Fracture Mechanism and Damage Constitutive Model of Freeze–Thaw Fissured Granite Subjected to Fatigue Loading

Abstract

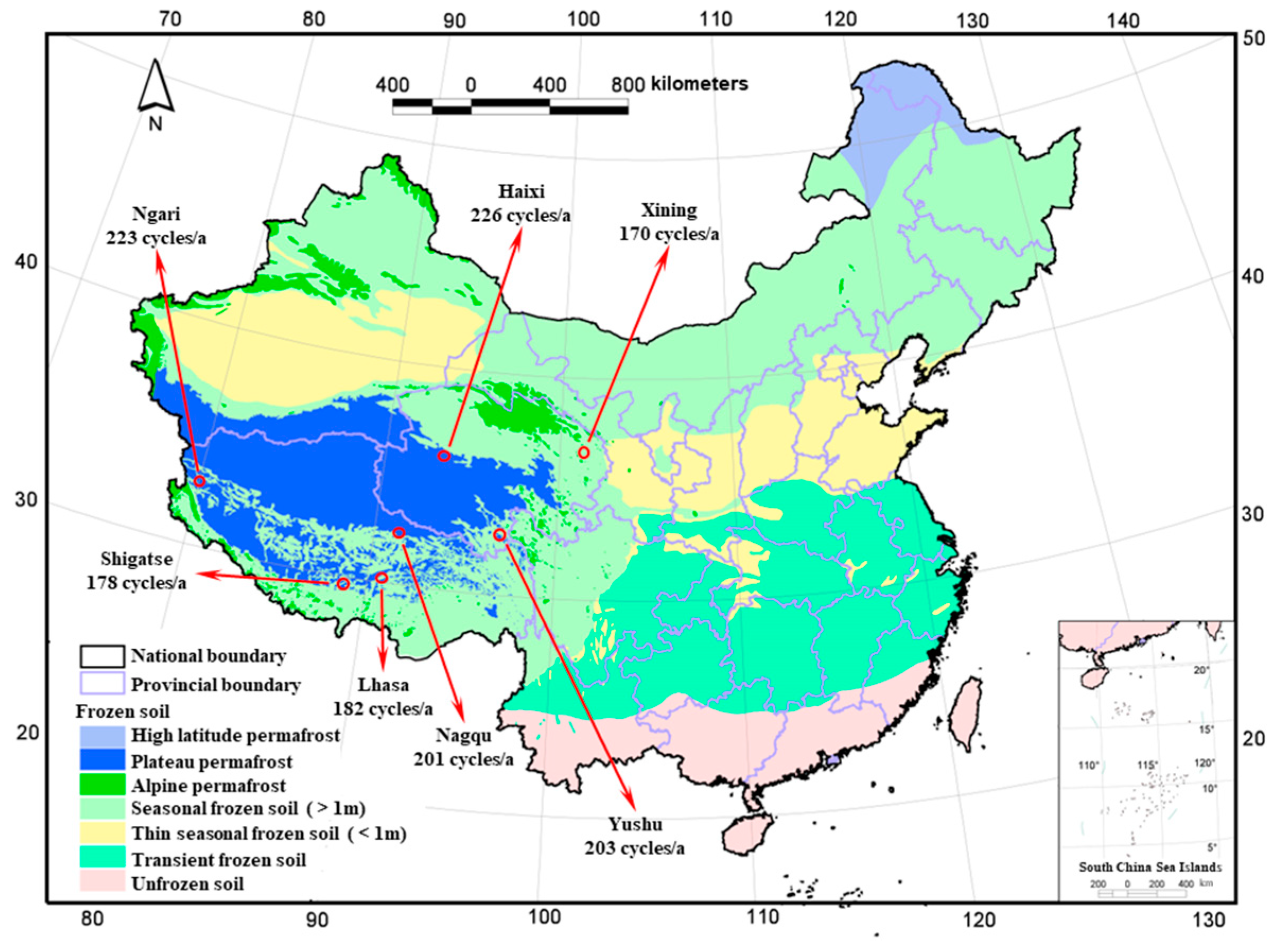

:1. Introduction

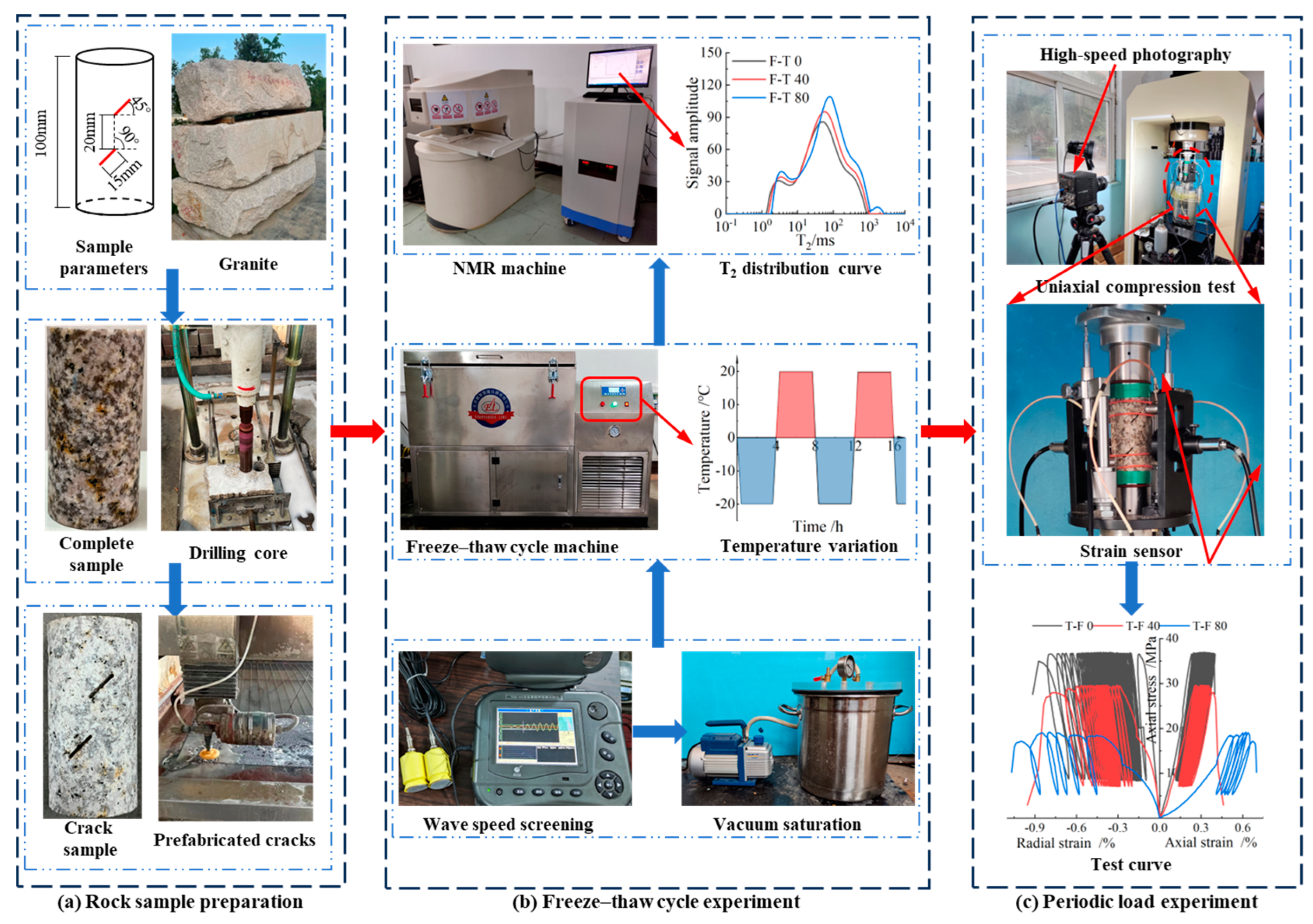

2. Materials and Methods

2.1. Test Procedure

2.2. Test Equipment

3. Results and Discussion

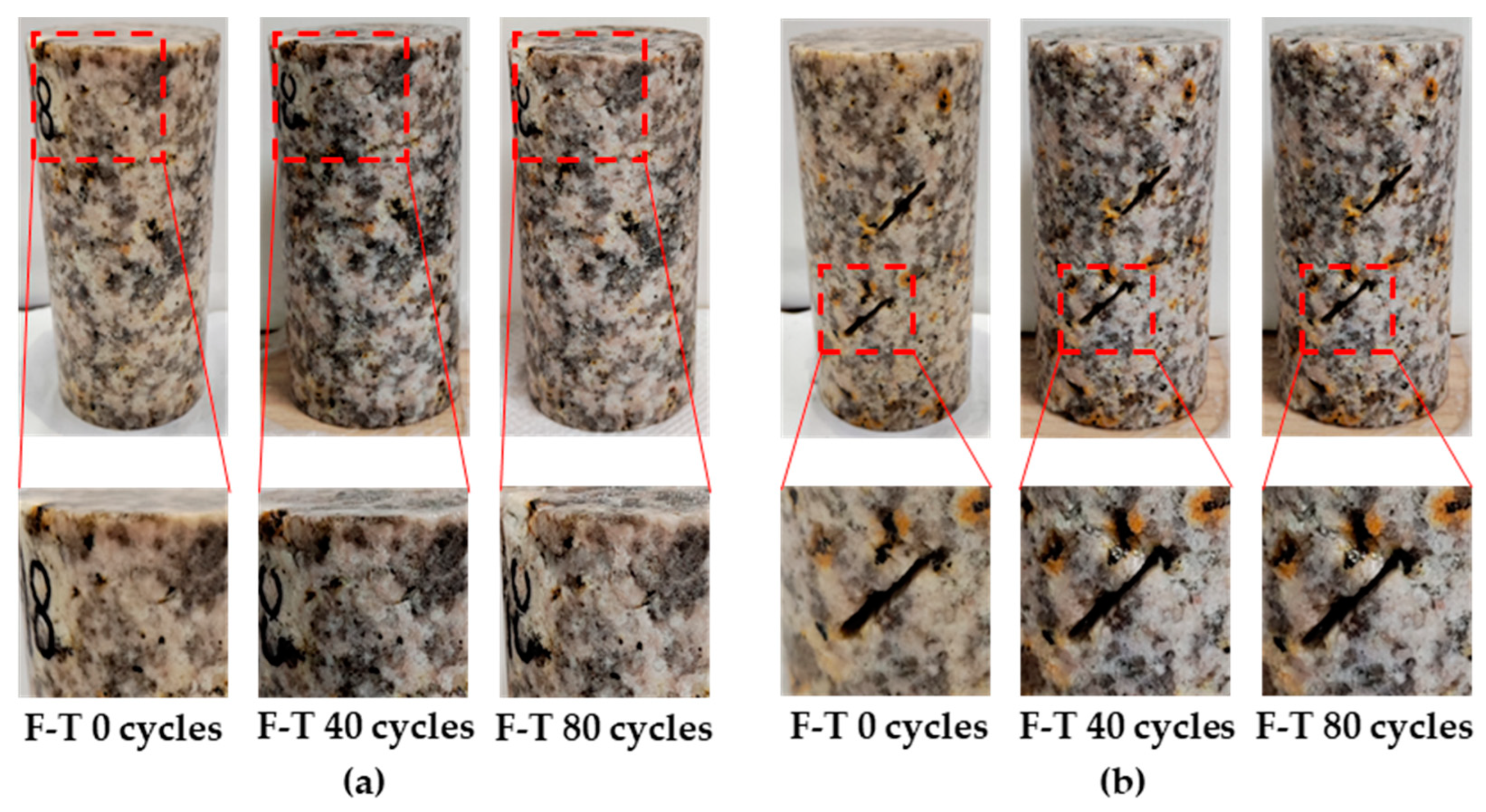

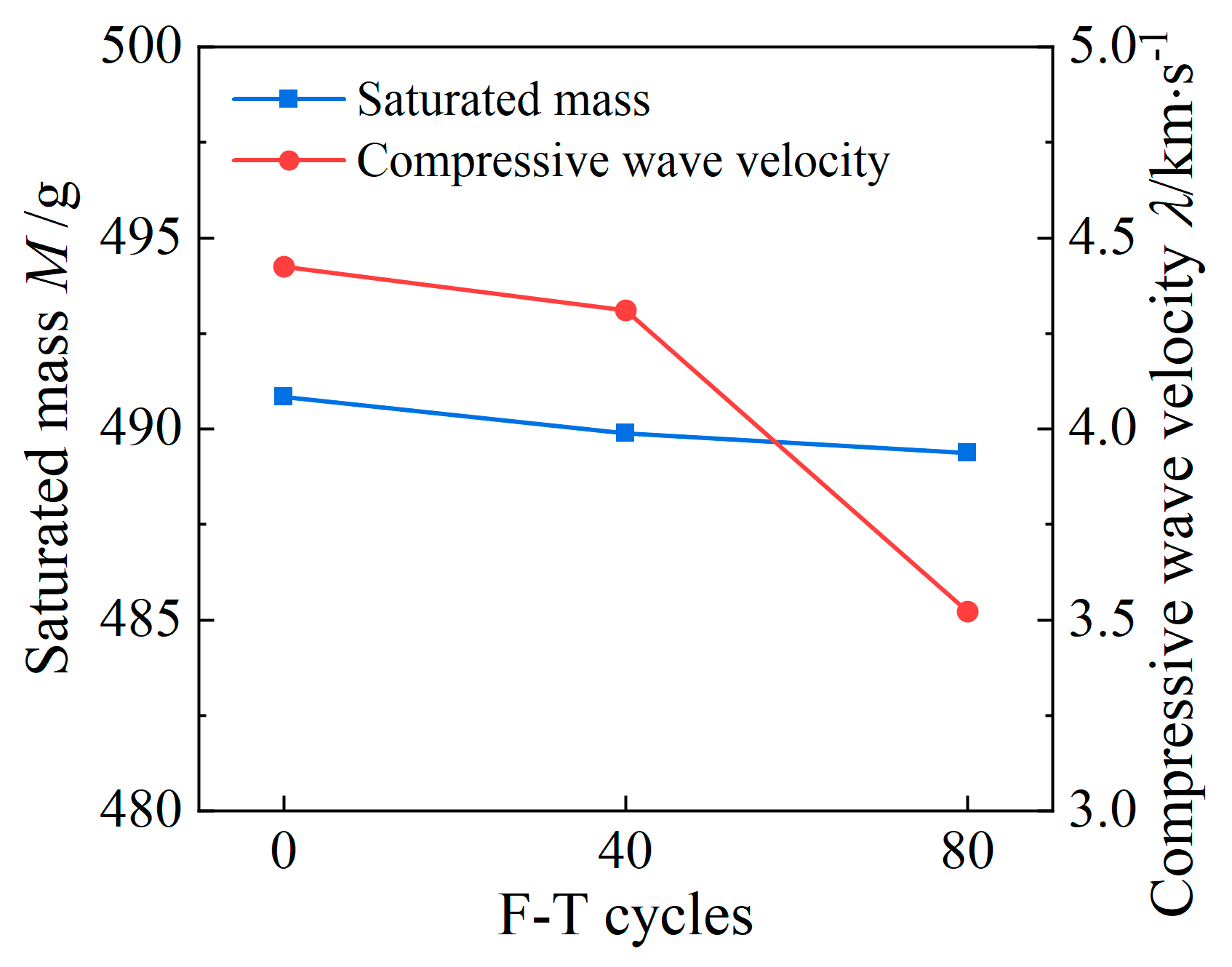

3.1. Macroscopic Damage Characteristics of Fractured Granite under Freeze–Thaw Cycles

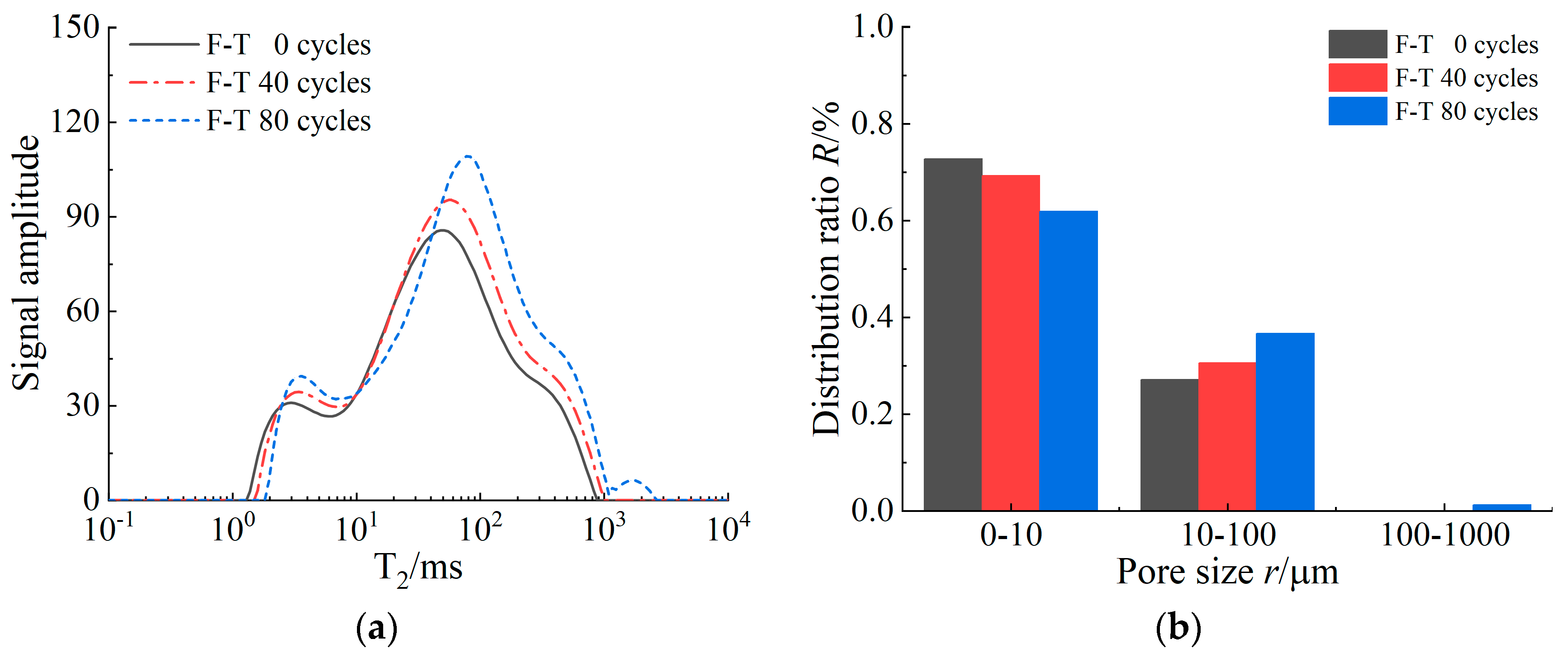

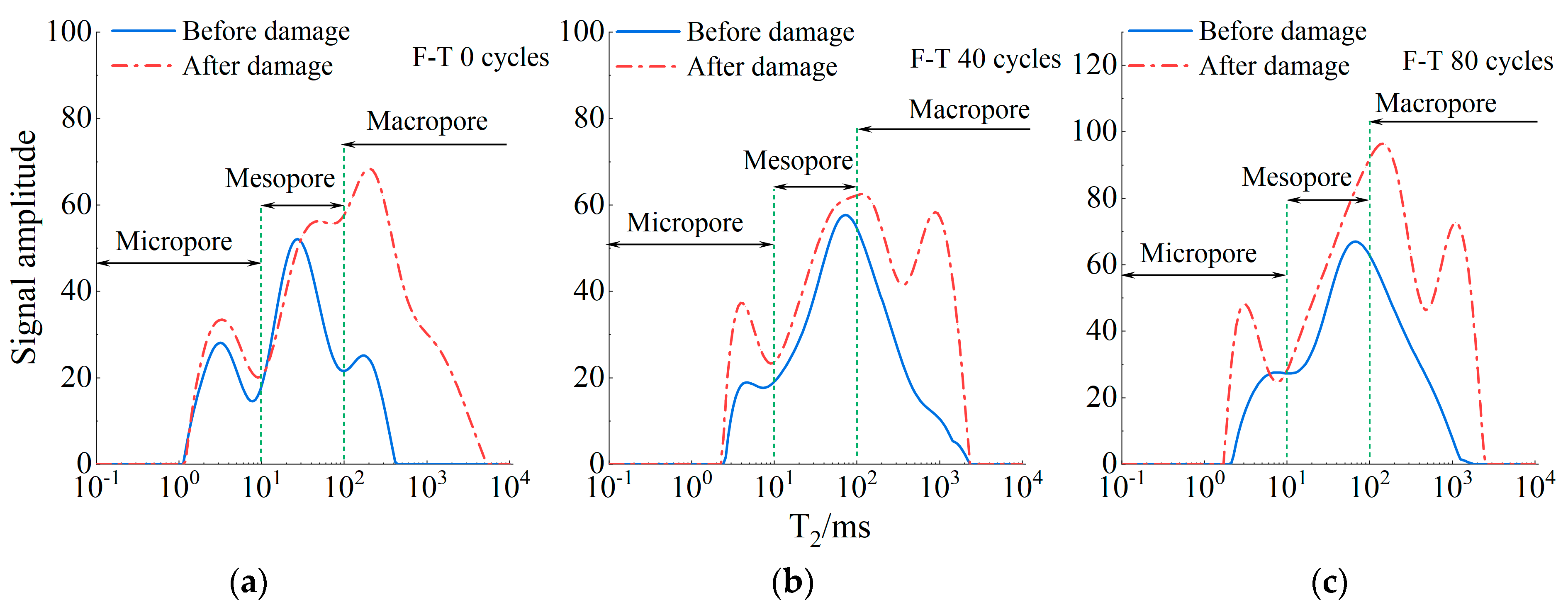

3.2. NMR T2 Spectrum and Pore Distribution Structure Analysis

3.3. Mechanical Property Analysis

3.4. Analysis of Damage and the Failure Mechanism under Freeze–Thaw and Fatigue Load

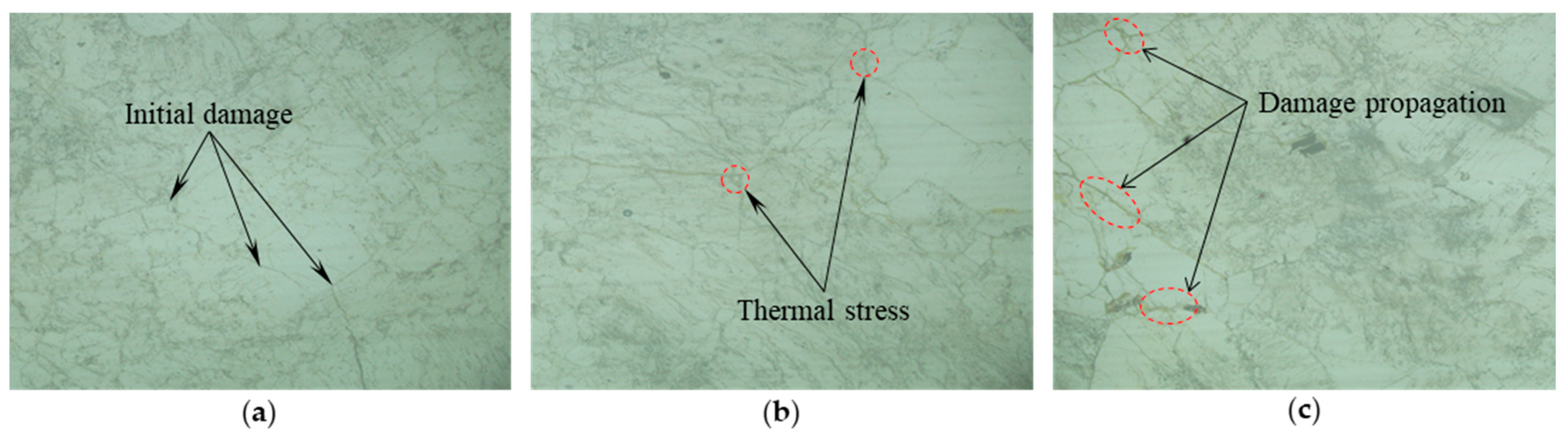

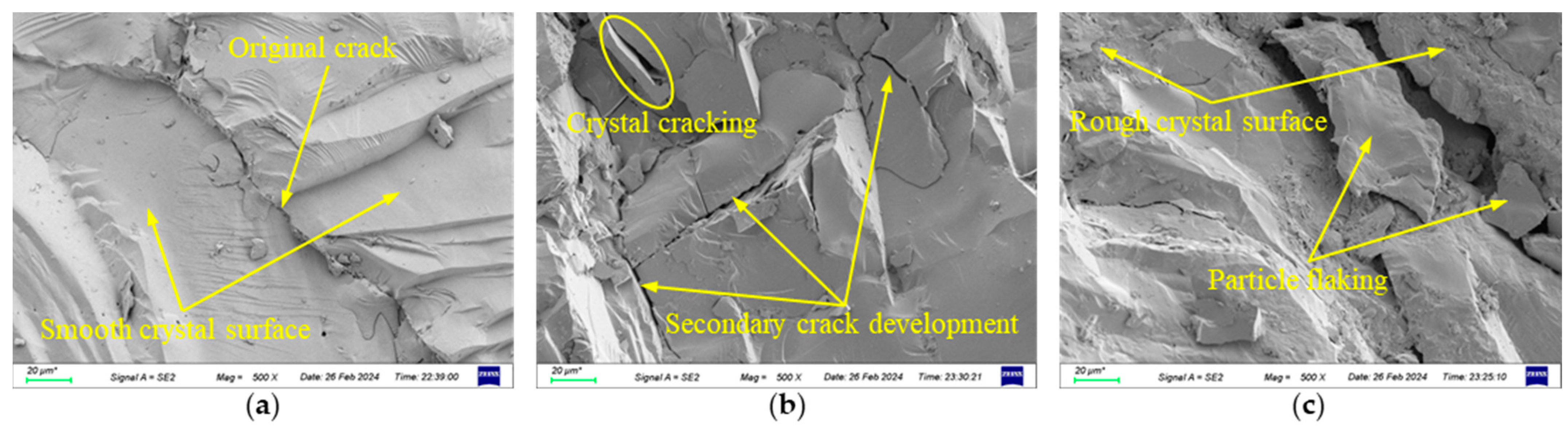

3.5. Destructive Characteristics and Crack Development Mechanism Analysis

4. Damage Constitutive Model of Fractured Granite under the Combined Action of Freeze–Thaw and Fatigue Load

4.1. Definition of Damage Variable

4.1.1. Definition of the Macroscopic Fracture Damage Variable

4.1.2. Definition of the Damage Variable under Uniaxial Load

4.1.3. Definition of the Damage Variable in Freeze–Thaw Action

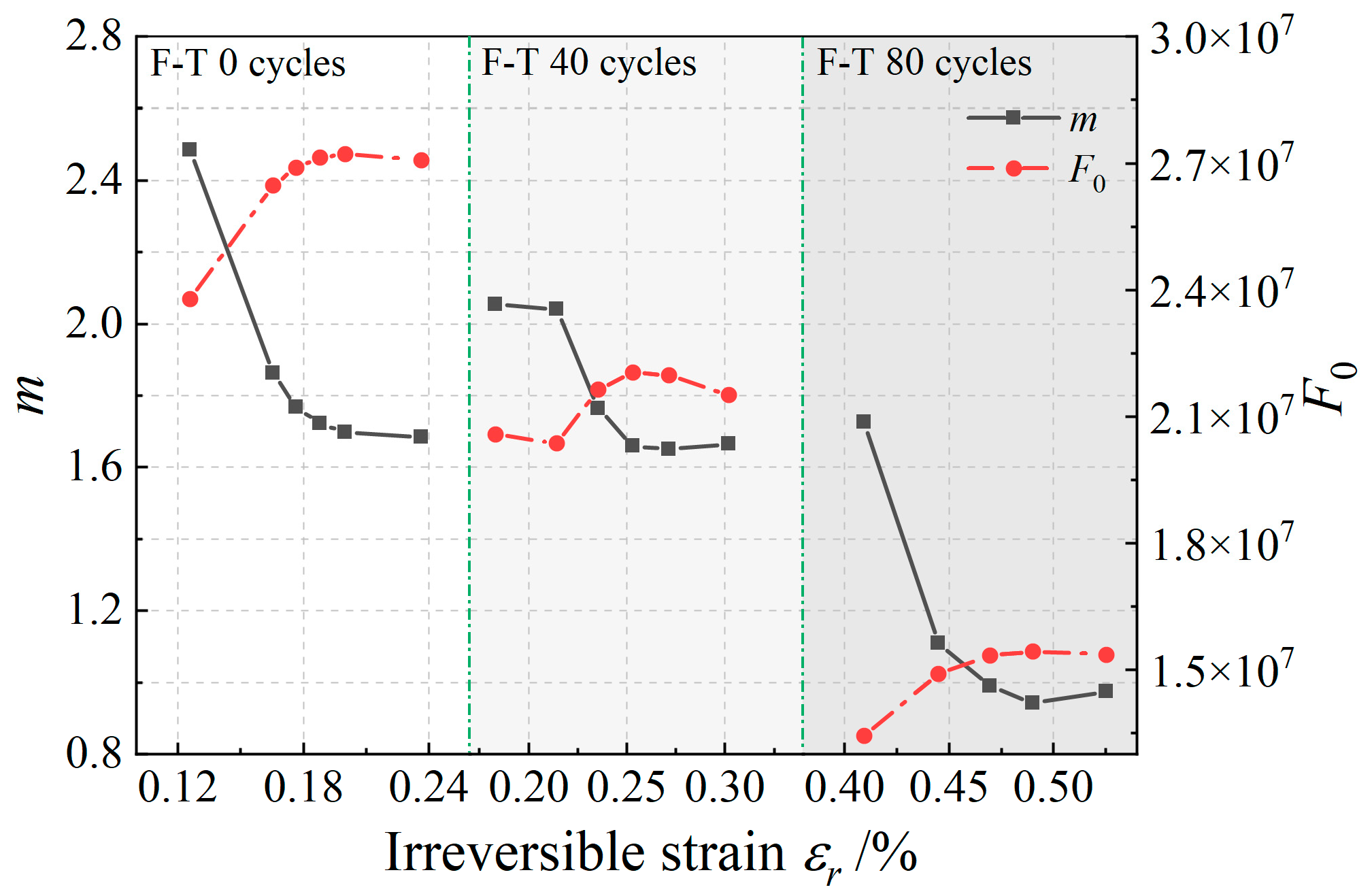

4.2. Fatigue Damage Constitutive Model Based on Internal Variables

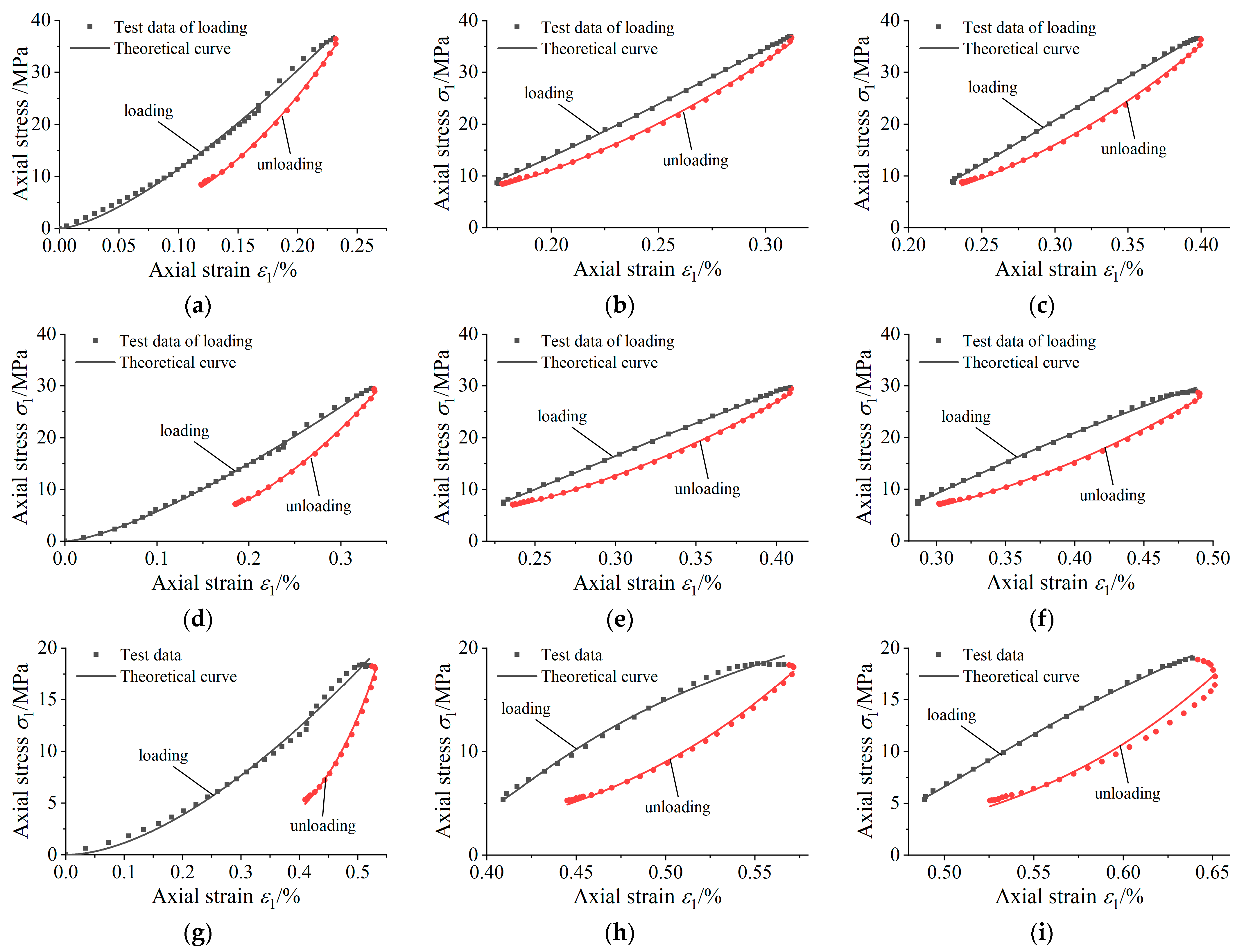

4.3. Validation of Parameters and Constitutive Models

5. Conclusions

- (1)

- Prefabricated cracks increase stress concentration in granite during freeze–thaw cycles, promoting freeze–thaw damage accumulation. After these cycles, the saturated mass and longitudinal wave velocity of cracked granite gradually decrease. Network micro-cracks and block-like spalling develop around the prefabricated cracks. The NMR T2 spectrum of the sample showed a three-peak distribution, with the second peak area accounting for more than 85%. After freezing and thawing, the peaks of the second wave of T2 spectral curves increased by 11.11% and 22.61%, respectively. The T2 spectrum of the fractured granite shifts significantly to the right after fatigue load failure, and the amplitude of the third peak increases notably.

- (2)

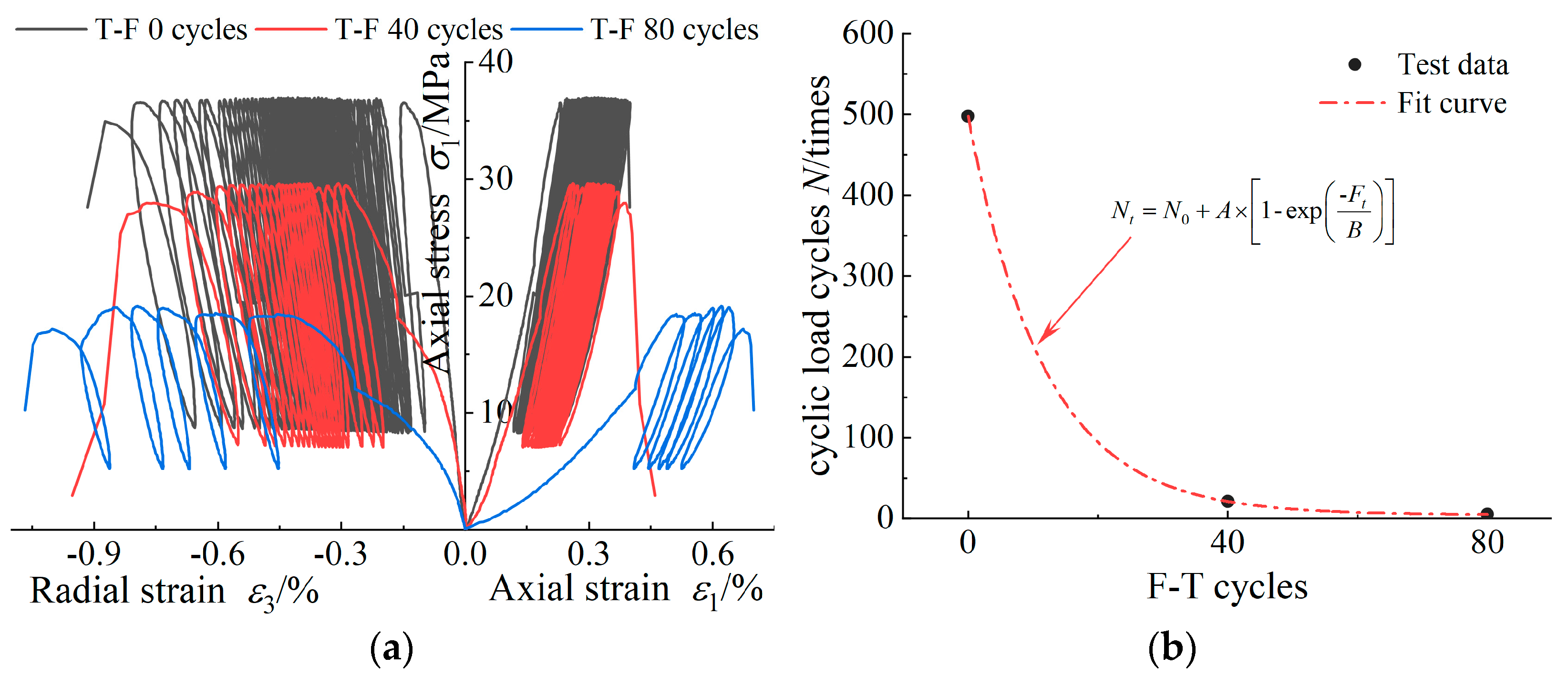

- Under fatigue load, the damage to the granite samples without freeze–thaw cycles is sudden and explosive. After freeze–thaw cycles, the failure of the granite specimens becomes more gradual. With an increasing number of freeze–thaw cycles, the granite samples endured 498, 21, and 5 loading cycles, respectively, demonstrating an exponential decrease in fatigue resistance. Freeze–thaw cycles weaken the internal structure of granite, reducing its bearing and energy storage capacities, but making the failure patterns more complex.

- (3)

- By integrating the irreversible strain evolution model, a fatigue damage constitutive model for fractured granite, encompassing initial fracture damage, freeze–thaw damage, and load damage, is established. This model effectively accounts for the combined effects of freeze–thaw cycles and fatigue load on fractured granite. The theoretical curves align well with experimental data, demonstrating good applicability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, X.F.; Fu, Z.; Wang, H.L. Quantitative method for freezing-thawing environment of concrete in Qinghai-Tibet plateau. Trans. Chin. Soc. Agric. Eng. 2018, 34, 169–175. [Google Scholar]

- Yu, W.B.; Zhang, T.Q.; Lu, Y.; Han, F.L.; Zhou, Y.F.; Hu, D. Engineering risk analysis in cold regions: State of the art and perspectives. Cold Reg. Sci. Technol. 2020, 171, 102963. [Google Scholar] [CrossRef]

- Zhang, X.F.; Lai, Y.M.; Yu, W.B.; Zhang, S.J. Non-linear analysis for the freezing–thawing situation of the rock surrounding the tunnel in cold regions under the conditions of different construction seasons, initial temperatures and insulations. Tunn. Undergr. Space Technol. 2002, 17, 315–325. [Google Scholar] [CrossRef]

- Tan, X.; Chen, W.; Yang, D.; Dai, Y.; Wu, G.; Yang, J.; Yu, H.; Tian, H.; Zhao, W. Study on the influence of airflow on the temperature of the surrounding rock in a cold region tunnel and its application to insulation layer design. Appl. Therm. Eng. 2014, 67, 320–334. [Google Scholar] [CrossRef]

- Luo, L.; Ma, W.; Zhang, Z.; Zhuang, Y.; Zhang, Y.; Yang, J.; Cao, X.; Liang, S.; Mu, Y. Freeze/Thaw-Induced Deformation Monitoring and Assessment of the Slope in Permafrost Based on Terrestrial Laser Scanner and GNSS. Remote Sens. 2017, 9, 198. [Google Scholar] [CrossRef]

- Shen, Y.J.; Luo, T.; Wei, X.; Li, X.T.; Long, J.; Wen, L.D.; Peng, H.; Ji, Y.J. Mechanism Analysis of the Influence of Freeze-Thaw on the Damage and Debonding Evolution of Sandstone-Concrete Interface. Geofluids 2022, 2022, 3550597. [Google Scholar] [CrossRef]

- Mateos, R.M.; García-Moreno, I.; Azañón, J.M. Freeze–thaw cycles and rainfall as triggering factors of mass movements in a warm Mediterranean region: The case of the Tramuntana Range (Majorca, Spain). Landslides 2012, 9, 417–432. [Google Scholar] [CrossRef]

- Strunden, J.; Ehlers, T.A.; Brehm, D.; Nettesheim, M. Spatial and temporal variations in rockfall determined from TLS measurements in a deglaciated valley, Switzerland. J. Geophys. Res.-Earth. 2015, 120, 1251–1273. [Google Scholar] [CrossRef]

- Collins, B.D.; Stock, G.M. Rockfall triggering by cyclic thermal stressing of exfoliation fractures. Nat. Geosci. 2016, 9, 395–400. [Google Scholar] [CrossRef]

- Stöcke, K.; Weise, F.; Kieslinger, A.; Eissner, W.; Walz, K.; de Quervain, F. Die Prüfung der natürlichen Bausteine. In Die Prüfung Nichtmetallischer Baustoffe; Springer: Berlin/Heidelberg, Germany, 1941; pp. 138–223. [Google Scholar]

- Deprez, M.; De Kock, T.; De Schutter, G.; Cnudde, V. A review on freeze-thaw action and weathering of rocks. Earth-Sci. Rev. 2020, 203, 103143. [Google Scholar] [CrossRef]

- Steiger, M. Crystal growth in porous materials—I: The crystallization pressure of large crystals. J. Cryst. Growth 2005, 282, 455–469. [Google Scholar] [CrossRef]

- Bellanger, M.; Homand, F.; Remy, J.M. Water behaviour in limestones as a function of pores structure: Application to frost resistance of some Lorraine limestones. Eng. Geol. 1993, 36, 99–108. [Google Scholar] [CrossRef]

- Meng, F.D.; Zhai, Y.; Li, Y.B.; Zhao, R.F.; Li, Y.; Gao, H. Research on the effect of pore characteristics on the compressive properties of sandstone after freezing and thawing. Eng. Geol. 2021, 286, 106088. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Cai, Y.T.; Huang, S.B.; Guo, Y.L.; Liu, G.F. Effect of water saturation on uniaxial compressive strength and damage degree of clay-bearing sandstone under freeze-thaw. Bull. Eng. Geol. Environ. 2020, 79, 2021–2036. [Google Scholar] [CrossRef]

- Che, Y.X.; Song, Y.J.; Ren, J.X.; Chen, J.X.; Guo, X.X.; Tan, H.; Hu, M.L. Creep characteristics of different saturated states of red sandstone after freeze-thaw cycles. Geofluids 2021, 2021, 6622380. [Google Scholar] [CrossRef]

- Huang, S.B.; Cai, Y.T.; Liu, Y.Z.; Liu, G.F. Experimental and theoretical study on frost deformation and damage of red sandstones with different water contents. Rock Mech. Rock Eng. 2021, 54, 4163–4181. [Google Scholar] [CrossRef]

- Ren, J.X.; Yun, M.C.; Cao, X.T.; Zhang, K.; Liang, Y.; Chen, X. Study on the mechanical properties of saturated red sandstone under freeze–thaw conditions. Environ. Earth Sci. 2022, 81, 376. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, S.H.; Li, C.H.; Han, J.Q. Energy dissipation and damage evolution for dynamic fracture of marble subjected to freeze-thaw and multiple level compressive fatigue loading. Int. J. Fatigue 2021, 142, 105927. [Google Scholar] [CrossRef]

- Yahaghi, J.; Liu, H.Y.; Chan, A.; Fukuda, D. Experimental and numerical studies on failure behaviours of sandstones subject to freeze-thaw cycles. Transp. Geotech. 2021, 31, 100655. [Google Scholar] [CrossRef]

- Xie, Y.; Ren, J.; Caoxi, T.; Chen, X.; Yun, M. Triaxial Compression Fracture Characteristics and Constitutive Model of Frozen–Thawed Fissured Quasi-Sandstone. Appl. Sci. 2022, 12, 6454. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.G.; Taheri, A.; Ke, B.; Liu, C.J.; Yang, X.R. Degradation of physical and mechanical properties of sandstone subjected to freeze-thaw cycles and chemical erosion. Cold Reg. Sci. Technol. 2018, 155, 37–46. [Google Scholar] [CrossRef]

- Qu, D.X.; Li, D.K.; Li, X.P.; Yi, L.U.O.; Xu, K. Damage evolution mechanism and constitutive model of freeze-thaw yellow sandstone in acidic environment. Cold Reg. Sci. Technol. 2018, 155, 174–183. [Google Scholar] [CrossRef]

- Liu, B.; Ma, Y.J.; Liu, N.; Han, Y.H.; Li, D.Y.; Deng, H.L. Investigation of pore structure changes in Mesozoic water-rich sandstone induced by freeze-thaw process under different confining pressures using digital rock technology. Cold Reg. Sci. Technol. 2019, 161, 137–149. [Google Scholar] [CrossRef]

- Liu, B.; Ma, Y.J.; Sheng, H.L. Experiments on mechanical properties of Cretaceous red sandstone after freeze-thaw process. Rock Soil Mech. 2019, 40 (Suppl. S1), 161–171. [Google Scholar]

- Huang, S.B.; Liu, Q.S.; Cheng, A.; Liu, Y.Z. A statistical damage constitutive model under freeze-thaw and loading for rock and its engineering application. Cold Reg. Sci. Technol. 2018, 145, 142–150. [Google Scholar] [CrossRef]

- Ni, J.; Chen, Y.L.; Wang, P.; Wang, S.R.; Peng, B.; Azzam, R. Effect of chemical erosion and freeze–thaw cycling on the physical and mechanical characteristics of granites. Bull. Eng. Geol. Environ. 2017, 76, 169–179. [Google Scholar] [CrossRef]

- Huang, S.B.; Yu, S.L.; Ye, Y.H.; Ye, Z.Y.; Cheng, A. Pore structure change and physico-mechanical properties deterioration of sandstone suffering freeze-thaw actions. Constr. Build. Mater. 2022, 330, 127200. [Google Scholar] [CrossRef]

- Mei, S.H.; Liang, X.L.; Wen, L.; Kou, Z.L. Experimental study on mechanical properties of freeze-thaw damaged red sandstone under combined dynamic and static loading. Shock Vib. 2021, 2021, 9980549. [Google Scholar] [CrossRef]

- Xu, J.; Pu, H.; Sha, Z.H. Mechanical behavior and decay model of the sandstone in Urumqi under coupling of freeze–thaw and dynamic loading. Bull. Eng. Geol. Environ. 2021, 80, 2963–2978. [Google Scholar] [CrossRef]

- Zhang, H.M.; Yuan, C.; Yang, G.S.; Wu, L.Y.; Peng, C.; Ye, W.J.; Moayedi, H. A novel constitutive modelling approach measured under simulated freeze–thaw cycles for the rock failure. Eng. Comput. 2021, 37, 779–792. [Google Scholar] [CrossRef]

- Zhang, H.M.; Meng, X.Z.; Yang, G.S. A study on mechanical properties and damage model of rock subjected to freeze-thaw cycles and confining pressure. Cold Reg. Sci. Technol. 2020, 174, 103056. [Google Scholar] [CrossRef]

- Song, Z.Y.; Wang, Y.; Konietzky, H.; Cai, X. Mechanical behavior of marble exposed to freeze-thaw-fatigue loading. Int. J. Rock Mech. Min. 2021, 138, 104648. [Google Scholar] [CrossRef]

- Fan, W.B.; Zhang, J.W.; Yang, Y.; Zhang, Y.; Dong, X.K.; Xing, Y. Study on the Mechanical Behavior and Constitutive Model of Layered Sandstone under Triaxial Dynamic Loading. Mathematics 2023, 11, 1959. [Google Scholar] [CrossRef]

- Xia, Y.J.; Liu, B.C.; Li, T.J.; Zhao, D.C.; Liu, N.; Tang, C.A.; Chen, J. Numerical Simulation of Failure Modes in Irregular Columnar Jointed Rock Masses under Dynamic Loading. Mathematics 2023, 11, 3790. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.Z.; Zhu, C.; Mao, T.Q. Fatigue failure identification using deformation and energy rate for hole-fissure contained granite under freeze–thaw and variable-frequency–variable-amplitude cyclic loads. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 834–851. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, S.H.; Li, C.H.; Han, J.Q. Investigation on fracture behaviors and damage evolution modeling of freeze-thawed marble subjected to increasing-amplitude cyclic loads. Theor. Appl. Fract. Mech. 2020, 109, 102679. [Google Scholar] [CrossRef]

- Wang, Y.; Han, J.Q.; Li, C.H. Acoustic emission and CT investigation on fracture evolution of granite containing two flaws subjected to freeze–thaw and cyclic uniaxial increasing-amplitude loading conditions. Constr. Build. Mater. 2020, 260, 119769. [Google Scholar] [CrossRef]

- Bagde, M.N.; Petroš, V. Waveform effect on fatigue properties of intact sandstone in uniaxial cyclical loading. Rock Mech. Rock Eng. 2005, 38, 169–196. [Google Scholar] [CrossRef]

- Vutukuri, V.S.; Lama, R.D.; Saluja, S.S. Handbook on Mechanical Properties of Rocks; Trans Tech Publications: Clausthal, Germany, 1980. [Google Scholar]

- Ge, X.R.; Lu, Y.F. Discussion on fatigue failure and irreversible deformation of rock under cyclic loading. J. Geotech. Eng. 1992, 14, 56–60. [Google Scholar]

- He, G.C.; Wu, W.Y.; Wang, Y.; Xue, Y.M.; Dai, B.; Zhang, Z.J. Fracture Characteristics and fatigue damage of noncoplanar fractured rocklike specimens under uniaxial graded cyclic loading and unloading. Geofluids 2021, 2021, 9993195. [Google Scholar] [CrossRef]

- Li, T.T.; Pei, X.; Guo, J.; Meng, M.H.; Huang, R.Q. An energy-based fatigue damage model for sandstone subjected to cyclic loading. Rock Mech. Rock Eng. 2020, 53, 5069–5079. [Google Scholar] [CrossRef]

- Liu, J.H.; Pu, S.Y.; Rao, J.Y. Visco-elastoplastic constitutive fatigue model for rocks. Adv. Civ. Eng. 2020, 2020, 4292043. [Google Scholar] [CrossRef]

- Yun, M.C.; Ren, J.X.; Zhang, L.; Zhang, K. Research on triaxial compressive mechanical properties and damage constructive model of post-thawing double-fractured quasi-sandstones with different angles. Heliyon 2024, 10, e34268. [Google Scholar] [CrossRef]

- Peng, K.; Zhou, J.Q.; Zou, Q.L.; Song, X. Effect of loading frequency on the deformation behaviours of sandstones subjected to cyclic loads and its underlying mechanism. Int. J. Fatigue 2020, 131, 105349. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, W.K.; Li, C.H. On anisotropic fracture and energy evolution of marble subjected to triaxial fatigue cyclic-confining pressure unloading conditions. Int. J. Fatigue 2020, 134, 105524. [Google Scholar] [CrossRef]

- Coates, G.R.; Xiao, L.; Prammer, M.G. NMR Logging: Principles and Applications; Haliburton Energy Services: Houston, TX, USA, 1999. [Google Scholar]

- Niu, C.Y.; Zhu, Z.M.; Zhou, L.; Li, X.H.; Ying, P.; Dong, Y.Q.; Deng, S. Study on the microscopic damage evolution and dynamic fracture properties of sandstone under freeze-thaw cycles. Cold Reg. Sci. Technol. 2021, 191, 103328. [Google Scholar] [CrossRef]

- Hao, J.W.; Li, Q.W.; Qiao, L.; Deng, N.F. Study on pore fractal characteristics and rock constitutive model of sandstone after high temperature. J. Huazhong Univ. Sci. Tech. (Nat. Sci. Ed.) 2024, 52, 142–148. [Google Scholar]

- Zhou, X.P.; Li, C.Q.; Zhou, L.S. The effect of microstructural evolution on the permeability of sandstone under freeze-thaw cycles. Cold Reg. Sci. Technol. 2020, 177, 103119. [Google Scholar] [CrossRef]

- Zhou, X.P.; Niu, Y.; Zhang, J.Z.; Shen, X.C.; Zheng, Y.; Berto, F. Experimental study on effects of freeze-thaw fatigue damage on the cracking behaviors of sandstone containing two unparallel fissures. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1322–1340. [Google Scholar] [CrossRef]

- Yang, S.Q.; Tian, W.L.; Liu, X.R.; Huang, Y.H.; Yang, J. An experimental study on failure mechanical behavior and cracking mechanism of rectangular solid sandstone containing two non-coplanar fissures under conventional triaxial compression. Theor. Appl. Fract. Mech. 2021, 114, 102975. [Google Scholar] [CrossRef]

- Zhou, X.P.; Zhang, J.Z.; Yang, S.Q.; Berto, F. Compression-induced crack initiation and growth in flawed rocks: A review. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 1681–1707. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.T.; Shi, Z.M.; Chen, J.C. Fatigue damage and fracture evolution characteristics of sandstone under multistage intermittent cyclic loading. Theor. Appl. Fract. Mech. 2022, 119, 103375. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.T.; Shi, Z.M. Deformation damage and acoustic emission characteristics of red sandstone under fatigue–creep interaction. Theor. Appl. Fract. Mech. 2022, 117, 103192. [Google Scholar] [CrossRef]

- Weibull, W.; Sweden, S. A statistical distribution function of wide applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar] [CrossRef]

- Sun, Y.; Zhai, C.; Xu, J.Z.; Cong, Y.Z.; Qin, L.; Zhao, C. Characterisation and evolution of the full size range of pores and fractures in rocks under freeze-thaw conditions using nuclear magnetic resonance and three-dimensional X-ray microscopy. Eng. Geol. 2020, 271, 105616. [Google Scholar] [CrossRef]

- Zhang, Q.S.; Yang, G.S.; Ren, J.X. New study of damage variable and constitutive equation of rock. Chin. J. Rock Mech. Eng. 2003, 22, 30–34. [Google Scholar]

- Liu, Y.; Dai, F. A damage constitutive model for intermittent jointed rocks under cyclic uniaxial compression. Int. J. Rock Mech. Min. 2018, 103, 289–301. [Google Scholar] [CrossRef]

- Arvydas, R.; Vladimir, C.; Viktor, G.; Jan, C. Uncertainty of the smeared crack model applied to RC beams. Eng. Fract. Mech. 2020, 233, 107088. [Google Scholar]

- Umberto, D.M.; Fabrizio, G.; Paolo, L.; Andrea, P. A combined ALE-cohesive fracture approach for the arbitrary crack growth analysis. Eng. Fract. Mech. 2024, 301, 109996. [Google Scholar]

| Item | Parameters |

|---|---|

| Equipment size | 1200 × 1000 × 1870 mm (long × wide × high) |

| Equipment weight | 3500 kg |

| Frame stiffness | 6 MN/mm |

| Maximum axial pressure | 1500 kN |

| Maximum confining pressure | 50 MPa |

| Dynamic load waveform | oblique wave, sine wave, triangular wave, and square wave |

| Dynamic load frequency | 0.001~1 Hz |

| Status | F-T Cycles | Micropore (r < 10 μm) | Mesopore (10 μm ≤ r < 100 μm) | Macropore (r ≥ 100 μm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T2a/ms | T2b/ms | Db | T2c/ms | T2d/ms | Db | T2e/ms | T2f/ms | Db | ||

| Integrity | 0 | 1.383 | 9.659 | 2.123 | 10.353 | 95.477 | 2.728 | 102.341 | 821.434 | 2.375 |

| 20 | 1.589 | 9.659 | 1.983 | 10.353 | 95.477 | 2.712 | 102.341 | 943.788 | 2.467 | |

| 40 | 1.956 | 9.659 | 1.820 | 10.353 | 95.477 | 2.658 | 102.341 | 2494.508 | 2.697 | |

| Post-destruction | 0 | 1.203 | 9.659 | 2.152 | 10.353 | 95.477 | 2.537 | 102.341 | 4994.505 | 2.778 |

| 20 | 2.409 | 9.659 | 1.833 | 10.353 | 95.477 | 2.516 | 102.341 | 2171.118 | 2.788 | |

| 40 | 1.825 | 9.659 | 1.568 | 10.353 | 95.477 | 2.516 | 102.341 | 2327.202 | 2.815 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, M.; Ren, J.; Song, Y.; Zhang, L.; Sun, C.; Chang, P.; Cao, X. Fracture Mechanism and Damage Constitutive Model of Freeze–Thaw Fissured Granite Subjected to Fatigue Loading. Appl. Sci. 2024, 14, 6324. https://doi.org/10.3390/app14146324

Yun M, Ren J, Song Y, Zhang L, Sun C, Chang P, Cao X. Fracture Mechanism and Damage Constitutive Model of Freeze–Thaw Fissured Granite Subjected to Fatigue Loading. Applied Sciences. 2024; 14(14):6324. https://doi.org/10.3390/app14146324

Chicago/Turabian StyleYun, Mengchen, Jianxi Ren, Yongjun Song, Liang Zhang, Chengwei Sun, Pengbo Chang, and Xitailang Cao. 2024. "Fracture Mechanism and Damage Constitutive Model of Freeze–Thaw Fissured Granite Subjected to Fatigue Loading" Applied Sciences 14, no. 14: 6324. https://doi.org/10.3390/app14146324

APA StyleYun, M., Ren, J., Song, Y., Zhang, L., Sun, C., Chang, P., & Cao, X. (2024). Fracture Mechanism and Damage Constitutive Model of Freeze–Thaw Fissured Granite Subjected to Fatigue Loading. Applied Sciences, 14(14), 6324. https://doi.org/10.3390/app14146324