Initiative to Increase the Circularity of HDPE Waste in the Construction Industry: A Physico-Mechanical Characterization of New Sustainable Gypsum Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Binder

2.1.2. Water

2.1.3. High-Density Polyethylene (HDPE)

2.2. Dosages and Sample Preparation

2.3. Experimental Programme

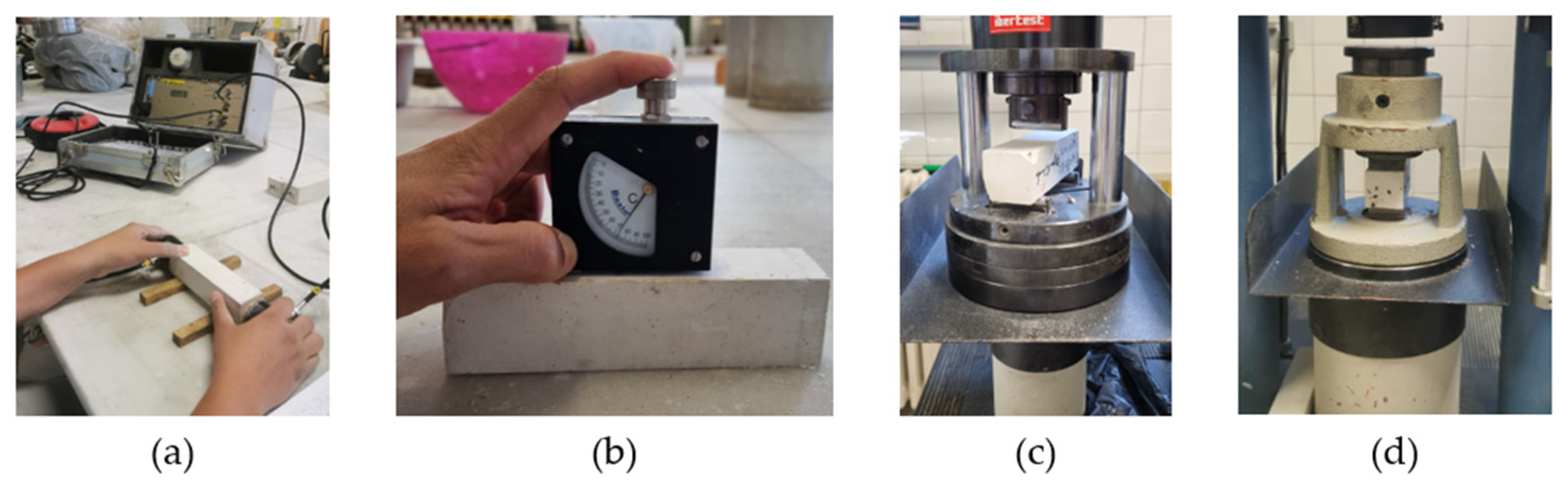

2.3.1. Physical Characterization Tests

2.3.2. Mechanical Characterization Tests

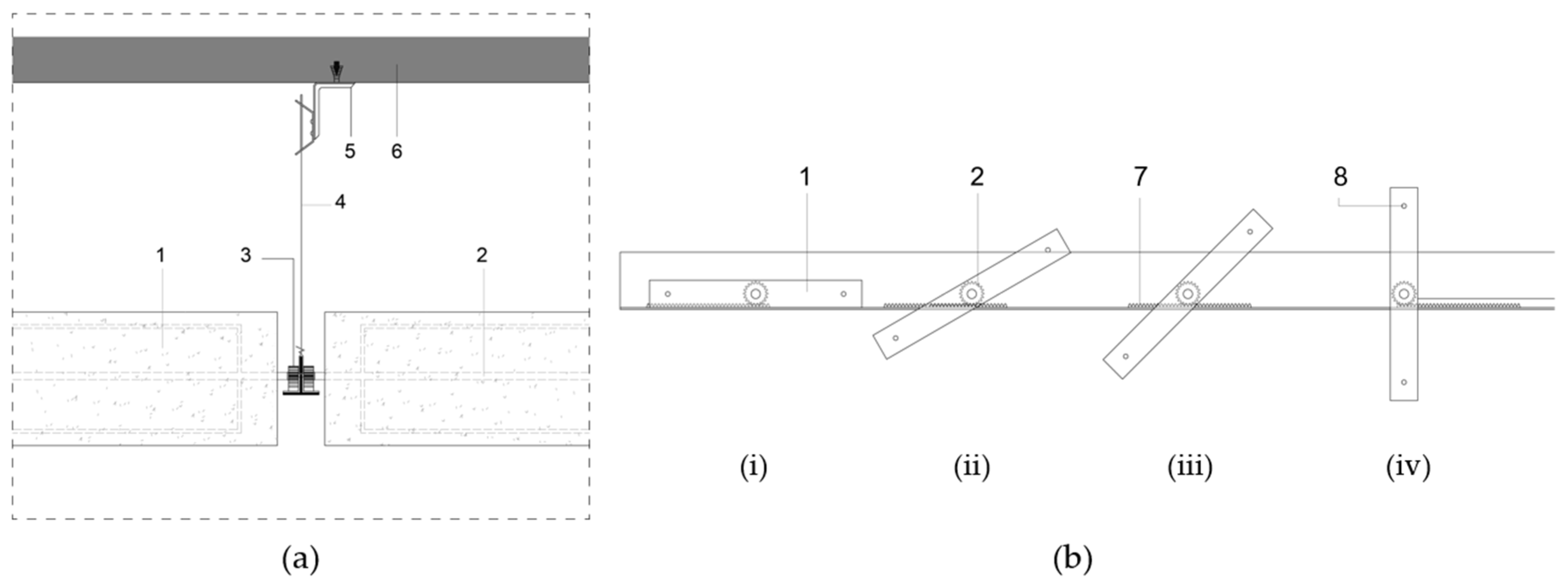

2.3.3. Precast Tests

3. Results and Discussion

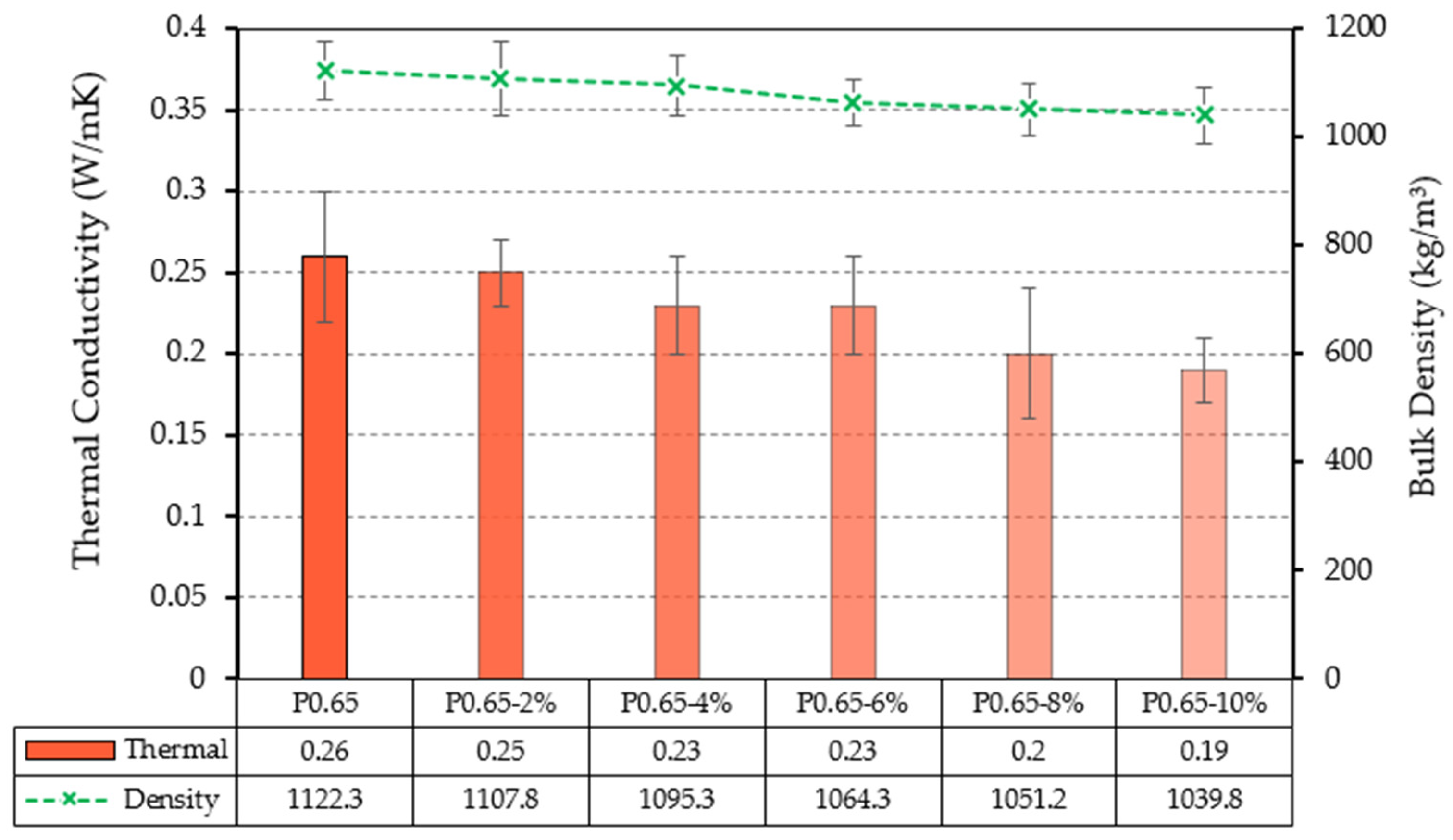

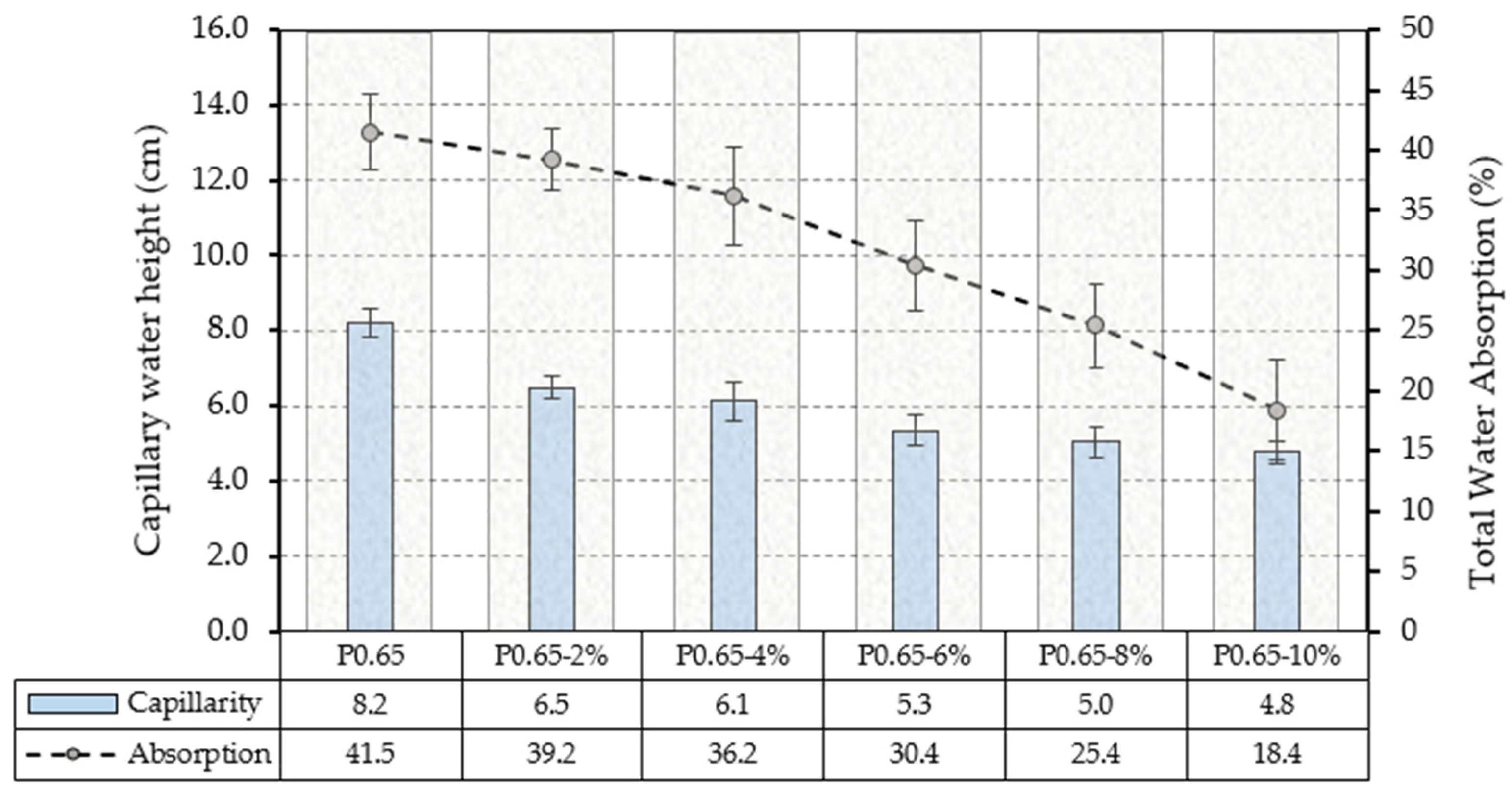

3.1. Physical Characterization Results

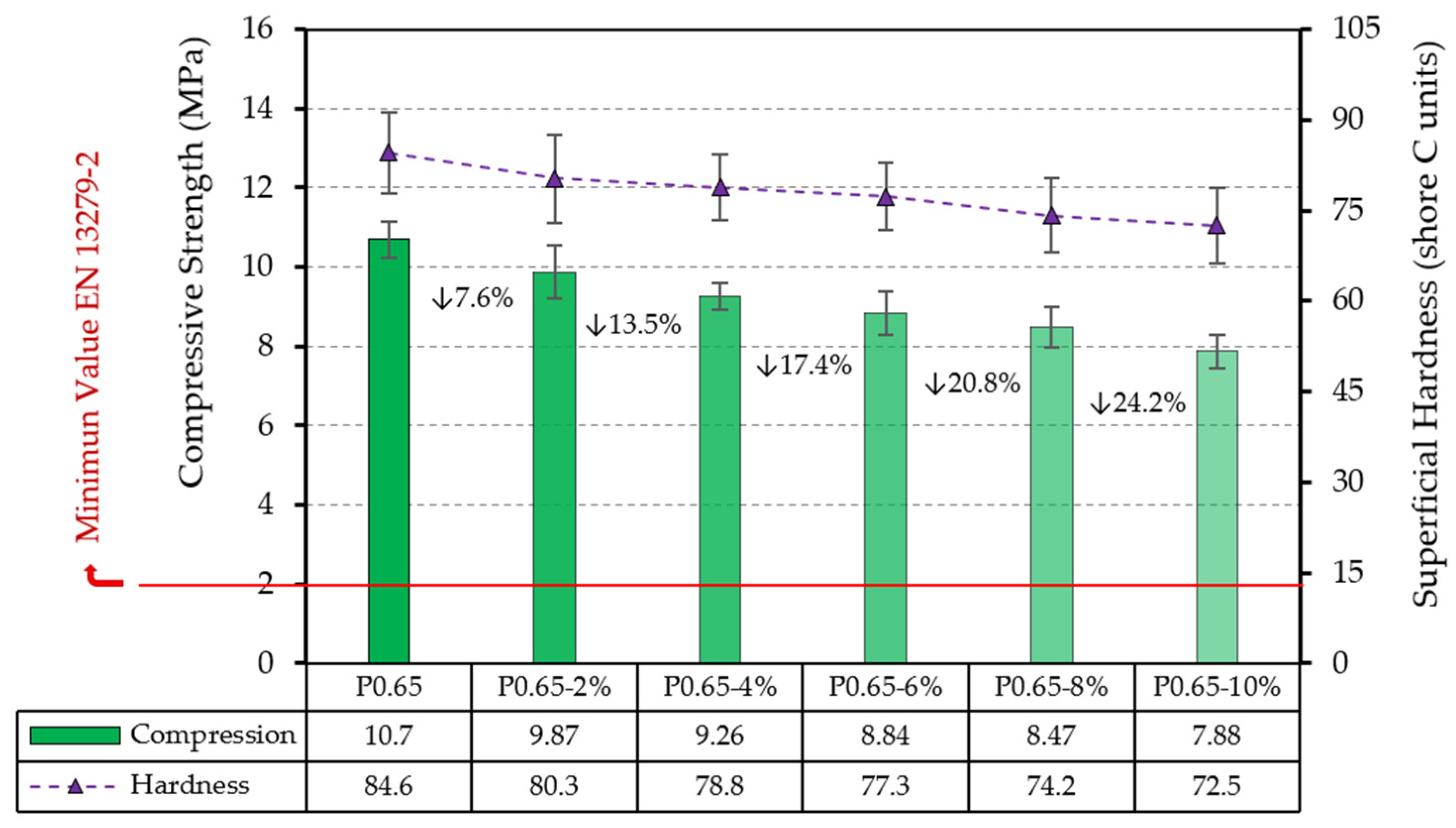

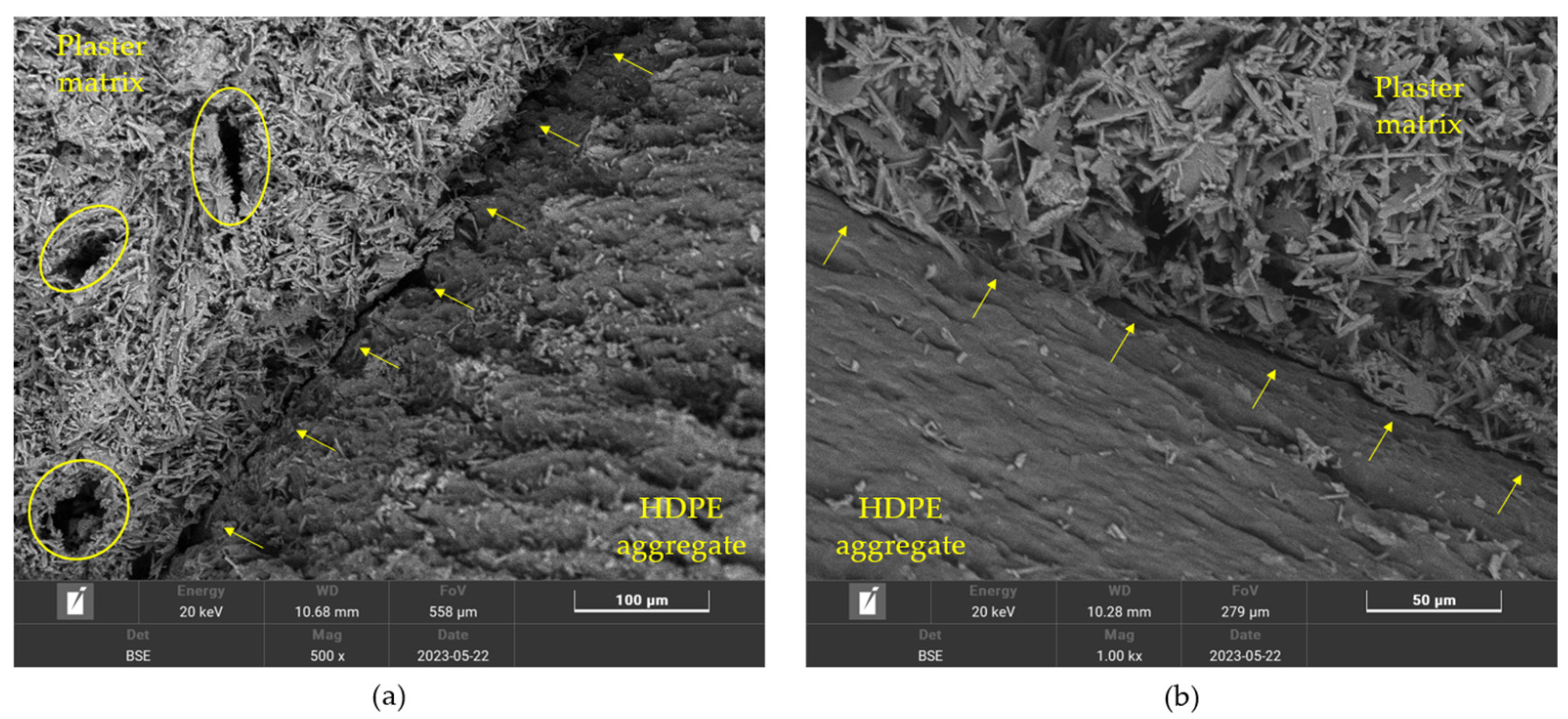

3.2. Mechanical Characterization Results

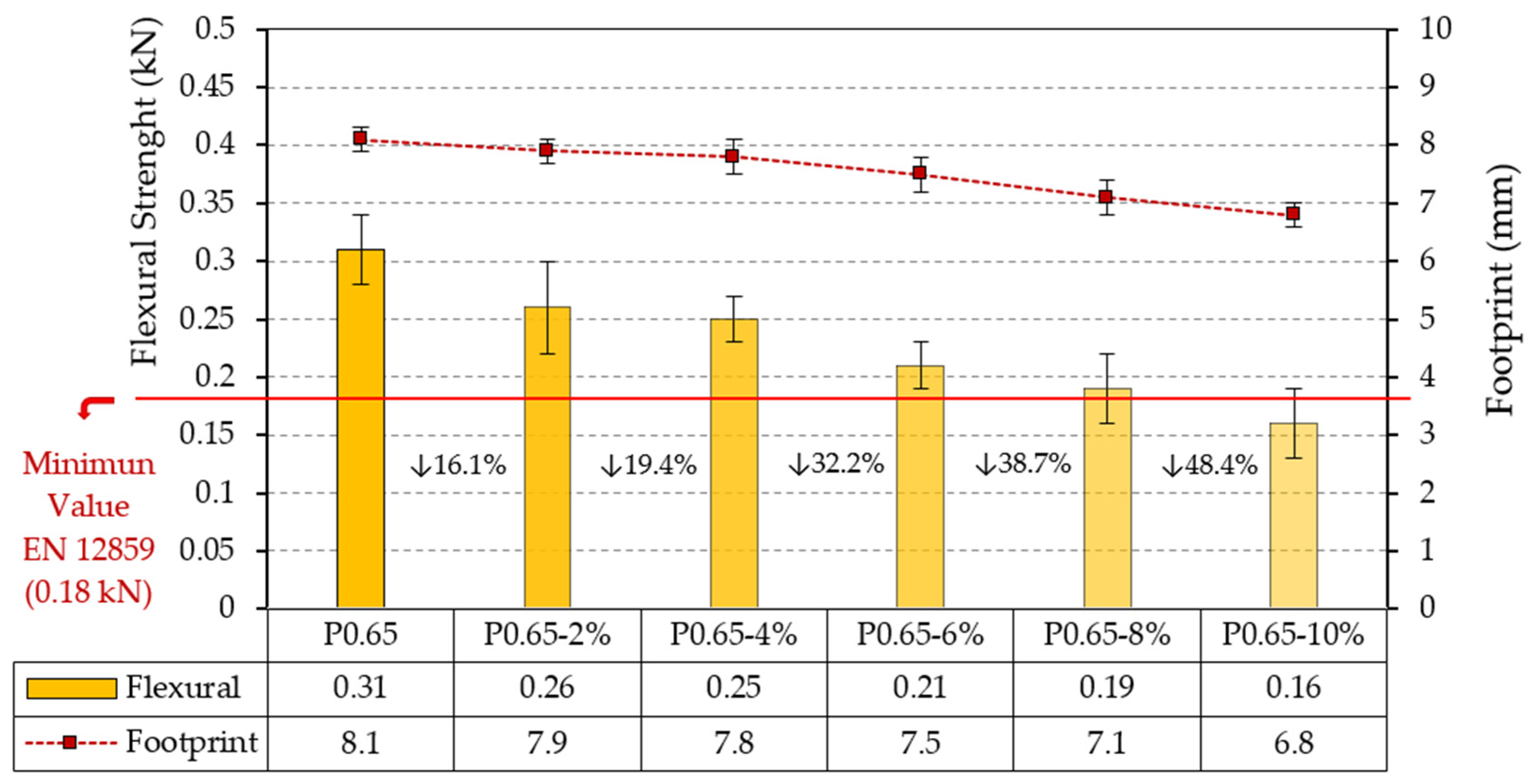

3.3. Precast Samples Results

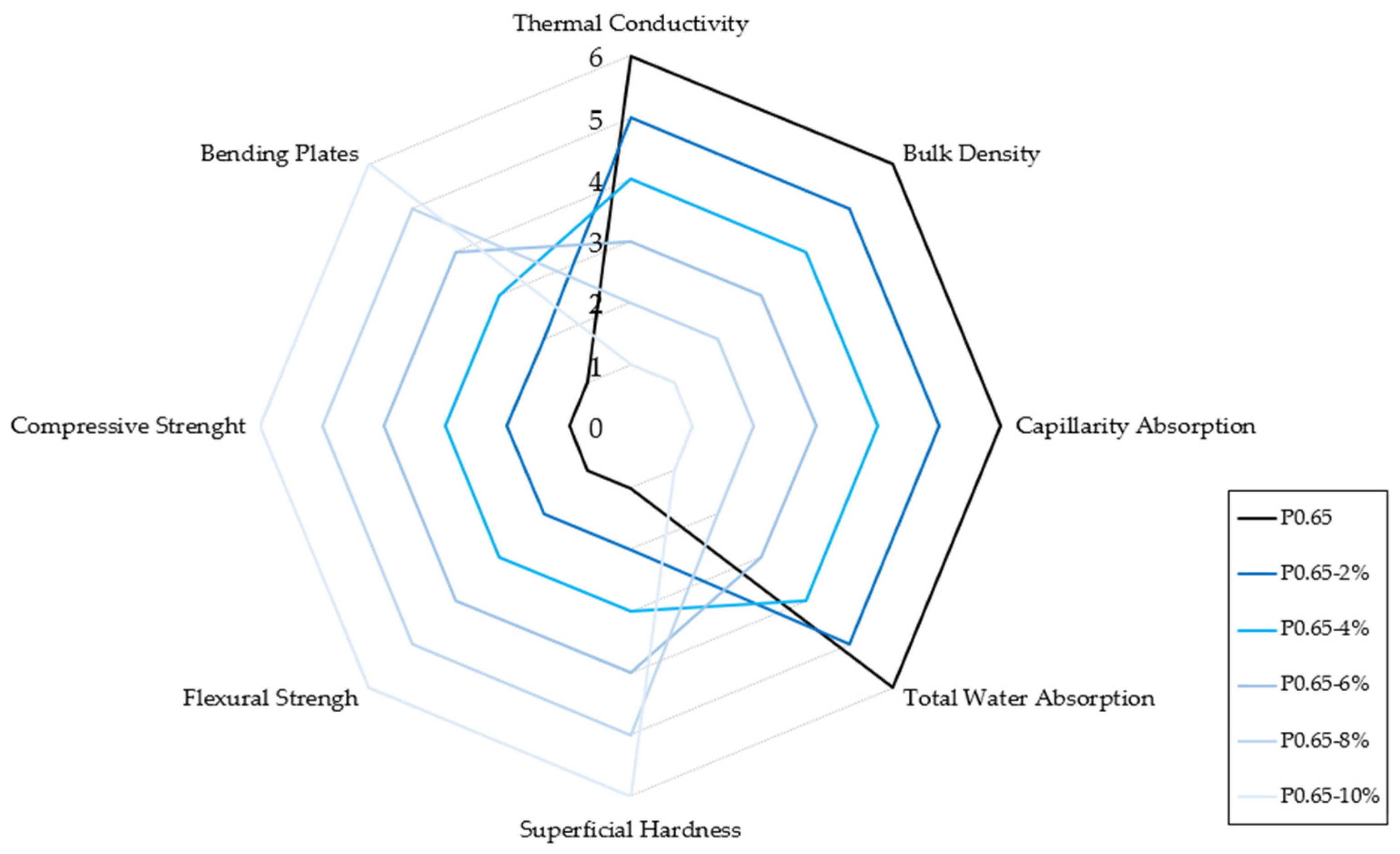

3.4. Studied Properties Qualitative Discussion

4. Conclusions

- Progressive HDPE waste incorporation allows a reduction in both thermal conductivity and final bulk density. In this sense, reductions of up to 26.7% and 7.35% have been achieved for each of these properties, respectively.

- A decrease in the water absorption capacity of the gypsum composites is observed as the amount of added plastic residue increases. In this sense, the P0.65-10% sample managed to reduce the height reached by the water after the capillary test by up to 23.1%.

- Regarding mechanical strength, a linear decrease in flexural and compressive strength, as well as surface hardness, was observed as more HDPE waste was added. Nevertheless, all the tested composites exceeded the minimum strength values required by UNE-EN 13279-2. However, after SEM analysis, irregular adhesion between the HDPE aggregate and the plaster matrix was revealed, as the recycled materials used did not undergo any prior surface treatment.

- Finally, in the plates study, all samples exceeded the flexural strength limit of 0.18 kN, except for the composite with 10% HDPE residue added. These results highlight the importance of conducting full-scale tests to better understand the performance of the materials developed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wiah, E.N.; Addor, J.A.; Alao, F.I. Transitional probabilities ford plastic waste management and implication on sustainability. Sustain. Environ. 2022, 8, 2118654. [Google Scholar] [CrossRef]

- Wamba, S.F.; Fotso, M.; Mosconi, E.; Chai, J. Assessing the potential of plastic waste management in the circular economy: A longitudinal case study in an emerging economy. Ann. Oper. Res. 2023, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Babaremu, K.O.; Okoya, S.A.; Hughes, E.; Tijani, B.; Teidi, D.; Akpan, A.; Igwe, J.; Karera, S.; Oyinlola, M.; Akinlabi, E.T. Sustainable plastic waste management in a circular economy. Heliyon 2022, 8, e09984. [Google Scholar] [CrossRef] [PubMed]

- Baran, B. Plastic waste as a challenge for sustainable development and circularity in the European Union. Ekon. I Prawo. Econ. Law 2020, 19, 7–20. [Google Scholar] [CrossRef]

- Ferreira, L.; Costa, M.H.; Del Rosario, E.; De Melo, D.; Rezende, P. Management of Plastic Waste and a Circular Economy at the End of the Supply Chain: A Systematic Literature Review. Energies 2022, 15, 976. [Google Scholar] [CrossRef]

- Balu, R.; Dutta, N.K.; Roy Choudhury, N. Plastic Waste Upcycling: A Sustainable Solution for Waste Management, Product Development, and Circular Economy. Polymers 2022, 14, 4788. [Google Scholar] [CrossRef] [PubMed]

- Abdelsalam, Z.; Almashan, N.; Ismael, N. Reinforcing Some Kuwaiti Soils with Shredded High-density Polyethylene (HDPE) Bits. Environ. Eng. Geosci. 2019, 25, 213–221. [Google Scholar] [CrossRef]

- Diaz-Silvarrey, L.S.; Zhang, K.; Phan, A.N. Monomer recovery through advanced pyrolysis of waste high density polyethylene (HDPE). Green. Chem. 2018, 20, 1813–1823. [Google Scholar] [CrossRef]

- Abeysinghe, S.; Gunasekara, C.; Bandara, C.; Nguyen, K.; Dissanayake, R.; Mendis, P. Engineering Performance of Concrete Incorporated with Recycled High-Density Polyethylene (HDPE)—A Systematic Review. Polymers 2021, 13, 1885. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, 1700782. [Google Scholar] [CrossRef]

- Mohammed, H.; Sadique, M.; Shaw, A.; Bras, A. The influence of incorporating plastic within concrete and the potential use of microwave curing: A review. J. Build. Eng. 2020, 32, 101824. [Google Scholar] [CrossRef]

- Poonyakan, A.; Rachakornkij, M.; Wecharatana, M.; Smittakorn, W. Potential Use of Plastic Wastes for Low Thermal Conductivity Concrete. Materials 2018, 11, 1938. [Google Scholar] [CrossRef] [PubMed]

- Badache, A.; Benosman, A.S.; Senhadji, Y.; Mouli, M. Thermo-physical and mechanical characteristics of sand-based lightweight composite mortars with recycled high-density polyethylene (HDPE). Constr. Build. Mater. 2018, 163, 40–52. [Google Scholar] [CrossRef]

- Arabani, M.; Pedram, M. Laboratory investigation of rutting and fatigue in glassphalt containing waste plastic bottles. Constr. Build. Mater. 2016, 116, 378–383. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rubio-de-Hita, P. Reuse of CD and DVD Wastes as Reinforcement in Gypsum Plaster Plates. Materials 2020, 13, 989. [Google Scholar] [CrossRef] [PubMed]

- Vidales Barriguete, A.; Del Río Merino, M.; Atanes Sánchez, E.; Piña Ramírez, C.; Viñas Arrebola, C. Analysis of the feasibility of the use of CDW as a low-environmental-impact aggregate in conglomerates. Constr. Build. Mater. 2018, 178, 83–91. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Del Río-Merino, M.; Vidales-Barriguete, A.; Piña-Ramírez, C.; Vitiello, V.; Santa Cruz-Astorqui, J.; Castelluccio, R. A review of the research about gypsum mortars with waste aggregates. J. Build. Eng. 2022, 45, 103338. [Google Scholar] [CrossRef]

- Del Río Merino, M.; Santa Cruz Astorqui, J.; Villoria Sáez, P.; Santos Jiménez, R.; González Cortina, M. Eco plaster mortars with addition of waste for high hardness coatings. Constr. Build. Mater. 2018, 158, 649–656. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Zhao, Y.; Shu, Z.; Wang, Y.; Zhang, Y.; Shen, X. Preparation of paper-free and fiber-free plasterboard with high strength using phosphogypsum. Constr. Build. Mater. 2020, 243, 118091. [Google Scholar] [CrossRef]

- Yu, Q.L.; Brouwers, H.J.H. Development of a self-compacting gypsum-based lightweight composite. Cem. Concr. Compos. 2012, 34, 1033–1043. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Diaz-Velilla, J.P.; Zúñiga-Vicente, J.A. Manufacture and characterisation of a new lightweight plaster for application in wet rooms under circular economy criteria. Case Stud. Constr. Mater. 2023, 19, e02380. [Google Scholar] [CrossRef]

- Erbs, A.; Nagalli, A.; Querne de Carvalho, K.; Mazer, W.; De Moraes, M.; Paz, D.; Lafayette, K. Development of plasterboard sheets exclusively from waste. J. Build. Eng. 2021, 44, 102524. [Google Scholar] [CrossRef]

- Álvarez, M.; Ferrández, D.; Guijarro-Miragaya, P.; Morón, C. Characterization and under Water Action Behaviour of a New Plaster-Based Lightened Composites for Precast. Materials 2023, 16, 872. [Google Scholar] [CrossRef] [PubMed]

- Romero-Gómez, M.I.; Silva, R.V.; Flores-Colen, I.; De Brito, J. Influence of polypropylene residues on the physico-mechanical and water-resistance properties of gypsum plasters. J. Clean. Prod. 2022, 371, 133674. [Google Scholar] [CrossRef]

- Jiménez Rivero, A.; De Guzmán Báez, A.; García Navarro, J. New composite gypsum plaster—Ground waste rubber coming from pipe foam insulation. Constr. Build. Mater. 2014, 55, 146–152. [Google Scholar] [CrossRef]

- Vidales-Barriguete, A.; Santa-Cruz-Astorqui, J.; Piña-Ramírez, C.; Kosior-Kazberuk, M.; Kalinowska-Wichrowska, K.; Atanes-Sánchez, E. Study of the mechanical and physical behavior of gypsum boards with plastic cable waste aggregates and their application to construction panels. Materials 2021, 14, 2255. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Rodríguez-Liñán, C.; Flores-Colen, I.; de Brito, J. Use of Polycarbonate Waste as Aggregate in Recycled Gypsum Plasters. Materials 2020, 13, 3042. [Google Scholar] [CrossRef]

- Romero-Gómez, M.I.; Rubio-De-Hita, P.; Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F. Recycling of low-density polyethylene waste to produce eco-friendly gypsum composites. WIT Trans. Ecol. Environ. 2022, 257, 73–81. [Google Scholar] [CrossRef]

- Herrero, S.; Mayor, P.; Hernández-Olivares, F. Influence of proportion and particle size gradation of rubber from end-of-life tires on mechanical, thermal and acoustic properties of plaster–rubber mortars. Mater. Des. 2013, 47, 633–642. [Google Scholar] [CrossRef]

- UNE-EN 13279-2:2014; Yesos de Construcción y Conglomerantes a Base de Yeso Para la Construcción. Parte 2: Métodos de Ensayo. AENOR: Madrid, Spain, 2014.

- Vidales-Barriguete, A.; Atanes-Sánchez, E.; Del Río-Merino, M.; Piña-Ramírez, C. Analysis of the improved water-resistant properties of plaster compounds with the addition of plastic waste. Constr. Build. Mater. 2020, 230, 116956. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Atanes-Sánchez, E.; Saíz, P. Dissolved recycled expanded polystyrene as partial replacement in plaster composites. J. Build. Eng. 2023, 65, 105697. [Google Scholar] [CrossRef]

- UNE-EN 13279-1; Yesos de Construcción y Conglomerantes a Base de Yeso para la Construcción. Parte 1: Definiciones y Especificaciones. AENOR: Madrid, Spain, 2006.

- Placo Saint-Gobain, Iberyola e-30/e35 Technical Information, 2022. Available online: https://www.placo.es/ (accessed on 14 November 2023).

- UNE-EN-13501-1; Clasificación en Función del Comportamiento Frente al Fuego de los Productos de Construcción y Elementos para la Edificación. Parte 2: Clasificación a Partir de Datos Obtenidos de los Ensayos de Resistencia al Fuego Excluidas. AENOR: Madrid, Spain, 2019.

- Ministerio de Fomento, Código Técnico de la Edificación: Documento Básico de Seguridad en caso de Incendio. 2022. Available online: https://www.codigotecnico.org/images/stories/pdf/seguridadIncendio/DBSI.pdf (accessed on 14 November 2023).

- Guijarro-Miragaya, P.; Ferrández, D.; Atanes-Sánchez, E.; Zaragoza-Benzal, A. Characterization of a New Lightweight Plaster Material with Superabsorbent Polymers and Perlite for Building Applications. Buildings 2023, 13, 1641. [Google Scholar] [CrossRef]

- Canal de Isabel II. Características Medias del Agua de Consumo en el Sistema de Distribución. Madrid, 2021. Available online: https://www.canaldeisabelsegunda.es/ (accessed on 14 November 2023).

- Emacin Corp. Duraflon Technical Information—High Density Polyethylene; Emacin Corp.: Carbondale, IL, USA, 2022. [Google Scholar]

- RILEM RC 25-PEM. Recommended tests to measure the deterioration of stone and to assess the effectiveness of treatment methods. Mater. Struct. 1980, 13, 175–253. [Google Scholar]

- UNE-EN-520:2005+A1:2010; Placas de Yeso Laminado. Definiciones, Especificaciones y Métodos de Ensayo. AENOR: Madrid, Spain, 2010.

- UNE-EN-1946-3; Prestaciones Térmicas de los Productos y Componentes Para Edificios. Criterios Particulares Para la Evaluación de los Laboratorios que Miden las Propiedades de Transmisión Térmica. Parte 3: Mediciones por el Método del Medidor de Flujo Térmico. AENOR: Madrid, Spain, 1999.

- UNE-EN-14246:2007; Placas de Escayola Para Techos Suspendidos. Definiciones, Especificaciones y Métodos de Ensayo. AENOR: Madrid, Spain, 2008.

- UNE 102042; Yesos y Escayolas de Construcción Aljez (o Piedra de Yeso). Otros Métodos de Ensayo. AENOR: Madrid, Spain, 2023.

- Ibertest. Máquinas de Ensayo de Resistencia. Series AUTOTEST y CIB. Madrid. 2022. Available online: www.ibertest.com (accessed on 20 January 2023).

- Doleželová, M.; Krejsová, J.; Scheinherrová, L.; Keppert, M.; Vimmrová, A. Investigation of environmentally friendly gypsum-based composites with improved water resistance. J. Clean. Prod. 2022, 370, 133278. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Atanes-Sánchez, E.; Saíz, P. Study of the hygroscopic properties of environmentally friendly lightened composites through waste recovery. Constr. Build. Mater. 2023, 404, 133219. [Google Scholar] [CrossRef]

- López-Zaldívar, O.; Lozano-Díez, R.; Herrero del Cura, S.; Mayor-Lobo, P.; Hernández-Olivares, F. Effects of water absorption on the microstructure of plaster with end-of-life tire rubber mortars. Constr. Build. Mater. 2017, 150, 558–567. [Google Scholar] [CrossRef]

- Yedra, E.; Ferrández, D.; Morón, C.; Gómez, E. New System to Determine the Evolution of the Dynamic Young’s Modulus from Early Ages in Masonry Mortars. Appl. Sci. 2020, 10, 8129. [Google Scholar] [CrossRef]

- San-Antonio-González, A.; Del Río Merino, M.; Viñas Arrebola, C.; Villoria-Sáez, P. Lightweight material made with gypsum and extruded polystyrene waste with enhanced thermal behavior. Constr. Build. Mater. 2015, 93, 57–63. [Google Scholar] [CrossRef]

- Del Rio Merino, M.; Villoria Sáez, P.; Longobardi, I.; Santa Cruz Astorqui, J.; Porras-Amores, C. Redesigning lightweight gypsum with mixes of polystyrene waste from construction and demolition waste. J. Clean. Prod. 2019, 220, 144–151. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rubio-de-Hita, P. Influence of polycarbonate waste on gypsum composites: Mechanical and environmental study. J. Clean. Prod. 2019, 218, 21–37. [Google Scholar] [CrossRef]

- Álvarez, M.; Santos, P.; Ferrández, D. Investigation of gypsum composites with different lightweight fillers: A physico-mechanical characterisation regarding possibilities for building applications. J. Build. Eng. 2023, 79, 107813. [Google Scholar] [CrossRef]

- Álvarez, M.; Santos, P.; Lopes, P.; Abrantes, D.; Ferrández, D. Performance Characterisation of a New Plaster Composite Lightened with End-of-Life Tyres Recycled Materials for False Ceiling Plates. Materials 2022, 15, 5660. [Google Scholar] [CrossRef] [PubMed]

- EN 12859; Gypsum Blocks—Definitions, Requirements and Test Methods. CEN: Toronto, ON, Canada, 2011.

- Pedreño-Rojas, M.A.; De Brito, J.; Flores-Colen, I.; Pereira, M.F.C.; Rubio-de-Hita, P. Influence of gypsum wastes on the workability of plasters: Heating process and microstructural analysis. J. Build. Eng. 2020, 29, 101143. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Atanes-Sánchez, E.; Morón, C. New lightened plaster material with dissolved recycled expanded polystyrene and end-of-life tyres fibres for building prefabricated industry. Case Stud. Constr. Mater. 2023, 18, e02178. [Google Scholar] [CrossRef]

- Álvarez, M.; Ferrández, D.; Morón, C.; Díaz-Velilla, P. Material de Escayola Aligerada con Polímeros Para uso en Placas y Paneles Prefabricados. 2018. Available online: https://www.upm.es/recursosidi/offers-resources/patentes/material-de-escayola-aligerada-con-polimeros-para-uso-en-placas-y-paneles-prefabricados/ (accessed on 22 November 2023).

- Ferrández, D.; Morón Fernández, C.; Álvarez Dorado, M.; Guijarro Miragaya, P. Material de Construcción Aligerado Para la Elaboración de Prefabricados. ES Patent ES-2841130_B2, 21 February 2022. [Google Scholar]

- Premrov, M.; Kuhta, M. Influence of fasteners disposition on behaviour of timber-framed walls with single fibre–plaster sheathing boards. Constr. Build. Mater. 2009, 23, 2688–2693. [Google Scholar] [CrossRef]

- European Comission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Brussels, 2019. Available online: https://sustainabledevelopment.un.org/post2015/transformingourworld (accessed on 20 November 2023).

| Standard | Thermal Conductivity (mW/m·K) | Water Vapour Diffusivity (µ) | Pureness Index (%) | Flexural Strength (MPa) |

| UNE-EN 13279-1 | 300 | 6 | >90 | >3 |

| Colour | Fire Reaction According to CTE DB-SI [37] | Granulometry (mm) | Water/Plaster Rate by Weight | pH |

| White | A1 | 0–0.2 mm | 0.7–0.8 | >6 |

| Appearance | Particle Size (mm) | Hardness (Units Shore D) | Tensile Strength (MPa) | Tensile Modulus (MPa) |

| Granulated | 1.4 | 70 | 31.7 | 1.38 |

| Elongation at Break (%) | Bending Strength (MPa) | Bending Modulus (GPa) | Compressive Strength (MPa) | Compressive Modulus (GPa) |

| 400 | 31.7 | 1.2 | 31.7 | 0.689 |

| Sample | Weight (g) | Volume Percentage (%) | ||||

|---|---|---|---|---|---|---|

| E-35 | Water | HDPE | E-35 | Water | HDPE | |

| P0.65 | 1000.0 | 650.0 | — | 60.60 | 39.40 | — |

| P0.65-2% | 980.2 | 636.8 | 14.5 | 59.40 | 38.60 | 2.00 |

| P0.65-4% | 960.4 | 623.6 | 29.0 | 58.20 | 37.80 | 4.00 |

| P0.65-6% | 940.6 | 610.4 | 43.5 | 57.00 | 37.00 | 6.00 |

| P0.65-8% | 920.8 | 597.2 | 58.0 | 55.80 | 36.20 | 8.00 |

| P0.65-10% | 901.0 | 584.0 | 72.5 | 54.60 | 35.40 | 10.00 |

| Series | Dimensions | Tests | Standard |

|---|---|---|---|

| SERIES I | 4 × 4 × 16 cm3 | Shore C Hardness | UNE-EN 13279-2 [31] |

| Flexural strength | |||

| Compressive strength | |||

| SERIES II | 4 × 4 × 16 cm3 | Capillarity water absorption | RILEM RC 25-PEM [40] |

| Total water absorption | UNE-EN 520 [41] | ||

| SERIES III | 24 × 24 × 2 cm3 | Thermal conductivity | UNE-EN 1946-3 [42] UNE-EN 14246 [43] |

| SERIES IV | 30 × 40 × 1.5 cm3 | Plates pure bending test | UNE-EN 14246 [43] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez, M.; Ferrández, D.; Zaragoza-Benzal, A.; Colorado-Pastor, B. Initiative to Increase the Circularity of HDPE Waste in the Construction Industry: A Physico-Mechanical Characterization of New Sustainable Gypsum Products. Appl. Sci. 2024, 14, 478. https://doi.org/10.3390/app14020478

Álvarez M, Ferrández D, Zaragoza-Benzal A, Colorado-Pastor B. Initiative to Increase the Circularity of HDPE Waste in the Construction Industry: A Physico-Mechanical Characterization of New Sustainable Gypsum Products. Applied Sciences. 2024; 14(2):478. https://doi.org/10.3390/app14020478

Chicago/Turabian StyleÁlvarez, Manuel, Daniel Ferrández, Alicia Zaragoza-Benzal, and Bryan Colorado-Pastor. 2024. "Initiative to Increase the Circularity of HDPE Waste in the Construction Industry: A Physico-Mechanical Characterization of New Sustainable Gypsum Products" Applied Sciences 14, no. 2: 478. https://doi.org/10.3390/app14020478

APA StyleÁlvarez, M., Ferrández, D., Zaragoza-Benzal, A., & Colorado-Pastor, B. (2024). Initiative to Increase the Circularity of HDPE Waste in the Construction Industry: A Physico-Mechanical Characterization of New Sustainable Gypsum Products. Applied Sciences, 14(2), 478. https://doi.org/10.3390/app14020478