Review on Engineering Application Status of Gob-Side Entry Retaining Technology in China

Abstract

1. Introduction

2. The Current Status of GSER Technology Development in China

| Classification by the Entry-Side Construction Method | Classification by Entry-Side Construction Materials | Technical Characteristics | Application Conditions | Development Trends |

|---|---|---|---|---|

| GSER with entry-side filling | GSER with entry-side filling of coal gangue: Gangue bags or the built gangue walls are used to fill the entry side. | Entry-side construction is the commonly used construction method for retained entry in the early days, which is characterized by simple craftsmanship, low cost, and reduced ground stacking of coal gangue. However, the support strength of manually constructed gangue filling walls in the entries is relatively low, resulting in poor control of the roof. The compactness of the filling body is low, and the labor intensity of workers is high, leading to severe air leakage in goaf areas | In thin coal seams with simple burial depth, no gas and spontaneous combustion | Combined with working face filling or roof-cutting. |

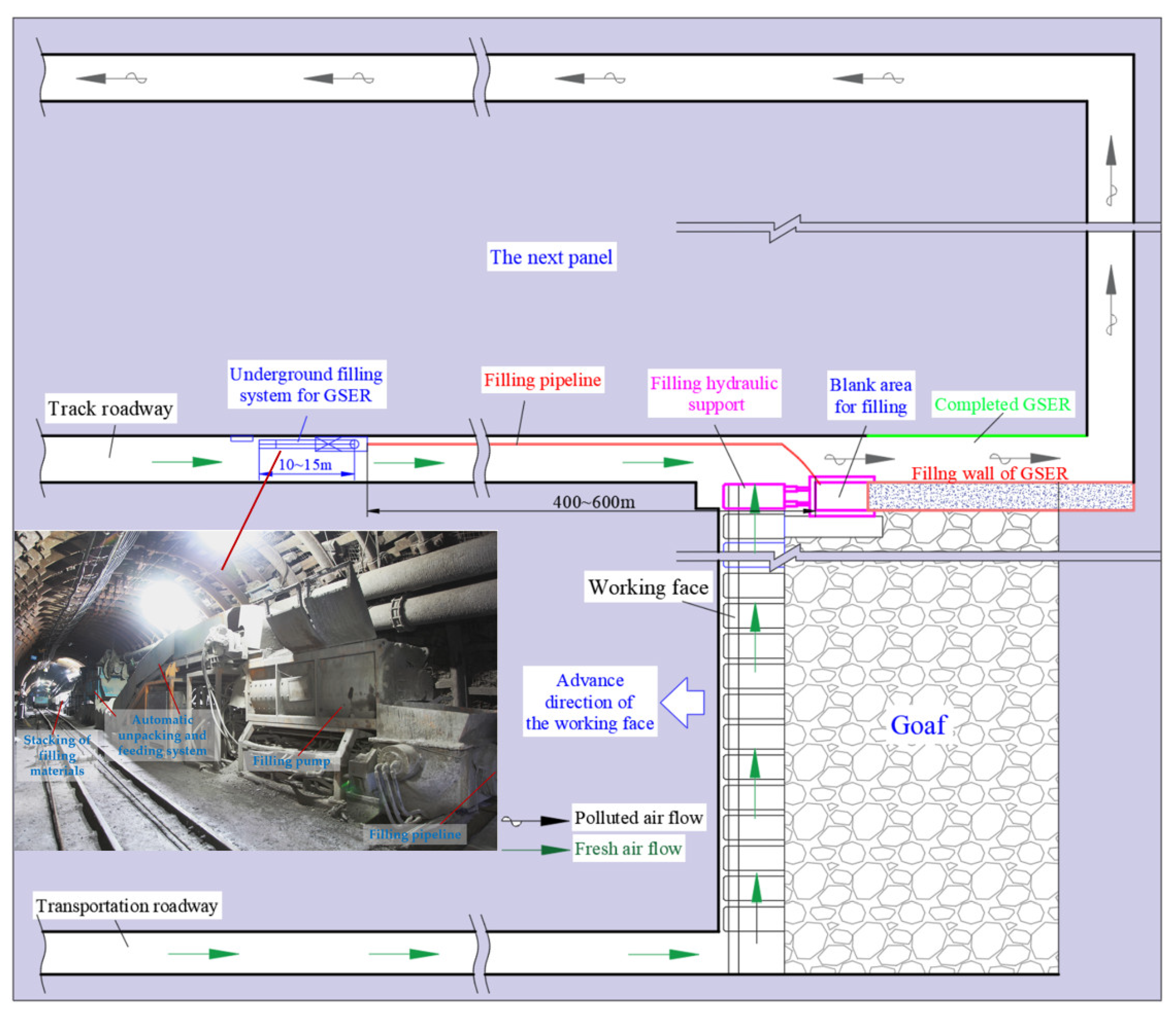

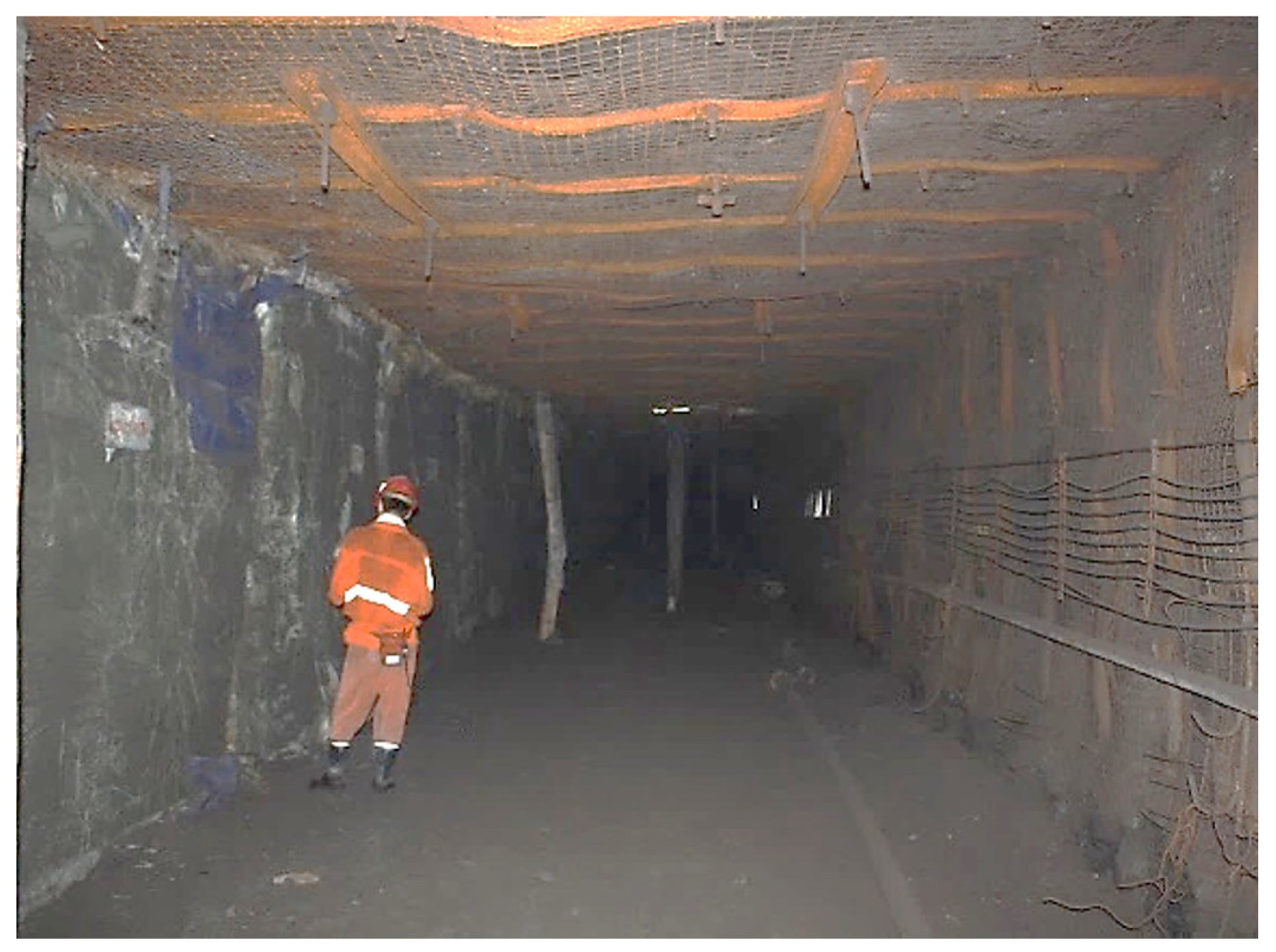

| GSER with entry-side concrete filling: It includes filling support and concrete filling, concrete block filling, steel-reinforced concrete piers and columns, and flexible formwork concrete filling. | The filling material is mainly composed of cement, sand, gravel and additives. After the dry material is evenly mixed in the ground plant at the designed ratio, it is transported to the underground mine using manual or automatic belts to complete the feeding and mixing with water and transported to the filling point by concrete pump. New materials such as high-performance concrete and flexible formwork concrete have been developed, which have the characteristics of rapid setting, early strength, fast forming, and high pumpability. They exhibit good sealing effect for goaf and are suitable for different engineering conditions and mechanical performance indicators. The highest strength of these materials after the curing time of 28 d can reach 50 MPa. | Good adaptability to mining conditions, suitable for thin, medium, and thick coal seams, especially for deep roadway engineering. The implementation effectiveness of GSER technology is shown in Figure 2. | Research and development of low-cost, large-scale, high-performance concrete materials or their combination with roof-cutting | |

| GSER with entry-side filling of high-water and ultra-high-water materials | The material is mainly composed of A and B materials mixed in a certain ratio. A and B materials are first mixed with water and stirred separately to maintain nonsolidification for a long time. After being transported to the filling site through two pipelines and mixed, they can be solidified into high-moisture solids in a short time, with a maximum volumetric moisture content of 94%. | Coal seams with shallow burial depth and low ground pressure. The on-site application effect is shown in Figure 3. | Combined with filling mining in the working face or roof-cutting | |

| GSER with entry-side paste filling | The materials are mainly prepared by proportioning raw materials such as gangue, fly ash, solid waste, and gelling agents. The filling material is prepared into a paste-like thick material and pumped through a dedicated pipeline to the goaf side of the working face to seal the frame and construct a retained wall to support the roof. However, the strength of this material is not high after final solidification. | Thin coal seams with small burial depths and low ground pressures. | Combined with the paste-filling mining of the working face, as shown in Figure 4. | |

| GSER with lateral roof-cutting | GSER with presplitting and roof-cutting self: 110 construction method and N00 construction method | The roof is automatically cut down along the entry-side wall due to the self-weight and overlying rock movement of the goaf-side roof, supplemented by blasting, hydraulic fracturing, etc., then a new entry-side wall can be formed. Consequently, supporting technologies and construction equipment such as advanced roof-cutting, constant resistance anchor cables, and cutting seam drilling vehicles are developed. However, the isolation effect of the goaf needs to be improved. | Coal seams with good geological conditions that are free of gas and spontaneous combustion. The implementation effectiveness of GSER technology is shown in Figure 5. | The sealing method of goaf, the prevention of coal spontaneous combustion, gas and other problems need to be solved. |

| GSER with entry-side wooden stacks, dense pillars and roof-cutting | The early method of GSER mainly used passive support such as wooden stacks or dense individual hydraulic supports to support the roadway roof and to some extent achieve goaf-side roof-cutting. Compared with wooden stack support and cutting strength, dense individual supports have slightly better material consumption and labor intensity, and the effect of roof-cutting on goaf isolation is poor. | Thin coal seams with good geological conditions, shallow burial depth, no gas, and no spontaneous combustion | Currently, there are few applications available. |

3. Parametric Study of GSER Application Status

3.1. Average Burial Depth of Coal Seams

3.2. Average Thickness of Coal Seams

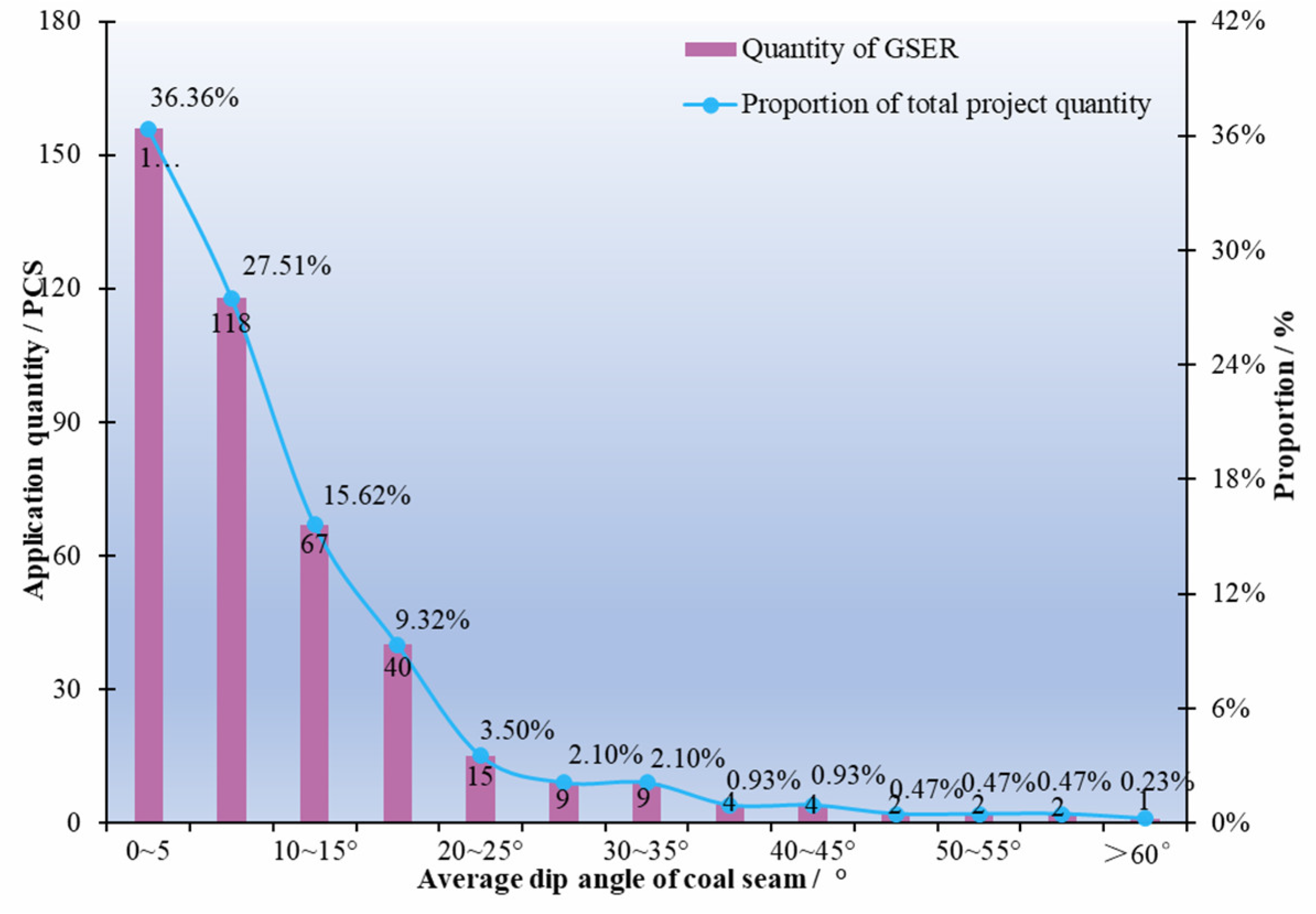

3.3. Average Dip Angle of Coal Seams

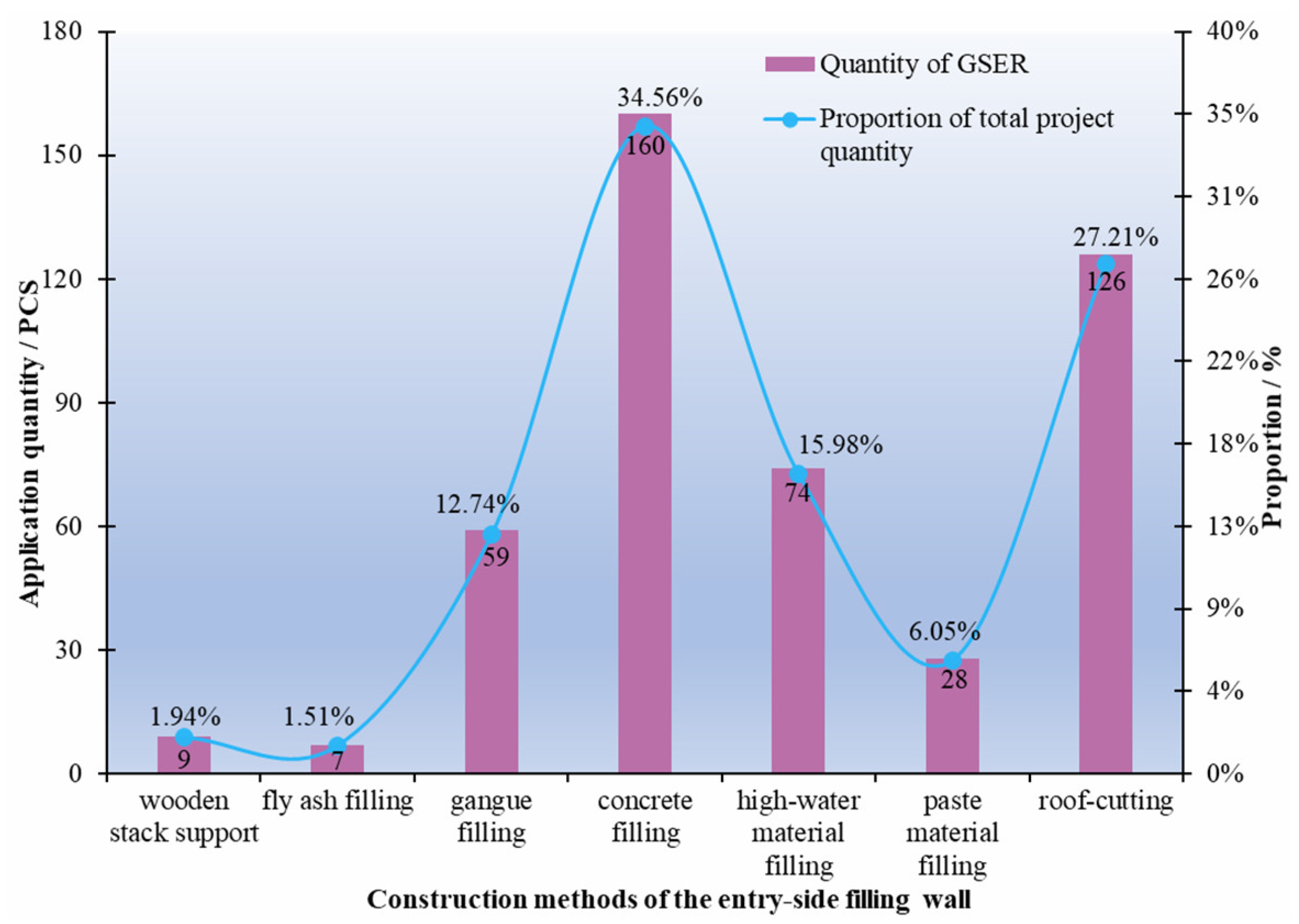

3.4. Construction Method of Entry-Side Filling Wall

3.5. Entry-Side Filling Width

3.6. Section Shape of the Retained Entry

3.7. Length of the Retained Entry

4. Discussion and Future Prospective

4.1. The Surrounding Rock Control Technology Adapted to Ground Pressure Appearance in GSER Technology

4.2. Rapid Construction Technology and High-Quality Filling Materials for GSER Technology

4.3. Intelligent GSER Equipment and Technical Systems

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.F. Pillarless Mining; China Coal Industry Publishing House: Beijing, China, 1986. [Google Scholar]

- Yuan, L.; Xue, J.H. Key Technology of Pillarless Coal and Gas Simultaneous Mining in Low Permeability Seam Group. Coal Sci. Technol. 2013, 41, 5–11. [Google Scholar]

- Yuan, L. Theory and Practice of Integrated Pillarless Coal Production and Methane Extraction in Multi-Seams of Low Permeability; China Coal Industry Publishing House: Beijing, China, 2008. [Google Scholar]

- Hua, X.Z. Development status and mi proved proposals on gob-side entry retaining support technology in China. Coal Sci. Technol. 2006, 34, 78–81. [Google Scholar]

- Yuan, S.L.; Yuan, W.H. Gob-Side Entry Retaining Mining Technology; China Coal Industry Publishing House: Beijing, China, 2013. [Google Scholar]

- Cheng, Z.H.; Qi, Q.X.; Kong, W.Y.; Ji, W.; Liu, X. Study on the reasonable layout of gob-side remained gateway of lower coal seam close to coal seam group. J. Min. Saf. Eng. 2015, 32, 453–458. [Google Scholar]

- Ding, K.; Tong, Y.D. The development and prospects of pillarless mining in China (Part 1). J. Coal Mine Des. 1984, 03, 11–16. [Google Scholar]

- Lu, S.L. Analysis of the rock behaviour and the stress in surrounding rock of the roadway in pillarless mining. J. China Coal Soc. 1981, 18, 29–37. [Google Scholar]

- Zhu, D.R.; Qian, M.G. The computer simulation of the main roof breaking of the longwall face. J. China Univ. Min. Technol. 1987, 1987, 4–12. [Google Scholar]

- Sun, H.H.; Wu, J.; Qiu, Y.X. Rules of ground pressure and strata control in gateway maintained in goaf. J. China Coal Soc. 1992, 17, 15–24. [Google Scholar]

- Sun, H.H.; Zhao, B.L. The Theory and Practice of Gob-Side Entry Retaining; China Coal Industry Publishing House: Beijing, China, 1993. [Google Scholar]

- He, T.J. The breaking place prediction of face end main roof flap top in the gob-side entry retaining. J. China Coal Soc. 2000, 25, 28–31. [Google Scholar]

- Li, H.M. Control design of roof rocks for gob-side entry. Chin. J. Rock Mech. Eng. 2000, 19, 651–654. [Google Scholar]

- Li, Y.F.; Hua, X.Z. Mechanical analysis of stability of key blocks of overlying strata for gob-side entry retaining and calculating width of roadside backfill. Rock Soil Mech. 2012, 33, 1134–1140. [Google Scholar]

- Guo, Q.Y.; Gao, M.T.; Zhou, M. Analysis on stability of entry surrounding rock of no-pillar mining. J. China Coal Soc. 2012, 37, 33–37. [Google Scholar]

- Kang, H.P.; Niu, D.L.; Zhang, Z.; Li, Z.; Fan, J.D. Deformation characteristics of surrounding rock and supporting technology of gob-side entry retaining in deep coal mine. Chin. J. Rock Mech. Eng. 2010, 29, 1977–1987. [Google Scholar]

- Zhang, N.; Han, C.L.; Kan, J.G.; Zheng, X.G. Theory and practice of surrounding rock control for pillarless gob-side entry retaining. J. China Coal Soc. 2014, 39, 1635–1641. [Google Scholar]

- Han, C.L.; Zhang, N.; Li, G.C.; Kan, J.G. Bed separation mechanism under sequential roof collapse condition in a gob-side entry retaining. J. China Univ. Min. Technol. 2012, 41, 893–899. [Google Scholar]

- Hua, X.Z.; Zhao, S.H.; Zhu, H. Research on combined support technique of gob-side entry retaining. Rock Soil Mech. 2006, 27, 2225–2228. [Google Scholar]

- Cao, S.G.; Chen, X.Z.; Yang, H.Y.; Wang, S.; Zou, D.J. Analysis on roadside control technology of gob-side entry retaining and applicable condition. Coal Sci. Technol. 2016, 44, 27–33. [Google Scholar]

- Chen, Y.; Bai, J.B.; Wang, X.Y.; Ma, S.Q.; Xu, Y.; Bi, T.F.; Yang, H.Q. Support technology research and application inside roadway of gob-side entry retaining. J. China Coal Soc. 2012, 37, 903–910. [Google Scholar]

- Bai, J.B.; Zhou, H.Q.; Hou, C.J.; Tu, X.Z.; Yue, D.Z. Development of Support Technology Beside Roadway in Goaf-Side Entry Retaining for Next Sublevel. J. China Univ. Min. Technol. 2004, 33, 183–186. [Google Scholar]

- Zhang, D.S.; Ma, L.Q.; Miao, X.X.; Dong, G.W. Factor Analysis on Deformation of Gob-side Entry Retaining with Entry-In Packing in Top-coal Caving Mining Face. J. China Univ. Min. Technol. 2006, 35, 1–6. [Google Scholar]

- Ma, L.Q.; Zhang, D.S.; Chen, T.; Fan, G.W. Study on packing body supporting resistance of entry-in packing for in-situ gob-side entry retaining in fully-mechanized top-coal caving mining face. Chin. J. Rock Mech. Eng. 2007, 26, 544–550. [Google Scholar]

- Kan, J.G.; Zhang, N.; Li, B.Y.; Si, G.Y. Analysis of supporting resistance of backfilling wall for gob-side entry retaining under typical condition. Rock Soil Mech. 2011, 32, 2778–2784. [Google Scholar]

- Xun, J.H.; Han, C.L. Strata Behavior and Control Countermeasures for the Gob-side Entry Retaining in the Condition of Large Mining Height. J. Min. Saf. Eng. 2012, 29, 466–473. [Google Scholar]

- Wang, J.; Gao, Y.F.; He, X.S.; Huang, W.P.; Gao, K.P.; Yang, L.; Feng, X.W. The analysis of roadside supporting parameters and the support technology in the concrete filled steel tubular column in goaf-side entry retaining. J. Min. Saf. Eng. 2015, 32, 943–949. [Google Scholar]

- Wu, S.K.; Zhang, J.W.; Xu, Y.L.; Tai, L.H.; Cao, Y. Research and engineering application on physical and mechanical properties of coal mine high water filling materials. J. Min. Saf. Eng. 2023, 40, 754–763. [Google Scholar]

- Zhao, C.Z.; Zhou, H.Q.; Qu, Q.D.; Guan, M.L. Preliminary test on mechanical properties of paste filling material. J. China Univ. Min. Technol. 2004, 33, 35–37. [Google Scholar]

- Bai, J.B.; Zhang, Z.Z.; Wang, X.Y.; Xu, Y.; Yan, S.; Xu, J. Stress control and surrounding rock strengthening mechanism of gob-side entry retaining with high-water content material filling and its application. Coal Sci. Technol. 2020, 50, 16–28. [Google Scholar]

- Chen, D.C.; Wang, X.Y.; Wu, S.; Zhang, T.F.; Fan, Z.Z.; Wang, X.D.; Li, M.L. Study on stability mechanism and control techniques of surrounding rock in gob-side entry retaining with flexible formwork concrete wall. J. Cent. S. Univ. 2023, 30, 2966–2982. [Google Scholar] [CrossRef]

- Xie, S.R.; Yue, S.S.; Chen, D.D.; Pan, H.; Suo, H.X.; Yang, J.H.; Qiao, S.X. Deviatoric stress evolution laws and control of surrounding rock at gob-side entry retaining in deep backfilling mining. J. China Coal Soc. 2018, 43, 1837–1846. [Google Scholar]

- Zhao, Y.M.; Zhang, N.; Zheng, X.G. Structural optimization of overlying strata for gob-side entry retaining in 1000 m deep mine with direct thick and hard roof. J. Min. Saf. Eng. 2015, 32, 714–720. [Google Scholar]

- Wang, W.J.; Fan, L.; Ma, Y.J.; Yuan, C. Comparison and cause analysis of roadway failure characteristics between gob-side entry retaining with roadway advance exaction and general gob-side entry retained method. J. Min. Saf. Eng. 2023, 40, 1129–1138. [Google Scholar]

- Jia, H.S.; Wang, L.; Peng, B.; Wang, G.Y.; Zhang, D.S.; Zhuo, J.; Wang, Y.B. Mechanism and application of classification “roof control-pressure relief” of gob-side entry retained with weakly caking compound roof. J. China Univ. Min. Technol. 2023, 52, 1191–1201. [Google Scholar]

- Wang, Y.J.; He, M.C.; Zhang, J.; Wang, Q.; Yang, J.; Hou, S.L. Roof Control Mechanism and Design Methods of Gob-Side Entry Retained by N00 Coal Mining Method. Rock Mech. Rock Eng. 2024, 57, 621–638. [Google Scholar] [CrossRef]

- Sun, X.M.; Liu, X.; Liang, G.F.; Wang, D.; Jiang, Y.H. Key parameters of gob-side entry retaining formed by roof cut and pressure releasing in thin coal seams. Chin. J. Rock Mech. Eng. 2014, 33, 1449–1455. [Google Scholar]

- He, M.C.; Gao, Y.B.; Gai, Q.K.; Yang, J. Mechanical principle and mining methods of automagical entry formation without coal pillars. Coal Sci. Technol. 2023, 51, 19–30. [Google Scholar]

- Wang, Y.J.; He, M.C.; Wang, Q.; Yang, J.; Wang, J.W.; Liu, H.; Chen, F. Design of equipment system and surrounding rock control for N00 mining method without coal pillar left and roadway excavation. J. China Coal Soc. 2022, 47, 4011–4022. [Google Scholar]

- Wang, Q.; He, M.C.; Yang, J.; Gao, H.K.; Jiang, B.; Yu, H.C. Study of a no-pillar mining technique with automatically formed gob-side entry retaining for longwall mining in coal mines. Int. J. Rock Mech. Min. Sci. 2018, 110, 1–8. [Google Scholar] [CrossRef]

- Huang, Y.L.; Zhang, J.X.; Zhang, Q.; Zan, D.F. Technology of gob-side entry retaining on its original position in fully-mechanized coalface with solid material backfilling. J. China Coal Soc. 2011, 36, 1624–1628. [Google Scholar]

- Zhang, J.X.; Jiang, H.Q.; Miao, X.X.; Zhou, N.; Zan, D.F. The rational width of the support body of gob-side entry in fully mechanized backfill mining. J. Min. Saf. Eng. 2013, 30, 159–164. [Google Scholar]

- Gong, P.; Ma, Z.G.; He, Z.X.; Xu, M.; Chen, T. Structural evolution mechanism of surrounding rock of gob side entry retaining in backfilling mining face. J. Min. Saf. Eng. 2023, 40, 764–785. [Google Scholar]

- Xu, Y.; Chen, J.; Bai, J.B. Control of floor heaves with steel pile in gob-side entry retaining. Int. J. Min. Sci. Technol. 2016, 26, 527–534. [Google Scholar] [CrossRef]

- Ivan, S.; Svitlana, S.; Krzysztof, S.; Oleksandr, I.; Krzysztof, Z.; Anna, Z. Floor Heave Control in Gob-Side Entry Retaining by Pillarless Coal Mining with Anti-Shear Pile Technology. App. Sci. 2024, 14, 4992. [Google Scholar]

- Li, Z.X.; Zhang, Y.D.; Ma, Q.; Zheng, Y.; Song, G.Y.; Yan, W.Z.; Zhang, Y.; Hu, L. The Floor Heave Mechanism and Control Technology of Gob-Side Entry Retaining of Soft Rock Floor. Sustainability 2023, 15, 6074. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Dai, J.; Chang, Q. Review on Engineering Application Status of Gob-Side Entry Retaining Technology in China. Appl. Sci. 2024, 14, 8888. https://doi.org/10.3390/app14198888

Zhao Y, Dai J, Chang Q. Review on Engineering Application Status of Gob-Side Entry Retaining Technology in China. Applied Sciences. 2024; 14(19):8888. https://doi.org/10.3390/app14198888

Chicago/Turabian StyleZhao, Yiming, Jingchen Dai, and Qingliang Chang. 2024. "Review on Engineering Application Status of Gob-Side Entry Retaining Technology in China" Applied Sciences 14, no. 19: 8888. https://doi.org/10.3390/app14198888

APA StyleZhao, Y., Dai, J., & Chang, Q. (2024). Review on Engineering Application Status of Gob-Side Entry Retaining Technology in China. Applied Sciences, 14(19), 8888. https://doi.org/10.3390/app14198888