Abstract

Gas pipelines are buried and installed across rivers to supply the gas necessary for daily life. When crossing rivers, gas pipelines are typically installed on bridges; however, when installation on bridges is not feasible, the pipelines are buried in riverbeds. This study utilized both a one-dimensional model (HEC-RAS) and two-dimensional models (SMS) to simulate river flow and estimate the potential for scour and deposition around buried pipelines. The hydrodynamic simulations considered critical factors, including sediment transport, river discharge, and geological characteristics, to derive the maximum scour depth and assess the risk of pipeline exposure. The findings from the long-term and short-term simulations confirmed that riverbed changes due to natural hydrological events do not exceed the minimum burial depth standards, thereby ensuring pipeline safety. In addition, the study proposed specific reinforcement measures tailored to local site conditions, addressing concerns of continuous subsidence and ensuring long-term structural stability. This research offers important insights into pipeline risk management and contributes to the development of more effective regulatory standards for gas pipelines buried in riverbeds, enhancing both their safety and environmental sustainability

1. Introduction

Gas pipelines supplying essential gas for daily life are regulated to ensure proper installation, maintenance, and safety management measures, thereby ensuring the safety of citizens. Typically, gas pipelines are buried underground or installed on bridges. However, when a gas pipeline must cross a river, burying it in the riverbed becomes a last resort. In such cases, it is essential to maintain and manage the burial depth to prevent the pipeline from being affected by changes in the riverbed. Hydrotechnical hazard categories [1] help in understanding the different ways that natural or human-induced changes in watercourses can impact pipelines. According to these categories, pipelines at water crossings can be affected by three primary types of channel movement: vertical channel movement, horizontal channel movement, and channel path movement.

Firstly, vertical channel movement involves changes in the riverbed elevation, which can significantly impact the stability of buried pipelines. This category includes scour depth, referring to the removal of sediment around the pipeline due to flowing water, potentially leading to the pipeline becoming exposed and damaged. It also includes degradation and aggradation; degradation is the process whereby the riverbed lowers due to scour, while aggradation is the raising of the riverbed due to sediment deposition. Both processes can affect the depth at which a pipeline is buried and its subsequent stability. Secondly, horizontal channel movement refers to the lateral shifting of the river channel, which can affect the banks and potentially the pipelines buried near them. This category includes bank scour, which occurs when riverbanks erode, leading to the exposure and destabilization of pipelines installed near the banks. It also includes encroachment, which happens when the river channel expands horizontally, encroaching onto adjacent land and potentially affecting infrastructure, including pipelines. Lastly, channel path movement describes the overall changes in the river’s course, posing significant risks to buried pipelines. This category includes avulsion, a rapid change in the river’s course, which can expose or even displace existing pipelines. It also includes meander cutoffs, which occur when the river creates a new, shorter path by cutting off a meander, leaving pipelines in the abandoned path exposed and unprotected.

Operational pipelines are exposed to various risks, including performance problems, corrosion, and serious damages resulting from hydraulic, geotechnical, or seismic hazards [2]. Excessive hydrodynamic forces can cause leakage at the bottom of the river, thereby accelerating corrosion in humid environments. High flow velocities and turbulent currents increase stress on the pipeline surface, potentially leading to cracks or fractures that facilitate corrosion processes. This is especially critical in areas where water and sediment interact closely with the pipeline material, increasing the likelihood of long-term degradation. Given the potential accidents from floods, earthquakes, and disruptions of gas pipelines due to river maintenance, the installation of river-crossing pipelines involves assessing foreseeable accident probabilities and damage impacts, followed by implementing risk mitigation measures [3]. The EU and countries such as the United States, Canada, and Russia have established gas pipeline-related databases and are making efforts to collect and analyze accident cases of buried pipelines to enhance safety management and accident prevention [4,5,6,7,8,9,10]. The operation of technological systems must be reliable in terms of functionality and safety [11,12]. The demands for safety are continuously increasing [13,14,15,16,17], and gas network operators should be concerned about accurate safety assessments whenever possible [18,19].

The safety of river-crossing pipelines is increasingly threatened, especially due to natural phenomena such as floods and scour. Studies have analyzed the risk factors of pipelines crossing rivers in urban environments and presented complex risk assessment systems that consider the interaction between urban infrastructure and the natural environment [10]. Previous studies take into account the various variables necessary to maintain the structural stability of pipelines, emphasizing the essential need for preparedness against natural disasters like floods and scour. Similarly, fatigue analysis and lateral stability evaluation methods for pipelines exposed due to river scour have been proposed, demonstrating through actual case studies that these risks can indeed occur [20]. This research provides clear evidence of how significantly pipeline exposure due to scour can impact long-term operations and offers practical alternatives necessary to maintain the stability of exposed pipelines. Additionally, scour prevention measures utilizing soil bioengineering have been suggested, introducing sustainable methods to effectively manage scour at pipeline crossing sections [21]. This approach supports an ecological method to ensure the long-term safety of pipelines through plant-based stabilization techniques. Furthermore, important tools for predicting and preparing for future scour risks have been developed by forecasting the scour depth of river-crossing pipelines using Support Vector Machines (SVMs) [22]. Such predictive models can contribute to maintaining pipeline safety and preventing potential accidents.

Using numerical analysis techniques to assess the safety of gas pipelines crossing rivers plays a crucial role in maintaining the stability of pipeline structures and predicting risk factors. Related studies quantitatively analyze the physical changes in gas pipelines and deformation due to external pressure, identifying the effects of various environmental factors on pipeline performance. For instance, some researchers focus on the buckling mechanisms of marine pipelines, explaining their physical deformation and suggesting methods to prevent pipeline failure due to buckling [23]. This research provides important data for identifying structural problems in gas pipelines. Other studies have addressed the effect of the pipeline arrangement on scour and flow velocity fields, analyzing in detail how pipeline arrangement impacts the scour process [24]. These studies present methods for evaluating pipeline safety using numerical analysis techniques and offer useful information for predicting the scour risk of gas pipelines crossing rivers. Additionally, analyses of the stress and deformation of buried gas pipelines exposed to buoyancy forces in liquefaction zones provide insights into how gas pipelines respond to various external forces, suggesting factors to consider for the safe design of pipelines [25]. Further research has evaluated the ability of corroded steel pipes to withstand compressive forces using nonlinear analysis after reinforcing them with FRP casing grouting [26]. This work provides important data on enhancing the structural stability of corroded pipelines, contributing to the development of pipeline maintenance plans. Studies have also analyzed how buried composite pipelines respond to stresses caused by fault movement, providing specific considerations when designing pipelines to withstand natural disasters such as earthquakes [27,28]. These previous studies offer valuable information for assessing the safety of gas pipelines crossing rivers using numerical analysis techniques. Through a quantitative analysis that accounts for the physical characteristics of pipelines, external pressure, and environmental factors, a foundation is established for predicting and addressing the various problems that may arise in pipeline design and maintenance.

Analysis results using numerical analysis techniques have shown that the burial depth of gas pipelines buried in rivers significantly influences their stability. Previous studies analyzing the safety of gas pipelines using numerical analysis techniques have performed mechanical behavior, pipe diameter, and parameter analyses to explore how gas pipelines are affected by the environment in which they are buried. In the case of gas pipelines buried in rivers, the burial depth has the greatest influence on pipeline exposure, so many countries are evaluating the safety of gas pipelines buried in rivers based on burial depth [2]. In the United States, the pipeline risk management standard of the API (American Petroleum Institute) stipulates the risks and potential damage mechanisms associated with river crossings, as well as lifecycle management and operations [29]. In the United Kingdom, the pipeline standard IGEM/TD/3 (Institution of Gas Engineers and Managers Transmission and Distribution Standard 3) has been established to describe the design of river-crossing pipelines, to assess the likelihood of unexpected accidents and the resulting damage impacts, and to mitigate the identified risks [30]. In Australia, following the pipeline design and installation standard AS (Australia Standards) 2885.1, environmental impact assessments must be conducted for all pipeline routes, and geological and hydraulic investigations should be carried out [31]. In Canada, the pipeline design, installation, and maintenance standard CSA (Canadian Standards Association) Z662-15 (oil and gas pipeline system) explicitly requires pipeline systems, including river crossings, to prepare risk assessments according to the pipeline integrity management program [32]. The Korea Gas Safety Corporation conducts regular safety assessments of gas supply facilities every five years. For the safety assessments of gas pipelines buried in rivers, a hydraulic investigation is performed following guidelines for the hydrodynamic safety assessment of buried pipelines [33]. These international standards highlight the global emphasis on comprehensive risk assessments for river-crossing pipelines, particularly concerning hydrodynamic factors and riverbed changes. However, despite these guidelines, challenges remain in accurately predicting and managing the impacts of hydrodynamic forces on buried pipelines due to complex environmental conditions. Therefore, there is a need for advanced analytical methods and tools that can enhance the safety evaluations of gas pipelines crossing rivers. Our research aims to fill this gap by employing hydrodynamic analysis to assess site-specific river conditions and propose reinforcement measures tailored to the local environmental context, particularly for rivers in Korea. In this context, our research aims to contribute by employing hydrodynamic analysis techniques to assess riverbed changes and analyze the safety issues of gas pipelines buried in rivers from a hydraulic perspective, ultimately proposing reinforcement measures to mitigate the identified risks. In this study, the hydrodynamic analysis tools SMS (Surface–Water Modeling System) [34,35] and HEC-RAS (Hydrologic Engineering Center—River Analysis System) [36] were used to examine riverbed changes in areas where buried pipelines cross rivers. The safety issues of gas pipelines buried in rivers were analyzed from the hydraulic aspect, and reinforcement measures were proposed. The next section describes the materials and methods used in this study, including the hydrodynamic models and safety assessment procedures. Following that, the results of the long-term and short-term simulations of riverbed changes and their implications for gas pipeline safety are presented. A comprehensive discussion then compares the findings with similar studies and evaluates the implications of the results for future safety standards. Finally, the paper concludes by summarizing the key findings and suggesting areas for future research and practical recommendations for reinforcing the safety of gas pipelines crossing rivers.

2. Materials and Methods

2.1. Hydrodynamic Safety Assessment of Buried Gas Pipelines in Riverbeds

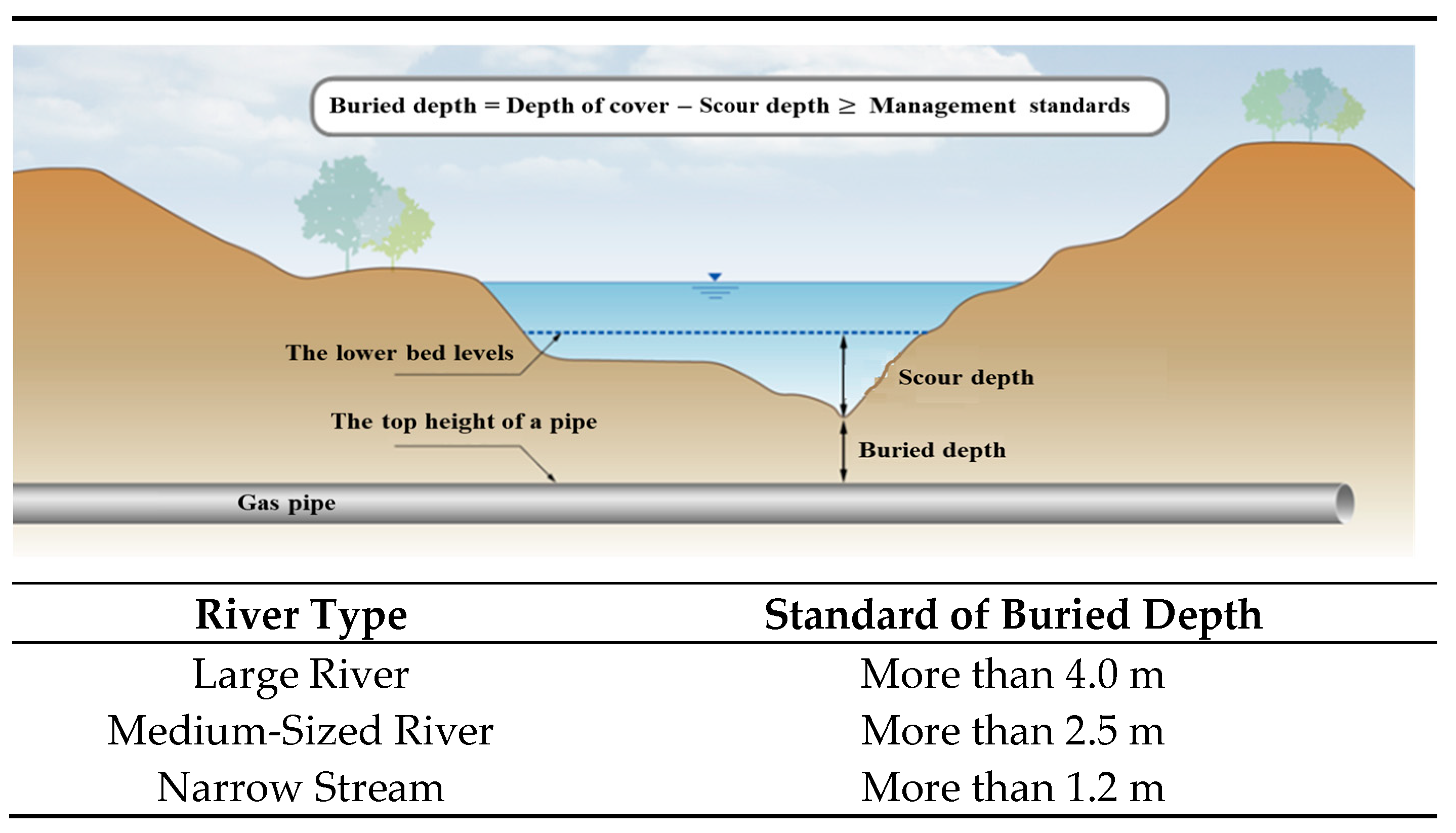

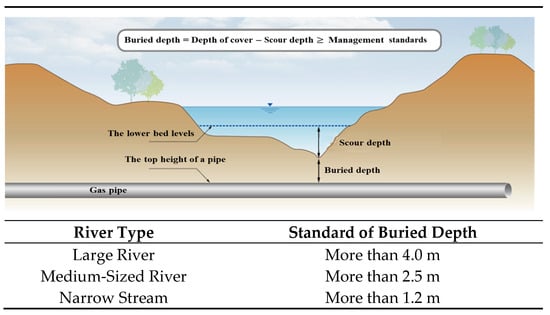

In Korea, when burying gas pipelines in rivers, the distance between the outer surface of the pipeline and the planned riverbed elevation varies based on the size of the watercourse, such as rivers, small streams, and canals. Figure 1 illustrates the standard burial depths for different types of watercourses, with large rivers requiring a burial depth of over 4.0 m, medium-sized rivers requiring depths over 2.5 m, and narrow streams requiring a minimum depth of 1.2 m. These depth standards are crucial in ensuring that the pipelines remain safely buried even during events of deposition or scour. Similarly, other countries such as the United States, the United Kingdom, Canada, and Australia also regulate burial depths based on regional safety considerations [37,38,39,40].

Figure 1.

Gas pipeline safety assessment guideline (Urban Gas Business Act, 2022).

For gas pipelines crossing rivers, maintaining the required burial depth becomes highly challenging due to the occurrence of deposition and scour. Figure 1 serves as a visual reference for the regulatory depth requirements, highlighting the importance of adhering to these standards to minimize the risk of pipeline exposure. Therefore, before any expected changes to the riverbed, a thorough hydraulic investigation should be conducted as part of the safety assessment. This requires periodic safety assessments and active management to prevent critical damage caused by riverbed changes.

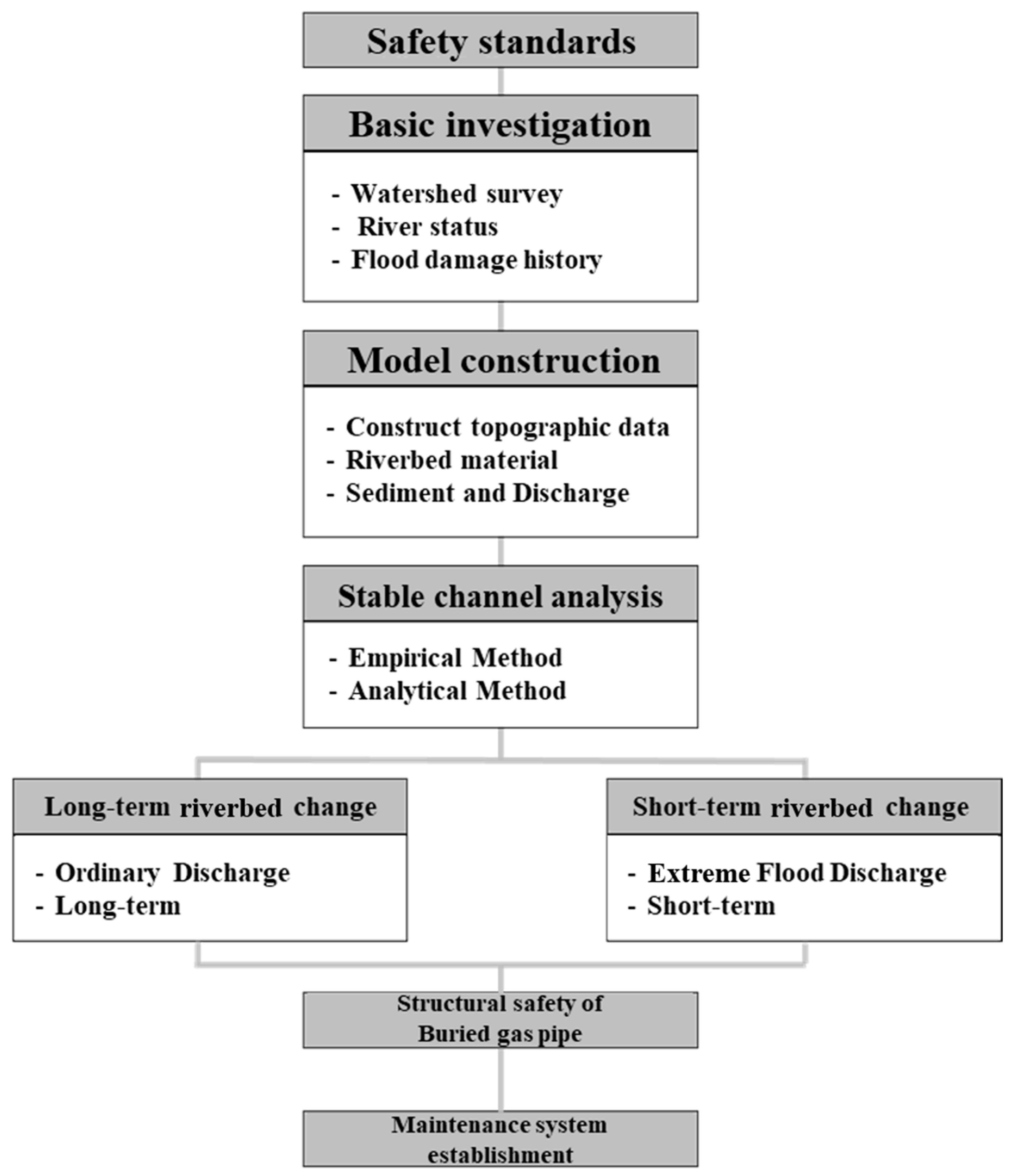

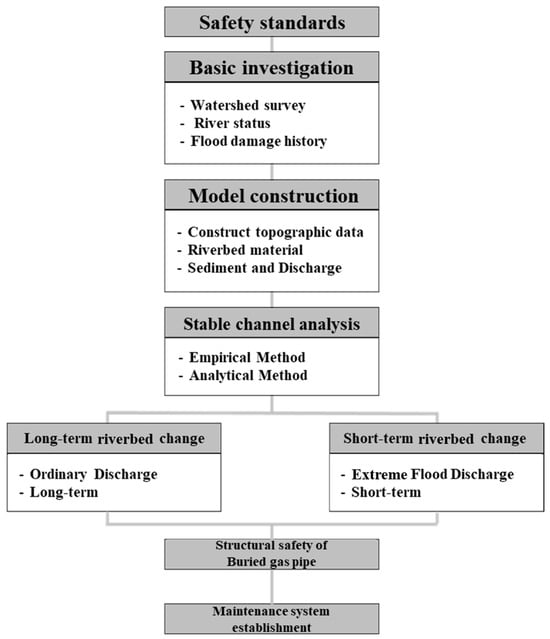

A hydrodynamic safety assessment for pipelines buried in rivers entails the consideration of several factors such as subsurface conditions, geological characteristics, riverbed change, scour, and deposition. The hydrodynamic analysis targets cases where pipelines are buried within sediment layers and when they are exposed due to scour or riverbed changes. The degree of sediment deposition and scour can be determined by sediment transport modeling, which is preceded by hydrodynamic modeling featuring the river width, flow rate, velocity, and geological conditions. Figure 2 illustrates the procedure for assessing the safety of buried gas pipelines, focusing on both long-term and short-term changes in riverbeds. The safety assessment is governed by defined safety standards. The basic investigation stage includes a watershed survey, river status assessment, and review of flood damage history. Based on these initial investigations, the model construction stage involves collecting and constructing topographic data, analyzing riverbed materials, and measuring sediment levels and discharge rates. Following this, the investigation of the stability of the river channel is conducted using both empirical and analytical methods.

Figure 2.

Hydrodynamic safety assessment process.

The long-term riverbed change assessment stage focuses on how the riverbed may change over an extended period under normal discharge conditions, including ordinary discharge and long-term changes occurring over several years or decades. For the long-term riverbed change analysis, this study employs the one-dimensional model HEC-RAS. HEC-RAS was chosen because it is a widely accepted and validated model developed by the U.S. Army Corps of Engineers, specifically designed for simulating one-dimensional steady and unsteady flow, sediment transport, and riverbed changes over long periods. Its robust capabilities in handling complex river networks and sediment transport modules and the ease of integrating hydrological data make it suitable for modeling long-term riverbed evolution. Additionally, HEC-RAS offers extensive documentation and user support and has been successfully applied in numerous studies, ensuring reliability and credibility in the results. In contrast, the short-term riverbed change assessment stage evaluates the immediate impacts on the riverbed due to extreme flood discharge and short-term changes occurring over hours. For the short-term riverbed change analysis, this study utilizes the two-dimensional models RMA2 and SED2D provided by SMS. These models were selected because they are capable of simulating detailed two-dimensional hydrodynamic and sediment transport processes, which are essential for capturing the localized effects of extreme flood events on riverbed morphology. RMA2 handles the hydrodynamic flow field, while SED2D simulates sediment transport and bed change. The integration within SMS provides a flexible and user-friendly platform for setting up complex geometries and boundary conditions. SMS also offers advanced mesh generation and visualization tools, which are crucial for accurately representing the study area’s topography and interpreting the simulation results. These features make RMA2 and SED2D particularly suitable for a short-term, high-resolution analysis of riverbed changes during extreme events. Through these assessments of long-term and short-term riverbed changes, the safety of the buried gas pipelines is ensured, and a maintenance system is established based on the results. This procedure represents a systematic approach to guaranteeing the safety of buried gas pipelines by comprehensively analyzing and preparing for both long-term and short-term changes in riverbed conditions.

2.2. Study Area Description

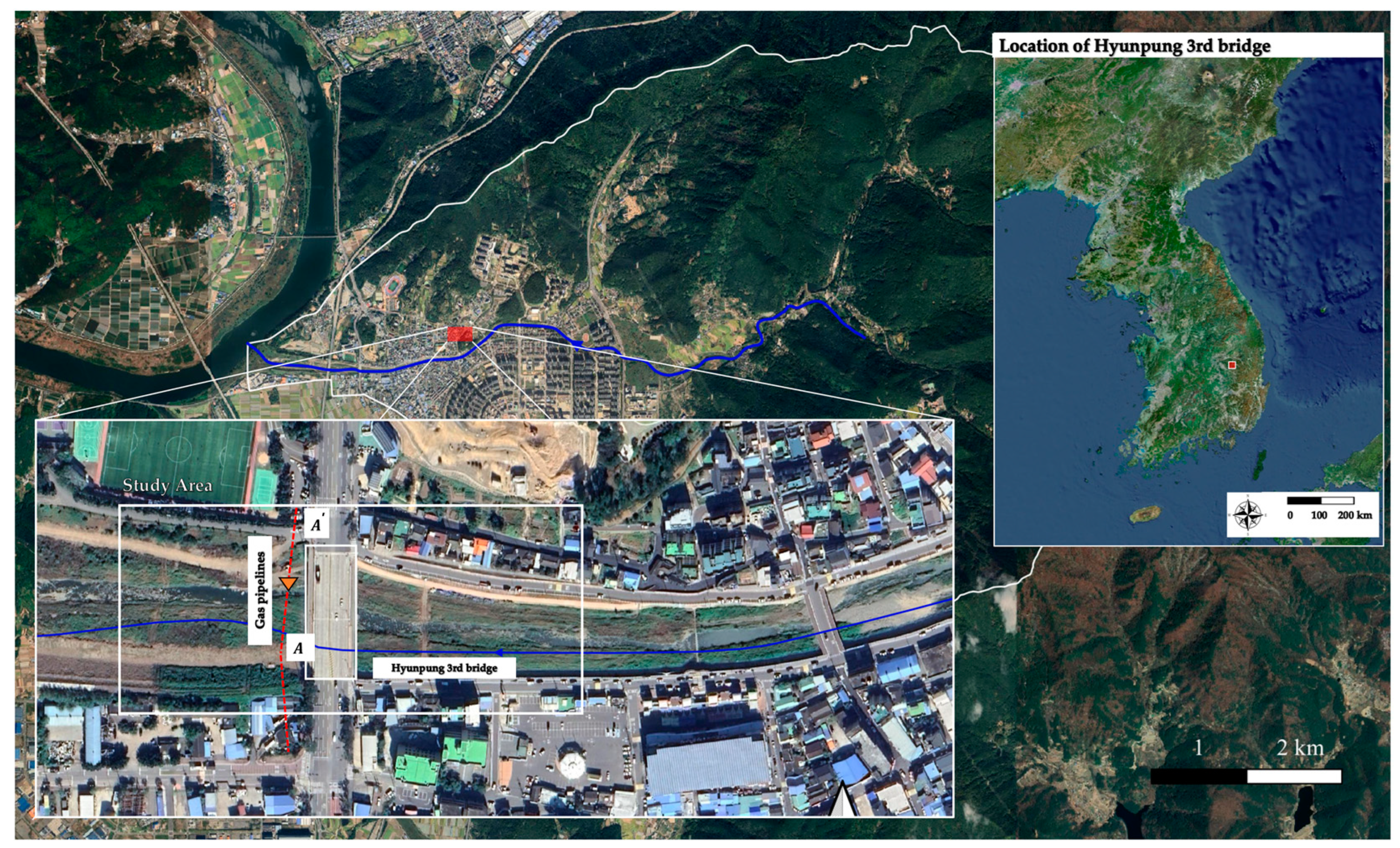

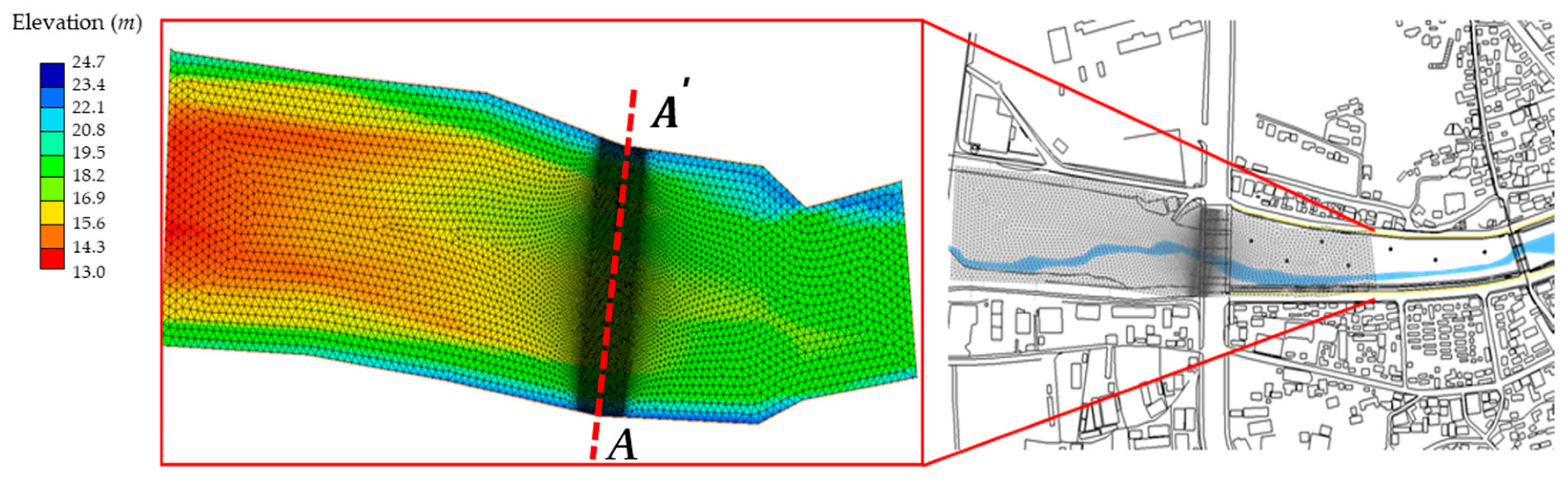

The study area for implementing the hydrodynamic safety assessment is the Hyunpung Stream, a tributary of the Nakdong River located in Daegu Metropolitan City, South Korea. The upper reaches of the Hyunpung Stream consist of sand and gravel, while the lower reaches are composed of silty sand, and the middle and lower reaches have relatively gentle slopes. Urban gas pipelines are buried under the Hyunpung Third Bridge location, as shown in Figure 3. This location is situated in the downstream section of the river and has a gentle slope.

Figure 3.

The location of the study area and the gas pipeline (A–A’).

Sediment can potentially influence the stability of river structures due to scour and reduce the flow passage area due to deposition. Moreover, when the sediment transport volume increases to a certain extent, sediment particles can cause friction and abrasion on the pipeline surface. This friction problem arises because suspended sediments collide with the pipeline, leading to material wear and potential damage over time. Increased friction can compromise the structural integrity of the pipeline and may accelerate corrosion processes, especially in areas with high sediment loads. Therefore, it is essential to consider not only the effects of sediment on river structures and flow capacity but also the direct impact on the pipeline surface itself. Therefore, estimating sediment transport is crucial for ensuring watershed stability and pipeline safety. To this end, a series of field investigations have been conducted to classify the sediment size and determine flow discharge. According to previous studies [41] and river survey results by the Ministry of Land, Infrastructure, and Transport [42], the Hyunpung Stream is characterized by sedimentary features rich in sand and clay. The proportion of sand increases slightly downstream, particularly in comparison to gravel. For flow discharge, daily discharge data were used to generate the flow duration curve, and discharges representing durations of 95, 185, 275, and 355 days were extracted. Although various functions for estimating sediment transport exist [43,44,45,46,47], the Ackers and White function was adopted for the calculation based on the guidelines presented in the Comparative Evaluation of Some Selected Sediment Transport Formulas [41]. This formula explains how sediment is transported in flows such as rivers, considering variables like flow velocity, particle size, and particle concentration. The Ackers and White function is widely used in various river and hydraulic engineering applications for predicting sediment transport. It plays a significant role in research and design related to river stability, sediment transport, and pollutant transport. The function is a valuable tool for predicting sediment movement in complex river and hydraulic systems. It considers the hydraulic and sedimentological characteristics of sediment and is used to estimate sediment transport under various environmental conditions. It is an important tool in engineering and environmental projects. The Ackers and White function is a total load function developed from flume data for relatively uniform gradations ranging from sand to fine gravel. Ackers and White derived the equation using dimensional analysis and fitted coefficients to the equation based on experiments that included a range of bed configurations such as ripples, dunes, and plane bed conditions. This function does not have an intuitive shear stress, excess shear stress, or excess stream power formulation, unlike most other equations. However, it is built on a very similar excess mobility power function. The sediment flux is a function of a transport parameter. The formula is based on dimensional analysis and can be expressed as follows:

where

- = Sediment flux;= Transport parameter;

- = Sediment specific gravity;

- = Median particle size;

- = Effective depth;

- = Shear velocity;

- = Average channel velocity;

- = Transition exponent (based on sediment size)

- which is simple, dimensionless, power function of excess mobility with transport potential as follows:

- = Empirical coefficient;

- = Sediment mobility;

- = Threshold mobility;

- = Empirical power coefficient.

In Equation (2), the empirical coefficients and play important roles in the characterization of sediment transport. The coefficient serves as an empirical scaling factor that adjusts the magnitude of the transport parameter . It is derived from experimental data and calibrated according to specific site conditions. This coefficient reflects the overall sediment transport capacity of the system and is necessary to ensure the model accurately represents the observed transport behavior under varying hydrodynamic conditions. The coefficient is an empirical exponent that governs the sensitivity of the transport parameter to changes in excess sediment mobility, defined by ). A higher value indicates a more pronounced response to increases in sediment mobility, while a lower value suggests a more gradual relationship. The value of is similarly determined through calibration and reflects the specific sediment characteristics and flow dynamics of the river being modeled. Both coefficients are essential for fine-tuning the sediment transport model to the specific hydrodynamic and sedimentary conditions of the river, thereby enhancing the accuracy of the predictions. By adjusting and , the model can account for a wide range of transport scenarios from minimal sediment movement to significant riverbed alterations.

2.3. Numerical Models and Governing Equations

To implement the hydrodynamic safety assessment, two widely applied models, HEC-RAS and SMS (RMA2 and SED2D), were employed. The HEC-RAS model was used to simulate long-term riverbed changes. The long-term simulation assumed that historical discharge patterns in the study area continued for a 20-year period, and flow rates were analyzed considering hydrological assessments from the river management agency. The operational lifespan of gas pipelines generally spans several decades, during which rivers undergo natural topographical changes and sediment transport processes. In the long-term simulation, a period of 20 years was set to evaluate these riverbed changes. This 20-year period enables the analysis of how cumulative riverbed variations over this duration affect the stability of the pipelines. This facilitates the identification of long-term risk factors and the establishment of preventive maintenance and management strategies. Riverbed changes were analyzed using design frequencies and flood volumes as outlined in the river management plan. The governing equations for the 1D unsteady flow analysis in HEC-RAS consist of the continuity equation and the momentum equation. The continuity equation represents the concept of mass conservation within the system and is expressed as follows:

where

- = Distance along the channel;

- = Time;

- = Flow rate;

- = Cross-sectional area;

- = Lateral inflow unit distance.

Equation (3) represents the principle of mass conservation within a river system. Rather than a traditional algebraic equation, it serves as a continuity equation, explaining the temporal and spatial variations in flow and cross-sectional area. This equation can be interpreted as follows. represents the rate of change of the cross-sectional flow area over time, expresses the spatial rate of change of the flow rate, and refers to the lateral inflow per unit distance along the river channel. This equation balances the inflow and outflow, ensuring mass conservation within the system. It is used to calculate how flow evolves over time, accounting for lateral inflows and spatial variations in flow. This relationship is essential for the accurate hydrodynamic modeling of rivers.

The momentum equation is based on the principle that the change in momentum is equal to the external forces acting on the system and can be expressed as Equation (4) for a single reach.

where

- = Acceleration of gravity;

- = Friction slope;

- = Velocity.

Detailed theoretical background information can be found in the Hydraulic Reference Manual published by the HEC-RAS river analysis system [37].

The SMS model was applied to calculate the hydrodynamic flow behavior and interpret the extent of riverbed changes. Floods are major factors that rapidly increase river flow velocity and discharge, promoting changes in the riverbed and riverbanks. Under such extreme hydrodynamic conditions, buried gas pipelines are at a higher risk of exposure or damage. Therefore, in the short-term simulation, potential flood events were modeled to evaluate the stability of the pipelines under extreme conditions. This approach allows for the analysis of immediate impacts on the pipelines during flood scenarios and the identification of risk factors. RMA2 of the SMS model was utilized to derive velocity field results corresponding to flood occurrences. Additionally, short-term riverbed changes were simulated using the sediment transport model, SED2D, in the SMS suite. The governing equations of RMA2 and SED2D are as follows. RMA2 solves the depth-integrated equations of fluid mass and momentum conservation in two horizontal directions.

where

- = Water depth;

- = Velocities in Cartesian directions;

- = Cartesian coordinates and time;

- = Density of fluid;

- = Eddy viscosity coefficient

- for xx = normal direction on x axis surface,

- for yy = normal direction on y axis surface,

- for xy and yx = shear direction on each surface;

- = Elevation of bottom;

- = Manning’s roughness;

- = Empirical wind shear coefficient;

- = Wind speed;

- = Wind direction;

- = Rate of Earth’s angular rotation;

- = Local latitude.

Equations (5)–(7) are solved by the finite element method using the Galerkin method of weighted residuals. The elements may be one-dimensional channel reaches or two-dimensional quadrilaterals or triangles, and may have curved (parabolic) sides. The shape (or basis) functions are quadratic for velocity and linear for depth. Integration in space is performed by Gaussian integration [35]. The SED2D model, which uses the water level and flow velocity values calculated in the RMA2 model, can simulate suspended sand concentrations and riverbed change using the transport and diffusion equation, and the transport and diffusion equation is as follows.

where

- = Concentration;

- = Effective diffusion coefficient in the x-direction;

- = Effective diffusion coefficient in the y-direction;

- = Coefficient for the source term;

- = Equilibrium concentration portion of the source term.

2.4. Composition of Input Data

2.4.1. Assessment of Bed Material Composition and Sediment Load in the Hyunpung Stream

According to the Development of a Guideline for the Selection of Sediment Transport Formulas [48], sediment load at measurement points can be estimated. The study area for the present research is the Hyunpung Third Bridge region in the Hyunpung Stream. The Hyunpung Stream Basic Plan provided the bed material composition, which is shown in Table 1. Table 1 presents the cumulative passing weight percentages of bed material composition in the Hyunpung Stream. The data indicate a dominance of coarse materials, such as gravel and cobble, particularly in the larger size fractions like LC (256 mm) and SC (128 mm). This suggests that the streambed is relatively resistant to scour, which could affect sediment transport dynamics and the risk of pipeline exposure due to scouring. The finer fractions, such as VFS (0.125 mm) and CM (0.0625 mm), make up a smaller percentage, indicating lower susceptibility to transport by normal river flow. However, these finer materials could become mobilized during flood events. This distribution of grain sizes plays a crucial role in determining the sediment transport capacity, and the higher proportion of coarser materials suggests a relatively stable riverbed with lower rates of sediment movement under normal flow conditions.

Table 1.

Passing weight percentage of bed material composition in the Hyunpung Stream.

The Ackers and White sediment transport equation, suitable for small to medium-sized rivers where the transport of sand and gravel is frequent, was applied. Consequently, the flow–sediment load results for the Hyunpung Stream Basin according to the sediment transport rate were derived, as shown in Table 2. Table 2 provides the flow duration analysis and sediment load results, highlighting the relationship between discharge and sediment transport across different flow conditions. The results show that the sediment load increases significantly during higher flow conditions, as seen during abundant flow (Q95), where the sediment transport rate reaches 8.21 tons/day. In contrast, under low flow (Q275), the sediment transport rate decreases to 1.24 tons/day. These findings underscore the importance of flow magnitude in sediment transport processes. The variation in sediment load across different flow conditions also emphasizes the need for dynamic management strategies that consider seasonal changes in discharge. Moreover, these results have direct implications for the stability of buried pipelines, as higher sediment loads during peak flows can lead to increased scouring and potential exposure of the pipeline.

Table 2.

Flow duration analysis and sediment load results of the study area.

Flow duration represents the annual situation of daily flow at a reference point, providing an understanding of the scale of and variability in available river flows through flow duration analysis. However, there is no gauging station in the Hyunpung Stream. Therefore, the flow data from the Hyunpung gauging station near the confluence with the Nakdong River were used, and the flow duration in the Hyunpung Stream was estimated using the specific discharge method, which expresses the flow rate of water per unit area of the watershed to normalize discharge rates, making it easier to estimate the discharge for different watersheds. Abundant flow corresponds to the 95th day, ordinary flow to the 185th day, low flow to the 275th day, and drought flow to the 355th day on the flow duration curve. The reference drought flow is the flow used as the standard for water use planning, corresponding to the lowest flow of the last 10 years or the second lowest flow of the last 20 years. In this task, the reference drought flow was adopted as the lowest flow of the last 10 years at the Hyunpung gauging station, and it was transferred using the specific discharge method.

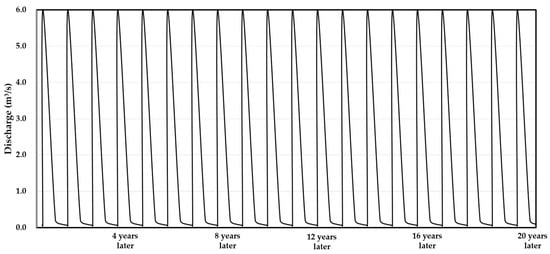

2.4.2. Boundary Conditions for Long-Term Riverbed Change Analysis

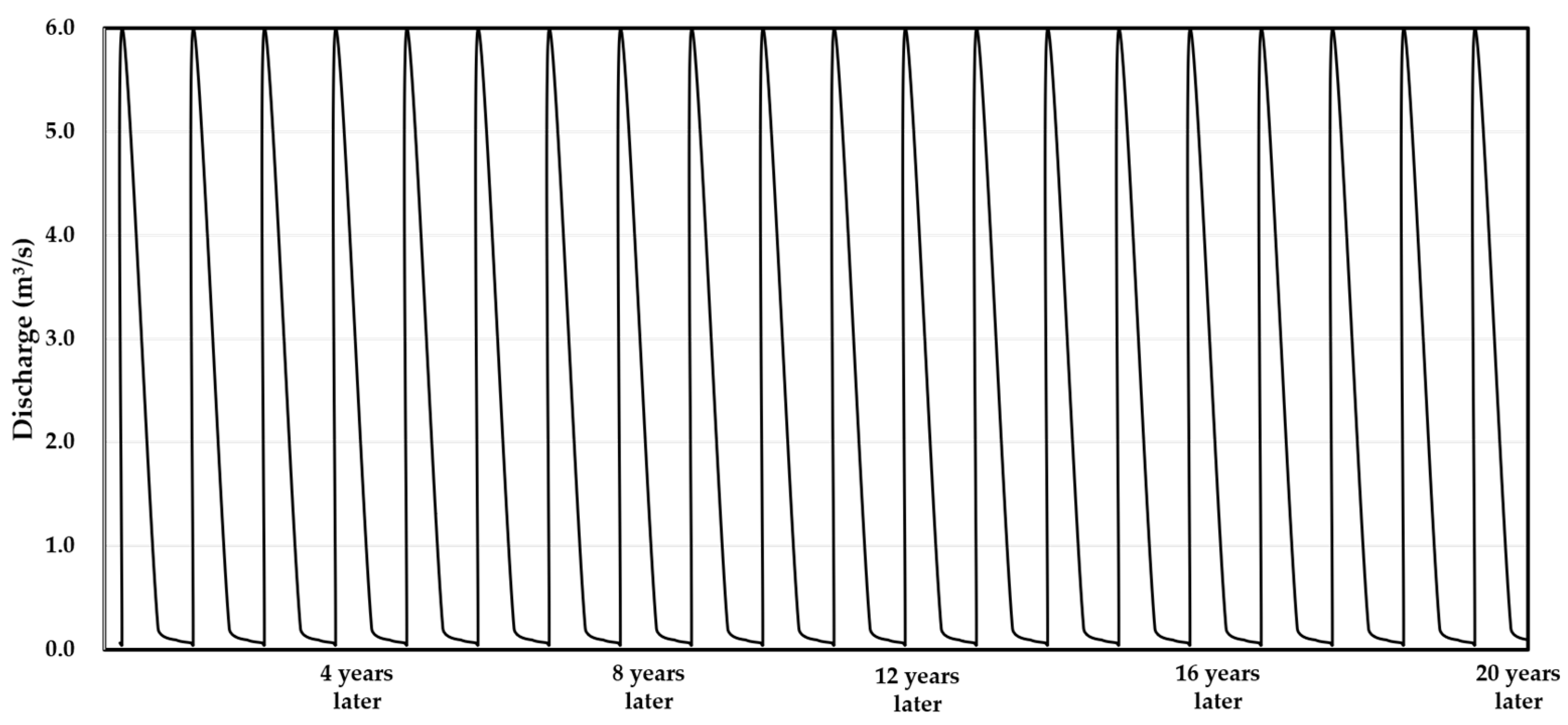

The topographical data constructed for measuring bed changes were prepared by reflecting the survey data from the River Basic Plan Report [43] and the survey results from the field investigation at the location where the gas pipeline is buried. When applying the HEC-RAS model for one-dimensional analysis, appropriate boundary conditions must be input to analyze the water level and flow velocity of the river. Generally, in the analysis of a steady non-uniform flow in rivers, the flow rate is input as the upstream boundary condition, and the water depth is input as the downstream boundary condition. Long-term bed changes were simulated under normal flow conditions over a long period, so boundary conditions that can be used to derive the water level and flow velocity during normal flow periods were reviewed. The upstream boundary condition of the model, the flow rate, was calculated based on the flow duration analysis for drought flow, low flow, ordinary flow, and abundant flow, and was applied by analyzing the monthly runoff data for the past 30 years from the River Basic Plan Report for the Hyunpung Stream [43]. In the River Basic Plan Report, when the observed flow data of the flood are valid, the flow with a specific return period is considered as the dominant discharge, which is calculated as 6.0 m3/s, as shown in Figure 4. The downstream boundary condition of HEC-RAS can be assigned as one of the critical depth, normal depth, or stage–discharge relationships. In this study, the normal depth was adopted as the downstream boundary condition. The roughness coefficient in rivers represents the degree of channel resistance, and it varies due to various complex factors such as changes in water depth, bed shape, bed changes, sediment load, type of vegetation, artificial bed excavation, and flow diversion between channels. To obtain a highly accurate roughness coefficient, it is necessary to observe and verify it continuously. The roughness coefficient was determined by reviewing the methods for estimating the roughness coefficient based on the presence of water level data and the previously established values for the main river and tributaries. and adopting the value of 0.030 deemed appropriate for the study area in the River Basic Plan Report [43].

Figure 4.

Upstream boundary conditions required for long-term simulations.

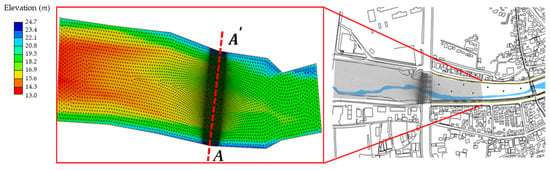

2.4.3. Boundary Conditions for Short-Term Riverbed Change Analysis

To predict short-term bed changes, the two-dimensional models, the river flow analysis model (RMA2) and sediment transport and deposition model (SED2D), were used to analyze the patterns of scouring and deposition at specific river cross-sections for the design flood event near the study area. Since the SED2D model cannot calculate water levels and velocities on its own, RMA2 was used first before SED2D to calculate these parameters. The basic assumption in the model is that the sediment deposition or scour calculated within the model does not significantly affect the flow characteristics. The study area was modeled to cover 300 m upstream and 300 m downstream from the Hyunpung Third Bridge, which serves as the reference point for the gas pipeline, as shown in Figure 5. To ensure mesh-independent solutions while preparing the topographical data, the mesh quality check function provided in SMS was activated. This maintained the length-to-width ratio below 1:10, and corner angles were kept between 10 and 150 degrees. Sharp changes in slope, which could cause computational instability, were minimized. Additionally, areas where solution variables such as u, v, and h change rapidly, and critical areas of interest, were modeled with higher density, while areas with less interest and stable flow characteristics were modeled with lower density. The area ratio between elements was kept within a factor of two.

Figure 5.

Construction of topographical data for short-term riverbed change.

To simulate short-term bed changes using the RMA2 model, it is necessary to input the flood discharge, water level boundary conditions, and roughness coefficients of the study area. For short-term simulations, specific flood events, such as those corresponding to a 100-year return period, were selected to assess the immediate impacts on the riverbed during extreme hydrological events. These events represent critical conditions that could expose or damage the pipelines within a short time frame. The selected flood event, based on regional hydrological data, provides a reasonable and conservative estimate of the potential short-term risks to the buried pipelines. For the flood discharge, since no tributaries are flowing into the study area, the design flood discharge corresponding to the 100-year return period was adopted based on the Clark unit hydrograph at the Hyunpoong Third Bridge point. The flood discharge estimation methods include the Clark unit hydrograph, the NRCS dimensionless unit hydrograph, and the Snyder unit hydrograph. The Clark unit hydrograph method, which better reflects the characteristics of the watershed, was chosen, and the flood discharge estimation results are shown in Table 3. For the downstream boundary conditions, since the purpose of the study is to analyze bed changes rather than to review flood levels, the normal depth corresponding to the discharge was calculated and applied. According to the suggested values in the River Basic Plan, a channel slope of 0.0004 and roughness coefficient of 0.030 (see Table 4) were applied.

Table 3.

Flood discharge estimation results for the study area.

Table 4.

Roughness coefficients for rivers and channel.

For the SED2D model, the sediment load boundary conditions were prescribed based on Table 2, and the relationship between sediment load and discharge at the target point and the Hyunpoong Stream was expressed using the sediment rating curve as shown below.

where

- = Sediment discharge;

- = Discharge;

- and = Empirical constants.

Equation (9) was log-transformed to enable linear regression analysis. The values of and were log-transformed as well. Using the log-transformed data, a linear regression analysis was performed to determine the values of and . The sediment rating curve can then be derived as

The empirical constants used in Equation (10) were derived from discharge and sediment load data and were used as the and values in the advection–diffusion equation presented in Equation (8). The particle-size distribution results of the study area shown in Table 5 were used as input data. In the SED2D model, particles with diameters of 4.75 mm, 2.0 mm, 0.84 mm, and 0.42 mm can be regarded as sand, while particles with diameters of 0.25 mm and 0.105 mm can be considered as silt and clay, respectively.

Table 5.

Particle-size distribution analysis by study area.

3. Results

3.1. Long-Term Riverbed Change

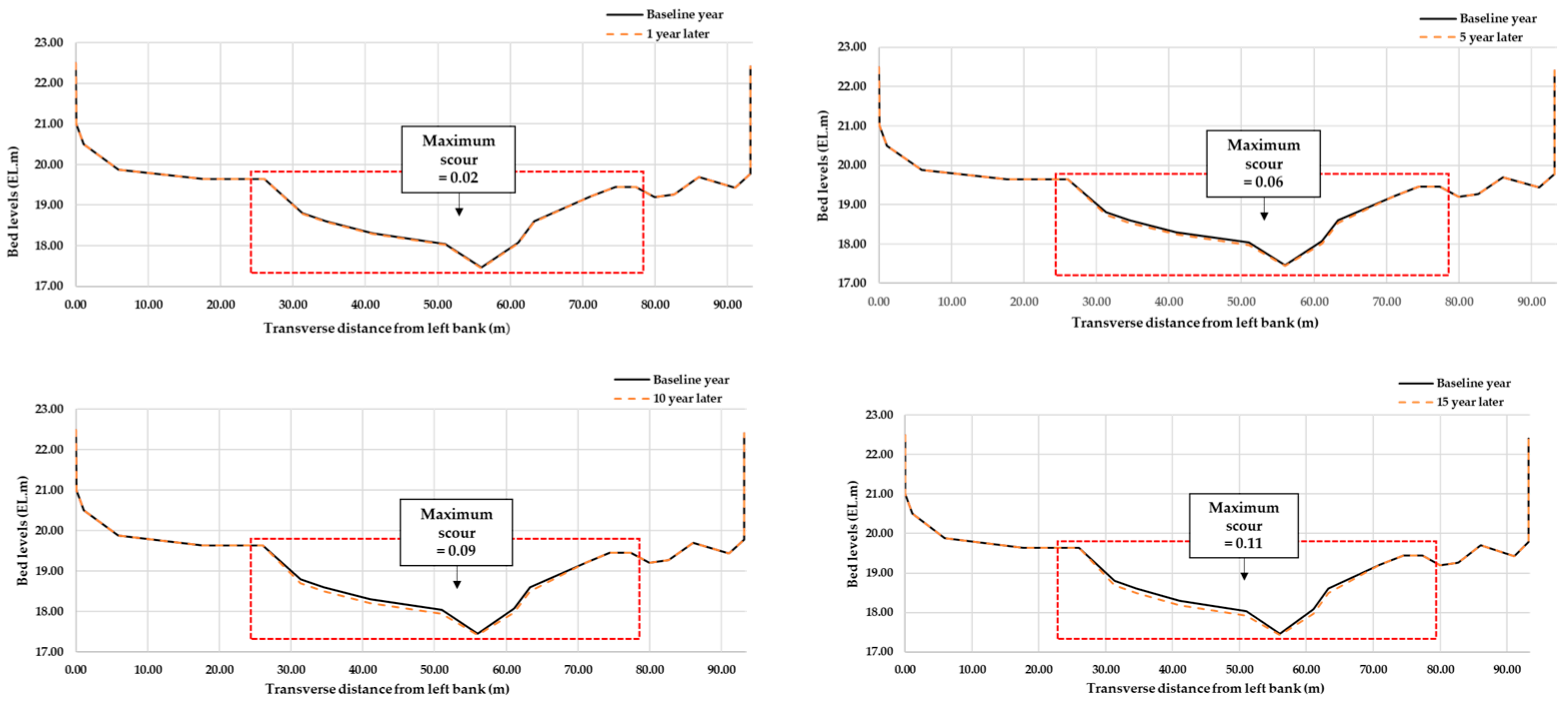

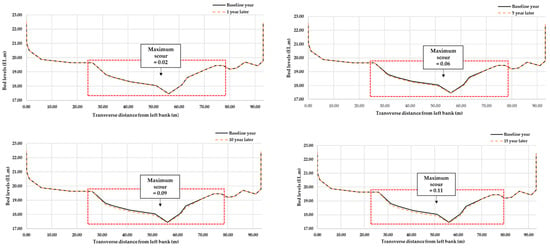

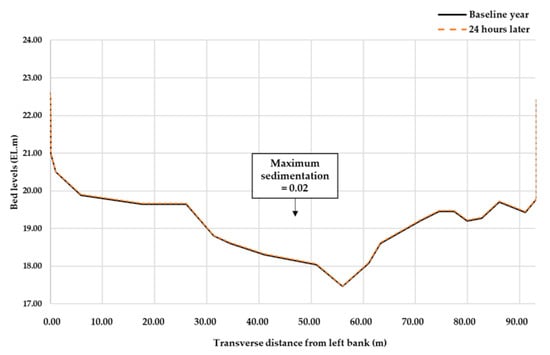

According to the long-term riverbed change simulation using HEC-RAS, the cross-section of the gas pipeline buried in the river exhibited a gradual progression of sediment scour as time passed. This analysis is critical for ensuring the safety and stability of the gas pipeline over extended periods. As illustrated in Figure 6, which shows the long-term riverbed change along the A–A’ section in Figure 3 and Figure 5, there were no significant changes in the riverbed on the left and right banks of the river segment over time. However, scour was prominent in areas near the deepest parts of the riverbed. This finding underscores the importance of monitoring flow dynamics and sediment transport to prevent potential risks to the infrastructure. The simulation predicted that after 20 years, the maximum scour depth would reach up to 13 cm. This gradual increase in scour depth can be attributed to the increased flow velocity at the burial site and downstream, which enhances shear forces that lead to sediment removal around the pipeline. The increase in flow velocity can be linked to various hydrological events, including seasonal floods and changes in river discharge patterns, highlighting the dynamic nature of river systems.

Figure 6.

Prediction of long-term riverbed change.

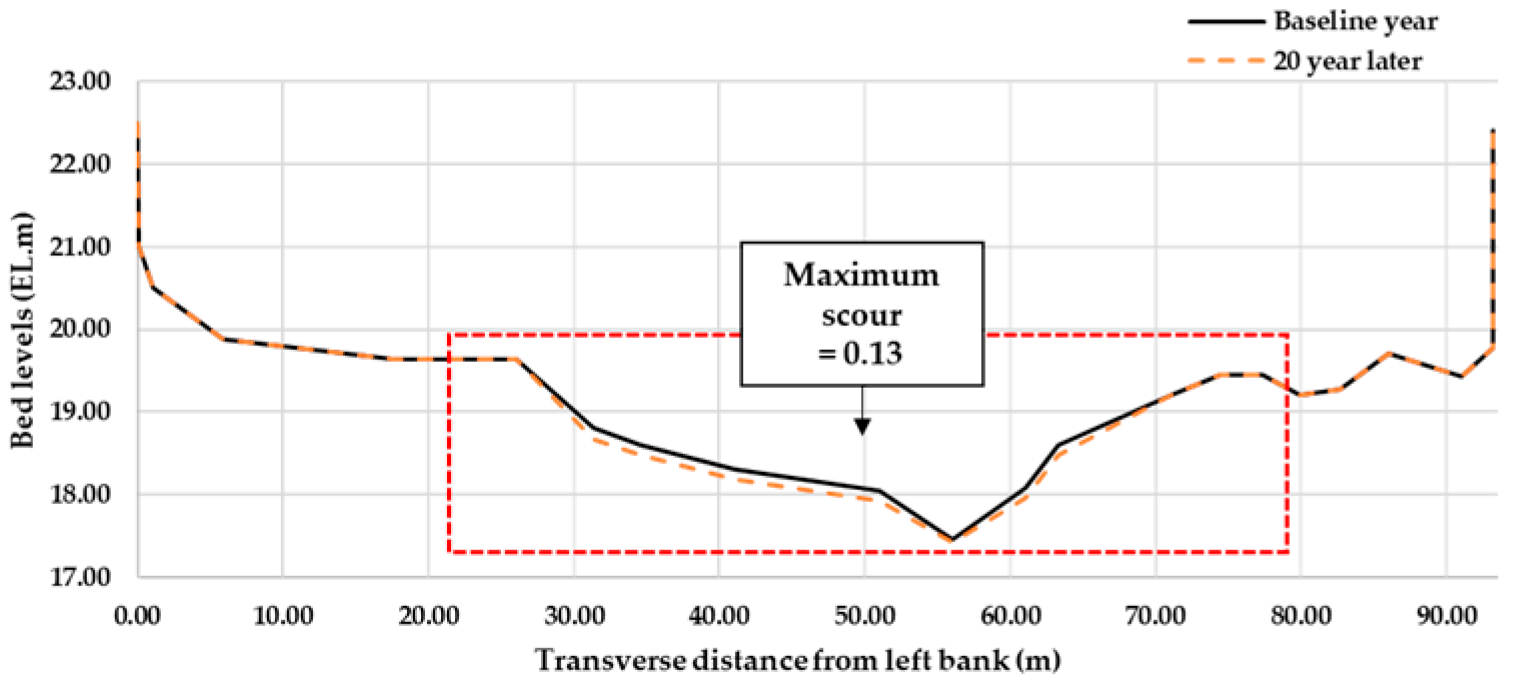

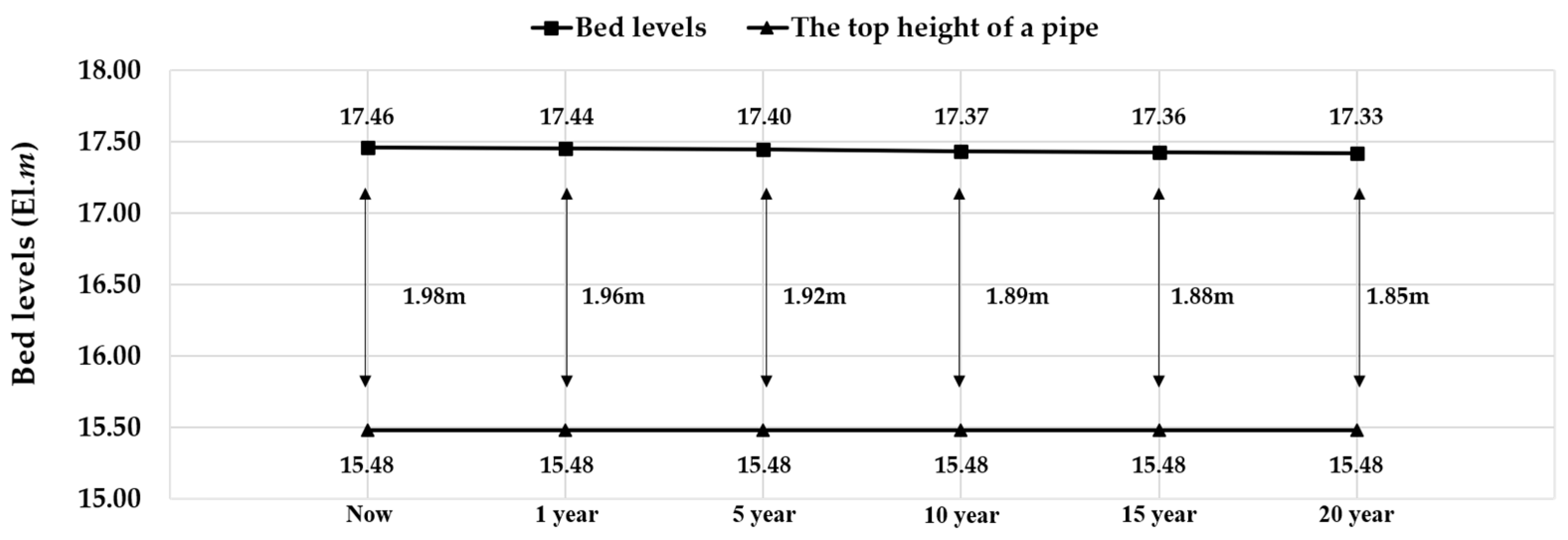

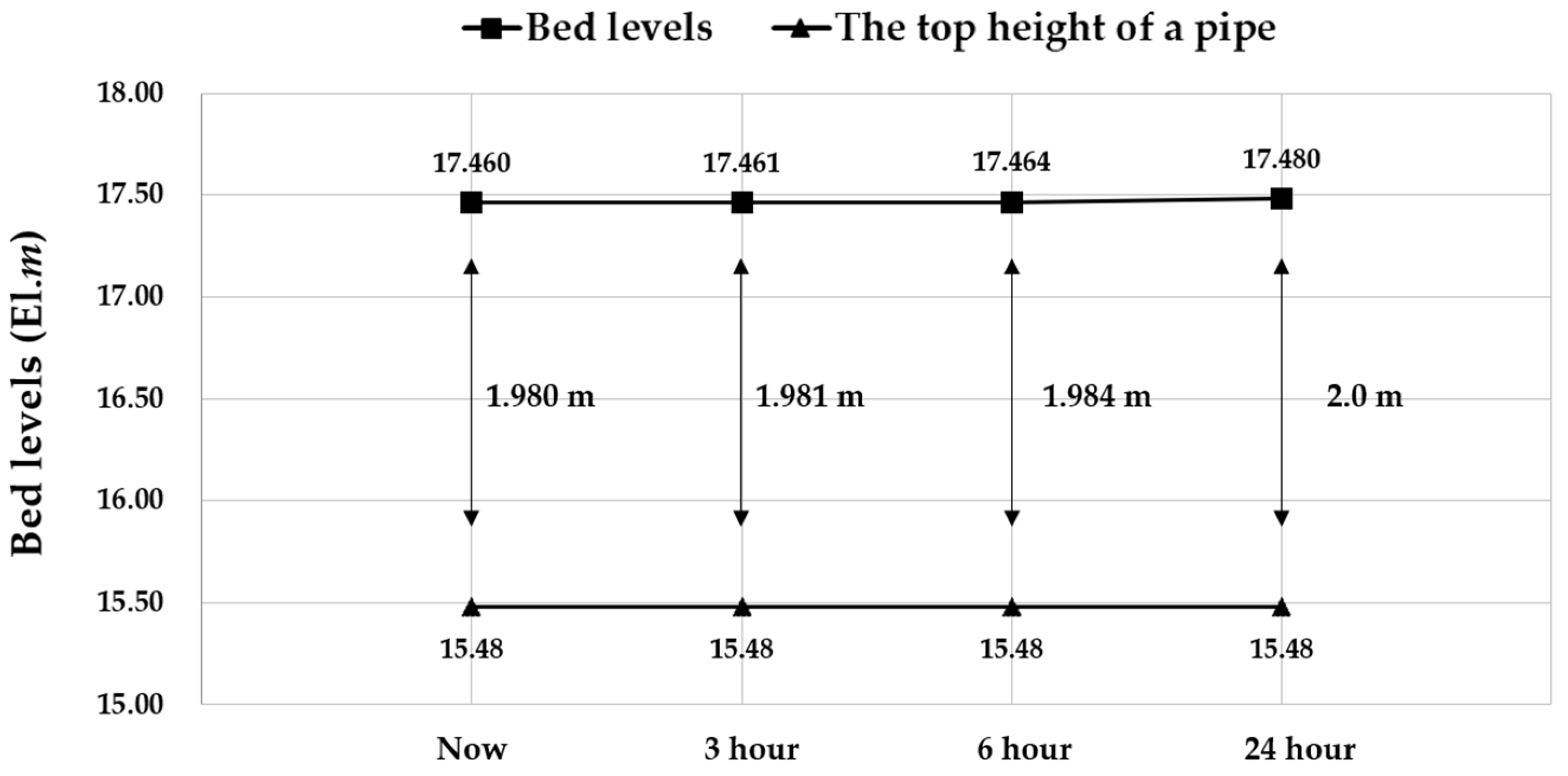

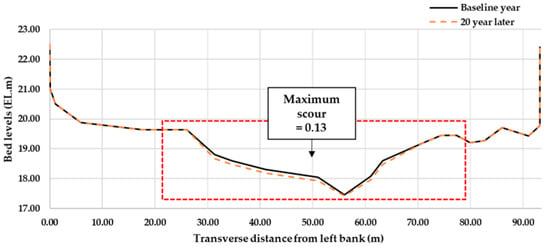

The burial depth of the gas pipeline at the location affected by long-term riverbed changes is detailed in Figure 7. At the evaluation site, the top height of the gas pipeline crossing the river is positioned at EL.15.48 m. The bed level at the pipeline’s location is currently at EL.17.46 m, but the long-term riverbed change simulation analysis indicates that bed level changes are occurring. It is predicted that after 20 years, as scouring progresses, the burial depth will reach 1.85 m. This means that there is still a water depth margin of 0.65 m compared to the regulatory guidelines for narrow streams shown in Figure 1. Although the gas pipeline is buried in a narrow stream with a low flow discharge and velocities, it is necessary to establish efficient application and management strategies for regulations and standards, considering changes in the installation environment and the operating conditions of the pipelines buried in the river. While the hydraulic methods used for predicting burial depth emphasize the need for continuous monitoring and maintenance to mitigate risks related to riverbed changes, as highlighted by this study, it is necessary to develop a rationalized burial depth management plan that fits the specific environmental conditions of the river at the study site.

Figure 7.

Changes in buried depth determined by long-term simulation.

3.2. Short-Term Riverbed Change

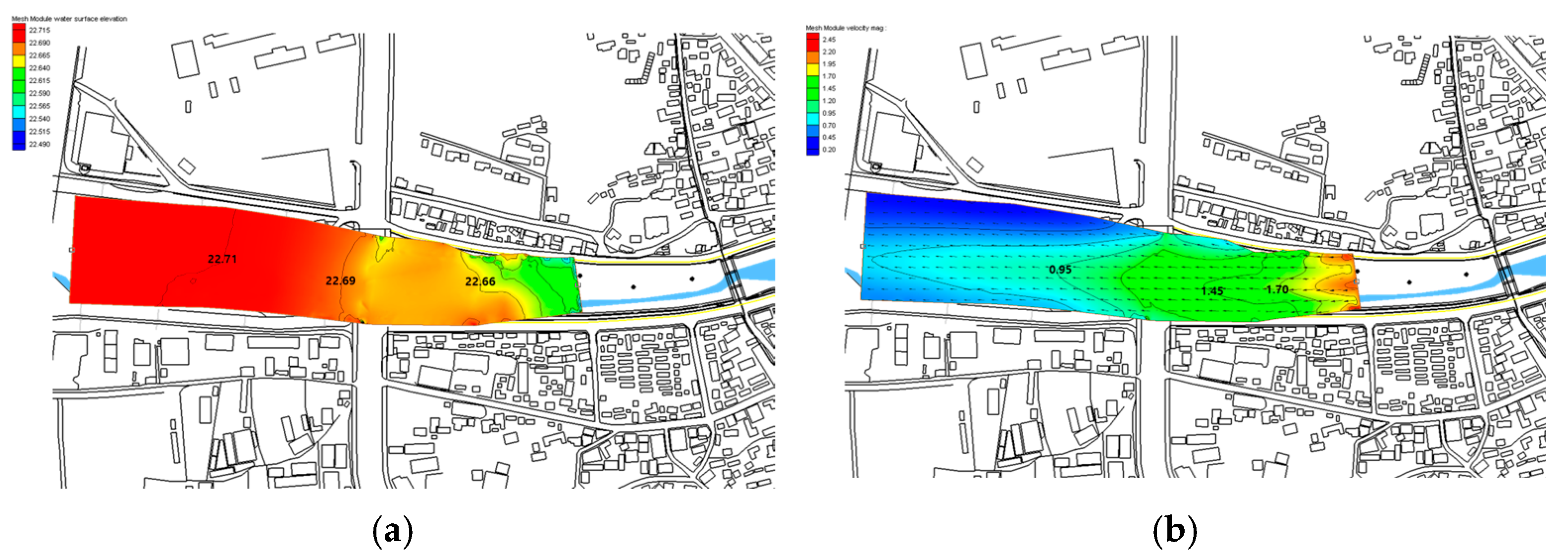

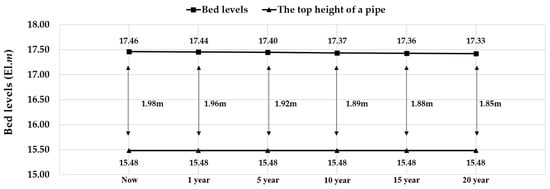

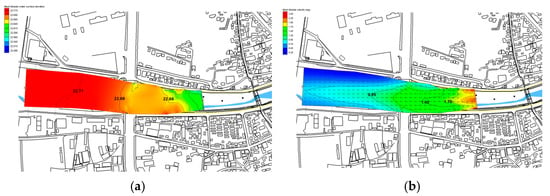

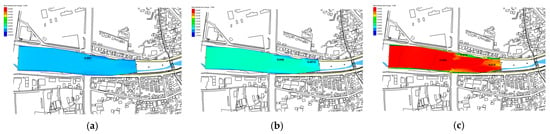

The short-term bed variations during the design flood corresponding to the 100-year return period were investigated by two-dimensional models (RMA2, SED2D). The hydrodynamic flow analysis must precede the sediment analysis, and the flow field describing the water level and velocity was obtained by RMA2. As shown in Figure 8, during the flood, the water level ranged from 22.66 m to 22.71 m, with the water level at the gas pipeline burial site measured at 22.69 m. As illustrated in Figure 8b, while passing through the bridge section, the velocity slightly decreased from 1.45 m/s to 0.95 m/s due to the expansion of the stream width.

Figure 8.

Flow characteristics: (a) water level; (b) flow velocity.

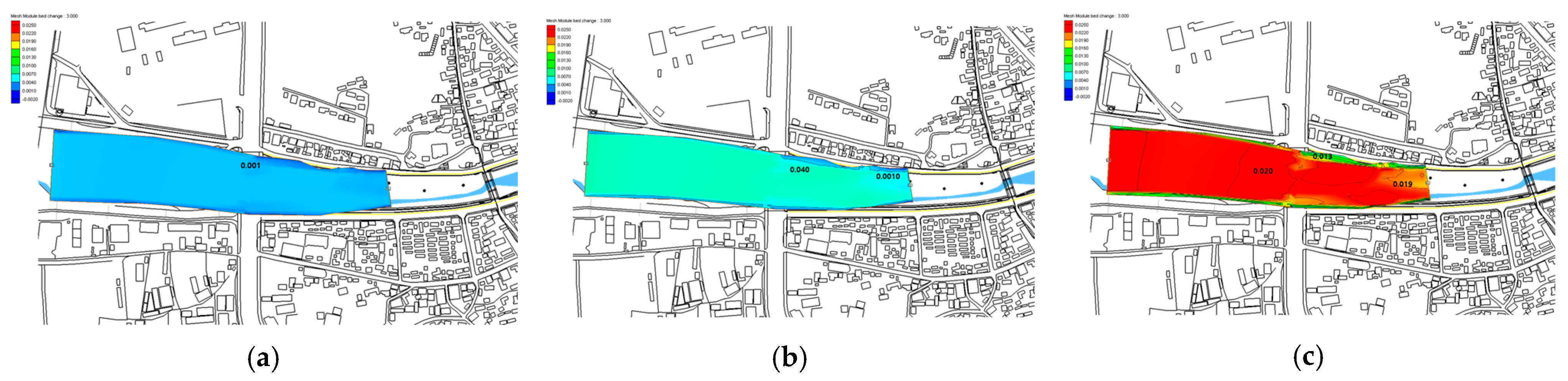

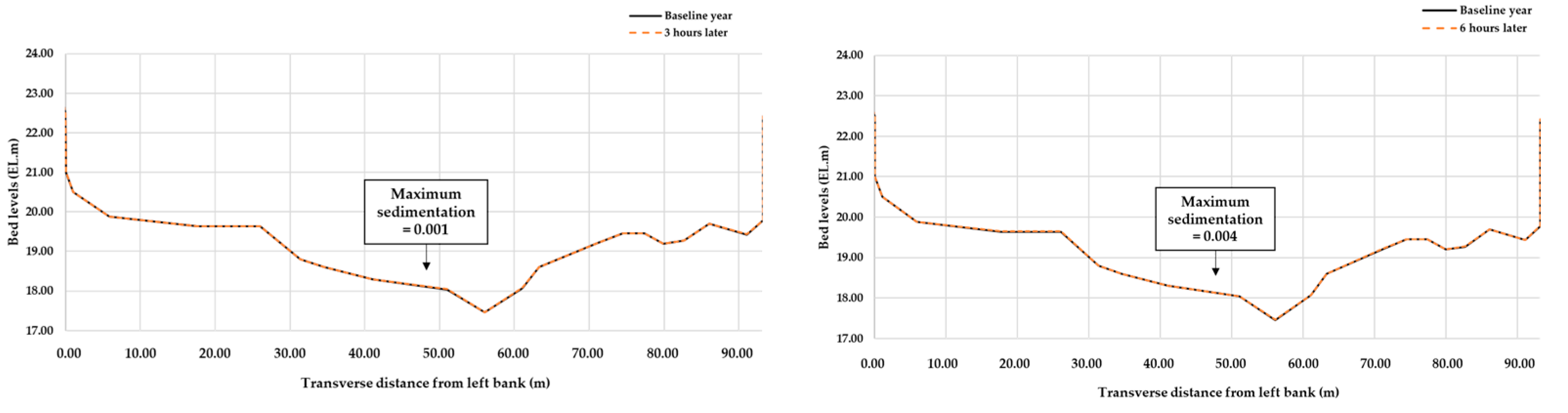

The analysis of short-term bed variations near Hyunpoong Bridge No. 3 revealed that deposition occurred throughout the river during the flood. The short-term bed variation analysis results over the flood duration are shown in Figure 9. Three hours after the flood onset, a deposition of 0.1 cm occurred, with minor changes in the riverbed and a slight scour observed along both banks. Six hours later, a deposition of 4 cm occurred along the narrow right bank of Hyunpoong Bridge No. 3. Deposition was prominent in the middle section of the study area, with specific sections showing an increased bed height due to accumulated sediments. This indicates that sediment transport began to deposit as the flood velocity decreased. After 24 h, 2 cm of deposition occurred across the study area, indicating changes in the dynamic equilibrium state of sediment transport due to changes in flow velocity during floods.

Figure 9.

Riverbed change and deposition patterns during design flood: (a) 3 h; (b) 6 h; (c) 24 h.

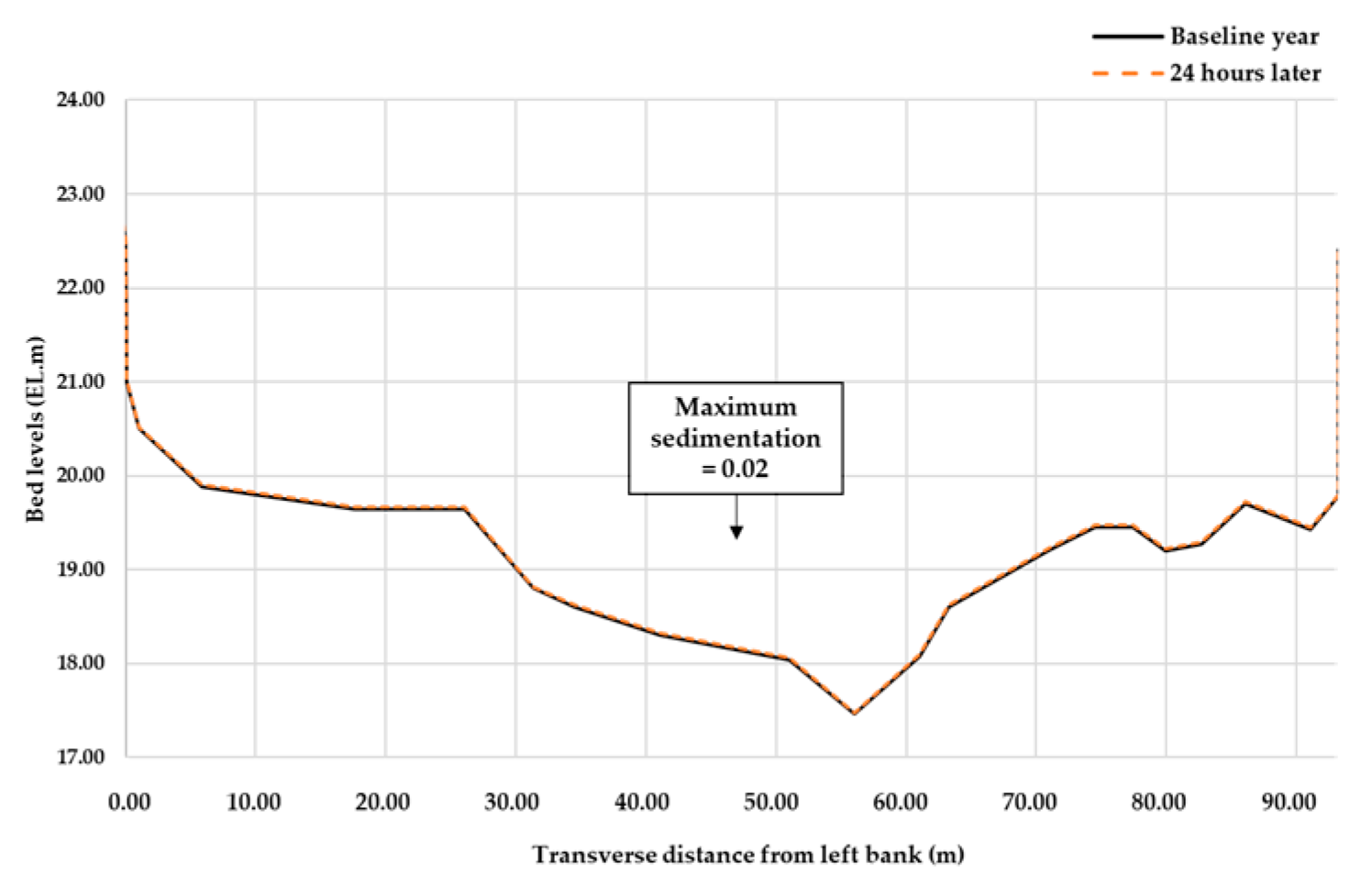

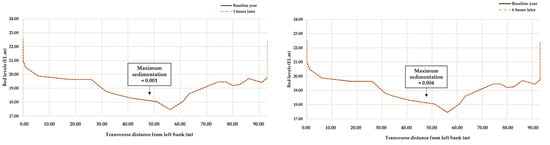

In the short-term riverbed variation simulation, it was confirmed that deposition gradually progressed over time in the cross-section where the gas pipeline is buried. As shown in Figure 10, fine deposition occurred in the central part of the riverbed during the flood period. Therefore, the two-dimensional short-term riverbed variation simulation demonstrates that the riverbed height changes over the course of the flood, with incoming sediments accumulating on the riverbed.

Figure 10.

Prediction of short-term riverbed change.

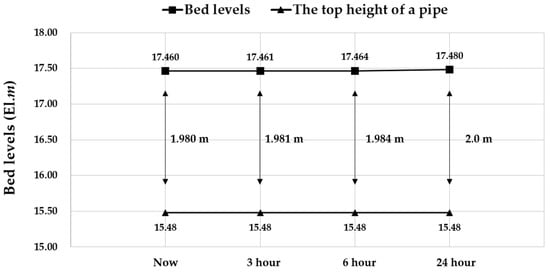

The burial depth due to short-term bed variations is shown in Figure 11. Before the flood, the burial depth was EL 1.98 m. Three hours after the beginning of the flood, there was a deposition of 0.1 cm. As the flood progressed and the maximum flow occurred six hours later, the deposition further increased to 0.4 cm. By the end of the flood, the maximum deposition reached 2 cm, resulting in a burial depth of 2.00 m. This indicates that the impact of scour was negligible throughout the flood event. Specifically, from the beginning of the flood to its end, the prediction results showed a maximum cumulative variation of 2 cm. This variation demonstrates that deposition was the predominant process affecting the riverbed during the flood, and sediments were steadily depositing on the riverbed, thus maintaining the stability of the buried pipeline. The results suggest that despite the dynamic conditions during the flood, the pipeline’s burial depth remained within safe limits, with negligible scour effects. This detailed analysis provides crucial insights into sediment dynamics and hydraulic behavior during flood events, ensuring that the infrastructure remains protected from potential scour-related damage. The findings emphasize the importance of considering short-term bed variations in hydraulic and sediment transport studies for effective river management and infrastructure safety.

Figure 11.

Short-term changes in buried depth by design flood.

The results of the long-term and short-term simulations indicate that while the current burial depth standard ensures the safety of gas pipelines under normal conditions, there are potential challenges in reflecting the spatial characteristics of the watercourse. The current burial depth standard, as shown in Figure 1, applies a uniform depth without considering the tributary nature of the watercourse, regardless of the spatial context of where the pipeline is buried. For example, a narrow stream classified as part of a larger river system may not always require the same burial depth standard as wider rivers. The current classification system may not fully account for local variations in flow velocity, sediment transport, and riverbed dynamics. This suggests that future safety standards should adopt more flexible and adaptive guidelines that consider the specific hydrological and geological conditions of each site. Furthermore, as concerns about climate change grow and the likelihood of more frequent and intense floods increases, it may become necessary to incorporate larger safety margins and a more regular monitoring of riverbed changes. The findings of this study provide valuable insights for improving pipeline safety management, advocating for adaptive standards that can respond to both long-term and short-term riverbed changes.

4. Discussion

The burial depth criteria for gas pipelines lying under the riverbed are determined by the size of the river. However, setting burial depths solely based on the size of the river lacks detailed consideration of the specific locations where gas pipelines are buried. To account for the environment on-site where gas pipelines are buried, it is necessary to develop effective management strategies and efficiently apply relevant regulations and standards to ensure the safety and stability of the pipelines. Therefore, to propose rational burial depth criteria, it is essential to conduct a hydrodynamic analysis for specific targets and assess the safety regionally.

In this study, the methodology for assessing the burial depth of river-crossing gas pipelines has been systematized using deposition estimation modeling along with hydrodynamic modeling. When using statistical methods, a statistical analysis such as confidence intervals and error margins is significant in determining and ensuring the reliability of the data used. However, this study applied a deterministic methodology using numerical simulation results, and hence, it is difficult to perform a statistical analysis. The simulation results offer valuable insights into potential risks by predicting trends in riverbed changes over time. The model results provide a useful foundation for understanding the scour processes that may affect pipeline safety.

Numerical simulations are widely employed in assessing the structural and environmental stability of gas pipelines, especially when dealing with complex conditions such as riverbed scour, sediment transport, and external mechanical forces. In recent studies, various numerical methods have been applied, from the finite element method to computational fluid dynamics and other advanced techniques. The use of hydrodynamic models, as employed in this study, distinguishes itself from other approaches that focus primarily on structural analysis. These studies provide a robust analysis of structural integrity but do not account for hydrodynamic factors such as river flow and sediment transport, which are crucial for understanding pipeline stability in river-crossing scenarios. In contrast, this study integrates both hydrodynamic and sediment transport models to assess environmental impacts on buried pipelines, which adds a layer of complexity to the safety assessment. The two-dimensional (2D) hydrodynamic modeling (SMS) used in this study offers significant advantages in predicting localized scouring and sediment deposition processes compared to traditional one-dimensional (1D) approaches like HEC-RAS, which were also employed here for long-term riverbed changes. It employs CFD to analyze velocity fields and local scour and focuses on specific fluid–pipeline interactions but may lack the broader timescale insights provided by a long-term hydrodynamic analysis. This dual-model approach allows for the integration of both detailed short-term simulations and larger-scale long-term assessments, making it a more comprehensive method for evaluating pipeline burial safety. A key advantage of this study’s methodology lies in its capacity to simulate both sediment transport and hydrodynamic changes across different timescales, which contrasts with the purely structural focus of studies like those by previous authors, where stress and deformation under specific geotechnical conditions are the primary concerns. The hydrodynamic analysis presented here can predict dynamic environmental changes that affect buried pipelines, offering a more holistic view of pipeline stability under hydrological stress.

However, the limitations of this approach must be acknowledged. While the inclusion of 2D modeling enhances the resolution and accuracy of the simulations, it also increases computational complexity and time. Moreover, without empirical data for validation, there is inherent uncertainty in the predicted results, as seen in studies that incorporate real-time monitoring data to improve accuracy. Future work should focus on integrating field data with these models to enhance the reliability of theirpredictions, as well as exploring optimization techniques to reduce computational costs. Although the model results are not validated against empirical data, they provide a useful foundation for understanding the scour processes that may affect pipeline safety. In cases where continuous scouring occurs near burial, or when the predicted results of short-term and long-term changes in the riverbed are deemed to be dangerous or require improvements, reinforcement measures should be implemented, tailored to site conditions. A hydrodynamic analysis for assessing the safety of gas pipelines can predict the sediment deposition and scour affecting buried pipelines through sediment simulation at the burial sites. By predicting riverbed changes and identifying potential damage, it is possible to establish safety measures for the gas pipelines.

Generally, reinforcement measures to reduce scour related to riverbed changes include alleviating turbulence and ensuring smooth river flow, thus minimizing impacts on the riverbed. According to the guidelines provided by the Ministry of Land, Infrastructure, and Transport of Korea [49] for maintaining riverbeds, riverbed maintenance facilities can be installed to prevent riverbed scour, degradation, and local scour or to protect structures, and it is specified that appropriate structures suitable for the characteristics of the river can be selected and applied. Existing riverbed maintenance facilities include various structures such as drop structures, sloping drop structures, and river crossing structures, which can be installed based on the shape of the river and the characteristics of riverbed change, as shown in Table 6.

Table 6.

Comparison of riverbed maintenance facilities.

To prevent riverbed scouring or to protect structures, facilities that can maintain the riverbed can be installed as a maintenance measure. Drop structures are generally reinforced concrete structures, while river crossing structures and sloping drop structures are flexible structures. It is advisable to select and apply appropriate structures based on the characteristics of the river. Drop structures are cost-effective but have the disadvantage of marring the river landscape due to the exposure of concrete chunks to the water surface, and they require periodic dredging. River crossing structures are easy to maintain but have high construction costs and poor economic efficiency, and there is a concern of the riverbed drying if the maintenance flow is low. Sloping drop structures, despite the disadvantages of requiring periodic dredging and the potential for structural damage, offer several advantages. These include a wide variety of materials available for use, no need for additional bed protection structures, relatively favorable aesthetics, and water quality improvement effects, making them suitable for maintaining the riverbed in urban rivers where city gas pipelines are buried. The protective methods for sloping drop structures based on the material include riprap, ecological stone mats, and concrete blocks. If the scouring depth is measured to be below the management criteria, the riprap method is deemed suitable considering construction costs and site conditions, while ecological stone mats are considered appropriate for urgent restoration needs.

5. Conclusions

When burying gas pipelines under riverbeds in the Republic of Korea, installations should comply with the burial depth criteria specified by the Urban Gas Business Act. Various river maintenance projects, environmental factors, and flood events cause changes in riverbed elevation. Therefore, the periodic checking and management of burial depth are essential for sustainable safety. The analysis of riverbed variations using 1D and 2D models for a buried pipeline across a river indicates that both scouring and deposition occur. This conclusion was reached by utilizing previously measured data and analysis results. To practically examine riverbed changes, it is necessary to investigate the variations in the riverbed of the area where the pipeline is buried each year and compare these with the results of long-term riverbed changes. Due to recent climate anomalies and localized heavy rains, there is a trend of rainfall patterns differing from the planned flood patterns, which makes continuous measurement before and after the flood season necessary.

This study systematized the methodology for checking the burial depth of river-crossing pipes using deposition estimation modeling in conjunction with hydrodynamic modeling. Through long-term and short-term deposition prediction targeting a narrow channel, it was shown that, despite the occurrence of scour and deposition, a burial depth of 1.2 m or more was maintained. To assess actual riverbed variations effectively, it is necessary to investigate bed changes in the pipeline-buried area annually and compare them with the results of a long-term riverbed change analysis. Based on this, if the monitoring data and predictions show similar trends, it is necessary to continue monitoring for riverbed management rather than conducting additional analyses. If scouring traces are found during scouring investigations, or if there is a significant difference between the current and previously measured pipeline depths, it is essential to determine whether temporary local scouring occurred due to abnormal floods or whether riverbed changes have occurred due to upstream or downstream river works. Additionally, if continuous scouring occurs at the survey points, further hydraulic evaluations should be conducted, and calibrations should be performed based on the monitoring data. Moreover, short-term and long-term riverbed change re-predictions should be conducted, and reinforcement measures suitable for the field conditions should be implemented.

In conclusion, the dynamic nature of river environments requires a comprehensive approach to determining burial depth criteria for gas pipelines. Integrating hydrodynamic safety assessments, periodic monitoring, and tailored reinforcement measures can ensure the safety and stability of buried gas pipelines. This approach acknowledges the complex and changing nature of river systems and the importance of adapting safety measures to specific regional conditions and ongoing environmental changes. By doing so, the safety and integrity of gas pipelines can be effectively maintained, minimizing the risk of exposure and damage due to riverbed change.

The current hydrodynamic analysis methodology has played a significant role in evaluating long-term riverbed changes, but it has certain limitations. While one-dimensional models are useful for simulating long-term riverbed changes, they have limitations in fully capturing complex topographical changes and diverse flow conditions. Additionally, applying uniform standards based on river classification is not appropriate, as regulations and standards should be efficiently applied according to the installation environment and operating conditions of the pipelines buried in the river. Therefore, future research should consider using two-dimensional or three-dimensional hydrodynamic models to simulate riverbed changes more accurately. Furthermore, implementing a real-time monitoring system to continuously collect data and incorporate it into simulations is necessary to enhance the reliability of prediction models. This approach will contribute to developing tailored management strategies that reflect actual site conditions, ultimately strengthening river management and infrastructure safety.

Author Contributions

Conceptualization, C.G.S.; Methodology, T.S.E. and E.T.S.; Analysis, T.S.E. and E.T.S.; Writing—Original Draft Preparation, T.S.E.; Writing—Review & Editing, C.G.S.; Funding Acquisition, J.P.P. All authors have read and agreed to the published version of the manuscript.

Funding

Korea Agency for Infrastructure Technology Advancement(KAIA) grant funded by the Ministry of Land, Infrastructure and Transport(Grant RS-2020-KAI156208).

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Dataset available on request from the authors.

Conflicts of Interest

Author Jong Pyo Park was employed by the company HECOREA Inc. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Canadian Energy Pipeline Association (CEPA). Pipeline Watercourse Management, Recommended Practices, 1st ed.; CEPA: Calgary, AB, Canada, 2014. [Google Scholar]

- Dooley, C.; Prestie, Z.; Ferris, G.; Fitch, M.; Zhang, H. Approaches for evaluating the vulnerability of pipelines at water crossings. In International Pipeline Conference; American Society of Mechanical Engineers: New York, NY, USA, 2014; Volume 46117. [Google Scholar]

- European Gas Incident Data Group (EGIG). Gas Pipeline Incidents; the 7th EGIG Report; EGIG, 2008. Available online: https://www.egig.eu/reports/$60/$64 (accessed on 8 August 2024).

- The Institution of Gas Engineers. Steel and PE Pipelines for Gas Distribution, 4th ed.; IGE Code TD1; Institution of Gas Engineers & Managers: Derby, UK, 2005; p. 1677. [Google Scholar]

- US Department of Transportation, Pipeline and Hazardous Materials Safety Administration Office of Pipeline Safety (DOT/PHMSA). Mechanical Damage; DOT-Final Report; PHMSA. 2009. Available online: https://www.phmsa.dot.gov/sites/phmsa.dot.gov/files/docs/technical-resources/pipeline/gas-distribution-integrity-management/65991/mechanicaldamagefinalreport.pdf (accessed on 11 September 2024).

- Mokrousov, S. Safety Measures, Regarding Transmission Pipeline Transport in the Russian Federation. In Lecture of Workshop on the Prevention of Water Pollution Due to Pipeline Accidents; 2005; Available online: https://unece.org/fileadmin/DAM/env/documents/2005/teia-wat/cp.teia.2005.1.e.ad.pdf (accessed on 11 September 2024).

- Pipeline Reports; The Transportation Safety Board of Canada (TSB): Gatineau, QC, Canada, 1996.

- Tuft, P.; Bonar, C. Review of Pipeline Incident Data to. 2004. Available online: https://www.pipeliner.com.au/review-of-pipeline-incident-data-to-2004 (accessed on 8 August 2024).

- International Gas Union (IGU), Study Group 3.4. Using or Creating Incident Databases for Natural Gas Transmission Pipelines: A Guideline; IGU: London, UK, 2006. [Google Scholar]

- Park, W.I.; Yoo, C.H.; Shin, D.I.; Kim, T.O.; Lee, H.R. A study on the risk assessment of river crossing pipeline in urban area. J. Korean Inst. Gas 2020, 24, 22–28. [Google Scholar]

- Abada, I.; Massol, O. Security of supply and retail competition in the European gas market. Some model based insights. Energy Policy 2011, 39, 4077–4088. [Google Scholar] [CrossRef]

- Fernandes, M.P.; Viegas, J.L.; Vieira, S.M. Segmentation of Residential Gas Consumers Using Clustering Analysis. Energies 2017, 10, 2047. [Google Scholar] [CrossRef]

- Tchórzewska-Cieślak, B.; Pietrucha-Urbanik, K.; Urbanik, M. Analysis of the gas network failure prediction sing the Monte Carlo simulation method. Eksploat. Niezawodn. 2016, 18, 254–259. [Google Scholar] [CrossRef]

- Tchórzewska-Cieślak, B. Method of Assessing of Risk of Failure in Water Supply System; European Safety and Reliability Conference (ESREL), Risk, Reliability and Societal Safety; Taylor & Francis: London, UK, 2007; Volume 2, pp. 1535–1539. [Google Scholar]

- Królikowska, J. Application of PHA method for assessing risk of failure on the example of sewage system in the city of Cracow. Annu. Set Environ. Prot. 2011, 13, 693–710. [Google Scholar]

- Ondrejka Harbulakova, V.; Estokova, A.; Stevulova, N.; Luptakova, A. Different aggressive media influence related to selected characteristics of concrete composites investigation. Int. J. Energy Environ. Eng. 2014, 5, 82. [Google Scholar] [CrossRef]

- Kent Muhlbauer, W. Pipeline Risk Management; Gulf Publishing Company: London, UK, 1992. [Google Scholar]

- Directive 2009/73/EC of the European Parliament and of the Council of 13 July 2009 Concerning Common Rules for the Internal market in Natural Gas and Repealing Directive 2003/55/EC. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32009L0073 (accessed on 12 March 2018).

- Tchórzewska-Cieślak, B.; Pietrucha-Urbanik, K.; Urbanik, M.; Rak, J.R. Approaches for Safety Analysis of Gas-Pipeline Functionality in Terms of Failure Occurrence: A Case Study. Energies 2018, 11, 1589. [Google Scholar] [CrossRef]

- Huang, C.; Luo, Y.; Wang, S. Safety assessment method for exposed crossing pipelines caused by river scouring. You-Qi Chuyun 2021, 40, 867–873. [Google Scholar]

- Maffra, C.R.B.; Sutili, F.J. The use of soil bioengineering to overcome scour problems in a pipeline river crossing in South America. Innov. Infrastruct. Solut. 2020, 5, 24. [Google Scholar] [CrossRef]

- Parsaie, A.; Haghiabi, A.H.; Moradinejad, A. Prediction of scour depth below river pipeline using support vector machine. KSCE J. Civ. Eng. 2019, 23, 2503–2513. [Google Scholar] [CrossRef]

- Seth, D.; Manna, B.; Shahu, J.T.; Fazeres-Ferradosa, T.; Pinto, F.T.; Rosa-Santos, P.J. Buckling mechanism of offshore pipelines: A state of the art. J. Mar. Sci. Eng. 2021, 9, 1074. [Google Scholar] [CrossRef]

- Kolahdouzan, F.; Afzalimehr, H.; Siadatmousavi, S.M.; Jourabloo, A.; Ahmad, S. The Effect of Pipeline Arrangement on Velocity Field and Scouring Process. Water 2023, 15, 1321. [Google Scholar] [CrossRef]

- Xia, M.; Zhang, H. Stress and deformation analysis of buried gas pipelines subjected to buoyancy in liquefaction zones. Energies 2018, 11, 2334. [Google Scholar] [CrossRef]

- Fu, H.; Zhang, J.; Wu, Z.; Chin, C.L.; Ma, C.K. Nonlinear analysis of axial-compressed corroded circular steel pipes reinforced by FRP-casing grouting. J. Constr. Steel Res. 2023, 201, 107689. [Google Scholar] [CrossRef]

- Soveiti, S.; Mosalmani, R. Mechanical behavior of buried composite pipelines subjected to strike-slip fault movement. Soil Dyn. Earthq. Eng. 2020, 135, 106195. [Google Scholar] [CrossRef]

- Ismail, S.; Sadek, S.; Najjar, S.; Mabsout, M. Nonlinear fnite element analysis of upheaval buckling of buried ofshore pipelines in medium dense sand with fnes. Innov. Infrastruct. Solut. 2018, 3, 29. [Google Scholar] [CrossRef]

- API RP 1133; Managing Hydrotechnical Hazards for Pipelines Located Onshore or within Coastal Zone Areas. 2nd ed. ACCURIS: Denver, CO, USA, December 2017.

- IGEM–TD/3; Steel and PE pipelines for Gas Distribution, 1 October 2015. Available online: https://cadentgas.com/getmedia/0cd3d877-0a71-45ac-b6e5-fcabe45292d7/F-1-Institution-of-Gas-Engineers-and-Managers-Steel-and-PE-Pipelines-for-Gas-Distribution-IGEM_TD_3-Edition-5-dated-July-20.pdf (accessed on 4 July 2024).

- Australian Standard AS 2885.1:2018; Pipelines—Gas and Liquid Petroleum, Part 1 Design and Construction. ABLIS: Victoria, Australia, 2018.

- CSA Z662-15; Oil and Gas Pipeline Systems Provides Authoritative Safety Guidelines for Kaohsiung’s New Pipeline Standard for Industrial and Urban Safety. Canadian Standards Association (CSA): Rexdale, ON, USA, 17 November 2015.

- Act No. 18814; Urban Gas Business Act. Ministry of Trade, Industry and Energy: Sejong, Republic of Korea, 3 February 2022.

- RMA2 WES Version 4.5; US Army, Engineer Research and Development Center Waterways Experiment Station Coastal and Hydraulics Laboratory. 2008. Available online: http://smsdocs.aquaveo.com/rma2.pdf (accessed on 10 June 2023).

- SED2D WES Version 4.3; US Army, Engineer Research and Development Center Waterways Experiment Station Coastal and Hydraulics Laboratory: 2006. Available online: https://citeseerx.ist.psu.edu/docment?repid=rep1&type=pdf&doi=434913a9c8f6043844541cfac0cad52e1dafc187 (accessed on 11 June 2023).

- Brunner, G.W. HEC-RAS River Analysis System: Hydraulic Reference Manual, Version 5.0. US Army Corps of Engineers–Hydrologic Engineering Center 547: 2016. Available online: https://www.hec.usace.army.mil/software/hec-ras/documentation/HEC-RAS%205.0%20Reference%20Manual.pdf (accessed on 11 June 2023).

- ASME B31.8; Gas Transmission and Distribution Piping System. The American Society of Mechanical Engineers: New York, NY, USA, 2010.

- BS 8010; Code of Practice for Pipelines. British Standard: London, UK, 2004.

- CSA Z662; Oil and Gas Pipeline Systems. Canadian Standard Association: Toronto, ON, Canada, 2003.

- Australia Standard AS 2885; Pipelines-Gas and Liquid Petroleum. Australia Standard: Sydney, Australia, 1987.

- Woo, H.S.; Yu, K.K. Comparative Evaluation of Some Selected Sediment Transport Formulas. KSCE J. Civ. Eng. 1990, 10, 67–75. [Google Scholar]

- Korea Land and Housing Corporation. Hyeonpung River Basic Plan; Korea Land and Housing Corporation: Daegu, Republic of Korea, 2009. [Google Scholar]

- Ackers, P.; White, W.R. Sediment Transport: New Approach and Analysis. J. Hydraul. Div. 1973, 99, 2041–2060. [Google Scholar] [CrossRef]

- Engelund, F.; Hansen, E. A monograph on Sediment Transport in Alluvial Streams; Teknisk Vorlag: Copenhangen, Denmark, 1967. [Google Scholar]

- Yang, C.T. Incipient motion and sediment transport. J. Hydraul. Div. 1973, 99, 1679–1704. [Google Scholar] [CrossRef]

- Yang, C.T. Unit stream power equation for gravel. J. Hydraul. Div. 1984, 110, 1783–1797. [Google Scholar] [CrossRef]

- Yang, C.T.; Wan, S. Comparisons of Selected Bed-Material Load Formulas. J. Hydraul. Eng. 1996, 122, 973–989. [Google Scholar] [CrossRef]

- Woo, H.S.; Yu, K.K. Development of a Guideline for the Selection of Sediment Transport Formulas; Korea Institute of Civil Engineering and Building Technology: Goyang-si, Korea, 1989. [Google Scholar]

- Ministry of Land, Infrastructure and Transport. Commentary on River Design Standards; Ministry of Land, Infrastructure and Transport: Seoul, Republic of Korea, 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).