The Preliminary Development of a Friction-Based Lateral Screw-Retained Dental Crown—A Comparison between the Prototype Surface Treatment and the Retention Strength

Abstract

1. Introduction

2. Materials and Methods

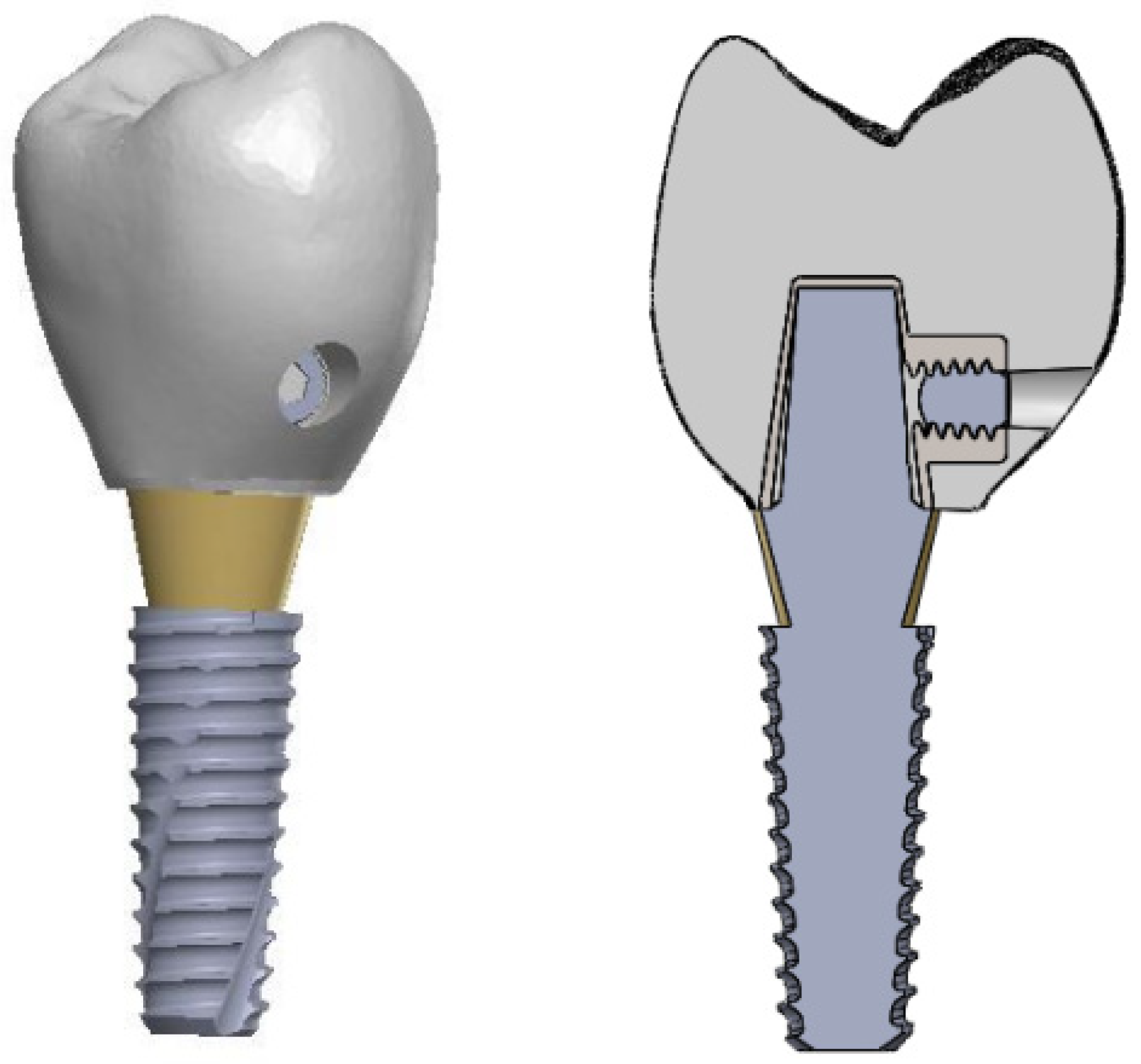

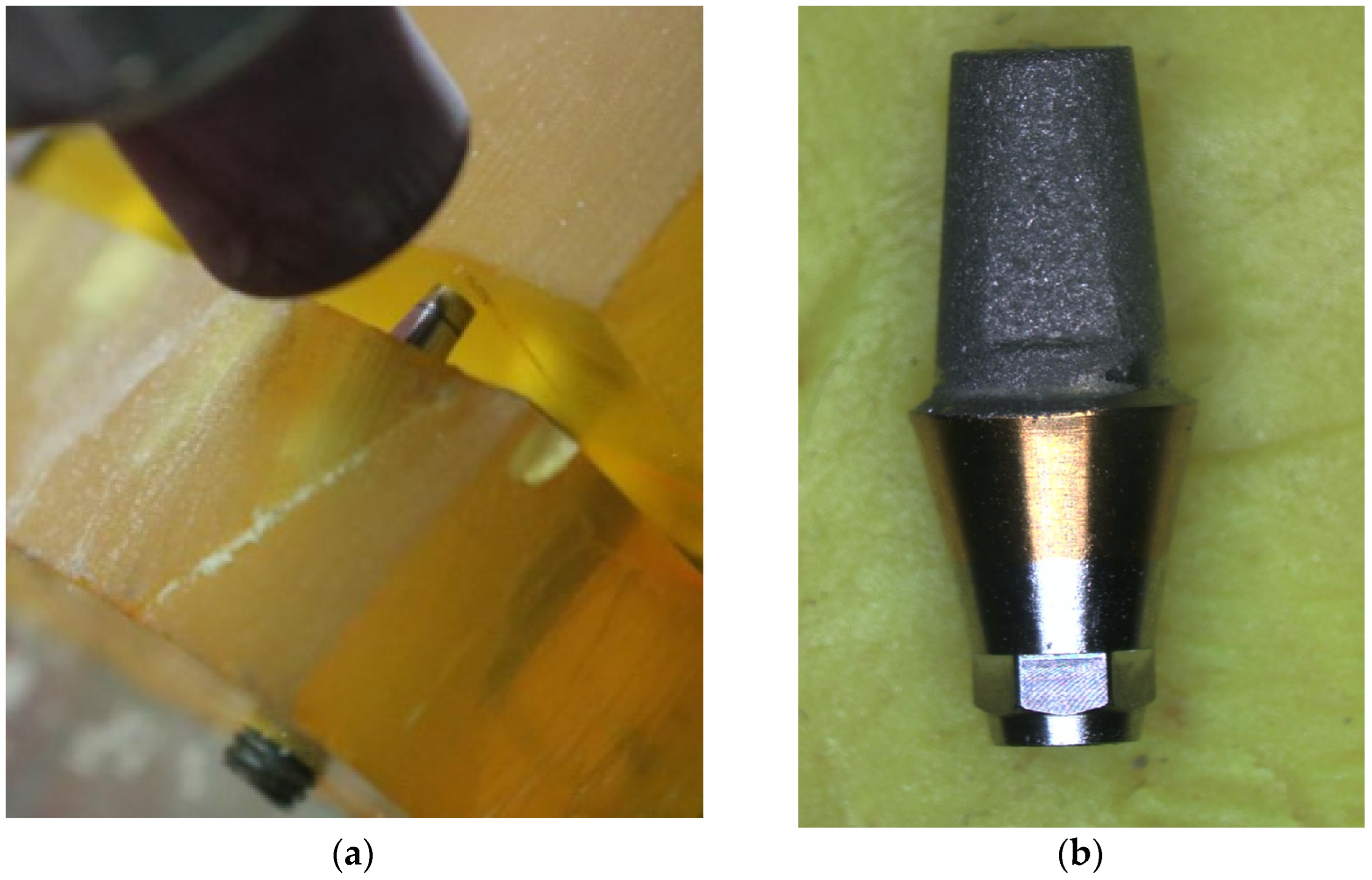

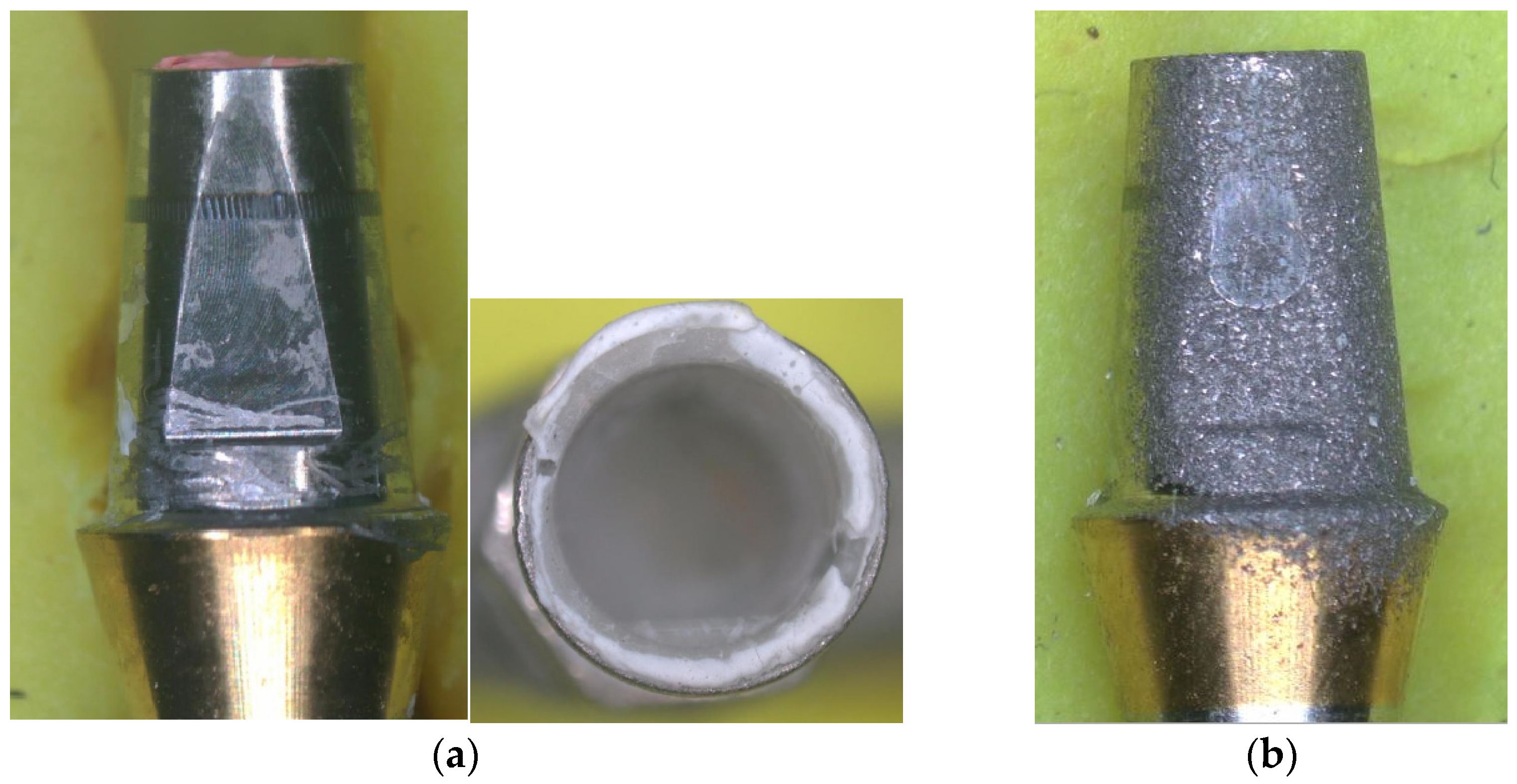

2.1. Prototype Design and Manufacturing

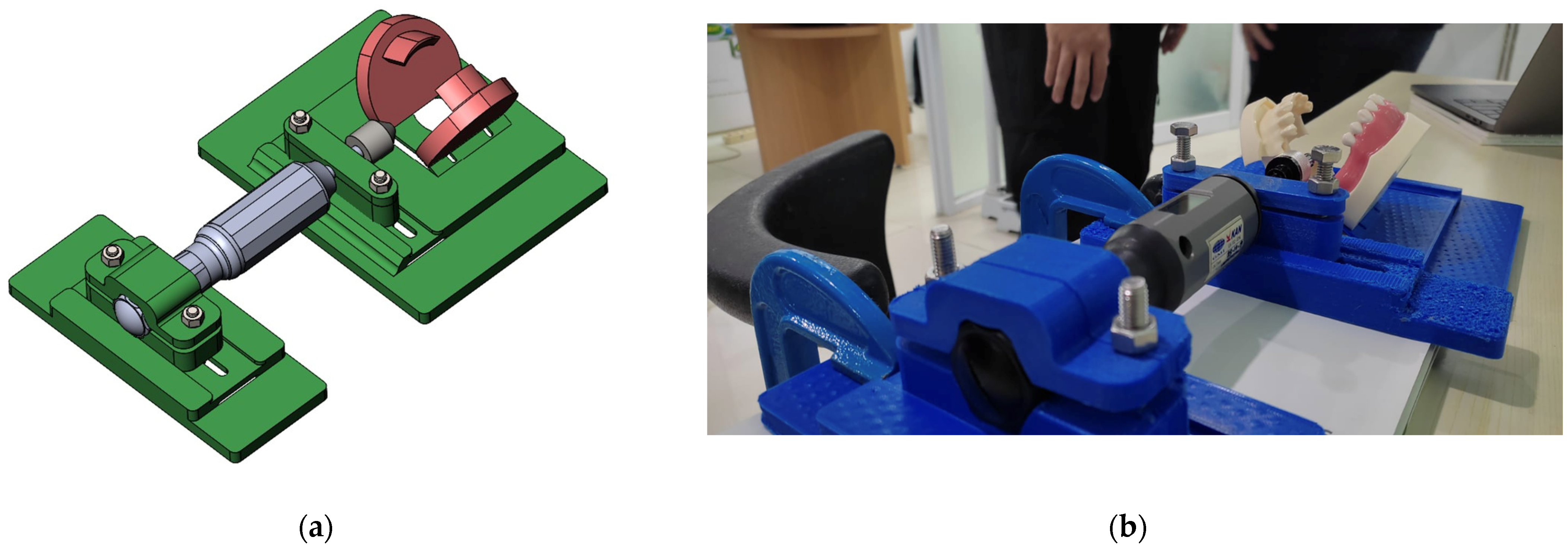

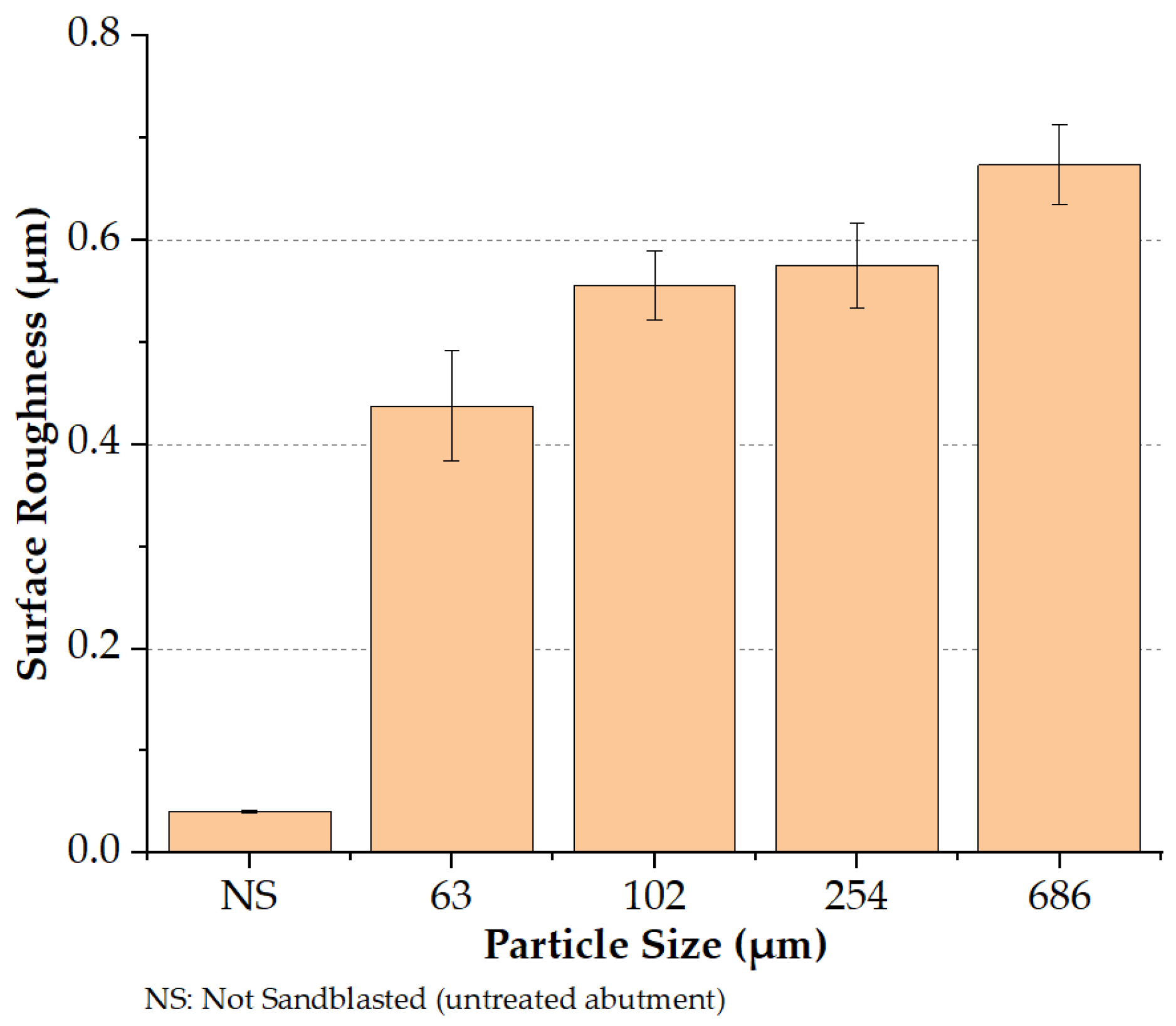

2.2. Coping Retention Test for Various Surface Roughness

2.3. Maximum Tightening Torque for Lateral Screw-Retained Implant

2.4. Coping Retention Test for Various Tightening Torques

2.5. Statistical Analysis

3. Results

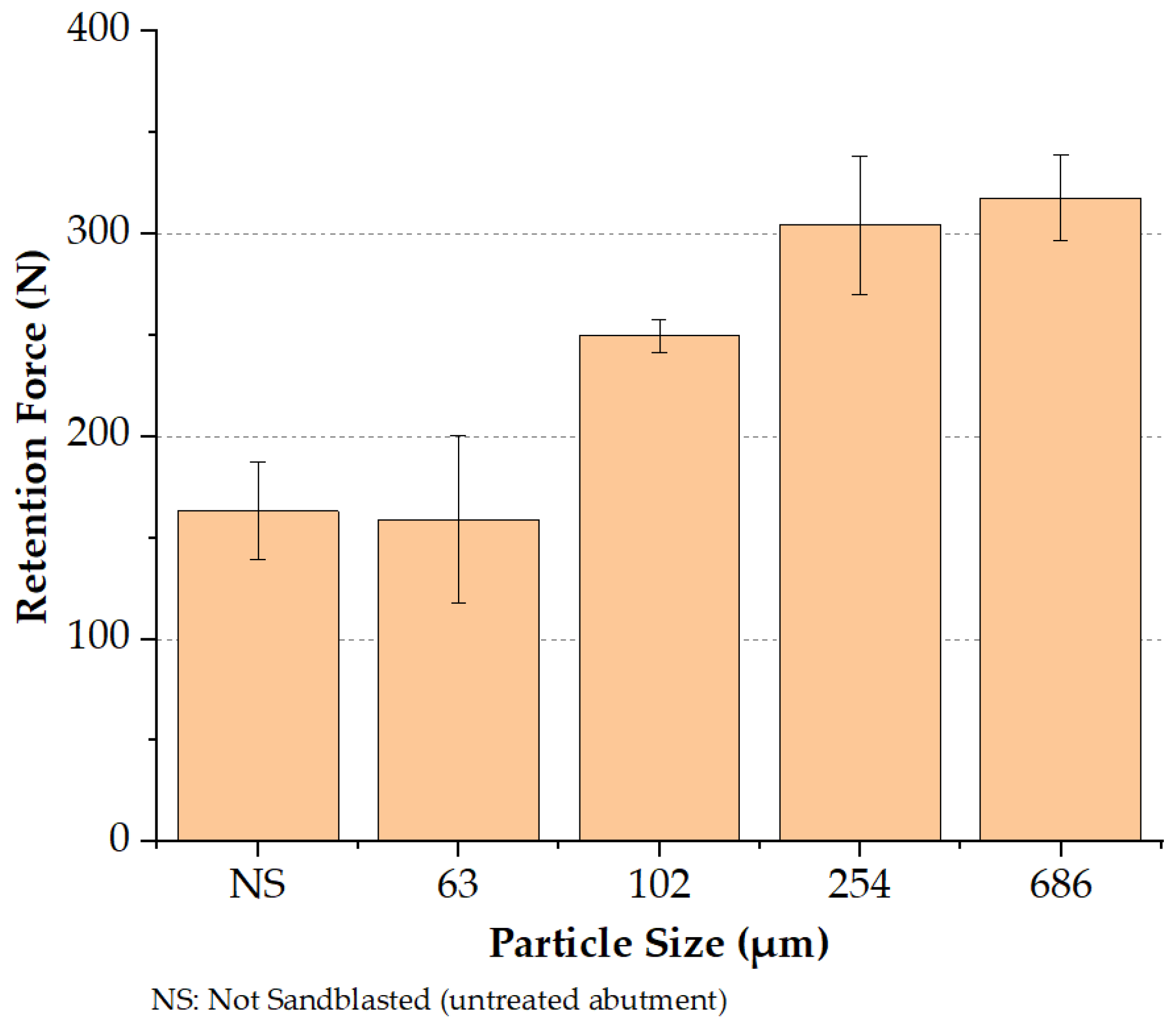

3.1. Coping Retention Based on Various Surface Roughness

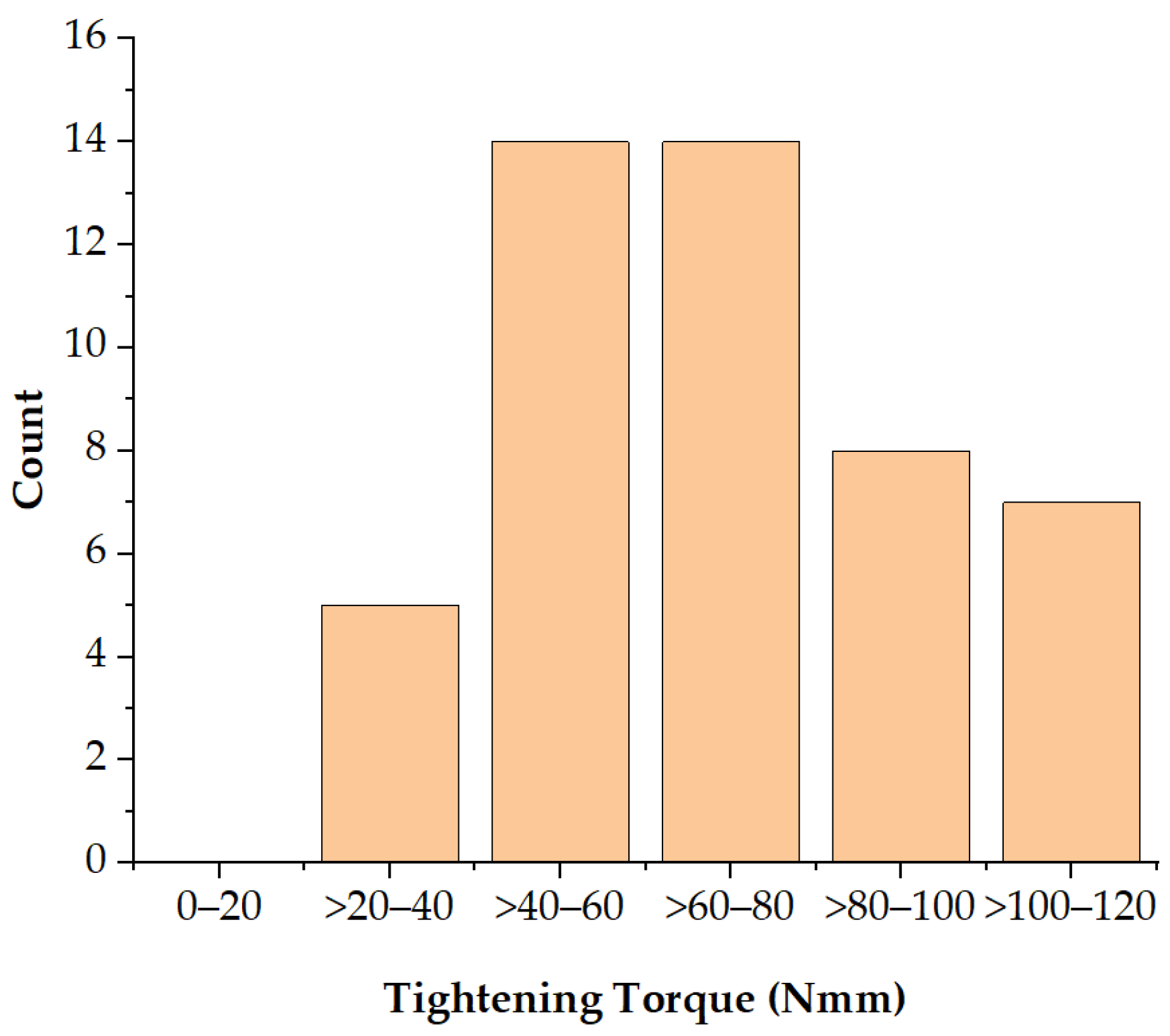

3.2. Hand Tightening Torque

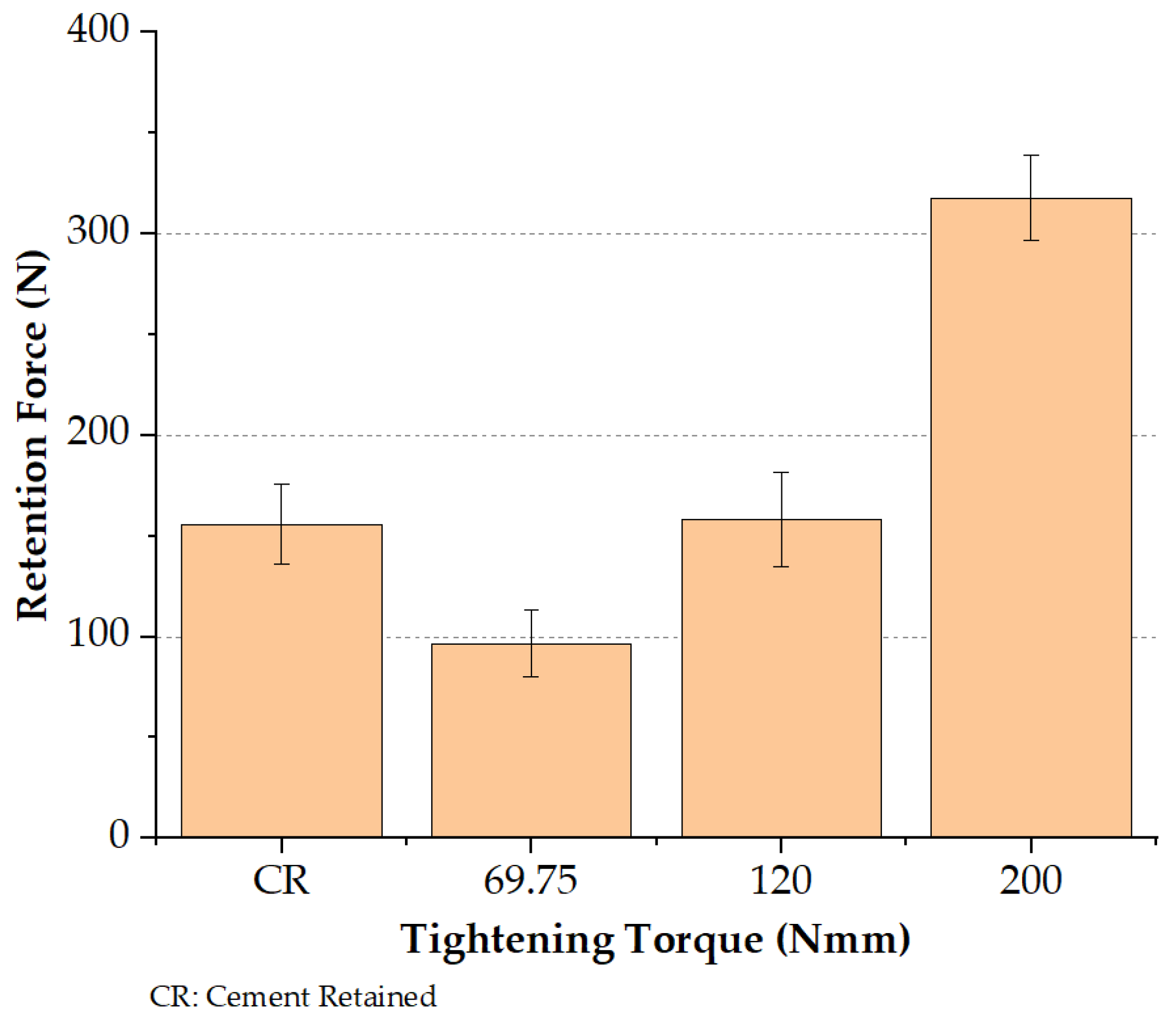

3.3. Coping Retention Based on the Tightening Torque

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Gender | Age | Height (cm) | Weight (kg) | Average Tightening Torque (Nmm) |

|---|---|---|---|---|

| Male | 25 | 169 | 55 | 109.33 |

| Male | 25 | 185 | 81 | 34.67 |

| Male | 26 | 180 | 82 | 75.00 |

| Male | 26 | 183 | 68 | 92.33 |

| Male | 26 | 170 | 100 | 71.00 |

| Male | 26 | 165 | 65 | 86.67 |

| Male | 26 | 171 | 64 | 50.00 |

| Male | 27 | 177 | 78 | 56.00 |

| Male | 28 | 173 | 66 | 53.00 |

| Male | 28 | 165 | 77 | 46.00 |

| Male | 29 | 178 | 85 | 101.67 |

| Male | 29 | 173 | 85 | 58.67 |

| Male | 30 | 180 | 92 | 61.00 |

| Male | 30 | 168 | 76 | 70.67 |

| Male | 30 | 168 | 70 | 67.33 |

| Male | 30 | 175 | 95 | 69.00 |

| Male | 31 | 168 | 72 | 88.67 |

| Male | 31 | 168 | 63 | 49.67 |

| Male | 31 | 167 | 82 | 118.00 |

| Male | 32 | 158 | 61 | 112.67 |

| Male | 32 | 168 | 84 | 55.00 |

| Male | 35 | 170 | 90 | 105.00 |

| Male | 35 | 186 | 100 | 90.67 |

| Male | 35 | 180 | 75 | 120.67 |

| Male | 36 | 198 | 112 | 70.33 |

| Male | 36 | 169 | 70 | 44.33 |

| Female | 26 | 148 | 45 | 55.67 |

| Female | 27 | 165 | 53 | 37.67 |

| Female | 27 | 163 | 49 | 71.00 |

| Female | 28 | 164 | 66 | 35.67 |

| Female | 29 | 164 | 48 | 52.00 |

| Female | 29 | 159 | 60 | 63.00 |

| Female | 30 | 162 | 58 | 87.33 |

| Female | 30 | 155 | 54 | 81.00 |

| Female | 30 | 155 | 50 | 73.67 |

| Female | 30 | 167 | 75 | 77.00 |

| Female | 30 | 167 | 78 | 36.67 |

| Female | 31 | 155 | 52 | 39.00 |

| Female | 34 | 158 | 70 | 50.00 |

| Female | 36 | 165 | 48 | 59.67 |

| Female | 36 | 165 | 58 | 50.67 |

| Female | 36 | 158 | 52 | 76.67 |

| Female | 36 | 173 | 90 | 100.33 |

| Female | 37 | 170 | 56 | 89.33 |

| Female | 38 | 153 | 60 | 66.33 |

| Female | 40 | 156 | 67 | 54.00 |

| Female | 42 | 158 | 62 | 64.67 |

References

- Pjetursson, B.; Asgeirsson, A.; Zwahlen, M.; Sailer, I. Improvements in Implant Dentistry over the Last Decade: Comparison of Survival and Complication Rates in Older and Newer Publications. Int. J. Oral Maxillofac. Implant. 2014, 29, 308–324. [Google Scholar] [CrossRef] [PubMed]

- Resnik, R. Misch’s Contemporary Implant Dentistry, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Reda, R.; Zanza, A.; Cicconetti, A.; Bhandi, S.; Guarnieri, R.; Testarelli, L.; Di Nardo, D. A Systematic Review of Cementation Techniques to Minimize Cement Excess in Cement-Retained Implant Restorations. Methods Protoc. 2022, 5, 9. [Google Scholar] [CrossRef] [PubMed]

- Makke, A.; Homsi, A.; Guzaiz, M.; Almalki, A. Survey of Screw-Retained versus Cement-Retained Implant Restorations in Saudi Arabia. Int. J. Dent. 2017, 2017, 5478371. [Google Scholar] [CrossRef] [PubMed]

- Caricasulo, R.; Malchiodi, L.; Ghensi, P.; Fantozzi, G.; Cucchi, A. The influence of implant-abutment connection to peri-implant bone loss: A systematic review and meta-analysis. Clin. Implant. Dent. Relat. Res. 2018, 20, 653–664. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.C.; Lee, J.; Kim, S.; Koo, K.T.; Kim, H.Y.; Yeo, I.S.L. Influence of implant-abutment connection structure on peri-implant bone level in a second molar: A 1-year randomized controlled trial. J. Adv. Prosthodont. 2019, 11, 147–154. [Google Scholar] [CrossRef] [PubMed]

- Link-Bindo, E.E.; Soltys, J.; Donatelli, D.; Cavanaugh, R. Common Prosthetic Implant Complications in Fixed Restorations. Compend. Contin. Educ. Dent. 2016, 37, 431. [Google Scholar]

- Wittneben, J.G.; Joda, T.; Weber, H.P.; Brägger, U. Screw retained vs. cement retained implant-supported fixed dental prosthesis. Periodontology 2000 2017, 73, 141–151. [Google Scholar] [CrossRef]

- Ma, S.; Fenton, A. Screw- Versus Cement-Retained Implant Prostheses: A Systematic Review of Prosthodontic Maintenance and Complications. Int. J. Prosthodont. 2015, 28, 127–145. [Google Scholar] [CrossRef]

- Veselinović, V.; Marin, S.; Trtić, Z.; Trtić, N.; Dolić, O.; Adamović, T.; Arbutina, R.; Šćepanović, M.; Todorović, A. Application of Semipermanent Cements and Conventional Cement with Modified Cementing Technique in Dental Implantology. Acta Stomatol. Croat. 2021, 55, 367–379. [Google Scholar] [CrossRef]

- El-Helbawy, N.; El-Hatery, A.; Ahmed, M. Comparison of Oxygen Plasma Treatment and Sandblasting of Titanium Implant-Abutment Surface on Bond Strength and Surface Topography. Int. J. Oral Maxillofac. Implant. 2016, 31, 555–562. [Google Scholar] [CrossRef][Green Version]

- Kurt, M.; Külünk, T.; Ural, Ç.; Külünk, Ş.; Danişman, Ş.; Savaş, S. The Effect of Different Surface Treatments on Cement-Retained Implant-Supported Restorations. J. Oral Implant. 2013, 39, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Drummond, L.G.R.; Segundo, R.M.H.; Oshima, H.M.S.; Shinkai, R.S.A. The effect of surface texture on the retention of single implant-supported crowns cemented on wide-platform abutments. Rev. Odonto Cienc. 2017, 32, 169–173. [Google Scholar] [CrossRef]

- Tan, K.M.; Masri, R.; Driscoll, C.F.; Limkangwalmongkol, P.; Romberg, E. Effect of axial wall modification on the retention of cement-retained, implant-supported crowns. J. Prosthet. Dent. 2012, 107, 80–85. [Google Scholar] [CrossRef] [PubMed]

- Derafshi, R.; Ahangari, A.H.; Torabi, K.; Farzin, M. Evaluation of the Effect of Axial Wall Modification and Coping Design on the Retention of Cement-retained Implant-supported Crowns. J. Dent. Res. Dent. Clin. Dent. Prospects 2015, 9, 35–39. [Google Scholar] [PubMed]

- Farzin, M.; Torabi, K.; Ahangari, A.H.; Derafshi, R. Effect of abutment modification and cement type on retention of cement-retained implant supported crowns. J. Dent. 2014, 11, 256. [Google Scholar]

- Wadhwani, C.; Hess, T.; Piñeyro, A.; Chung, K.-H. Effects of Abutment and Screw Access Channel Modification on Dislodgement of Cement-Retained Implant-Supported Restorations. Int. J. Prosthodont. 2013, 26, 54–56. [Google Scholar] [CrossRef] [PubMed]

- Lewinstein, I.; Block, L.; Lehr, Z.; Ormianer, Z.; Matalon, S. An in vitro assessment of circumferential grooves on the retention of cement-retained implant-supported crowns. J. Prosthet. Dent. 2011, 106, 367–372. [Google Scholar] [CrossRef]

- Biyani, R.; Ali, M.; Belles, D.; Powers, J.M. Effect of Metal Extension of Crown in the Screw Access Channel of a Posterior Implant Abutment on the Retention of Cement Retained Prosthesis. J. Oral Implant. 2015, 41, 537–541. [Google Scholar] [CrossRef]

- Bresciano, M.; Schierano, G.; Manzella, C.; Screti, A.; Bignardi, C.; Preti, G. Retention of luting agents on implant abutments of different height and taper. Clin. Oral Implants Res. 2005, 16, 594–598. [Google Scholar] [CrossRef]

- Nematollahi, F.; Beyabanaki, E.; Alikhasi, M. Cement Selection for Cement-Retained Implant-Supported Prostheses: A Literature Review. J. Prosthodont. 2016, 25, 599–606. [Google Scholar] [CrossRef]

- Linkevicius, T.; Puisys, A.; Vindasiute, E.; Linkeviciene, L.; Apse, P. Does residual cement around implant-supported restorations cause peri-implant disease? A retrospective case analysis. Clin. Oral Implants Res. 2013, 24, 1179–1184. [Google Scholar] [CrossRef] [PubMed]

- Scarano, A.; Inchingolo, F.; Scogna, S.; Leo, L.; Greco Lucchina, A.; Mavriqi, L. Peri-implant disease caused by residual cement around implant-supported restorations: A clinical report. J. Biol. Regul. Homeost. Agents 2021, 35, 211–216. [Google Scholar] [CrossRef] [PubMed]

- Da Rocha, P.V.B.; Freitas, M.A.; De Morais Alves Da Cunha, T. Influence of screw access on the retention of cement-retained implant prostheses. J. Prosthet. Dent. 2013, 109, 264–268. [Google Scholar] [CrossRef] [PubMed]

- Sailer, I.; Karasan, D.; Todorovic, A.; Ligoutsikou, M.; Pjetursson, B.E. Prosthetic failures in dental implant therapy. Periodontology 2000 2022, 88, 130–144. [Google Scholar] [CrossRef] [PubMed]

- Hamed, M.T.; Abdullah Mously, H.; Khalid Alamoudi, S.; Hossam Hashem, A.B.; Hussein Naguib, G. A Systematic Review of Screw versus Cement-Retained Fixed Implant Supported Reconstructions. Clin. Cosmet. Investig. Dent. 2020, 12, 9–16. [Google Scholar] [CrossRef]

- Shadid, R.; Sadaqah, N.; Shadid, B.R.; Rayyan, M.M.; Makarem, H.A.; Oh, K.C.; Moon, H.S.; Pera, F.; Pesce, P.; Bevilacqua, M.; et al. A Comparison Between Screw- and Cement-Retained Implant Prostheses. A Literature Review. J. Oral Implant. 2012, 38, 298–307. [Google Scholar] [CrossRef]

- Kenneth, H.; Reena, G.C. Cement-retained versus screw-retained implant restorations: Achieving optimal occlusion and esthetics in implant dentistry. J. Prosthet. Dent. 1997, 77, 28–35. [Google Scholar]

- Andersson, B.; Odman, P.; Lindvall, A.M.; I Brånemark, P. Cemented single crowns on osseointegrated implants after 5 years: Results from a prospective study on CeraOne. Int. J. Prosthodont. 1998, 11, 212–218. [Google Scholar]

- Gervais, M.; Hatzipanagiotis, P.; Wilson, P. Cross-pinning: The philosophy of retrievability applied practically to fixed, implant-supported prostheses. Aust. Dent. J. 2008, 53, 74–82. [Google Scholar] [CrossRef]

- Sambrook, R.; Judge, R.; Abuzaar, M. Strategies for restoration of single implants and use of cross-pin retained restorations by Australian prosthodontists. Aust. Dent. J. 2012, 57, 409–414. [Google Scholar] [CrossRef]

- Sambrook, R.J.; Judge, R.B. The cross-pin retained implant supported restoration: A study of gasket placement and leakage. Aust. Dent. J. 2012, 57, 415–420. [Google Scholar] [CrossRef] [PubMed]

- Sánchez Lasheras, F.; Rodríguez, J.G.; Mauvezín-Quevedo, M.; Martín-Fernández, E.; Bobes-Bascarán, J.; de Llanos-Lanchares, H.; Álvarez-Arenal, Á. Does the transversal screw design increase the risk of mechanical complications in dental implants? A finite elements analysis. Int. J. Numer. Methods Biomed. Eng. 2019, 35, e3205. [Google Scholar] [CrossRef] [PubMed]

- Hasan, S.F.; Abood, A.Z. Effect of Various Particle Size of Sand-blast on Roughness and Shear Bond Strength of Ips E.max Press With Ceramic Veneer Materials (An in Vitro Study). Malays. J. Med. Health Sci. 2022, 18, 45–52. [Google Scholar]

- Haider, A.; Jaffery, S.H.I.; Khan, A.N.; Qadir, N.; Jing, X. Effect of Cerium on Mechanical, Metallurgical and Biomedical Properties of NiCrMoB Dental Alloy. SSRN Electron. J. 2023, 24, 5082–5093. [Google Scholar] [CrossRef]

- Finger, C.; Stiesch, M.; Eisenburger, M.; Breidenstein, B.; Busemann, S.; Greuling, A. Effect of sandblasting on the surface roughness and residual stress of 3Y-TZP (zirconia). SN Appl. Sci. 2020, 2, 1700. [Google Scholar] [CrossRef]

- Yuda, A.W.; Supriadi, S.; Saragih, A.S. Surface modification of Ti-alloy based bone implant by sandblasting. In Proceedings of the International Symposium of Biomedical Engineering (ISBE), Padang, Indonesia, 13–14 July 2019; Volume 2193. [Google Scholar] [CrossRef]

- Sameera, Y.; Rai, R. Tightening torque of implant abutment using hand drivers against torque wrench and its effect on the internal surface of implant. J. Indian Prosthodont. Soc. 2020, 20, 180–185. [Google Scholar] [CrossRef]

- Haack, J.E.; Sakaguchi, R.L.; Sun, T.; Coffey, J.P. Elongation and preload stress in dental implant abutment screws. Int. J. Oral Maxillofac. Implant. 1995, 10, 529–536. [Google Scholar]

- Mohammed, H.H.; Lee, J.-H.; Bae, J.-M.; Cho, H.-W. Effect of abutment screw length and cyclic loading on removal torque in external and internal hex implants. J. Adv. Prosthodont. 2016, 8, 62–69. [Google Scholar] [CrossRef]

- Bishti, S.; Siouri, J.; Wolfart, S.; Tuna, T. Retention Forces of Implant-Supported Single Crowns and Fixed Dental Prostheses after Cementation: An In-Vitro Study. Oral 2022, 2, 29–40. [Google Scholar] [CrossRef]

- Sarfaraz, H.; Hassan, A.; Kamalakanth Shenoy, K.; Shetty, M. An in vitro study to compare the influence of newer luting cements on retention of cement-retained implant-supported prosthesis. J. Indian Prosthodont. Soc. 2019, 19, 166–172. [Google Scholar] [CrossRef]

- Nagasawa, Y.; Hibino, Y.; Nakajima, H. Retention of crowns cemented on implant abutments with temporary cements. Dent. Mater. J. 2014, 33, 835–844. [Google Scholar] [CrossRef] [PubMed]

- Rahmania, A.; Tanti, I.; Gita, F. The association of normal mouth opening with gender and height. J. Int. Dent. Med. Res. 2017, 10, 406–409. [Google Scholar]

- Anilkumar, P.; Chokhani, D.S.; Mangrulkar, S.K.; Gupta, I.; Singh, R.; Kumar, S. A comparative study of retention of cement retained implant prosthesis cemented with different luting cements. Int. J. Health Sci. 2022, III, 9136–9144. [Google Scholar] [CrossRef]

- Keum, E.C.; Shin, S.Y. A comparison of retentive strength of implant cement depending on various methods of removing provisional cement from implant abutment. J. Adv. Prosthodont. 2013, 5, 234–240. [Google Scholar] [CrossRef][Green Version]

- Dähne, F.; Meißner, H.; Böning, K.; Arnold, C.; Gutwald, R.; Prause, E. Retention of different temporary cements tested on zirconia crowns and titanium abutments in vitro. Int. J. Implant. Dent. 2021, 7, 62. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.H.; Wu, J.H.; Li, H.Y.; Wang, P.-P.; Lee, H.E.; Du, J.K. Fracture resistance of different metal substructure designs for implant-supported porcelain-fused-to-metal (PFM) crowns. J. Dent. Sci. 2013, 8, 314–320. [Google Scholar] [CrossRef][Green Version]

- Osak, P.; Maszybrocka, J.; Zubko, M.; Rak, J.; Bogunia, S.; Łosiewicz, B. Influence of Sandblasting Process on Tribological Properties of Titanium Grade 4 in Artificial Saliva for Dentistry Applications. Materials 2021, 14, 7536. [Google Scholar] [CrossRef]

- Kunt, G.E.; Ceylon, G.; Yilmaz, N. Effect of surface treatments on implant crown retention. J. Dent. Sci. 2010, 5, 131–135. [Google Scholar] [CrossRef][Green Version]

- Jemat, A.; Ghazali, M.J.; Razali, M.; Otsuka, Y. Surface Modifications and Their Effects on Titanium Dental Implants. BioMed Res. Int. 2015, 2015, 791725. [Google Scholar] [CrossRef]

- De Campos, T.N.; Adachi, L.K.; Miashiro, K.; Yoshida, H.; Shinkai, R.S.; Neto, P.T.; Moreira Arantes Frigerio, M.L. Effect of surface topography of implant abutments on retention of cemented single-tooth crowns. Int. J. Periodontics Restor. Dent. 2010, 30, 409–413. [Google Scholar]

- Erdem, M.A.; Karatasli, B.; Kose, O.D.; Kose, T.E.; Çene, E.; Aya, S.A.; Cankaya, A.B. The Accuracy of New and Aged Mechanical Torque Devices Employed in Five Dental Implant Systems. BioMed Res. Int. 2017, 2017, 8652720. [Google Scholar] [CrossRef] [PubMed]

- Pincha, S.; Shetty, S.; Mithra, A.N. Accuracy of Implant Torque Wrenches after Clinical Service. J. Interdiscip. Dent. 2018, 8, 13. [Google Scholar] [CrossRef]

- Shiba, H.; Sato, Y.; Furuya, J.; Osawa, T.; Isobe, A.; Hayashi, M.; Kitagawa, N. Experimental study on the factors affecting torque of beam-type implant torque wrenches. BMC Oral Health 2021, 21, 344. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Lee, J.B.; Kim, M.Y.; Yoon, J.H.; Choi, S.H.; Kim, Y.T. Mechanical and biological complication rates of the modified lateral-screw-retained implant prosthesis in the posterior region: An alternative to the conventional Implant prosthetic system. J. Adv. Prosthodont. 2016, 8, 150–157. [Google Scholar] [CrossRef] [PubMed]

- Varalakshmi Reddy, S.; Sushender Reddy, M.; Rajaneesh Reddy, C.; Pithani, P.; Santosh Kumar, R.; Kulkarni, G. The Influence of Implant Abutment Surface Roughness and the Type of Cement on Retention of Implant Supported Crowns. J. Clin. Diagn. Res. 2015, 9, ZC05–ZC07. [Google Scholar] [CrossRef]

- Abou Obaid, A.; Al-Khudairy, R. Effect of Abutment Height and Cement Thickness on the Retention of Cement-Retained Implant-Supported Restorations. Adv. Dent. Oral Health 2018, 9, 555767. [Google Scholar] [CrossRef]

- Seong, W.J.; Grami, S.; Jeong, S.C.; Conrad, H.J.; Hodges, J.S. Comparison of Push-In versus Pull-Out Tests on Bone-Implant Interfaces of Rabbit Tibia Dental Implant Healing Model. Clin. Implant. Dent. Relat. Res. 2013, 15, 460–469. [Google Scholar] [CrossRef]

- Oliscovicz, N.F.; Shimano, A.C.; Junior, É.M.; Lepri, C.P.; Dos Reis, A.C. Analysis of Primary Stability of Dental Implants Inserted in Different Substrates Using the Pullout Test and Insertion Torque. Int. J. Dent. 2013, 2013, 194987. [Google Scholar] [CrossRef]

| Group | Sample | Ra (μm) | Retention (N) |

|---|---|---|---|

| Not Sandblasted (NS) | Sample 1 | 0.04 | 153.82 |

| Sample 2 | 0.04 | 129.28 | |

| Sample 3 | 0.04 | 191.93 | |

| Sample 4 | 0.04 | 177.05 | |

| Sample 5 | 0.04 | 165.02 | |

| Sandblasted 63 μm (SB63 T200) | Sample 1 | 0.35 | 135.36 |

| Sample 2 | 0.44 | 102.20 | |

| Sample 3 | 0.49 | 209.68 | |

| Sample 4 | 0.47 | 179.87 | |

| Sample 5 | 0.44 | 168.42 | |

| Sandblasted 102 μm (SB102 T200) | Sample 1 | 0.55 | 251.86 |

| Sample 2 | 0.59 | 259.77 | |

| Sample 3 | 0.51 | 237.29 | |

| Sample 4 | 0.59 | 249.85 | |

| Sample 5 | 0.54 | 250.13 | |

| Sandblasted 254 μm (SB254 T200) | Sample 1 | 0.51 | 305.06 |

| Sample 2 | 0.62 | 307.08 | |

| Sample 3 | 0.58 | 350.70 | |

| Sample 4 | 0.60 | 253.86 | |

| Sample 5 | 0.57 | 305,18 | |

| Sandblasted 686 μm (SB686 T200) | Sample 1 | 0.73 | 320.07 |

| Sample 2 | 0.68 | 327.69 | |

| Sample 3 | 0.67 | 287.07 | |

| Sample 4 | 0.62 | 343.86 | |

| Sample 5 | 0.67 | 310.67 |

| Gender | Mean | Standard Deviation | Minimum | Maximum |

|---|---|---|---|---|

| Male | 75.28 | 24.94 | 34.67 | 120.67 |

| Female | 62.92 | 18.47 | 35.67 | 100.33 |

| Overall | 69.75 | 22.91 | 34.67 | 120.67 |

| Group | Sample | Retention (N) |

|---|---|---|

| Cement Retained (CR) | Sample 1 | 153.33 |

| Sample 2 | 145.181 | |

| Sample 3 | 186.66 | |

| Sample 4 | 160.19 | |

| Sample 5 | 133.78 | |

| Lateral Screw (Tightening Torque 69.75 Nmm) (SB686 T69.75) | Sample 1 | 100.33 |

| Sample 2 | 108.14 | |

| Sample 3 | 110.66 | |

| Sample 4 | 95.23 | |

| Sample 5 | 68.97 | |

| Lateral Screw (Tightening Torque 120 Nmm) (SB686 T120) | Sample 1 | 161.828 |

| Sample 2 | 187.31 | |

| Sample 3 | 149.676 | |

| Sample 4 | 124.51 | |

| Sample 5 | 169.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Supriadi, S.; Whulanza, Y.; Mahendra, T.A.; Dewi, R.S.; Kusdhany, L.S.; Mathar, P.R.; Umas, R.A. The Preliminary Development of a Friction-Based Lateral Screw-Retained Dental Crown—A Comparison between the Prototype Surface Treatment and the Retention Strength. Appl. Sci. 2024, 14, 660. https://doi.org/10.3390/app14020660

Supriadi S, Whulanza Y, Mahendra TA, Dewi RS, Kusdhany LS, Mathar PR, Umas RA. The Preliminary Development of a Friction-Based Lateral Screw-Retained Dental Crown—A Comparison between the Prototype Surface Treatment and the Retention Strength. Applied Sciences. 2024; 14(2):660. https://doi.org/10.3390/app14020660

Chicago/Turabian StyleSupriadi, Sugeng, Yudan Whulanza, Tri Ardi Mahendra, Ratna Sari Dewi, Lindawati S. Kusdhany, Pelangi Raihan Mathar, and Rizki Aldila Umas. 2024. "The Preliminary Development of a Friction-Based Lateral Screw-Retained Dental Crown—A Comparison between the Prototype Surface Treatment and the Retention Strength" Applied Sciences 14, no. 2: 660. https://doi.org/10.3390/app14020660

APA StyleSupriadi, S., Whulanza, Y., Mahendra, T. A., Dewi, R. S., Kusdhany, L. S., Mathar, P. R., & Umas, R. A. (2024). The Preliminary Development of a Friction-Based Lateral Screw-Retained Dental Crown—A Comparison between the Prototype Surface Treatment and the Retention Strength. Applied Sciences, 14(2), 660. https://doi.org/10.3390/app14020660