Abstract

Different coal failure impact types exhibit different damage statuses and failure modes, resulting in distinct signal characteristics of infrared radiation (IR) and acoustic emission (AE). This paper combines IR and AE monitoring methods to innovatively establish coal damage and failure precursor warning models and obtains the IR and AE precursor characteristics for different coal failure impact types. This research shows that there is a good correspondence between IR and AE timing and spatial distribution of different coal impact types. As the impact tendency increases, the intensity of IR and AE signals increases with coal failure, and the AE positioning points and IR high-temperature areas tend to concentrate. The coal body gradually changes from tensile failure to shear failure. The shear cracks in the failure stage of coal with no, weak, and strong impact are 39.9%, 50.9%, and 53.7%, respectively. The IR and AE instability precursor point of coal with no, weak, and strong impact occurred at 55.2%, 66.3%, and 93.4% of coal failure, respectively. After the IR and AE combined instability precursor point, the dissipated energy and combined damage variable increase rapidly, and the coal body will undergo instability and failure. The research results provide a theoretical basis for comprehensive monitoring of coal body failure and rock burst.

1. Introduction

Coal mine rock bursts are extremely destructive, often accompanied by phenomena such as loud noises, coal and rock mass ejection, and shock waves. Rock burst disasters seriously restrict the efficient and safe production of coal mines. Impact tendency refers to the natural property of whether coal rock mass can experience rock bursts. The impact tendency of coal is an important discriminant indicator for evaluating rock burst risk [1,2]. The physical properties of different coal impact types are greatly different, and the signals released during failure, such as thermal, acoustic, seismic, magnetic, and electrical signals, also exhibit significant differences [3,4,5]. Infrared radiation (IR) is the thermal effect released during the process of crack propagation and friction in coal. Changes in infrared radiation temperature (IRT) can characterize the extent of failure and the form of crack propagation in coal [6,7,8]. The acoustic emission (AE) is the elastic wave released during the coal failure process. The time series signal, waveform spectrum characteristics, and spatial location of the AE are related to the internal damage and fracture evolution of coal. IR and AE techniques have been widely used for monitoring coal deformation and failure. In-depth research on the IR and AE characteristics of different coal impact types reveals the relationship between IR, AE, and coal mass damage and failure precursors is of great significance for the IR and AE comprehensive monitoring of rock bursts.

The IR method for coal rock offers the advantages of intuitive images, real-time monitoring, and non-contact, and it has been successfully applied to monitor coal mass damage and failure [9,10]. The IR of coal rock is mainly caused by the temperature changes resulting from crack propagation effect, friction effect, and thermoelastic effect [11,12,13,14]. In general, coal rock shear failure and internal friction effects typically result in an increase in IRT [15], while tensile failure generally leads to a decrease in IRT [16]. Currently, extensive research has been conducted on the IR characteristics of coal rock failure, the influence of fracture modes on IR, IR signal denoising, the quantitative relationship between IR and coal rock damage, and IRT and area precursor indicators [17,18,19,20], and certain results have been achieved. Tang et al. [21] employed IR experiments and particle flow PFC2D simulation methods to investigate the influence of the degree of damage on the IRT variation in the coal. Before the coal instability, the IRT of the coal with greater strength exhibited a sudden increase, whereas the IRT of the coal with less strength initially decreased and then increased. Khan et al. [22] studied the IRT variation in sandstone failure under both uniaxial and shear loading modes and found that the AIRT increased during shear failure and the AIRT decreased during tensile failure. Ma et al. [23] established a quantitative relationship between coal rock damage microelement failure and IR parameters and quantitatively characterized coal rock damage using IR parameters. Impact-prone coal fails more rapidly than non-impact coal, the precursor characteristics are more inconspicuous, and the prediction of rock bursts is more difficult [24,25,26]. Therefore, the damage status and instability IR precursor characteristics of different coal impact types need to be revealed.

The AE signal, which contains abundant information on coal failure [27,28,29], is widely used in monitoring coal damage and rock bursts. The AE time series and frequency domain distribution correspond to the damage state and fracture scale of the coal rock [30,31]. Before the failure of the coal, the AE time series signals (count, energy, amplitude) rapidly increases and the main frequency rapidly decreases. The spatial location of the AE corresponds to the damage and fracture location of the coal mass. In the concentrated area of the coal rock fracture, the AE positioning points are dense and have high energy. Recently, some scholars have used the RA-AF characteristics of the AE to predict the fracture modes of coal and rock at different stages [32,33,34]. Tensile failure AE signal duration and rise time are short, AF value is high, and RA value is low, while the shear crack AE signal duration and rise time are long [35]. In coal and rock disaster monitoring, the combined IR and AE method is helpful to accurately and effectively analyze the damage and failure state of the coal mass. Liu et al. [36] used the impact number of the AE and IR change rate to classify the stages of sandstone crack evolution, thereby identifying high- and low-damage zones in the sandstone. Zhang, Chen et al. [37,38] found that the AE appeared later than the IR signals. Combining AE and IR monitoring can avoid the lag of the AE and the spatial limitations of IR. Currently, the comprehensive monitoring of IR and AE mainly focuses on the same type of coal, and there is little research on the relationship between the IR, AE, and damage status and instability precursors of different impact types of coal bodies.

This paper intends to establish a coupling monitoring method between the IR and AE, fully utilizing their respective advantages, namely non-contact and contact monitoring, surface monitoring, and point monitoring methods. The experiment selects three typical different impact types of coal bodies, synchronously monitors and analyzes the spatiotemporal distribution of the IR and AE during the different impact types of coal body failure, and reveals the relationship between the IR, AE, mechanical properties, and failure modes of the different impact types of coal. On this basis, we establish a comprehensive IR and AE instability precursor index and damage model of the coal body and obtain the instability precursor of different coal impact types. Finally, based on the law of energy evolution, an analysis is conducted on the damage and instability precursor mechanisms of the different coal impact types. The research results will further reveal the evolution law of coal instability and failure of different impact types, providing a theoretical basis for the comprehensive monitoring of rock bursts using IR and AE.

2. Experimental Methods

2.1. Specimen Preparation

The coal specimens used in the experiment were taken from no, weak, and strong impact coal seams in typical mining areas of China. The selection and preparation of coal samples for the experiment refer to the international laboratory test methods of rock mechanics and coal impact inclination (GT/T 25217, 2e2010) [39]. The large coal mass taken out was sealed with plastic wrap and transported to the laboratory for processing into cube specimens. The specimen size was 50 × 50 × 100 mm, and the upper and lower ends of the specimen were flat with an error of less than ±0.02 mm. There are more than 10 coal specimens for each impact type. The mechanical and impact index basic parameters of the three impact types of coal specimens are shown in Table 1. The three impact types of coal specimens prepared have significant differences in mechanical and impact propensity indicators, meeting the requirements of the IR and AE experiments on different coal impact types.

Table 1.

Impact index parameters of different coal impact types.

2.2. Experimental Apparatus

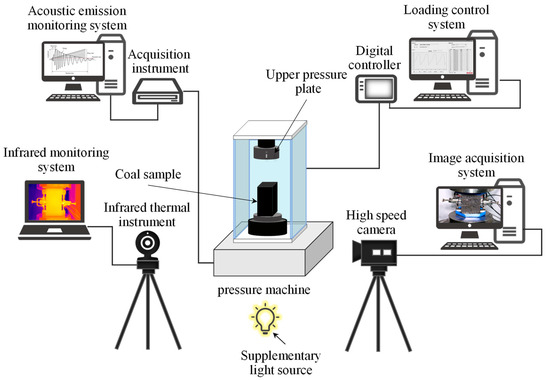

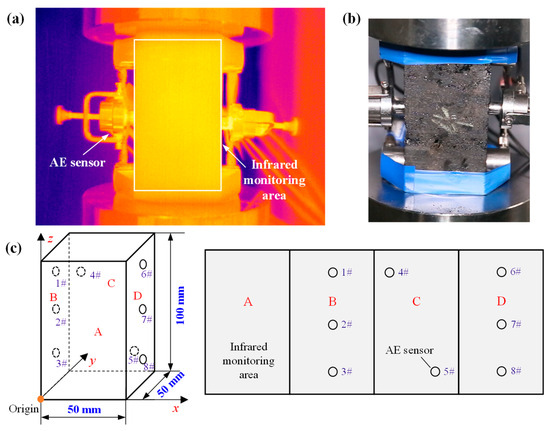

The IR and AE test system for coal failure is shown in Figure 1, which mainly includes three parts: loading control, IR monitoring and AE monitoring. The IR monitoring area and the layout of the AE sensors is shown in Figure 2.

Figure 1.

Experimental schematic diagram.

Figure 2.

Infrared monitoring area and layout of AE sensors: (a) infrared monitoring area; (b) layout of AE sensors; (c) AE sensor positioning coordinates.

- (1)

- The loading system adopts a micro-computer-controlled pressure machine. The displacement is 0.3 μm, the maximum test force is 600 kN, the sampling frequency is 1 kHz. It can collect and record mechanical and deformation parameters such as load and displacement during coal failure in real time.

- (2)

- The IR monitoring instrument model is Optris PI 450 (Optris, Berlin, Germany), with an optical resolution of 382 × 288. It can capture up to 80 Hz thermal images per second and accurately measure three temperature ranges: −20–100 °C, 0–250 °C, and 120–800 °C, with a temperature sensitivity of 0.04 K, and can accurately analyze the IRT change during coal body failure.

- (3)

- The AE monitoring adopts an 8-channel full waveform soft DS5 series acquisition instrument(Ruandao, Beijing, China), with a maximum sampling frequency of 10 MHz and an input signal voltage range of ±10 V. The response frequency of the AE sensor is 50–400 kHz, and the amplification factors of the preamplifier are adjustable at 20, 40, and 60 dB.

2.3. Testing Procedure

Put the different types of coal specimens into the laboratory one day in advance to reduce the error between the specimens and the ambient temperature. Connect and debug various monitoring systems such as the press machines, infrared thermal imagers, AE instrument, and high-speed camera. Adjust the position of the infrared thermal imager to be approximately 0.5 m away from the specimen with the lens facing directly towards the coal specimen observation surface to achieve optimal resolution. The specimen outline and observation surface appear clearly in the infrared lens, and the sampling frequency is set to 20 Hz. The AE adopts full waveform continuous acquisition, the sampling frequency is set to 3 MHz, and the magnification is set to 40 dB. To accurately determine the damage and failure location of the coal body, a total of 8 RS-2A piezoelectric sensors(Ruandao, Beijing, China) are used. Before the experiment, a lead-breaking experiment was used to simulate the AE source signal, and the coupling degree of each AE sensor with the sample and the signal receiving performance were judged. The sensor layout is shown in Figure 2b,c. The specific coordinates of the AE sensor are shown in Table 2. The pressure-testing machine adopts a displacement control mode of 5 μm/s. To ensure sufficient contact between the press plate and the specimen, a preload force of 500 N is applied to the specimen. All systems are ready and synchronized to start experimental data collection. After the experiment is completed, take photos to record the damaged coal specimens.

Table 2.

Coordinates of AE sensors.

3. Results and Analysis

3.1. IR and AE Time Series Distribution of Different Coal Impact Types

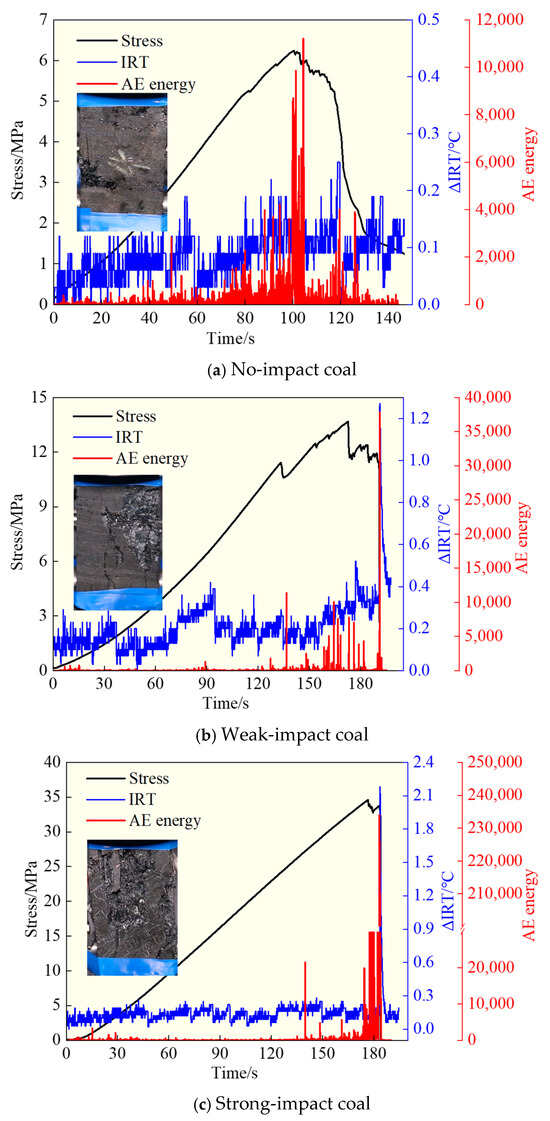

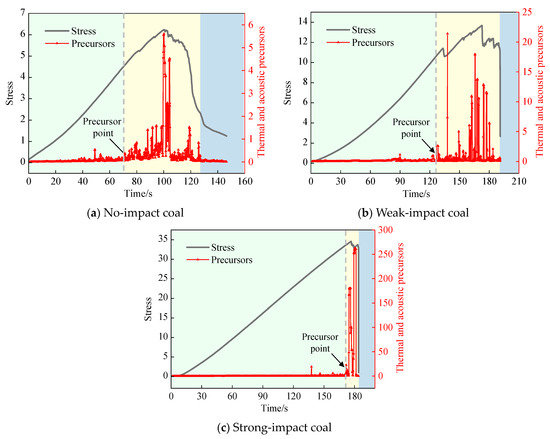

The average and maximum infrared radiation temperature (AIRT and MIRT) and AE count and energy are commonly used for the analysis of IR and AE time series signals. This paper uses the AE energy and MIRT variation as examples to obtain the time series distribution of IR and AE for three coal impact types: no, weak, and strong, as shown in Figure 3.

Figure 3.

Time series characteristics of IR and AE of different coal impact types.

As the load increases, the particles inside the no-impact coal undergo sliding and friction, and the IRT and AE energy slowly increase synchronously (Figure 3a). Near the stress peak, both IRT and AE energy reach their maximum values. After reaching the peak stress, the coal body continues to experience compression and friction, accompanied by fluctuations in IRT and AE energy. Weak-impact coal exhibits fluctuating changes in AE energy before coal body failure. At the moment of stress drop, the AE energy suddenly increases, corresponding to an increase in IRT fluctuations (Figure 3b). Strong-impact coal exhibits fewer AE signals and no significant changes in IRT during the early stages of loading. A small amount of stress drop occurs before the main failure, which generates a large amount of AE energy and increasing IRT fluctuations (Figure 3c).

There is a good correlation between the IRT and AE energy of the different impact types of coal. The IRT increases slowly when AE energy occurs intensively and increases rapidly when AE energy increases abruptly. At the moment of main failure, the IRT and AE signals reach their maximum values instantaneously. With the increase in coal impact tendency, the intensity of the IR and AE signals gradually increases. The MIRT variation in strong-impact coal is 1.71 and 8.72 times that of weak-impact coal and no-impact coal, respectively. The maximum AE energy of strong-impact coal is 6.18 and 20.87 times that of weak-impact coal and no-impact coal, respectively.

3.2. IR and AE Spatial Distribution of Different Coal Impact Types

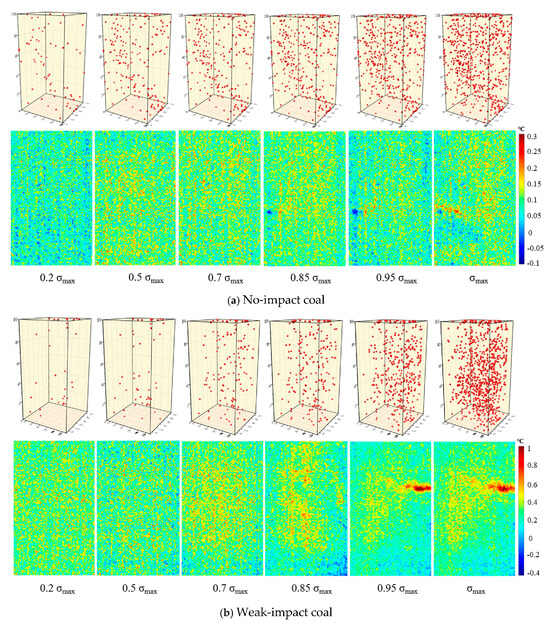

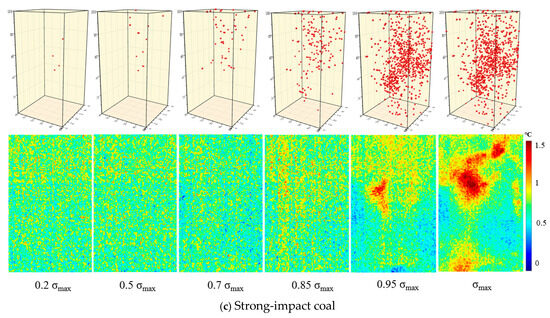

The spatial distribution of the AE locations and the infrared thermal image of coal failure are shown in Figure 4. The infrared thermal image is the difference between real-time IRT data and initial first-second data.

Figure 4.

Spatial distribution characteristics of IR and AE of different coal impact types.

As shown in Figure 4a, at the initial loading stage of 0.2σmax for no-impact coal, the AE localization points are relatively scattered, and the IRT distribution is uniform. As the stress increases, at 0.5σmax–0.85σmax, the IRT rises, and the AE localization points gradually increase, but the distribution is still scattered. At 0.95 σmax and σmax, the AE localization points continue to increase, and the IRT of the coal body further rises, but there is no high-temperature concentration area. As shown in Figure 4b, weak-impact coal exhibits a small number of AE localization points at 0.2σmax–0.5σmax, and the IRT distribution is uniform. As the stress increases, the AE localization points and IRT gradually increase. When reaching 0.95σmax, the AE localization points become dense and the infrared high-temperature area becomes concentrated. At σmax, the coal body becomes unstable and fails, resulting in a dense appearance of numerous AE localization points. As shown in Figure 4c, strong-impact coal only produces a small number of AE localization points before 0.7σmax, and the IRT distribution is uniform without significant changes. After 0.85σmax, the number of AE localization points and IRT rapidly increase, and the high-temperature area becomes concentrated. At σmax, the strong-impact coal undergoes impact failure, with a large number of AE localization points and infrared high-temperature concentration areas appearing in the middle of the coal body.

Comparing different types of coal impact, it can be seen that AE location and infrared thermal image evolution have good consistency. The infrared high-temperature concentration area, the dense area of AE positioning points, and the location of the coal damage correspond to each other (Figure 4b,c), but there are significant differences among the different types of coal impact. The distribution of the AE localization points of the no-impact coal is scattered, and the infrared thermal image has no high-temperature concentration area. The weak-impact coal AE localization points and infrared high-temperature areas gradually become concentrated. The strong-impact coal AE localization points mainly occur before the coal failure, and the AE localization points and infrared high-temperature areas are most concentrated.

3.3. Damage Status and Failure Mode of Different Coal Impact Types

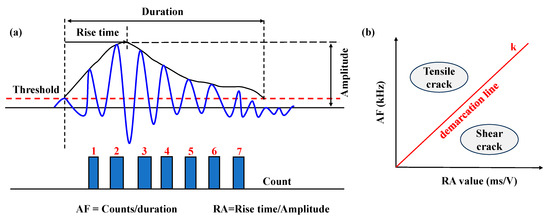

The RA-AF distribution of the AE can reflect the damage status and failure mode of the coal rock [40,41]. The tensile failure AE signal duration and rise time are short, AF value is high, RA value is low, while the shear crack AE signal duration and rise time are long. Shear failure, on the contrary, has a long duration and rise time of the AE signal, high RA value, and low AF value [42,43,44]. A typical coal rock AE waveform information and RA-AF crack classification are shown in Figure 5. Among them, AF is the ratio of AE counts to duration (Equation (1)), and RA is the ratio of AE rise time to amplitude (Equation (2)).

Figure 5.

Distribution characteristics of AF-RA about different coal impact types: (a) AE waveform information; (b) RA-AF crack classification.

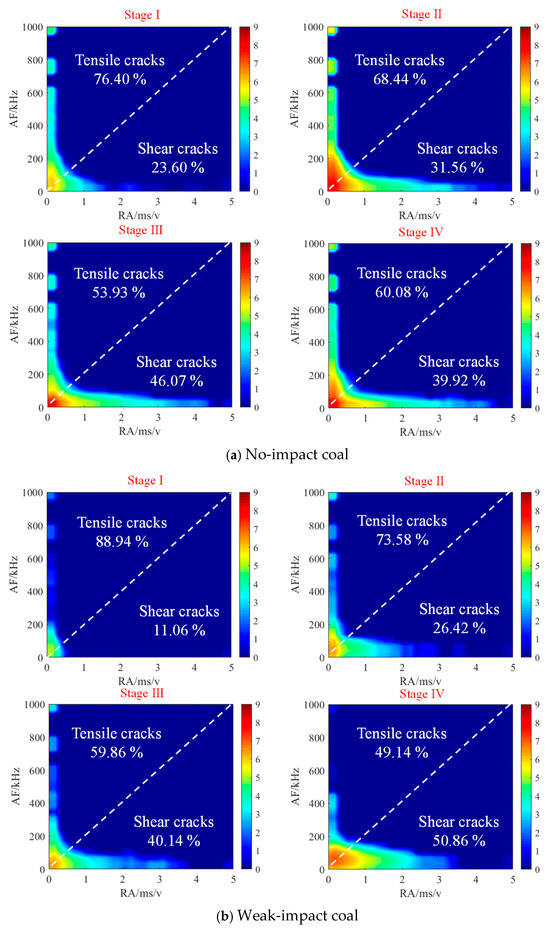

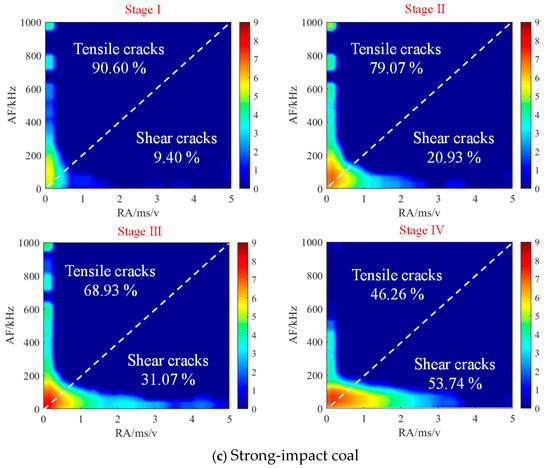

Relevant scholars have studied the slope of the RA-AF boundary line k and found that the value of k is generally 100–500 times that of the coal and rock materials [45,46,47]. This paper takes k = 200 as the dividing line to analyze the failure modes about different coal impact types. Cracks above k = 200 are classified as tensile cracks, while those below are classified as shear cracks. For convenience of analysis, based on the stress variation law of coal, the process of coal failure under load is divided into four stages: (I) compaction stage, (II) elastic stage, (III) plastic stage, and(IV) failure stage. The damage status and failure mode of the different coal impact types are shown in Figure 6, and the proportion of tensile and shear cracks is shown in Table 3.

Figure 6.

Distribution characteristics of AF-RA of different coal impact types under different loading stages.

Table 3.

Proportion of tensile and shear cracks at different stages.

From Figure 6 and Table 3, it can be observed that during the coal body failure process, there are more AE signals associated with tensile failure and fewer signals related to shear failure. For the same coal impact type, as the degree of damage increases, the proportion of the tensile failure AE signals gradually decreases, while the proportion of the shear failure AE signals gradually increases. For example, the tensile cracks in coal with no, weak, and strong impact decreased from 76.4%, 88.9%, and 90.6% in stage I to 60.1%, 49.1%, and 46.3% in stage IV, respectively. For the different coal impact types, as the impact tendency increases, the proportion of the tensile failure AE signals gradually increases in stages I, II, and III of loading, but the magnitude of the increase gradually decreases. In failure stage IV, as the impact tendency increases, the AE signal of the tensile failure gradually decreases, and the proportion of the AE signal of the shear failure gradually increases. For example, the shear cracks in the failure stage IV coal with no, weak, and strong impact are 39.9%, 50.9%, and 53.7%, respectively. As the impact tendency increases, the coal structure becomes dense, and the tensile failure gradually changes to shear failure. When shear failure occurs, the coal body experiences severe fracture and friction, and the IRT and AE signals rapidly increase. The shear failure location corresponds to the dense area of the AE positioning points and the high-temperature concentration area of the infrared thermal imaging. The stronger the impact tendency of coal, the denser the AE positioning points and the larger the range and intensity of the infrared high-temperature area.

3.4. IR and AE Combined Instability Precursors of Different Coal Impact Types

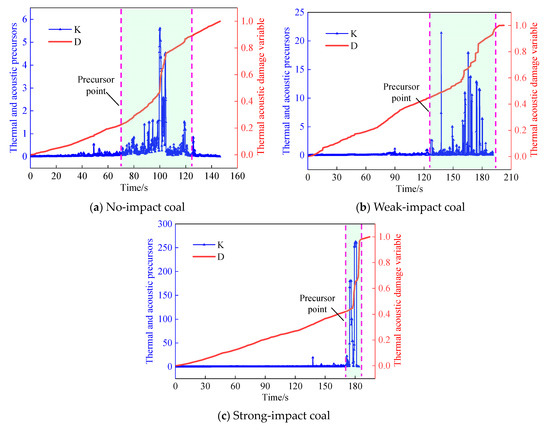

The damage and failure of coal under load generate IR and AE signals. The IR and AE signals have sensitivity and are precursors to stress and internal damage changes in the coal rock mass [37,38]. This paper combines the advantages of IR and AE signals to establish a combined IR and AE sensitivity index, K, for different coal impact types.

The formula is as follows:

where is the variation coefficient of IRT, is the variation coefficient of AE signal, is the stress at moment i, and is the peak stress.

Among them, the formula for the variation coefficient of IRT is:

The formula for the variation coefficient of AE signal is:

Among them, and are as follows:

where is the IRT value at time i, is the standard deviation of IRT, is the AE energy at time i, and is the standard deviation of AE energy.

The combined index K value represents the degree of mutation of the IRT and AE signals during the coal body failure. The larger the K value, the greater the fluctuation and sensitivity of the IRT and AE signals. According to Formula (3), the IRT and AE sensitive combined index K for different coal impact types is calculated as shown in Figure 7. When the combined index K appears dense and increases rapidly, the coal body will be unstable and failure. In this paper, the moment P is defined as the precursor time of the coal body instability failure (Figure 7). From the variation in the combined index K, it can be seen that there are significant differences in the peak value and instability precursor time of the combined index K for different coal impact types. The peak values of the combined index K for no-, weak-, and strong-impact coal are 5.63, 21.54, and 264.93, respectively, indicating that strong-impact coal has the strongest IRT and AE sensitivity, followed by weak-impact coal, and no-impact coal has the weakest sensitivity. The IRT and AE sensitive instability precursor time of no-, weak-, and strong-impact coal is 71.23 s, 126.50 s, and 171.74 s, respectively, for 55.2%, 66.3%, and 93.4% of the coal body instability failure. Therefore, as the impact tendency increases, the IRT and AE sensitivity of the coal gradually increases, but the occurrence time of the instability precursors becomes later and later.

Figure 7.

IR and AE combined instability precursors of different coal impact types.

4. Discussion

4.1. IR and AE Combined Damage Evolution Analysis of Different Coal Impact Types

Under external stress, the microcracks and pores within the coal body undergo closure, displacement, and connectivity. The failure process of coal under load will generate IR and AE signals, which are directly related to the evolution of internal defects in the coal [48,49]. This paper combines the IR and AE signals to describe the damage characteristics of the coal body.

According to the damage variable D introduced by Kachanov et al. [50], D is defined as:

where is the damaged area, is the initial non-destructive area.

According to the principle of strain equivalence, the relationship between strain , stress , and effective stress is obtained as follows:

Based on material mechanics, the damage variable D can be obtained as:

where is stress, is strain, and E is the elastic modulus.

According to the theory of damage mechanics, the strength of coal specimens follows a Weibull distribution [51], and its probability density function is:

where is the deformation amount (strain) of the specimen; m, α is a constant related to the shape, scale, and distribution of internal defects of the specimen; is a measure of the micro element damage rate of the specimen during the loading process.

The relationship between the damage parameter D and the probability density function of elemental failure is [52]:

During uniaxial compression, coal undergoes strain due to the action of force. When the strain increases from 0 to ε, the damage variable D can be obtained by integrating Equation (12) as follows:

The damage caused by micro rupture during the deformation process of coal under load has a consistent statistical distribution pattern with the accumulation of IRT and AE energy.

The IRT and AE energy accumulation of the specimen at strain ε are:

where and represent the accumulated IRT and AE energy at the time of sample instability and failure, respectively.

By integrating Equations (14) and (15):

By combining Equation (13) with Equations (16) and (17), the coal damage variable based on the IR and AE signals can be obtained:

Based on previous research on damage coupling [53,54], and by combining IR and AE damage variables, the combined IR and AE coal body damage model is obtained as follows:

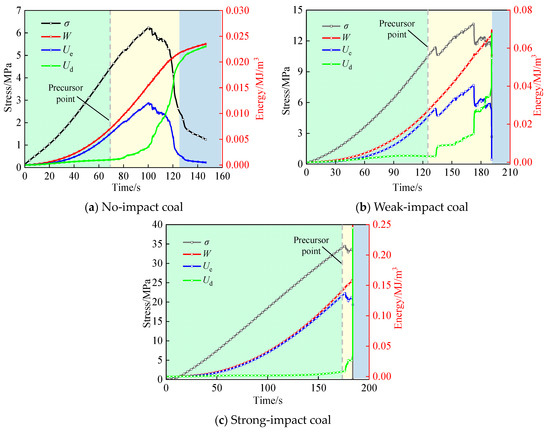

The coal body damage changes based on the IR and AE being calculated using Equation (20), as shown in Figure 8.

Figure 8.

Damage curves of different coal impact types based on thermoacoustic analysis.

As the loading increases, the combined damage variable DIA of IR and AE gradually increases. After the combined instability precursor point, that is, when the sensitive combined index K of IRT and AE appears dense, the combined damage variable DIA gradually increases rapidly. This indicates that a large number of microcracks are developing and expanding in the coal body, and the coal body damage is increasing rapidly. After the main failure occurs, the coal body loses its load-bearing capacity, and the damage variable DIA approaches the critical value of 1. Comparing different types of impact coal, as the impact tendency increases, the combined damage variable DIA accelerates its growth rate, and the acceleration stage gradually approaches the moment of coal body failure.

The IR method has the advantage of non-contact, which can observe the changes in the IRT field on the surface of the coal in real time and intuitively. The AE method is a type of point monitoring that requires coupling contact with coal rock masses. By arranging the AE sensors in different positions of the coal rock and using the AE signals to time the difference, the damaged and failure positions of the coal are located. This paper establishes the IR and AE combined damage model, fully utilizing the respective advantages of the IR and AE monitoring methods, namely non-contact and contact monitoring, surface monitoring, and point monitoring methods, which can effectively extract thermal and acoustic physical information from coal failure damage, reduce the testing error of a single monitoring method, and better establish the direct relationship between thermal, acoustic and coal failure damage. However, the coupling model for coal damage established in this paper requires synchronous input of the IR and AE monitoring data, that is, real-time synchronous IR and AE monitoring, which puts forward higher requirements for the difficulty of monitoring.

4.2. Analysis of Damage and Failure Precursor Mechanism of Different Coal Impact Types Based on Energy Evolution

The damage and failure of coal bodies are accompanied by the release and transformation of energy. It is of great significance to reveal the damage with the IR and AE mechanisms of different coal impact types from the perspective of energy. Based on the quantification of energy conservation, the relationship between energy and the previous research results [55,56,57,58] and the relationship between the total energy, elastic energy, and dissipated energy of the coal damage and failure process is established, as shown in Equations (21)–(24).

where is the total energy, is the elastic energy, is the dissipated energy, and are the principal stress and strain, and and are the stress and strain at time i.

The energy evolution during the loading process of the different coal impact types is calculated using Equations (22)–(24), as shown in Figure 9. No-impact coal exhibits a high degree of primary pore and fracture development, strong connectivity, and soft texture, with certain plastic characteristics [59,60]. During the loading process, the particles and cracks in the coal body undergo friction with each other, the internal energy is slowly released in the form of dissipated energy, and the IRT and AE signals gradually increase (Figure 9a). The weak-impact coal has a lower degree of development in its primary fissure structure, weaker connectivity, and a denser structure. The skeleton has a certain load-bearing capacity and exhibits overall brittle characteristics [59,60]. In the early stages of coal loading, the external input energy mainly accumulates in the form of elastic energy, and the released dissipated energy and generated IRT and AE signals are relatively lower. Due to the brittleness of coal, when the stress drop occurs, cracks in the coal body rapidly develop and expand, and the dissipated energy increases rapidly, corresponding to a sudden increase in IRT and AE signals (Figure 9b). The pore and fracture development degree of strong impact coal is very low, with a dense and hard structure and strong load-bearing capacity of the skeleton [61]. In the early stages of coal loading, the externally input energy is almost entirely stored in the form of elastic properties inside the coal body, and the dissipated energy hardly increases. At the moment of coal failure, the accumulated elastic energy is rapidly released and converted into dissipated energy, resulting in a rapid increase in IRT and AE signals (Figure 9c).

Figure 9.

Energy evolution characteristics about different coal impact types.

Combining the IR and AE combined instability precursor index (Figure 7) and the coal energy evolution law (Figure 9), it can be seen that before the IRT and AE combined instability precursor point, the energy inside the coal is mainly accumulated in the form of elastic energy, with less dissipated energy being released. After the IRT and AE combined instability precursor point, the dissipated energy increases rapidly. At this time, the internal damage of the coal body intensifies, and instability failure is about to occur. As the impact tendency increases, the development of primary pores in the coal decreases and the structure becomes denser. During the early and middle stages of coal loading, the damage degree is minimal, and internal energy accumulates. Near the moment of failure, the coal body gradually transitions from tensile failure to shear failure (Figure 6). The stronger the impact tendency, the faster and more severe the shear failure, the more dissipated the energy released by the coal body failure, the stronger the IR and AE signals generated, and the closer the precursor point of instability is to the moment of coal body instability failure.

At present, there are methods for monitoring rock bursts, such as microseismic, electromagnetic, IR and AE approaches. The microseismic monitoring method is usually used for dynamic monitoring in large areas, and it is not sensitive enough to fractures with low intensity. The electromagnetic radiation monitoring method has obvious non-contact advantages, but electromagnetic radiation is easily interfered with by electrical equipment and cable circuits. Coal damage and failure generate IR while also releasing elastic waves, which generate AE signals. As a non-contact method, IR does not require direct contact with the coal body, but the IR mainly monitors the changes in the IRT on the surface of the coal body [14,62]. AE, as a contact monitoring method, can monitor the internal damage changes of the coal and rock mass, but it requires a large number of sensors to be deployed on the coal and rock mass, which often has problems such as heavy workload, easy interference from mechanical vibration, and the complex propagation path of elastic waves in the rock mass [63,64]. This paper combines IR and AE monitoring, integrates the IR data of the coal surface temperature field with the AE data of internal coal damage, and establishes the IR and AE sensitive combined index K and combined damage model. It fully utilizes the advantages of IR and AE signals, which can significantly reflect the damage and failure information of coal bodies and improve the accuracy of monitoring and early warning for different impact types coal.

5. Conclusions

In this paper, the IR and AE temporal and spatial distributions of different coal impact types were analyzed, the relationship between IR, AE, and coal damage and fracture mode was revealed, and the combined IR and AE instability precursor and damage model for different coal impact types were established. The following conclusions are summarized:

- (1)

- There is a good correspondence between the IR and AE time series and spatial distribution of different coal impact types. As the impact tendency increases, the intensity of the IR and AE signals released by the coal failure gradually increases, and the distribution of the AE localization points and infrared high-temperature area are gradually concentrated.

- (2)

- During the loading process, the coal body gradually transitions from tensile failure to shear failure. As the impact tendency increases, the proportion of the shear failure AE signals gradually increases during the failure stage, and the shear cracks of no-, weak-, and strong-impact coal are 39.9%, 50.9%, and 53.7%, respectively.

- (3)

- The combined IRT and AE sensitivity index K for different coal impact types is established. As the impact tendency increases, the IRT and AE sensitivity gradually increases, but the occurrence time of the failure precursors becomes later and later. The IRT and AE sensitive instability precursor of no-, weak-, and strong-impact coal appear as 55.2%, 66.3%, and 93.4%, respectively, of the coal instability and failure.

- (4)

- The combined damage variable DIA based on IR and AE is established. Before the IR and AE combined precursor point, the dissipated energy released by coal is less, and the DIA slowly increases. After the IR and AE combined precursor point, the dissipated energy and DIA increase rapidly, and the coal body will undergo instability and failure.

Author Contributions

Conceptualization, S.Y.; methodology, S.Y.; validation, Z.L. and E.W.; formal analysis, Z.L. and Y.L.; investigation, Y.N. and Y.L.; resources, Y.N. and H.Y.; data curation, S.Y. and Y.L.; writing—original draft preparation, S.Y. and Y.L.; writing—review and editing, Z.L. and E.W.; project administration, H.Y.; funding acquisition, S.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the National Natural Science Foundation of China (Grant number: 52304268, 52074280), the China Postdoctoral Science Foundation (Grant number: 2023M733771), the Jiangsu Funding Program for Excellent Postdoctoral Talent (Grant number: 2022ZB505), and the Fundamental Research Funds for the Central Universities (Grant number: 2023QN1030).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the finding of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lu, Z.G.; Ju, W.J.; Wang, H.; Zhang, J.W.; Yi, K.; Feng, Y.L.; Sun, L.W. Experimental study on anisotropic characteristics of impact tendency and failure model of hard coal. Chin. J. Rock. Mech. Eng. 2019, 038, 757–768. [Google Scholar] [CrossRef]

- Liu, X.F.; Wang, X.R.; Wang, E.Y.; Kong, X.G.; Zhang, C.; Liu, S.J.; Zhao, E.L. Effects of gas pressure on bursting liability of coal under uniaxial conditions. J. Nat. Gas. Sci. Eng. 2017, 39, 90–100. [Google Scholar] [CrossRef]

- Zang, Z.S.; Li, Z.H.; Zhao, E.L.; Kong, X.G.; Niu, Y.; Yin, S. Electric potential response characteristics and constitutive model of coal under axial static load–dynamic load coupling. Nat. Resour. Res. 2023, 32, 2821–2844. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Jiang, Y.D. Acoustic emission and thermal infrared precursors associated with bump-prone coal failure. Int. J. Coal Geol. 2010, 83, 11–20. [Google Scholar] [CrossRef]

- Qiu, L.M.; Liu, Z.T.; Wang, E.Y.; He, X.Q.; Feng, J.J.; Li, B.L. Early-warning of rock burst in coal mine by low-frequency electromagnetic radiation. Eng. Geol. 2020, 279, 105755. [Google Scholar] [CrossRef]

- Li, Z.H.; Yin, S.; Niu, Y.; Cheng, F.Q.; Liu, S.J.; Kong, Y.H.; Sun, Y.H.; Wei, Y. Experimental study on the infrared thermal imaging of a coal fracture under the coupled effects of stress and gas. J. Nat. Gas. Sci. Eng. 2018, 55, 444–451. [Google Scholar] [CrossRef]

- Cao, K.W.; Dong, F.R.; Yu, Y.H.; Khan, N.M.; Hussain, S.; Alarifi, S.S. Infrared radiation response mechanism of sandstone during loading and fracture process. Theor. Appl. Fract. Mech. 2023, 126, 103974. [Google Scholar] [CrossRef]

- Hao, T.X.; Li, F.; Tang, Y.J.; Wang, Z.H.; Zhao, L.Z. Infrared radiation characterization of damaged coal rupture based on stress distribution and energy. ACS Omega 2022, 7, 28545–28555. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.Q.; Ma, L.Q.; Liu, W.; Khan, N.M.; Cao, G.H.; Fang, Y.M.; Wang, H. Research on the denoising method of infrared thermogram during rock fracture. Infrared Phys. Technol. 2023, 131, 104651. [Google Scholar] [CrossRef]

- Tian, H.; Li, Z.H.; Liu, Z.; Yin, S.; Niu, Y.; Zhang, Q.C.; Chen, D. Visual characterization of coal gas desorption using infrared radiation. Energy 2024, 289, 130052. [Google Scholar] [CrossRef]

- Wu, L.X.; Liu, S.J.; Wu, Y.H.; Wang, C.Y. Precursors for rock fracturing and failure—Part I: IRR image abnormalities. Int. J. Rock. Mech. Min. 2006, 43, 473–482. [Google Scholar] [CrossRef]

- Sun, H.; Ma, L.Q.; Liu, W.; Spearing, A.J.S.; Han, J.; Fu, Y. The response mechanism of acoustic and thermal effect when stress causes rock damage. Appl. Acoust. 2021, 180, 108093. [Google Scholar] [CrossRef]

- Sun, H.; Liu, X.L.; Zhang, S.G.; Nawnit, K. Experimental investigation of acoustic emission and infrared radiation thermography of dynamic fracturing process of hard-rock pillar in extremely steep and thick coal seams. Eng. Fract. Mech. 2020, 226, 106845. [Google Scholar] [CrossRef]

- Ma, L.Q.; Sun, H. Spatial-temporal infrared radiation precursors of coal failure under uniaxial compressive loading. Infrared Phys. Technol. 2018, 93, 144–153. [Google Scholar] [CrossRef]

- Sun, H. Infrared radiation response mechanism and quantitative characterization during damage evolution of loading coal and rock. China Univ. Min. Technol. 2020. [Google Scholar] [CrossRef]

- Yin, S.; Li, Z.H.; Wang, E.Y.; Li, X.L.; Tian, H.; Niu, Y. Infrared temperature evolution law and thermal effect mechanism of concrete impact failure. J. Build. Eng. 2024, 91, 109592. [Google Scholar] [CrossRef]

- Liu, W.; Ma, L.Q.; Sun, H.; Khan, N.M. Using the characteristics of infrared radiation b-value during the rock fracture process to offer a precursor for serious failure. Infrared Phys. Technol. 2021, 114, 103644. [Google Scholar] [CrossRef]

- Lou, Q.; He, X.Q. Experimental study on infrared radiation temperature field of concrete under uniaxial compression. Infrared Phys. Technol. 2018, 90, 20–30. [Google Scholar] [CrossRef]

- Xiao, F.K.; He, J.; Liu, Z.J.; Shen, Z.L.; Liu, G. Analysis on warning signs of damage of coal samples with different water contents and relevant damage evolution based on acoustic emission and infrared characterization. Infrared Phys. Technol. 2019, 97, 287–299. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Liu, Y.; Cai, X.; Chang, Y.; Gao, S. Infrared radiation characteristics of sandstone exposed to impact loading. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 2555–2562. [Google Scholar] [CrossRef]

- Tang, Y.J.; Hao, T.X.; Liu, J.; Li, F.; Zhao, Z.; Wang, Z.H.; Wang, H.C.; Liu, X. Characterization of infrared radiation and fracture evolution during destabilization of coal bodies with different degrees of damage. Rock Soil. Mech. 2023, 44, 2907–2920. [Google Scholar] [CrossRef]

- Khan, N.M.; Ma, L.Q.; Feroze, T.; Wang, D.L.; Cao, K.W.; Gao, Q.Q.; Wang, H.; Hussain, S.; Zhang, Z.T.; Alarifi, S. Investigating average infrared radiation temperature characteristics during shear and tensile cracks in sandstone under different water contents. Infrared Phys. Technol. 2023, 135, 104968. [Google Scholar] [CrossRef]

- Ma, L.Q.; Sun, H.; Ngo, I.; Han, J. Infrared radiation quantification of rock damage and its constitutive modeling under loading. Infrared Phys. Technol. 2022, 121, 104044. [Google Scholar] [CrossRef]

- Yin, S.; Li, Z.; Wang, E.; Niu, Y.; Tian, H.; Li, X.; Li, H.Y.; Yang, C.J. The infrared thermal effect of coal failure with different impact types and its relationship with bursting liability. Infrared Phys. Technol. 2024, 138, 105263. [Google Scholar] [CrossRef]

- Li, Z.H.; Lou, Q.; Wang, E.Y.; Kong, B.; Niu, Y.; Li, G.A. Experimental study of acoustic-electric and thermal infrared characteristics of roof rock failure. J. China Univ. Min. Technol. 2016, 45, 1098–1103. [Google Scholar] [CrossRef]

- Wang, C.L.; Lu, Z.J.; Liu, L.; Chuai, X.S.; Lu, H. Predicting points of the infrared precursor for limestone failure under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2016, 88, 34–43. [Google Scholar] [CrossRef]

- Di, Y.Y.; Wang, E.Y.; Huang, T. Identification method for microseismic, acoustic emission and electromagnetic radiation interference signals of rock burst based on deep neural networks. Int. J. Rock Mech. Min. Sci. 2023, 170, 105541. [Google Scholar] [CrossRef]

- Ding, Z.W.; Li, X.F.; Huang, X.; Wang, M.B.; Tang, Q.B.; Jia, J.D. Feature extraction; recognition, and classification of acoustic emission waveform signal of coal rock sample under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2022, 160, 105262. [Google Scholar] [CrossRef]

- Su, G.S.; Huang, L.; Qin, Y.Z.; Yan, X. Experimental study of the “AE quiet period” on the eve of brittle failure in hard rock. Eng. Fail. Anal. 2024, 162, 108391. [Google Scholar] [CrossRef]

- Jiang, Y.J.; Liang, B.; Wang, D.; Luan, H.J.; Zhang, G.C.; Dong, L.; Chen, L.G. Experimental study on failure mechanical properties and acoustic emission characteristics of soft rock–coal combination under dynamic disturbance. Eng. Fail. Anal. 2024, 158, 108016. [Google Scholar] [CrossRef]

- Xu, C.; Wang, W.H.; Wang, K.; Hu, K.; Cao, Z.G.; Zhang, Y. Influence of coal-rock interface inclination on the damage and failure law of original coal-rock combination. Eng. Fail. Anal. 2024, 161, 108275. [Google Scholar] [CrossRef]

- Yu, X.; Zuo, J.P.; Mao, L.T.; Xu, X.W.; Lei, B.; Zhao, S.K. Uncovering the progressive failure process of primary coal-rock mass specimens: Insights from energy evolution, acoustic emission crack patterns, and visual characterization. Int. J. Rock Mech. Min. Sci. 2024, 178, 105773. [Google Scholar] [CrossRef]

- Du, K.; Luo, X.Y.; Liu, M.H.; Liu, X.L.; Zhou, J. Understanding the evolution mechanism and classification criteria of tensile-shear cracks in rock failure process from acoustic emission (AE) characteristics. Eng. Fract. Mech. 2024, 296, 109864. [Google Scholar] [CrossRef]

- Bi, J.; Zhao, Y.; Wu, Z.J.; Li, J.S.; Wang, C.L. Research on crack classification method and failure precursor index based on RA-AF value of brittle rock. Theor. Appl. Fract. Mech. 2024, 129, 104179. [Google Scholar] [CrossRef]

- Dong, L.J.; Zhang, Y.H.; Ma, J. Micro-crack mechanism in the fracture evolution of saturated granite and enlightenment to the precursors of instability. Sensors 2020, 20, 4595. [Google Scholar] [CrossRef]

- Liu, W.; Ma, L.Q.; Sun, H.; Khan, N.M. An experimental study on infrared radiation and acoustic emission characteristics during crack evolution process of loading rock. Infrared Phys. Technol. 2021, 118, 103864. [Google Scholar] [CrossRef]

- Chen, G.Q.; Li, Y.; Chen, Y.F.; Ma, G.; Wu, Z.L. Thermal-acoustic sensitivity analysis of fractured rock with different lithologies. Chin. J. Rock Mech. Eng. 2022, 41, 1945–1957. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, B.L.; Zhao, T.B. Study on the law of failure acoustic–thermal signal of weakly cemented fractured rock with different dip angles. Rock Mech. Rock Eng. 2023, 56, 4557–4568. [Google Scholar] [CrossRef]

- GB/T 25217.2; The National Standards Compilation Groups of People′s Republic of China. GB/T 25217.2—2010 Methods for Test, Monitoring and Prevention of Rock Burst—Part2: Classification and Laboratory Test Method on Bursting Liability of Coal. Standards Press of China: Beijing, China, 2010. (In Chinese)

- Zhang, X.; Li, Z.H.; Wang, E.Y.; Li, B.L.; Song, J.J.; Niu, Y. Experimental investigation of pressure stimulated currents and acoustic emissions from sandstone and gabbro samples subjected to multi-stage uniaxial loading. Bull. Eng. Geol. Environ. 2021, 80, 7683–7700. [Google Scholar] [CrossRef]

- Zhao, Q.C.; Tu, M.; Fu, B.J.; Li, J.W.; Dang, J.X.; Qi, C. Acoustic emission and failure characteristics of coal and rock under single-free-face true triaxial loading. Eng. Fail. Anal. 2024, 161, 108299. [Google Scholar] [CrossRef]

- Jiang, X.Y.; Wu, D.; Zhao, Z.X.; Yang, Y.; Tian, J.W.; Wang, F.L. Experimental and numerical study on the damage evolution and acoustic emission multi-parameter responses of single flaw sandstone under uniaxial compression. Theor. Appl. Fract. Mech. 2024, 133, 104535. [Google Scholar] [CrossRef]

- Zheng, K.; Wang, C.L.; Zhao, Y.; Bi, J.; Niu, Y.; Lian, S.L. A dominant frequency-based hierarchical clustering method for evaluating the mode-II fracture mechanisms of shale using the acoustic emission technique. Theor. Appl. Fract. Mech. 2024, 134, 104644. [Google Scholar] [CrossRef]

- Radhika, V.; Kishen, J.M.C. A comparative study of crack growth mechanisms in concrete through acoustic emission analysis: Monotonic versus fatigue loading. Constr. Build. Mater. 2024, 432, 136568. [Google Scholar] [CrossRef]

- Shen, F.; He, S.Q.; Song, D.Z.; He, X.Q.; Yang, G. Response characteristics of acoustic emission signal and judgment criteria for different fracture modes. Eng. Fract. Mech. 2024, 296, 109862. [Google Scholar] [CrossRef]

- Yang, H.Z.; Wang, E.Y.; Wang, X.R.; Song, Y.; Chen, D.; Wanga, D.M.; Li, J.Y. Predicting the failure of rock using critical slowing down theory on acoustic emission characteristics. Eng. Fail. Anal. 2024, 163, 108474. [Google Scholar] [CrossRef]

- Liu, Q.; Song, D.; Qiu, L.; Xiao, Y.Z.; Yin, S.; Peng, Y.J.; Cao, Y.L.; Wang, H.; Gao, L. An experimental study of the resistivity response on fracture process of sandstone with pre-existing flaw. Theor. Appl. Fract. Mech. 2022, 121, 103487. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Wu, W.R.; Yao, X.L.; Liang, P.; Tian, B.Z.; Huang, Y.L.; Liang, J.L. Acoustic emission, infrared characteristics and damage evolution of granite under uniaxial compression. Rock Soil. Mech. 2020, 41, 139–146. [Google Scholar] [CrossRef]

- Li, B.; He, Y.Z.; Li, L.; Zhang, J.X.; Shi, Z.; Zhang, Y.P. Damage evolution of rock containing prefabricated cracks based on infrared radiation and energy dissipation. Theor. Appl. Fract. Mech. 2023, 125, 103853. [Google Scholar] [CrossRef]

- Kachanov, L.M. Time of the rupture process under creep conditions. Izy Akad. Nank S. S. R. Otd Tech Nauk. 1958, 8, 26–31. [Google Scholar]

- Cao, W.G.; Zhao, M.H.; Liu, C.X. Study on the model and its modifying method for rock softening and damage based on Weibull random distribution. Chin. J. Rock Mech. Eng. 2004, 23, 3226–3231. [Google Scholar] [CrossRef]

- Xie, H.P. Damage Mechanics of Rock and Concrete; China University of Mining and Technology Press: Xuzhou, China, 1990. [Google Scholar]

- Zang, Z.S.; Li, Z.H.; Niu, Y.; Yin, S. Experimental investigation of the fracture and damage evolution characteristics of flawed coal based on electric potential and acoustic emission parameter analyses. Eng. Fract. Mech. 2024, 295, 109740. [Google Scholar] [CrossRef]

- Yang, H.Z.; Wang, X.R.; Wang, E.Y.; Song, Y.; Chen, D.; Zhang, Y.D.; Liu, W.Z. Macro-micro crack and damage evolution characteristics of concrete: After the action of acidic drying-saturation cycle. Constr. Build. Mater. 2024, 411, 134601. [Google Scholar] [CrossRef]

- Xie, H.; Li, L.; Ju, Y.; Peng, R.; Yang, Y. Energy analysis for damage and catastrophic failure of rocks. Sci. China Technol. Sci. 2011, 54, 199–209. [Google Scholar] [CrossRef]

- Yin, S.; Song, D.Z.; He, X.Q.; Lou, Q.; Qiu, L.M.; Li, Z.L.; Chen, P.; Li, J.; Liu, Y. Structural health monitoring of building rock based on stress drop and acoustic-electric energy release. Struct. Control Health Monit. 2022, 29, e2875. [Google Scholar] [CrossRef]

- Yang, H.Z.; Wang, E.Y.; Cheng, D.Q.; Wang, X.R.; Li, B.L.; Song, Y.; Wang, D.M.; Liu, W.Z. Characteristics of energy evolution and acoustic emission response of concrete under the action of acidic drying-saturation processes cycle. J. Build. Eng. 2023, 74, 106928. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, X.L.; Tan, Y.L.; Wang, R.S.; Xie, W.Q.; Wang, E.Z.; Liu, X.S.; Shang, J.L. Experimental study of loading system stiffness effects on mechanical characteristics and kinetic energy calculation of coal specimens. Rock Mech. Rock Eng. 2024, 1–17. [Google Scholar] [CrossRef]

- Mo, Y.L.; Li, H.Y.; Sun, Z.X.; Li, L.; Wang, J.D. Analysis on effect of primary fractures structure on physical and mechanical properties of coal rock. Coal Sci. Technol. 2020, 48, 25–34. [Google Scholar] [CrossRef]

- Sun, Z.X. The Coal Rock Mesoscopie Structure Characteristies and Its Effect on Bursting Liability. Master’s Thesis, Liaoning Technical University, Fuxin, China, 2016. [Google Scholar]

- Ju, W.J.; Lu, Z.G.; Gao, F.Q.; Zhao, Y.X.; Li, W.Z.; Sun, Z.Y.; Hao, X.J. Research progress and comprehensive quantitative evaluation index of coal rock bursting liability. Chin. J. Rock Mech. Eng. 2021, 40, 1839–1856. [Google Scholar] [CrossRef]

- Liu, W.; Ma, L.Q.; Gao, Q.Q.; Wang, H.; Fang, Y.M.; Ma, Q.; Sun, H.; Zhang, Z.T. Failure precursors recognition method for loading coal and rock using the fracture texture features of infrared thermal images. Infrared Phys. Technol. 2024, 139, 105319. [Google Scholar] [CrossRef]

- Lou, Q.; Song, D.Z.; He, X.Q.; Li, Z.L.; Qiu, L.M.; Wei, M.H.; He, S.Q. Correlations between acoustic and electromagnetic emissions and stress drop induced by burst-prone coal and rock fracture. Saf. Sci. 2019, 115, 310–319. [Google Scholar] [CrossRef]

- Wang, X.R.; Shan, T.C.; Liu, S.X.; Li, Z.H.; Liu, X.F.; Wang, E.Y.; Li, N.; Wang, J.H. Thermal-damage effects on fracturing evolution of granite under compression-shear loading. Theor. Appl. Fract. Mech. 2024, 133, 104581. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).