAE Int. J. Engines 2017, 10, 689–694. [Google Scholar] [CrossRef]

- Bladfält, S.L.; Grane, C.; Friström, J. Field study investigating gear shifter usability in car rental scenario. Rep. Stud. Health Sci. 2016, 22, 201–205. [Google Scholar]

- Cho, H. Calibration algorithm for SBW position detection. In Proceedings of the Transactions of the Korean Society of Automotive Engineers 2020 Spring Conference, Samcheok, Korea, 1–4 July 2020. [Google Scholar]

- When It Comes to Automatic Shifters, It’s Proceed with Caution. Available online: https://www.consumerreports.org/car-safety/automatic-shifters-proceed-with-caution (accessed on 28 December 2023).

- Can Unfamiliarity with a Shifter-Gear Lever Cause a Tragedy? Available online: https://www.consumerreports.org/cro/news/2015/02/can-unfamiliarity-with-a-gear-shift-lever-cause-a-tragedy/index.htm (accessed on 28 December 2023).

- Andersson, L.; Lenshof, S. Development of an Intuitive Shift-by-Wire Gear Selector. Bachelor’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2015. [Google Scholar]

- Bladfält, S.; Grane, C.; Bengtsson, P. Comparison of Usability between Gear Shifters with Varied Visual and Haptic Patterns and Complexities. Multimodal Technol. Interact. 2020, 4, 24. [Google Scholar] [CrossRef]

- Choi, G.; Kim, H.; Jeong, Y.; Son, M.; Beck, D. A Study on Ergonomic Layout of Automotive Electronic Shift Buttons. Appl. Sci. 2022, 12, 9222. [Google Scholar] [CrossRef]

- Toomath, J.; White, W. New Zealand survey of driver exposure to risk of accidents. Accid. Anal. Prev. 1982, 14, 407–411. [Google Scholar] [CrossRef]

- Office for Government Policy Coordination. Framework Act on Youth, Article 3 (1). Available online: https://elaw.klri.re.kr/kor_service/lawView.do?hseq=54732&lang=ENG (accessed on 28 December 2023).

- Michon, J.A. Generic Intelligent Driver Support; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- De Craen, S.; Twisk, D.; Hagenzieker, M.; Elffers, H.; Brookhuis, K. Do young novice drivers overestimate their driving skills. In Proceedings of the Young Researchers Seminar in SWOW, Brno, Czech Republic, 27–30 May 2007. [Google Scholar]

- Kinnear, N.; Kelly, S.W.; Stradling, S.; Thomson, J. Understanding how drivers learn to anticipate risk on the road: A laboratory experiment of affective anticipation of road hazards. Accid. Anal. Prev. 2013, 50, 1025–1033. [Google Scholar] [CrossRef]

- Abbasi, E.; Li, Y. A Comprehensive Review of Driver’s Attention and the Evaluation Methods. Comput. Res. Prog. Appl. Sci. Eng. 2021, 7, 1–4. [Google Scholar] [CrossRef]

- Khan, M.Q.; Lee, S. Gaze and eye tracking: Techniques and applications in ADAS. Sensors 2019, 19, 5540. [Google Scholar] [CrossRef]

- Le, A.S.; Suzuki, T.; Aoki, H. Evaluating driver cognitive distraction by eye tracking: From simulator to driving. Transp. Res. Interdiscip. Perspect. 2020, 4, 100087. [Google Scholar] [CrossRef]

- Née, M.; Contrand, B.; Orriols, L.; Gil-Jardiné, C.; Galéra, C.; Lagarde, E. Road safety and distraction, results from a responsibility case-control study among a sample of road users interviewed at the emergency room. Accid. Anal. Prev. 2019, 122, 19–24. [Google Scholar] [CrossRef]

- Peng, Y.; Boyle, L.N.; Hallmark, S.L. Driver’s lane keeping ability with eyes off road: Insights from a naturalistic study. Accid. Anal. Prev. 2013, 50, 628–634. [Google Scholar] [CrossRef]

- Singh, J. Learning based driver drowsiness detection model. In Proceedings of the 2020 3rd International Conference on Intelligent Sustainable Systems (ICISS), Coimbatore, India, 3–5 December 2020; pp. 698–701. [Google Scholar]

- Vermeeren, A.P.; Law, E.L.-C.; Roto, V.; Obrist, M.; Hoonhout, J.; Väänänen-Vainio-Mattila, K. User experience evaluation methods: Current state and development needs. In Proceedings of the 6th Nordic Conference on Human-Computer Interaction: Extending Boundaries, Reykjavik, Iceland, 16–20 October 2010; pp. 521–530. [Google Scholar]

- Yogasara, T.; Popovic, V.; Kraal, B.; Chamorro-Koc, M. General characteristics of anticipated user experience (AUX) with interactive products. In Proceedings of the 4th World Conference on Design Research: Diversity and Unity (IASDR 2011), Delft, The Netherlands, 31 October–4 November 2011; pp. 1–11. [Google Scholar]

- Chattratichart, J.; Jordan, P. Simulating ‘Lived’ User Experience-Virtual Immersion and Inclusive Design. In Proceedings of the IFIP TC13 International Conference on Human-Computer Interaction (INTERACT ’03), Zurich, Switzerland, 1–5 September 2003. [Google Scholar]

- Sánchez-Adame, L.M.; Urquiza-Yllescas, J.F.; Mendoza, S. Measuring anticipated and episodic UX of tasks in social networks. Appl. Sci. 2020, 10, 8199. [Google Scholar] [CrossRef]

- Lipp, K. User Experience beyond Usability. User Behavior 2012, pp. 13–19. Available online: https://www.researchgate.net/publication/254530996_User_Experience_Beyond_Usability (accessed on 28 December 2023).

- Eilu, E. Anticipated User Experience (AUX) Framework for Implementing Electronic Participation in a Developing Country Context. Ph.D. Thesis, Makarere University, Kampala, Uganda, 2019. [Google Scholar]

- Tonnis, M.; Broy, V.; Klinker, G. A survey of challenges related to the design of 3d user interfaces for car drivers. In Proceedings of the 3D User Interfaces Conference (3DUI’06), Alexandria, VA, USA, 25–26 March 2006; pp. 127–134. [Google Scholar]

- Bhise, V.D. Ergonomics in the Automotive Design Process; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Naddeo, A.; Cappetti, N.; Ippolito, O. Dashboard Reachability and Usability Tests: A Cheap and Effective Method for Drivers’ Comfort Rating; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Bernhard, C.; Hecht, H. Mirror or camera? Acceptance and valuation of camera-monitor systems. Transp. Res. Interdiscip. Perspect. 2022, 13, 100512. [Google Scholar] [CrossRef]

- Likert, R. A technique for the measurement of attitudes. Arch. Psychol. 1932, 22, 55. [Google Scholar]

- Joshi, A.; Kale, S.; Chandel, S.; Pal, D.K. Likert scale: Explored and explained. Br. J. Appl. Sci. Technol. 2015, 7, 396–403. [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics Using SPSS, 3rd ed.; Sage: London, UK; New York, NY, USA, 2009. [Google Scholar]

- Lawsuits Blame Range Rover Gear Shifter for Deadly Rollaway. Available online: https://www.cbsnews.com/news/range-rover-lawsuits-gear-shifter-deadly-rollaway (accessed on 28 December 2023).

- Wickens, C.D.; Gordon, S.E.; Liu, Y.; Lee, J. An Introduction to Human Factors Engineering; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2004; Volume 2. [Google Scholar]

- Sanders, M.S.; McCormick, E.J. Human Factors in Engineering and Design; Industrial Robot: An International Journal; McGraw Hill: New York, NY, USA, 1993. [Google Scholar]

- Ottesen, J.L. Concentrated window analysis results. AACE Int. Trans. 2006, C111. [Google Scholar]

- Hartwich, F.; Beggiato, M.; Krems, J.F. Driving comfort, enjoyment and acceptance of automated driving–effects of drivers’ age and driving style familiarity. Ergonomics 2018, 61, 1017–1032. [Google Scholar] [CrossRef]

- Canonica, A.C.; Alonso, A.C.; Brech, G.C.; Peterson, M.; Luna, N.M.S.; Busse, A.L.; Jacob-Filho, W.; Rosa, J.L.; Soares-Junior, J.M.; Baracat, E.C. Adaptation to the driving simulator and prediction of the braking time performance, with and without distraction, in older adults and middle-aged adults. Clinics 2023, 78, 100168. [Google Scholar] [CrossRef]

- Delmas, M.; Camps, V.; Lemercier, C. Should my automated car drive as I do? Investigating speed preferences of drivengers in various driving conditions. PLoS ONE 2023, 18, e0281702. [Google Scholar] [CrossRef]

- Hjelmervik, H.; Westerhausen, R.; Hirnstein, M.; Specht, K.; Hausmann, M. The neural correlates of sex differences in left–right confusion. NeuroImage 2015, 113, 196–206. [Google Scholar] [CrossRef]

- Chen, K.B.; Savage, A.B.; Chourasia, A.O.; Wiegmann, D.A.; Sesto, M.E. Touch screen performance by individuals with and without motor control disabilities. Appl. Ergon. 2013, 44, 297–302. [Google Scholar] [CrossRef]

- Feng, F.; Liu, Y.; Chen, Y. Effects of quantity and size of buttons of in-vehicle touch screen on drivers’ eye glance behavior. Int. J. Hum. Comput. 2018, 34, 1105–1118. [Google Scholar] [CrossRef]

- Cooper, P.J.; Meckle, W.; Nasvadi, G. The safety of vehicles imported from right-hand-drive vehicle configuration countries when operated in a left-hand-drive vehicle environment. Accid. Anal. Prev. 2009, 41, 108–114. [Google Scholar] [CrossRef]

- Chevalot, N.; Wang, X. An experimental investigation of the discomfort of arm reaching movements in a seated position. SAE Trans. 2004, 98–103. [Google Scholar]

- Stevens, A.; Quimby, A.; Board, A.; Kersloot, T.; Burns, P. Design Guidelines for Safety of In-Vehicle Information Systems; TRL Limited: Wokingham, UK, 2002. [Google Scholar]

- Hsee, C.K.; Leclerc, F. Will products look more attractive when presented separately or together? J. Consum. Res. 1998, 25, 175–186. [Google Scholar] [CrossRef]

- Jacoby, L.L.; Debner, J.A.; Hay, J.F. Proactive interference, accessibility bias, and process dissociations: Valid subject reports of memory. J. Exp. Psychol. Learn. Mem. Cogn. 2001, 27, 686. [Google Scholar] [CrossRef]

- Brown, C.L.; Feinberg, F. Bolstering: How Does Choice Distort Product Evaluations? Working paper; The University of Michigan: Ann Arbor, MI, USA, 2004. [Google Scholar]

- Green, P.; Paelke, G.; Clack, K. Instrument Panel Controls in Sedans: What Drivers Prefer and Why; The University of Michigan: Ann Arbor, MI, USA, 1989. [Google Scholar]

- Shaw, G.; Dalrymple, G.; Ragland, C. Air bag interaction with and injury potential from common steering control devices. Annu. Proc. Assoc. Adv. Automot. Med. 1998, 42, 244–259. [Google Scholar]

- Wang, X.; Trasbot, J. Effects of target location, stature and hand grip type on in-vehicle reach discomfort. Ergonomics 2011, 54, 466–476. [Google Scholar] [CrossRef]

- Tideman, M.; van der Voort, M.C.; van Houten, F.J. Design and evaluation of a virtual gearshift application. In Proceedings of the 2004 IEEE Intelligent Vehicles Symposium, Parma, Italy, 14–17 June 2004; pp. 465–470. [Google Scholar]

- Salamin, P.; Thalmann, D.; Vexo, F. Comfortable manipulation of a virtual gearshift prototype with haptic feedback. In Proceedings of the EuroHaptics ’06, Paris, France, 3–6 July 2006. [Google Scholar]

| Operation Method | Lever Slide | Button Push | Dial Rotation | |

|---|---|---|---|---|

| In-Vehicle Location | ||||

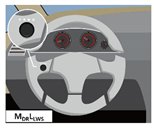

| Near the steering wheel |  | Not adopted yet |  | |

| Manufacturer (Model) | PORSCHE (TAYCAN and PANAMERA [2024~]) | BMW (I3), CHEVROLET (ID4), HYUNDAI (CONA [2022~], GRANDEUR 7, IONIQ 5, IONIQ 6, SONATA [2024], and SANTAFE [2024]), and KIA (EV9) | ||

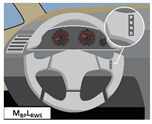

| Center facia upper/middle part |  |  |  | |

| Manufacturer (Model) | KIA (LAY), LAND ROVER (DEFENDER 130), NISSAN (QUEST), and TOYOTA (SIENNA) | CHEVROLET (SUBURBAN and TAHOE), GMC (YUKON), HONDA (ACCORD and ODYSSEY), and LINCOLN (CONTINENTAL, MKC, MKZ, and MKX) | CHRYSLER (200, 300, PACIFICA, and VOYAGER) and RAM (2500, 3500, 1500, and CHASSIS CAB) | |

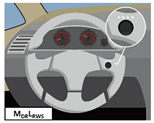

| Center facia lower part |  |  | Not adopted yet | |

| Manufacturer (Model) | GENESIS (G90 [2021]), HONDA (ACCORD [~2018], CR-V, PILOT [~2015], and ODYSSEY [~2017]), HYUNDAI (CASPER, STAREX, and STARIA), and KIA (CARNIVAL [~2014]) | GMC (ACADIA and TERRAIN), HONDA (ODYSSEY), HYUNDAI (SANTAFE, GRANDEUR, and STARIA), LINCOLN (AVIATOR, CORSAIR, NAUTILUS, and NAVIGATOR), and JAGUAR (I-PACE) | ||

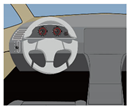

| Center console |  |  |  | |

| Manufacturer (Model) | CHEVROLET (SPARK, MALIBU, TRAX, and TRAILBLAZER), DODGE (CHALLENGER, DURANGO, and CHARGER), FORD (MUSTANG), GENESIS (G70), HYUNDAI (AVANTE, VELOSTER, and KONA N), JAGUAR (F-TYPE, F-PACE, E-PACE, and X-TYPE), JEEP (CHEROKEE, COMPASS, and WRANGLER), KIA (K3, K9, SPORTAGE [~2014], STINGER MEISTER, and CARNIVAL), LAND ROVER (DEFENDER, DISCOVERY, NEW RANGE ROVER, EVOQUE, and VELAR), LINCOLN (MKT, MKS, and NAVIGATOR [~2017]), and PORCHE (CAYENNE, TURBO S, and 911) | CHEVROLET (CORVETTE C8 STINGRAY and VOLT), HONDA (ACURA NSX, PILOT, and TLX), and HYUNDAI (AZERA, TUCSON, PALISADE, SONATA, CONA [~2021], NEXO, and TUCSON) | GENESIS (G80, G90, GV70, GV60, and GV80), DODGE (DURANGO [2014~2017]), FORD (EXPLORER and EXPEDITION), JAGUAR (XF, XJ, XK, and XE), JEEP (GRAND CHEROKEE, WAGONEER, and GRAND WAGONEER), KIA (K5, K8, SELTOS, SPORTAGE, CARNIVAL, NIRO EV6, and SORENTO), and LAND ROVER (LR4, RANGE ROVER, EVOQUE [~2019], and VELAR [~2020]) | |

| Group | Age (Years) | Driving Experience (Driving Distance in the Last Five Years {km}) | ||||||

|---|---|---|---|---|---|---|---|---|

| Experience | Age | N | Mean | SD | Range | Mean | SD | Range |

| Novice | Young adulthood | 15 | 23.3 | 2.40 | 19–26 | 731 | 1372 | 0–5000 |

| Middle-aged | 6 | 47.8 | 11.2 | 37–63 | 2500 | 2739 | 0–5000 | |

| Total | 21 | 30.3 | 13.1 | 19–63 | 1237 | 1965 | 0–5000 | |

| Experienced | Young adulthood | 9 | 26.9 | 4.20 | 21–34 | 65,889 | 49,994 | 13,000–150,000 |

| Middle-aged | 10 | 40.6 | 4.38 | 36–49 | 73,500 | 47,458 | 25,000–160,000 | |

| Total | 19 | 34.1 | 8.18 | 21–49 | 69,895 | 47,457 | 13,000–160,000 | |

| Total | 40 | 32.1 | 11.1 | 19–63 | 33,849 | 74,404 | 0–160,000 | |

| Lever Slide (MLS) | Button Push (MBP) | Dial Rotation (MDR) |

|---|---|---|

|  |  |

| Left Wheel Spoke (LLWS) | Right Wheel Spoke (LRWS) | Upper Center Fascia (LUCF) | Lower Center Fascia (LLCF) | Center Console (LCC) |

|---|---|---|---|---|

|  |  |  |  |

| Operation Method | Lever Slide (MLS) | Button Push (MBP) | Dial Rotation (MDR) | |

|---|---|---|---|---|

| In-Vehicle Location | ||||

| Left wheel spoke (LLWS) |  |  |  | |

| Right wheel spoke (LRWS) |  |  |  | |

| Upper center fascia (LUCF) |  |  |  | |

| Lower center fascia (LLCF) |  |  |  | |

| Center console (LCC) |  |  |  | |

| Measures | Description (Question) |

|---|---|

| Accuracy | This design will help me shift gears accurately without errors. |

| Efficiency | This design will help me shift gears efficiently in terms of eye and hand movements. |

| Rapidity | This design will help me shift gears quickly. |

| Learnability | This design can be learned without much effort. |

| Intuitiveness | This design meets my expectations. |

| Safety | This design will help me drive safely. |

| Preference | I like this design (I am willing to use/buy it). |

| Memorability | This design will be easy to use again even after a period of not using it. |

| Satisfaction | I am generally satisfied with this design (this design is excellent). |

| Measure | Accuracy | Efficiency | Rapidity | Learnability | Intuitiveness | Safety | Preference | Memorability | Satisfaction | |

|---|---|---|---|---|---|---|---|---|---|---|

| Design | ||||||||||

| MLSLLWS | 2.65 (1.82) | 3.38 (2.07) | 3.56 (1.99) | 3.30 (1.94) | 2.68 (1.67) | 2.40 (1.55) | 2.45 (1.80) | 3.63 (2.03) | 2.50 (1.69) | |

| MLSLRWS | 3.08 (1.70) | 4.00 (2.08) | 4.45 (1.99) | 3.75 (1.92) | 3.28 (1.74) | 3.00 (1.65) | 2.98 (1.91) | 4.05 (1.83) | 3.03 (1.83) | |

| MLSLUCF | 4.18 (1.85) | 3.40 (1.85) | 3.58 (1.62) | 4.25 (1.84) | 3.75 (1.68) | 3.43 (1.62) | 2.90 (1.55) | 4.30 (1.70) | 2.90 (1.55) | |

| MLSLLCF | 4.90 (1.52) | 4.50 (1.59) | 4.48 (1.58) | 5.03 (1.72) | 4.68 (1.56) | 4.80 (1.34) | 4.35 (1.64) | 5.13 (1.51) | 4.33 (1.46) | |

| MLSLCC | 5.60 (1.26) | 4.90 (1.60) | 5.13 (1.36) | 5.88 (1.28) | 5.55 (1.54) | 5.18 (1.47) | 5.08 (1.58) | 5.70 (1.20) | 5.03 (1.54) | |

| MBPLLWS | 2.80 (1.67) | 3.73 (1.97) | 4.10 (1.98) | 3.60 (1.91) | 2.93 (1.69) | 2.73 (1.63) | 2.60 (1.68) | 3.70 (1.83) | 2.73 (1.65) | |

| MBPLRWS | 3.53 (1.69) | 4.58 (1.99) | 4.50 (1.89) | 4.20 (1.77) | 3.68 (1.85) | 3.33 (1.76) | 3.50 (1.85) | 4.33 (1.83) | 3.75 (1.88) | |

| MBPLUCF | 4.15 (1.67) | 4.23 (1.69) | 4.00 (1.69) | 4.50 (1.71) | 3.93 (1.54) | 3.90 (1.60) | 3.40 (1.65) | 4.55 (1.54) | 3.43 (1.55) | |

| MBPLLCF | 4.48 (1.48) | 4.55 (1.52) | 4.45 (1.41) | 4.98 (1.31) | 4.58 (1.34) | 4.53 (1.30) | 4.38 (1.58) | 5.00 (1.15) | 4.35 (1.41) | |

| MBPLCC | 4.83 (1.43) | 4.33 (1.58) | 4.55 (1.48) | 4.90 (1.57) | 4.90 (1.53) | 4.70 (1.44) | 4.50 (1.83) | 5.03 (1.44) | 4.48 (1.74) | |

| MDRLLWS | 2.73 (1.68) | 3.08 (1.95) | 3.50 (1.93) | 3.28 (1.95) | 2.65 (1.72) | 2.43 (1.58) | 2.40 (1.75) | 3.50 (1.85) | 2.40 (1.72) | |

| MDRLRWS | 2.80 (1.49) | 3.78 (1.98) | 3.65 (1.90) | 3.33 (1.89) | 2.80 (1.70) | 2.70 (1.57) | 2.65 (1.75) | 3.45 (1.87) | 2.60 (1.58) | |

| MDRLUCF | 3.60 (1.78) | 3.93 (1.90) | 3.83 (1.71) | 4.00 (1.78) | 3.28 (1.69) | 3.38 (1.75) | 3.13 (1.76) | 4.08 (1.67) | 3.18 (1.78) | |

| MDRLLCF | 4.25 (1.58) | 4.10 (1.60) | 4.18 (1.47) | 4.30 (1.67) | 4.05 (1.45) | 4.03 (1.49) | 4.00 (1.48) | 4.60 (1.52) | 3.85 (1.44) | |

| MDRLCC | 4.20 (1.62) | 4.28 (1.71) | 4.33 (1.58) | 4.53 (1.57) | 4.33 (1.69) | 4.08 (1.70) | 4.05 (1.88) | 4.63 (1.51) | 4.15 (1.67) | |

| In-Vehicle Location Considered in This Study | Operation Method | Total | |||||

|---|---|---|---|---|---|---|---|

| MLS | MBP | MDR | |||||

| LLWS | 1 | 0 | 1 | 2 | |||

| LRWS | 1 | 2 | 0 | 3 | |||

| LUCF | 1 | 0 | 0 | 1 | |||

| LLCF | 8 | 6 | 0 | 14 | |||

| LCC | 9 | 3 | 3 | 15 | |||

| Total | 20 | 11 | 4 | 35 | |||

| In-Vehicle Location ‘not’ Considered in This Study | Operation method | Total | |||||

| MLS | MBP | MDR | |||||

| Picture | N | Picture | N | Picture | N | ||

| Left side of the steering wheel |  | 2 |  | 2 |  | 1 | 5 |

| Right side of the steering wheel |  | 1 |  | 2 |  | 0 | 4 |

| Total | 3 | 4 | 1 | 8 | |||

| Major Finding | Research Question | Answer (Illustration) | |||

|---|---|---|---|---|---|

| A (MDR < MLS, MBP) | What is the best ergonomic operation method for electronic gearshifts? |  |  | ||

| MLS | MBP | ||||

| B-1 (LLWS < LRWS < LUCF, LLCF, LCC) | What is the best ergonomic in-vehicle location for electronic gearshifts? |  |  |  | |

| LUCF | LLCF | LCC | |||

| B-2 (LUCF < LLCF, LCC) |  |  | |||

| LLCF | LCC | ||||

| C-1 (MLSLCF, MBPLCC < MLSLCC) | What is the best ergonomic combination of operation method and in-vehicle location for electronic gearshifts? |  | |||

| MLSLCC | |||||

| C-2 (MLSLRWS < MBPLRWS, MLSLUCF < MBPLUCF) |  |  | |||

| MBPLRWS | MBPLUCF | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, S.; Park, J.; Kim, H.; Kang, H.; Beck, D. An Ergonomic Study on the Operation Method and In-Vehicle Location of an Automotive Electronic Gearshift. Appl. Sci. 2024, 14, 672. https://doi.org/10.3390/app14020672

An S, Park J, Kim H, Kang H, Beck D. An Ergonomic Study on the Operation Method and In-Vehicle Location of an Automotive Electronic Gearshift. Applied Sciences. 2024; 14(2):672. https://doi.org/10.3390/app14020672

Chicago/Turabian StyleAn, Sehee, Jiwon Park, Hanul Kim, Hyemin Kang, and Donghyun Beck. 2024. "An Ergonomic Study on the Operation Method and In-Vehicle Location of an Automotive Electronic Gearshift" Applied Sciences 14, no. 2: 672. https://doi.org/10.3390/app14020672

APA StyleAn, S., Park, J., Kim, H., Kang, H., & Beck, D. (2024). An Ergonomic Study on the Operation Method and In-Vehicle Location of an Automotive Electronic Gearshift. Applied Sciences, 14(2), 672. https://doi.org/10.3390/app14020672