Abstract

Due to increasing emissions and global warming, in parallel with the increasing world population and energy needs, IMO has introduced severe rules for ships. Energy efficiency on ships can be achieved using the organic and inorganic Rankine cycle (RC) driven by exhaust heat from marine diesel engines. In this study, toluene, R600, isopentane, and n-hexane as dry fluids; R717 and R718 as wet fluids; and R123, R142b, R600a, R245fa, and R141b as isentropic fluids are selected as the working fluid because they are commonly used refrigerants, with favorable thermal properties, zero ODP, low GWP and are good contenders for this application. The cycle and exergy efficiencies, net power, and irreversibility of marine diesel engine exhaust-driven simple RC and RC with a recuperator are calculated. For dry fluids, the most efficient fluid at low turbine inlet temperatures is n-hexane at 39.75%, while at high turbine inlet temperatures, it is toluene at 41.20%. For isentropic fluids, the most efficient fluid at low turbine inlet temperatures is R123 with 23%, while at high turbine inlet temperatures it is R141b with 23%. As an inorganic fluid, R718 is one of the most suitable working fluids at high turbine inlet temperatures of 300 °C onboard ships with a safety group classification of A1, ODP of 0, and GWP100 of 0, with a cycle efficiency of 33%. This study contributes to significant improvements in fuel efficiency and reductions in greenhouse gas emissions, leading to more sustainable and cost-effective maritime operations.

1. Introduction

Due to the ever-increasing energy costs, the topic of energy efficiency is gaining more value each day. One way to improve energy efficiency is to recover waste heat in systems. Since sea transport is the most economical method in international trade, cargo ships are extensively used. These ships with large engines have a very high energy consumption. Apart from running the engines of commercial ships, there is a continuous need for energy to keep other electronic systems operational. Therefore, recovering energy from the exhaust of the ship’s engine and converting it back into electrical energy through recycling will significantly enhance energy efficiency. One system that can be designed for this purpose is the organic Rankine cycle (ORC), which has some differences from the traditional Rankine cycle [1].

The Rankine cycle converts mechanical energy into electrical energy using a working fluid. This cycle is widely employed in various industrial thermodynamic applications and energy production [2]. The Rankine cycle consists of four main components: the boiler, turbine, condenser, and pump [3]. The boiler is where water in the cycle is vaporized at high temperatures and pressure. The flow energy of the steam obtained from the boiler is converted into mechanical energy by turning the turbine blades. The rotating blades move the turbine rotor. After the work is completed in the turbine, the steam goes to the condenser at low pressure and temperature. The condenser condenses the steam back into liquid water. The heat generated during this process is exchanged with the working fluid and released into the surroundings. The pump transports the condensed water back to the steam generator. The condensed water is subjected to vaporization again by bringing it back to high temperature and pressure. The Rankine cycle generally operates with this loop. In the steam generator, water is vaporized, and the resulting steam expands in the turbine, producing mechanical energy [4]. This cycle is commonly used to generate electricity in thermal power plants, nuclear power plants, and some industrial facilities.

ORC is a cycle used in low-temperature applications and can convert heat from low-temperature sources such as solar energy, geothermal energy, and industrial waste heat recovery into electrical energy [5]. Like the Rankine cycle, the ORC is a vapor-based thermodynamic cycle. The fundamental difference between these two cycles arises from the characteristics of the liquid refrigerant they use. The Rankine cycle typically utilizes inorganic liquid refrigerants like water or water-based mixtures. In this cycle, water is vaporized and is commonly used to generate electricity in thermal power plants. On the other hand, ORC uses organic liquid refrigerants. These fluids have low boiling points and vaporization characteristics. The Rankine cycle generally harnesses heat from high-temperature sources. In contrast, ORC can more effectively utilize heat from low-temperature sources. The ORC has the advantage of efficiently converting heat from low-temperature sources into electrical energy, making it an ideal choice for applications such as industrial waste heat recovery. Due to these features, ORC plays a significant role in sustainable energy production and efficiency [6].

The Rankine cycle typically utilizes inorganic liquid refrigerants. Water is the most common and economically used inorganic working fluid. Water-based mixtures can also be used, especially in the evaporator, to reduce the risk of freezing at low temperatures. On the other hand, the ORC uses organic working fluids. These fluids are used in low-temperature applications due to their low boiling point characteristics [7]. Examples of organic working fluids include components such as R134a, R245fa, R600, and pentane. The ORC is designed to harness heat from low-temperature sources more effectively. Therefore, organic working fluids are more commonly used in low-temperature applications. In contrast, inorganic working fluids like water and water-based mixtures are used in high-temperature applications and industrial thermal power plants. The preferred refrigerants for these cycles are selected based on the application’s requirements, environmental conditions, and efficiency goals [8].

The working fluids used in RC can generally be classified into three categories: dry, isentropic, and wet. These terms are used based on various physical properties of the fluid. Dry fluid refers to the refrigerant in a completely vaporized state. In other words, if the fluid exists solely in the vapor phase and has no presence in the liquid phase, it is termed a dry fluid. Dry fluids are typically used in evaporator devices, where the refrigerant is entirely in the vapor phase [9]. For instance, dry fluids are commonly used in household cooling systems such as air conditioners and refrigerators. Dry fluids are also generally used in gas turbines.

The term isentropic describes the condition where a fluid undergoes an isentropic process. An isentropic process is a process where entropy is kept constant. An isentropic fluid is a fluid in thermodynamic equilibrium, where its entropy is constant. Isentropic fluids are often used to model ideal conditions (e.g., the Brayton cycle in jet engines) [10]. They can also be used in steam engines.

Wet fluids represent fluids that exist in both the liquid and vapor phases. In other words, it signifies a mixture state with some portion in the liquid phase and some in the vapor phase. Wet fluids often represent a situation observed in real engineering applications and systems [11]. For example, it could denote the state where liquid refrigerant begins to evaporate in an evaporator or where gas starts to condense in a compressor. Wet fluid systems are typically observed in extensive industrial cooling facilities, energy production plants, and large-scale air conditioning systems. Also, they are generally used in the liquefaction of gases (e.g., in cryogenic cooling systems).

In recent years, academic studies on ORC systems have increased, turning a topic that was less explored into a significant research interest. Zhao and colleagues, for example, designed a new system using the ORC to recover waste heat generated during silicon production [12]. CFD analysis showed that this design increased energy efficiency by 64.14% and exergy efficiency by 72.13%. Their economic evaluation indicated that the system would pay for itself in approximately four years. They concluded that the ORC provides a significant advantage in recovering system waste heat. Kong and team developed an energy integration scheme using the ORC to recover energy generated during the purification process of isopropanol–butanol–ethanol fermentation [13]. Their study showed a 100% reduction in low-pressure steam consumption and a 58.80% reduction in cooling water consumption using the ORC for energy optimization. They utilized R600a as the working fluid in their cycle. Mubashir and colleagues proposed a new system for waste heat recovery in an internal combustion engine [14]. They conducted energy and exergy analyses for their system, evaluating configurations using both the Brayton cycle and ORC to generate power from the waste heat of a 470 °C engine. Their results indicated that the ORC was the most efficient system for waste heat recovery in internal combustion engines. Zakeralhoseini and Schiffmann conducted a waste heat recovery calculation using an ORC-based system for a high-speed turbopump at a small scale [15]. Their experimental and numerical studies showed that using the ORC increased the turbo pump’s efficiency by 30% and reduced the reverse flow ratio by 50%. They emphasized the usefulness of the ORC system in recovering waste heat from turbo pumps. Tsimpoukis and team investigated the integration of an ORC unit into an injector-assisted CO2 cooling system with a standard discharge for compressors [16]. According to their yearly performance analysis for the city of Athens, Greece, they found that working with isopentane resulted in the highest energy production of 10.36 MWh annually, leading to a 3.69% decrease in energy consumption for the cooling system. Anastasovski and colleagues examined various approaches for integrating the ORC into thermal process systems [17]. They compared and systematized all the methods they studied in a general scheme for integrating the ORC with low-temperature industrial waste heat sources. Their findings indicated that using ORC improved efficiency in low-temperature waste heat processes. Mondejar and team evaluated using ORC systems for waste heat recovery on ships [18]. Their results showed that using ORC in engines using low-sulfur fuel reduced fuel consumption by 10% to 15%. Holik and colleagues performed a two-objective optimization using commercial software to increase power output and reduce the total heat exchanger surface area [19]. They compared configurations using exhaust gas temperatures of 394.2 °C and mass flow rates of 0.306 kg/s, analyzing fluids such as water, ethanol, toluene, and hexamethyl disiloxane. Their study concluded that ethanol was the most efficient fluid for power output and heat exchanger characteristics in ORC systems. In summary, these studies collectively demonstrate the versatility and efficiency of the ORC in various applications, emphasizing its potential in waste heat recovery and energy optimization across different industries.

Toluene is an organic component commonly used in the R-410A mixture, a refrigerant widely employed in air conditioning systems and some commercial and industrial cooling applications [20]. Toluene is included in this mixture to enhance its performance. R600 (isobutane) is a natural hydrocarbon gas frequently used in household refrigeration devices such as refrigerators and freezers [21]. It is considered an environmentally friendly option among natural refrigerants. Isopentane is another hydrocarbon gas used as a refrigerant, especially in industrial cooling systems and commercial refrigeration devices [22]. Natural refrigerants like isopentane are valued for their eco-friendly and energy-efficient characteristics. n-hexane, also known as R-40A, is a type of hydrocarbon refrigerant [23]. This refrigerant can be used in industrial cooling systems, particularly industrial air conditioning systems. Hydrocarbons like hexane are among the options for natural refrigerants. R-717, commonly known as ammonia, is a natural refrigerant. It is typically used in industrial cooling systems, especially in the food industry [24]. This refrigerant is preferred due to its low-cost, high-energy efficiency, and environmentally friendly characteristics. R-718 represents water. Water is a coolant in various industrial applications and steam-based energy systems [25]. For instance, water can be used in energy production with steam turbines and industrial cooling systems. R-123 is a dichlorotrifluoroethane compound commonly used in large-scale commercial and industrial air conditioning systems [24]. This refrigerant is preferred for its high efficiency and low toxicity. R-142b is a chlorodifluoromethane compound that was once widely used but has now been replaced by environmentally friendly alternatives [24]. It has been especially utilized in commercial refrigeration and air conditioning systems. R-600a is a natural hydrocarbon gas known as isobutane [25]. This refrigerant is used in small cooling devices such as household refrigerators and freezers. R-245fa is a pentafluoropropane compound often used in industrial waste heat recovery and the ORC as a refrigerant [23]. Although R-245fa has been used extensively in ORC systems, its high greenhouse gas content has caused it to be phased out by several environmental restrictions, such as the European Union’s F-Gas Regulation. Manufacturers favor substitutes with less of an impact on the environment over R-245fa. R-141b is a dichlorofluoromethane compound and used to be one of the older types of refrigerants [26]. However, it has generally been replaced by environmentally friendly alternatives and was previously used in commercial refrigeration systems and some industrial applications.

The usage of specific chemicals in various industries, including those utilized as working fluids in ORC systems, has been increasingly impacted by PFAS (Per- and Polyfluoroalkyl Substances) regulations. PFAS production, usage, and disposal are subject to stricter regulations from regulatory agencies such as the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA). This includes restricting the amount of PFAS in products and outright outlawing specific PFAS compounds.

The detailed descriptions of each fluid’s characteristics and applications are provided in Table 1.

Table 1.

Descriptions of fluids’ characteristics and applications.

The International Maritime Organization (IMO) amended MARPOL Annex VI in 2011 to require operational and technological energy efficiency measures to lower the quantity of CO2 emissions from international vessels. On 1 January 2013, the Ship Energy Efficiency Management Plan (SEEMP) and the Energy Efficiency Design Index (EEDI) were enacted. In 2021, IMO member states enacted additional energy efficiency measures to lower international shipping’s carbon intensity by a minimum of 40% by 2030 compared to 2008.

Additionally, within the scope of this study, the effect of adding a recuperator to the designed RC system on efficiency has been investigated. These calculations were performed separately for each working fluid used in the RC design, and the results were compared. Recuperators can be employed to enhance efficiency in specific thermodynamic cycles. In the RC, a recuperator can heat the feedwater by using the heat of the water leaving the condenser. This ensures the vapor has higher temperatures and more energy [1].

Recuperators are particularly useful in systems with reduced heat emissions to the environment, facilities where energy recovery occurs, and continuously operating industrial applications [27]. This enhances system efficiency, reduces energy consumption, and minimizes environmental impacts. Recuperators recover waste heat from a system and convert this heat into usable energy for beneficial purposes. This results in energy savings and increases the overall efficiency of the system. Recuperators enable the system to operate more efficiently by recovering the energy of hot gases or liquids within the system instead of losing it as waste heat. This translates to reduced energy consumption. The recovery of waste heat can help reduce energy costs, significantly saving long-term operating expenses. By promoting energy savings, recuperators contribute to a decrease in fossil fuel consumption, subsequently reducing environmental impacts. Lower energy consumption can contribute to reducing greenhouse gas emissions and environmental pollution. In large-scale HVAC systems, recuperators can recover waste heat from indoor air units or outdoor air intakes for use in beneficial tasks such as heating or hot water production [1].

Furthermore, exergy analysis and irreversibility calculations have been conducted in another section of this study. These calculations were performed separately for each fluid used in the ORC design, and the results were compared. Exergy is a concept in thermodynamics that measures the quality or availability of energy [28]. It indicates how efficiently energy is utilized compared to the conditions of the system’s surroundings. Higher exergy indicates that energy is more practical and of higher quality, whereas lower exergy suggests less valuable energy. Exergy analysis of a cooling system is used to assess the system’s energy efficiency, identify energy losses, and optimize system performance. Exergy analysis is a crucial tool for improving the energy efficiency of cooling systems and using resources more effectively. Irreversibility, in thermodynamics, indicates how effective a thermodynamic process is or how efficiently a process occurs. It shows how much loss or energy waste is inherent in a process. In thermodynamics, the more irreversible a process is, the less efficient it is. The irreversibility value of a cooling system is used to determine how effective the system is or how efficient the process is. This value is obtained by comparing the actual and ideal processes [29].

Water is the preferred working fluid for large-scale Rankine cycles that use high-temperature energy sources in a wide range of efficient cycle configurations, from saturated nuclear power plants to coal-fired ultra-supercritical cycles. However, steam’s thermodynamic features require multistage, capital-intensive turbines, complex plant systems, and liquid formation during expansion; these limitations render steam an unsuitable working fluid for low temperature and power output applications.

The ORC aims to generate power from moderate-temperature, distributed energy sources cost effectively. This is accomplished by selecting a suitable working fluid capable of facilitating a basic plant arrangement and a low-cost turbine without liquid formation.

Although the traditional Rankine cycle (RC) and the organic Rankine cycle (ORC) share the same principle, they have many differences [30]. A comparison between the RC and ORC is provided in Table 2.

Table 2.

Comparison between RC and ORC.

In this study, a traditional RC and ORC system designed to recover the energy released during the full-load operation of a ship engine is presented. The designed system incorporates eleven working fluids, comprising four dry, two wet, and five isentropic conditions. In this work, the Engineering Equation Solver (EES) [M1] [HK2] (V11.898) and NIST Reference Fluid Thermodynamic and Transport Properties Database (REFPROP) (V10) commercial software are employed to obtain the thermophysical properties of each refrigerant used in the RC, and calculations are performed accordingly.

2. Thermodynamic Analysis

2.1. Selection of Working Fluid

In this study, the following working fluids are utilized for a case marine diesel engine because they are commonly used refrigerants, with favorable thermal properties, zero ODP, low GWP and are good contenders for this application: toluene, R600, isopentane, and n-hexane as dry fluids; R717 and R718 as wet fluids; and R123, R142b, R600a, R245fa, and R141b as isentropic fluids. The properties of working fluids in this study are provided in Table 3 [31].

Table 3.

Properties of working fluids.

2.2. System Design

This study performed a thermodynamic analysis of a marine diesel engine exhaust gas-driven RC for used ships. Technical data, operating data, and heat balance for the marine diesel engine are provided in Table 4, Table 5 and Table 6, respectively. The values are provided for 100% load [33].

Table 4.

Technical data for marine diesel engine.

Table 5.

Operating data for marine diesel engine.

Table 6.

Heat balance at full load for marine diesel engine.

The pump, recuperator, and expander types are a centrifugal pump, a counterflow plate heat exchanger, and an axial turbine. Also, the condenser is seawater-cooled with counterflow and a plate heat exchanger.

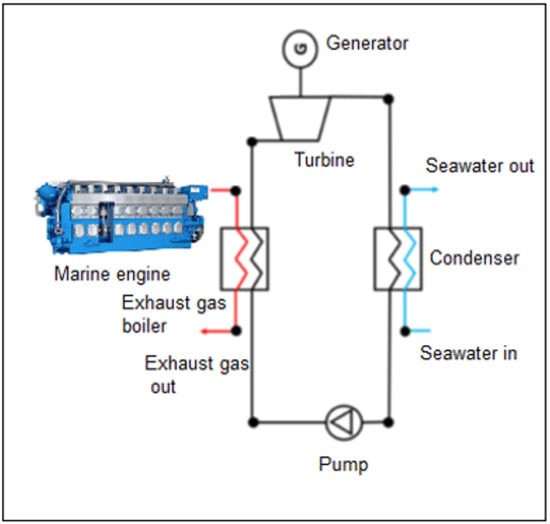

The designed simple RC system within the scope of this study is illustrated in Figure 1. Simple RC systems in ship engines harness energy recovery by evaluating the hot gases and waste heat emitted from the ship’s engine exhaust. When the ship’s engine operates, exhaust gases are released at high temperatures. These hot gases are directed into the exhaust gas boiler. The working fluid in the boiler begins to evaporate in this hot environment. The evaporation process signifies the transition of the liquid to the vapor phase and the gaining of expansion potential by the vapor. The resulting vapor expands in a turbine, converting it into mechanical energy. During this expansion phase, the turbine rotates, driving a generator to produce electrical energy. The steam exiting the turbine typically enters a cooling system. In this stage, the vapor is condensed back into the liquid phase. This process ensures that the liquid working fluid returns to the boiler. With the liquid returning to the boiler, the RC system completes a cycle, and the process begins anew.

Figure 1.

Simple RC system.

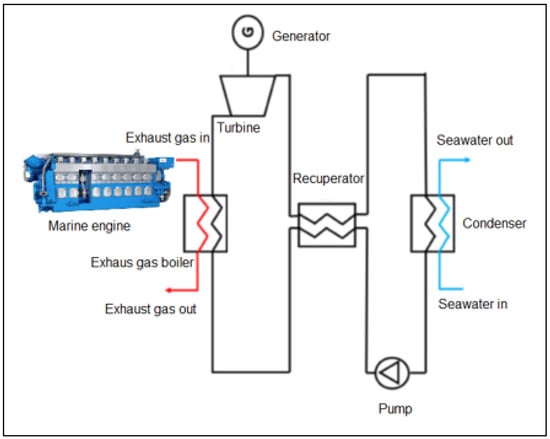

The designed RC with a recuperator system within the scope of this study is provided in Figure 2. Passing the liquid working fluid through the recuperator enhances system efficiency and recovers more energy from waste heat. The hot fluid emitted from the exhaust of the ship’s engine enters the exhaust gas boiler. At this stage, the liquid working fluid begins to vaporize, and during the vaporization process, the temperature rises. The recuperator facilitates the heat transfer between the hot vapor-containing fluid and the cold fluid, which will be used later in the system. This process increases system efficiency by recovering waste heat. The energy of the hot vapor is transferred to the working fluid, which cools in the recuperator, condensing some of the vapor back into liquid form. The cooled fluid passing through the recuperator is typically sent back to the exhaust gas boiler with the assistance of a pump. Having regained heat and carrying vaporization potential, this fluid starts the cycle anew. This process establishes a loop within the system, and passing the liquid working fluid through the recuperator enhances the boiler’s efficiency. When returned to the boiler, the liquid passing through the recuperator starts at a lower temperature. However, while recuperators improve efficiency by recovering waste heat, they also introduce additional pressure drops and require more complex control systems, which should be considered in this study.

Figure 2.

RC system with recuperator.

Operations Challenges and Potential Limitations

The marine diesel engine exhaust heat-driven organic and inorganic Rankine cycle is required to increase the ship’s energy efficiency. However, several operational difficulties and possible restrictions are associated with its application in maritime environments. These operational and technological limits are taken into consideration when outlining the challenges and limitations. The Clarksons Research World Fleet Register, the open literature, and ship owners and an engine manufacturer provided the data for the review [18].

- Weight and Space Restrictions

Challenge: Ship space is limited, and adding an ORC system may result in severe weight and space issues;

Limitation: Careful design is needed to integrate ORC equipment, such as heat exchangers, pumps, and turbines, inside the ship’s current layout without compromising cargo or operations areas.

- b.

- Corrosion and Fouling

Challenge: Because of the severe conditions in marine environments, including high humidity and exposure to saltwater, ORC components may experience corrosion;

Limitation: Heat exchangers fouling from saltwater or other impurities can raise maintenance expenses and downtime while decreasing heat transmission efficiency.

- c.

- Integration with Existing Systems

Challenge: Integrating an ORC system with the ship’s current propulsion and power systems can be challenging;

Limitation: Significant customization and possible retrofitting may be necessary due to compatibility concerns with the ship’s current energy management and control systems and potential interaction with other onboard machinery.

- d.

- Variable Heat Source

Challenge: Ship waste heat availability is only sometimes constant and is significantly variable when engine loads fluctuate under various operating circumstances;

Limitation: Waste heat availability and temperature fluctuations can substantially impact the ORC system’s efficiency, making it less effective in some situations.

- e.

- Efficiency at Partial Loads

Challenge: Because ships frequently sail at different speeds and loads, the amount of heat they can provide varies;

Limitation: When waste heat is not produced sufficiently to support optimal operation at partial loads, ORC systems may perform less efficiently overall.

- f.

- Maintenance and Reliability

Challenge: The ORC technology makes the ship’s machinery more complex and needs specialist upkeep;

Limitation: In distant maritime locations where repair facilities may be few, the requirement for routine maintenance and the possibility of system breakdowns might raise operating costs and decrease reliability.

- g.

- Initial Cost and Economic Viability

Challenge: A considerable upfront financial expenditure is required to install and integrate ORC systems;

Limitation: Although ORC systems provide good economic benefits, smaller ships or ships with fewer operating hours may need help to offset the initial expenses.

- h.

- Environmental Conditions

Challenge: Ships operate in various environmental circumstances, from tropical to polar regions;

Limitation: Due to variations in ambient temperatures and weather, the effectiveness of the system’s working fluid and overall efficiency may need to be adjusted for ORC systems.

- i.

- Safety Considerations

Challenge: Using organic fluids, which are frequently toxic or combustible, adds to the safety hazards;

Limitation: Strong safety procedures and maybe additional safety equipment are needed to ensure the ORC system operates safely, especially in the event of leaks or malfunctions.

- j.

- Regulatory Compliance

Challenge: It is imperative to comply with international marine rules concerning safety, emissions, and environmental effects;

Limitation: To comply with these rules, ORC systems may need further certifications, modifications, and monitoring systems, which will increase the implementation’s complexity and cost.

2.3. Assumptions

The following assumptions are made to simply the model.

- Kinetic and potential energy changes are negligible;

- All the components are steady flow;

- The working fluid at the pump inlet is saturated liquid;

- The working fluid at the turbine inlet is saturated vapor;

- The isentropic efficiencies of the pump and turbine are 0.85 [34,35];

- The generator efficiency is 0.95.

- The condenser temperature is 35 °C.

The operating conditions of the Rankine cycles depend on turbine inlet temperatures. In this study, turbine inlet temperatures have been changed for working fluids. To compare the various fluids, the working fluid is assumed to be saturated vapor at the turbine inlet.

The pressures of toluene change between 276 kPa and 3286 kPa; for R600, the pressures change between 1526 kPa and 3114 kPa; for isopentane, the pressures change between 721.2 kPa and 1570 kPa; for n-hexane, the pressures change between 240 kPa and 1787 kPa; for R717, the pressures change between 6257 kPa and 10,886 kPa; for R718, the pressures change between 101.4 kPa and 8588 kPa; for R142-b, the pressures change between 2074 kPa and 3582 kPa; for R123, the pressures change between 768.8 kPa and 2496 kPa; for R600a, the pressures change between 1984 kPa and 4645 kPa; for R245-fa, the pressures change between 1269 kPa and 2815 kPa; for R141-b, the pressures change between 677.2 kPa and 3949 kPa, depending on turbine inlet temperatures.

2.4. Governing Equations

The mass balance for a general steady flow system is

mass flow rates in kg/s

The energy balance for a general steady flow system is

the rate of energy in W

The first law in W

Exergy balance for a general steady flow system is

Net power from RC is

The rate of heat transfer from the exhaust gas is

The flow exergy of a flowing fluid is

For a steady-flow system, the reversible power is

The exergy efficiency of the system is

Irreversibility in J and W for the system, respectively, is

3. Results

In this study, the condenser temperature of 35 °C for effective heat transfer was chosen because the maximum seawater temperature is 32 °C, according to the Loydu Rules for the Classification of Naval Ships [36]. The mass flow rate of seawater through the condenser changes depending on the seawater inlet temperature.

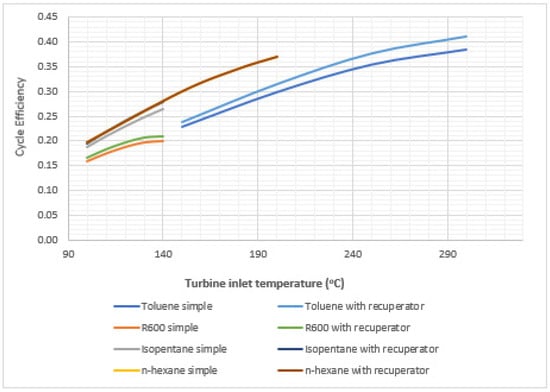

The efficiency of a simple cycle and a cycle with a recuperator for dry fluid is illustrated in Figure 3. The following can be seen in the figure:

Figure 3.

Cycle efficiency for dry fluids.

- If the turbine inlet temperature is above 200 °C, the highest efficiency among dry fluids is achieved in the RC system with a recuperator using toluene;

- For the turbine inlet temperature of 300 °C, the efficiency of the toluene in the recuperator system is calculated to be 38%;

- If the turbine inlet temperature is below 200 °C, the recuperator system with n-hexane yields the highest efficiency;

- For a turbine inlet temperature of 200 °C, the efficiency of the n-hexane in the recuperator system is 37%;

- It has been observed that using a recuperator in dry fluids increases the cycle efficiency by approximately 2%.

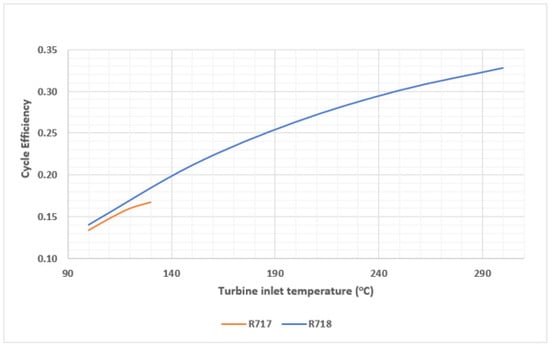

Figure 4 illustrates the efficiency of a simple RC for wet fluid. The highest efficiency among the wet fluids compared in this study is obtained from R718.

Figure 4.

Cycle efficiency for wet fluids.

- For a turbine inlet temperature of 300 °C, the efficiency of the R718 fluid is calculated to be 33%;

- Additionally, due to the significantly broader operating range of R718 compared to R717, using R718 as the wet fluid in RC systems is seen as more advantageous.

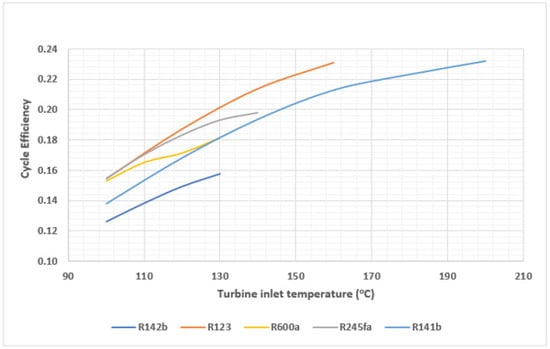

The efficiency of a simple RC for isentropic fluid is illustrated in Figure 5. The following can be seen in the figure:

Figure 5.

Cycle efficiency for isentropic fluids.

- If the turbine inlet temperature is above 160 °C, the highest efficiency among isentropic fluids is obtained from R141b;

- For a turbine inlet temperature of 200 °C, the efficiency of the R141b fluid is calculated to be 23%;

- If the turbine inlet temperature is below 160 °C, the highest efficiency among isentropic fluids is obtained from R123;

- For a turbine inlet temperature of 160 °C, the efficiency of R123 is calculated to be 23%;

- In situations where the turbine inlet temperature is below 160 °C, the efficiency ranking among isentropic fluids is as follows: R123, R245fa, R600a, R141b, and R142b.

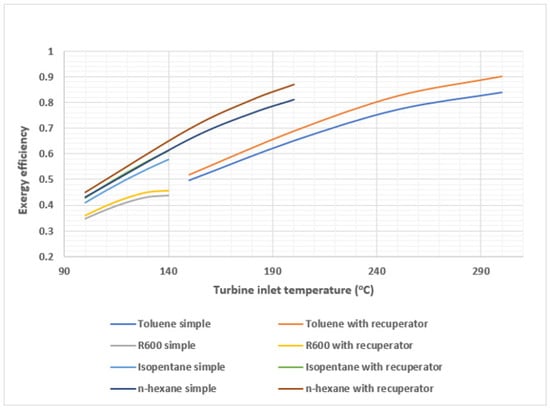

The exergy efficiency of a simple cycle and a cycle with a recuperator for dry fluids is illustrated in Figure 6. The following can be seen in the figure:

Figure 6.

Exergy efficiency for dry fluids.

- If the turbine inlet temperature is above 200 °C, the highest exergy efficiency among dry fluids is obtained from the recuperator-based RC system using toluene;

- For a turbine inlet temperature of 300 °C, the exergy efficiency of toluene fluid in the recuperator-based ORC system is calculated as 90%;

- If the turbine inlet temperature is below 200 °C, the highest exergy efficiency among dry fluids is obtained from the recuperator-based RC system using n-hexane;

- For a turbine inlet temperature of 200 °C, the exergy efficiency of n-hexane fluid in the recuperator-based RC system is calculated to be 86%;

- Additionally, it has been observed that using a recuperator in RC systems increases the exergy efficiency by approximately 5%.

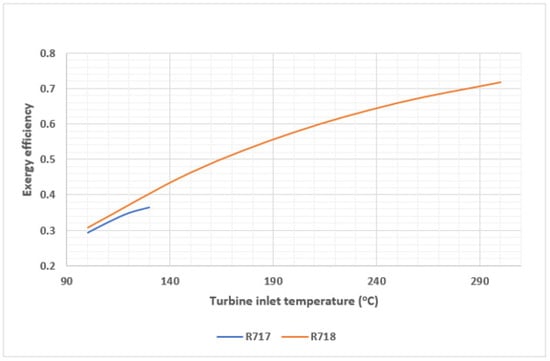

The exergy efficiency for wet fluid is illustrated in Figure 7. The following can be seen in the figure:

Figure 7.

Exergy efficiency for wet fluids.

- The highest exergy efficiency among the wet fluids compared in this study belongs to R718;

- For a turbine inlet temperature of 300 °C, the exergy efficiency of the R718 is calculated to be 71%.

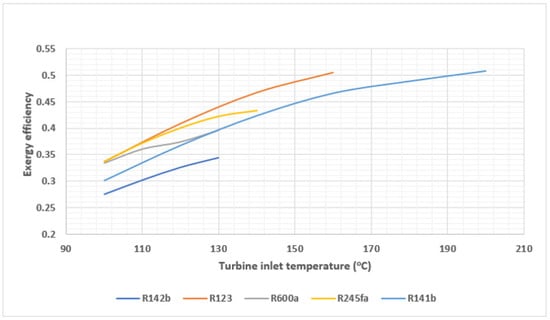

The exergy efficiency for isentropic fluid is illustrated in Figure 8. The following can be seen in the figure:

Figure 8.

Exergy efficiency for isentropic fluids.

- If the turbine inlet temperature is above 160 °C, the highest exergy efficiency among isentropic fluids is obtained from R141b;

- For a turbine inlet temperature of 200 °C, the exergy efficiency of the R141b fluid is calculated to be 50%;

- If the turbine inlet temperature is below 160 °C, the highest exergy efficiency among isentropic fluids is obtained from R123;

- For a turbine inlet temperature of 160 °C, the exergy efficiency of the R123 fluid is calculated to be 50%.

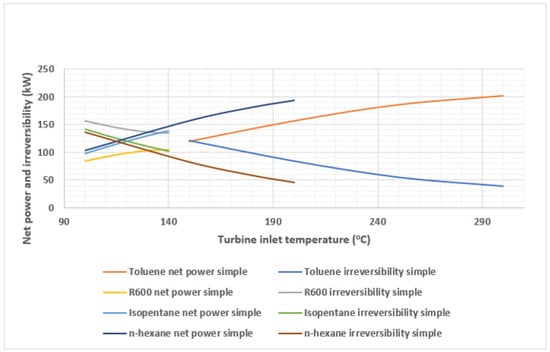

The net power and irreversibility for a simple RC with dry fluid are illustrated in Figure 9. The following can be seen in the figure:

Figure 9.

Net power and irreversibility for dry fluids with simple ORC.

- The highest net power among dry fluids above a turbine inlet temperature of 200 °C is obtained from toluene;

- For a turbine inlet temperature of 300 °C, the net power obtained from the toluene is calculated to be 201.094 kW;

- If the turbine inlet temperature is below 200 °C, the highest net power among dry fluids is obtained from n-hexane;

- For a turbine inlet temperature of 200 °C, the net power obtained from the n-hexane is calculated to be 193.93 kW;

- Additionally, Figure 9 shows that irreversibility and net power are inversely proportional. Irreversibility decreases as net power increases.

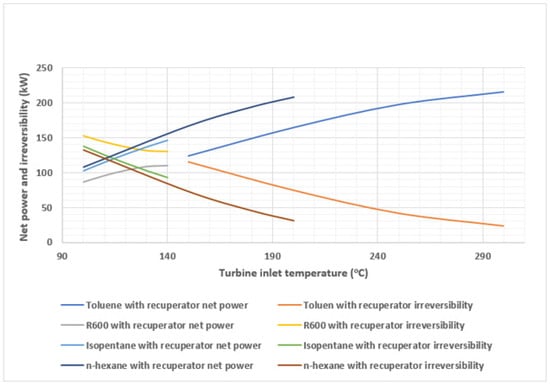

The net power and irreversibility for a dry fluid in RC with a recuperator are illustrated in Figure 10. The following can be seen in the figure:

Figure 10.

Net power and irreversibility for dry fluids of RC with recuperator.

- The highest net power among dry fluids with a turbine inlet temperature above 200 °C is obtained from toluene;

- For a turbine inlet temperature of 300 °C, the net power obtained from the toluene fluid is calculated to be 215.512 kW;

- If the turbine inlet temperature is below 200 °C, the highest net power among dry fluids is obtained from n-hexane;

- For a turbine inlet temperature of 200 °C, the net power obtained from the n-hexane is calculated to be 207.894 kW;

- Additionally, as shown in Figure 10, irreversibility and net power are inversely proportional. Irreversibility decreases as net power increases.

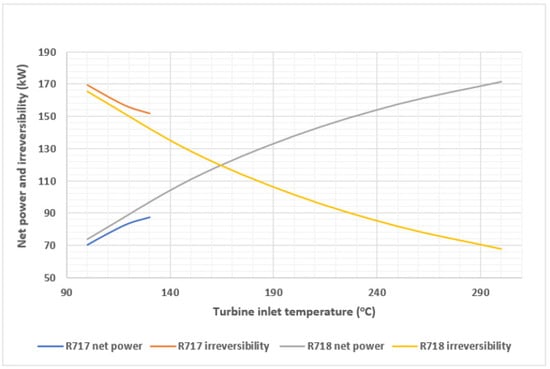

The net power and irreversibility for a wet fluid in RC are illustrated in Figure 11. The following can be seen in the figure:

Figure 11.

Net power and irreversibility for wet fluids.

- In simple RC systems, the net power of R718 is calculated to be higher than that of R717 at each temperature.

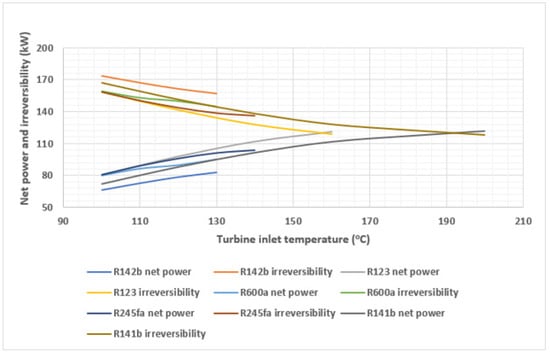

The net power and irreversibility of an isentropic fluid in a simple RC are illustrated in Figure 12. The following can be seen in the figure:

Figure 12.

Net power and irreversibility for isentropic fluids.

- For turbine inlet temperatures above 160 °C, the highest net power among isentropic fluids is obtained from R141b;

- In cases where the turbine inlet temperature is below 130 °C, the highest net power is obtained from R123.

The proposed system design, with waste heat of diesel engine onboard ships enables not only improved energy efficiency, fuel savings, reduction in greenhouse gas emissions, and compliance with environmental regulations but also economic competitiveness, promoting technological innovation, increased operational flexibility, broader impact, contribution to the circular economy, potential for retrofitting existing fleets, and stimulating job creation and industry growth.

4. Conclusions

In this study, thermodynamic analysis for a seawater-cooled and marine diesel engine exhaust-driven organic and inorganic RC has been carried out. The cycle efficiencies for a simple RC and an RC with a recuperator for the marine engine have been investigated. The systems’ cycle efficiencies, exergy efficiencies, net power, and irreversibility have been computed versus turbine inlet temperature by keeping the condensing temperature constant. The net power and irreversibility of the system have been calculated at full load for marine diesel engines.

The cycle and exergy efficiencies of RC are highly dependent on the working fluid.

For dry fluids, the most efficient fluid at low turbine inlet temperatures is n-hexane, while at high turbine inlet temperatures it is toluene.

For isentropic fluids, the most efficient fluid at low turbine inlet temperatures is R123, while at high turbine inlet temperatures it is R141b. The results demonstrate that when the turbine inlet temperature in the RC system with a recuperator is above 200 °C, the dry fluid with the highest efficiency is toluene. When it is below 200 °C, dry fluid with the highest efficiency is n-hexane. Although toluene and n-hexane have an ODP of 0 and a low GWP of 3, they have higher flammability. R123, which features higher toxicity, and R141b have a high GWP.

For wet fluids, R718 is one of the most suitable working fluids at low and high turbine inlet temperatures for marine diesel engine exhaust heat onboard ships with a safety group classification of A1, ODP of 0, and GWP100 of 0 at high temperatures among compared fluids. For a turbine inlet temperature of 300 °C, R718 has a cycle efficiency of 33%, exergy efficiency of 71%, net power of 171.544 kW, and irreversibility of 67.773 kW at a whole load of marine diesel engine. R718 is environmentally friendly, abundant in nature, and can be used safely onboard ships.

This study contributes to significant improvements in fuel efficiency and reductions in greenhouse gas emissions, leading to more sustainable and cost-effective maritime operations.

Author Contributions

Investigation, H.K.; Formal analysis, C.E.; Methodology, H.K. and C.E.; Project administration, H.K.; Resources, C.E.; Validation, C.E.; Writing—original draft, H.K.; Writing—review and editing, C.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analyzed during this study are included in this published article.

Conflicts of Interest

No conflict of interest exists in the submission of this manuscript, and the manuscript is approved by all authors for publication.

Nomenclature

| rate of energy (W) | |

| specific enthalpy (kJ/kg) | |

| I | irreversibility (kJ/kg) |

| mass flow rate (kg/s) | |

| rate of heat transfer (W) | |

| s | specific entropy (kJ/kg·K) |

| V | velocity (m/s) |

| power (W) | |

| rate of exergy (W) | |

| Greek | |

| flow exergy (kJ/kg) | |

| efficiency | |

| Abbreviations | |

| CFD | Computational Fluid Dynamics |

| ECHA | European Chemicals Agency |

| EEDI | Energy Efficiency Design Index |

| EPA | U.S. Environmental Protection Agency |

| GWP | Global Warming Potential |

| IMO | International Maritime Organization |

| ODP | Ozone Depletion Potential |

| ORC | Organic Rankine Cycle |

| PFAS | Per- and Polyfluoroalkyl Substances |

| RC | Rankine Cycle |

| SEEMP | Ship Energy Efficiency Management Plan |

| General Subscript | |

| ex | exergy |

| exh | exhaust |

| in | inlet |

| out | outlet |

| rev | reversible |

| th | thermal |

References

- Bellos, E.; Lykas, P.; Tzivanidis, C. Thermodynamic investigation of a novel organic Rankine cycle including partial evaporation, dual-phase expander, flash tank, dry expander, and recuperator for waste heat recovery. Therm. Sci. Eng. Prog. 2023, 46, 102244. [Google Scholar] [CrossRef]

- Tian, H.; Liu, P.; Shu, G. Challenges and opportunities of Rankine cycle for waste heat recovery from internal combustion engine. Prog. Energy Combust. Sci. 2021, 84, 100906. [Google Scholar] [CrossRef]

- Qu, J.; Feng, Y.; Zhu, Y.; Zhou, S.; Zhang, W. Design and thermodynamic analysis of a combined system including steam Rankine cycle, organic Rankine cycle, and power turbine for marine low-speed diesel engine waste heat recovery. Energy Convers. Manag. 2021, 245, 114580. [Google Scholar] [CrossRef]

- Alshammari, F.; Alghafis, A.; Alatawi, I.; Alshammari, A.S.; Alzamil, A.; Alrashidi, A. Potential of Variable Geometry Radial Inflow Turbines as Expansion Machines in Organic Rankine Cycles Integrated with Heavy-Duty Diesel Engines. Appl. Sci. 2023, 13, 12139. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X.; Cai, J.; Wang, R.; Bian, X.; Wang, J.; Tian, H.; Shu, G. Selection maps of dual-pressure organic Rankine cycle configurations for engine waste heat recovery applications. Appl. Therm. Eng. 2023, 228, 120478. [Google Scholar] [CrossRef]

- Turja, A.; Sadat, K.; Khan, Y.; Ehsan, M. Cascading the Transcritical CO2 and Organic Rankine Cycles with Supercritical CO2 Cycles for Waste Heat Recovery. Int. J. Thermofluids 2023, 20, 100508. [Google Scholar] [CrossRef]

- Jafari, M.; Khan, M.; Ghamdi, S.; Jaworski, A.; Asfand, F. Waste heat recovery in iron and steel industry using organic Rankine cycles. Chem. Eng. J. 2023, 477, 146925. [Google Scholar] [CrossRef]

- Varis, C.; Ozkilic, S. In a biogas power plant from waste heat power generation system using Organic Rankine Cycle and multi-criteria optimization. Case Stud. Therm. Eng. 2023, 44, 102729. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, L.; Cong, H.; Li, X. Synthesis of waste heat recovery using solar organic Rankine cycle in the separation of benzene/toluene/p-xylene process. Energy 2022, 255, 124443. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Zhang, Y.; Zhang, C. A method used to comprehensively evaluate dry and isentropic organic working fluids based on temperature-entropy diagram. Energy 2023, 263, 125855. [Google Scholar] [CrossRef]

- Herath, H.; Wijewardane, M.; Ranasinghe, R.; Jayasekera, J. Working fluid selection of Organic Rankine Cycles. Energy Rep. 2020, 6, 680–686. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, H.; Li, S.; Li, W.; Pan, P.; Liu, T.; Wu, L.; Xu, G. Thermodynamic and economic analysis of a novel design combining waste tire pyrolysis with silicon production waste heat recovery and organic Rankine cycle. Energy 2023, 283, 128500. [Google Scholar] [CrossRef]

- Kong, J.; Wan, G.; Yan, J.; Yi, Q.; Hao, X.; Liu, X.; Re, L. Design and control of extraction combined with extractive distillation for separation isopropanol-butanol-ethanol-water with organic Rankine cycle. Sep. Purif. Technol. 2023, 313, 123443. [Google Scholar] [CrossRef]

- Mubashir, W.; Adnan, M.; Zaman, M.; Imran, M.; Naqvi, S.; Mehmood, A. Thermo-economic evaluation of supercritical CO2 Brayton cycle integrated with absorption refrigeration system and organic Rankine cycle for waste heat recovery. Therm. Sci. Eng. Prog. 2023, 44, 102073. [Google Scholar] [CrossRef]

- Zakeralhoseini, S.; Schiffmann, J. Design, computational and experimental investigation of a small-scale turbopump for organic Rankine cycle systems. Energy Convers. Manag. 2023, 287, 117073. [Google Scholar] [CrossRef]

- Tsimpoukis, D.; Syngounas, E.; Bellos, E.; Koukou, M.; Tzivanidis, C.; Anagnostatos, S.; Vrachopoulos, M. Optimization analysis of Organic Rankine Cycle powered by waste heat of a supermarket transcritical CO2 multi-ejector refrigeration cycle. J. Clean. Prod. 2023, 418, 138106. [Google Scholar] [CrossRef]

- Anastasovski, A.; Rasković, P.; Guzović, Z. A review of heat integration approaches for organic Rankine cycle with waste heat in production processes. Energy Convers. Manag. 2020, 221, 113175. [Google Scholar] [CrossRef]

- Mondejar, M.; Andreasen, J.; Pierobon, L.; Larsen, U.; Thern, M.; Haglind, F. A review of the use of organic Rankine cycle power systems for maritime applications. Renew. Sustain. Energy Rev. 2018, 91, 126–151. [Google Scholar] [CrossRef]

- Holik, M.; Živić, M.; Virag, Z.; Barac, A. Optimization of an organic Rankine cycle constrained by the application of compact heat exchangers. Energy Convers. Manag. 2019, 188, 333–345. [Google Scholar] [CrossRef]

- Chowdhury, A.; Ehsan, M. A Critical Overview of Working Fluids in Organic Rankine, Supercritical Rankine, and Supercritical Brayton Cycles Under Various Heat Grade Sources. Int. J. Thermofluids 2023, 20, 100426. [Google Scholar] [CrossRef]

- Liu, Q.; Shen, A.; Duan, Y. Parametric optimization and performance analyses of geothermal organic Rankine cycles using R600a/R601a mixtures as working fluids. Appl. Energy 2015, 14, 410–420. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Y.; Xia, X.; Pan, H.; Zhang, S.; Liu, Z. Experimental evaluation of organic Rankine cycle using zeotropic mixture under different operation conditions. Energy 2023, 264, 126188. [Google Scholar] [CrossRef]

- Bishal, S.; Faysal, D.; Ehsan, M.; Salehin, S. Performance evaluation of an integrated cooling and power system combining supercritical CO2, gas turbine, absorption refrigeration, and organic Rankine cycles for waste energy recuperating system. Results Eng. 2023, 17, 100943. [Google Scholar] [CrossRef]

- Elahi, A.; Mahmud, T.; Alam, M.; Hossain, J.; Biswas, B. Exergy analysis of organic Rankine cycle for waste heat recovery using low GWP refrigerants. Int. J. Thermofluids 2022, 16, 100243. [Google Scholar] [CrossRef]

- Faruque, W.; Raihan; Uddin, M.; Salehin, S.; Ehsan, M. A Comprehensive Thermodynamic Assessment of Cascade Refrigeration System Utilizing Low GWP Hydrocarbon Refrigerants. Int. J. Thermofluids 2022, 15, 100177. [Google Scholar] [CrossRef]

- Ganesan, P.; Eikevik, T.; Hamid, K.; Wang, R.; Yan, H. Thermodynamic analysis of cascade high-temperature heat pump using new natural zeotropic refrigerant mixtures: R744/R600 and R744/R601. Int. J. Refrig. 2023, 154, 215–230. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Sun, Y.; Wang, H.; Guo, H.; Gong, M. Optimization method for mixed refrigerants in Joule–Thomson refrigerators with fixed-temperature heat loads. Appl. Therm. Eng. 2023, 233, 121198. [Google Scholar] [CrossRef]

- Corigliano, O.; Algieri, A.; Fragiacomo, P. Turning Data Center Waste Heat into Energy: A Guide to Organic Rankine Cycle System Design and Performance Evaluation. Appl. Sci. 2024, 14, 6046. [Google Scholar] [CrossRef]

- Elmaihy, A.; Rashad, A.; Elweteedy, A.; Nessim, W. Energy and exergy analyses for organic Rankine cycle driven by cooling water of passenger car engine using sixteen working fluids. Energy Convers. Manag. 2023, 20, 100415. [Google Scholar] [CrossRef]

- Pereiraa, J.; Ribeiroa, J.; Mendesa, R.; Vazb, G.; Andréa, J. ORC based micro-cogen[eration systems for residential application—A state of the art review and current challenges. Renew. Sustain. Energy Rev. 2018, 92, 728–743. [Google Scholar] [CrossRef]

- NIST Standard Reference Database 23. Available online: https://www.nist.gov/publications/nist-standard-reference-database-23-reference-fluid-thermodynamic-and-transport (accessed on 3 July 2024).

- ASHRAE Standard. Available online: https://www.ashrae.org/Library/Resources/Standards.pdf (accessed on 10 June 2024).

- Wartsila. Product Guide. Available online: https://cdn.wartsila.com/docs/default-source/product-files/engines/ms-engine/product-guide-o-e-w20.pdf (accessed on 20 June 2024).

- Ally, M.; Sharma, V. Variability of absorption heat pump efficiency for domestic water heating and space heating based on time-weighted bin analysis. Appl. Therm. Eng. 2018, 130, 515–527. [Google Scholar] [CrossRef]

- Jamil, M.; Elmutasim, S.; Zubair, S. Exergo-economic analysis of a hybrid humidification dehumidification reverse osmosis (HDH-RO) system operating under different retrofits. Energy Convers. Manag. 2018, 158, 286–297. [Google Scholar] [CrossRef]

- Rules for the Classification of Naval Ships. Available online: https://www.turkloydu.org/pdf-files/turk-loydu-kurallari/cilt-e/chapter-107-naval-ship-technology-ship-operation-installations-and-auxiliary-systems-2022-JAN.pdf (accessed on 3 June 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).